1. Introduction

The effects of climate change, mainly related to changes in air temperature, rainfall, and climate patterns, directly affect the environment, the economy, and society, altering ecosystems and placing significant stress on biotic and abiotic components. The agricultural sector is no exception, threatened by the changes currently underway and how they manifest themselves (rising air temperatures, increased frequency of extreme events, etc.), which are undermining the ability to meet food demand and crop yields [

1,

2].

Crops are increasingly vulnerable to changing ecosystem conditions due to extreme environmental stresses, which hinder their ability to adapt to adverse effects. Therefore, it is urgent to find sustainable methods for protecting crops from their cultivation environment [

3,

4,

5]. In addition, growing urbanization and increased land consumption direct agriculture to areas less appropriate for productive purposes [

6,

7], where boundary conditions may be more extreme, to ensure that food and nutritional demands are met. In fact, agricultural production is progressively influenced by significant changes on a global scale, such as the increased frequency of the arrival of new types of insects, which can bring about a new era in the development and use of agricultural nets, increasing production performance. In many contexts, agricultural nets are even replacing plant protection products, especially in exclusive crops, such as the organic ones [

8,

9,

10].

To mitigate the hazards posed by abiotic stresses, in relation to site-specific features such as excessive heat, light, wind, rainfall and hail, the use of agricultural nets for crop protection is spreading in Mediterranean countries such as Italy, Spain and Israel [

11,

12,

13,

14], with the further aim of proposing, at the same time, sustainable, safe and healthy food systems, oriented towards higher quantity and quality production. There are numerous types of nets on the market, which differ according to specific structural attributes of the threads (shape, size, etc.) that influence net properties such as weight, porosity, shading factor, and air permeability [

15,

16,

17,

18]. Among the different types of agrotextiles, rain protection nets have only recently become available for purchase, due to the growing need for products capable of protecting crops from extreme weather events. In fact, anti-rain nets are mainly used to protect crops from damage caused by severe weather events, although they cause a decrease in the ventilation rate and an increase in relative air humidity [

19,

20,

21]. In this regard, it is worth emphasizing the importance of protecting crops from heavy rainfall, as it can alter crop yields and create an ideal environment for the development of various diseases [

22,

23,

24,

25,

26,

27,

28]. Nevertheless, excessive humidity levels and inadequate ventilation rates can generate significant alterations in the photosynthetic processes of plants, so controlling the flow of water and air through the use of protection nets is one of the main techniques for improving yield quality, also allowing the farmer to limit the use of phytosanitary products, with a view to complying with the new eco-sustainable production plans [

8,

29,

30,

31,

32].

However, the agricultural nets used are produced without any clear technical guidance to ensure their efficient and effective use. In this sense, scientific research plays a fundamental role in investigating the possibility of producing nets capable of selectively filtering solar radiation and helping to regulate the microclimate in plant growing environments [

33,

34,

35,

36]. In addition, a further knowledge gap to be filled is related to the definition of how the geometric features of the net influence rain permeability, similarly to what has been extensively investigated in the past regarding air permeability, radiometric properties, and mechanical characteristics.

Currently, there is no internationally recognized scientific index in the literature with which to classify agricultural nets according to their ability to protect crops from rain, nor are there any codified procedures for testing the rainwater permeability of nets and making comparisons between them in relation to their greater or lesser rain-protection function. A test methodology should start with the parameters that affect the passage of water through the nets and that mainly concern the rainfall and the nets installation. In this regard, analyzing rainfall intensity—defined as the ratio of rain height to event duration—becomes essential, particularly when evaluating rainfall by dividing it into downpours of constant intensity. Also, the inclination of the net with respect to the rainfall and the geometric characteristics of the agricultural nets themselves influence the anti-rain net’s performance.

Greenhouse and screen-house coverings are currently realized through nets with different properties, which limit ventilation and solar radiation while allowing rainfall to pass through, causing radical decay. Therefore, it is necessary to integrate or replace them with nets that limit rain penetration, to prevent crops that are more sensitive to water, such as thin-skinned fruit trees, from rotting, thus fighting the adverse rainfall effects, and also preserving the crop’s microclimate. Anti-rain nets perform as described above, and the characterization of their rainfall permeability index would allow conscious choices regarding their use as material for greenhouse coverings, either alone or to supplement currently used nets.

In view of the above, this research work aims to identify test standards for assessing the rainwater permeability index of agrotextiles used in crop protection. The primary objective is to optimize the design of agricultural nets with rain-protection functions, ultimately developing new products for sustainable agriculture. In this regard, evaluating the nets’ rain permeability is crucial for determining whether they can be used as a greenhouse covering material to supplement or replace currently used nets, as well as identifying the most effective weave orientation and slope for maximizing agro-textile performance. Thus, we intend to investigate whether the analyzed net promotes all the oxygen exchanges required for vegetative-productive balance and maximizes light capture capacity, to avoid altering the photosynthetic process, which would compromise plant productivity.

