Abstract

The present study aimed to evaluate the anaerobic co-digestion process of chicken manure and corn stover to identify the key parameters that influence methane production. Results from both batch and semi-continuous tests showed that co-digestion enhanced methane production, with an optimal chicken manure to corn stover ratio of 2:1 under experimental conditions. When this ratio was maintained, methane production increased by 36% in batch tests, resulting in a biochemical methane potential of 333 mL/g VS. In semi-continuous tests, co-digestion at a hydraulic retention time of 30 days resulted in a methane production increase of 39%, corresponding to a methane yield of 318 mL/g VS. The inclusion of chicken manure proved effective in improving buffer capacity by generating ammonium bicarbonate, which facilitated stable operation during the digestion process. The observed improvement in methane production could be ascribed to the C/N ratio and the increased biodegradability of chicken manure. These findings offer valuable insights into optimizing anaerobic co-digestion to achieve higher methane production levels.

1. Introduction

As the demand for energy continues to increase and fossil fuel resources are being depleted, the need for renewable energy sources has become more pressing. The development of renewable energy production technologies has been further accelerated due to the climate change caused by greenhouse gas emissions [1]. Anaerobic digestion (AD) is widely considered to be a highly effective renewable energy technology [2,3]. In recent years, a multitude of policies, laws, and plans have been introduced globally to support the advancement of bioenergy technologies [4]. Animal manure and crop residues are popular feedstocks for biogas production due to their promising potential [5]. China, for example, produces approximately 300 million tons of chicken manure (CM) and 400 million tons of corn straw annually, which results in major environmental pollution concerns [6]. Upon converting organic waste into biogas, mainly composed of methane, through AD technology and utilizing the resultant digestate in agricultural fields, an integrated approach is provided for waste treatment, energy production, and green organic agriculture [7]. Indeed, it is one of the most appropriate methods for managing organic solid waste and a crucial technological pathway for carbon reduction [8,9].

Corn stover (CS) has long been widely recognized as a desirable substrate for anaerobic digestion due to its abundant availability and high potential for methane production [10]. However, the high carbon–to–nitrogen ratio (ranging from 50 to 70) of corn stover leads to the accumulation of volatile fatty acids (VFAs) during the anaerobic digestion process, which causes a rapid reduction in pH and can impede the activity of methanogens, thereby affecting the overall process. Consequently, the anaerobic digestion of corn stover alone can be challenging [10,11,12]. On the other hand, chicken manure exhibits a significantly lower carbon–to–nitrogen ratio, typically ranging from 5 to 8. While this may seem advantageous, it renders chicken manure unsuitable as a single substrate for efficient anaerobic digestion. In fact, the digestion process with chicken manure alone often results in instability or even unfeasibility [13,14]. As such, it is imperative to explore alternative strategies to tackle these challenges. One such approach is co-digestion, which has shown great potential in overcoming the limitations of single-substrate digestion [15,16]. Upon combining these two substrates, it is anticipated that the drawbacks associated with single digestion can be mitigated, and the overall efficiency of the anaerobic digestion process can be improved. Accordingly, the present study aims to investigate the co-digestion of chicken manure and corn stover.

The carbon–to–nitrogen (C/N) ratio is a critical parameter that impacts the digestion process. The optimal C/N ratio for anaerobic microorganisms in the digester has traditionally been considered to be between 20 and 30 [17,18]. However, recent findings suggest that a lower C/N ratio is more conducive to anaerobic fermentation and methane production. For instance, Zhang et al., 2013 demonstrated that optimal methane production could be achieved at a C/N ratio of 15.8 [19], while Zhu (2007) suggested that anaerobic digestion was most effective when the C/N ratio is 15 [20]. Kumar et al., 2010 also found that a C/N ratio within a range of 13.9 to 19.6 was appropriate for digestion [21]. Co-digestion of different substrates may enhance the stability of anaerobic processes through improved nutrition and carbon–nitrogen balance and may alleviate the inhibitory effects of toxic substances, such as ammonia nitrogen, sulfide, and heavy metals, thereby boosting methane production stability [15,16,22]. However, thus far, only batch tests have been conducted to evaluate the potential increase in methane production resulting from the co-digestion of chicken manure and corn stover. Thus, the effectiveness of this approach in actual operating biogas reactors has not yet been confirmed. To gain a better understanding of the synergistic effects of co-digestion, continuous flow experiments are necessary. Thus, the objectives of this study are twofold. Firstly, aiming to assess the performance of anaerobic co-digestion of chicken manure and corn stover using both batch and continuous tests. Secondly, seeking to identify the key parameters that influence the increase in methane production, including the impact of the C/N ratio. By addressing these objectives, this study aims to provide valuable insights into the potential benefits of co-digestion and contribute to the optimization of biogas production processes.

