Energy Efficiency of Glasshouses and Plant Factories for Sustainable Urban Farming in the Desert Southwest of the United States of America

Abstract

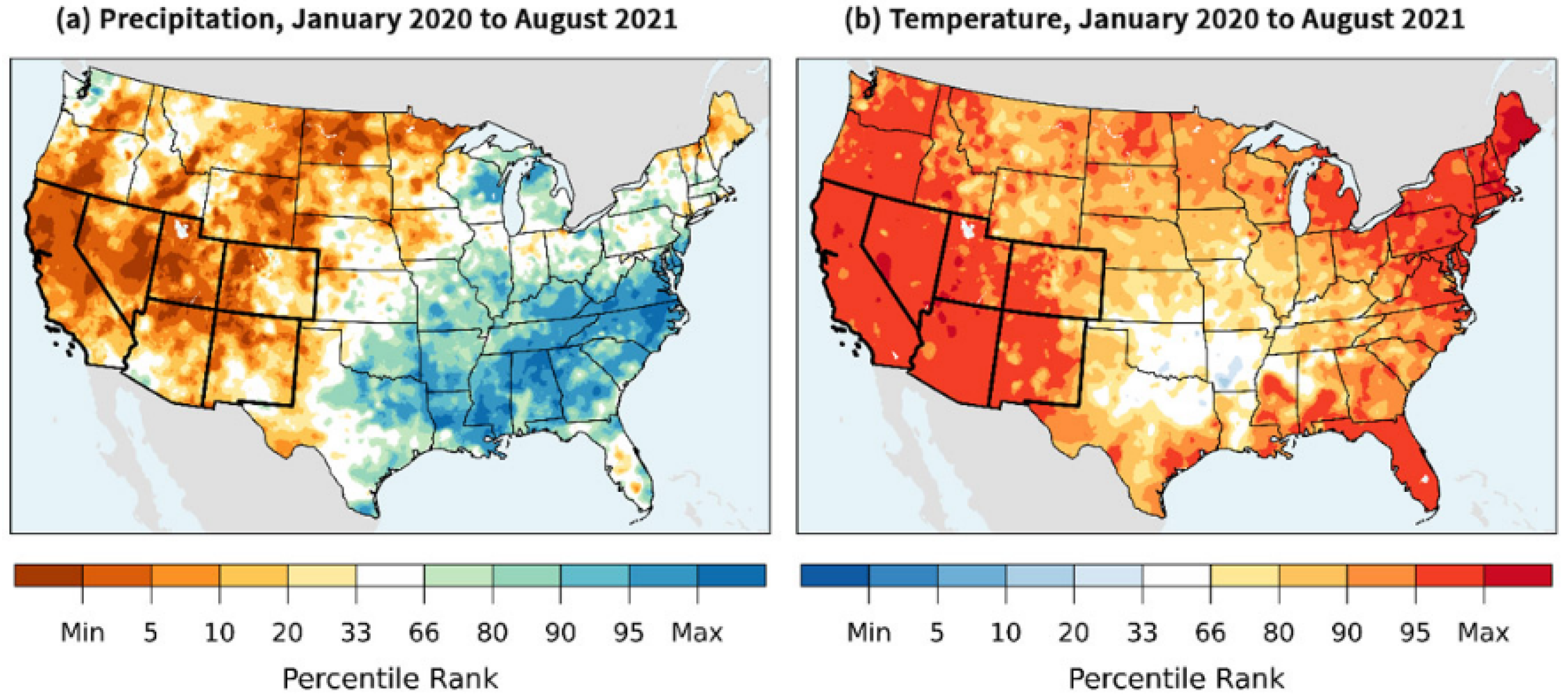

:1. Introduction

2. Urban Agriculture/Farming

3. Artificial Lighting

4. Water Use Efficiency

5. Energy Utilization by Humidity, Ventilation, and Air Conditioning

6. Future Recommendations

Designing an Urban Plant Factory in the Desert Southwest

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Laity, J.J. Deserts and Desert Environments; John Wiley & Sons: Chichester, UK, 2009; Volume 3. [Google Scholar]

- Dong, J.; Gruda, N.; Li, X.; Cai, Z.; Zhang, L.; Duan, Z. Global Vegetable Supply towards Sustainable Food Production and a Healthy Diet. J. Clean. Prod. 2022, 369, 133212. [Google Scholar] [CrossRef]

- Brazel, A.J. Dust and Climate in the American Southwest. In Paleoclimatology and Paleometeorology: Modern and Past Patterns of Global Atmospheric Transport; Springer: Dordrecht, The Netherlands, 1989; pp. 65–96. [Google Scholar]

- Available online: https://www.census.gov/content/dam/Census/library/visualizations/2019/demo/desert-southwest.pdf (accessed on 4 January 2024).

