Abstract

Using nylon bag techniques, Cornell net carbohydrates and protein systems (CNCPS), and scanning electron microscopy, the authors examined the digestibility and structure of Vicia ervilia (ervil, bitter vetch) after steam flaking, roasting, and microwave processing. During the in situ technique, the samples were incubated at 0, 2, 4, 6, 8, 12, 16, 24, 36, and 48 h. For the description of the ruminal DM (dry matter) and CP (crude protein) degradation kinetics of treated and untreated Vicia ervilia, different models were selected as the best fit for the dry matter (DM) and crude protein (CP) degradation parameters of steam flaked samples. The results showed that both the steam flaking and microwave treatment samples contained high levels of non-protein nitrogen and buffer soluble protein, respectively. In comparison with steam flaking and microwave treatment, roasting decreased and increased the buffer soluble protein and neutral detergent insoluble protein, respectively. The control treatments showed the highest levels of neutral detergent soluble protein and the lowest levels of acid detergent soluble protein. Moreover, steam flaking and roasting decreased and increased the amount of acid detergent insoluble protein, respectively. When using dry heat (microwave and roasting), the acid detergent soluble and insoluble protein fractions were increased. As a result of this experiment, the nitrogen fractions were altered using heat processing. Hence, protein fermented feed and ruminal fermentation conditions can be expressed using these results.

1. Introduction

In addition to its high nutritional value and nitrogen fixation capacity, bitter vetch (Vicia ervilia), also known as ervil, can be grown in poor soils [1]. Traditionally, heat treatment has been used to increase ruminants’ ability to utilize protein from a variety of feeds. The microbial degradation of legume seed proteins in the rumen is relatively unknown [2]. The protein requirements of ruminants are expressed as Ruminal Degradable Protein (RDP) and Undegradable Dietary Protein (UDP). Protozoal and bacterial activity determine ruminal degradability, as well as the site where the bacteria attach. In order to determine whether legume seeds are suitable for use as animal feed, it is necessary to evaluate the extent of the nutrient’s association and the antinutritional effects. Many antinutritive factors can also be destroyed using heat treatment in some legume seeds [3]. Various treatment methods, such as dry-heating (roasting), heat-moisture (steam flaking), physical processing (grinding), and microwave treatment, affect the ruminal degradation of cereal grains. In the case of highly degradable feeds, heat processing is known to increase their disappearance rate [4]. According to McNiven et al. [5], flame roasting reduced the loss of dry matter and crude protein in the rumen but did not have an effect on nutrient digestibility in the gut. For roasted barley grain, Robinson and McNiven [5] observed low rates of dry matter degradation but no effects on the extent of degradability. It has been shown that barley grain treated using steam flaking, flame roasting and exploring may reduce the crude protein in the rumen [5]. In a study by Fiems et al. [6], ruminal crude protein degradability was decreased after the barley grain was processed using steam flaking. Several methods for determining the rate of the degradation of feedstuffs in the rumen have been described, including the incubation of nylon bags for different periods of time in the rumen [7]. The in sacco method is a more accurate way of simulating the rumen environment than any other method used for estimating ruminal protein and carbohydrate digestion [8]. Although this technique has its advantages, it also has some limitations. One of the possible issues is that the residue present in the bags after incubation might be contaminated with microbial N, which would result in an overestimation of rumen escape N. In spite of its limitations, it is a reasonably useful technique for determining rumen degradation characteristics [9]. The aim of the research was to assess how effectively these models could be used to determine the parameters related to the degradability of DM (dry matter), CP (crude protein), nano structures, and protein fractions of untreated and heat treated samples after steam flaking, microwave treatment, and roasting, using in situ scanning electron microscope, and Cornell net carbohydrates and protein systems (CNCPS) methods.

2. Materials and Methods

2.1. Methods of Preparation and Processing of Samples

The authors collected a sample of Vicia ervilia from a dairy farm in the northwest of Iran. The experimental treatments included grinding and then roasting, microwaving, and steam flaking. In the milling process, the treatments were screened at 2.0 mm. Steam flakes were prepared by treating with steam at 100 °C for 30 min, passing the sample through rollers, letting them air for 48 h, then sealing them in plastic bags. A roasting treatment at 120 °C for 10 min and a microwave irradiation (Nasional at 800 watts) for 3 min were performed. For the nylon bag technique, fabric bags (4 cm × 6 cm; 47-μm pore size) were used.

2.2. Chemical Analysis

For the preparation of the samples, oven drying was performed (65 °C for 24 h). The dry matter, ash (924.05), crude protein (948.13) and ether extract (954.02) of the experimental treatments were determined according to the procedures of AOAC [10]. The neutral detergent fiber (NDF) and acid detergent fiber (ADF) of the treatments were determined using the methods of Van Soest et al. [11].

