Advancements in Microalgal Biorefinery Technologies and Their Economic Analysis and Positioning in Energy Resource Market

Abstract

1. Introduction

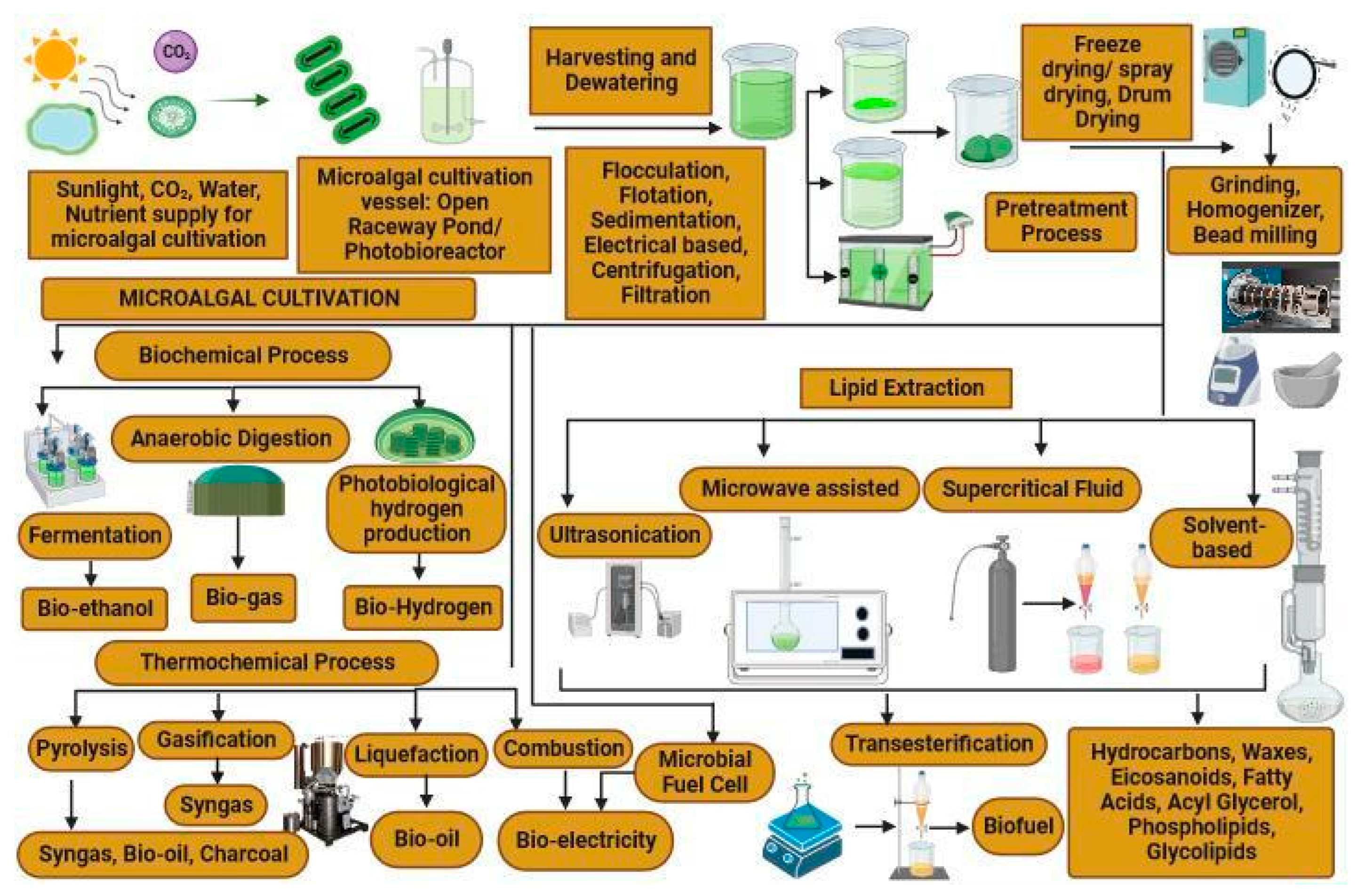

2. Microalgal Biorefinery Products

3. Comparative Product Analysis of Microalgal Biorefinery with the Resources Leading the Energy Market

4. Existing and Emerging Microalgal Cultivation Technologies for Biorefinery Products

4.1. Open System

4.2. Closed System

4.3. Hybrid Culture System

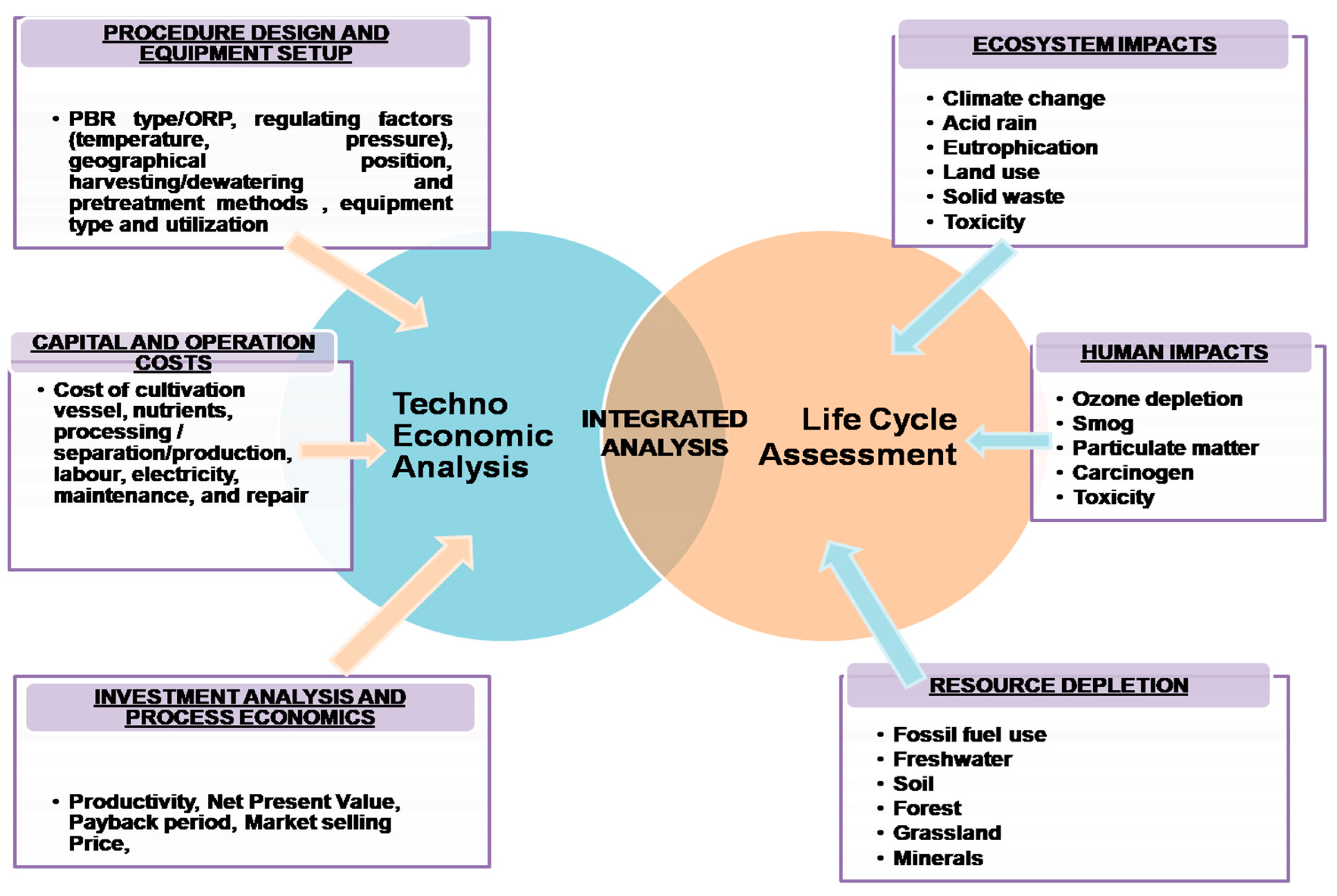

5. Techno-Economic Assessment and Life Cycle Assessment of Biorefinery Products

6. Market Strategies for Emerging Microalgal Biorefinery Technologies and Future Challenges

7. Integration of Market Strategies for Microalgal Biorefinery Technologies with Environmental Bioremediation

8. Future Directions and Recommendation

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Shahsavari, A.; Akbari, M. Potential of solar energy in developing countries for reducing energy-related emissions. Renew. Sustain. Energy Rev. 2018, 90, 275–291. [Google Scholar] [CrossRef]

- Baicha, Z.; Salar-García, M.J.; Ortiz-Martínez, V.M.; Hernández-Fernández, F.J.; de los Ríos, A.P.; Labjar, N.; Lotfi, E.; Elmahi, M. A critical review on microalgae as an alternative source for bioenergy production: A promising low cost substrate for microbial fuel cells. Fuel Process. Technol. 2016, 154, 104–116. [Google Scholar] [CrossRef]

- Bioenergy Market (By Product Type: Solid Biomass, Liquid Biofuel, Biogas, Others; By Feedstock: Agricultural Waste, Wood and Woody Biomass, Solid Waste, Others: By Application: Power generation, Heat Generation, Transportation, Others; By Technology: Gasification, Fast Pyrolysis, Fermentation, Others)—Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2022–2030, 2022, Precedence Research. Available online: https://www.precedenceresearch.com/bioenergy-market (accessed on 9 January 2023).

- Biorefinery Market by Type (First Generation, Second Generation and Third Generation), Technology (Industrial Biotechnology, Physico-Chemical, and Thermochemical), Product (Energy Driven, and Material Driven) and Region—Global Forecast to 2027, 2022, Markets and Markets. Available online: https://www.marketsandmarkets.com/Market-Reports/biorefinery-market-108797809.html (accessed on 9 January 2023).

- Algae Biofuel Market Size is Projected to Reach USD 15.39 billion by 2030, Growing at a CAGR of 8.76%: Straits Research. 2022. Available online: https://www.globenewswire.com/en/news-release/2022/07/26/2486263/0/en/Algae-Biofuel-Market-Size-is-projected-to-reach-USD-15-39-billion-by-2030-growing-at-a-CAGR-of-8-76-Straits-Research.html (accessed on 9 January 2023).

- Microalgae Market by Type (Spirulina, Chlorella, Dunaliella Salina, and Aphanizomenon Flos-Aquae), Application (Dietary Supplements, Food/Feed, Pharmaceutical, Cosmetic, and Others): Global Opportunity Analysis and Industry Forecast 2021-2028, 2021, Allied Market Research. Available online: https://www.alliedmarketresearch.com/microalgae-market-A13419 (accessed on 9 January 2023).

