Bio-Resource Availability in Ireland: A Practical Review of Potential Replacement Materials for Use in Horticultural Growth Media

Abstract

1. Introduction

2. Materials and Methods

2.1. Quantification of Potential Available Forest Resources

2.2. Quantification of Potentially Available Agro-Wastes

2.3. Review of Agronomic Performance of Alternative Growth Media

3. Availability of Local Raw Bio-Resources Excluding Imports

3.1. Availability of Wood and Forest Residues

3.2. Availability of Straw from Field Crops

| Type | 5-Year Average Annual Cropping (ha) | Quantity Produced (t) 1 | Total Volume Produced (m3) | Competing Uses | Reference | Potentially Available for Growth Media (m3) 2 |

|---|---|---|---|---|---|---|

| Wheat straw | 60,440 | 246,000 | 1,824,500 | c.93% of total combined cereals straw baled (wheat, barley, oats) [45], of which 60–90% is used for bedding and feed [35,45], and 8.5–8.9% is used for mushroom compost (excluding oat straw) [35,45] | [30,31,32,33,44] | 145,960 |

| Barley straw | 186,280 | 710,052 | 5,266,219 | see above | [30,31,32,33,44] | 421,298 |

| Oats straw | 26,500 | 113,622 | 842,697 | see above | [30,31,32,33,44] | 67,416 |

| Oilseed rape straw | 12,460 | 27,910 | 207,002 | c.25% baled [45] | [30,31,32,33,44] | 155,252 |

| Bean straw | 27,340 | 38,796 | 287,737 | Amount used as animal feed and animal bedding unknown—est 90% | [30,31,32,33] | 28,774 |

| Miscanthus | 593 3 | 5930 | 31,997 | The amount used in energy production and animal bedding figures unknown.—est 60% | [48] | 12,799 |

| Willow | 278 3 | 2780 | 18,533 4 | First harvest in 3–4 years [37] Amount used in energy production unknown.—est 60% | [36] | 7413 |