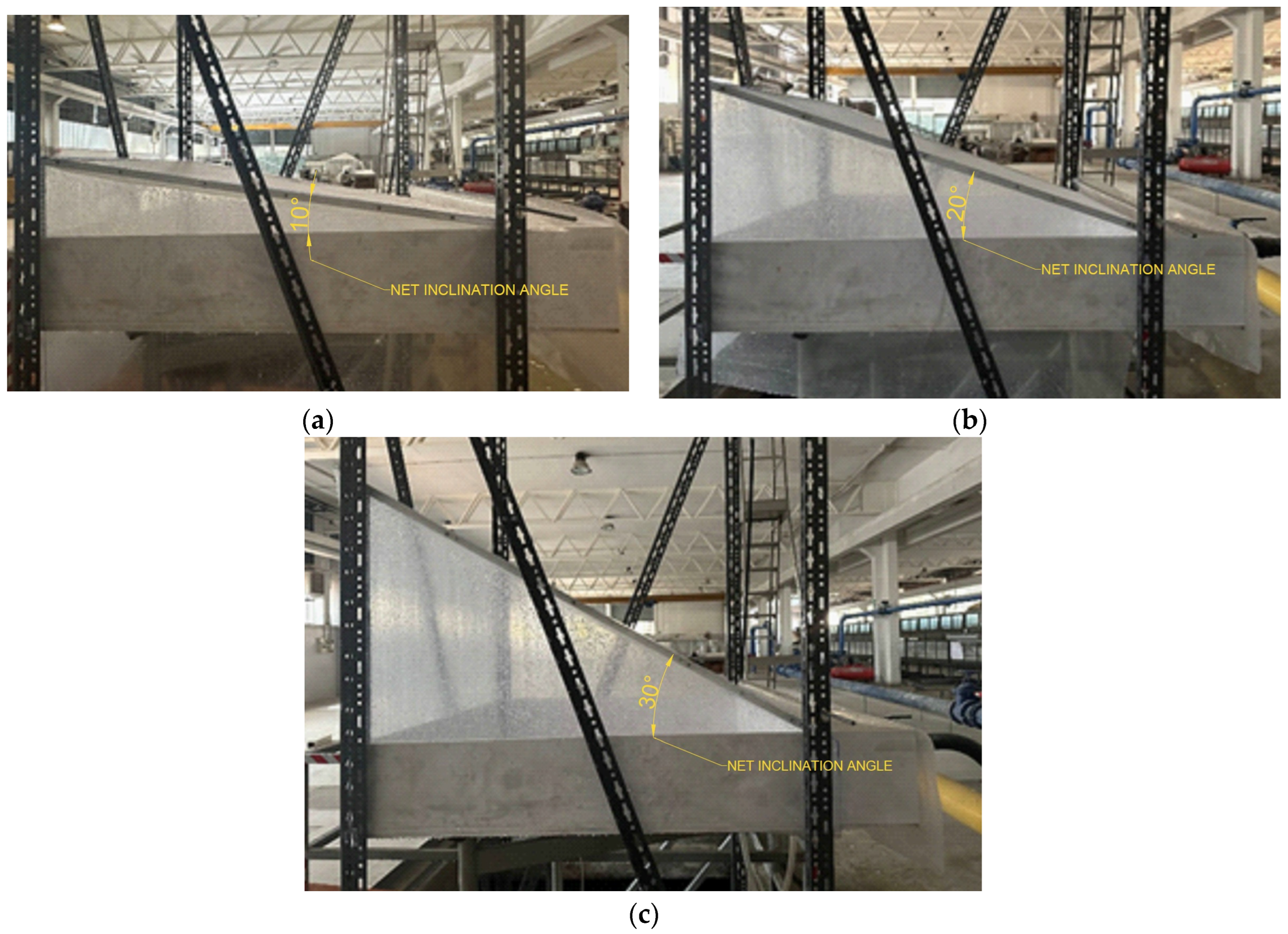

For this purpose, a rainfall simulator was set up at laboratory level, capable of reproducing rain in open field conditions. Preliminary tests were then carried out to identify the optimal rainfall duration for subsequent tests, and a calculation model was defined to evaluate the percolation rate and water runoff rate on the nets under investigation. The assessment of the water permeability coefficient of the crop protection nets was performed by considering three different net inclination angles (10°, 20°, and 30°) and two different warp orientations (warp perpendicular to the slope, which is the correct assembly mode, and warp parallel to the slope), with a rainfall duration of 10 min. Indeed, the study of rainfall plays an essential role in analyzing the performance of crop protection nets, helping to ensure ecosystem services. Therefore, laboratory experiments were planned, using the rainfall simulator to recreate the rainfall event and collect a variety of information, to study its effects on the applications under study.

To appreciate the rain-resistant properties of agrotextiles, an anti-rain net, explicitly produced to protect fruit tree crops from meteoric events, was tested.

2. Materials and Methods

2.1. Experimental Set Up of Laboratory Equipment for Testing Water Permeability

The study of rain permeability in agricultural nets required a preliminary activity to design a model that could simulate field conditions in the laboratory, albeit with an appropriate scale factor to be considered. To this end, a design activity was undertaken to define all the elements required to accurately reproduce the main rainfall characteristics, with reference to rainfall intensity. The simulator used for the tests was subsequently assembled.