- Sheppard, P.R.; Comrie, A.C.; Packin, G.D.; Angersbach, K.; Hughes, M.K. The Climate of the US Southwest. Clim. Res. 2002, 21, 219–238. [Google Scholar] [CrossRef]

- Steenburgh, W.J.; Redmond, K.T.; Kunkel, K.E.; Doesken, N.; Gillies, R.R.; Horel, J.D.; Hoerling, M.P.; Painter, T.H.; Rasmussen, R. Present Weather and Climate: Average Conditions. In Assessment of Climate Change in the Southwest United States: A Report Prepared for the National Climate Assessment; Garfin, G., Ed.; Island Press: Washington, DC, USA, 2013; pp. 56–73. [Google Scholar]

- Sanderson, M.A.; Liebig, M.A.; Hendrickson, J.R.; Kronberg, S.L.; Toledo, D.; Derner, J.D.; Reeves, J.L. Long-Term Agroecosystem Research on Northern Great Plains Mixed-Grass Prairie Near Mandan, North Dakota. Can. J. Plant Sci. 2015, 95, 1101–1116. [Google Scholar] [CrossRef]

- Hirt, P.; Snyder, R.; Hester, C.; Larson, K. Water Consumption and Sustainability in Arizona: A Tale of Two Desert Cities. J. Southwest 2017, 59, 264–301. [Google Scholar] [CrossRef]

- Achakulwisut, P.; Anenberg, S.C.; Neumann, J.E.; Penn, S.L.; Weiss, N.; Crimmins, A.; Fann, N.; Martinich, J.; Roman, H.; Mickley, L.J. Effects of Increasing Aridity on Ambient Dust and Public Health in the US Southwest under Climate Change. GeoHealth 2019, 3, 127–144. [Google Scholar] [CrossRef]

- Nelson, G.; Bogard, J.; Lividini, K.; Arsenault, J.; Riley, M.; Sulser, T.B.; Mason-D’Croz, D.; Power, B.; Gustafson, S.; Herrero, M.; et al. Income growth and climate change effects on global nutrition security to mid-century. Nat. Sustain. 2018, 1, 773–781. [Google Scholar] [CrossRef]

- Available online: https://www.drought.gov/news/new-noaa-report-exceptional-southwest-drought-exacerbated-human-caused-warming (accessed on 4 January 2024).

- Garfin, G.M. Climate change challenges and solutions for water managers. In Shared Borders, Shared Waters: Arizona, Israeli-Palestinian and Colorado River Basin Water Challenges; CRC Press: Boca Raton, FL, USA, 2013; pp. 187–202. [Google Scholar]

- Armanda, D.T.; Guinée, J.B.; Tukker, A. The second green revolution: Innovative urban agriculture’s contribution to food security and sustainability–A review. Glob. Food Secur. 2019, 22, 13–24. [Google Scholar] [CrossRef]

- Langemeyer, J.; Madrid-Lopez, C.; Mendoza Beltran, A.; Villalba Mendez, G. Urban Agriculture—A Necessary Pathway towards Urban Resilience and Global Sustainability? Landsc. Urban Plan. 2021, 210, 104055. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Chong, C.; Wang, C.-H.; Wang, X. A Decision Support Framework for the Design and Operation of Sustainable Urban Farming Systems. J. Clean Prod. 2020, 268, 121928. [Google Scholar] [CrossRef]

- Eigenbrod, C.; Gruda, N. Urban vegetable for food security in cities. A review. Agron. Sustain. Dev. 2015, 35, 483–498. [Google Scholar] [CrossRef]

- Harris, T. Input-Output Model, State of Nevada (IMPLAN); University Center for Economic Development, University of Nevada: Reno, NV, USA, 2011. [Google Scholar]

- Gatzke, H. Developing a Local Food Industry in Nevada; University of Nevada Cooperative Extension: Reno, NV, USA, 2012. [Google Scholar]

- Allen, J.A.; Mason, A.C. Urban food forests in the American Southwest. Urban Agric. Reg. Food Syst. 2021, 6, e20018. [Google Scholar] [CrossRef]

- Santos, M.J.P.L. Smart cities and urban areas—Aquaponics as innovative urban agriculture. Urban For. Urban Green. 2016, 20, 402–406. [Google Scholar] [CrossRef]

- Gruda, N.; Tanny, J. Protected Crops. In Horticulture—Plants for People and Places; Dixon, G.R., Aldous, D.E., Eds.; Springer: Dordrecht, The Netherlands, 2014; Volume 1, pp. 327–405. [Google Scholar]

- Baeza, E.J.; Van Breugel, A.J.B.; Hemming, S.; Stanghellini, C. Smart greenhouse covers: A look into the future. In Proceedings of the XI International Symposium on Protected Cultivation in Mild Winter Climates and I International Symposium on Nettings, Tenerife, Spain, 27–31 January 2019; Volume 1268, pp. 213–224. [Google Scholar]