3.3. Availability of Distillery/Brewers Spent Grain

3.4. Availability of Paper and Cardboard Waste, Municipal Composted Green Wastes, Digestates and Spent Mushroom Compost

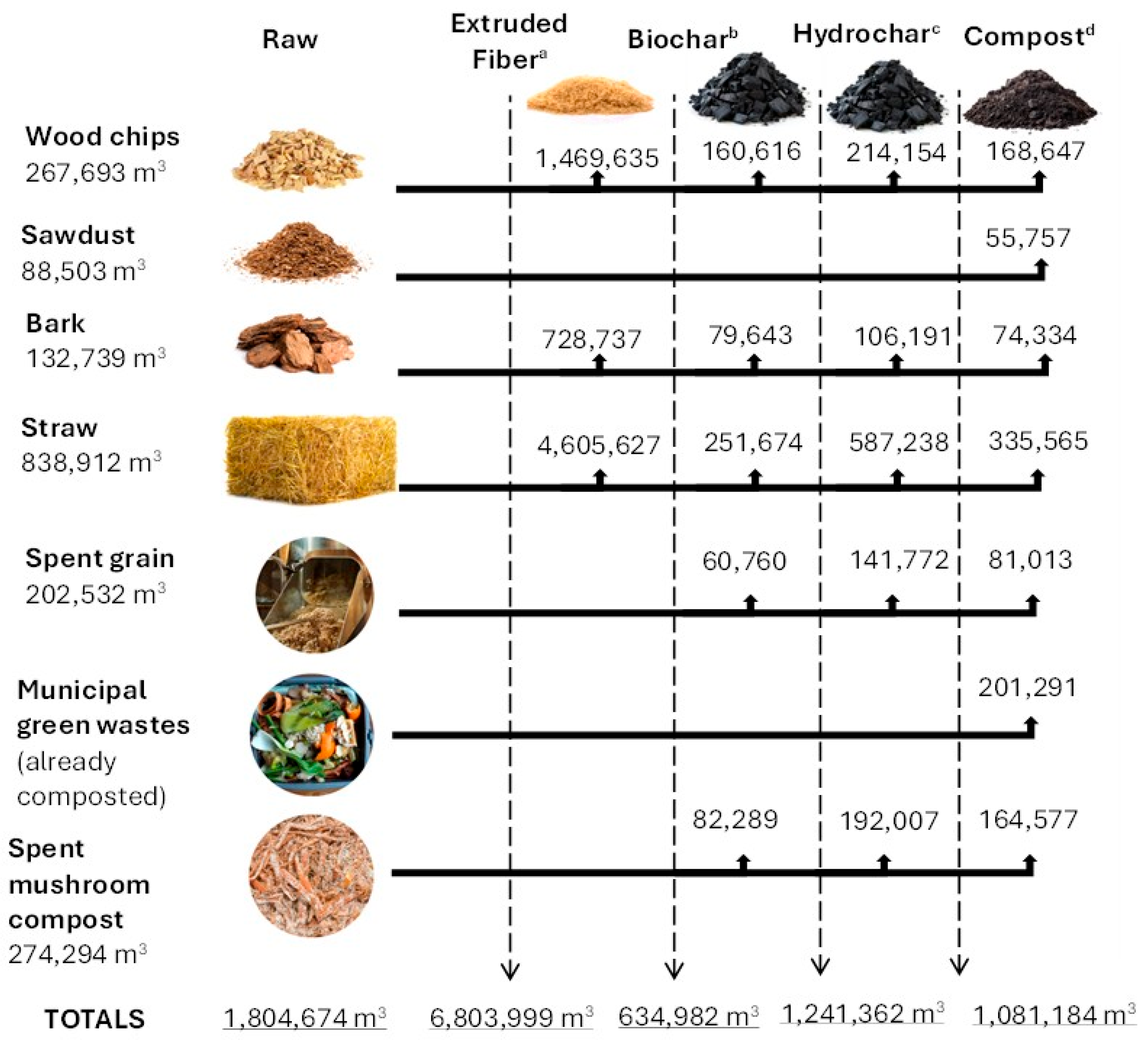

4. Biomass Processing Pathways for Production of Growth Media and Minimum Irish Estimates

4.1. Mechanical Alteration (Chipping, Milling, Extruding Fibers)

4.2. Pyrolysis and Hydrothermal Carbonization to Produce Biochars and Hydrochars

4.3. General Composting

4.4. Estimates of Potential Volumes That Could Be Produced from Available Resources in Ireland

5. Recent Agronomic Effectiveness Results from Alternative Material Use in Horticultural Growth Media

5.1. Raw and Mechanically Altered Materials as Growth Media (Milled, Shavings, Dust, Chopped, Extruded Fibers)

5.2. Thermally Carbonized Products (Bio- and Hydrochars) as Growth Media Constituents

5.3. Composted Materials as Growth Media Constituents

6. Identified Physico-Chemical Challenges of Alternative Growth Media Constituents and Opportunities

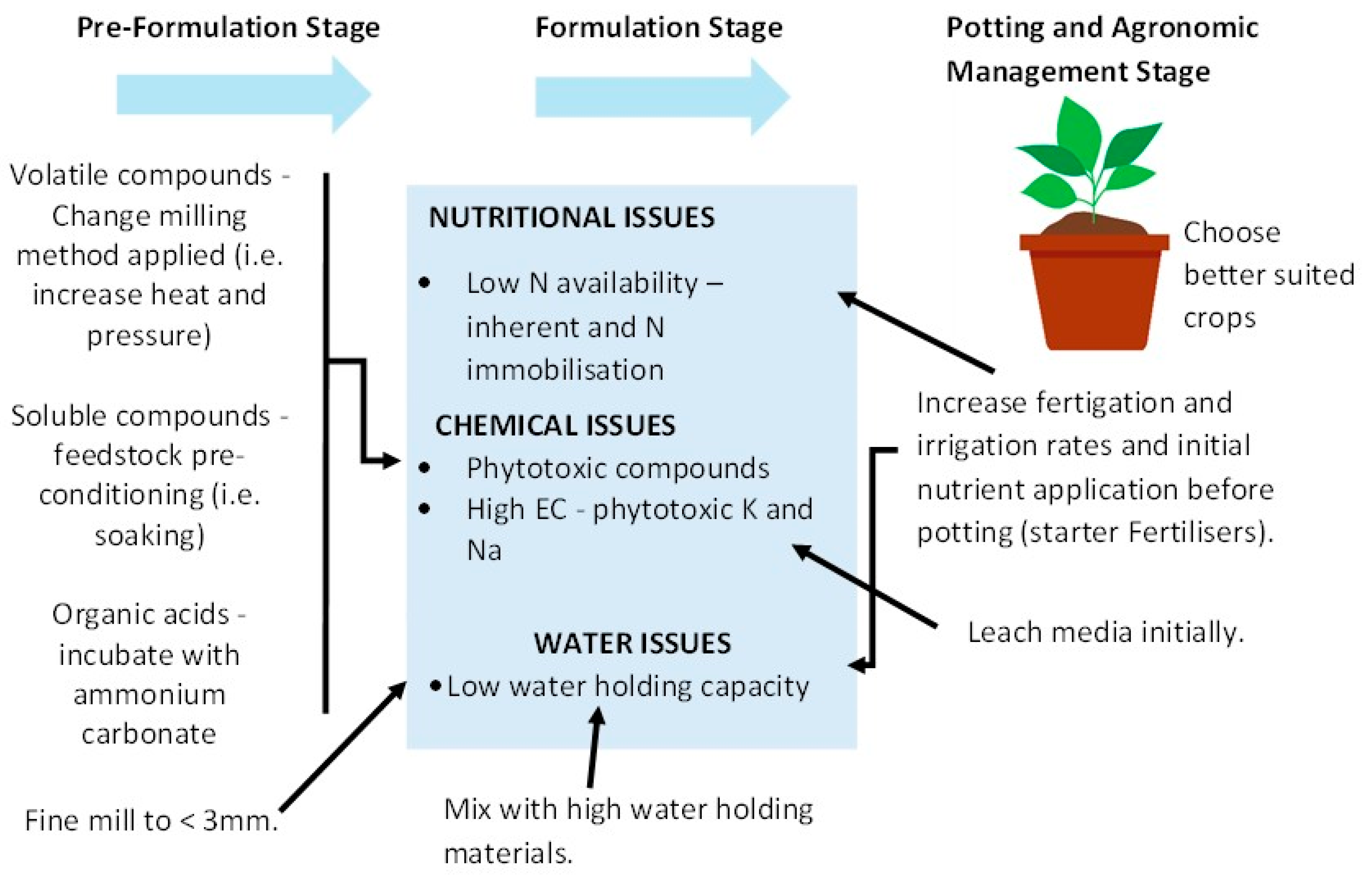

6.1. Challenges with Wood and Plant Fiber

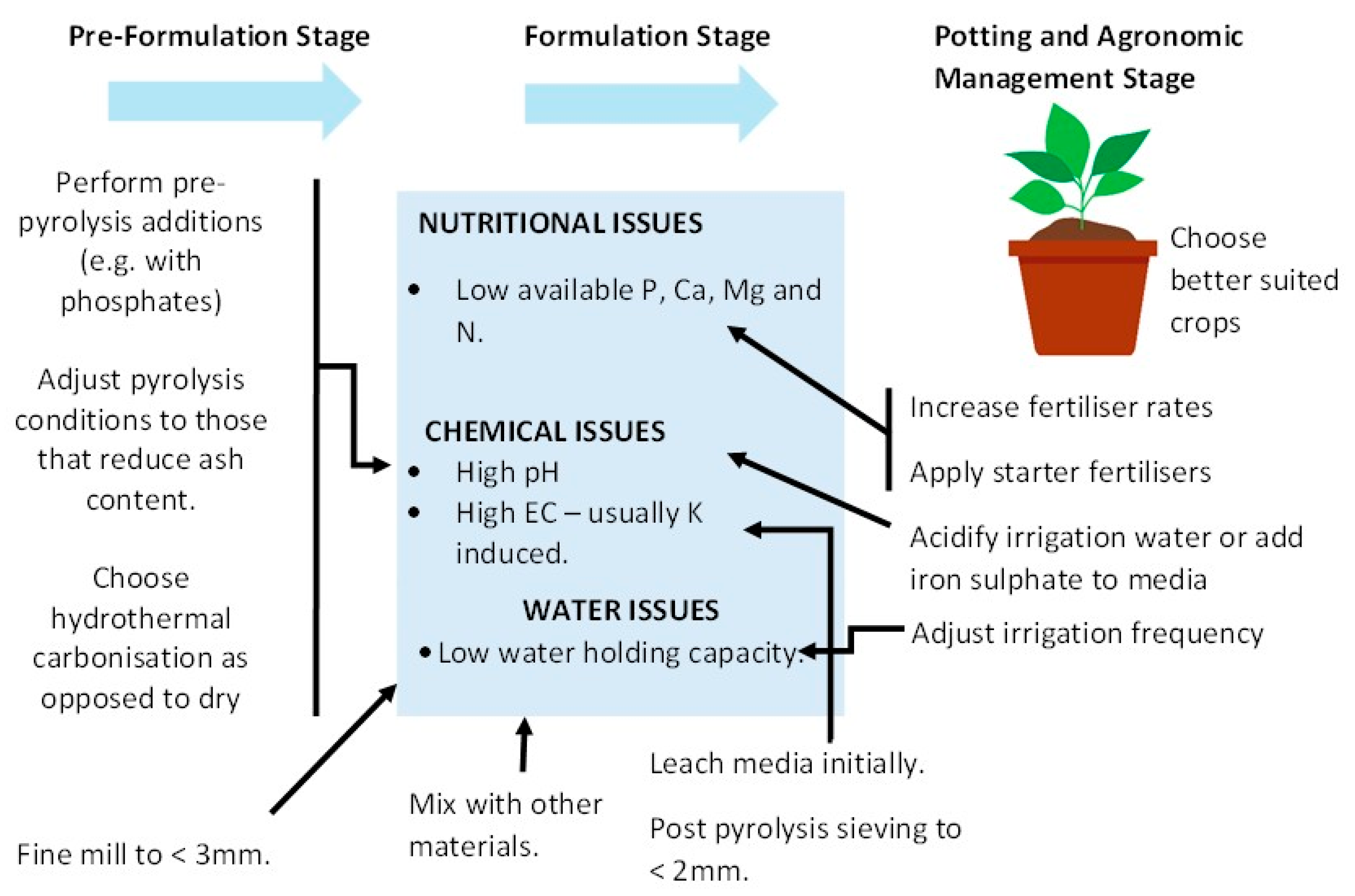

6.2. Challenges with Biochars/Hydrochars

6.3. Challenges with Composted Materials

6.4. Are Multi-Mix Growth Media the Answer?

7. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Barrett, G.E.; Alexander, P.D.; Robinson, J.S.; Bragg, N.C. Achieving environmentally sustainable growing media for soilless plant cultivation systems—A review. Sci. Hortic. 2016, 212, 220–234. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal; European Union: Brussels, Belgium, 2019. [Google Scholar]

- Prasad, M. Review of the Use of Peat Moss in Horticulture; Final Report of the Chairman of the Working Group; Department of Housing, Local Government and Heritage: Dublin, Ireland, 2021. Available online: https://www.researchgate.net/publication/358277197_Review_of_the_use_of_Peat_Moss_in_Horticulture/citations#fullTextFileContent (accessed on 12 October 2024).

