Abstract

Adobera, a genuine, brick-shaped, lightly ripened, unstretched pasta filata-like cheese from Western México, is one of the most important market-share wise but is usually made with raw milk and prepared following artisanal procedures. A pasteurized milk cheese is needed to assess its safety and guarantee standardized quality features. However, no commercial Adobera cheese culture is available, as specific lactic acid bacteria relevant for its production have not been thoroughly identified. This study is aimed at comparing the technological and quality features of Adobera cheeses made with pasteurized milk inoculated with a mixture of autochthonous lactic acid bacteria (Lactobacillus and Leuconostoc strains) to those of traditional raw milk cheeses, hypothesizing that no significant differences would be found between them. Milk pasteurization promoted water retention into the cheese matrix, impacting its texture and color profiles. Raw milk cheeses were harder, more cohesive, and less elastic than pasteurized milk cheeses. Ripening markers were significantly higher in raw milk cheeses at all sampling times, although its evolution over time showed that the starter culture could exhibit similar proteolytic activity than that of native milk microbiota under favorable ripening conditions. The principal component analysis revealed apparent overall differences between raw Adobera cheeses and those made with pasteurized cheese milk.

1. Introduction

Mexico has several kinds of genuine cheese; at least seventeen of them are produced using non-standardized raw milk [1]. Although potentially hazardous from the safety standpoint and variable in composition due to seasonal changes in milk composition, these cheeses are valued because of their sensory quality and as part of local cultural heritage. Their production is generally carried out in small regions through artisanal processes [2,3]. Recent research efforts have been focused on preserving authentic Mexican cheeses’ know-how while clearly defining their specific features [2,4]. In some cases, cheese identity protection has been achieved through collective trademarks, as with Cotija, Bola de Ocosingo, Poro, and Crema de Chiapas cheeses, although its impact culturally and economic wise is yet to be assessed [5]. However, key information on most authentic Mexican cheese varieties, such as standard manufacturing procedures and ripening conditions, cheese microbiota involved in their production and well-defined quality descriptors remain limited [1]. Extending our knowledge on these issues is paramount for developing strategies to preserve artisanal cheese identity while increasing the possibility to market them effectively [6]. Currently, most available reports on artisanal Mexican cheeses are related to cheese microbiota and microbial safety issues [7,8,9,10,11,12,13]. Adobera cheese is a raw cow milk, yellowish-to-ivory, semihard, brick-shaped, unripened-to-lightly-ripened, unstretched pasta filata-like Mexican cheese. It is primarily produced in municipalities of Los Altos and Sierra de Amula regions in Jalisco, one of the largest milk-producing regions in Mexico [4,14]. A mildly flavored product with sliceable to crumbly texture, artisanal Adobera cheese exhibits some peculiarities. Although it is considered a fresh cheese (43–63% moisture), its relatively low water activity and pH, and high proteolysis levels generate a product that melts upon heating [4]; however, scientific reports on Adobera cheese are still scarce.

Due to its regional, small-scale origin, and raw milk-made nature, microbiological safety of Adobera cheese could be compromised, as its microbial counts could be high, including some potentially pathogenic strains. It is considered that cheese pH development during the process could represent a crucial factor to prevent the survival of these microorganisms [15,16]. The lack of a proper preservation procedure for cheese milk is a significant concern; thus, various larger manufacturers have started applying proper thermal preservation techniques to prevent Adobera cheese for being a possible source of food-transmitted diseases [17]. However, cheese flavor intensity and complexity are expected to be somehow restrained [18].

Cheesemilk pasteurization is the treatment of choice for assessing cheese microbial safety and shelf life. The primary purpose of pasteurization is to eliminate all pathogens in milk while reducing counts of spoilage microorganisms [19]. As some Adobera cheese manufacturers have started to pasteurize milk to comply with the current Mexican legislation, the impact of milk thermal treatment on Adobera cheese composition and quality characteristics needs to be studied, as compositional and microstructural changes due to milk heat treatments are expected [20]. More consistent product composition is attained when starter cultures, either as bulk or direct vat set (DVS) cultures, are used to inoculate cheese milk instead of relying on native milk microbiota. Starter cultures allow reaching the desirable acidity at a specific time range, help delimit curd cutting time, and contribute to cheese flavor and texture development in a more precise way. Moreover, these cultures could deliver additional microbial protection to cheese, inhibiting selected milk pathogens such as Listeria monocytogenes [21]. However, no commercial Adobera cheese culture is available, as specific lactic acid bacteria relevant for its production has not been entirely isolated and identified. Vázquez-Velázquez et al. [6] compared another raw-milk, artisanal Mexican cheese (Bola de Ocosingo), with pasteurized milk cheeses added with preselected combinations of native lactic acid bacteria isolated and reported no significant differences between them, sensory wise. The most abundant bacterial and fungal species found in Adobera cheese have been previously described [22]. On the other hand, Ruvalcaba-Gómez et al. [7] recently reported the possible roles of bacteria involved in Adobera cheese manufacturing through DNA sequencing analyses, thus opening the possibility to evaluate bacteria isolated from the cheese itself and from its cheesemaking environment as starter cultures in pasteurized cheese milk, which is much-needed to assess its safety and guarantee standardized quality features. Therefore, this study aims to evaluate the effect of cheese milk pasteurization and a predefined mixed lactic acid bacteria starter culture on the manufacturing of laboratory-scale Adobera cheese, comparing their compositional and textural properties with those of an artisanal-like raw milk Adobera cheese, and hypothesizing that no differences are found between them. The information presented could be used by Mexican cheese manufacturers as supporting information to produce safe, authentic Adobera cheese with standard physicochemical properties.