2. Materials and Methods

2.1. Substrates and Inoculum

In the present study, chicken manure and corn stover were employed as substrates. The chicken manure was obtained from a local poultry farm in Daqing, China, and underwent a meticulous manual separation process to eliminate undesirable components such as feathers, eggshells, and sand. Subsequently, it was stored in a laboratory room set at a temperature of 4 °C. The corn stover was sourced from the experimental base at Heilongjiang Bayi Agricultural University, also located in Daqing, China. After maize harvesting, the stalk was left to naturally dry before being ground into 40-mesh fragments by a 9F-290 plant shredder, which was then stored in a storeroom with a temperature of 4 °C. The inoculum utilized in this study was obtained from a laboratory-scale digester that had been operating at 37 °C for a period exceeding 5 months. The digester processed mixtures of manure and CS. The characteristics of the substrates and inoculum are presented in Table 1 and were compared with data available in the published literature sources.

Table 1.

Characteristics of inoculum, substrates, and compared to the literature.

2.2. Batch Test for Biochemical Methane Potential Assay

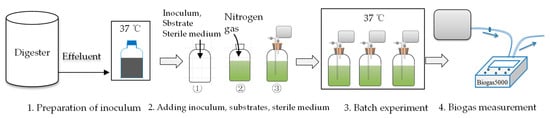

Biochemical methane potential (BMP) assays were conducted in accordance with the standardized protocol outlined in VDI 4630 [25], utilizing a laboratory apparatus specifically designed for this purpose (Figure 1). To achieve this, conical flasks with a total volume of 1 L and a working volume of 0.8 L were employed as digesters. The final VS added to the digesters was 15 g with an inoculum–to–substrate ratio of 2:1. The present study aimed to investigate the synergistic impact of different mixing ratios (1:0, 2:1, 1:1, 1:2, and 0:1 on a volatile solids basis) on the co-digestion performance of cattle manure and corn stover. In order to elucidate the effect of these mixing ratios, six groups of assays were established in triplicate. It is important to note that one of these groups served as a control, consisting solely of inoculum, inorganic salt, and deionized water. The inorganic salts were supplemented in digesters as micro-nutrition and macro-nutrition with the following components (in mg/L): NaHCO3 1000 MgCl2·6H2O 100, CaCl2·2H2O 75, Na2MoO4·4H2O 0.01, H3BO3 0.05, MnCl2·4H2O 0.5, ZnCl2 0.05, CuCl2 0.03, NiCl2·6H2O 0.05, CoCl2·2H2O 0.5, Na2SeO3 0.05 [26,27]. After the addition of substrate, inoculum, and inorganic salts, a 3-min flush with 99.99% nitrogen gas was carried out to eliminate the presence of air within the digesters. Following this, the sealed digesters were placed under incubation at a temperature of 37 °C for a duration of 50 days until biogas production ceased. Throughout the experimental period, daily measurements of biogas volume and composition, specifically methane (CH4) and carbon dioxide (CO2), were recorded.

Figure 1.

The procedure for the batch test, ① addition of substrate, inoculum, and inorganic salts, ② flush with 99.99% nitrogen gas, and ③ sealed digester.

Methane production kinetics in this study were fitted using the modified Gompertz model shown in Equation (1), and BMP was predicted [23].

where P is the cumulative methane production (mL/g) at time t, P0 is the BMP (mL/g), Rmax is the maximum gas production rate (mL/(g·d)), t is the duration of the assays (d), e is Euler’s constant, and λ is the lag phase time (d).