- Mulholland, B.J.; Waldron, K.; Watson, A.; Moates, G.; Whiteside, C.; Davies, J.; Newman, S.; Hickinbotham, R. Developing a methodology to replace peat in UK horticulture with responsibly sourced alternative raw materials. Acta Hortic. 2019, 1266, 109–120. [Google Scholar] [CrossRef]

- Bragg, N.; Alexander, P. A review of the challenges facing horticultural researchers as they move toward sustainable growing media. Acta Hortic. 2019, 1266, 7–14. [Google Scholar] [CrossRef]

- Nguyen, V.T.H.; Kraska, T.; Winkler, W.; Aydinlik, S.; Jackson, B.E.; Pude, R. Primary Mechanical Modification to Improve Performance of Miscanthus as Stand-Alone Growing Substrates. Agronomy 2022, 12, 420. [Google Scholar] [CrossRef]

- Aurdal, S.M.; Woznicki, T.L.; Haraldsen, T.K.; Kusnierek, K.; Sønsteby, A.; Remberg, S.F. Wood Fiber-Based Growing Media for Strawberry Cultivation: Effects of Incorporation of Peat and Compost. Horticulturae 2022, 9, 36. [Google Scholar] [CrossRef]

- Di Lonardo, S.; Cacini, S.; Becucci, L.; Lenzi, A.; Orsenigo, S.; Zubani, L.; Rossi, G.; Zaccheo, P.; Massa, D. Testing new peat-free substrate mixtures for the cultivation of perennial herbaceous species: A case study on Leucanthemum vulgare Lam. Sci. Hortic. 2021, 289, 110472. [Google Scholar] [CrossRef]

- Hirschler, O.; Osterburg, B.; Weimar, H.; Glasenapp, S.; Ohmes, M.-F. Peat Replacement in Horticultural Growing Media: Availability of Bio-Based Alternative Materials; Thünen Institute: Braunschweig, Germany; Hamburg, Germany, 2022. [Google Scholar]

- DAFM. Working Paper to Address Challenges Related to Peat Supply in the Horticulture Sector; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2022.

- Séamus Boland, Irish Rural Link. Final Report on the Assessment of the Levels and Suitability of Current Indigenous Peat Stocks and Identification of Sub-Thirty Hectare Sites and Other Recommendations to Support Domestic Horticulture Industry as It Transitions to Peat Alternatives; Séamus Boland, Irish Rural Link (IRL): Dublin, Ireland, 2022. [Google Scholar]

- Growing Media Ireland. Irish Horticultural Peat Industry 2021; Opening Statement: Athlone, Ireland, 2021; Available online: https://data.oireachtas.ie/ie/oireachtas/committee/dail/33/joint_committee_on_agriculture_and_the_marine/submissions/2021/2021-02-16_opening-statement-john-neenan-chairperson-growing-media-ireland-clg-gmi_en.pdf (accessed on 6 January 2025).

- Galvin, L.F. Physical properties of Irish peats. Ir. J. Agric. Res. 1976, 15, 207–221. [Google Scholar]

- IPCC. Ireland’s Peatland Conservation Action Plan 2020: Halting the Loss of Peatland Biodiversity; Irish Peatland Conservation Council: Geneva, Switzerland, 2009; p. 152. [Google Scholar]

- O’Brien, A. Over 390,000t of peat exported in 2022—Minister. Agriland. 15 May 2023. Available online: https://www.agriland.ie/farming-news/over-390000t-of-peat-exported-in-2022-minister/ (accessed on 6 January 2025).

- IPCC. End the Sale of Peat Moss Compost in the Retail Sector; IPCC: Geneva, Switzerland, 2024. [Google Scholar]

- DAFM. Horticulture; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2020.

- COFORD. All Ireland Roundwood Production Forecast 2021–2040; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2021; ISBN 978-1-902696-92-8.

- COFORD. All Ireland Roundwood Production Forecast 2021–2040—Methodology; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2021; ISBN 978-1-902696-93-5.

- COFORD. Forests and Wood Products, and Their Importance in Climate Change Mitigation: A Series of COFORD Statements; Department of Agriculture, Food and the Marine, Agriculture: Dublin, Ireland, 2022; ISBN 978-1-902696-94-2.

- COFORD. Wood Supply and Demand on the Island of Ireland to 2030; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2022; ISBN 978-1-902696-97-3.

- COFORD. Wood Supply and Demand on the Island of Ireland to 2025; Department of Agriculture, Food and the Marine, Agriculture: Dublin, Ireland, 2018; ISBN 978-1-902696-86-7.

- Whelan, D. ITGA submission on the Department of Agriculture, Food and the Marine’s Statement of Strategy 2020–2023. In Forestry and Timber Yearbook (2020); Irish Timber Growers Association: Dublin, Ireland, 2020. [Google Scholar]

- O’driscoll, E. An overview of wood fibre use in ireland (2016). In Forestry and Timber Yearbook (2018); Irish Timber Growers Association: Dublin, Ireland, 2018. [Google Scholar]

- O’Driscoll, E. An overview of wood fibre use in Ireland. In Forestry and Timber Yearbook (2019); Irish Timber Growers Association: Dublin, Ireland, 2019. [Google Scholar]

- O’Driscoll, E. An overview of wood fibre use in Ireland (2018). In Forestry and Timber Yearbook 2020; Irish Timber Growers Association: Dublin, Ireland, 2020. [Google Scholar]

- Magner, D. Roundwood forecast supply to increase to 7.9 million m3 by 2035. In Forestry and Timber Yearbook (2021); Irish Timber Growers Association: Dublin, Ireland, 2021. [Google Scholar]

- Magner, D. Timber production from private forests increased by 63% from 2015 to 2021. In Forestry and Timber Yearbook (2023); Irish Timber Growers Association: Dublin, Ireland, 2023. [Google Scholar]

- FAO; ITTO; United Nations. Forest Product Conversion Factors; FAO: Rome, Italy; ITTO: Yokohama, Japan; United Nations: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Teagasc. Harvest Report 2022; Teagasc: Carlow, Ireland, 2022. [Google Scholar]

- Teagasc. Harvest Report 2023; Teagasc: Carlow, Ireland, 2023. [Google Scholar]

- Teagasc. Harvest Report 2020; Crops Knowledge Transfer Department, Teagasc: Carlow, Ireland, 2020. [Google Scholar]

- Teagasc. Harvest Report 2021; Teagasc: Carlow, Ireland, 2021. [Google Scholar]

- Teagasc. Fact Sheet Energy-13: Straw for Energy. 2020. Available online: https://www.teagasc.ie/media/website/rural-economy/rural-development/diversification/Energy-13-Straw-for-Energy.pdf (accessed on 14 November 2024).

- Nolan, A.; Mc Donnell, K.; Devlin, G.J.; Carroll, J.P.; Finnan, J. Potential availability of non-woody biomass feedstock for pellet production within the Republic of Ireland. Int. J. Agric. Biol. Eng. 2010, 3, 63–73. [Google Scholar] [CrossRef]

- Robb, S. Where to Next for Willow and Miscanthus. 2022. Available online: https://www.farmersjournal.ie/where-to-next-for-willow-and-miscanthus-684693 (accessed on 23 July 2024).