- Taki, M.; Ajabshirchi, Y.; Ranjbar, S.F.; Rohani, A.; Matloobi, M. Modeling and Experimental Validation of Heat Transfer and Energy Consumption in an Innovative Greenhouse Structure. Inf. Process. Agric. 2016, 3, 157–174. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy management strategies for commercial greenhouses. Appl. Energy 2014, 114, 880–888. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Shariati, H.M.; Rafiee, S.; Mousazadeh, H. Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew. Sustain. Energy Rev. 2014, 29, 316–324. [Google Scholar] [CrossRef]

- De Villiers, D.S.; Wien, H.C.; Reid, J.E.; Albright, L.D. Energy use and yields in tomato production: Field, high tunnel and greenhouse compared for the northern tier of the USA (Upstate New York). Acta Hortic. 2011, 893, 373–380. [Google Scholar] [CrossRef]

- Agrilyst Press Release. Agrilyst releases third State of Indoor Farming survey; The Report Notes That 51 Percent of Respondents Currently Operate Profitable Indoor Farms. Produce Grower. 2018. Available online: https://www.producegrower.com/news/agrilyst-state-of-indoor-farming-survey/ (accessed on 4 January 2024).

- Urbano, B.; Barquero, M.; González-Andrés, F. The environmental impact of fresh tomatoes consumed in cities: A comparative LCA of long-distance transportation and local production. Sci. Hortic. 2022, 301, 111126. [Google Scholar] [CrossRef]

- Weidner, T.; Yang, A.; Hamm, M.W. Energy optimisation of plant factories and greenhouses for different climatic conditions. Energy Convers. Manag. 2021, 243, 114336. [Google Scholar] [CrossRef]

- Goto, E. Plant production in a closed plant factory with artificial lighting. In Proceedings of the VII International Symposium on Light in Horticultural Systems, Wageningen, The Netherlands, 15–19 October 2012; Volume 956, pp. 37–49. [Google Scholar]

- Kozai, T.; Niu, G. Plant Factory as a Resource-Efficient Closed Plant Production System. In Plant Factory; Academic Press: London, UK, 2016; pp. 69–90. [Google Scholar]

- Avgoustaki, D.D.; Xydis, G. Plant Factories in the Water-Food-Energy Nexus Era: A Systematic Bibliographical Review. Food Secur. 2020, 12, 253–268. [Google Scholar] [CrossRef]

- Graamans, L.; Tenpierik, M.; van den Dobbelsteen, A.; Stanghellini, C. Plant Factories: Reducing Energy Demand at High Internal Heat Loads through Façade Design. Appl. Energy 2020, 262, 114544. [Google Scholar] [CrossRef]

- Choi, E.J.; Kim, J.; Lee, S.M. Annual Energy Demand Analysis of a Lettuce Growing Plant Factory According to the Environmental Changes. J. Bio-Environ. Control 2023, 32, 278–284. [Google Scholar] [CrossRef]

- Kalantari, F.; Tahir, O.M.; Akbari Joni, R.; Fatemi, E. Opportunities and Challenges in Sustainability of Vertical Farming: A Review. J. Landsc. Ecol. 2018, 11, 35–60. [Google Scholar] [CrossRef]

- Kozai, T. Sustainable Plant Factory: Closed Plant Production Systems with Artificial Light for High Resource Use Efficiencies and Quality Produce. Acta Hortic. 2013, 1004, 27–40. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Outlook 2019; IEA: Paris, France, 2019. [Google Scholar]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy Efficient Operation and Modeling for Greenhouses: A Literature Review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant Factories versus Greenhouses: Comparison of Resource Use Efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Zhang, Y.; Kacira, M. Comparison of Energy Use Efficiency of Greenhouse and Indoor Farming Systems. Eur. J. Hortic. Sci. 2020, 85, 310–320. [Google Scholar] [CrossRef]

- Liu, S.; Teng, P. Way Forward. In High-Tech Plant Factories: Challenges and Way Forward; S. Rajaratnam School of International Studies: Singapore, 2017; pp. 11–17. Available online: www.jstor.org/stable/resrep17149.6 (accessed on 6 April 2020).