2.3. In Situ Ruminal Procedure

The rumen degradability of feed was measured using three fistulated Gizel sheep. A sheep’s diet consists of 60% roughage and 40% concentrate. Five grams of the samples were placed inside nylon bags (4 × 6 cm; 47-μm pore size) and incubated (durations 0, 2, 4, 8, 16, 24 and 48 h). After they were taken out of the rumen, the nylon bags were washed under cold water with the zero time bags (that had not been incubated in the rumen) for 20 min, and then they were dried at 65 ℃ for 48 h. An analysis of the residues was conducted after they were weighed.

2.4. Crude Protein Fractionation

In accordance with Sniffen et al. [12], the CP was divided into five fractions (A, B1, B2, B3 and C), based on the recommended standardization procedures by Licitra et al. [13]. A fraction A contains non-protein nitrogen (NPN), which is calculated by subtracting the total nitrogen from the true protein nitrogen, based on the equations of protein degradation in the rumen; fraction C cannot contain insoluble nitrogen in acid detergent (ADIN); the B fraction can be classified into rapid (B1), intermediate (B2), and slow (B3) fractions [12]. A comprehensive analysis of the precipitated true protein, buffer insoluble protein, neutral detergent insoluble protein (NDIP), and acid detergent insoluble protein (ADIP) was performed by Licitra et al. [13]. In order to determine the true protein, Kjeldahl analysis was performed on the residue following precipitation with trichloroacetic acid (TCA) and filtration. To obtain the crude protein fractions B1–B3, the following subtractions were performed: B1 was calculated by subtracting the true protein from the buffer-insoluble protein; B2 was calculated by subtracting the buffer-insoluble protein from the NDIP; and B3 was calculated by subtracting the ADIP from the NDIP.

2.5. Calculations and Statistical Analysis

As illustrated in Table 1; different models (Ørskov and McDonald [14] including and not including lag time; Dhanoa [15] with and without lag time; France [16] without lag time) were considered for describing the ruminal DM and CP degradability kinetics of treated and untreated Vicia ervilia, where p reflected the degradation at time t, a soluble fraction, b insoluble fraction, c rate of degradation, t was the time of incubation, l was the lag time (time interval before degradation commences), k, d was the mathematical constant. A Statistical Analysis System was deployed to analyze the DM and CP disappearance in situ and the Cornell data. Duncan’s multiple range tests were applied to compare the means. To estimate the ruminal degradation parameters, each model was fitted using nonlinear regression, using SAS PROC NLIN (Cary, NC, USA) [17].

Table 1.

Models.

3. Results

3.1. Chemical Analysis

The compositions of the treatments are summarized in Table 2. A chemical composition change occurred during processing. In comparison with the other treatments, steam flaking showed a lower DM (p < 0.05). Steam flaking, roasting, and microwave heating lost CP content, respectively, from 20.82, 21.62, and 21.37 percent. It was found that the microwave treatment led to higher NDF and lower ADF amounts, which were considered significantly different (p < 0.05). CA and EE did not yield statistically significant differences (p > 0.05).

Table 2.

Chemical composition data of the experimental treatments (%DM).

3.2. In Situ DM and CP Disappearance

The DM and CP disappearances at different stages of incubation are shown in Table 3. Increasing the incubation time resulted in more DM and CP disappearing from the nylon bags. After several incubation times, the parameters of the DM and CP were found to differ among the treatments. As compared to the other treatments, steam flaking demonstrated a greater in situ disappearance of DM and CP at 48 h (p < 0.05). Steam flaking and intact grain led to an increased retention time in the rumen. According to the results obtained at 0 h, steam flaking resulted in a higher CP and DM disappearance than other treatments. It was found that in situ DM and CP disappearance were lower in roasting samples at 48 h than in other treatments (p < 0.05), similar to observations made with protein supplements subjected to different protective methods.

Table 3.

DM and CP disappearance of treated and untreated Vicia ervilia from incubated in situ trials, expressed as percentages.

3.3. Determine DM Degradability Parameters Using Digestive Models

Various mathematical models were considered as potential options for describing the ruminal DM and CP degradation kinetics for treated as well as untreated samples, based on data collected using the in situ polyester bag method. Table 4 displays the DM degradability parameters. Five models were used: Ørskov and McDonald with and without lag time [14], Dhanoa with and without lag time [15], and France without lag time [16]. The degree of variability in disappearance was found to be linked to the washout fraction of the treatments, as well as to the impact of the heat treatment on altering the feeds’ fractional degradation rate; plus, as a result, the pattern of ruminal degradability for the treatments. The choice of goodness-of-fit models was based on the coefficient of determination (r-square) calculated for the different models, convergence or non-convergence, and the biological justification. The results show that the France [16] model is the best fitted model to determine the components of the DM degradability of control and roasting. The Dhanoa with lag time model is the best fitted model based on the model of the coefficient of the determination value for roasting; however, the presence of lag time cannot be proved for this treatment on the basis of biological justification and the problem of convergence in the final fitted model for the Ørskov model with lag time. For the microwave treatment, models with the lag phase ran into trouble in the convergence and the closest fitted model also had a lower coefficient of determination than the rest of the models; therefore, the lag time could not be verified. Given that the highest coefficient of determination obtained for the Dhanoa without lag time model, this model can be selected as the optimal model to fit the DM degradability using microwave treatment. For steam flaking, although the Ørskov with lag time model had a higher coefficient of determination, the excellence of Ørskov with the lag time model cannot be verified with steam flaking because there is no biological justification for the lag time. In general, the Dhanoa without lag time model is the best model based on the different models of the coefficient of determination. The France model also provides a better prediction of the roasting treatment compared to the Ørskov models.