- Caslin, B.; Finnan, J.; Johnston, C.; McCracken, A.; Walsh, L. Short Rotation Coppice Willow; Best Practice Guidelines; Teagasc and AFBI: Carlow, Ireland, 2015. [Google Scholar]

- EPA. National Waste Statistics; EPA: Wexford, Ireland, 2023.

- DAFM. Forest Statistics Ireland 2023; Department of Agriculture, Food & the Marine: Wexford, Ireland, 2023.

- Sosa, A.; Klvac, R.; Coates, E.; Kent, T.; Devlin, G. Improving Log Loading Efficiency for Improved Sustainable Transport within the Irish Forest and Biomass Sectors. Sustainability 2015, 7, 3017–3030. [Google Scholar] [CrossRef]

- O’Tuama, P.; Purser, P.; Wilson, F.; Dhubháin, Á.N. Challenges and opportunities—Sitka spruce in Ireland. In Introduced Tree Species in European Forests: Opportunities and Challenges; Krumm, F., Vítková, L., Eds.; European Forest Institute: Joensuu, Finland, 2016; pp. 344–351. [Google Scholar]

- Magner, D. Weak home market driving increased pulpwood exports. Farmers J. 2023. Available online: https://www.farmersjournal.ie/more/forestry/weak-home-market-driving-increased-pulpwood-exports-780897 (accessed on 23 July 2024).

- Knaggs, G.; O’Driscoll, E. Woodflow and Forest-Based Biomass Energy Use on the Island of Ireland (2018); COFORD: Dublin, Ireland, 2019. [Google Scholar]

- Wallace, M. Economic Impact Assessment of the Tillage Sector in Ireland; Tillage Industry Ireland: Dublin, Ireland, 2020; Available online: https://www.ifa.ie/wp-content/uploads/2020/08/2020-Economic-Impact-Assessment-of-the-Tillage-Sector-in-Ireland.pdf (accessed on 10 October 2024).

- Teagasc. Mushroom Sector Development Plan to 2020; Teagasc Mushroom Stakeholder Consultative Group: Carlow, Ireland, 2013. [Google Scholar]

- SIM. The Straw Incorporation Measure (SIM) 2022; Article 28 of Regulation (EU) No 1305/2013 of the European Parliament and of the Council of 17 December 2013 (Agri-Environment-Climate); Department of Agriculture, Food and the Marine: Portlaoise, Ireland, 2022.

- DAFM. Report on Consultation on the Potential for Growing Fibre Crops and Whether These Crops Have a Viable Market; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2022.

- Styles, D.; Thorne, F.; Jones, M.B. Energy crops in Ireland: An economic comparison of willow and Miscanthus production with conventional farming systems. Biomass Bioenergy 2008, 32, 407–421. [Google Scholar] [CrossRef]

- Barry-Ryan, E.C.U.a.C. Overview of the Irish brewing and distilling. Brew. Sci. 2022, 75, 9–16. [Google Scholar]

- Kieran, M.; Lynch, E.J.S.; Elke, K. Arendt. Brewers’ spent grain: A review with an emphasison food and health. J. Inst. Brew. 2016, 122, 549–771. [Google Scholar]

- Abolore, R.S.; Pradhan, D.; Jaiswal, S.; Jaiswal, A.K. Characterization of Spent Grain from Irish Whiskey Distilleries for Biorefinery Feedstock Potential to Produce High-Value Chemicals and Biopolymers. Appl. Sci. 2024, 14, 11577. [Google Scholar] [CrossRef]

- Fitzgerald, R.J. Incorporation of Novel Brewers’ Spent Grain (BSG)-Derived Protein Hydrolysates and Blended Ingredient in Functional Foods for Older Adults and Assessment of Health Benefits In Vivo; Department of Agriculture, Food and the Marine: Dublin, Ireland, 2022.

- Akunna, J.C.; Walker, G.M. Co-products from malt whisky production and their utilisation. In The Alcohol Textbook: A Reference for the Beverage, Fuel and Industrial Alcohol Industries; Walker, G.M., Abbas, C., Ingledew, W.M., Pilgrim, C., Eds.; Lallemand Biofuels & Distilled Spirits: Gwinnett County, GA, USA, 2017; pp. 529–537. [Google Scholar]

- Umego, E.C.; Barry-Ryan, C. Review of the valorization initiatives of brewing and distilling byproducts. Crit. Rev. Food Sci. Nutr. 2023, 64, 8231–8247. [Google Scholar] [CrossRef]

- Naibaho, J.; Korzeniowska, M. The variability of physico-chemical properties of brewery spent grain from 8 different breweries. Heliyon 2021, 7, 2405–8440. [Google Scholar]

- Ikram, S.; Huang, L.; Zhang, H.; Wang, J.; Yin, M. Composition and Nutrient Value Proposition of Brewers Spent Grain. J. Food Sci. 2017, 82, 2232–2242. [Google Scholar] [CrossRef]

- Bianco, A.; Melito, S.; Garau, M.; Giannini, V.; Zara, G.; Assandri, D.; Oufensou, S.; Coronas, R.; Pampuro, N.; Budroni, M. The potential use of brewers’ spent grain-based substrates as horticultural bio-fertilizers. Front. Sustain. Food Syst. 2024, 8, 1404914. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Stavrinides, M.; Moustakas, K.; Tzortzakis, N. Utilization of paper waste as growing media for potted ornamental plants. Clean Technol. Environ. Policy 2018, 21, 1937–1948. [Google Scholar] [CrossRef]

- Jordan, S.N.; Holland, L.B.; Linnane, S.U. Spent Mushroom Compost Management and Options for Use; Environmental Protection Agency: Wexford, Ireland, 2012.

- Maher, M.J.; Magette, W.L.; Smyth, S.; Duggan, J.; Dodd, V.A.; Hennerty, M.J.; McCabe, T. Managing Spent Mushroom Compost; Teagasc: Dublin, Ireland, 2000; ISBN 1 84170 113 0. [Google Scholar]

- Northway Mushrooms. Submission 32 Northway Mushrooms Public Consultation; National Parks and Wildlife: Dublin, Ireland, 2020.

- Lee, J.S.; Rezaei, H.; Gholami Banadkoki, O.; Yazdan Panah, F.; Sokhansanj, S. Variability in Physical Properties of Logging and Sawmill Residues for Making Wood Pellets. Processes 2024, 12, 181. [Google Scholar] [CrossRef]

- Dittrich, C.; Pecenka, R.; Løes, A.-K.; Cáceres, R.; Conroy, J.; Rayns, F.; Schmutz, U.; Kir, A.; Kruggel-Emden, H. Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties. Agronomy 2021, 11, 1185. [Google Scholar] [CrossRef]

- Tumbure, A.; Bishop, P.; Bretherton, M.; Hedley, M. Co-Pyrolysis of Maize Stover and Igneous Phosphate Rock to Produce Potential Biochar-Based Phosphate Fertilizer with Improved Carbon Retention and Liming Value. ACS Sustain. Chem. Eng. 2020, 8, 4178–4184. [Google Scholar] [CrossRef]

- Lakshman, V.; Brassard, P.; Hamelin, L.; Raghavan, V.; Godbout, S. Pyrolysis of Miscanthus: Developing the mass balance of a biorefinery through experimental tests in an auger reactor. Bioresour. Technol. Rep. 2021, 14, 100687. [Google Scholar] [CrossRef]