2.3. Anaerobic Co-Digestion of Chicken Manure and Corn Stover in Semi-Continuous Mode

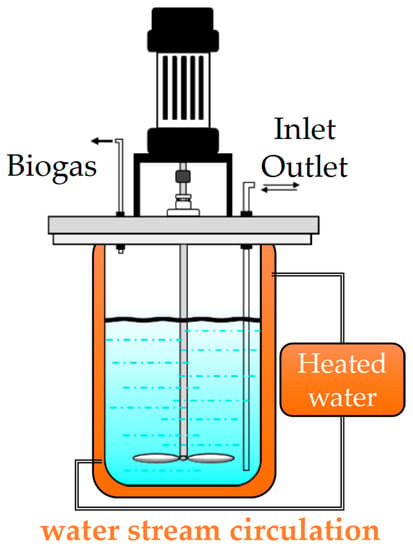

Semi-continuous tests were conducted in five parallel 10 L continuously stirred tank reactors (CSTRs) with an effective volume of 8 L (Figure 2). The reactors were maintained at a temperature of 37 °C with a heated water stream circulated within the reactor jacket. The substrates were homogeneously mixed via continuous mechanical stirring (100 r/min). Varying mixing ratios (1:0, 2:1, 1:1, 1:2, and 0:1, VS basis) of CM and CS were used as substrates for anaerobic mono-digestion or co-digestion. The feeding and hydraulic retention time (HRT) were 3% and 30 days, resulting in an organic loading rate (OLR) of 1.0 g VS/(L·d). The operation of feeding and discharge was conducted regularly on a daily basis. The biogas volume was recorded with LML-1 wet biogas meters. The biogas content (CH4 and CO2) and pH value were measured daily, while ammonia concentration, total alkalinity, and VFAs in the effluent were determined every 10 days.

Figure 2.

The digester schematic for the continuous test.

2.4. Analytic Methods

Biogas volume was measured using a wet gas meter and calibrated to standard conditions (0 °C, 1.013 bar). Biogas samples were examined using gas chromatography (BIOGAS 5000, Geotech, Coventry, UK). pH values were measured using a pH meter (B-712, HORIBA, Kyoto, Japan). Triplicate samples were collected for the determination of TS, VS, total ammoniacal nitrogen (TAN), and alkalinity following the APHA methods [28]. Briefly, TS and VS were determined using gravimetric analysis following sample drying at 105 °C and 600 °C for a minimum of 24 and 6 h, respectively. TAN was assayed using spectrophotometry at 420 nm subsequent to treatment with Nessler’s reagent. Before analysis, the SCOD sample underwent centrifugation at 8000 rpm for 15 min and filtration through a 0.22 mm filter. The elemental composition (C, H, O, and N) in substrates was analyzed using an elemental analyzer (Elementar, Model Vario EL III, Langenselbold, Germany). Total VFAs were measured using a Shimadzu GC-2010 Plus chromatograph equipped with a flame ionization detector and a capillary column (Rtx-wax) with dimensions of 30 m in length, 0.25 mm in inner diameter, and coated with a 0.25 μm-thick film. The temperature program for the column comprised an initial temperature of 60 °C with a 5-min hold, followed by a heating rate of 10 °C per minute up to 140 °C with a 2-min hold, and finally, a further heating rate of 20 °C per minute up to 230 °C with a 2-min hold. The injector and detector were maintained at temperatures of 230 °C and 250 °C, respectively.

The theoretical methane potential (TMP) of substrates were determined using the Buswell formula described in Equations (2) and (3) [29]. This calculation was used to estimate the biogas yield under ideal conditions. The biodegradability of the substrate was assessed using Equation (4). Finally, the co-digestion performance index (CPI) was calculated (Equation (5)) to evaluate the co-anaerobic digestion synergy [30]. These calculations aid in understanding the potential for biogas production from the given substrate and highlight the importance of optimizing mixing ratios for maximum methane yield.

where n, x, y, and z is the content of elements C, O, H, and N, respectively; TMP is the theoretical methane potential (mL/g VS); Bio is the substrate biodegradability (%); BMP is the experimental methane yield (mL/g VS); CPIi,n is the co-digestion performance index; Bi,n is the BMP or methane yield (mL/g) of the co-digested substrates, Bo,n is the BMP or methane yield (mL/g) of mono-substrate; Boi,n is the weighted BMP or methane yield (mL/g) of mixtures.

2.5. Statistical Analysis

Statistical analysis was performed with the method of One-Way ANOVA provided by the software Origin version 9.1.

3. Results and Discussions

3.1. Characteristics of Substrate

Table 1 presents the characteristics of two types of waste, namely CM and CS. The VS (%TS) of CM and CS were 68.7% and 84.5%, respectively, indicating that organic matter constitutes the primary component of dried CS and CM. The chemical formulas of C11.8H12.5O6.3N and C78.2H122O42.6N were employed to describe the elemental composition of CS and CM, respectively, as shown in Table 1. Based on Equations (2) and (3), the TMP of CM and CS were determined to be 460 and 550 mL/g VS, with methane contents of 47% and 55%, respectively. In anaerobic conditions, complete digestion of 1 g of CM and CS produces 0.05 and 0.01 g of NH3-N, mainly in the form of ammonium bicarbonate (NH4HCO3) [31], which can be converted to 0.18 g and 0.03 g of alkalinity as CaCO3. Ammonia concentration is a significant factor that affects methane production. According to Rajagopal et al., 2013 low levels of TAN (50–200 mg/L) promote the growth of anaerobic microorganisms, while high levels (>1500 mg/L) of TAN inhibit the AD process [32]. In general, insufficient nitrogen limited the biogas production of corn straw, whereas excess nitrogen inhibited the AD of chicken manure [10,11]. Additionally, the C/N ratio is another essential factor that influences methane production. Compared to the optimal range of 20–30 for the growth of anaerobes [17,18], CS has a high C/N ratio of 67.1, while CM has a low C/N ratio of 10.1, and neither is appropriate for anaerobic mono-digestion. Therefore, anaerobic mono-digestion of CM or CS is not recommended, and a primary strategy to balance the nutritional components of these wastes is through co-digestion, adjusting the appropriate C/N ratio, and ammonia nitrogen level.