Table 4.

Degradation parameters for DM in the in situ trial.

3.4. Determine CP Degradability Parameters Using Digestive Models

The CP degradability parameters are shown in Table 5. For each model, the coefficients of determination (r-square) were calculated, convergence or non-convergence was determined, and the biological justification was used to select the best models. According to the results, the Dhanoa is the best fitted model for calculating the coefficients of determination based on the different non-convergence models for the control, microwave treatment, and steam flaking. For roasting treatment, the Ørskov without lag time is the best fitted model. Dry roasting reduced the soluble fraction, and rate of degradation. Reports have shown that the heat-treatment of various types of seeds, including cotton, lupins, canola, faba bean, soybean, and legumes, has a comparable impact on the degradation of CP in the rumen.

Table 5.

Degradation parameters for CP in the in situ trial.

3.5. Crude Protein Fractions of Treatments

Protein fractions of Vicia ervilia are listed in Table 6. The fraction “B1” was found to be the highest for microwave treatment and the lowest for roasting. The A fraction for steam flaking and roasting was higher than the other treatments. The neutral detergent soluble protein (B2) fraction was highest for grinding Vicia ervilia (control) and roasting. The B3 fraction for roasting and microwave treatment was higher than the other treatments.

Table 6.

Protein fractions of treatments (% CP).

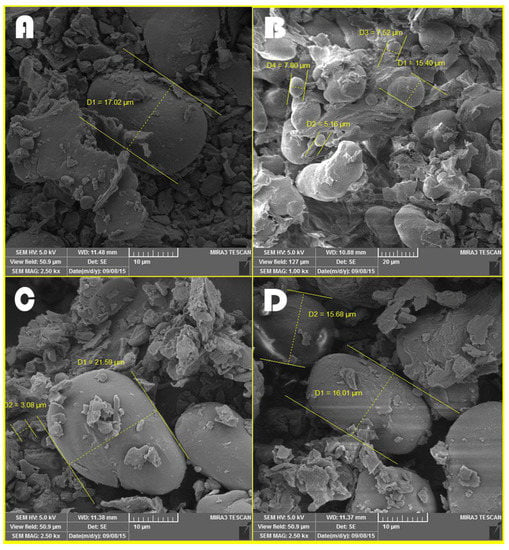

3.6. Microscopic Images Taken from Different Treatments before the Ruminal Incubation Time

The treatments’ effects on the surface of the granules of starch and protein matrix are clearly visible in the SEM (scanning electron microscope) images. The SEM images taken from steam flaking, microwaving, and roasting Vicia ervilia grain are shown in Figure 1. According to the images taken of the treatments, heat processing changed the physical and chemical properties. In all treatments involving physical and heat processing, cracking in the protein matrix and starch granules has occurred. According to the images and compared to the control, the steam flaking and microwaved samples show swelling and cracking in the starch granules, the granules’ size has increased due to gelatinization, and they have lost their crystalline structure depending on the duration of processing (A, C). Roasting causes a reduction in size and shrinkage of the starch granules due to the impact of heat processing on their structure. It appears that roasting does not result in any swelling of the starch granules. This phenomenon can be spotted in the SEM images. In the microwave heat treatment, the cracking is from the inside to the outside and causes the denaturation of the protein matrix. For the roasting treatments, the effects of heat treatment for 10 min caused shrinkage in the starch granules and some cracking (D). Changes in protein digestibility can change the properties of digestible starch because the starch granules are contained in a matrix of protein; roasting seeds can reduce the digestion of starch by increasing the resistance of the protein matrix, which reduces access to the starch contents for microorganisms.

Figure 1.

SEM image for treatments at zero incubation time. (A) Steam flaking, (B) Control, (C) Microwaving (3 min), (D) Roasting (10 min).