- Malek, A.A. Economic Assessment of Biomass Based Power Generation. In Biomass, Biorefineries and Bioeconomy; IntechOpen: Vienna, Austria, 2022; Volume 21. [Google Scholar]

- Brown, A.; Waldheim, L.; Landälv, I.; Saddler, J.; Ebadian, M.; McMillan, J.D.; Bonomi, A.; Klein, B. Advanced Biofuels—Potential for Cost Reduction; IEA Bioenergy: Paris, France, 2020; Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/02/T41_CostReductionBiofuels-11_02_19-final.pdf (accessed on 9 January 2023).

- Bleakley, S.; Hayes, M. Algal proteins: Extraction, application, and challenges concerning production. Foods 2017, 6, 33. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.M.; Ren, L.J.; Zhao, Q.Y.; Ji, X.J.; Huang, H. Microalgae for the production of lipid and carotenoids: A review with focus on stress regulation and adaptation. Biotechnol. Biofuels 2018, 11, 272. [Google Scholar] [CrossRef] [PubMed]

- Silvello, M.A.D.C.; Gonçalves, I.S.; Azambuja, S.P.H.; Costa, S.S.; Silva, P.G.P.; Santos, L.O.; Goldbeck, R. Microalgae-based carbohydrates: A green innovative source of bioenergy. Bioresour. Technol. 2022, 344, 126304. [Google Scholar] [CrossRef] [PubMed]

- Giraldo-Calderón, N.D.; Romo-Buchelly, R.J.; Arbeláez-Pérez, A.A.; Echeverri-Hincapié, D.; Atehortúa-Garcés, L. Microalgae biorefineries: Applications and emerging technologies. DYNA 2018, 85, 219–233. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, F.; Wu, Y.R. Emerging Technologies for Conversion of Sustainable Algal Biomass into Value-Added Products: A State-of-the-Art Review. Sci. Total Environ. 2021, 784, 147024. [Google Scholar] [CrossRef]

- Algae Market (Type: Microalgae and Macroalgae: And Production Method: Harvesting and Cultivation {Open Raceway Pond and Photobioreactors})—Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2022–2031, 2022, Transparency Market Research. Available online: https://www.transparencymarketresearch.com/algae-market.html (accessed on 9 January 2023).

- Molinuevo-Salces, B.; Riaño, B.; Hernández, D.; Cruz García-González, M. Microalgae and Wastewater Treatment: Advantages and Disadvantages. In Microalgae Biotechnology for Development of Biofuel and Wastewater Treatment; Alam, M.A., Wang, Z., Eds.; Springer: Singapore, 2019; pp. 505–533. ISBN 978-981-13-2264-8. [Google Scholar] [CrossRef]

- Ubando, A.T.; Ng, E.A.S.; Chen, W.H.; Culaba, A.B.; Kwon, E.E. Life cycle assessment of microalgal biorefinery: A state-of-the-art review. Bioresour. Technol. 2022, 360, 127615. [Google Scholar] [CrossRef]

- Mahmud, R.; Moni, S.M.; High, K.; Carbajales-Dale, M. Integration of techno-economic analysis and life cycle assessment for sustainable process design—A review. J. Clean. Prod. 2021, 317, 128247. [Google Scholar] [CrossRef]

- Thomassen, G.; Van Dael, M.; Van Passel, S. The potential of microalgae biorefineries in Belgium and India: An environmental techno-economic assessment. Bioresour. Technol. 2018, 267, 271–280. [Google Scholar] [CrossRef]

- Sivaramakrishnan, R.; Suresh, S.; Kanwal, S.; Ramadoss, G.; Ramprakash, B.; Incharoensakdi, A. Microalgal Biorefinery Concepts’ Developments for Biofuel and Bioproducts: Current Perspective and Bottlenecks. Int. J. Mol. Sci. 2022, 23, 2623. [Google Scholar] [CrossRef] [PubMed]