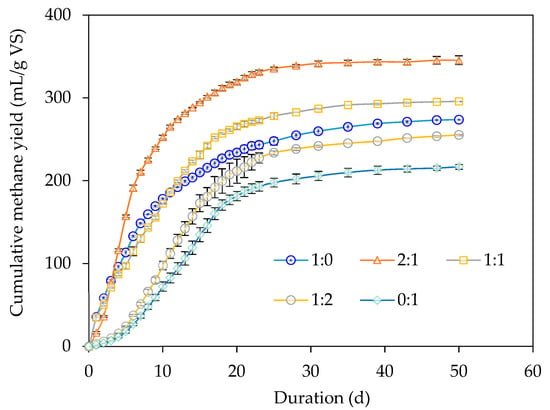

3.2. Effect of Mixing Ratios on Biochemical Methane Potential

As shown in Figure 3 and Table 2, during 50-day batch digestion tests, the impact of different mixing ratios (1:0, 2:1, 1:1, 1:2, and 0:1) of CM and CS on BMP was investigated. Based on the inorganic salts outlined in Section 2.2, the pH values and TAN concentrations during the AD process were determined to be 7.1–7.3 and 0.6–0.8 g/L, respectively, indicating the efficient performance of batch tests [33]. Methane production was immediately observed during batch digestion tests, with 90% of the final methane production occurring in the first 20–30 days. To maintain a preferable methane production rate, an HRT of 30 days was recommended. Finally, 55.3%, 62.1%, 53.8%, 45.2%, and 38.7% of VS were removed, and cumulative methane production values of 274, 346, 296, 255, and 217 mL/g VS were attained after a 48-day digestion for mixing ratios of 1:0, 2:1, 1:1, 1:2, and 0:1, respectively. An increase (17.5–59.4%) in methane production was observed for all co-digestion ratios when compared with the mono-digestion of CS due to the high VS removal rate of CM. The optimal mixing ratio for the co-digestion of chicken manure and corn stover was determined to be 2:1 in the current experiment, resulting in the highest methane production.

Figure 3.

Results of the cumulative methane yield of anaerobic co-digestion of chicken manure and corn stover under different mixing ratios in the batch model.

Table 2.

Summary of the AD performance in batch experiment.

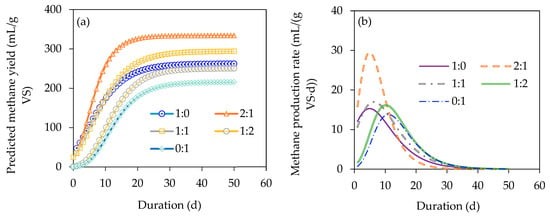

The modified Gompertz model, which has been extensively utilized in predicting the BMP and maximum methane production rate (Rmax) [34], was employed to evaluate the performance of anaerobic digestion systems, as depicted in Table 3. Results indicated that the model exhibited a high degree of fitting accuracy, as evidenced by the correlation coefficient (R2) range of 0.987–0.999. Predicted BMPs at various ratios (1:0, 2:1, 1:1, 1:2, and 0:1) of CM and CS show minor differences in measured values. The maximum BMP value of 333 mL/g VS was observed at a mixing ratio of 2:1, which was 28.3%, 19.6%, 41.1%, and 51.2% higher than those of other mixing ratios, respectively. Additionally, Rmax initially rose, followed by a decline with an increase in the CS ratio (Table 3). The maximum Rmax of 29 mL/(d·g VS) was observed on day 5 at the mixing ratio of 2:1 (Figure 4b), which was 70–120% higher than those of the other mixing ratios. Furthermore, biodegradability was determined to be 59.5%, 70.5%, 58.6, 49.1%, and 39.4% for mixing ratios of 1:0, 2:1, 1:1, 1:2, and 0:1, respectively, according to Equation (4). Significant differences were observed in biodegradability between the different ratio groups, as shown in Table 2. The times required to achieve 90% BMP (T90) for varying mixing ratios were observed to increase with the rising proportion of CS, primarily due to low biodegradability during the AD process, with values of 25, 19, 20, 22, and 30 days, respectively. Previous studies have reported on the anaerobic co-digestion of multiple substrates to enhance methane production. The inclusion of manure in the straw digester demonstrated an increase both in methane production rates and total methane production [15,35]. Our analysis reveals that the optimal mixing ratio for co-digestion of chicken manure and corn stover is 2:1 in the current experimental, which produces the highest values of BMP, Rmax, and biodegradability.