- De Halleux, D.; Gauthier, L. Energy Consumption Due to Dehumidification of Greenhouses under Northern Latitudes. J. Agric. Eng. Res. 1998, 69, 35–42. [Google Scholar] [CrossRef]

- Cai, W.; Bu, K.; Zha, L.; Zhang, J.; Lai, D.; Bao, H. Energy Consumption of Plant Factory with Artificial Light: Challenges and Opportunities. arXiv 2024, arXiv:2405.09643. [Google Scholar]

- Harbick, K.; Albright, L.D. Comparison of Energy Consumption: Greenhouses and Plant Factories; International Society for Horticultural Science (ISHS): Leuven, Belgium, 2016; pp. 285–292. [Google Scholar]

- Graamans, L.; van den Dobbelsteen, A.; Meinen, E.; Stanghellini, C. Plant Factories; Crop Transpiration and Energy Balance. Agric. Syst. 2017, 153, 138–147. [Google Scholar] [CrossRef]

- Engler, N.; Krarti, M. Review of Energy Efficiency in Controlled Environment Agriculture. Renew. Sustain. Energy Rev. 2021, 141, 110786. [Google Scholar] [CrossRef]

- Lefers, R.M.; Tester, M.; Lauersen, K.J. Emerging Technologies to Enable Sustainable Controlled Environment Agriculture in the Extreme Environments of Middle East-North Africa Coastal Regions. Front. Plant Sci. 2020, 11, 801. [Google Scholar] [CrossRef] [PubMed]

- Amani, M.; Foroushani, S.; Sultan, M.; Bahrami, M. Comprehensive Review on Dehumidification Strategies for Agricultural Greenhouse Applications. Appl. Therm. Eng. 2020, 181, 115979. [Google Scholar] [CrossRef]

- Costantino, A.; Comba, L.; Sicardi, G.; Bariani, M.; Fabrizio, E. Energy Performance and Climate Control in Mechanically Ventilated Greenhouses: A Dynamic Modelling-Based Assessment and Investigation. Appl. Energy 2021, 288, 116583. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D.; Fang, Y. Methodologies of Control Strategies for Improving Energy Efficiency in Agricultural Greenhouses. J. Clean. Prod. 2020, 274, 122695. [Google Scholar] [CrossRef]

- Lopez, A.; Valera, D.L.; Molina-Aiz, F.D.; Pena, A. Sonic Anemometry to Evaluate Airflow Characteristics and Temperature Distribution in Empty Mediterranean Greenhouses Equipped with Pad–Fan and Fog Systems. Biosyst. Eng. 2012, 113, 334–350. [Google Scholar] [CrossRef]

- Nasrollahi, H.; Ahmadi, F.; Ebadollahi, M.; Najafi Nobar, S.; Amidpour, M. The Greenhouse Technology in Different Climate Conditions: A Comprehensive Energy-Saving Analysis. Sustain. Energy Technol. Assess. 2021, 47, 101455. [Google Scholar] [CrossRef]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A Review on Hydroponics and the Technologies Associated for Medium-and Small-Scale Operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Carotti, L.; Pistillo, A.; Zauli, I.; Meneghello, D.; Martin, M.; Pennisi, G.; Gianquinto, G.; Orsini, F. Improving Water Use Efficiency in Vertical Farming: Effects of Growing Systems, Far-Red Radiation and Planting Density on Lettuce Cultivation. Agric. Water Manag. 2023, 285, 108365. [Google Scholar] [CrossRef]

- Rufí-Salís, M.; Parada, F.; Arcas-Pilz, V.; Petit-Boix, A.; Villalba, G.; Gabarrell, X. Closed-Loop Crop Cascade to Optimize Nutrient Flows and Grow Low-Impact Vegetables in Cities. Front. Plant Sci. 2020, 11, 596550. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Bonarrigo, G.; Verheust, Y.; Roccaro, P.; Van Hulle, S. Water Reuse in Closed Hydroponic Systems: Comparison of GAC Adsorption, Ion Exchange and Ozonation Processes to Treat Recycled Nutrient Solution. Aquacult. Eng. 2017, 78, 190–195. [Google Scholar] [CrossRef]

- David, L.H.; Pinho, S.M.; Agostinho, F.; Costa, J.I.; Portella, M.C.; Keesman, K.J.; Garcia, F. Sustainability of Urban Aquaponics Farms: An Emergy Point of View. J. Clean. Prod. 2022, 331, 129896. [Google Scholar] [CrossRef]

- Wirza, R.; Nazir, S. Urban Aquaponics Farming and Cities—A Systematic Literature Review. Rev. Environ. Health 2021, 36, 47–61. [Google Scholar] [CrossRef] [PubMed]

- Elbreki, A.M.; Muftah, A.F.; Sopian, K.; Jarimi, H.; Fazlizan, A.; Ibrahim, A. Experimental and economic analysis of passive cooling PV module using fins and planar reflector. Case Stud. Therm. Eng. 2021, 23, 100801. [Google Scholar] [CrossRef]

- Yokoyama, R. Energy Consumption and Heat Sources in Plant Factories. In Plant Factory Using Artificial Light; Anpo, M., Fukuda, H., Wada, T., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 177–184. [Google Scholar]