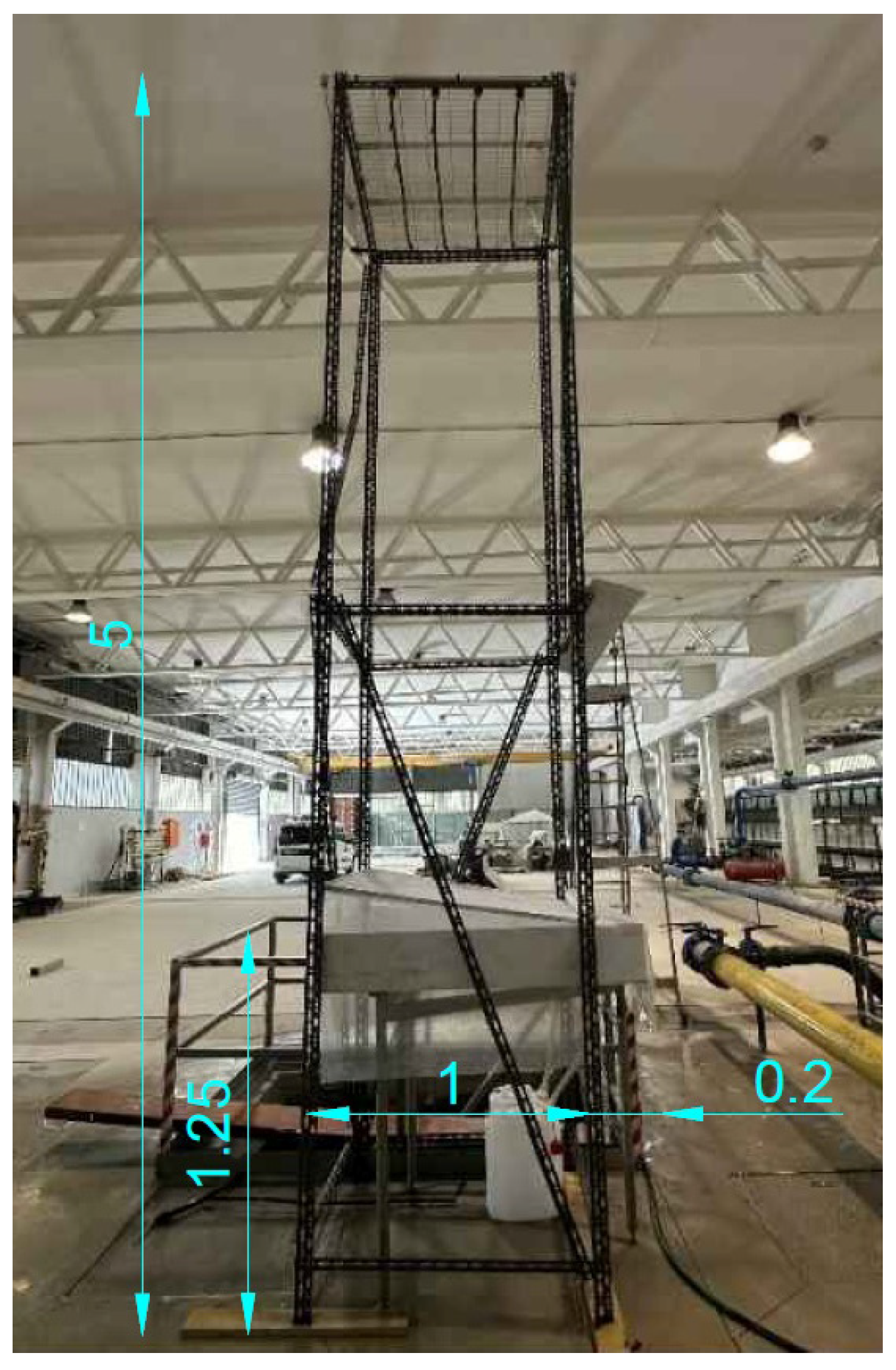

The rainfall simulator (

Figure 1) was installed at the Hydraulic Modelling Laboratory of the Department of Civil, Environmental, Land, Building Engineering and Chemistry (DICATECh) of the Polytechnic University of Bari. As shown in

Figure 1, the structure consists of a tower with plan dimensions of 1.20 m × 1.00 m and a height of 5.00 m, measured from the laboratory floor level. Eight corner profiles in perforated steel were used to realize the frame, each 2.50 m high, and cross-braced L-shaped profiles. The profiles used are assembled with galvanized bolts and retaining screws.