- Koyande, A.K.; Show, P.L.; Guo, R.; Tang, B.; Ogino, C.; Chang, J.-S. Bio-processing of algal bio-refinery: A review on current advances and future perspectives. Bioengineered 2019, 10, 574–592. [Google Scholar] [CrossRef] [PubMed]

- Siddiki, S.Y.A.; Mofijur, M.; Kumar, P.S.; Ahmed, S.F.; Inayat, A.; Kusumo, F.; Badruddin, I.A.; Khan, T.M.Y.; Nghiem, L.D.; Ong, H.C.; et al. Microalgae Biomass as a Sustainable Source for Biofuel, Biochemical and Biobased Value-Added Products: An Integrated Biorefinery Concept. Fuel 2022, 307, 121782. [Google Scholar] [CrossRef]

- Paliwal, C.; Nesamma, A.A.; Jutur, P.P. Industrial scope with high-value biomolecules from microalgae. In Sustainable Downstream Processing of Microalgae for Industrial Application; CRC Press: Boca Raton, FL, USA, 2019; pp. 83–98. [Google Scholar] [CrossRef]

- Okeke, E.S.; Ejeromedoghene, O.; Okoye, C.O.; Ezeorba, T.P.C.; Nyaruaba, R.; Ikechukwu, C.K.; Oladipo, A.; Orege, J.I. Microalgae Biorefinery: An Integrated Route for the Sustainable Production of High-Value-Added Products. Energy Convers. Manag. X 2022, 16, 100323. [Google Scholar] [CrossRef]

- Singh, N.; Goyal, A.; Moholkar, V.S. Microalgal bio-refinery approach for utilization of Tetradesmus obliquus biomass for biodiesel production. Mater. Today Proc. 2020, 32, 760–763. [Google Scholar] [CrossRef]

- Arora, K.; Kaur, P.; Kumar, P.; Singh, A.; Patel, S.K.S.; Li, X.; Yang, Y.-H.; Bhatia, S.K.; Kulshrestha, S. Valorization of Wastewater Resources into Biofuel and Value-Added Products Using Microalgal System. Front. Energy Res. 2021, 9, 646571. [Google Scholar] [CrossRef]

- Prabakar, D.; Manimudi, V.T.; Suvetha, K.S.; Sampath, S.; Mahapatra, D.M.; Rajendran, K.; Pugazhendhi, A. Advanced biohydrogen production using pretreated industrial waste: Outlook and prospects. Renew. Sustain. Energy Rev. 2018, 96, 306–324. [Google Scholar] [CrossRef]

- Thangam, K.R.; Santhiya, A.; Sri, S.R.A.; MubarakAli, D.; Karthikumar, S.; Kumar, R.S.; Thajuddin, N.; Soosai, M.R.; Varalakshmi, P.; Moorthy, I.G.; et al. Bio-Refinery Approaches Based Concomitant Microalgal Biofuel Production and Wastewater Treatment. Sci. Total Environ. 2021, 785, 147267. [Google Scholar] [CrossRef]

- Sarma, S.; Sharma, S.; Rudakiya, D.; Upadhyay, J.; Rathod, V.; Patel, A.; Narra, M. Valorization of microalgae biomass into bioproducts promoting circular bioeconomy: A holistic approach of bioremediation and biorefinery. 3 Biotech 2021, 11, 378. [Google Scholar] [CrossRef]

- Khoo, C.G.; Dasan, Y.K.; Lam, M.K.; Lee, K.T. Algae biorefinery: Review on a broad spectrum of downstream processes and products. Bioresour. Technol. 2019, 292, 121964. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Danquah, M.K. Chapter 9-Dewatering and Drying of Algal Cultures. In Handbook of Microalgae-Based Processes and Products; Jacob-Lopes, E., Maroneze, M.M., Queiroz, M.I., Zepka, L.Q., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 207–224. ISBN 978-0-12-818536-0. [Google Scholar] [CrossRef]

- Hu, Y.; Bassi, A. Extraction of Biomolecules from Microalgae; Elsevier Inc.: Amsterdam, The Netherlands, 2020; ISBN 9780128185360. [Google Scholar] [CrossRef]

- Shukla, M.; Kumar, S. Algal biorefineries for biofuels and other value-added products. In Biorefining of Biomass to Biofuels; Springer: Cham, Switzerland, 2018; pp. 305–341. [Google Scholar] [CrossRef]

- Fan, L.; Zhang, H.; Li, J.; Wang, Y.; Zhou, W. Algal biorefinery to value-added products by using combined processes based on thermochemical conversion: A review. Algal Res. 2020, 47, 101819. [Google Scholar] [CrossRef]

- Lakatos, G.E.; Ranglová, K.; Manoel, J.C.; Grivalsky, T.; Kopecky, J.; Masojídek, J. Bioethanol production from microalgae polysaccharides. Folia Microbiol. 2019, 64, 627–644. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, P.K.; Mishra, S.C.P.; Maiti, S.; Paliwal, C.; Mishra, S.K.; Ghosh, T.; Chokshi, K.; Patel, P.; Bharadia, J.N. Solar driven Solvent Extractor and Process for Extraction of Microalgal Lipids Using the Same. Patent US20150057459A1, 26 February 2015. [Google Scholar]

- Wang, K.; Khoo, K.S.; Chew, K.W.; Selvarajoo, A.; Chen, W.-H.; Chang, J.-S.; Show, P.L. Microalgae: The Future Supply House of Biohydrogen and Biogas. Front. Energy Res. 2021, 9, 158. [Google Scholar] [CrossRef]

- Elshobary, M.E.; Zabed, H.M.; Yun, J.; Zhang, G.; Qi, X. Recent insights into microalgae-assisted microbial fuel cells for generating sustainable bioelectricity. Int. J. Hydrog. Energy. 2021, 46, 3135–3159. [Google Scholar] [CrossRef]

- Wang, S.; Mukhambet, Y.; Esakkimuthu, S. Integrated microalgal biorefinery—Routes, energy, economic and environmental perspectives. J. Clean. Prod. 2022, 348, 131245. [Google Scholar] [CrossRef]

- Branco-Vieira, M.; Mata, T.; Martins, A.; Freitas, M.; Caetano, N. Economic analysis of microalgae biodiesel production in a small-scale facility. Energy Rep. 2020, 6, 325–332. [Google Scholar] [CrossRef]

- Mutanda, T.; Naidoo, D.; Bwapwa, J.K.; Anandraj, A. Biotechnological applications of microalgal oleaginous compounds: Current trends on microalgal bioprocessing of products. Front. Energy Res. 2020, 8, 598803. [Google Scholar] [CrossRef]

- Kim, H.S.; Devarenne, T.P.; Han, A. Microfluidic systems for microalgal biotechnology: A review. Algal Res. 2018, 30, 149–161. [Google Scholar] [CrossRef]

- Khemiri, S.; Khelifi, N.; Nunes, M.C.; Ferreira, A.; Gouveia, L.; Smaali, I.; Raymundo, A. Microalgae biomass as an additional ingredient of gluten-free bread: Dough rheology, texture quality and nutritional properties. Algal Res. 2020, 50, 101998. [Google Scholar] [CrossRef]