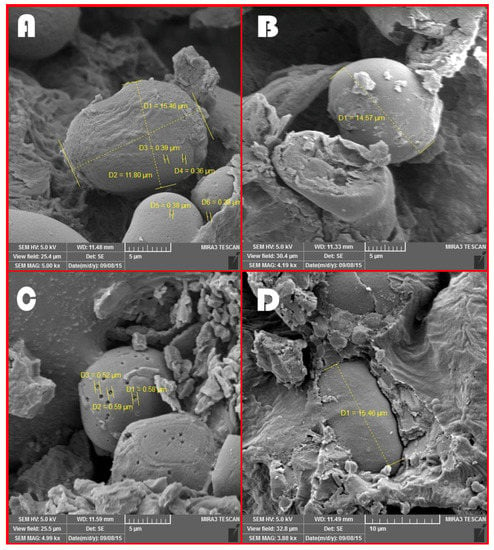

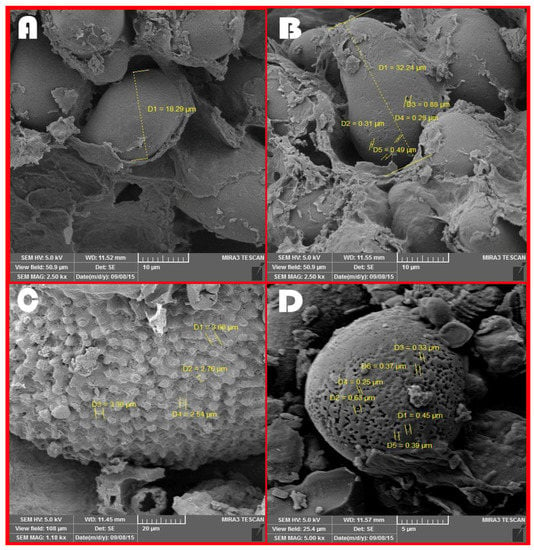

3.7. Microscopic Images Taken from Different Treatments at 48 h of Ruminal Incubation Time

The SEM images of the treatments are shown in Figure 2 and Figure 3. Comparisons of the digestion channels and the size of the starch granules are shown in Table 7. Investigation of the treatments after 48 h of incubation showed that the number and diameter of the digestion channels compared to the size of the starch granules were different; it was highest for the microwave treatment, which shows the high degradability of this treatment. For the control treatment at 48 h of incubation, time shrinkage, cracking and low digestion channels on the surface starch granules are visible (Figure 2A,B). For the microwave treatment, the proportion of the digestion channels compared to the size of the starch granules was higher than the other treatments; in this treatment, part of the starch granule is also surrounded by a visible protein matrix (Figure 2C,D). The presence of the protein matrix that surrounds the starch granules can also reduce the extent of starch digestion. For the steam flaking treatment, swelling and cracking in the starch granules occurred and the size of the granules increased due to gelatinization, which provides conditions for the activities of the microorganisms and enzymes involved in digestion (Figure 3A,B).

Figure 2.

SEM image for treatments at 48 h of incubation time. (A,B) Control (shrinkage, cracking and the digestion channels of the starch granules are visible); (C,D) Microwave treatment ((C) digestion channels of the starch granule are visible; (D) part of the starch granule is visible and surrounded by a protein matrix).

Figure 3.

SEM image for treatments at 48 h of incubation time. (A,B) Steam flaking; (C,D) Roasting.

Table 7.

Comparison of the digestion channels with the size of the starch granule in different treatments.

4. Discussion

4.1. Chemical Composition

There is a possibility that some amino acids were partially removed during the heating process, which contributed to the loss of protein. High drying temperatures induce the NDF values. The field’s NDF value was best approximated with the microwave treatment. The trend towards an increased NDF with increased microwave exposure was confirmed by other researchers.

4.2. In Situ Dry Matter and Crude Protein Disappearance

The rumen degradability decreased from 0.83 (raw) to 0.47 (136 °C/15 min) after pressure toasting [18]. Rumen degradation can be reduced through heat treatments [19]. A study conducted by Taghizadeh et al. [20] observed that the DM and CP in cotton seed meal disappeared at 48 h at a rate of 43.19% and 46.46%, respectively. It has been reported that the heat treatment of soybean meal decreases the rumen degradability of DM and CP, but increases its intestinal availability [21]. Ljøkjel et al. [22] found that treating barley grain at 100 °C and 150 °C decreased CP degradation. It is thought that the intensity of the effect is influenced by the time of exposure and the temperature reached [23,24], as well as the particle’s size and moisture during processing. Protein availability in the intestinal tract should increase as rumen protein degradation decreases. The bypass protein is increased with heat treatment, but optimal heat conditions have not been found for each legume seed [25]. In addition, prolonged treatment with high temperature may lead to Maillard reactions of carbohydrates with amino acids, reducing the animal’s amino acid availability. In a study by Paya et al. [26], 69% of DM and 55.6% of CP had disappeared by 48 h after soybean meal preparation. It was found by Fiems et al. [6] that steam processing reduced the degradation rate of the CP in barley and wheat. The types, varieties, and processing can all contribute to these differences. In comparison with dry rolled barley, Engstrom et al. [27] found that steam rolling reduced DM disappearance from in sacco samples at 0, 8 and 24 h, and starch disappearance by 21.2% at 0 h and 12.8% at 8 h of incubation. This was consistent with the findings of Fathi Nassri [21] and Ljøkjel et al. [22]. DM and CP degradation is reduced with heat treatment, in part because microbial proteolysis enzyme receptor sites are blocked, and in part due to protein solubility being reduced [28]. The starch granule’s size and the contents of the intracellular space (protein matrix, starch) were observed to influence DM disappearance with incubation time and chemical composition. A strong correlation was found between in situ DM disappearance and chemical composition [29].