- Nakabo, Y. Design and control of smart plant factory. In Smart Plant Factory; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–55. [Google Scholar]

- Ohyama, K.; Kozai, T.; Kubota, C.; Chun, C.; Hasegawa, T.; Yokoi, S.; Nishimura, M. Coefficient of performance for cooling of a home-use air conditioner installed in a closed-type transplant production system. Shokubutsu Kojo Gakkaishi 2002, 14, 141–146. [Google Scholar] [CrossRef]

- Shaari, A.M.; Razuan, M.S.M.; Taweekun, J.; Batcha, M.F.M.; Abdullah, K.; Sayuti, Z.; Ahmad, M.A.; Mohamad Tahir, M.A. Energy profiling of a plant factory and energy conservation opportunities. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 80, 13–23. [Google Scholar] [CrossRef]

- Shelford, T.J.; Both, A.J. On the Technical Performance Characteristics of Horticultural Lamps. AgriEngineering 2021, 3, 716–727. [Google Scholar] [CrossRef]

- Murase, H. The Latest Development of Laser Application Research in Plant Factory. Agric. Agric. Sci. Proc. 2015, 3, 4–8. [Google Scholar] [CrossRef]

- Joshi, J.; Zhang, G.; Shen, S.; Supaibulwatana, K.; Watanabe, C.K.A.; Yamori, W. A Combination of Downward Lighting and Supplemental Upward Lighting Improves Plant Growth in a Closed Plant Factory with Artificial Lighting. HortScience 2017, 52, 831–835. [Google Scholar] [CrossRef]

- Li, K.; Yang, Q.-C.; Tong, Y.-X.; Cheng, R. Using Movable Light-emitting Diodes for Electricity Savings in a Plant Factory Growing Lettuce. HortTechnology 2014, 24, 546–553. [Google Scholar] [CrossRef]

- Lee, X.H.; Chang, Y.Y.; Sun, C.C. Highly energy-efficient agricultural lighting by B+R LEDs with beam shaping using micro-lens diffuser. Opt. Commun. 2013, 291, 7–14. [Google Scholar] [CrossRef]

- Balasus, J.; Blank, J.; Babilon, S.; Hegemann, T.; Khanh, T.Q. Energy efficient lighting in plant factories: Addressing utilance. Agronomy 2021, 11, 2570. [Google Scholar] [CrossRef]

- Pimentel, D.; Berger, B.; Filberto, D.; Newton, M.; Wolfe, B.; Karabinakis, E.; Nandagopal, S. Water resources: Agricultural and environmental issues. Bioscience 2004, 54, 909. [Google Scholar] [CrossRef]

- USGS. Sources of Nutrients and Pesticides. Available online: https://pubs.usgs.gov/circ/circ1225/pdf/sources.pdf (accessed on 4 January 2017).

- USGS NAWQA: Nutrient Delivery to the Gulf of Mexico. Available online: https://water.usgs.gov/nawqa/sparrow/gulf_findings/faq.html (accessed on 4 January 2017).

- Papio, G.A. Development of a New Hydroponic Nutrient Management Strategy and a Tool to Assess Microclimate Conditions in Indoor Leafy Green Production. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 2021. [Google Scholar]

- Gruda, N.S. Advances in soilless culture and growing media in today’s horticulture—An Editorial. Agronomy 2022, 12, 2773. [Google Scholar] [CrossRef]

- Khan, M.M.; Akram, M.T.; Alam, A.; Khan, M.A.; Al-Maskri, A.; Qadri, R.; Al-Busaidi, W. Hydroponic Systems for Cultivation of Horticultural Crops. In Hydroponics: The Future of Sustainable Farming; Springer US: New York, NY, USA, 2024; pp. 149–165. [Google Scholar]

- Scaltrito, E.; Cristiano, G.; Sdao, A.E.; Gruda, N.S.; Loconsole, D.; De Lucia, B. Influence of water spraying intervals and indole-3-butyric acid concentrations on Salvia rooted cuttings quality in a closed aeroponics system. Sci. Hortic. 2024, 337, 113452. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the circularity to the next level: A special issue on the circular economy. J. Ind. Ecol. 2017, 21, 476–482. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015; Volume 100. [Google Scholar]

- Ahmed, A.K.; Cresswell, G.C.; Haigh, A.M. Comparison of sub-irrigation and overhead irrigation of tomato and lettuce seedlings. J. Hortic. Sci. Biotechnol. 2000, 75, 350–354. [Google Scholar] [CrossRef]

- Carmassi, G.; Incrocci, L.; Maggini, R.; Malorgio, F.; Tognoni, F.; Pardossi, A. Modeling salinity build-up in recirculating nutrient solution culture. J. Plant Nutr. 2005, 28, 431–445. [Google Scholar] [CrossRef]