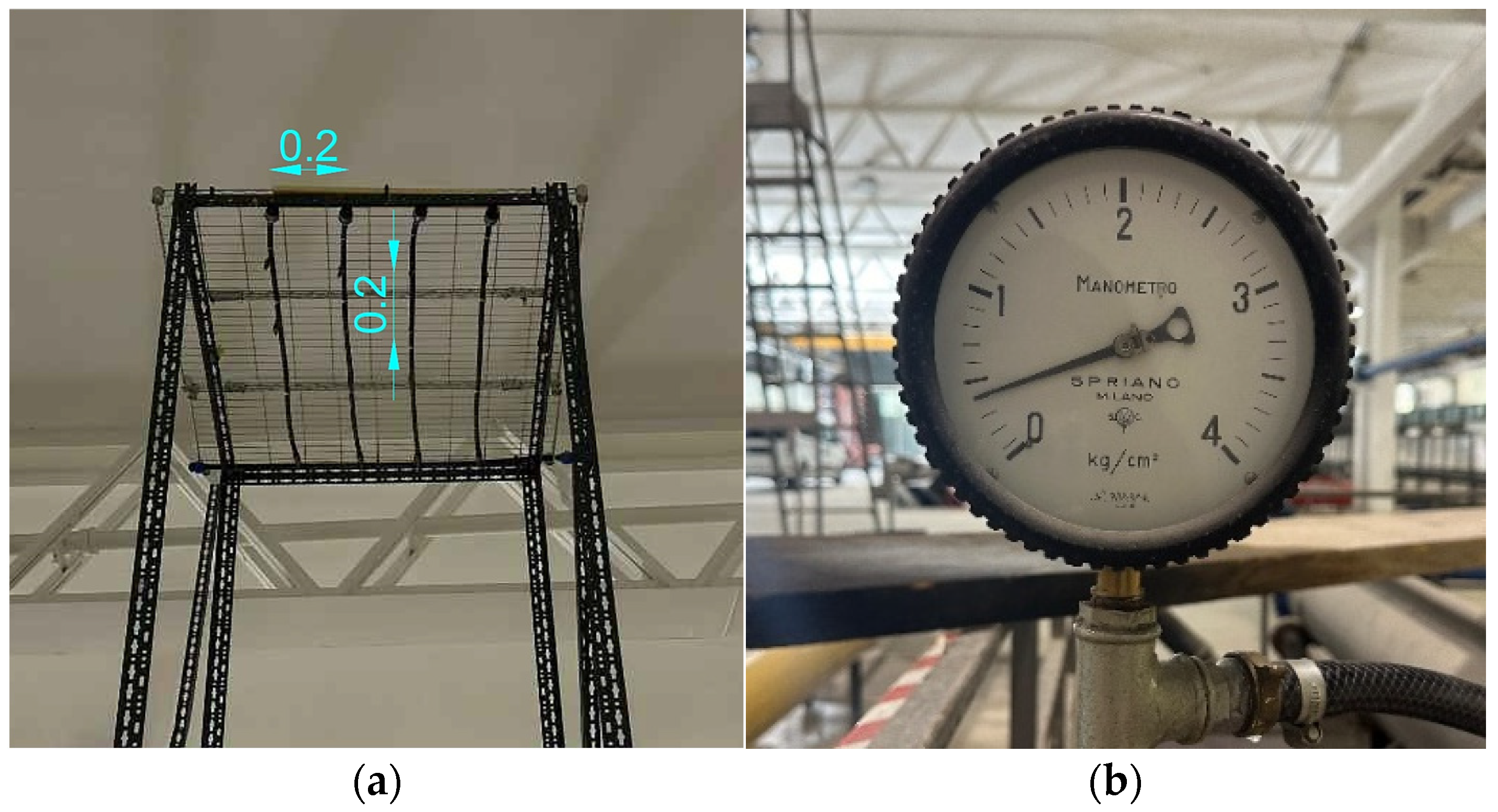

The net sample measured 1.00 m × 1.00 m on a horizontal projection and was assembled and installed at a height of 1.25 m from the floor, inside metal frames set up with different inclinations of 10°, 20°, and 30°. The different angles of the net’s experimental tests represent the most frequent use of the standard net’s installation. On top of the rainfall simulator, 24 sprinklers were installed to simulate rainfall conditions, covering the net sample area, as shown in

Figure 2a. The flow to supply the sprinklers was provided through a pipe linked to the water storage tank installed in the laboratory, to avoid hydraulic load fluctuations and ensure a constant water supply, thereby dampening pressure fluctuations. On the same pipe, a pressure gauge, as shown in

Figure 2b, was installed, allowing the pressure, and, consequently, the rainfall intensity to be varied, thereby simulating different operating conditions. The pressure gauge (Spriano, Milano, Italy) is circular in shape and features a bracket for quick attachment to a control panel. As shown in

Figure 2b, it features a circular scale with values ranging from 0 to 4 kg/cm

2, or 0 to 0.4 MPa, with markings every 0.1 unit and numerical indications every 1 unit. At the bottom of the instrument, there is a connector for insertion into the pipe.

The sprinklers installed and shown in

Figure 2a are 360° dynamic micro-sprinklers with an arched, long-range jet—a type commonly used for irrigating open-field horticulture. They are characterized by a maximum flow rate of 130 L/h, an operating radius of 4.50 m, and can irrigate an area of 16 m

2 up to a pressure of 2.0 bar. The sprinklers were positioned inside a 16 mm diameter pipe, plugged into a threaded slot at 30 mm from the pipe.

Figure 3 below illustrates that the artificial rainwater crossing the net (

MP) falls into a basin measuring 1.00 m × 1.00 m, with a hole at the minimum level to which a plastic bin is connected, which collects the rainfall in a container placed below the net. The water collected corresponds to the water penetrated through the agronets. Similarly, the water flowing over the net (

MR), corresponding to the water runoff, falls in an adjacent basin measuring 0.20 m × 1.00 m, protruding with respect to the model, and is collected in another plastic bin (

Figure 3). In this sense, plastic film has been placed on the sides to prevent runoff water from falling back into the tank collecting

MP.

2.2. Tested Net

For this research, an anti-rain net for crop protection with 7% porosity and a warp thread diameter of 0.280 mm, hereinafter referred to as AR (

Figure 4), was tested. It is made of HDPE transparent threads, and, as illustrated in the subsequent

Figure 4, a very tightly woven warp fabric characterizes it. Different devices defined the net geometrical characteristics. To determine the net thread thickness, a micrometer with ±0.01 mm accuracy was used. The size of the voids was determined using a digital microscope (Dino-Lite Europe, IDCP B.V., model Dino-Lite AM3013T, Dino-Lite Europe, IDCP B.V., Almere, The Netherlands) with a ±0.04 mm accuracy and 200X magnification, along with the Dino-Capture 2 software (Dino-Lite Europe, IDCP B.V., version 2.0, Dino-Lite Europe, IDCP B.V., Almere, The Netherlands). Finally, due to an excessively narrow mesh, an analytical calculation enabled us to determine the porosity value based on the diameters of the monofilaments oriented along the warp and weft directions, as well as the lengths of the voids between filaments in the warp and weft directions.

As can be seen in

Figure 4, it was found that the net has a flat weft and a microstructure with a monofilament warp, a mesh size of 0.03 × 0.94 mm

2 and a weight of 250 ± 5% g/m

2. The net has a round monofilament warp with a 0.280 mm diameter and a rhomboid weft thread, with section diagonals measuring 0.490 mm and 0.220 mm. The weft density is equal to 7 yarns/cm, and the warp density is 32 yarns/cm.

