Abstract

Livestock production is the main economic engine of the Azores. Given the role nutrition plays in animal performance and the context of limited Averages sharing the same letter are noagricultural area of the archipelago, optimising the quality and availability of the fodder used in feeds takes on an important role in increasing the competitiveness and viability of the industry. This work evaluated the potential of NIR spectroscopy to quantify several chemical and biological parameters used to assess silage quality in the specific agroclimatic context of the Azores. Reference values were determined for 400 grass silage and 400 corn silage samples. The corresponding NIR spectra were extracted, and mathematical models capable of correlating these readings with the various parameters were built. The best results were obtained for crude protein, neutral detergent fibre, acid detergent fibre, and crude ash for both fresh and dry samples. For the biological parameters concerning gas production, no satisfactory results were reached. It was concluded that it was feasible to build models capable of accurately predicting these important quality parameters, which demonstrates that NIRS is a viable technique that can be used in the Azores to perform a close and timely monitoring of forage quality and to facilitate the management and optimisation of diets.

1. Introduction

As a region, the Azores are highly economically dependent on livestock production. With a limited agricultural area, there are serious challenges to obtaining a sustainable increase in production, which must necessarily come from optimising the available resources and achieving maximum production at minimum cost [1].

Animal feed, one of the most decisive aspects of production, is, therefore, emerging as an area of particular interest, and, in general, the study and characterization of feeds for animal production has been gaining preponderance. The reasons for this include the need to design diets that, in addition to offering the maximum differential between feed costs and product sales, also allow for the reduction of negative environmental impacts [2].

Whether directly or in the form of silage, pastures are the predominant source of food for dairy cows in the world [3]. This is also the case in the Azores, including the use of forage crops for preservation so that they can be employed in periods of greater scarcity of food to ensure that ruminant animals are fed adequately and at a controlled cost throughout the year, especially in the winter [4,5].

Monitoring forage quality, whether as pasture or silage, thus becomes an important vehicle for pasture management and the design of diets to maximize animal welfare, longevity, and performance [6,7]. All these developments typically rely on laboratory analysis, which tends to be impractical, time consuming, expensive, and with possible negative impacts on the environment due to the chemicals they rely on. It is therefore difficult to set up a quality-monitoring system that provides results on a regular, timely, and affordable basis [8]. On the other hand, the more information that is available on the nutritional value of forage, the more effective adapting the methods of preparation and handling for the maximization of its nutritional benefits can be.

It is in this context that near infrared reflectance spectroscopy (NIR) appears. Since its first application in agriculture by Norris in 1964, it has been used with increasing frequency as an alternative to conventional analyses to predict the chemical composition of forages as well as other products [9]. It is, for example, commonly applied in the pharmaceutical, textile, oil, and cosmetics industries, among others [10], both in the context of quality control and in the processes themselves [11].

This technique offers several important advantages over traditional approaches [12]. In addition to being a reliable analytical method that can be used both qualitatively (for identification) and quantitatively (for dosage), and applicable to solid or liquid samples, it is a universal, rapid, non-destructive, and user-friendly technique, as it does not require sample pre-treatment, does not consume chemical reagents, and does not generate waste.

In contrast, reference [13] points out that this technique is purely empirical and requires similar samples to be analysed by similar methods. In fact, the main challenge to its application is the establishment of calibration equations that are based on chemical analyses performed on a large number of samples. Reference [14] even considers that the most critical point of NIR analysis is the quality of the laboratory analyses used for calibration. The chemical composition of the samples has to be previously known for the determination of the calibration equations [15]. Reference [16] states that more accurate determinations are obtained when samples from all the treatments to be analysed are used in the calibration equations.

This work’s aim was to evaluate the potential of near infrared spectroscopy as a fast and non-destructive method to determine the chemical composition of forages in the Azores in the broader context of using this technique to support the quality control of forages used in animal feed in the archipelago.

2. Materials and Methods

2.1. Experiment Design

This study was carried out in the Azorean archipelago (Figure 1). The Azores archipelago is constituted by nine islands divided into three groups: the Western Group (Flores, Corvo), the Central Group (Terceira, Faial, Pico, São Jorge, Graciosa), and the Eastern Group (São Miguel, Santa Maria). The area occupied by the islands and islets that together make up the archipelago is equivalent to about 2.5% of Portuguese territory (2322 Km2). The islands themselves are of unequal size; the three largest, São Miguel (745.8 Km2), Pico (448.4 Km2), and Terceira (403.4 Km2), represent 70% of the total area of the archipelago; São Jorge (245.9 Km2), Faial (173.8 Km2), and Flores (141.6 Km2) are of intermediate size; and Santa Maria (97.1 Km2), Graciosa (61.2 Km2), and Corvo (17.2 Km2) are the smallest. According to UNESCO’s criteria, which defines “small islands” as insular areas with an area of less than 1000 Km2, all the Azorean islands can be considered small [17].

Figure 1.

The Azorean archipelago.

The Azores have a temperate oceanic climate (Table 1). The minimum temperature is reached in February and the maximum is reached in August. Relative atmospheric humidity is typically high, reaching up to 95% in high-altitude native forests. The rainfall regime typically peaks in January or February, and it has its minimum in July [17].

Table 1.

Features of the Azorean archipelago (source: IPMA, “Instituto Português do Mar e da Atmosfera”).

Given its territorial dispersion and varied altitude, the Azores have agroclimatic conditions that are propitious for the exploitation of various types of agricultural production. In fact, there are few extensions of natural vegetation with little or no human intervention. The ones that exist are located mainly on the islands of Terceira, Pico, and Flores.

2.2. Silage Collection

In the Azores archipelago, the forages most used to prepare grass silage are perennial ryegrass (Lolium perene L.) from permanent pastures and Italian ryegrass (Lolium multiflorum Lam.) sown between September and October and harvested between April and June. The use of these is alternated with the use of corn (Zea mays L.), which is practically the only cereal grown for this purpose. Thus, in corn silage, hybrid corn (FAO 300) is mainly used that is sown between April and May and harvested between the end of August and September.

To ensure the variability and heterogeneity of the silages used in the calibration, a requirement for a good predictive capacity, the silage samples (grass and corn) were collected over a period of 5 years and originated from several silage processes and from various producers. In addition, it was possible to rely on the collaboration of agricultural associations and cooperation of several islands, which enabled a more comprehensive analysis at the archipelago level.

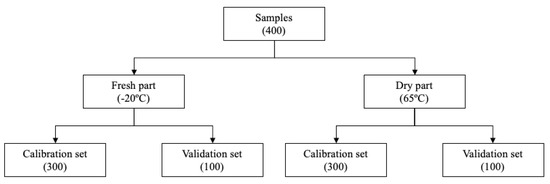

For this study, 400 grass silage samples and 400 corn samples were collected. Each sample was divided into two parts. One part was kept at −20 °C (fresh sample) for the determination of pH and ammoniacal nitrogen, and the other part was dried at 65 °C for further analytical analysis of the remaining chemical and biological parameters (dry sample). NIR spectra were taken for both parts, and independent calibrations were performed for each. During the calibration process, the samples used were further divided into a calibration set (300 samples) and a validation set (100 samples). Figure 2 summarizes how the samples of each forage type were separated and used.