- Thanigaivel, S.; Priya, A.K.; Kumar, P.S.; Shiong, K.K.; Hoang, T.K.; Rajendran, S.; Soto-Moscoso, M. Exploration of effective biorefinery approach to obtain the commercial value-added products from algae. Sustain. Energy Technol. Assess. 2022, 53, 102450. [Google Scholar] [CrossRef]

- Torres, A.; Padrino, S.; Brito, A.; Díaz, L. Biogas production from anaerobic digestion of solid microalgae residues generated on different processes of microalgae-to-biofuel production. Biomass Convers. Bioref. 2021, 1–14. [Google Scholar] [CrossRef]

- Chew, K.W.; Yap, J.Y.; Show, P.L.; Suan, N.H.; Juan, J.C.; Ling, T.C.; Lee, D.-J.; Chang, J.-S. Microalgae biorefinery: High value products perspectives. Bioresour. Technol. 2017, 229, 53–62. [Google Scholar] [CrossRef] [PubMed]

- De Bhowmick, G.; Sarmah, A.K.; Sen, R. Zero-waste algal biorefinery for bioenergy and biochar: A green leap towards achieving energy and environmental sustainability. Sci. Total Environ. 2018, 650, 2467–2482. [Google Scholar] [CrossRef] [PubMed]

- Zabed, H.M.; Akter, S.; Yun, J.; Zhang, G.; Zhang, Y.; Qi, X. Biogas from Microalgae: Technologies, Challenges and Opportunities. Renew. Sustain. Energy Rev. 2020, 117, 109503. [Google Scholar] [CrossRef]

- Zuccaro, G.; Yousuf, A.; Pollio, A.; Steyer, J.-P. Microalgae Cultivation Systems. In Microalgae Cultivation for Biofuels Production; Elsevier: London, UK, 2020; pp. 11–29. [Google Scholar] [CrossRef]

- Saha, S.K.; Murray, P. Exploitation of Microalgae Species for Nutraceutical Purposes: Cultivation Aspects. Fermentation 2018, 4, 46. [Google Scholar] [CrossRef]

- Liyanaarachchi, V.C.; Premaratne, M.; Ariyadasa, T.U.; Nimarshana, P.; Malik, A. Two-stage cultivation of microalgae for production of high-value compounds and biofuels: A review. Algal Res. 2021, 57, 102353. [Google Scholar] [CrossRef]

- Ummalyma, S.B.; Sirohi, R.; Udayan, A.; Yadav, P.; Raj, A.; Sim, S.J.; Pandey, A. Sustainable Microalgal Biomass Production in Food Industry Wastewater for Low-Cost Biorefinery Products: A Review. Phytochem. Rev. 2022, 3, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.S.; Lee, S.Y.; Chew, K.W.; Lam, M.K.; Lim, J.W.; Ho, S.-H.; Show, P.L. A review on microalgae cultivation and harvesting, and their biomass extraction processing using ionic liquids. Bioengineered 2020, 11, 116–129. [Google Scholar] [CrossRef]

- Costa, J.A.V.; Freitas, B.C.B.; Santos, T.D.; Mitchell, B.G.; Morais, M.G. Open Pond Systems for Microalgal Culture. In Biofuels from Algae, 2nd ed.; Pandey, A., Chang, J.-S., Soccol, C.R., Lee, D.-J., Chisti, Y., Eds.; Biomass, Biofuels, Biochemicals; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 9; pp. 199–223. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Chakravarthy, M.; Kumar, R.R.; Yogendran, D.; Yuvaraj, D.; Jayamuthunagai, J. Aquatic biomass (algae) as a future feed stock for bio-refineries: A review on cultivation, processing and products. Renew. Sustain. Energy Rev. 2015, 47, 634–653. [Google Scholar] [CrossRef]

- Mohan, S.V.; Hemalatha, M.; Chakraborty, D.; Chatterjee, S.; Ranadheer, P.; Kona, R. Algal biorefinery models with self-sustainable closed loop approach: Trends and prospective for blue-bioeconomy. Bioresour. Technol. 2019, 295, 122128. [Google Scholar] [CrossRef]

- Benemann, J.R.; Woertz, I.; Lundquist, T. Autotrophic Microalgae Biomass Production: From Niche Markets to Commodities. Ind. Biotechnol. 2018, 14, 3–10. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sharma, A.; Singh, Y.; Chen, W.H. Production of a Sustainable Fuel from Microalgae Chlorella Minutissima Grown in a 1500 L Open Raceway Ponds. Biomass Bioenergy 2021, 149, 106073. [Google Scholar] [CrossRef]

- Romagnoli, F.; Ievina, B.; Perera, W.A.A.R.P.; Ferrari, D. Novel stacked modular open raceway ponds for microalgae biomass cultivation in biogas plants: Preliminary design and modelling. Environ. Clim. Technol. 2020, 24, 1–19. [Google Scholar] [CrossRef]

- Sirohi, R.; Pandey, F.K.; Ranganathan, P.; Singh, S.; Udayan, F.; Awasthi, M.K.; Hoang, A.T.; Chilakamarry, C.R.; Kim, S.H.; Sim, S.J. Design and applications of photobioreactors—A review. Biores. Technol. 2022, 349, 126858. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.S.; Show, P.L.; Ling, T.C.; Chen, C.Y.; Ho, S.H.; Tan, C.H.; Nagarajan, D.; Phong, W.N. Photobioreactors. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 313–352. [Google Scholar] [CrossRef]

- Gupta, P.L.; Lee, S.M.; Choi, H.J. A mini review: Photobioreactors for large scale algal cultivation. World J. Microbiol. Biotechnol. 2015, 31, 1409–1417. [Google Scholar] [CrossRef]

- Assuno, J.; Malcata, F.X. Enclosed “non-conventional” photobioreactors for microalga production: A review. Algal Res. 2020, 52, 102–107. [Google Scholar] [CrossRef]

- Hülsen, T.; Züger, C.; Gan, Z.M.; Batstone, D.J.; Solley, D.; Ochre, P.; Porter, B.; Capson-Tojo, G. Outdoor demonstration-scale flat plate photobioreactor for resource recovery with purple phototrophic bacteria. Water Res. 2022, 216, 118327. [Google Scholar] [CrossRef]

- Ting, H.; Haifeng, L.; Shanshan, M.; Zhang, Y.; Zhidan, L.; Na, D. Progress in microalgae cultivation photobioreactors and applications in wastewater treatment: A review. Int. J. Agric. Biol. Eng. 2017, 10, 1–29. [Google Scholar]

- Erbland, P.; Caron, S.; Peterson, M.; Alyokhin, A. Design and performance of a low-cost, automated, large-scale photobioreactor for microalgae production. Aquac. Eng. 2020, 90, 102103. [Google Scholar] [CrossRef]

- Díez-Montero, R.; Belohlav, V.; Ortiz, A.; Uggetti, E.; García-Galán, M.J.; García, J. Evaluation of daily and seasonal variations in a semi-closed photobioreactor for microalgae-based bioremediation of agricultural runoff at full-scale. Algal Res. 2020, 47, 101859. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Mehariya, S.; Bhatia, R.K.; Kumar, M.; Pugazhendhi, A.; Awasthi, M.K.; Atabani, A.E.; Kumar, G.; Kim, W.; Seo, S.-O.; et al. Wastewater based microalgal biorefinery for bioenergy production: Progress and challenges. Sci. Total Environ. 2021, 751, 141599. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.H.; Tan, X.; Ho, S.-H.; Lam, S.S.; Show, P.L.; Nguyen, T.H.P. Conceptual design of a hybrid thin layer cascade photo-bioreactor for microalgal biodiesel synthesis. Int. J. 2020, 44, 9757–9771. [Google Scholar] [CrossRef]