Only one anti-rain net was tested in this study, which limits the replicability of the methodology. In any case, this study does not aim to identify a general law for determining the optimal rainfall duration. However, the methodology used is functional to understanding the rainfall duration for which it is appropriate to perform net tests. In this specific case, the AR anti-rain net, whose characteristics are defined in this sub-paragraph, is used.

2.3. Calculation Model

Currently, there is no internationally recognized index in the literature that allows nets to be classified according to their greater or lesser capacity to protect crops against rain. At the same time, it is not possible to identify a codified standard procedure, with which to compare different agronets in terms of their anti-rain function while maintaining their capacity to protect against insects, for example, according to the dimensional and construction characteristics of the net, such as the type and section of the yarn, porosity, etc.

One of the parameters investigated to define the capacity of agricultural nets to protect crops from atmospheric agents is rainfall intensity, defined as the ratio between the height of rain that falls on the net and the rainfall duration, conventionally evaluated by dividing the rain into a succession of bursts of constant intensity.

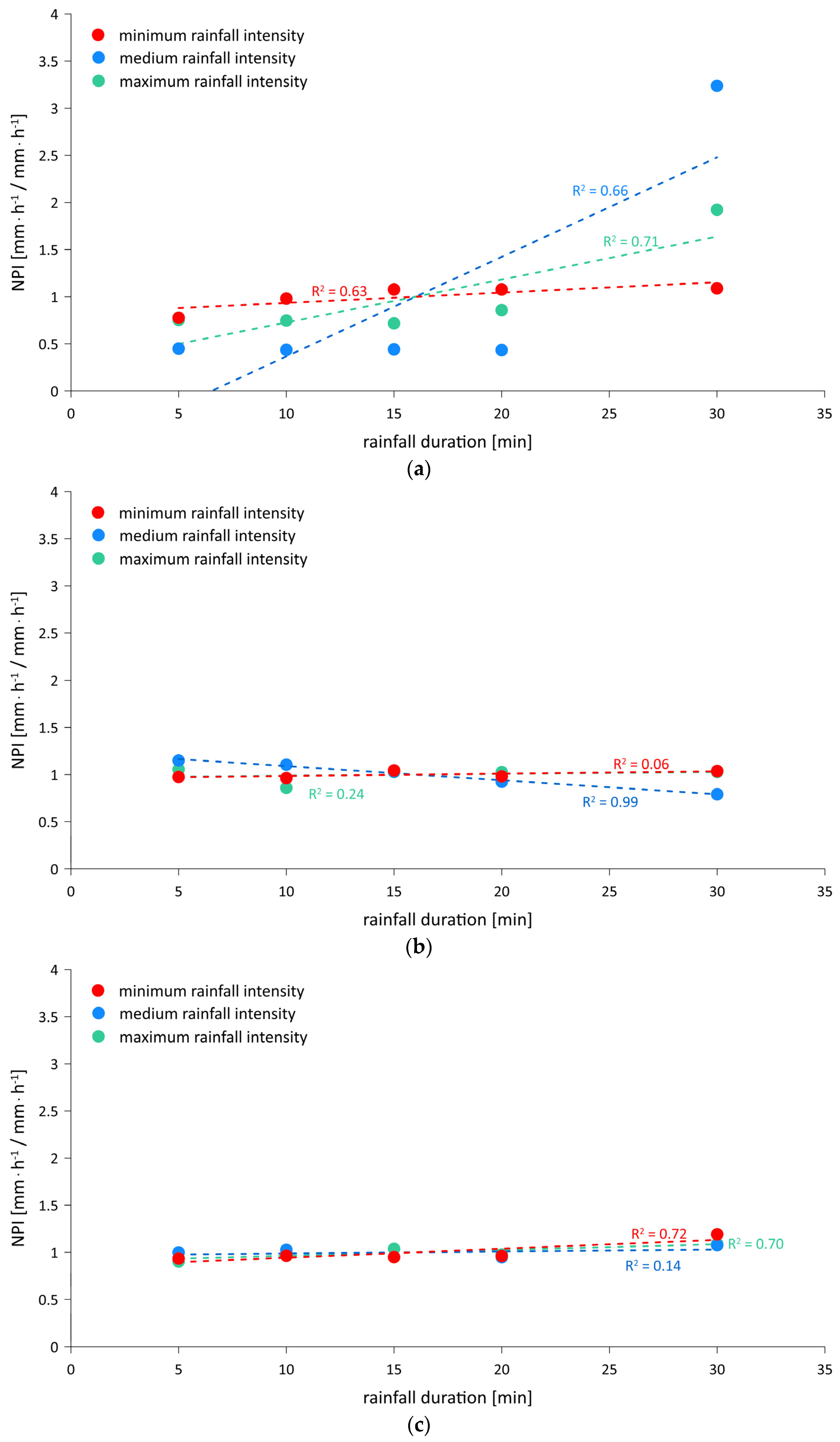

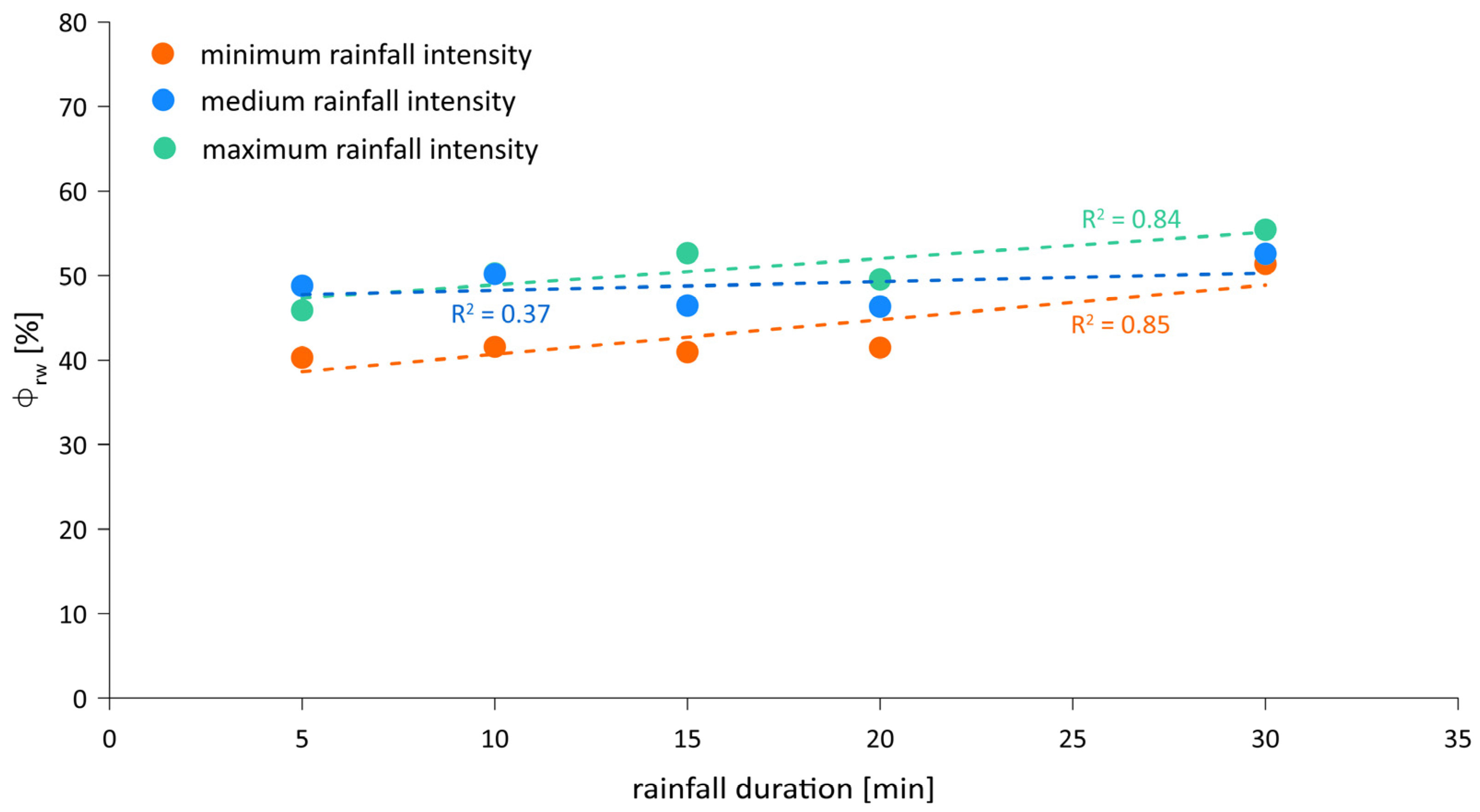

To determine the optimal rainfall duration for the laboratory rain simulator, a calculation model was defined to interpret the results obtained from the preliminary tests. The results are synthetically represented by the determination of the water permeability coefficient of the used agronet, as a function of the net inclination (10°, 20°, and 30°), the rainfall duration (5, 10, 15, 20, and 30 min), and the rainfall intensity.

The following Equations (1) and (2) were used to determine the water runoff

R and rainwater permeability index

Φrw of the tested agronet under the action of a simulated laboratory rainfall for a predetermined duration:

where

Φrw is the rainwater permeability index [%]

MPB (

Figure 3) is the mass of the bin containing the total mass of water passing through the net [kg]