Figure 2.

Scheme of the use and partition of the samples for each silage.

2.3. Traditional Methods

2.3.1. Determination of the Chemical Parameters

For the determination of chemical parameters, part of the collected samples was dried at 65 °C in an oven with forced air circulation until it achieved a constant weight. Then, it was ground in a Retsch mill with a 1 mm sieve. For analytical characterization, the scheme of Weende [18] was used to determine the DM (dry matter, method 930.15), ash (crude ash method 942.05), EE (ethereal extract method 920.39), and crude protein (method 954.01). NDF (neutral detergent fibre), ADF (acid detergent fibre), and ADL (acid detergent lignin) were measured by the methods proposed by [19]. Both NDF and ADF were expressed without residual ash. For the silages, pH was determined according to [20], and ammoniacal nitrogen was determined following the method described by [21].

2.3.2. Determination of Biological Parameters

In vitro dry matter digestibility and organic matter digestibility were measured according to the method of [22] as modified by [23].

Gas production was determined according to [24], which consists of incubating 200 mg of dry matter from the sample in a 100 mL calibrated glass syringe to which 30 mL of a mixture of rumen juice and inoculant medium (Menke medium mixture) are added, in a ratio of 1:2 v/v and held in CO2. The inoculant medium was prepared using the buffer solutions (reduced and mineral solutions) as described by Menke [24]

Afterwards, the glass syringe was incubated at 39 ± 0.5 °C in an electrically heated isothermal oven equipped with a rotor, which rolled continuously at 1–2 rpm. The gas production was measured manually, directly from the syringe, at 4, 8, 12, 24, 48, 72, and 96 h after the onset of incubation. Differences in the composition and activity of the rumen were controlled by three parallel measurements, a blank test, and incubation of a roughage and a concentrate standard as described by [24].

The gas production constants used were based on the model of [25] and fitted to the gas production kinetics curve of [26]:

where is the gas production at time ; is the gas production of the immediately soluble fraction (mL 200 mg˗1 DM); is the gas production of the insoluble fraction (mL 200 mg˗1 DM); is the gas production rate constant for the insoluble fraction (mL·h˗1); and is the incubation time (in hours).

The rumen fluid for each digestibility and gas production experiment was collected in the local slaughterhouse as described by [27], where the following conditions were observed: for each experiment, rumen was collected from five healthy dairy cows that had been fed ryegrass (Lolium multiflorum) and silage-based corn in the preceding days. Rumen fluid was collected within 10 min of slaughter, filtered using a cheesecloth, and preserved at 39 °C under anaerobic conditions until being delivered to the animal nutrition laboratory, which happened within 30 min of being collected [28].

2.4. Statistical Analysis

Assumptions of normality and homogeneity of variance were checked with Shapiro–Wilk and Levene’s tests, respectively. The data were analysed by one-way analysis of variance (ANOVA). The means were compared for significance using Duncan’s Multiple Range Test. All statistical analyses were performed using the IBM SPSS Statistics 27 program (SPSS Inc., Chicago, IL, USA). Values were expressed as mean ± standard mean error (SEM), and comparisons were considered statistically significant if the p-value was lower than 0.05.

2.5. Non-Destructive Method—NIR Spectroscopy

In all, four independent calibrations were performed for each parameter in order to assess the predictive capacity of each type of forage (grass silage and corn silage) and preservation (samples preserved at −20 °C and dry).

2.5.1. Spectra Collection

Spectra were collected using a LabSpec Pro Portable spectrophotometer from ASDinc. (Boulder, CO, USA) with an InGaAs detector available at the Animal Nutrition and Feeding Laboratory of the Azores University. The spectrum was obtained in the 450–2500 nm range with 50 scans per spectrum, in reflectance mode, although calibration was then performed in the near infrared zone (780–2500 nm).

The samples were placed in Petri boxes and processed by the spectrometer. Before and after each sample was processed, a white ceramic plate was used as a reference. The reflectance (R) values were converted into absorbance (A) values using the formula A = log(1/R). The reference values of the different parameters collected according to traditional methods for each sample were associated with the corresponding spectrum.

2.5.2. Calibration

Calibration models were developed to correlate the NIR spectral data with the reference values of the parameters under study. The PLS method was the one used on each calibration set for the determination of the calibration equations. In the construction of all PLS models, the procedure always followed the same contours.

Calibrations were performed with untreated spectra (log (1/R)) and combinations of the following mathematical pre-treatments: first derivative, SNV, and MSC. This was conducted to decide which was the most advantageous. After selecting the pre-treatment to be applied to the set of spectra, the maximum number of factors to be considered was established. This value had to be less or equal to the number of samples considered in the calibration. Excessively high values can induce overfitting. To ensure a more robust model, the equations were developed using cross-validation over the calibration set. This was also used to estimate the optimal number of terms. After balancing, the number of factors used was chosen automatically by the software in order to minimize the error. Several factor limits were tested until the best result was obtained.

After identifying the best pre-treatment and number of factors, outlier samples for each parameter were removed from the calibration set. These were determined according to the Mahalanobis distance. Less than 10% of outliers were identified and removed. After the development of the PLS model, an external validation was performed, as the sample set was large enough to allow it.

It was found that, in general, the best results were obtained with SNV + Det when the samples were fresh, which is explained by the fact that these are treatments specially oriented towards the removal of noise related to diffuse reflectance, which the lack of homogeneity of fresh samples provides.

The R2 (calculated on the calibration set), the SEC, and the RPD were used for a first evaluation of the predictive capacity of the model. It should be noted that the calibration with the lowest error is not always the most advantageous, since it can use an excessive number of factors or consider too many outliers, which leads to overfitting and compromises the predictive value for new samples. The choice of the best calibration equations was thus made with the external validation based on the values for R2, SEP, and RPD calculated on the corresponding validation set. It was considered that values for the coefficient of determination R2 equal to or greater than 0.9, combined with values of RPD equal to or greater than 3, meant a reliable prediction was possible [29]. Note that a high R2 coupled with a high error suggests that there may be some weakness in the actual predictive ability of the calibration, a weakness that is usually reflected in the corresponding RPD. In the case of this work, it was observed that the prediction accuracy (SEP) was very similar to the calibration error (SEC), which is an indicator of a robust calibration model and the use of heterogeneous calibration and validation sets.

3. Results

3.1. Traditional Methods

The calibration process depends on the prior identification of reference values for the calibration parameters. This was carried out using traditional analysis techniques. Overall, it was observed that the differences between maximum and minimum values for virtually every parameter being studied confirmed that the chemical composition and nutritional value database were representative of a wide range of conditions. The calibration and validation sets that were considered were shown to cover similar varieties for each component.