- Deprá, M.C.; Mérida, L.G.; de Menezes, C.R.; Zepka, L.Q.; Jacob-Lopes, E. A new hybrid photobioreactor design for microalgae culture. Chem. Eng. Res. Des. 2019, 144, 1–10. [Google Scholar] [CrossRef]

- Song, C.; Han, X.; Qiu, Y.; Liu, Z.; Li, S.; Kitamura, Y. Microalgae carbon fixation integrated with organic matters recycling from soybean wastewater: Effect of pH on the performance of hybrid system. Chemosphere 2020, 248, 126094. [Google Scholar] [CrossRef] [PubMed]

- Zahedi, A.; Labbafi, S. Optimization of Biomass Growth for a Novel Quadruple Renewable Geothermal/Hydro/Biomass/Solar Hybrid System. Fuel 2021, 306, 121694. [Google Scholar] [CrossRef]

- de Assis, L.R.; Calijuri, M.L.; Assemany, P.P.; Silva, T.A.; Teixeira, J.S. Innovative Hybrid System for Wastewater Treatment: High-Rate Algal Ponds for Effluent Treatment and Biofilm Reactor for Biomass Production and Harvesting. J. Environ. Manag. 2020, 274, 111183. [Google Scholar] [CrossRef]

- Wang, T.; Ni, Z.; Kuang, B.; Zhou, L.; Chen, X.; Lin, Z.; Jia, J. Two-stage hybrid microalgal electroactive wetland-coupled anaerobic digestion for swine wastewater treatment in South China: Full-scale verification. Sci. Total Environ. 2022, 820, 153312. [Google Scholar] [CrossRef]

- Leong, Y.K.; Huang, C.-Y.; Chang, J.-S. Pollution prevention and waste phycoremediation by algal-based wastewater treatment technologies: The applications of high-rate algal ponds (HRAPs) and algal turf scrubber (ATS). J. Environ. Manag. 2021, 296, 113193. [Google Scholar] [CrossRef]

- Cheenakula, D.; Hoffstadt, K.; Krafft, S.; Reinecke, D.; Klose, H.; Kuperjans, I.; Grömping, M. Anaerobic digestion of algal–bacterial biomass of an Algal Turf Scrubber system. Biomass Convers. Biorefin. 2022, 1–15. [Google Scholar] [CrossRef]

- Kardel, K.; Blersch, D.M.; Carrano ALKardel, K.; Blersch, D.M.; Carrano, A.L. Custom design of substratum topography increases biomass yield in algal turf scrubbers. Environ. Eng. Sci. 2018, 35, 856–863. [Google Scholar] [CrossRef]

- Wang, Y.N.; Pang, H.; Yu, C.; Li, C.; Wang, J.H.; Chi, Z.Y.; Xu, Y.P.; Li, S.Y.; Zhang, Q.; Che, J. Growth and nutrients removal characteristics of attached Chlorella sp. using synthetic municipal secondary effluent with varied hydraulic retention times and biomass harvest intervals. Algal Res. 2022, 61, 102600. [Google Scholar] [CrossRef]

- Park, J.B.; Montemezzani, V.; Picken, C.; Rendle, D.; Craggs, R.J. Effect of algal contact time and horizontal water velocity on the performance of Filamentous Algal Nutrient Scrubbers (FANS). J. Environ. Manag. 2022, 312, 114882. [Google Scholar] [CrossRef] [PubMed]

- Vázquez-Romero, B.; Perales, J.A.; Pereira, H.; Barbosa, M.; Ruiz, J. Techno-Economic Assessment of Microalgae Production, Harvesting and Drying for Food, Feed, Cosmetics, and Agriculture. Sci. Total Environ. 2022, 837, 155742. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, S.; Ramaswamy, S. Comparison of Productivity and Economic Analysis of Microalgae Cultivation in Open Raceways and Flat Panel Photobioreactor. Bioresour. Technol. Rep. 2019, 8, 100328. [Google Scholar] [CrossRef]

- Hoffman, J.; Pate, R.C.; Drennen, T.; Quinn, J.C. Techno-economic assessment of open microalgae production systems. Algal Res. 2017, 23, 51–57. [Google Scholar] [CrossRef]

- Schade, S.; Meier, T. Techno-economic assessment of microalgae cultivation in a tubular photobioreactor for food in a humid continental climate. Clean Technol. Environ. Policy 2021, 23, 1475–1492. [Google Scholar] [CrossRef]

- Smetana, S.; Sandmann, M.; Rohn, S.; Pleissner, D.; Heinz, V. Autotrophic and heterotrophic microalgae and cyanobacteria cultivation for food and feed: Life cycle assessment. Bioresour. Technol. 2017, 245, 162–170. [Google Scholar] [CrossRef]

- Mu, D.; Xin, C.; Zhou, W. Life Cycle Assessment and Techno-Economic Analysis of algal biofuel production. In Microalgae Cultivation for Biofuels Production; Yousuf, A., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 281–292. [Google Scholar] [CrossRef]

- Fasaei, F.; Bitter, J.H.; Slegers, P.M.; Van Boxtel, A.J.B. Techno-economic evaluation of microalgae harvesting and dewatering systems. Algal Res. 2018, 31, 347–362. [Google Scholar] [CrossRef]

- Hossain, N.; Mahlia, T.M.I.; Zaini, J.; Saidur, R. Techno-economics and Sensitivity Analysis of Microalgae as Commercial Feedstock for Bioethanol Production. Environ. Prog. Sustain. Energy 2019, 38, 13157. [Google Scholar] [CrossRef]

- DeRose, K.; DeMill, C.; Davis, R.W.; Quinn, J.C. Integrated techno economic and life cycle assessment of the conversion of high productivity, low lipid algae to renewable fuels. Algal Res. 2019, 38, 101412. [Google Scholar] [CrossRef]

- Masoumi, S.; Dalai, A.K. Techno-economic and life cycle analysis of biofuel production via hydrothermal liquefaction of microalgae in a methanol-water system and catalytic hydrotreatment using hydrochar as a catalyst support. Biomass Bioenergy 2021, 151, 106168. [Google Scholar] [CrossRef]

- Chen, P.H.; Quinn, J.C. Microalgae to biofuels through hydrothermal liquefaction: Open-source techno-economic analysis and life cycle assessment. Appl. Energy 2021, 289, 116613. [Google Scholar] [CrossRef]

- Jaumard, B.; Chen, L.; Devaux, F. Techno-Economic Assessment and Life Cycle Assessment of CO2 to Biofuel via Micro-Algae Process. In Proceedings of the 15th Greenhouse Gas Control Technologies Conference, Virtual, 15–18 March 2021. [Google Scholar] [CrossRef]

- Valdovinos-García, E.M.; Barajas-Fernández, J.; Olán-Acosta, M.Á.; Petriz-Prieto, M.A.; Guzmán-López, A.; Bravo-Sánchez, M.G. Techno-Economic Study of CO2 Capture of a Thermoelectric Plant Using Microalgae (Chlorella vulgaris) for Production of Feedstock for Bioenergy. Energies 2020, 13, 413. [Google Scholar] [CrossRef]

- Algae Products Market by Type (Lipids, Carotenoids, Carrageenan, Alginate, Algal Protein), Facility Type, Form (Liquid, Solid), Source (Brown Algae, Green Algae, Red Algae, Blue-Green Algae), and Region—Global Forecast to 2026. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/algae-product-market-250538721.html (accessed on 25 December 2022).