Table 3.

The kinetic parameters fitted using the modified Gompertz model.

Figure 4.

Results of (a) predicted biochemical methane potential and (b) the methane production rate of anaerobic co-digestion under different mixing ratios analyzed using the modified Gompertz model.

3.3. Effect of Mixing Ratios on AD Performance in Semi-Continuous Tests

The TAN, pH, and VFA are commonly utilized as indicators for assessing the long-term stability of a digester. Table 4 presents a recapitulation of the CSTR performance, considering the TAN, pH, and VFA levels for different mixing ratios (1:0, 2:1, 1:1, 1:2, and 0:1) of CM and CS. During the experimental period, the TAN concentration decreased from 1.76 to 0.22 g/L in response to a decrease in the CM ratio. TAN is a vital element serving as a source of alkalinity and buffering capacity during AD processes [31]. However, its concentration exceeding 1.5–3.0 g/L can lead to an inhibitory effect [32,36], implying the possibility of ammonia inhibition causing mono-digestion of CM (1.76 g/L) in CSTR. Furthermore, the pH in the digesters decreased from 7.68 to 7.08 with a decrease in the CM ratio, whereas the VFA concentrations were recorded at 0.31–0.45 g/L, significantly lower than the inhibitory acid concentration [37]. In summary, these results collectively demonstrate the satisfactory performance of co-digestion of CM and CS in CSTR.

Table 4.

Summary of the CSTR performance in the steady stage.

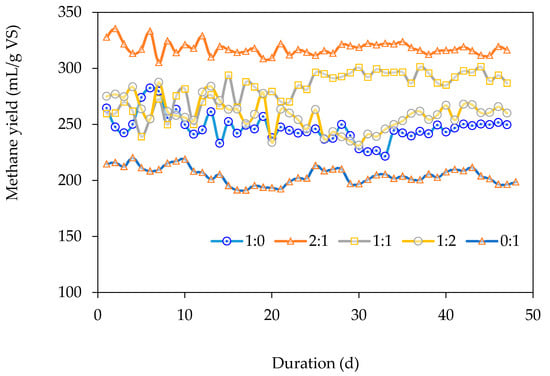

The performance of methane production in CSTRs, as illustrated in Figure 5, demonstrates successful operation for a period of 45 days or more. The variations in methane yield among the different groups of substrate ratios investigated were significant. Initially, an increasing ratio of CS to CM from 0:1 to 1:2 was observed to significantly enhance the methane yield, which was followed by a slight decline at a CS to CM ratio of 1:1. A sharp reduction was observed as the substrate composition shifted towards 100% corn stover, as shown in Table 4. A maximum methane yield of 318 mL/g VS was achieved with a mixing ratio of 2:1, representing a 28.7%, 9.2%, 22.7%, and 55.1% higher yield compared to the 1:0, 1:1, 1:2, and 0:1 ratio, respectively. Under continuous conditions, the methane yield was slightly lower than that observed in batch tests. Generally, the methane yields from mixtures of CM and CS were approximately 300 mL/g VS, which is comparable to other feedstocks with high energy density, such as food wastes, as reported by Bi et al., 2020 [37]. Table 5 highlights previous studies on the anaerobic co-digestion of chicken manure and corn stover, where the CM to CS ratio was set from 3:1 to 1:3, indicating that substrate ratios significantly enhance methane yield. It has been proven that a higher CM/CS ratio is beneficial to methane production and that increasing digestion time may result in more methane production in batch conditions [24,38,39]. Our analysis indicates that the optimal mixing ratio for the co-digestion of chicken manure and corn stover is 2:1 in the current experimental, which maximizes methane production.

Figure 5.

Effect of mixing ratios on the anaerobic co-digestion performance of chicken manure and corn stover.

Table 5.

Previous research studies on anaerobic co-digestion of chicken manure and corn stover.