4.3. Determine DM Degradability Parameters Using Digestive Models

Fathi et al. [21] obtained the DM soluble fraction values for soybean grain using the models of France, Ørskov, and Lopez, which were 47.96%, 45.31% and 41.08%, respectively—these do not match the values obtained in this study. In a study by Fathi [21], the percentage of DM and CP disappearance for heated whole soybeans were found to be less than raw soybeans. The difference in the rate of disappearance depends on the method and duration of washing, the effect of the heat process on the degradation rate, and the change in the pattern of the feeds’ ruminal degradability. Gonzalez et al. [30] reported that the soluble fraction, insoluble fraction (function of time), and effective degradability of the DM of Vicia ervilia are 29.2%, 59.7%, and 62.7%, respectively. The effect of different treatments on the DM degradation parameters showed that steam flaking and roasting had higher and lower degradability, respectively. Dry roasting reduced the soluble fraction, rate of degradation, and increased the degradation part. The temperature and time of exposure affect the intensity of these effects [31]. As well as irreversible bonding between carbohydrate aldehydes and amino acids, mainly lysine’s e-amino group, this effect is a result of the bonds (crosslinking) between and within proteins. It was reported by Lindberg [32] that rapeseed and soybean meals did not exhibit pronounced ruminal degradation when moderately heated. In the rumen, the digestibility of raw fiber depends on the amount of forage consumed and the digestive capacity of the animal. It has been possible to develop different mathematical models that describe the ratio of rumen disappearance through the application of various mathematical models to estimate the parameters of a feed’s degradability, and to formulate hypotheses about the biological principles governing ruminal digestion separation [33].

4.4. Determine CP Degradability Parameters Using Digestive Models

Based on Mc Meniman and Armstrong’s study [34], heating faba beans did not increase protein flow to the cattle’s duodenum, but 105 °C did not protect the protein. In Yu’s [18] study, dry roasting at a lower temperature (110 °C) did not affect the soluble fraction, rate of degradation, or the degradation degree, but the degradability of rumen protein was higher than that of raw beans. The authors’ results are comparable to those reported in those studies. In the rumen, dry roasting at 110 °C increased crude protein fermentation. Subjecting beans to high-temperature steaming (at 136 °C) can significantly enhance their protein value. In a study by Sadeghi and Shawrang [35], microwave irradiation for 7 min decreased both the water-soluble and potentially degradable components of corn grain starch (p < 0.05).

4.5. Crude Protein Fractions of Treatments

The ADIN fractions for roasting and microwave treatment were higher than the other treatments. However, the increase in ADIN after heat treatment is in agreement with other results [36,37,38]. Fraction B1 is rapidly degraded by rumen microorganisms but the heat treatment of feedstuffs can decrease B1 by blocking reactive sites for microbial proteolytic enzymes [28]. Heat processing reduced the buffer soluble protein, which was consistent with the results of other studies [39,40,41]. The destiny of fraction B2 relies on the speed of digestion and passage; some of it is degraded in the rumen, the rest passes through to the intestine. Fraction B3 is less susceptible to degradation in the rumen as it is linked to the cell wall [12]. The CNCPS model presupposes that ruminal bacteria cannot break down the ADIN (C fraction). Thus, the CP of steam flaking is highly degradable in the rumen. These dissimilarities are explained by differences in the processing techniques, methodology, and the variations in the type of feed.

4.6. Microscopic Images Taken from Different Treatments before the Ruminal Incubation Time

The increase in the size of the starch granules and gelatinization depends on the type of seed and the intracellular content because Vicia ervilia has lower starch and higher protein than other grains, such as wheat, barley and sorghum. The extent of starch gelatinization in animal feeds is positively correlated with its digestibility [42]. The processing method used (i.e., steam flaking, pelleting, expanding, extrusion) and various operational factors (including water addition level, temperature, and retention time) affect the extent of starch gelatinization. According to research by McDonough et al. [43], adding more water during tempering leads to higher flake moisture, which enhances both the structural integrity of the flakes and the degree of starch gelatinization. Ruminants benefit from heat processing since the molecular structure of proteins is changed, which reduces the degradation of proteins in the rumen and optimizes their utilization of protein.