- Gokhale, J.S.; Hude, M.P.; Yadav, G.D.; Thomas, M.; Kozinski, J.; Dalai, A.K. Hydrothermal processing of waste pine wood into industrially useful products. J. Indian Chem. Soc. 2022, 9, 100647. [Google Scholar] [CrossRef]

- Domingues, R.R.; Trugilho, P.F.; Silva, C.A.; Melo, I.; Melo, L.C.A.; Magriotis, Z.M.; Sanchez-Monedero, M.A. Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS ONE 2017, 12, e0176884. [Google Scholar] [CrossRef]

- Sedmihradská, A.; Pohořelý, M.; Jevič, P.; Skoblia, S.; Beňo, Z.; Farták, J.; Čech, B.; Hartman, M. Pyrolysis of wheat and barley straw. Res. Agric. Eng. 2020, 66, 8–17. [Google Scholar] [CrossRef]

- Yu, Y.; Lau, A.; Sokhansanj, S. Hydrothermal carbonization and pelletization of moistened wheat straw. Renew. Energy 2022, 190, 1018–1028. [Google Scholar] [CrossRef]

- Zhang, D.; Peng, Q.; Yang, R.; Lin, W.; Wang, H.; Zhou, W.; Qi, Z.; Ouyang, L. Slight carbonization as a new approach to obtain peat alternative. Ind. Crops Prod. 2023, 202, 117041. [Google Scholar] [CrossRef]

- Maaoui, A.; Ben Hassen Trabelsi, A.; Ben Abdallah, A.; Chagtmi, R.; Lopez, G.; Cortazar, M.; Olazar, M. Assessment of pine wood biomass wastes valorization by pyrolysis with focus on fast pyrolysis biochar production. J. Energy Inst. 2023, 108, 101242. [Google Scholar] [CrossRef]

- Boutaieb, M.; Guiza, M.; Román, S.; Ledesma Cano, B.; Nogales, S.; Ouederni, A. Hydrothermal carbonization as a preliminary step to pine cone pyrolysis for bioenergy production. C. R. Chim. 2021, 23, 607–621. [Google Scholar] [CrossRef]

- Rada Arias, E.; Bertero, M.; Jozami, E.; Feldman, S.R.; Falco, M.; Sedran, U. Pyrolytic conversion of perennial grasses and woody shrubs to energy and chemicals. SN Appl. Sci. 2019, 2, 116. [Google Scholar] [CrossRef]

- Bhakta, A.K.; Snoussi, Y.; Garah, M.E.; Ammar, S.; Chehimi, M.M. Brewer’s Spent Grain Biochar: Grinding Method Matters. C J. Carbon Res. 2022, 8, 46. [Google Scholar] [CrossRef]

- da Silva Araújo, F.P.; de Souza Cupertino, G.; de Cássia Superbi de Sousa, R.; de Castro Santana, R.; Pereira, A.F. Use of biochar produced from brewer’s spent grains as an adsorbent. Biomass Convers. Biorefin. 2024. [Google Scholar] [CrossRef]

- Atallah, E.; Zeaiter, J.; Ahmad, M.N.; Leahy, J.J.; Kwapinski, W. Hydrothermal carbonization of spent mushroom compost waste compared against torrefaction and pyrolysis. Fuel Process. Technol. 2021, 216, 106795. [Google Scholar] [CrossRef]

- Gaffney, M.; Lee, A.; Prasad, M.; Cassidy, J. Municipal organic wastes in crop production. Tresearch 2017, 12, 20–21. [Google Scholar]

- Czekała, W.; Janczak, D.; Pochwatka, P.; Nowak, M.; Dach, J. Gases Emissions during Composting Process of Agri-Food Industry Waste. Appl. Sci. 2022, 12, 9245. [Google Scholar] [CrossRef]

- Chavez-Rico, V.S.; Bodelier, P.L.E.; van Eekert, M.; Sechi, V.; Veeken, A.; Buisman, C. Producing organic amendments: Physicochemical changes in biowaste used in anaerobic digestion, composting, and fermentation. Waste Manag. 2022, 149, 177–185. [Google Scholar] [CrossRef]

- Breitenbeck, G.A.; Schellinger, D. Calculating the Reduction in Material Mass And Volume during Composting. Compos. Sci. Util. 2004, 12, 365–371. [Google Scholar] [CrossRef]

- Schroeter-Zakrzewska, A.; Komorowicz, M. The Use of Compost from Post-Consumer Wood Waste Containing Microbiological Inoculums on Growth and Flowering of Chrysanthemum (Chrysanthemum × grandiflorum Ramat./Kitam.). Agronomy 2022, 12, 1274. [Google Scholar] [CrossRef]

- Prasad, M. Evaluation of woodwastes as a substrate for ornamental crops watered by capillary and drip irrigation. Acta Hortic. 1980, 99, 93–104. [Google Scholar] [CrossRef]

- Poleatewich, A.; Michaud, I.; Jackson, B.; Krause, M.; DeGenring, L. The Effect of Peat Moss Amended with Three Engineered Wood Substrate Components on Suppression of Damping-Off Caused by Rhizoctonia solani. Agriculture 2022, 12, 2092. [Google Scholar] [CrossRef]

- González-Orozco, M.; Prieto-Ruíz, J.; Aldrete, A.; Hernández-Díaz, J.; Chávez-Simental, J.; Rodríguez-Laguna, R. Nursery Production of Pinus engelmannii Carr. with Substrates Based on Fresh Sawdust. Forests 2018, 9, 678. [Google Scholar] [CrossRef]

- Cepuliene, R.; Butkeviciene, L.M.; Steponaviciene, V. Nutrient Use Efficiency and Cucumber Productivity as a Function of the Nitrogen Fertilization Rate and the Wood Fiber Content in Growing Media. Plants 2024, 13, 2911. [Google Scholar] [CrossRef]

- Ferrer-Villasmil, V.; Fuentealba, C.; Reyes-Contreras, P.; Rubilar, R.; Cabrera-Barjas, G.; Bravo-Arrepol, G.; Escobar-Avello, D. Extracted Eucalyptus globulus Bark Fiber as a Potential Substrate for Pinus radiata and Quillaja saponaria Germination. Plants 2024, 13, 789. [Google Scholar] [CrossRef] [PubMed]

- Mahmoud, S.H.; Abou-Hussein, S.D.; El-Tanahy, A.M.M. Corn cobs as growing media for production of cucumber plants in agriculture sector: A new trend. J. Plant Nutr. 2024, 48, 1200–1213. [Google Scholar] [CrossRef]

- Thiessen, M.E.; Fields, J.S.; Abdi, D.E. Physical Properties and Crop Performance of Four Substrate Fibers in Greenhouse Petunia Production. Horticulturae 2024, 10, 279. [Google Scholar] [CrossRef]

- Woznicki, T.L.; Sønsteby, A.; Aurdal, S.M.; Kusnierek, K.; Haraldsen, T.K. Optimizing Peat and Wood Fiber Blends: Impacts of Liming and Fertilization on Growth of Petunia (Petunia × hybrida Vilm.) and Basil (Ocimum basilicum L.). Horticulturae 2024, 10, 895. [Google Scholar] [CrossRef]

- Fascella, G.; Mammano, M.M.; D’Angiolillo, F.; Rouphael, Y. Effects of conifer wood biochar as a substrate component on ornamental performance, photosynthetic activity, and mineral composition of pottedRosa rugosa. J. Hortic. Sci. Biotechnol. 2017, 93, 519–528. [Google Scholar] [CrossRef]