MB is the mass of the empty bin [kg]

TM (

Figure 3) is the total water mass [kg]

R is the net runoff water [%]

MRB (

Figure 3) is the mass of the bin containing the total runoff water mass [kg]

The rainwater permeability index Φrw is a parameter used to account for the interaction of the nets with rain. It is a quantitative indicator of the capacity of an agronet to let rainwater pass through to the crops and soil below. The rainwater permeability index Φrw for the laboratory tests, carried out using a rain simulator equipped with water sprinklers, was defined as the ratio of the amount of water that penetrates through a net sample to the total amount of water that falls on the net sample.

To analyze the data, a Normalized Permeability Index (

NPI) was defined, obtained by dividing the rainwater permeability index

Φrw by the average of all rainwater permeability indices identified in relation to a specific net slope and rainfall intensity, and defined in Equation (3) below:

where

Φrw,i is the i-th rainwater permeability index identified at a given rainfall duration and intensity and net slope;

n is the number of measurements, in this specific case five (at 5, 10, 15, 20, 30 min) for a specific net slope and rainfall intensity.

Regarding the

NPI datasets, the Standard Deviation (SD) at each rainfall duration was determined using Equation (4):

where

N is the number of measurements, in this specific case three as three different rainfall intensities are considered;

µNPI is the NPIi mean value.

The SDs, as defined by varying the net inclination, were then summed, yielding an overall value at each rainfall duration. The optimal rainfall duration was therefore defined as the time duration at which the sum of the SDs is minimum, to understand the overall variability of a larger dataset, and to compare the variability between different groups. The sum of the variances allowed for the calculation of a value representing the total variability of all the data, which helped determine which of the five datasets (corresponding to the five different rainfall durations tested) exhibited the lowest overall variability [

37].