Table 2 reflects the statistical characterization regarding the chemical composition and determination of digestibility of grass and corn silages for the total set of samples (400 grass silages + 400 corn silages).

Table 2.

Descriptive statistics of the different parameters studied for grass silages and corn silages from the total set of samples.

It can be observed that, in the case of grass silages, the maximum values of DM (84.68 g/100 DM) and NDF (81.45 g/100 DM) are especially high, while the minimum of CP (4.41 g/100 DM) is low. In the case of corn silages, the maximum value of NDF (68.83 g/100 DM) is particularly high. The average values for both silages are close to the reference ranges.

Regarding the variability of the samples, reflected by the value of the standard deviation, and the coefficient of variation, it was found to be wide, which proves their heterogeneity. Even so, the corn silage shows, in general, less variability than the grass silage.

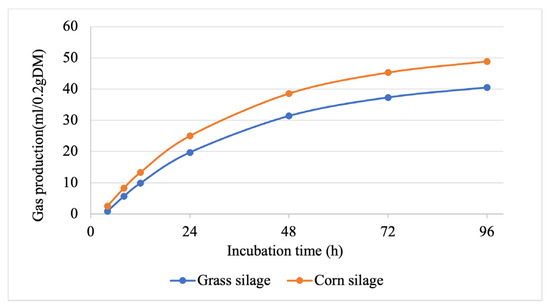

Table 3 shows the values obtained for the sample counts after developing McDonald’s (1981) model and fitting it to the gas production kinetics curve of Ørskov and McDonald (1979). In general, varied results were obtained. For grass silages, the values determined for were between −18.95 mL/0.2 g DM and 2.89 mL/0.2 g DM, while for , which also shows high standard deviation, they ranged between 19.99 mL/0.2 g DM and 92.92 mL/0.2 g DM. For corn and grass silages, the variation was of the same order as for grass silages (3.76 mL/0.2 g DM and 2.10 mL/0.2 g DM, respectively), with the values ranging between −17.21 and 2.66 for the former and between −9.75 and 0.62 for the latter. For , on the other hand, a much lower variation can be seen compared to grass silages (8.38 mL/0.2 g DM for corn silages), with values between 42.39 mL/0.2 g DM and 88.22 mL/0.2 g DM for corn silages. Overall, corn silages were, on average, responsible for the highest gas production after 96 h (48.88 mL/0.2 g DM), followed by grass silages (40.51 mL/0.2 g DM).

Table 3.

Descriptive statistics for the different parameters of in vitro gas production for grass silages and corn silages. Averages of the in vitro fermentation kinetics of the different forages.

The distribution of the different mean values, determined for the fermentation kinetics curves of the two sets of samples, are arranged in the following graphs. The higher gas production in corn silages is evident (Figure 3).

Figure 3.

Cumulative mean gas production over incubation time for grass silage and corn silage.

3.2. NIR Spectroscopy

After the analysis of all the samples, spectra were taken, and the reference values of the different parameters to be predicted were associated using the Indico-Pro software.

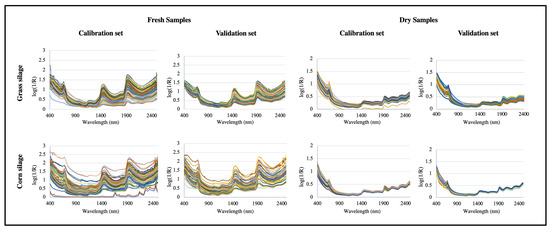

Figure 4 shows all the NIR spectra obtained for all the samples analysed by the reference methods. The spectra were collected between 450 and 2500 nm.

Figure 4.

Set of original spectra (without mathematical transformations) in the Vis/NIR region of the different samples for the calibration and validation set of grass silages and corn silages. Each color represents a different sample.

Overall, it was possible to observe a good homogeneity between the calibration and validation sets. It can also be seen that the amplitude and peaks of the readings for the fresh samples were more intense than those observed in the dry samples, which can be justified by the expectable higher noise due to light scattering induced by the inhomogeneity of the samples. This characteristic will tend to be minimized by the applied pre-treatments, namely MSC, SNV, or derivatization.

Table 4, Table 5, Table 6 and Table 7 summarize the statistical values that measure the performance of the calibration equations so that the best pre-treatment could be determined. The performance of the external validation is also presented.

Table 4.

Mathematical treatments and statistical performance of calibration and validation for the grass silages (dry and fresh) for the different chemical parameters and digestibilities.

Table 5.

Mathematical treatments and statistical performance of calibration for the different grass silages (dry and fresh) for the different parameters of in vitro gas production.

Table 6.

Mathematical treatments and statistical performance of calibration and validation for the different corn silages (dry and fresh) for the different chemical parameters and digestibilities.

Table 7.

Mathematical treatments and statistical performance of calibration for the different corn silages (dry and fresh) for the different parameters of in vitro gas production.

Good results were obtained for most parameters considered in the study, with the equations showing the highest predictive capacity for CP and NDF for all samples, both fresh and dry. For these parameters, R2 values were always equal to or greater than 0.87, with the RPD varying between 3.08 and 13.62. The model also showed particularly good performance in predicting ADF, with the worst predictive ability of this parameter occurring for fresh grass silages, where the R2 obtained was 0.78 and the RPD was 3.13. The worst-performing parameters were N-NH3/N (best result obtained for fresh grass silages with an R2 of 0.65 and an RPD of 2.75), pH (best result obtained for fresh grass silages with an R2 of 0.8 and an RPD of 3.14 but with values below 0.62 and 2.75, respectively, for the other sample sets), and EE (values of maximum 0.63 and 2.95 for R2 and RPD, respectively, with the exception of corn silage, where they were slightly better). The calibration models also did not prove capable of predicting gas production with great accuracy. Considering the average values of R2 and RPD, the best predictive ability was achieved for corn silage followed by grass silage, with the best results being achieved for dry fodder.

Table 4 shows the results obtained for grass silages, with the predictive performance for PB and NDF being noteworthy (R2 of 0.97 and 0.95, and RPD of 7.00 and 4.28, respectively). The calibration equation parameters of in vitro gas production for these silages proved unreliable (Table 5), with the maximum R2 being 0.79 for gas production at 24 h and the RPD not exceeding 3.83.

For corn silages, it is again the statistics for the dry samples that showed the best results (Table 6). In this case, we can highlight the crude ash with an R2 of 0.94 and an RPD of 5.82. The calibration equations for the in vitro gas production parameters for corn silages also proved unreliable (Table 7), which is in line with the findings for grass silage, with the maximum R2 being 0.78 for gas production at 96 h and the RPD not exceeding 3.04.