4.7. Microscopic Images Taken from Different Treatments at 48 h of Ruminal Incubation Time

For instance, the high temperature treatment of sorghum reduces its digestibility, which was explained as stemming from the polymerization of prolamin, and from crosslinked prolamin (via disulphide bonds) [44]. However, in the case of the roasting treatment, visible digestion channels can be observed. Prolonged roasting can reduce starch digestibility by increasing the resistance of the protein network and hindering rumen microorganisms from accessing and breaking down feed starch. Consequently, the degradability of this treatment was found to be the lowest among all of the treatments. The treatment values obtained from the images in this study were consistent with the degradability of the DM and CP obtained using the in situ method. McNiven [5] reported that barley grain treated with steam flaking, flame roasting, and exploring, could decrease ruminal crude protein. Similarly, Ljøkjel et al. [22] found that heat treatment reduced the ruminal degradation of starch in both barley grain and pea grain. Srakaew et al. [45] and Kokić et al. [46] found that microorganisms have access to more starch in the rumen due to heat and moisture. The disorganization of the starch granules in the grain’s endosperm and disruption of the protein matrix may be to blame for this problem. Since starch digestion is not complete, the grains continue to be processed to expand the gelatinization of the starch and, thereby, its digestibility [47].

5. Conclusions

According to the analysis of the SEM images, it was found that the structure of the feed materials’ surface strongly correlates with its DM and CP degradation values. The surface structure was determined using the different treatment methods.

Because steam flaking has a high degradability, it can be used in diet formulations to improve the digestion processes in animals. This study points towards the benefits of steam flaking over other methods, and additional studies are recommended to investigate the aspects of rumen health, processing, and transport (life cycle), as well as animal-related factors, to arrive at a complete cost-benefit overview.

Author Contributions

Conceptualization, A.T.; methodology, M.T., A.H., H.M. and Y.M.; software, Y.M. and V.P.; validation, A.T., M.M. and A.H.; formal analysis, Y.M. and M.M.; investigation, H.M.; resources, A.T. and M.L.; data curation, M.T. writing—original draft preparation, M.T. and V.P.; writing—review and editing, M.L. and V.P.; supervision, A.T. and M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been supported by the University of Tabriz, International and Academic Cooperation Directorate, in the framework of the Tabriz U-300 program. Open Access Funding is covered by the University of Applied Sciences Technikum Wien/Austria.

Institutional Review Board Statement

The protocol of this work was approved by the experimental animal ethics committee of the University of Tabriz/Iran.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from Akbar Taghizadeh upon reasonable request.

Acknowledgments

This work has been supported by the University of Tabriz, International and Academic Cooperation Directorate, in the framework of the Tabriz U-300 program.

Conflicts of Interest

The authors declare that they bear no conflict of interest.

References

- Farran, M.T.; Dakessian, P.B.; Darwish, A.H.; Uwayjan, M.G.; Dbouk, H.K.; Sleiman, F.T.; Ashkarian, V.M. Performance of broilers and production and egg quality parameters of laying hens fed 60% raw or treated common Vetch (Vicia sativa) Seeds. Poult. Sci. 2001, 80, 203–208. [Google Scholar] [CrossRef]

- Aguilera, J.F.; Bustos, M.; Molina, E. The degradability of legume seed meals in the rumen: Effect of heat treatment. Anim. Feed Sci. Technol. 1992, 36, 101–112. [Google Scholar] [CrossRef]

- Liener, I.E. (Ed.) Toxic Constituents of Plant Foodsluffs, 2nd ed.; Academic Press: New York, NY, USA, 1980; 502p. [Google Scholar]

- National Research Council: Nutrient Requirements of Dairy Cattle; National Academies Press: Washington, DC, USA, 2001.

- McNiven, M.A.; Hamilton, R.M.G.; Robinson, P.H.; De Leeuiwe, J.W. Effect of flame roasting on the nutritional quality of common cereal grains for ruminants and non-ruminants. Anim. Feed Sci. Technol. 1994, 47, 31–40. [Google Scholar] [CrossRef]

- Fiems, L.O.; Cottyn, B.G.; Boucque, C.V.; Vanacker, J.M.; Buysse, F.X. Effect of grain processing on in Sacco digestibility and gigestibility and degradability in the rumen. Arch. Anim. Nut. 1990, 40, 713–721. [Google Scholar]

- Palangi, V.; Macit, M.; Bayat, A.R. Mathematical models describing disappearance of Lucerne hay in the rumen using the nylon bag technique. S. Afr. J. Anim. Sci. 2020, 50, 719–725. [Google Scholar] [CrossRef]

- Eslampeivand, A.; Taghizadeh, A.; Safamehr, A.; Palangi, V.; Paya, H.; Shirmohammadi, S.; Abachi, S. Nutritive value assessment of orange pulp ensiled with urea using gas production and nylon bag techniques. Biomass Conv. Bioref. 2022. [Google Scholar] [CrossRef]

- Huhtanen, P.; Ahvenjärvi, S. Problems in determining metabolisable protein value of dairy cow diets and the impact on protein feeding. Animal 2022, 16, 100539. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International; AOAC International: Rockville, MD, USA, 2005. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber and non-starch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Sniffen, C.J.; Connor, J.D.O.; Van Soest, P.J.; Fox, D.G.; Russell, J.B. A net carbohydrate and protein system for evaluating cattle diets: 11. Carbohydrate and protein availability. J. Anim. Sci. 1992, 70, 3562. [Google Scholar] [CrossRef]