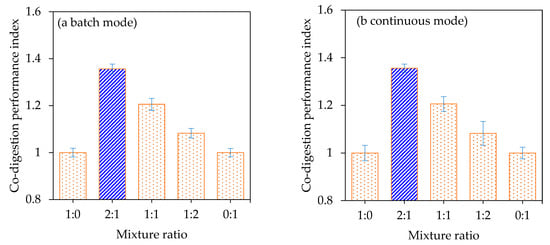

3.4. Synergistic Effects of Anaerobic Co-Digestion of Chicken Manure and Corn Stover

In this study, the CPI values were utilized as a metric to evaluate the antagonistic (CPI < 1), additive (CPI = 1), and synergistic (CPI > 1) interactions during the co-digestion of chicken manure and corn stover. Results derived from batch and continuous tests demonstrated that all co-digestion processes exhibited a CPI value greater than 1, ranging from 1.08 to 1.39 (Figure 6). The synergistic effect was observed to initially increase and then decrease with an increase in the corn stover proportion. The highest CPI values of 1.36 and 1.39 were obtained with a mixing ratio of 2:1 in batch and continuous models, respectively, indicating that the co-digestion of the mixture demonstrated a superior promoting effect in the continuous experiments. In prior batch experiments, CPI ranged from 1.01 to 1.42 for chicken manure [11] and 1.44 to 1.87 for piggy manure co-digestion with corn stover [40]. Karki et al., 2021 reported that co-digestion could aid in achieving a better carbon–to–nitrogen balance, whereby a higher proportion of manure in the mixture could offset the accumulation of VFAs, leading to an improvement in methane production [15]. These findings suggest that co-anaerobic digestion is not merely the addition of substrates and that an appropriate ratio can significantly enhance the synergistic effect. Furthermore, our results indicate that co-digestion of chicken manure and corn stover improved anaerobic digestion performance, with a 2:1 ratio resulting in a substantial enhancement of the synergistic effect under experimental conditions.

Figure 6.

Results of co-digestion performance index (CPI) of anaerobic co-digestion under different mixing ratios.

4. Conclusions

Corn stover was anaerobically treated with chicken manure in both batch and continuous modes. Anaerobic co-digestion of chicken manure corn stover could enhance the methane production of CSTR and methane yield from the substrate. The optimum CM/CS ratio was 2:1 in the current study, corresponding to the C/N ratio of 15.1. The methane production at the optimum CM/CS ratio was enhanced by 36–39%, corresponding to the methane yield of 333 and 318 mL/g VS in batch and continuous mode, respectively. The addition of chicken manure enhanced the buffer capacity in the digesters. The C/N ratio and the higher biodegradation of chicken manure might be the main reasons for the improved methane production during co-digestion.

Author Contributions

Conceptualization, X.Y. and Y.W. (Yanjie Wang); methodology, L.Y.; software, S.B.; validation, X.Y., Y.W. (Yanhong Wang) and Y.H.; formal analysis, X.Y.; investigation, X.Y.; resources, S.B. and W.W.; data curation, X.Y.; writing—original draft preparation, X.Y.; writing—review and editing, S.B.; visualization, J.L.; supervision, S.B.; project administration, S.B.; funding acquisition, S.B. and W.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Heilongjiang Province Science and Technology Research Project (2022ZXJ08B0), the Guidance Project of Daqing City (zd-2021-91), Heilongjiang Bayi Agricultural University Support Program for San Heng San Zong (ZRCQC202009), the Project of Heilongjiang Bayi Agricultural University’s scientific research start-up plan for introducing talents (XYB202022).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Klinlampu, C.; Chimprang, N.; Sirisrisakulchai, J. The Sufficient Level of Growth in Renewable Energy Generation for Coal Demand Reduction. Energ. Rep. 2023, 9, 843–849. [Google Scholar] [CrossRef]

- Dutta, S.; He, M.; Xiong, X.; Tsang, D.C.W. Sustainable Management and Recycling of Food Waste Anaerobic Digestate: A Review. Bioresour. Technol. 2021, 341, 125915. [Google Scholar] [CrossRef]

- Gao, X.; Li, Z.; Zhang, K.; Kong, D.; Gao, W.; Liang, J.; Liu, F.; Du, L. Layer Inoculation as a New Technology to Resist Volatile Fatty Acid Inhibition during Solid-State Anaerobic Digestion: Methane Yield Performance and Microbial Responses. Fermentation 2023, 9, 535. [Google Scholar] [CrossRef]

- Nikolausz, M.; Kretzschmar, J.A.O. Anaerobic Digestion in the 21st Century. Bioengineering 2020, 7, 157. [Google Scholar] [CrossRef]

- Jia, W.; Qin, W.; Zhang, Q.; Wang, X.; Ma, Y.; Chen, Q. Evaluation of Crop Residues and Manure Production and Their Geographical Distribution in China. J. Clean. Prod. 2018, 188, 954–965. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Chen, C.; Liu, G.; He, Y.; Liu, X. Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Bioresour. Technol. 2013, 149, 406–412. [Google Scholar] [CrossRef]