4. Discussion

4.1. Traditional Methods vs. Non-Destructive Method—NIR Spectroscopy

Forages are the main and most important source of nutrients for ruminant livestock [30], and forage conservation is key to productivity and efficiency in ruminant production, with silage being the most common type of forage [31,32]. Silage quality depends, on the one hand, on its nutritional value, which is directly linked to its composition, and, on the other hand, on its preservation quality. However, the composition and nutritive value of forages are extremely variable both overall and within the various forage types. This leads to them having different contributions to production systems, ranging from foods unable to sustain animal maintenance to those with very high nutritional value [33]. Thus, it is important to understand and know the nutritional value of forages in order to design diets and perform management that optimises commercial gains since feed directly influences the productive and reproductive performance of animals [30].

NIR spectroscopy has been used for decades in agriculture as an efficient tool for the evaluation of a large number of parameters and criteria. NIRS has demonstrated unquestionable advantages not only in the analysis of soil, forage, silage, and faeces but also in the analysis of agri-food products such as feed and dairy products. A new generation of instruments even makes it possible to apply this technique away from the constraints of the laboratory, meaning immediate and on-site information can be obtained, which makes more timely and informed decision making possible [34].

The NIRS calibration process starts with the determination via traditional methods of the parameters of interest of all the samples under study (see Table 2 and Table 3). The values obtained in this study were found to be in line with the results reported in the literature. It was also observed that the corn silage coefficient of corn silages was systematically lower than that of grass silages, which indicates a greater homogeneity in the treatment of the former.

Once all the parameters of interest have been determined by conventional methods, the calibration process continues with the collection of the spectra of all samples for both the calibration and validation sets (Figure 4). It was found that they present a profile that displays a similar pattern throughout the tested range, which indicates similar components in the various analysed samples, which is consistent with that presented by [35].

For the collected spectra (Figure 4), it can be observed that the most intense bands are located around 1450 nm due to the first O-H overtone and 1950 nm resulting from combinations of O-H vibrations, which correspond to the moisture content [36]. These readings are consistent with that reported by [37], who reported peaks at 1450 nm and 1970 nm. Note that these bands are more intense in the fresh samples than in the dry samples. In turn, the spectral peaks around 1198 nm are associated with the second C-H overtone and are related to the fat content, and the peaks at 2266 nm and 2430 nm refer to the combinations of vibrations, which is also consistent with that reported by [38], who observed these peaks at 2312 nm and 2352 nm. The less intense peak around 1685 nm, attributed to the first C-H overtone, is directly correlated with protein content. It is also possible to see an absorption band around 1500 nm (N-H first overtone) related to protein, which is more pronounced in the dry samples.

It is also possible to verify that there is greater uniformity in the readings of dry samples compared to fresh samples. This happens because the NIR spectra, besides containing information about the chemical composition of the sample, also relate its physical information. In the case of solids, the surface and scattering of the sample must be considered because the surface morphology and refractive index affect the scattering properties of solid materials. As can be seen in Figure 4 in the near-infrared spectral region, with increasing wavelength, absorbance and light scattering efficiency also increase, while band overlap and penetration depth decrease. Thus, inhomogeneous particles, for example, due to significant variations in their degree of compaction and size or in their surface finish, can lead to a misaligned baseline [39] and cause significant differences between the spectra. Unsurprisingly, dried and ground samples are much more homogeneous than fresh ones, so the baseline is naturally closer. This only illustrates the importance of pre-treatments in obtaining consistent results for varied samples.

It should also be noted that the fresh samples were not subjected to any homogenization step in order to simulate a field use, which is the preferred usage scenario, as it has the advantage of minimizing delays between sampling and parameter determination and provides more flexibility in sample preparation, as mentioned by [40].

4.2. Fresh vs. Dry Samples

According to [41], DM is one of the most important forage evaluation parameters, as it is directly related to production costs. It is, however, a parameter for which it is not always possible to obtain good calibrations, as discussed by [42], because it is dependent on moisture content, which is particularly susceptible to noise, for example, as a result of poor handling.

In the case of grass silages, reference [43] report calibrations with R2 values greater than 0.99. In contrast, reference [44] was able to obtain an R2 of 0.80 (6.7%). The results obtained in this work for the calibration models of grass silages are presented in Table 4. Using the SNV pre-treatment, an R2 for DM of 0.84 (2.89%) was achieved for the dry samples, whereas, for the fresh samples, an R2 of 0.75 (3.07%) was achieved with the mathematical treatment SNV + Det. The obtained RPD was greater than 3 in both cases (3.81 for the dry samples and 3.63 for the fresh samples).

For corn silages (Table 6), the best R2 obtained in this study was 0.8 (0.97%) for the dry samples using the MSC pre-treatment and 0.7 (0.83%) for the fresh samples after employing the SNV + Det combination. The RPD was again greater than 3 in both cases (3.20 and 4.43, respectively). These results compare to those obtained by [45,46], who, in trials using fresh corn silage samples, obtained R2 values of 0.9 and 0.96 (1.58%), respectively, with the latter reporting a lower R2 of 0.78 (1.3%) when using dry samples. Reference [40], in turn, indicated an R2 of 0.85 (27.4 g/Kg) and an RPD of 2.4 also using fresh samples.

The pH and ammoniacal nitrogen parameters give information about the state of conservation of a silage. In general, these parameters were the ones that presented the worst results for all the forages, both dry and fresh, and it should be noted that in the literature there are not many references to the determination of these parameters using NIR spectroscopy, and those that exist present inconsistent and typically not very good results.

In grass silages (Table 4), the best results for pH were obtained for the fresh samples, with an R2 of 0.8 (0.11%) and an RPD of 3.14, using the SNV + Det pre-treatments, while the best result for the dry samples was found using the SNV mathematical treatment (R2 of 0.6 (0.3%) and RPD of 1.10). These compare with the results obtained by [44] for dry samples (R2 of 0.70 (0.34%)) and [47] for fresh samples (R2 of 0.91 and RPD of 3.64). Regarding ammoniacal nitrogen, it ranged between an R2 of 0.49 (2.1%) and an RPD of 1.04 for dry samples and an R2 of 0.65 (1.25%) and an RPD of 2.75 for fresh samples. In contrast, in a comparative study between fresh and dry grass silage samples, the author of [48] reported that he usually found better results with dry samples for every parameter, namely for ammoniacal nitrogen, with dry samples reaching an R2 of 0.89 (0.023%) as opposed to 0.79 (0.028%) for the fresh samples. The same author also reported better results for the pH when using dry samples (R2 of 0.92 (0.11%)) compared to fresh samples (R2 of 0.91 (0.13%)), although here the results are quite similar.