- Licitra, G.; Hernandez, T.M.; Van Soest, P.J. Standardization of procedures for nitrogen fractionation of ruminant feeds. Feed Sci. Technol. 1996, 57, 347–358. [Google Scholar] [CrossRef]

- Ørskov, E.R.; McDonald, L. The estimation of protein degradability in the rumen from incubation measurements weighted according to rate of passage. J. Agric. Sci. 1979, 92, 499–503. [Google Scholar] [CrossRef]

- Dhanoa, M.S.; France, J.; Siddons, R.C.; Lopez, S.; Buchanan, S.J.G. A non-linear compartmental model to describe for age degradation kinetics during incubation in polyester bags in the rumen. Br. J. Nut. 1995, 73, 3–15. [Google Scholar] [CrossRef] [PubMed]

- France, J.; Thornley, J.H.M.; Lopez, S.; Siddons, R.C.; Dhanoa, M.S.; Van Soest, P.J.; Gill, M. On the two-compartment model for estimating extent of feed degradation in the rumen. J. Theor. Biol. 1990, 146, 269–287. [Google Scholar] [CrossRef] [PubMed]

- SAS Institute Inc. SAS/CONNECT® 9.4 User’s Guide, 4th ed.; SAS Institute Inc.: Cary, NC, USA, 2018. [Google Scholar]

- Yu, P.; Goelema, J.O.; Holmes, H.G.; Tamminga, S. Influence of pressure toasting on rumen degradation characteristics of lactating dairy cows. In Proceedings of the 8th AAAP Animal Science Congress, Chiba, Japan, 13–18 October 1996; pp. 694–695. [Google Scholar]

- Palangi, V.; Macit, M. In situ crude protein and dry matter ruminal degradability of heat-treated barley. Rev. Méd. Vét. 2019, 170, 123–128. [Google Scholar]

- Taghizadeh, A.; Safamehr, A.; Palangi, V.; Mehmannavaz, Y. The determination of metabolizable protein of some feedstuffs used in ruminant. Res. J. Biol. Sci. 2008, 3, 804–806. [Google Scholar]

- Fathi Nasri, M.H.; Danesh Mesgaran, M.; France, J.; Cant, J.P.; Kebreab, E. Evaluation of Models to Describe Ruminal Degradation Kinetics from In Situ Ruminal Incubation of Whole Soybeans. J. Dairy Sci. 2006, 89, 3087–3095. [Google Scholar] [CrossRef]

- Ljøkjel, K.; Harstad, O.M.; Prestløkken, E.; Skrede, A. In situ digestibility of protein in barley grain and peas in dairy cows: Influence of heat treatment and glucose addition. Anim. Feed Sci. Technol. 2003, 87, 87–104. [Google Scholar] [CrossRef]

- Stern, M.D.; Santos, K.A.; Satter, L.D. Protein degradation on rumen and amino acids absorption in the small intestine of lactating dairy cattle fed heat-treated whole soybeans. J. Dairy Sci. 1985, 68, 45–56. [Google Scholar] [CrossRef]

- Waltz, D.M.; Stern, M.D. Evaluation methods for protecting soybean protein from degradation by rumen bacteria. Anim. Feed Sci. Technol. 1989, 25, 11–122. [Google Scholar] [CrossRef]

- Iommelli, P.; Zicarelli, F.; Musco, N.; Sarubbi, F.; Grossi, M.; Lotito, D.; Tudisco, R. Effect of cereals and legumes processing on in situ rumen protein degradability: A review. Fermentation 2022, 8, 363. [Google Scholar] [CrossRef]

- Paya, H.; Taghizadeh, A.; Janamohamadi, H.; Moghadam, G.A. Ruminal dry matter and crude protein degradability of some tropical (Iranian) feeds used in ruminant diets estimated using the in situ and in vitro techniques. J. Biol. Sci. 2008, 3, 720–725. [Google Scholar]

- Engstrom, D.F.; Mathison, G.W.; Goonewardene, L.A. Effect of_-glucan, starch and fiber content and steam vs. dry rolling of barley grain on its degradability and utilization by steers. Anim. Feed Sci. Technol. 1992, 37, 33–46. [Google Scholar] [CrossRef]

- Burakowska, K.; Górka, P.; Kent-Dennis, C.; Kowalski, Z.M.; Laarveld, B.; Penner, G.B. Effect of heat-treated canola meal and glycerol inclusion on performance and gastrointestinal development of Holstein calves. J. Dairy Sci. 2020, 103, 7998–8019. [Google Scholar] [CrossRef]