- Top 10 Companies in Microalgae Market, Meticulous Blog. 2022. Available online: https://meticulousblog.org/top-10-companies-in-microalgae-market/ (accessed on 25 December 2022).

- Bhattacharya, M.; Goswami, S. Microalgae–A green multi-product biorefinery for future industrial prospects. Biocatal. Agric. Biotechnol. 2020, 25, 101580. [Google Scholar] [CrossRef]

- Banu, J.R.; Kavitha, S.; Gunasekaran, M.; Kumar, G. Microalgae based biorefinery promoting circular bioeconomy-techno economic and life-cycle analysis. Bioresour. Technol. 2020, 302, 122822. [Google Scholar] [CrossRef] [PubMed]

- Koyande, A.K.; Chew, K.W.; Rambabu, K.; Tao, Y.; Chu, D.-T.; Show, P.-L. Microalgae: A potential alternative to health supplementation for humans. Food Sci. Hum. Wellness 2019, 8, 16–24. [Google Scholar] [CrossRef]

- Algatechnologies, Ltd. Available online: https://www.algatech.com/ (accessed on 25 December 2022).

- BASF SE. Available online: www.basf.com (accessed on 25 December 2022).

- ADM. Available online: www.adm.com (accessed on 25 December 2022).

- Corbion NV. Available online: www.corbion.com (accessed on 25 December 2022).

- Cyanotech Corporation. Available online: www.cyanotech.com (accessed on 25 December 2022).

- E.I.D. Parry India Ltd. Available online: https://www.eidparry.com/ (accessed on 25 December 2022).

- Fenchem Biotek Ltd. Available online: http://www.fenchem.com (accessed on 25 December 2022).

- Royal DSM. Available online: https://www.dsm.com (accessed on 25 December 2022).

- Schipper, K.; Al-Jabri, H.M.S.; Wijffels, R.H.; Barbosa, M.J. Techno-economics of algae production in the Arabian Peninsula. Bioresour. Technol. 2021, 331, 125043. [Google Scholar] [CrossRef]

- Roostaei, J.; Zhang, Y. Spatially Explicit Life Cycle Assessment: Opportunities and Challenges of Wastewater-based Algal BioFuels in the United States. Algal Res. 2017, 24, 395–402. [Google Scholar] [CrossRef]

- Porcelli, R.; Dotto, F.; Pezzolesi, L.; Marazza, D.; Greggio, N.; Righi, S. Comparative life cycle assessment of microalgae cultivation for non-energy purposes using different carbon dioxide sources. Sci. Total Environ. 2020, 721, 137714. [Google Scholar] [CrossRef]

- Juneja, A.; Murthy, G.S. Evaluating the potential of renewable diesel production from algae cultured on wastewater: Techno-economic analysis and life cycle assessment. Aims Energy 2017, 5, 239–257. [Google Scholar] [CrossRef]

- Gholkar, P.; Shastri, Y.; Tanksale, A. Renewable hydrogen and methane production from microalgae: A techno-economic and life cycle assessment study. J. Clean. Prod. 2021, 279, 123726. [Google Scholar] [CrossRef]

- Somers, M.D.; Quinn, J.C. Sustainability of carbon delivery to an algal biorefinery: A techno-economic and life-cycle assessment. J. CO2 Util. 2019, 30, 193–204. [Google Scholar] [CrossRef]

- Ranganathan, P.; Savithri, S. Techno-economic analysis of microalgae-based liquid fuels production from wastewater via hydrothermal liquefaction and hydroprocessing. Bioresour. Technol. 2019, 284, 256–265. [Google Scholar] [CrossRef] [PubMed]

- Xin, C.; Addy, M.M.; Zhao, J.; Cheng, Y.; Cheng, S.; Mu, D.; Liu, Y.; Ding, R.; Chen, P.; Ruan, R. Comprehensive techno-economic analysis of wastewater-based algal biofuel production: A case study. Bioresour. Technol. 2016, 211, 584–593. [Google Scholar] [CrossRef] [PubMed]

- Olguín, E.J.; Sánchez-Galván, G.; Arias-Olguín, I.I.; Melo, F.; González-Portela, R.; Cruz, L.; De Philippis, R.; Adessi, A. Microalgae-Based Biorefineries: Challenges and Future Trends to Produce Carbohydrate Enriched Biomass, High-Added Value Products and Bioactive Compounds. Biology 2022, 11, 1146. [Google Scholar] [CrossRef] [PubMed]

- Ryan, D.; Jennifer, M.; Christopher, K.; Nicholas, G.; Eric, T. Process Design and Economics for the Production of Algal Biomass: Algal Biomass Production in Open Pond Systems and Processing Through Dewatering for Downstream Conversion; Technical Report NREL/TP-5100-64772; National Renewable Energy Laboratory: Golden, CO, USA, 2016; 119p. [Google Scholar] [CrossRef]

- Granata, T. Dependency of Microalgal Production on Biomass and the Relationship to Yield and Bioreactor Scale-up for Biofuels: A Statistical Analysis of 60+ Years of Algal Bioreactor Data. BioEnergy Res. 2017, 10, 267–287. [Google Scholar] [CrossRef]

- Rafa, N.; Ahmed, S.F.; Badruddin, I.A.; Mofijur, M.; Kamangar, S. Strategies to Produce Cost-Effective Third-Generation Biofuel from Microalgae. Front. Energy Res. 2021, 9, 749968. [Google Scholar] [CrossRef]

- Ronglian, W.; Jiesheng, M.; Lu, Z.; Jianming, W. Water Pollution Restoration Simulation Method and System based On Hydrodynamic Coupling Water Quality Model. Patent CN114996977B, 4 November 2022. [Google Scholar]

- Guohong, C.; Shicong, S. Cooling System for Producing Biodiesel. Patent CN217900297U, 25 November 2022. [Google Scholar]

- He, Q.; Wang, J.; Hilliard, V.M. Culture Systems and Methods of Using Same. Patent US11339360B2, 24 May 2022. [Google Scholar]

- Felby, C.; Mayer, S.; Orozco, Y.C. Biofuel Composition Comprising Lignin. Patent US11306264B2, 19 April 2022. [Google Scholar]

- Falco, R. Methods and Systems for Efficient Bioreactor Mixing and Light Utilization that Embody Low Process Energy and Scalability. Patent JP7127913B2, 28 April 2022. [Google Scholar]

- Dong, W.; Junhui, C. Screening Method and Application of Chemical Inducer for Improving Oil Production of Green Algae. Patent CN111440727B, 21 October 2022. [Google Scholar]

- Kim, S. Biogas Purification System and Purification Method Using the Same. Patent KR102368058B1, 25 February 2022. [Google Scholar]

- Hailong, H. Heating and Stirring Device for Biodiesel Refining from Illegal Cooking Oil. Patent CN210645948U, 2 June 2020. [Google Scholar]