In the case of corn silages (Table 6), the results obtained for these parameters were not much better. For pH, for the dry samples, the R2 was 0.56 (0.24) and the RPD was 1.38 (one of the lowest RPD found), while for the fresh samples, it was an R2 of 0.62 (0.045) and an RPD of 2.75. As for ammoniacal nitrogen, in the dried samples, an R2 of 0.4 (2.64%) and an RPD of 0.78 (the lowest RPD) was obtained, which contrasts with the results observed for the fresh samples, which improved to an R2 of 0.62 (0.75%) and an RPD of 2.81, which was very close to 3. By comparison, reference [46], who tested NIR spectroscopy with fresh samples, was able to obtain an R2 of only 0.14 (0.49) for pH and a reasonable R2 of 0.82 (0.24%) for ammoniacal nitrogen. The author of [48], on the other hand, obtained an R2 of 0.78 (0.0063) and 0.62 (0.080) for pH for dry and fresh samples, respectively, while for ammoniacal nitrogen, he obtained an R2 of 0.77 (0.007%) and 0.72 (0.008%) for dry and fresh samples, respectively. References [35,40] reported an R2 for pH for dry samples of 0.36 (0.06) and 0.51 (0.18), respectively.

Crude protein (CP) was, without doubt, the parameter for which the best results were obtained in all forages. It is also one of the most studied parameters in NIR spectroscopy in the analysis of different forages and one of the most important metrics in their evaluation with the purpose of designing diets and for the nutritional monitoring of animals. The results obtained are usually associated with an R2 > 0.9.

For the dry grass silage samples (Table 4), the R2 was 0.97 (0.23 g/100 g DM) and the RPD was 7, while for the fresh samples, the R2 was 0.87 (0.79 g/100 g DM) and the RPD was 3.68. These results compare to those obtained by [35], who achieved an R2 of 0.90 for dried grass silages. Reference [49], on the other hand, obtained an R2 of 0.93. For fresh samples, the best R2 was 0.87, which was below but not far from the 0.92 found by [43], 0.94 (0.34%) obtained by [50], and 0.96 (0.58 g/100 g DM) achieved by [51], which corresponded to an RPD of 5.0.

For the dry corn silage samples (Table 6), the R2 was 0.93 (0.18 g/100 g DM) and the RPD was 4.07, while the fresh samples showed an R2 of 0.91 (0.22 g/100 g DM) and an RPD of 3.67. For fresh samples, [46] achieved an R2 of 0.83 (0.58%), while reference [40] obtained an R2 of 0.91 (6.5 g/Kg DM) and an RPD of 4.8.

In general, the results obtained for NDF and ADF make it possible for robust predictions to be made. The same is not true for ADL, where the results tended to be worse, which is consistent with the fact that this is a parameter less studied in the literature.

In the case of dry grass silage samples (Table 4), the best calibration equations for NDF reached an R2 of 0.95 (1.12 g/100 g DM) with an RPD of 4.28, while for the fresh samples, the R2 was 0.94 (0.93 g/100 DM) and the RPD was 3.83. Regarding the ADF, the R2 obtained for the dried samples was 0.91 (0.99 g/100 g DM) and the RPD was 3.58, while, for the fresh samples, an R2 of 0.78 (0.12 g/100 g DM) and RPD of 3.13 were obtained. As for the ADL, the R2 of the best calibration equations obtained was comparatively lower, being 0.51 (1.99 g/100 g DM) with an RPD of 1.30 for the dry samples, while for the fresh samples, it was 0.61 (0.99 g/100 g DM) with an RPD of 2.88. These values compare to those obtained by [47] for finely chopped fresh samples, who achieved an R2 of 0.89 (1.03 g/Kg) and an RPD of 3.08 for ADL and an R2 of 0.95 (4.53 g/Kg) with an RPD of 4.69 for NDF, which suggests that an effort to standardise fresh samples may have beneficial effects on this parameter but does not correspond to the intended aim of this study, which was to calibrate a NIR spectrophotometer to take readings on lightly worked samples. Regarding the NDF, for dry grass silage samples, reference [51] reported an R2 of 0.95 (1.79 g/100 g) and an RPD of 4.6, while for ADF, an R2 of 0.92 (1.40 g/100 g) and an RPD of 3.6 were obtained, which is in line with that achieved in this study. Reference [44], on the other hand, obtained calibration equations for dry samples with R2 values ranging between 0.80 (4.0%DM) for ADF and 0.75 (6.6%DM) for NDF, which is below that achieved in this work.

For corn silages (Table 6), calibration to determine NDF using the dry samples resulted in an R2 of 0.91 (1.14 g/100 g DM) and an RPD of 4.89. For the fresh samples, an R2 of 0.87 (1.84 g/100 g DM) and an RPD of 3.08 was achieved. The ADF showed an R2 of 0.89 (1.11 g/100 g DM) and an RPD of 3.59 for the dried samples, while for the fresh samples, the R2 was 0.82 (0.99 g/100 g DM) and the RPD obtained was 3.96. Regarding ADL, the dry samples of corn silage reached an R2 of 0.75 (0.68 g/100 g) and an RPD of 2.24. The fresh samples had an R2 of 0.68 (0.65 g/100 g DM) and an RPD of 2.50. These results are better than those reported by [40], who found an R2 of 0.60 (67.1 g/Kg DM) with an RPD of 1.2 for the determination of NDF in dry samples and an R2 of 0.86 (22.1 g/Kg DM) and an RPD of 2.1 for ADF on the same samples. For NDF, reference [35] obtained an R2 of 0.95 (2.10%DM) for dry samples.

For grass silages (Table 4), EE showed an R2 of 0.58 (0.47 g/100 g DM) and an RPD of 1.48 on dry samples, while for fresh samples, the R2 was 0.62 (0.39 g/100 g DM) and the RPD was 2.95. By comparison, for finely chopped fresh samples, reference [47] achieved an R2 of 0.88 (0.61 g/Kg) and an RPD of 2.56, again suggesting that an effort to make fresh samples more homogeneous may translate into better results, although the RPD remained below 3.

In corn silages (Table 6), calibration for NDF for the dry samples resulted in an R2 of 0.91 (1.14 g/100 g DM) and an RPD of 4.89. For the fresh samples, an R2 of 0.87 (1.84 g/100 g DM) and an RPD of 3.08 was achieved. The ADF showed an R2 of 0.89 (1.11 g/100 g DM) and an RPD of 3.59 for the dried samples, while for the fresh samples, the R2 was 0.82 (0.99 g/100 g DM) and the RPD was 3.96. Regarding ADL, the dry samples of corn silage reached an R2 of 0.75 (0.68 g/100 g) and an RPD of 2.24. The fresh samples had an R2 of 0.68 (0.65 g/100 g DM) and an RPD of 2.50. These results are better than those obtained by [40], who reported an R2 of 0.60 (67.1 g/Kg DM) and an RPD of 1.2 for the determination of NDF in dry samples and an R2 of 0.86 (22.1 g/Kg DM) and RPD of 2.1 for ADF on the same samples. For NDF, reference [35] obtained an R2 of 0.95 (2.10%DM) for dry samples.