- Agung Putra, P.; Yuliando, H. Soilless Culture System to Support Water Use Efficiency and Product Quality: A Review. Agric. Agric. Sci. Proc. 2015, 3, 4–8. [Google Scholar]

- Orsini, F.; Pennisi, G.; Zulfiqar, F.; Gianquinto, G. Sustainable use of resources in plant factories with artificial lighting (PFALs). Eur. J. Hortic. Sci. 2020, 85, 297–309. [Google Scholar] [CrossRef]

- Munoz, P.; Anton, A.; Nunez, M.; Paranjpe, A.; Arino, J.; Castell, X.; Montero, J.I.; Rieradevall, J. Comparing the environmental impacts of greenhouse versus open-field tomato production in the Mediterranean region. Acta Hortic. 2008, 801, 1591–1596. [Google Scholar] [CrossRef]

- Montero, J.I.; Stanghellini, C.; Castilla, N. Greenhouse technology for sustainable production in mild winter climate areas: Trends and needs. Acta Hortic. 2009, 807, 33–44. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Neocleous, D.; Savvas, D. NaCl accumulation and macronutrient uptake by a melon crop in a closed hydroponic system in relation to water uptake. Agric. Water Manag. 2016, 165, 22–32. [Google Scholar] [CrossRef]

- Martinez-Mate, M.A.; Martin-Gorriz, B.; Martínez-Alvarez, V.; Soto-García, M.; Maestre-Valero, J.F. Hydroponic system and desalinated seawater as an alternative farm-productive proposal in water scarcity areas: Energy and greenhouse gas emissions analysis of lettuce production in southeast Spain. J. Clean. Prod. 2018, 172, 1298–1310. [Google Scholar] [CrossRef]

- Al-Kodmany, K. The Vertical Farm: A Review of Developments and Implications for the Vertical City. Buildings 2018, 8, 24. [Google Scholar] [CrossRef]

- Srivastava, A.; Chinnasamy, P. Water management using traditional tank cascade systems: A case study of semi-arid region of Southern India. SN Appl. Sci. 2021, 3, 281. [Google Scholar] [CrossRef]

- Haro-Monteagudo, D.; Palazón, L.; Beguería, S. Long-term sustainability of large water resource systems under climate change: A cascade modeling approach. J. Hydrol. 2020, 582, 124546. [Google Scholar] [CrossRef]

- Katsoulas, N.; Elvanidi, A.; Karatsivou, E.; Vassiliadis, V. Development of a water flow and nutrients concentration simulation model for cascade hydroponic systems. Acta Hortic. 2022, 1377, 655–662. [Google Scholar] [CrossRef]

- Elvanidi, A.; Benitez Reascos, C.M.; Gourzoulidou, E.; Kunze, A.; Max, J.F.J.; Katsoulas, N. Implementation of the circular economy concept in greenhouse hydroponics for ultimate use of water and nutrients. Horticulturae 2020, 6, 83. [Google Scholar] [CrossRef]

- Jurga, A.; Pacak, A.; Pandelidis, D.; Kaźmierczak, B. Condensate as a water source in terrestrial and extra-terrestrial conditions. Water Resour. Ind. 2023, 29, 100196. [Google Scholar] [CrossRef]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive review on climate control and cooling systems in greenhouses under hot and arid conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Tavan, M.; Wee, B.; Brodie, G.; Fuentes, S.; Pang, A.; Gupta, D. Optimizing sensor-based irrigation management in a soilless vertical farm for growing microgreens. Front. Sustain. Food Syst. 2021, 4, 622720. [Google Scholar] [CrossRef]

- Langenfeld, N.J.; Pinto, D.F.; Faust, J.E.; Heins, R.; Bugbee, B. Principles of nutrient and water management for indoor agriculture. Sustainability 2022, 14, 10204. [Google Scholar] [CrossRef]

- Yep, B.; Zheng, Y. Aquaponic trends and challenges—A review. J. Clean. Prod. 2019, 228, 1586–1599. [Google Scholar] [CrossRef]

- Pinho, S.M.; David, L.H.; Garcia, F.; Keesman, K.J.; Portella, M.C.; Goddek, S. South American fish species suitable for aquaponics: A review. Aquacult. Int. 2021, 29, 1427–1449. [Google Scholar] [CrossRef]

- Van Ginkel, S.W.; Igou, T.; Chen, Y. Energy, water and nutrient impacts of California-grown vegetables compared to controlled environmental agriculture systems in Atlanta, GA. Resour. Conserv. Recycl. 2017, 122, 319–325. [Google Scholar] [CrossRef]

- Yorifuji, R.; Obara, S. Economic design of artificial light plant factories based on the energy conversion efficiency of biomass. Appl. Energy 2022, 305, 117850. [Google Scholar] [CrossRef]