2.4. Experimental Protocol for Water Permeability Tests

The tests were carried out according to a procedure designed to evaluate the rain permeability coefficient of the tested agronet, which is a valuable index for comparing the different agricultural nets with one another. However, the laboratory simulation of meteoric phenomena posed some difficulties, linked to accurately simulating the physical properties of rainfall. To date, no system has yet been realized that can guarantee a reliable simulation of rainfall over a large surface area. Artificial rainfall generation, in fact, is of particular interest in many research fields, because it guarantees the repeatability of events and the control of boundary conditions, which is impossible to achieve with field applications.

In the present research, the first step was to select an agricultural net with specific geometric characteristics, including porosity, mesh size, thread size, type of fabric, etc., to retrieve samples of adequate size for the planned tests. A test protocol was therefore developed to evaluate the Φrw values, defining the methods necessary to ensure the significance of the results, first to determine the optimal rainfall duration to be used in subsequent tests.

To this end, preliminary tests were first carried out on the AR net, using a 1.00 m2 (in horizontal projection) sample of this net. The tests were performed by varying the inclination of the net samples (10°, 20°, 30°), the pressure applied to the water by means of the pressure gauge (0.04 MPa, 0.08 MPa, 0.11 MPa) and the rainfall duration (30 min, 20 min, 15 min, 10 min, 5 min), thus identifying n values of Φrw,i. Every single value was then divided by the average value of all Φrw,i indices, determined regarding a definite net slope and rainfall intensity, thus identifying the NPI. Normalization allows indicators that originally had different scales to be compared directly, expressing them all on the same scale. The NPI was then used to evaluate how permeability coefficient values were distributed in relation to the central tendency of the data, to identify the rainfall duration corresponding to the minimum distance between the i-th Φrw,i indices, and the average value.

The three different pressure values were chosen because they yield rainfall heights between 10 mm and 18 mm for a 10 min rainfall duration, which is approximately the average rainfall height value of about 16 mm characteristics of the southern Italy area for the same rainfall duration [

38]. In addition, it has been observed that the minimum pressure applied (0.04 MPa) corresponds to the maximum rainfall intensity (approximately 88 mm/h). In comparison the average pressure of 0.08 MPa corresponds to the minimum rainfall intensity (approximately 39 mm/h). When the highest-pressure value (0.11 MPa) is applied, the rainfall intensity value falls between the two previously indicated values (approximately 74 mm/h).