The calibration equations achieved for the prediction of the CB value for grass silages (Table 3) showed an R2 of 0.9 (0.25 g/100 g DM) and an RPD of 4.18 for the dry samples and an R2 of 0.71 (1.69 g/100 g DM) and an RPD of 2.84 for the fresh samples. These values are better than those obtained by [44] for dry samples (R2 of 0.73 (1.2%)) and worse than those achieved for finely chopped fresh samples by [47], who achieved an R2 of 0.95 (1.04 g/KG) and an RPD of 2.83.

For corn silages (Table 6), an R2 value of 0.94 (1.06 g/100 g) and an RPD of 5.82 was obtained using the dry samples, while an R2 of 0.92 (1.12 g/100 g) and an RPD of 3.19 was achieved for the fresh samples. By comparison, reference [49] reported obtaining an R2 of 0.77 (0.42%) for dried samples.

The predictive ability for biological parameters did not prove to be as good as that achieved for the chemical parameters. This can be explained by the fact that parameters determined with biological methods are subject to greater uncontrolled variability due to a multitude of sources of experimental and sampling errors that can affect the calibration process. In fact, there are few results in the literature pertaining to the use of NIR spectroscopy for the prediction of parameters such as digestibility and kinetics of gas production, especially in forages. Despite this, and although the performance indicators of the calibration equations were below the levels considered in this study as required for a reliable prediction to be possible, the obtained results were generally better than those reported in the literature, which may be related to the high number of samples used.

In the case of this study, the best calibration equations obtained for the prediction of DMD in grass silage (Table 4) revealed an R2 of 0.78 (1.7%) and an RPD of 2.98 for dry samples, while, for fresh samples, the R2 was 0.71 (1.69%) and the RPD was 2.84. In OMD, the R2 obtained was 0.68 (1.37%) and the RPD was 3.91 for the dry samples, while for the fresh samples, the R2 value was 0.61 (1.48%) and the RPD was 3.81. These values are better than those reported by [44] for the prediction of DMD in dry samples, as they achieved an R2 of 0.60 (3.6%).

For corn silages (Table 6), the R2 obtained for DMD was 0.81 (1.08%) and the RPD was 3.03 for dry samples, while with fresh samples, an R2 of 0.72 (1.10%) and an RPD of 2.98 was achieved. As for the OMD, the R2 was 0.65 (1.65%) and the RPD was 2.09 for the dried samples, and the R2 was 0.51 (0.98%) and the RPD was 3.13 for the fresh samples. Although they cannot be considered reliable, especially in the case of OMD, the indicators obtained surpass those presented by [46], who reported an R2 of 0.53 (2.18%) for the prediction of DMD in fresh samples, and [52] for the prediction of OMD in fresh samples, who reported an R2 of 0.53 (30 g/Kg DM) and an RPD of 1.3.

4.3. Gas Production

Figure 3 presents the cumulative gas production. It can be observed that corn silages maintain higher gas production than grass silages throughout the whole fermentation period (96 h). The fermentation kinetics are described based on the model of [4], and the results for the in vitro gas production kinetics are summarized in Table 3. It was found that the cumulative gas production values were significantly different (p < 0.05) at all incubation times except 72 h.

As with the biological parameters, there are not many papers exploring the application of NIR spectroscopy to the prediction of gas production parameters in forages, and those that exist typically report poor results, such as the ones obtained in this work, where the best calibration equations were found for the prediction of gas production in dry grass silage (Table 5) at 24 h (R2 of 0.77 and RPD of 3.83). In the case of corn silage, the best result was for 96 h with the dry samples (R2 of 0.75 and RPD of 3.04).

For the gas production kinetics parameters, no robust values were found. The best results were obtained using SNV + Det pre-treatment, which is in line with studies done in rumen degradation by [53,54]. The indicators obtained in this work compare with those achieved by [55].

5. Conclusions

Through this study, it was concluded that it is possible to apply this technique to forages from the Azorean agroclimatic zone to accurately predict important chemical parameters for a qualitative evaluation, namely CP, NDF, ADF, and crude ash. It also was possible to obtain good approximations for other parameters, such as DM.

In the case of biological parameters, namely parameters related to gas production, it did not prove possible to obtain good calibrations in general, which is in line with what has been reported in the literature, where there are few studies on the use of NIRS to estimate gas production parameters. That said, the obtained results were generally better than those found in the literature, which is possibly due to the large number of samples included in this study, with solid results being achieved for gas production at 24 h and total gas production (96 h).

Although the results tended to be better for dry samples, which presume a homogenization process that reduces the noise to which the spectra are subjected, it was also found that there were no great differences to the predictions using fresh samples. This means that the application of the technique on fresh samples, with reading conducted on site, is feasible, and it is possible to integrate the NIRS in the regular monitoring of the properties of the fodder used in animal feeding. It is thus possible to perform timely adjustments to the diets, with the goal of maximizing animal performance, considering the agroclimatic characteristics of the Azores.

Author Contributions

Writing—original draft preparation, formal analysis, conceptualization, investigation, C.S.A.M.M.D.; writing—review and editing, H.P.B.N.; supervision, A.E.S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by INV2MAC Project (Potencial aprovechamiento de biomasa generada a partir de especies vegetales invasoras de la Macaronesia para uso industrial, MAC2/4.6a/229) and was approved in the first call of the territorial cooperation programme MAC towards FEDER funds and the Regional Directorate of Science and Technology of the Azorean Regional Secretariat for the Sea, Science and Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Borba, A. Estudo do Valor Nutritivo e da Qualidade da Proteína de Algumas Forragens Açorianas; Tese de Doutoramento, Universidade dos Açores: Angra do Heroísmo, Portugal, 1992. [Google Scholar]

- Givens, D.I.; Deaville, E.R. The current and future role of near infrared reflectance spectroscopy in animal nutrition: A review. Aust. J. Agric. Res. 1999, 50, 1131–1145. [Google Scholar] [CrossRef]

- Tufan, T.; Arslan, C.; Önk, K.; Sari, M.; Tilki, M. Effects of feeding by hay, grass silage and corn silage on growth performance, rumen fluid and blood serum parameters in beef cattle. Rev. Med. Vet. 2016, 167, 99–105. [Google Scholar]

- Maduro Dias, C.S.A.M.M.; Nunes, H.P.B.; Vouzela, C.F.M.; Madruga, J.S.; Borba, A.E.S. Influence of the Season on the Nutritive Value and Gas Production of Opuntia ficus-indica and Agave americana L. in Ruminant Feed. Animals 2023, 13, 1008. [Google Scholar] [CrossRef] [PubMed]

- McDonalds, P.; Edwards, E.A.; Greenhalgh, J.F.D.; Morgan, C.A. Animal Nutrition; Longman Scientific & Technical: New York, NY, USA, 1995. [Google Scholar]