- Villarreal-Guerrero, F.; Kacira, M.; Fitz-Rodríguez, E.; Kubota, C.; Giacomelli, G.A.; Linker, R. Comparison of three evapotranspiration models for a greenhouse cooling strategy with natural ventilation and variable high pressure fogging. Sci. Hortic. 2012, 134, 210–221. [Google Scholar] [CrossRef]

- Turner, W.J.N.; Logue, J.M.; Wray, C.P. A combined energy and IAQ assessment of the potential value of commissioning residential mechanical ventilation systems. Build. Environ. 2013, 60, 194–201. [Google Scholar] [CrossRef]

- Wheeler, E.F.; Both, A.J. Evaluating Greenhouse Mechanical Ventilation System Performance—Part 3 of 3; Rutgers NJAES Cooperative Extension: New Brunswick, NJ, USA, 2002; p. E277. [Google Scholar]

- Yildirim, N.; Bilir, L. Evaluation of a hybrid system for a nearly zero energy greenhouse. Energy Convers. Manag. 2017, 148, 1278–1290. [Google Scholar] [CrossRef]

- Giacomelli, G.A. Considerations for energy management of greenhouse heating and cooling. In Proceedings of the Southern Greenhouse Vegetable Growers Association Conference, Shreveport, LA, USA, 19–20 July 2002. [Google Scholar]

- Geng, J.; Li, H.; Pang, J.; Zhang, W.; Chen, D. Dynamics and environmental controls of energy exchange and evapotranspiration in a hilly tea plantation, China. Agric. Water Manag. 2020, 241, 106364. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Saridakis, G.; Dalamagkidis, K.; Dolianitis, S.; Kaliakatsos, I. Development of an intelligent indoor environment and energy management system for greenhouses. Energy Convers. Manag. 2010, 51, 155–168. [Google Scholar] [CrossRef]

- Fuchs, M.; Dayan, E.; Presnov, E. Evaporative cooling of a ventilated greenhouse rose crop. Agric. For. Meteorol. 2006, 138, 203–215. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nguyen, X.P. Integrating renewable sources into energy system for smart city as a sagacious strategy towards clean and sustainable process. J. Clean. Prod. 2021, 305, 127161. [Google Scholar] [CrossRef]

- Karduri, R.K. Integrating renewable energy into existing power systems: Challenges and opportunities. Int. J. Adv. Res. Manag. Archit. Technol. Eng. 2018, 4, 213–223. [Google Scholar]

- Kittas, C.; Bartzanas, T.; Jaffrin, T. Temperature gradients in a partially shaded large greenhouse equipped with evaporative cooling pads. Biosyst. Eng. 2003, 85, 87–94. [Google Scholar] [CrossRef]

- Franco, A.; Valera, D.L.; Peña, A. Energy efficiency in greenhouse evaporative cooling techniques: Cooling boxes versus cellulose pads. Energies 2014, 7, 1427–1447. [Google Scholar] [CrossRef]

- Practical Off-Grid Living. How to Build a Passive Greenhouse for Year-Round Produce in the Desert. Practical Off-Grid Living. Available online: https://www.practicaloffgridliving.com/how-to-build-a-passive-greenhouse-for-year-round-produce-in-the-desert/ (accessed on 17 September 2024).

- Available online: https://solargis.com/resources/free-maps-and-gis-data?locality=usa (accessed on 19 September 2024).

- Gruda, N.; Bisbis, M.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production—A review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

| Parameters | Glasshouse | Plant Factory |

|---|---|---|

| Energy source | Primarily relies on natural with supplemental artificial lighting | Utterly dependent on artificial lighting |

| Energy efficiency (Electric and Fossil fuel) | Generally, less energy efficient | Highly energy efficient |

| Growing environment | Semi- and fully controlled environment | Fully controlled environment, allowing precise management of environmental parameters |

| Production time | Ideal for crops that can thrive with seasonal variation | Suitable for year-round production |

| Production method | Mostly single-layer production | Mostly multilayer vertical stacked production |

| Production density | Low density per unit area | High density per unit area |

| External environment | Influenced by the external weather | Less influenced by the external weather |

| Carbon footprint | Carbon footprint is lower | Carbon footprint is higher |

| Operating cost | Lower cost and less energy intensive | Higher cost and energy intensive |

| Outlook/structure | Single glass structure | Single- or multistory building envelope |

| Energy Consumption and Reduction Factors | Research Summary | Potential Strategy | References |

|---|---|---|---|

| Energy efficiency | The use of energy and the carbon footprint are substantially elevated. | A precise energy simulation model can reduce the energy costs. | [44] |

| Controlled-environment agriculture is energy intensive. The energy cost depends on the facility’s location and the external environment. | Appropriate design of the production methods for the specific location enhances the energy efficiency. | [39,45] | |