- Atelge, M.R.; Krisa, D.; Kumar, G.; Eskicioglu, C.; Nguyen, D.D.; Chang, S.W.; Atabani, A.E.; Al-Muhtaseb, A.H.; Unalan, S. Biogas Production from Organic Waste: Recent Progress and Perspectives. Waste Biomass Valorization 2020, 11, 1019–1040. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Z.; Ran, W.; Yuan, H.; Li, X. Performance and microbial community dynamics in anaerobic co-digestion of chicken manure and corn stover with different modification methods and trace element supplementation strategy. Bioresour. Technol. 2021, 325, 124713. [Google Scholar] [CrossRef]

- Lü, F.; Wang, Z.; Zhang, H.; Shao, L.; He, P. Anaerobic digestion of organic waste: Recovery of value-added and inhibitory compounds from liquid fraction of digestate. Bioresour. Technol. 2021, 333, 125196. [Google Scholar] [CrossRef]

- Croce, S.; Wei, Q.; D’Imporzano, G.; Dong, R.; Adani, F. Anaerobic digestion of straw and corn stover: The effect of biological process optimization and pre-treatment on total bio-methane yield and energy performance. Biotechnol. Adv. 2016, 34, 1289–1304. [Google Scholar] [CrossRef]

- Yu, Q.; Sun, C.; Liu, R.; Yellezuome, D.; Zhu, X.; Bai, R.; Liu, M.; Sun, M. Anaerobic co-digestion of corn stover and chicken manure using continuous stirred tank reactor: The effect of biochar addition and urea pretreatment. Bioresour. Technol. 2021, 319, 124197. [Google Scholar] [CrossRef]

- Li, Y.; Xu, H.; Yi, X.; Zhao, Y.; Jin, F.; Chen, L.; Hua, D. Study of two-phase anaerobic digestion of corn stover: Focusing on the conversion of volatile fatty acids and microbial characteristics in UASB reactor. Ind. Crops Prod. 2021, 160, 113097. [Google Scholar] [CrossRef]

- Manogaran, M.D.; Shamsuddin, R.; Mohd Yusoff, M.H.; Lay, M.; Siyal, A.A. A review on treatment processes of chicken manure. Clean. Circ. Bioecon. 2022, 2, 100013. [Google Scholar] [CrossRef]

- Song, Y.; Qiao, W.; Zhang, J.; Dong, R. Process Performance and Functional Microbial Community in the Anaerobic Digestion of Chicken Manure: A Review. Energies 2023, 16, 4675. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.C.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Kumar Khanal, S. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sust. Energ. Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Zheng, Z.; Cai, Y.; Zhang, Y.; Zhao, Y.; Gao, Y.; Cui, Z.; Hu, Y.; Wang, X. The effects of C/N (10–25) on the relationship of substrates, metabolites, and microorganisms in “inhibited steady-state” of anaerobic digestion. Water Res. 2021, 188, 116466. [Google Scholar] [CrossRef]

- Yan, Z.; Song, Z.; Li, D.; Yuan, Y.; Liu, X.; Zheng, T. The effects of initial substrate concentration, C/N ratio, and temperature on solid-state anaerobic digestion from composting rice straw. Bioresour. Technol. 2015, 177, 266–273. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef]

- Zhu, N. Effect of low initial C/N ratio on aerobic composting of swine manure with rice straw. Bioresour. Technol. 2007, 98, 9–13. [Google Scholar] [CrossRef]

- Kumar, M.; Ou, Y.L.; Lin, J.G. Co-composting of green waste and food waste at low C/N ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef]

- Nag, R.; Auer, A.; Markey, B.K.; Whyte, P.; Nolan, S.; Flaherty, V.; Russell, L.; Bolton, D.; Fenton, O.; Richards, K.; et al. Anaerobic digestion of agricultural manure and biomass—Critical indicators of risk and knowledge gaps. Sci. Total Environ. 2019, 690, 460–479. [Google Scholar] [CrossRef]

- Wandera, S.M.; Qiao, W.; Algapani, D.E.; Bi, S.; Yin, D.; Qi, X.; Liu, Y.; Dach, J.; Dong, R. Searching for possibilities to improve the performance of full-scale agricultural biogas plants. Renew. Energ. 2018, 116, 720–727. [Google Scholar] [CrossRef]

- Yu, Q.; Cui, S.; Sun, C.; Liu, R.; Sarker, M.; Guo, Z.; Lai, R. Synergistic Effects of Anaerobic Co-Digestion of Pretreated Corn Stover with Chicken Manure and Its Kinetics. Biotechnol. Appl. Biochem. 2021, 193, 515–532. [Google Scholar] [CrossRef]