- Vahidi, M.F.; Gharechahi, J.; Behmanesh, M.; Ding, X.Z.; Han, J.L.; Salekdeh, G.H. Diversity of microbes colonizing forages of varying lignocellulose properties in the sheep rumen. PeerJ 2021, 9, e10463. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, J.; Andres, S. Rumen Degradability of some feed legume seeds. Anim. Res. 2003, 52, 17–25. [Google Scholar] [CrossRef]

- Haese, E.; Titze, N.; Rodehutscord, M. In situ ruminal disappearance of crude protein and phytate from differently processed rapeseed meals in dairy cows. J. Sci. Food Agric. 2022, 102, 2805–2812. [Google Scholar] [CrossRef] [PubMed]

- Lindberg, J.E. Nitrogen metabolism in sheep. 2. A comparision between rumen degradability of nitrogen and organic matter in Sacco and in vivo in sheep fed rations with hay. Barley and various protein supplement. Swed. J. Agric. Res. 1984, 14, 37–43. [Google Scholar]

- Palangi, V. Identification of ruminal fermentation curves of some legume forages using particle swarm optimization. Animals 2023, 13, 1339. [Google Scholar] [CrossRef]

- McMeniman, N.P.; Armstrong, D.G. The flow of amino acids into the small intestine of cattle when fed heated and unheated beans (Vicia faba). J. Agric. Sci. 1979, 93, 181–188. [Google Scholar] [CrossRef]

- Sadeghi, A.A.; Shawrang, P. Effects of microwave irradiation on ruminal protein and starch degradation of corn grain. Anim. Feed Sci. Technol. 2006, 127, 113–123. [Google Scholar] [CrossRef]

- Arieli, A.; Ben-Moshe, A.; Zamwel, S.; Tagari, H. In situ evaluatuion of ruminal and intestinal digestibility of heat-treated whole cottonseeds. J. Dairy Sci. 1989, 72, 1228–1233. [Google Scholar] [CrossRef] [PubMed]

- Polan, C.E.; Stieve, D.E.; Garrett, J.L. Protein preservation and ruminal degradation of ensiled forage treated with heat, formic acid, ammonia, or microbial inoculant. J. Dairy Sci. 1998, 81, 765–776. [Google Scholar] [CrossRef] [PubMed]

- Golshan, S.; Pirmohammadi, R.; Khalilvandi-Behroozyar, H. Microwave irradiation of whole soybeans in ruminant nutrition: Protein and carbohydrate metabolism in vitro and in situ. Vet. Res. Forum 2019, 10, 343. [Google Scholar] [PubMed]

- Li, Y.; Cheng, Y.; Zhang, Z.; Wang, Y.; Mintah, B.K.; Dabbour, M.; Ma, H. Modification of rapeseed protein by ultrasound-assisted pH shift treatment: Ultrasonic mode and frequency screening, changes in protein solubility and structural characteristics. Ultrason. Sonochemistry 2020, 69, 105240. [Google Scholar] [CrossRef]

- Tang, S.Q.; Du, Q.H.; Fu, Z. Ultrasonic treatment on physicochemical properties of water-soluble protein from Moringa oleifera seed. Ultrason. Sonochemistry 2021, 71, 105357. [Google Scholar] [CrossRef]

- Erickson, P.S.; Kalscheur, K.F. Nutrition and feeding of dairy cattle. In Animal Agriculture; Academic Press: New York, NY, USA, 2020; pp. 157–180. [Google Scholar]

- Ren, Y.; Quilliam, C.; Weber, L.P.; Warkentin, T.D.; Tulbek, M.C.; Ai, Y. Effects of pulse crop types and extrusion parameters on the physicochemical properties, in vitro and in vivo starch digestibility of pet foods. Cereal Chem. 2022, 99, 625–639. [Google Scholar] [CrossRef]

- McDonough, C.M.; Anderson, B.J.; Rooney, L.W. Structural characteristics of steam-flaked sorghum. Cereal Chem. 1997, 74, 542–547. [Google Scholar] [CrossRef]

- Ezeogu, L.I.; Duodu, K.G.; Taylor, J.R.N. Effects of endosperm texture and cooking conditions on the in vitro starch digestibility of sorghum and maize flours. J. Cereal Sci. 2005, 42, 33–44. [Google Scholar] [CrossRef]

- Srakaew, W.; Wachirapakorn, C.; Cherdthong, A.; Wongnen, C. Ruminal Degradability and Bypass Nutrients of Alkaline or Steam-Treated Cassava Chip and Corn Grain. Tropic. Anim. Sci. J. 2021, 44, 451–461. [Google Scholar] [CrossRef]

- Kokić, B.; Dokić, L.; Pezo, L.; Jovanović, R.; Spasevski, N.; Kojić, J.; Hadnađev, M. Physicochemical Changes of Heat-Treated Corn Grain Used in Ruminant Nutrition. Animals 2022, 12, 2234. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, S.; Ai, L. Physical barrier effects of dietary fibers on lowering starch digestibility. Curr. Opin. Food Sci. 2022, 48, 100940. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).