| Artificial lighting | Lighting consumes up to 70% of electricity-controlled environment agriculture applications. | A novel targeted light strategy can improve lighting efficiency. | [46] |

| Façade design for solar light | Transparent façades enhance energy efficiency by utilizing natural solar energy instead of artificial lighting, reducing electricity consumption by 9.4% in the the UAE, 7.6% in the Netherlands, and 7.4% in Sweden. | Façade design reduces energy demand. | [31] |

| Harvesting solar cell | Integrating low-energy cooling systems with transparent infrared-harvesting solar cells that enhance energy generation and reduce temperatures. | Low-energy cooling and infrared-harvesting solar cells increase solar energy efficiency. | [45] |

| Ventilation | Ventilation increases energy consumption by 18.4%, and on-off ventilation at a rate of one air renewal per hour increases energy consumption by 12.6%. | Modeling and simulation of the dehumidification ventilation process reduce the greenhouse energy cost. | [24,42,47] |

| Humidity and temperature control | Dehumidification via controlled condensation recaptures latent energy for greenhouse heating, while hygroscopic materials convert condensation heat into usable warmth, lowering humidity and energy use. | Adsorption of water vapor using hygroscopic material for the dehumidification process reduces operational costs. | [48] |

| Temperature and humidity are crucial greenhouse controls that affect crop yield and energy use. Combining traditional control methods with AI algorithms has become a trend to reduce energy consumption and optimize greenhouse climates for crops. | Numerical simulation and artificial neural network algorithms are strategies to reduce energy consumption. | [49] | |

| The pad-fan systems, fogging systems, and shading screens are effective processes for reducing the greenhouse temperature. | The evaporative pad cooling system maintains more favorable conditions | [50] | |

| Greenhouse heating | The solar rock bed (SRB) is the most effective energy-saving method in hot semi-desert areas. The night curtain system performs best in other climate zones, demonstrating climate sensitivity by lowering heating demand by 12% in very cold mountainous regions and 32% in dry climates. | Solar rock bed modeling is the most effective system for reducing greenhouse heating costs. | [51] |

| A different model for the energy efficiency | Energy model algorithms such as the state space model, SQP, transfer function model, hybrid control, intelligence control, adaptive control, feedback, and feedforward control for the specific crop are essential strategies for reducing energy costs. | Advanced control algorithm model increases energy efficiency. | [38] |

| Hydroponic production | Advances in platforms like Raspberry Pi and Arduino, along with new sensors and actuators, are set to revolutionize precision agriculture, making controlled-environment farming more affordable and efficient for small-scale producers. | Hydroponic system increases water use efficiency. And aeroponic system is more water-efficient than hydroponic practices. | [52,53] |

| Closed-loop systems save 40% of irrigation water and 35–54% of nutrients while reducing eutrophication, but they may cause nutrient deficiencies and require more infrastructure, raising environmental impacts. | A closed-loop system is the most efficient for irrigation. | [54,55] | |

| Aquaponics enhance sustainability by mimicking natural processes in a controlled system, making it suitable for urban areas with limited agricultural land even though it is environmentally friendly. | Aquaponics is a sustainable production system. | [56,57] | |

| The water use efficiency of aeroponics systems is higher than that of hydroponic systems. | [53] | ||

| Solar energy | Solar energy can aid climate mitigation, and photovoltaic energy may reduce this competition and provide benefits across the food–energy–water nexus. | Photovoltaics enhance solar power efficiency and renewable energy application | [58] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azad, M.O.K.; Gruda, N.S.; Naznin, M.T. Energy Efficiency of Glasshouses and Plant Factories for Sustainable Urban Farming in the Desert Southwest of the United States of America. Horticulturae 2024, 10, 1055. https://doi.org/10.3390/horticulturae10101055

Azad MOK, Gruda NS, Naznin MT. Energy Efficiency of Glasshouses and Plant Factories for Sustainable Urban Farming in the Desert Southwest of the United States of America. Horticulturae. 2024; 10(10):1055. https://doi.org/10.3390/horticulturae10101055

Chicago/Turabian StyleAzad, Md Obyedul Kalam, Nazim S. Gruda, and Most Tahera Naznin. 2024. "Energy Efficiency of Glasshouses and Plant Factories for Sustainable Urban Farming in the Desert Southwest of the United States of America" Horticulturae 10, no. 10: 1055. https://doi.org/10.3390/horticulturae10101055

APA StyleAzad, M. O. K., Gruda, N. S., & Naznin, M. T. (2024). Energy Efficiency of Glasshouses and Plant Factories for Sustainable Urban Farming in the Desert Southwest of the United States of America. Horticulturae, 10(10), 1055. https://doi.org/10.3390/horticulturae10101055