- Lianshui, X. Sewage Treatment Device for Extracting Biodiesel from Illegal Cooking Oil. Patent CN212246485U, 29 December 2020. [Google Scholar]

- Hongfeng, Z.; Xuebin, F.; Zhenhai, C.; Yuxian, C.; Wensheng, C.; Xueting, T.; Shan, L. A kind of Filtering Extraction Element for Production of Biodiesel. Patent CN208320779U, 4 January 2019. [Google Scholar]

- Jianmin, L.; Baoshi, L.; Yan, L. Biodiesel Antioxidant Composition and Preparation Method and Application Thereof. Patent CN112521988B, 21 October 2022. [Google Scholar]

- Baosheng, G.; Qian, Y.; Yonghao, Y.; Mingxiong, X.; Fang, H.; Xinzu, S.; Xiaonan, L.; Chen, T.; Xi, C. Method for Extracting High-Purity Phycocyanin and co-Producing Polysaccharide from Spirulina. Patent CN110964100B, 14 October 2022. [Google Scholar]

| Title | Cultivation Type | Biomass/Biorefinery Product | TEA | LCA | Reference | |

|---|---|---|---|---|---|---|

| 1 | Techno-economics and sensitivity analysis of microalgae as a commercial feedstock for bioethanol production | Closed system PBR | Biomass: 56 t ha−1 Bioethanol yield: 31,119.49 gal yr−1 | Total production cost: SGD 2.22 M Total bioethanol selling price: USD 2.87 M By-product sale price: USD 1.6 M | - | [86] |

| ORP | Biomass: 28 t ha−1 Bioethanol: 25,968.13 gal yr−1 | |||||

| 2 | Integrated techno-economic and life cycle assessment of the conversion of high productivity, low lipid algae to renewable fuels | Biochemical (ATS) | Biomass (ref): 1215 t AFDW biomass day−1 Purchase cost: USD 515 t−1 AFDW | Fuel selling price: USD 12.85 GGE−1 | GWP: 111.2 g CO2eq MJ fuel−11 | [87] |

| Thermal (ATS) | Biomass (ref): 1215 t AFDW biomass day−1 Purchase cost: USD 515 t−1 AFDW | Fuel selling price: USD 10.41 GGE−1 | GWP: −2 g CO2eq MJ fuel−11 | |||

| 3 | Techno-economic and life cycle analysis of biofuel production via hydrothermal liquefaction of microalgae in a methanol–water system and catalytic hydrotreatment using hydro char as a catalyst support | Combustion | Biomass: 200 dry metric tonnes day−1 O2 content: 14.5 wt% HHV of 33.4 MJ kgbiocrude oil−1 | Fuel selling price: USD 2.2 L−1 | GWP: −1.13 gCO2-eq MJ−1 | [88] |

| Activation | Biomass: 200 dry metric tonnes day−1 O2 content: (3.1 wt%) HHV: 42 MJ kgbiofuel−1 | |||||

| 4 | Microalgae to biofuels through hydrothermal liquefaction: open-source techno-economic analysis and life cycle assessment | ORP | MFSP of USD 1.17 LGE−1 biomass purchase price: USD 4.44 GGE−1 HTL: USD 0.45 LGE−1 (USD 1.69 GGE−1) | GWP: +23 g CO2 eq MJ−1 Net energy ratio: 0.30 Acidification: 1.8 × 10–4 kg SO2 eq MJ−1 Ecotoxicity: 1.4 × 10−1 CTUe MJ−1 Eutrophication: 3.5 × 10−3 kg N eq MJ−1 Human health: Carcinogenic: 1.54 × 10−9 Non-carcinogenic 6.72 × 10−9 CTUh MJ−1 Ozone depletion: 5.4 × 10−9 kg CFC-11 eq MJ−1 Photochemical ozone formation: 2.7 × 10−3 kg O3 eq MJ−1 Fossil fuel depletion: 0.26 MJsurplus MJfuel Respiratory effects: 4.3 × 10−5 kg PM2.5 eq MJ−1 | [89] | |

| 5 | Techno-economic assessment and life cycle assessment of CO2 to biofuel via micro-algae process | ORP | Biomass productivity: 30 g-algae/m²-day | CAPEX is EUR 928 M OPEX is EUR 102 M/y Biofuel production cost: EUR 1186/t | GHG emissions: 26.6 g-CO2/MJ | [90] |

| 6 | Techno-economic study of CO2 capture of a thermoelectric plant using microalgae (Chlorella vulgaris) for production of feedstock for bioenergy | ORP | Biomass productivity: 12.7 g/m2/day | Operating costs range from USD 4.75 to 6.55/kg CO2 Capture: 102.13 tons/year Production Cost among the most efficient scenario w.r.t. energy consumption USD 4.75/kg–USD 6.55/kg | - | [91] |

| Company Name | Location | Compounds | Products | Reference | |

|---|---|---|---|---|---|

| 1. | Algatechnologies, Ltd. | Israel | Astaxanthin, fucoxanthin | AstaPure® Arava, FucoVital Fuxocanthin, Astapure, AstaPure®Max, BioGlena™, FucoVital™, Bioecolians | [97] |

| 2. | BASF SE | Beta carotene, lutein, linoleic acid, omega-3 fatty acids, saccharides, vitamins | Dehyton® AO 45, algal betaine, Betatene®. Dry n-3®, Lucarotin®, LycoVit® | [98] | |

| 3. | ADM | United States | DHA | Onavita DHA Algal Oil, Onavita Flaxseed Oil | [99] |

| 4. | Corbion NV | Amsterdam, the Netherlands | Omega-3 fatty acids | AlgaPrime™ DHA. | [100] |

| 5. | Cyanotech Corporation | USA | Spirulina biomass, microalgal extracts | BioAstin® Hawaiian Astaxanthin® Hawaiian Spirulina | [101] |

| 6. | E.I.D. Parry India Ltd. | India | Chlorophyll, essential vitamins, minerals, and fatty acids, astaxanthin, zeaxanthin, lutein | SpiruZan® (Spirulina with Astaxanthin) Parry Organic Spirulina, FlexPro MD®, USPlus® Saw Palmetto | [102] |

| 7. | Fenchem Biotek Ltd. | China | Betacarotene, astaxanthin, zeaxanthin, lutein | AstaSuper™ Astaxanthin, BetaOne™, Hawaiian Astaxanthin Softgels, Water DispersiblePowder | [103] |

| 8. | Royal DSM N.V. | The Netherlands | EPA, DHA vitamins, carotenoids, cannabinoids, zeaxanthin | OPTISHARP® redivivo® Lycopene FloraGLO® Lutein CaroCare® (natural Beta-Carotene) AstaSana™ | [104] |

| Title | Cultivation Type/Process | Environmental Remediation | Biomass/Biorefinery Product | TEA | LCA | Reference | |

|---|---|---|---|---|---|---|---|

| 1. | Evaluating the potential of renewable diesel production from algae cultured on wastewater: techno-economic analysis and life cycle assessment | ORP | Use of flue gas and wastewater | Biomass: 3550 kg/h Biocrude oil: 1222 kg/hr | The total cost of production: USD 38,645/ha Renewable diesel: USD 1.75/L (USD 6.62/gal). Bio-oil production plant: 105 MM w.r.t. Renewable diesel: 10 M L yr−1 (2.7 M gallon Lyr−1) Renewable diesel price: USD 6.62/gal | Fossil fuel energy used: 241.6 MJ per 1000 MJ Net energy value: 758.4 MJ per 1000 MJ GHG emissions: –3.73 kg CO2 eq./L Renewable diesel | [108] |