- Rathnayake, D.; Creber, H.; Van Poucke, R.; Sohi, S.; Meers, E.; Mašek, O.; Ronsse, F. Biochar from sawmill residues: Characterization and evaluation for its potential use in the horticultural growing media. Biochar 2021, 3, 201–212. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Prasad, M.; Kavanagh, A.; Tzortzakis, N. Biochar Type and Ratio as a Peat Additive/Partial Peat Replacement in Growing Media for Cabbage Seedling Production. Agronomy 2019, 9, 693. [Google Scholar] [CrossRef]

- Fascella, G.; Mammano, M.M.; D’Angiolillo, F.; Pannico, A.; Rouphael, Y. Coniferous wood biochar as substrate component of two containerized Lavender species: Effects on morpho-physiological traits and nutrients partitioning. Sci. Hortic. 2020, 267, 109356. [Google Scholar] [CrossRef]

- Prasad, M.; Tzortzakis, N.; McDaniel, N. Chemical characterization of biochar and assessment of the nutrient dynamics by means of preliminary plant growth tests. J. Environ. Manag. 2018, 216, 89–95. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Prasad, M.; Kavanagh, A.; Tzortzakis, N. Biochar Type, Ratio, and Nutrient Levels in Growing Media Affects Seedling Production and Plant Performance. Agronomy 2020, 10, 1421. [Google Scholar] [CrossRef]

- Guo, Y.; Niu, G.; Starman, T.; Gu, M. Growth and development of Easter lily in response to container substrate with biochar. J. Hortic. Sci. Biotechnol. 2018, 94, 80–86. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Prasad, M.; Tzortzakis, N. Wood-Based Biochar Ratio Used for Partial Peat Replacement in Growing Media for Antirrhinum majus Pot Production. Agriculture 2024, 14, 1860. [Google Scholar] [CrossRef]

- Vaughn, S.F.; Kenar, J.A.; Thompson, A.R.; Peterson, S.C. Comparison of biochars derived from wood pellets and pelletized wheat straw as replacements for peat in potting substrates. Ind. Crops Prod. 2013, 51, 437–443. [Google Scholar] [CrossRef]

- Prasad, M.; Maher, M.J. Evaluation of composted botanic materials as components of a reduced-peat growing media for nursery stock. Eur. Compos. Netw. ECN 2006, 9, 1–7. [Google Scholar]

- Mininni, C.; Grassi, F.; Traversa, A.; Cocozza, C.; Parente, A.; Miano, T.; Santamaria, P. Posidonia oceanica (L.) based compost as substrate for potted basil production. J. Sci. Food Agric. 2015, 95, 2041–2046. [Google Scholar] [CrossRef]

- Adamczewska-Sowińska, K.; Sowiński, J.; Jamroz, E.; Bekier, J. Combining Willow Compost and Peat as Media for Juvenile Tomato Transplant Production. Agronomy 2021, 11, 2089. [Google Scholar] [CrossRef]

- Adamczewska-Sowinska, K.; Sowinski, J.; Jamroz, E.; Bekier, J. Compost from willow biomass (Salix viminalis L.) as a horticultural substrate alternative to peat in the production of vegetable transplants. Sci. Rep. 2022, 12, 17617. [Google Scholar] [CrossRef]

- Marutani, M.; Clemente, S. Compost-Based Growing Media Improved Yield of Leafy Lettuce in Pot Culture. Agronomy 2021, 11, 1762. [Google Scholar] [CrossRef]

- Gilbert, J.; Siebert, S. Overview of Bio-Waste Collection, Treatment & Markets Across Europe; European Compost Network ECN: Bochum, Germany, 2022. [Google Scholar]

- Zhang, R.-H.; Duan, Z.-Q.; Li, Z.-G. Use of Spent Mushroom Substrate as Growing Media for Tomato and Cucumber Seedlings. Pedosphere 2012, 22, 333–342. [Google Scholar] [CrossRef]

- Massa, D.; Malorgio, F.; Lazzereschi, S.; Carmassi, G.; Prisa, D.; Burchi, G. Evaluation of two green composts for peat substitution in geranium (Pelargonium zonale L.) cultivation: Effect on plant growth, quality, nutrition, and photosynthesis. Sci. Hortic. 2018, 228, 213–221. [Google Scholar] [CrossRef]

- Zawadzińska, A.; Salachna, P.; Nowak, J.S.; Kowalczyk, W.; Piechocki, R.; Łopusiewicz, Ł.; Pietrak, A. Compost Based on Pulp and Paper Mill Sludge, Fruit-Vegetable Waste, Mushroom Spent Substrate and Rye Straw Improves Yield and Nutritional Value of Tomato. Agronomy 2021, 12, 13. [Google Scholar] [CrossRef]

- Adamczewska-Sowinska, K.; Sowinski, J.; Jamroz, E.; Bekier, J. The effect of peat replacement in horticulture media by willow (Salix viminalis L.) biomass compost for cucumber transplant production. Front. Plant Sci. 2024, 15, 1348073. [Google Scholar] [CrossRef]

- Mechergui, T.; Vanderschaaf, C.L.; Jhariya, M.K.; Banerjee, A.; Raj, A. Sheep manure compost: A viable growing substrate for lettuce seedling production. J. Soil Sci. Plant Nutr. 2024, 24, 5108–5119. [Google Scholar] [CrossRef]

- Dickson, R.W.; Helms, K.M.; Jackson, B.E.; Machesney, L.M.; Lee, J.A. Evaluation of Peat Blended with Pine Wood Components for Effects on Substrate Physical Properties, Nitrogen Immobilization, and Growth of Petunia (Petunia × hybrida Vilm.-Andr.). HortScience 2022, 57, 304–311. [Google Scholar] [CrossRef]

- Woznicki, T.; Jackson, B.E.; Sønsteby, A.; Kusnierek, K. Wood Fiber from Norway Spruce—A Stand-Alone Growing Medium for Hydroponic Strawberry Production. Horticulturae 2023, 9, 815. [Google Scholar] [CrossRef]

- Jackson, B.E. Methods for mitigating toxicity in fresh wood substrates. Greenh. Manag. 2020. Available online: https://www.greenhousemag.com/article/growing-media-methods-for-mitigating-toxicity-in-fresh-wood-substrates/ (accessed on 14 November 2024).

- Michel, J.-C.; Durand, S.; Jackson, B.E.; Fonteno, W.C. Analyzing rehydration efficiency of hydrophilic (wood fiber) vs potentially hydrophobic (peat) substrates using different irrigation methods. Acta Hortic. 2021, 1317, 343–350. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Antoniou, O.; Tzionis, A.; Prasad, M.; Tzortzakis, N. Alternative soilless media using olive-mill and paper waste for growing ornamental plants. Environ. Sci. Pollut. Res. Int. 2018, 25, 35915–35927. [Google Scholar] [CrossRef]

- Zhou, W.; Liao, J.; Zhou, B.; Yang, R.; Lin, W.; Zhang, D.; Wang, H.; Qi, Z. Rapidly reducing phytotoxicity of green waste for growing media by incubation with ammonium. Environ. Technol. Innov. 2023, 31, 103136. [Google Scholar] [CrossRef]

- Escuer, O.; Karp, K.; Escuer-Gatius, J.; Raave, H.; Teppand, T.; Shanskiy, M. Hardwood biochar as an alternative to reduce peat use for seed germination and growth of Tagetes patula. Acta Agric. Scand. Sect. B-Soil Plant Sci 2021, 71, 408–421. [Google Scholar] [CrossRef]