- VDL. VDI standard procedures 4630. In Fermentation of Organic Materials Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests; Verein Deutscher Ingenieure, Beuth Verlag: Berlin, Germany, 2006; p. 92. [Google Scholar]

- Bi, S.; Westerholm, M.; Qiao, W.; Mahdy, A.; Xiong, L.; Yin, D.; Fan, R.; Dach, J.; Dong, R. Enhanced methanogenic performance and metabolic pathway of high solid anaerobic digestion of chicken manure by Fe2+ and Ni2+ supplementation. Waste Manag. 2019, 94, 10–17. [Google Scholar] [CrossRef]

- Li, Q.; Qiao, W.; Wang, X.; Takayanagi, K.; Shofie, M.; Li, Y.Y. Kinetic characterization of thermophilic and mesophilic anaerobic digestion for coffee grounds and waste activated sludge. Waste Manag. 2015, 36, 77–85. [Google Scholar] [CrossRef]

- Water Environment Federation; American Public Health Association. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2005; p. 21. [Google Scholar]

- Buswell, A.M.; Sollo, F.W. The Mechanism of the Methane Fermentation. J. Am. Chem. Soc. 1948, 70, 1778–1780. [Google Scholar] [CrossRef]

- Ning, Z.; Zhang, H.; Li, W.; Zhang, R.; Liu, G.; Chen, C. Anaerobic digestion of lipid-rich swine slaughterhouse waste: Methane production performance, long-chain fatty acids profile and predominant microorganisms. Bioresour. Technol. 2018, 269, 426–433. [Google Scholar] [CrossRef]

- Hao, T.; Xiao, Y.; Varjani, S. Transiting from the inhibited steady-state to the steady-state through the ammonium bicarbonate mediation in the anaerobic digestion of low-C/N-ratio food wastes. Bioresour. Technol. 2022, 351, 127046. [Google Scholar] [CrossRef]

- Rajagopal, R.; Massé, D.I.; Singh, G. A critical review on inhibition of anaerobic digestion process by excess ammonia. Bioresour. Technol. 2013, 143, 632–641. [Google Scholar] [CrossRef]

- Meegoda, J.A.-O.; Li, B.; Patel, K.; Wang, L.B. A Review of the Processes, Parameters, and Optimization of Anaerobic Digestion. Int. J. Environ. Res. Public Health 2018, 15, 2224. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Kobayashi, T.; Kumar, G.; Xu, K. Anaerobic co-digestion on improving methane production from mixed microalgae (Scenedesmus sp., Chlorella sp.) and food waste: Kinetic modeling and synergistic impact evaluation. Chem. Eng. J. 2016, 299, 332–341. [Google Scholar] [CrossRef]

- Ye, J.; Li, D.; Sun, Y.; Wang, G.; Yuan, Z.; Zhen, F.; Wang, Y. Improved biogas production from rice straw by co-digestion with kitchen waste and pig manure. Waste Manag. 2013, 33, 2653–2658. [Google Scholar] [CrossRef]

- Yenigün, O.; Demirel, B. Ammonia inhibition in anaerobic digestion: A review. Process Biochem. 2013, 48, 901–911. [Google Scholar] [CrossRef]

- Bi, S.; Hong, X.; Yang, H.; Yu, X.; Fang, S.; Bai, Y.; Liu, J.; Gao, Y.; Yan, L.; Wang, W.; et al. Effect of hydraulic retention time on anaerobic co-digestion of cattle manure and food waste. Renew. Energ. 2020, 150, 213–220. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Liu, X.; Chen, C.; Xiao, X.; Feng, L.; He, Y.; Liu, G. Evaluating Methane Production from Anaerobic Mono- and Co-digestion of Kitchen Waste, Corn Stover, and Chicken Manure. Energy Fuels 2013, 27, 2085–2091. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; He, Y.; Zhang, C.; Liu, X.; Chen, C.; Liu, G. Anaerobic co-digestion of chicken manure and corn stover in batch and continuously stirred tank reactor (CSTR). Bioresour. Technol. 2014, 156, 342–347. [Google Scholar] [CrossRef]

- Tian, P.; Gong, B.; Bi, K.; Liu, Y.; Ma, J.; Wang, X.; Ouyang, Z.; Cui, X. Anaerobic Co-Digestion of Pig Manure and Rice Straw: Optimization of Process Parameters for Enhancing Biogas Production and System Stability. Int. J. Environ. Res. Public Health 2023, 20, 804. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).