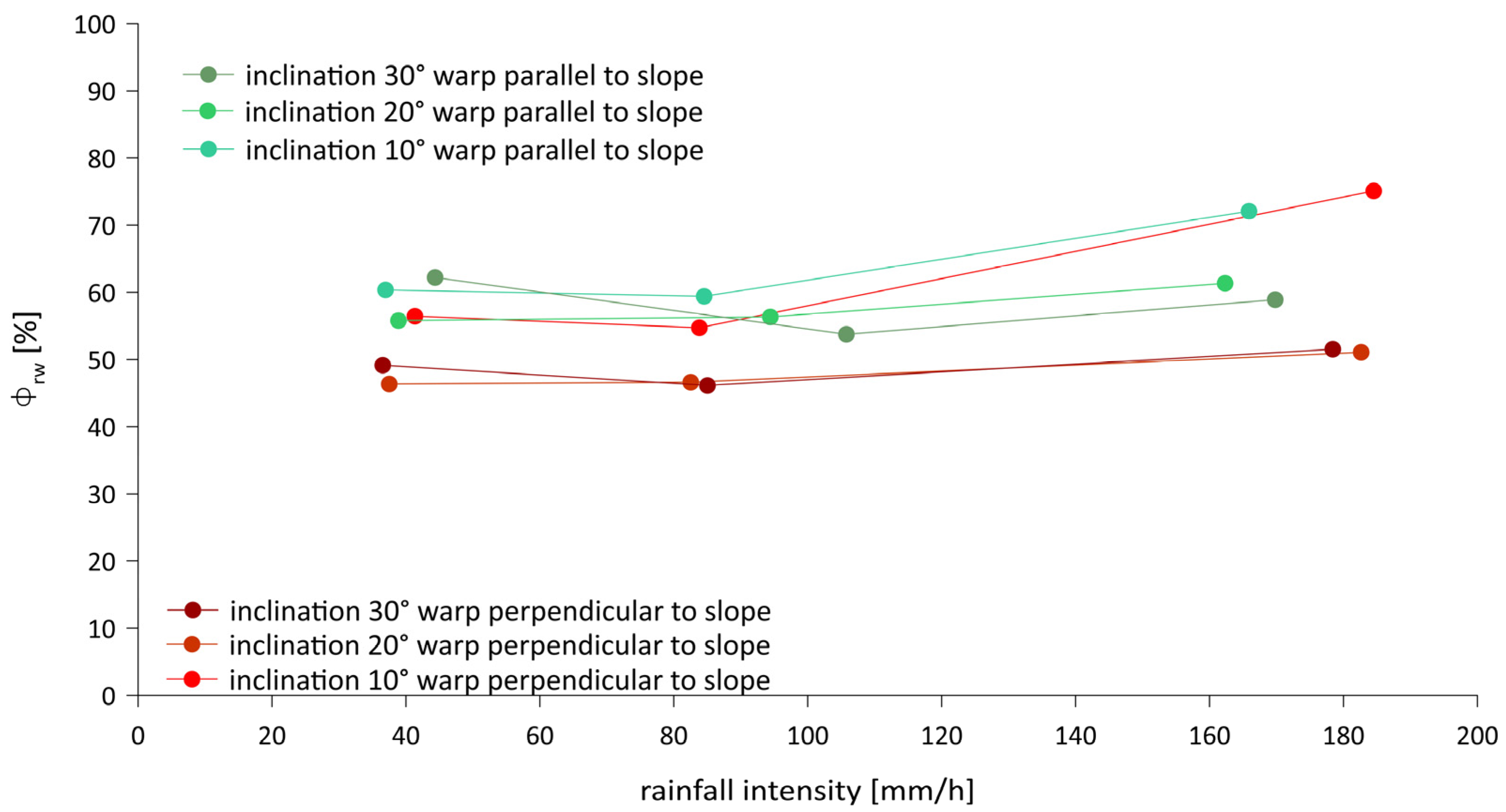

Known the optimal rainfall duration value, corresponding to the minimum value of the sum of SD, tests were carried out to determine the

Φrw values of the AR net by varying the rainfall intensity from a minimum of about 39 mm/h to a maximum of about 170 mm/h, the net inclination and the warp orientation, assumed perpendicular or parallel to the slope (

Figure 5). In this way, the amount of water flowing over the net and the amount of water percolating through it—respectively collected in plastic bins, which were weighed at the end of each test—were determined.

Figure 5 illustrates the three different slopes tested in this research work to clarify better how the nets, at varying angles, were impacted by the simulated rainfall. In addition, considering that one of the purposes of this article is to propose a standard procedure for laboratory experimental tests, we graphically illustrate the operative conditions for carrying out these tests.

Laboratory tests were carried out in the absence of solar radiation, at an ambient air temperature of 26–28 °C and a relative humidity of 50–70%. Φrw,i values were determined under stationary conditions, having discarded the first 5 min of rainfall. For each rainfall intensity value, the test was repeated three times, and then the average value was calculated. The quantification of the water percolating through the net MP and of the water flowing over it MR made it possible to define the Φrw of the agricultural net as a function of the variation in the net inclination and the rainfall intensity and duration, using Equations (1) and (2).

4. Conclusions

Defining which factors must be considered in the design phase of crop protection nets, to “customize” their production according to the main characteristics of use, will enable further innovation of agrotextiles to make them more performant and suitable for the purposes and uses for which they are intended. Anti-rain nets, in the current climate change scenario increasingly characterized by less frequent but more intense rainfall events, require an engineering process to enhance their performance in terms of rain permeability.

The study carried out concerned the definition of a test standard for an agricultural net with anti-rain characteristics, to determine its water permeability properties when used for tree crops. To achieve this, laboratory tests were carried out, which yielded a set of data. The interpretation of this data enabled an initial assessment of the research’s purpose.

The absence of a test standard for evaluating the Φrw index of agrotextiles required preliminary tests to define the optimal rainfall duration. Tests carried out using the laboratory rain simulator at varying rainfall intensity, rainfall duration, and net slope made it possible to identify a duration with which to carry out the subsequent tests equal to 10 min, since the sum of the SDs is minimal at this value.

After establishing the methods for performing the tests, an agricultural net with an anti-rain function was tested. The tests showed that the Φrw indices characterized the anti-rain net with differences becoming evident as the orientation of the warp compared to the slope and the inclination of the agrotextile changed. It was found that the best performance in terms of rainfall resistance is achieved when the anti-rain net has its warp oriented perpendicular to the slope and a 20° inclination, resulting in a Φrw index of less than 50% for all considered rainfall intensity values.

The methodology proposed in this paper has some limitations regarding the evaluation of the Φrw index evaluation, due to the characteristics of the laboratory rain simulator that do not allow for an accurate replication of open-field conditions. This occurs because the distance between the sprinklers and the tested net is about 5 m, since the laboratory height constitutes an upper limit that cannot be exceeded. In open fields, the rainfall height is obviously greater, so the data are affected by the limitations of this model. Similarly, even the need to periodically replace the sprinklers constitutes a model limitation; this is necessary because sprinklers are prone to clogging due to the chemical composition of water. This activity was performed periodically but could not be scheduled. Replacement was carried out whenever rainfall distribution was uneven due to clogging of one or more sprinklers.

At the conclusions of the study presented in this work, it becomes clear that the research reveals numerous areas for in-depth investigation, necessitating an expansion of the number of agrotextiles to be tested, selected based on an assessment of the current state and trends of the agricultural nets market. For the selected agrotextiles, water permeability tests must be carried out using the device and standards outlined in this work to ensure the significance of the results. In this way, it will be possible to compare different agrotextiles with anti-rain function, as well as with anti-insect nets, with the priority aim of obtaining useful information for the improvement of their design and the optimization of their technical performance, and to identify an innovative prototype of a smart and sustainable anti-rain net, which can also contribute to reducing the plastic footprint of agriculture.

In addition, further research fields concern the possible development of agrotextiles that merge several functions (anti-rain, anti-insect, etc.) and that guarantee, above all, the regulation of the microclimate in the environments used for crop cultivation, making it possible to maximize production yields while limiting the space required.

In conclusion, this study aimed to identify a possible standardization procedure for testing net rainfall permeability, as each manufacturer provides rainfall permeability values that are not derived from standard procedures. For this reason, the product information sheets contain data that is not obtained uniformly by all manufacturers. Therefore, to fill this gap, this research provides elements to standardize agricultural net testing, to be performed by varying the inclination (10°, 20°, 30°) and identifying the optimal rainfall duration based on different possible rainfall intensities and installation directions.