- Mwangi, R.W.; Mustafa, M.; Kappel, N.; Csambalik, L.; Szabó, A. Practical applications of spent mushroom compost in cultivation and disease control of selected vegetables species. J. Mater. Cycles Waste Manag. 2024, 26, 1918–1933. [Google Scholar] [CrossRef]

- López-Fabal, A.; López-López, N. Using gorse compost as a peat-free growing substrate for organic strawberry production. Biol. Agric. Hortic. 2022, 39, 19–35. [Google Scholar] [CrossRef]

- Vandecasteele, B.; Debode, J.; Willekens, K.; Van Delm, T. Recycling of P and K in circular horticulture through compost application in sustainable growing media for fertigated strawberry cultivation. Eur. J. Agron. 2018, 96, 131–145. [Google Scholar] [CrossRef]

- Criscione, K.S.; Fields, J.S.; Owen, J.S.; Fultz, L.; Bush, E. Evaluating Stratified Substrates Effect on Containerized Crop Growth under Varied Irrigation Strategies. HortScience 2022, 57, 400–413. [Google Scholar] [CrossRef]

- Abdi, D.E.; Beasley, J.; Fields, J. Reducing Phosphorus Loss in Short-Cycle Horticultural Production Using Activated Aluminum-Amended Substrates and Modified Fertigation Practices. Plants 2024, 13, 2473. [Google Scholar] [CrossRef]

- Traversari, S.; Cardarelli, M.; Brambilla, M.; Cutini, M.; Burchi, G.; Fedrizzi, M.; Massa, D.; Orlandini, A.; Cacini, S. Trichoderma atroviride Enhances Impatiens walleriana Hook. f Growth and Flowering in Different Growing Media. Plants 2024, 13, 583. [Google Scholar] [CrossRef]

| Crop | Estimated Straw Yields (t/ha) | Reference |

|---|---|---|

| Winter wheat | 4.2 | [34] |

| Summer wheat | 3 | [34] |

| Winter barley | 4.2 | [34] |

| Summer barley | 3.6 | [34] |

| Winter oats | 4.7 | [34] |

| Summer oats | 3.9 | [34] |

| Oil seed rape | 2.2 | [35] |

| Beans | 3.7 | [35] |

| Willow and Miscanthus | 10 | [36] |

| Material | Mechanical Process | Final Bulk Density of Product (kg/m3) | Estimated Product Yield (% Mass to Volume Change) | Reference |

|---|---|---|---|---|

| Soft wood | Sawdust | 232 | 431 | [62] |

| Willow | Chipped | 150 | 667 | [37] |

| Miscanthus | Hammer milled | 160 | 625 | [6] |

| Forest residues | Twin screw extrusion | 182 | 549 | [63] |

| Paper waste | Shredded | 107 | 935 | [58] |

| Type of Feedstocks | Thermal Carbonization Conditions | Expected Yield (% w/w) | Reference |

|---|---|---|---|

| Agro-wastes e.g., wheat, barley, oats | 300–600 °C, dry | 24–60% | [68] |

| Agro-wastes e.g., wheat, barley, oats | 100–220 °C, wet | 63–71% | [69] |

| Woody shrub clippings, forest residues, pine bark | 350–750, dry | 32–60% | [67,70] |

| Pine cones | 500–700 °C, wet | 18–84% | [71,72] |

| Grass clippings–Miscanthus, pasture grass | 425–575 °C, dry | 20–33% | [65,73] |

| Brewers spent grains | 500–850 °C, dry | 15–63% | [74,75] |

| Spent mushroom compost | 225–250 °C, wet | 34–73% | [76] |

| Type of Feedstocks | Composting Conditions/Details | Expected Product Yield (% w/w) | Reference |

|---|---|---|---|

| Green wastes–vegetable, household waste | 2–4 m3/min airflow, covered with insulation, 50 days | 38–40% | [78] |

| Green wastes | Forced aeration, heated (30–50 °C), 60 days | 37% | [79] |

| Woody chips, forest residues | uncovered windrows, 100 days | 87% (63% of initial volume) | [80] |

| Bark | uncovered windrows, 100 days | 73% (56% of initial volume) | [80] |

| Feedstock | Ratio with Peat (v/v) | Growth Media Characteristics | Crops Grown | Yield Result as Compared to Control | Reference | ||

|---|---|---|---|---|---|---|---|

| BD g/L | pH | EC dS/m | |||||

| Irish peat | 100% | 56–101 | 4.2–6.0 | 0.3 | - | - | [13] |

| Scots pine (hammer milled) | 10–30% | 95–138 | 5.7–6.1 | 0.39–0.42 | Radish (Raphanus sativus) | Increased yields by 14 to 24% (compared to 70% peat + 30% perlite control) | [83] |

| Miscanthus (milled and screened) | 100% | 120–160 | 6.2–6.3 | 0.4–0.7 | Chinese cabbage (Brassica rapa subsp. Pekinensis) | Reduced yields by −44 to −56% (compared to coir control) | [6] |

| Miscanthus (chopped) | 100% | 100 | 6.3 | 0.3 | Chinese cabbage (Brassica rapa subsp. Pekinensis) | Reduced yields by −61% (compared to coir control) | [6] |

| Fresh pine sawdust mixed with composted pine bark | 20–70% | nr | 4.5–4.8 | 0.07–0.09 | Apache pine (Pinus engelmannii) | Mixed results: increased shoot yields by 7 to 17% for 20, 30 & 50% blends but reduced yields by −2 to −12% for 40, 60 and 70% blends (compared to 50% peat + 50% composted bark control) | [84] |

| Scots pine (disc refined fiber) | 10–30% | 70–91 | 5.4–6 | 0.35–0.36 | Radish (Raphanus sativus) | Increased yields by 5 to 15% (compared to 70% peat + 30% perlite control) | [83] |

| Scots pine (screw extruded fiber) | 10–30% | 75–130 | 5.2–5.7 | 0.3 | Radish (Raphanus sativus) | Reduced shoot yields by −6 to −14% (compared to 70% peat + 30% perlite control) | [83] |

| Wood (disc refined fiber) + sewage sludge | 25–100% | 370 | 4.5 | nr | Strawberry (Fragaria × ananassa) | All reduced yields by about 6% except for the 75% blend | [7] |

| Soft wood fiber | 25–100% | 230–390 | 5.9–6.6 | 3.7–5.1 | Cucumber (Cucumis sativus L.) | All had reduced biomass yields but had similar (to peat) fruit mass except the 50% mix which had greater fruit mass | [85] |

| Eucalyptus bark fiber (hammer milled) | 25–75% | nr | nr | nr | Pinus radiata and Q. saponaria | All had similar to peat biomass for Q. saponaria, For Pinus radiata All mixes were similar to peat except for the 75% bark mix that had significantly reduced biomass | [86] |

| Corn cobs (hammer milled) | 100% | 150 | 6.1 | 0.36 | Cucumber (Cucumis sativus L.) | Similar yields to corn cobs + peat (no peat control) | [87] |

| Pine wood and bark fiber (extruded) | 65% (with aged pine bark, not peat) | 143 | nr | nr | Petunia (Petunia × hybrida Vilm.) | Reduced shoot mass compared to a 65:35% peat: aged pine bark mix | [88] |

| Norway spruce fiber (disc-refined) | 25–100% | nr | nr | nr | Petunia (Petunia × hybrida Vilm.) & Basil (Ocimum basilicum L.) | General reduction in Petunia biomass of about 40% compared to peat as wood fiber content in growth media increased. Reduced biomass of basil at 100 and 75% wood fiber and similar yields for 50 and 25% wood fiber | [89] |