| 2. | Renewable hydrogen and methane production from microalgae: A techno-economic and life cycle assessment study | ORP | Waste gases from pressure swing adsorption and unpolluted wastewater | Biomass: 12,790 kg h−1 Hydrogen: 1239 kg h−1 | Microalgae cost: USD 0.5/kg (INR32.5/kg) total capital investment (TCI) of USD 144.6 M/INR9.40 B | Life cycle climatic change impact: 7.56 kg CO2-eq/kg H2. | [109] |

| Methane: 3484.96 kg/h | TCI: USD 78.61 M Million/ INR5.11 B | Life cycle climatic change impact: 1.18 kg CO2 eq/ kg of CH4 | |||||

| 3. | Sustainability of carbon delivery to an algal biorefinery: A techno-economic and life-cycle assessment | ORP | CO2sources: atmosphere; power plant waste emissions; concentrated from waste sources and compressed inorganic carbon in the form of hydrogen carbonate; organic carbon in cellulosic sugars (corn stover) | Biomass (constant/ baseline): 506 metric tons day−1 | MFSP, USD 6.47 GGE−1, Effective cost range: 135–400 USD metric ton−1 carbon | GWP: 28.1g CO2-eq MJ−1 NER: 0.13 MJ MJ−1 | [110] |

| Pure sources of gaseous CO2: uncompressed (pipeline transportation ≤40 km) and compressed and supercritical (pipeline transportation ≤100 km): Effective cost: <0.50 USD GGE−1 GWP: <20 g CO2-eq MJ−1 | |||||||

| 4. | Techno-economic analysis of microalgae-based liquid fuels production from wastewater via hydrothermal liquefaction and hydroprocessing | ORP | Wastewater | Algal productivity: 586 tonnes /day hydrocarbon fuels productivity (tonnes per annum) Diesel: 6471 Jet: 21,083 Gasoline: 54,981 H2: 391 | Minimum selling price (MSP) (hydrocarbon fuels): USD 4.3/GGE | - | [111] |

| 5. | Comprehensive techno-economic analysis of wastewater-based algal biofuel production: a case study | PBR | Wastewater | - | Total project Investment: 5,352,657 Total Annual cost: 1,977,831 selling price of biofuel: USD 2.23/gallon Cost savings and revenue: wastewater treatment cost saving 564,768 Syngas income 47,607 | - | [112] |

| Patent Number | Title | Earliest Priority | Publication Date | Inventor | Applicant | Reference | |

|---|---|---|---|---|---|---|---|

| 1. | CN114996977B | Water pollution restoration simulation method and system based on hydrodynamic coupling water quality model | 3 August 2022 | 4 November 2022 | Wei Ronglian Min Jiesheng, Zhou Lu, Wu Jianming | Zhejiang Yuansuan Technology Co ltd | [117] |

| 2. | CN217900297U | Cooling system for producing biodiesel | 26 July 2022 | 25 November 2022 | Chen Guohong, Shen Shicong | Kunming Decheng Renewable Resources Technology Co ltd | [118] |

| 3. | US11339360B2 | Cultural systems and methods of using the same | 21 July 2020 | 24 May 2022 | Qinghua He, Jin Wang, Matthew Hilliard | Auburn University | [119] |

| 4. | US11306264B2 | Biofuel composition comprising lignin | 18 February 2019 | 19 April 2022 | Claus Felby, Stefan Mayer, Yohanna Cabrera OROZCO | Kobenhavns Universitet AP Moller Maersk AS | [120] |

| 5. | JP7127913B2 | Methods and systems for efficient bioreactor mixing and light utilization that embody low process energy and scalability | Priority claimed from US16/419,974 | 28 April 2022 | Robert Falco | SolarClean Fuels, LLC | [121] |

| 6. | CN111440727B | Screening method and application of chemical inducer for improving oil production of green algae | 6 March 2020 | 21 October 2022 | Wei Dong, Chen Junhui | The South China University of Technology SCUT | [122] |

| 7. | KR102368058B1 | Biogas purification system and purification method using the same | 1 November 2021 | 25 February 2022 | Sangjin Kim | Ecosystems Co., Ltd. | [123] |

| 8. | CN210645948U | Heating and stirring device for biodiesel refining from illegal cooking oil | 3 September 2019 | 2 June 2020 | Hao Hailong | Yantai Grein Energy Technology Co Ltd. | [124] |

| 9. | CN212246485U | Sewage treatment device for extracting biodiesel from illegal cooking oil | 27 April 2020 | 29 December 2020 | Xiao Lianshui | Jiangxi Guanniu Biotechnology Co ltd | [125] |

| 10. | CN208320779U | A kind of filtering extraction element for the production of biodiesel | 12 March 2018 | 4 January 2019 | Zhao Hongfeng, Fu Xuebin, Cao Zhenhai, Chen Yuxian, Cui Wensheng, Tang Xueting, Liu Shan | Shangqiu Haotian Environmental Protection Machinery Equipment Co Ltd. | [126] |

| 11. | CN112521988B | Biodiesel antioxidant composition and preparation method and application thereof | 18 September 2019 | 21 October 2022 | Lin Jianmin, Li Baoshi, Li Yan | Sinopec Research Institute of Petroleum Processing China Petroleum and Chemical Corp | [127] |

| 12. | CN110964100B | Method for extracting high-purity phycocyanin and co-producing polysaccharide from spirulina | 30 December 2019 | 14 October 2022 | Ge Baosheng, Yu Qian, Yin Yonghao, Xue Mingxiong, Huang Fang, Sun Xinzu, Li Xiaonan, Tian Chen, Chen Xi | Beihai Sbd Bio Science & Technology Co ltd China University of Petroleum UPC East China | [128] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chanana, I.; Kaur, P.; Kumar, L.; Kumar, P.; Kulshreshtha, S. Advancements in Microalgal Biorefinery Technologies and Their Economic Analysis and Positioning in Energy Resource Market. Fermentation 2023, 9, 202. https://doi.org/10.3390/fermentation9030202

Chanana I, Kaur P, Kumar L, Kumar P, Kulshreshtha S. Advancements in Microalgal Biorefinery Technologies and Their Economic Analysis and Positioning in Energy Resource Market. Fermentation. 2023; 9(3):202. https://doi.org/10.3390/fermentation9030202

Chicago/Turabian StyleChanana, Ishita, Parneet Kaur, Lokender Kumar, Pradeep Kumar, and Sourabh Kulshreshtha. 2023. "Advancements in Microalgal Biorefinery Technologies and Their Economic Analysis and Positioning in Energy Resource Market" Fermentation 9, no. 3: 202. https://doi.org/10.3390/fermentation9030202

APA StyleChanana, I., Kaur, P., Kumar, L., Kumar, P., & Kulshreshtha, S. (2023). Advancements in Microalgal Biorefinery Technologies and Their Economic Analysis and Positioning in Energy Resource Market. Fermentation, 9(3), 202. https://doi.org/10.3390/fermentation9030202