- Wilkins, R.J. Forages and their role in animal systems. In Forage Evaluation in Ruminant Nutrition; Wilkins, R.J., Givens, D.I., Owen, E., Axford, R.F.E., Omed, H.M., Eds.; Cabi Publishing: New York, NY, USA, 2000; pp. 1–14. [Google Scholar]

- Dale, L.M.; Thewis, A.; Boudry, C.; Rotar, I.; Pacurar, S.F.; Abbas, Q.; Dardenne, P.; Baeten, V.; Pfister, J. Discrimination of grassland species and their classification in botanical families by laboratory scale NIR hyperspectral imaging: Preliminary results. Talanta 2013, 116, 149–154. [Google Scholar] [CrossRef]

- Bruno-Soares, A.M.; Murray, I.; Paterson, R.M.; Abreu, J.M.F. Use of near infrared reflectance spectroscopy (NIRS) for the prediction of chemical composition and nutritional attributes of green crop cereals. Anim. Feed Sci. Thecnol. 1998, 75, 15–25. [Google Scholar] [CrossRef]

- Stuth, J.W.; Tolleson, D.R. Managing the nutritional status of grazing animals using near infrared spectroscopy. Compend. Contin. Educ. Vet. 2000, 22, 108–115. [Google Scholar]

- Naes, T.; Isaksson, T.; Fearn, T.; Davies, T. A User-Friendly Guide to Multivariate Calibration and Classification; NIR Publications: Chichester, UK, 2002. [Google Scholar]

- Siesler, H.W.; Ozaki, Y.; Kawata, S.; Heise, M. Near-Infrared Spectroscopy: Principles, Instrumens, Applications; Wiley-VCH: Weinheim, Germany, 2008. [Google Scholar]

- Reich, G. Near-infrared spectroscopy and imaging: Basic principles and pharmaceutical applications. Adv. Drug Deliv. Rev. 2005, 7, 1109–1143. [Google Scholar] [CrossRef]

- Uden, P. Laboratoy Methods for Evaluating the Nutritive Value of Untreated and Treated Fibrous By-Products; Elsevier Science Publishing Company Inc.: Amsterdam, The Netherlands, 1984. [Google Scholar]

- Barton, F.E.; Coleman, S.W. Potential of near infrared reflectance spectroscopy for measuring forage quality. Anim. Sci. 1981, 108, 73–76. [Google Scholar]

- Coleman, S.W.; Barton, F.E.; Meyer, R.D. Calibration of near infrared reflectance spectrometer for prediction of forage quality. Anim. Sci. 1982, MP112, 102–111. [Google Scholar]

- Reeves, J.B. Near infrared spectroscopic analysis of lignin components in sodium chlorite-treated and untreated forages and forage by-products. J. Dairy Sci. 1988, 72, 388–397. [Google Scholar] [CrossRef]

- Azevedo, E.B. Modelacão do Clima Insular à Escala Local. Modelo CIELO Aplicado à Ilha Terceira; Tese de Doutotamento, Universidade dos Açores: Angra do Heroísmo, Portugal, 1996. [Google Scholar]

- A.O.A.C. (Association of Official Analytical Chemists). Official Methods of Analysis, 12th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1999. [Google Scholar]

- Goering, H.K.; Van Soest, P.J. Forage Fiber Analysis (Apparatus, Reagents, Procedures, and Some Applications); Agriculture Handbook 379; ARS USDA: Washington, DC, USA, 1970.

- Kung, L.; Grieve, D.B.; Thomas, J.W.; Huber, J.T. Added ammonia or microbial inocula for fermentation and nitrogenous compounds of alfalfa ensiled at various percents of dry matter. J. Dairy Sci. 1984, 67, 299–306. [Google Scholar] [CrossRef]

- Moselhy, M.A.; Nunes, H.P.; Borba, A.E.S. Effect of replacement of ordinary ruminant feed with Hedychium gardnerianum or Pittosporum undulatum on in vitro rumen fermentation characteristics. Int. J. Adv. Res. 2014, 2, 91–104. [Google Scholar]

- Tilley, J.M.A.; Terry, R.A. A two-stage technique for the in vitro digestion of forage crops. Grass Forage Sci. 1963, 18, 104–111. [Google Scholar] [CrossRef]

- Alexander, R.H.; McGowan, M. The routine determination of in vitro digestibility of organic matter in forages. An investigation of the problems associated with continuous large-scale operation. J. Br. Grassl. Soc. 1966, 21, 140–147. [Google Scholar] [CrossRef]

- Menke, K.H.; Steingass, H. Estimation of the energetic feed value obtained from chemical analysis and in vitro gas production using rumen fluid. Anim. Res. Dev. 1988, 28, 7–55. [Google Scholar]

- McDonald, P. The Biochemistry of Silage; John Wiley and Sons, Ltd.: Chichester, UK, 1981. [Google Scholar]

- Ørskov, E.R.; McDonald, P. The estimation of protein degradability in the rumen from incubation measurements weighted according to rate of passage. J. Agric. Sci. 1979, 92, 499–503. [Google Scholar] [CrossRef]

- Borba, A.E.S.; Correia, P.J.A.; Fernandes, J.M.M.; Borba, A.F.R.S. Comparsion of three sources of inocula for predicting apparent digestibility of ruminant feedstuffs. Anim. Res. 2001, 50, 265–273. [Google Scholar] [CrossRef]

- Nunes, H.P.B.; Maduro Dias, C.S.A.M.; Borba, A.E.S. Bioprospecting essential oils of exotic species as potentialmitigations of ruminant enteric methanogenesis. Heliyon 2023, 9, 12786. [Google Scholar] [CrossRef]

- Williams, P.C.; Sobering, D.C. How Do We Do It: A Brief Summary of the Methods We Use in Developing near Infrared Calibration. In Near Infrared Spectroscopy: The Future Waves; Davis, A.M.C., Williams, P., Eds.; NIR Publications: Chichester, UK, 1996; pp. 185–188. [Google Scholar]

- Molano, M.L.; Cortés, M.L.; Ávila, P.; Martens, S.D.; Muñoz, L.S. Ecuaciones de calibración en espectroscopía de reflectancia en el infrarrojo cercano (NIRS) para predicción de parámetros nutritivos en forrajes tropicales. Trop. Grassl.–Forrajes Trop. 2016, 4, 139–145. [Google Scholar] [CrossRef]

- Weinberg, Z.G.; Muck, R.E. New trends and opportunities in the development and use of inoculants for silage. FEMS Microbiol. Rev. 1996, 19, 53–68. [Google Scholar] [CrossRef]

- Drouin, P.; Tremblay, J.; Chaucheyras-Durand, F. Dynamic succession of microbiota during ensiling of whole plant corn following inoculation with Lactobacillus buchneri and Lactobacillus hilgardii alone or in combination. Microorganisms 2019, 7, 595. [Google Scholar] [CrossRef] [PubMed]