| Feedstock & Pyrolysis Conditions | Ratio with Peat (v/v) | Growth Media Characteristics | Crops Grown | Yield Result as Compared to Control | Reference | ||

|---|---|---|---|---|---|---|---|

| BD g/L | pH | EC dS/m | |||||

| Irish peat | 100% | 56–101 | 4.2–6.0 | 0.3 | - | - | [13] |

| Pine forest residues (450 °C, 48 h) | 25–75% | 375–505 | 6.6–7.8 | 5.5–14.6 | Beach rose (Rosa rugosa Thunb) | All reduced shoot yields by −8 to −57% | [90] |

| Sitka spruce sawmill residues (550 °C, 4 min) | 25–100% | 180–280 | 5.9–9.9 | 0.2–0.4 | Tomato (Solanum lycopersicum) | 25 and 50% blends improved shoot yields up to 40% while 75 & 100% blends reduced yields by up to −86% | [91] |

| Beech spruce & pine mix (400–700 °C, 15–30 min) | 5–20% | nr | 5.0–5.9 | 0.038–0.047 | Cabbage (Brassica oleracea var. capitata) | All reduced shoot yields from −30 to 44% | [92] |

| Conifer wood (conditions nr) | 25–75% | 375–505 | 6.5–7.8 | 5.5–14.6 | Lavender (Lavandula angustifolia) | All reduced shoot yields from −35 to −70% | [93] |

| Beech, spruce and ash mix (450–600 °C, mins nr) | 10–50% | nr | 5–8.3 | 0.21-0.39 | Tomato (Solanum lycopersicum) | All reduced shoot yields from −10 to −53% | [94] |

| Beech, spruce & pine (500–600 °C, mins nr) | 7.5 & 15% | nr | 5.1 & 5.4 | 0.33 and 0.21 | Lettuce (Lactuca sativa) | Yield reduction of −49 and −6% | [95] |

| Pine wood (450 °C, mins nr) | 20–80% | 100–160 | nr | nr | Easter Lily (Lilium longiflorum Thunb.) | No significant differences in plant height between all ratios mixes and peat. | [96] |

| Beech, spruce & pine mix (700 °C, 15–30 min) | 5–20% | 170–250 | 6.4–7.8 | 0.68–0.96 | Antirrhinum majus | No significant effect on plant biomass | [97] |

| Wheat straw (temperature nr, 3 h) | 5–15% | 141–148 | 5.4–5.6 | 1.72–1.9 | Marigold (Tagetes patula L.) | Improved shoot yields by 6.5–15% | [98] |

| Compost Type | Ratio with Peat (v/v) | Growth Media Characteristics | Crops Grown | Yield Result as Compared to Control | Reference | ||

|---|---|---|---|---|---|---|---|

| BD g/L | pH | EC dS/m | |||||

| Irish peat | 100% | 56–101 | 4.2–6.0 | 0.3 | - | - | [13] |

| Green waste | 45% with coir | 210 | 7.8 | 0.77 | Oxeye daisy (Leucanthemum vulgare) | Yield increased by 48% | [8] |

| Green waste (mixed green refuse including urban prunings) | 30–50% | 180–280 | 6.7–7.5 | 0.24–0.45 | Geranium (Pelargonium zonale L.) | Increased yields by up to 6.7% except for a 50% blend treatment | [106] |

| Green waste (40% fruit-vegetable waste) | 25–30% | 220–310 | 5.6–6.1 | 1.5–1.6 | Tomato (Solanum lycopersicum) | Increased shoot yields by range 21–62% | [107] |

| Green waste (urban pruning and trimmings) | 30–100% | 281–365 | 6.7–8.4 | 0.71–1.44 | Basil (Ocimum basilicum) | Reduced shoot yields by −20 to −64% | [100] |

| Green waste (municipal + sewage sludge) | 100% | 600 | 7.6 | nr | Strawberry (Fragaria × ananassa) | Reduced shoot yields by −12% (compared to coir control) | [7] |

| Green waste (botanic wastes) | 25–100% | 137–176 | nr | nr | Escallonia laevis ‘Gold Brian’, Euonymus europaeus, Viburnum tinus, Euryops pectinatus and Olearia × haastii | Similar yields to peat | [99] |

| Forest residues (willow) | 100% | nr | 7–6.6 | 0.2–0.3 | Tomato (Solanum lycopersicum), cucumber (Cucumis sativus) | Reduced yields by −97% for tomato and −74% for cucumber | [102] |

| Composted spent mushroom compost and pasteurized | 20–50% (with vermiculite or perlite) | 277–396 | 6–6.9 | 1.28–1.58 | Cucumber (Cucumis sativus) and Tomato (Solanum lycopersicum) | Yielded similar biomass yields to peat | [105] |

| Composted willow chips with mycelium | 50–90% | nr | nr | nr | Cucumber (Cucumis sativus) | Yielded similar biomass yields to peat at 50 and 75% rates | [108] |

| Composted sheep manure | 25–100% | 368–641 | 6.4–6.7 | 1.0–1.4 | Lettuce (Lactuca sativa L.) | All yielded similar to peat seedling biomass | [109] |

| Physio-Chemical Challenges of Material | Compost Feedstock | Reference | Possible Solution |

|---|---|---|---|

| Reduced availability of N | Gorse Ulex europaeus | [118] | Increase N fertilizer rates. Add nutrients pre-composting. |

| High N availability | Mixed green waste | [119] | Reduce N fertigation. |

| High EC; mainly due to high chloride concentration (high salinity) | Mixed green waste | [106] | Mix with inert materials. |

| Low pH | Post consumer wood | [81] | Apply lime. |

| Low water availability | Municipal garden waste and sewage digestate | [7] | Adjust irrigation rates. Mix with other materials. |

| High salinity (K, Na, Ca, Cl, sulphates, and nitrates) | Spent mushroom compost | [59,117] | Mix with other materials, Long-term weathering |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tumbure, A.; Pulver, C.; Black, L.; Walsh, L.; Prasad, M.; Leahy, J.J.; Corbett, E.; Gaffney, M.T. Bio-Resource Availability in Ireland: A Practical Review of Potential Replacement Materials for Use in Horticultural Growth Media. Horticulturae 2025, 11, 378. https://doi.org/10.3390/horticulturae11040378

Tumbure A, Pulver C, Black L, Walsh L, Prasad M, Leahy JJ, Corbett E, Gaffney MT. Bio-Resource Availability in Ireland: A Practical Review of Potential Replacement Materials for Use in Horticultural Growth Media. Horticulturae. 2025; 11(4):378. https://doi.org/10.3390/horticulturae11040378

Chicago/Turabian StyleTumbure, Akinson, Christian Pulver, Lisa Black, Lael Walsh, Munoo Prasad, James J. Leahy, Eoghan Corbett, and Michael T. Gaffney. 2025. "Bio-Resource Availability in Ireland: A Practical Review of Potential Replacement Materials for Use in Horticultural Growth Media" Horticulturae 11, no. 4: 378. https://doi.org/10.3390/horticulturae11040378

APA StyleTumbure, A., Pulver, C., Black, L., Walsh, L., Prasad, M., Leahy, J. J., Corbett, E., & Gaffney, M. T. (2025). Bio-Resource Availability in Ireland: A Practical Review of Potential Replacement Materials for Use in Horticultural Growth Media. Horticulturae, 11(4), 378. https://doi.org/10.3390/horticulturae11040378