- Beever, D.E.; Mould, F.L. Forage evaluation for efficient ruminant livestock production. In Forage Evaluation Ruminant Nutrition; Givens, D.I., Owen, E., Axford, R.F.E., Omed, H., Eds.; CABI Publishing: Wallingford, UK, 2002. [Google Scholar]

- Vincent, B.; Dardenne, P. Application of NIR in Agriculture. In Near-Infrared Spectroscopy Theory, Spectral Instrumentation, and Applications; Ozaki, Y., Huck, C., Tsuchikawa, S., Engelsen, S.B., Eds.; Springer Nature Singapore: Singapore, 2021. [Google Scholar]

- Corson, D.C.; Waghorn, G.C.; Ulyatt, M.J.; Lee, J. NIRS: Forage analysis and livestock feeding. Proc. N. Z. Grassl. Assoc. 1999, 61, 127–132. [Google Scholar] [CrossRef]

- Cozen, J.P. Multivariate Calibration, A Practical Guide for Developing Methods in the Quantitative Analytical Chemistry; Bruker Optik: Ettlingen, Germany, 2014. [Google Scholar]

- Cozzolino, D.; Fassio, A.; Gimenez, A. The use of near infrared reflectance spectroscopy (NIRS) to predict the composition of whole maize plants. J. Sci. Food Agric. 2000, 81, 142–146. [Google Scholar] [CrossRef]

- Murray, I. The NIR spectra of homologous series of organic compounds. In NIR/NIT Conference; Hollo, J., Kaffka, K.J., Gonczy, J.L., Eds.; Akademiai Kiado: Budapest, Hungary, 1986; pp. 13–28. [Google Scholar]

- Metrohm. NIR Spectroscopy. A Guide to Near-Infrared Spectroscopic Analysis of Industrial Manufacturing Processes; Metrohm: Herisau, Switzerland, 2013. [Google Scholar]

- Cozzolino, D.; Fassio, A.; Fernández, E.; Restaino, E.; La Manna, A. Measurement of chemical composition in wet whole maize silage by visible and near infrared reflectance spectroscopy. Anim. Feed Sci. Technol. 2006, 129, 329–336. [Google Scholar] [CrossRef]

- Cozzolino, D. Applied spectroscopy reviews use of infrared spectroscopy for infield measurement and phenotyping of plant properties: Instrumentation, data analysis, and examples use of infrared spectroscopy for in-field measurement and phenotyping of plant properties. Appl. Spectrosc. Rev. 2014, 49, 564–584. [Google Scholar] [CrossRef]

- Baker, C.W.; Givens, S.I.; Deavile, E.R. Prediction of organic matter digestibility in vivo of grass silage by near infrared reflectance spectroscopy: Effect of calibration metgod, residual moisture and particle size. Anim. Feed Sci. Technol. 1994, 50, 17–26. [Google Scholar] [CrossRef]

- Kennedy, C.A.; Shelford, J.A.; Williams, P.C. Near infrared spectroscopy analysis of intac grass silage and fresh grass for dry matter, crude protein, and acid detergent fiber. In Near Infrared Spectroscopy: The Future Waves, Proceedings of the 7th International Conference on Near Infrared Spectroscopy, Montreal, QC, Canada, 6–11 August 1995; Davies, A.M.C., Wilhams, P., Eds.; NIR Publications: Chichester, UK, 1996. [Google Scholar]

- Restaino, E.A.; Fernández, E.G.; La Manna, A.; Cozzolino, D. Prediction of the nutritive value of pasture silage by near infrared spectroscopy (NIRS). Chil. J. Agric. Res. 2009, 69, 560–566. [Google Scholar] [CrossRef]

- Zicarelli, F.; Sarubbi, F.; Iommelli, P.; Grossi, M.; Lotito, D.; Tudisco, R.; Infascelli, F.; Musco, N.; Lombardi, P. Nutritional Characteristics of corn silage produced in Campania region estimated by Near infrared spectroscopy (NIRS). Agronomy 2023, 13, 634. [Google Scholar] [CrossRef]

- Reeves, J.B.; Blosser, T.H. Near infrared spectroscopy for analyzing undried silage. J. Dairy Sci. 1989, 72, 79–88. [Google Scholar] [CrossRef]

- Park, R.S.; Agnew, R.E.; Gordon, F.J.; Steen, R.W.J. The use of near infrared reflectance spectroscopy (NIRS) on undried samples of grass silage to predct chemical composition and digestibility parameters. Anim. Feed Sci. Technol. 1998, 72, 155–167. [Google Scholar] [CrossRef]

- Sørensen, L.K. Prediction of fermentation parameters in grass and corn silage by near infrared spectroscopy. J. Dairy Sci. 2004, 87, 3826–3835. [Google Scholar] [CrossRef]

- Alomar, D.; Fuchslocher, R.; Cuevas, J.; Mar-dones, R.; Cuevas, E. Prediction of the composition of fresh pastures by near infrared reflectance or interactance-reflectance spectroscopy. Chil. JAR 2009, 69, 198–206. [Google Scholar] [CrossRef]

- De la Roza, B.; Martinez, A.; Modroño, S.; Snatos, B. Determination of the quality of fresh silage by near infrared reflectance spectroscopy. In Near Infrared Spectroscopy: The Future Waves, Proceedings of the 7th International Conference on Near Infrared Spectroscopy, Montreal, QC, Canada, 6–11 August 1995; Davies, A.M.C., Wilhams, P., Eds.; NIR Publications: Chichester, UK, 1996. [Google Scholar]

- Villamarín, B.; Fernández, E.; Mendéz, J. Analysis of grass silage from northwestern Spain by near-infrared reflectance spectroscopy. J. AOAC Int. 2002, 85, 541–545. [Google Scholar] [CrossRef]

- Givens, D.I.; Baker, C.W.; Zamine, B. Regions of normalized near infrared reflectance difference spectra related to the rumen digestion of straw. Anim. Feed Sci. Technol. 1992, 36, 1–12. [Google Scholar] [CrossRef]

- Lundberg, K.M.; Hoffman, P.C.; Bauman, L.M.; Berzaghi, P. Prediction of Forage Energy Content by Near Infrared Reflectance Spectroscopy and Summative Equations. Prof. Anim. Sci. 2004, 20, 262–269. [Google Scholar] [CrossRef]

- Deaville, E.R.; Givens, D.I. Regions of normalized near infrared reflectance difference spectra related to the rumen degradation of fresh grass, grass silage and maize silage. Anim. Feed Sci. Technol. 1998, 72, 41–51. [Google Scholar] [CrossRef]

- Herrero, M.; Murray, I.; Fawcett, R.H.; Dent, J.B. Prediction of in vitro gas production of Kikuyu grass by near-infrared reflectance spectroscopy. Anim. Feed Sci. Technol. 1996, 60, 51–67. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).