2. Materials and Methods

2.1. Lactic-Acid Bacteria Strains

2.1.1. Recovery and Growth

As a part of a preceding research project, 21 bacterial species were isolated from artisanal Adobera cheeses from Los Altos de Jalisco region, identified by phenotyping using the bioMerieux® API-50 CH system and kept at the strain collection of Los Altos University Center, University of Guadalajara, Mexico until used (data not shown). Lactic acid bacteria from three different genus (Lactobacillus, Leuconostoc, and Lactococcus) were retrieved from the collection, inoculated on Man, Rogosa and Sharpe (MRS; DifctoTM, Becton, Dickinson and Company, Franklin Lakes, NJ, USA) agar plates and incubated under microaerophilic conditions at 37 °C for subsequent evaluation.

2.1.2. Growth Kinetics and Acidifying Capacity

Growth and acidifying activity of the selected strains were obtained by inoculating sterile reconstituted skim milk (Nestlé, México city, México) with a bacterial suspension (1% v/v) containing approximately 1 × 108 colony-forming units per mL (CFU/mL). Inoculated milk was incubated at 37 °C for 12 h and sampled every hour. From each sample, 1 mL aliquots were taken and serial-diluted to inoculate by spreading on MRS agar plates and incubated under microaerophilic conditions (24 h, 37 °C), followed by CFU count. Meanwhile, acidifying capacity was assessed by pH measurement of the inoculated milk every hour. From the phenotyping, growth kinetics, and acidification activity results, three strains were selected to evaluate their proteolytic activity and lactic acid generation capacity.

2.1.3. Assessment of Proteolytic and Acidifying Activities by FTIR

The three selected LAB (identified in coded form as Lactobacillus A-53, Lactobacillus A-151, and Leuconostoc A-100 because of intellectual property issues) were inoculated into sterile skim milk (1% v/v of a 1 × 108 CFU/mL bacterial suspension) and incubated at 37 °C for 12 h. Every hour, infrared spectra were obtained using a Bruker Vertex 70 Fourier transform infrared spectrometer (FTIR, Bruker, Billerica, MA, USA) operating in the mid-infrared range (400 to 4000 cm−1). Attenuated total reflectance (ATR) spectra were obtained from 60 scans at a resolution of 4 cm−1; increases in absorbance at selected wavenumbers and its comparison against spectra of non-inoculated milk were taken as indicators of proteolysis extent and acid accumulation produced by the LAB species and used as indicators of their potential technological features. All tests were made in duplicate.

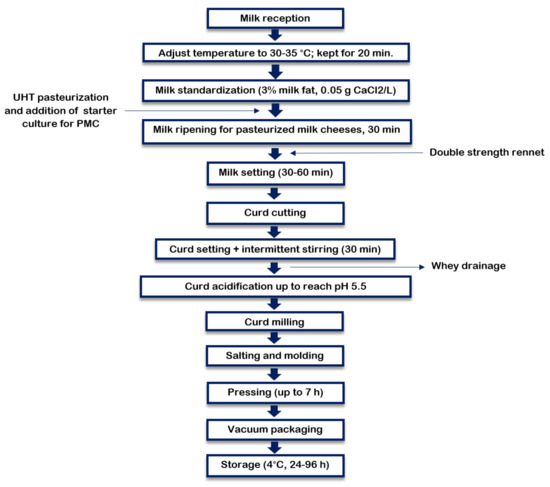

2.2. Experimental Cheeses

Fresh raw bovine milk was obtained from local, family owned dairy farms in Tepetitla, Tlaxcala, México and kept under refrigeration until used. Milk composition was determined using an infrared-based analyzer (MilkoScan S 54B, FOSS Electric A/S, Hillerød, Denmark). Three 8-L milk samples were heated up to 35 °C, standardized to 3% fat with fresh skim milk, and 0.5 g/L calcium chloride was added to increase calcium concentration in the cheese milk serum. The average protein-to-fat ratio in all cheeses was 0.83 ± 0.01. Three batches of either raw milk cheese (RMC) or pasteurized milk cheese (PMC) were prepared as indicated in Figure 1 and as described below in detail.

Figure 1.

Manufacturing procedure of benchtop scale Adobera cheese (Modified from Ruvalcaba et al., 2020 [4]).

2.2.1. Raw Milk Cheeses (RMC)

Milk was placed into a water bath and kept at 32 °C for 20 min. Afterward, 1 mL of microbial double-strength rennet (Cuamix™ Chr. Hansen, Mexico city, Mexico) previously 1:10 diluted in distilled water was added to cheese milk and left undisturbed until curd formation (30–35 min). Curd was cut into 1-cm cubes using stainless-steel curd cutters, then held under the whey for 30 min and intermittently stirred to promote syneresis. The whey was drained, and cheese curds were kept at room temperature until reaching pH 5.5. Acidified curd was manually broken to pieces, dry-salted with 1 g NaCl/100 g curd, transferred into rectangular stainless-steel molds, and pressed at 4 °C for 24 h to obtain cheese bricks of about 250 g. Later, cheeses were removed from the molds, lightly aged (48 h, 4 °C), vacuum-packed, and stored at 4 °C until analysis.

2.2.2. Pasteurized Milk Cheeses (PMC)

A 1:1:1 mixed culture of the three previously selected LAB strains (Lactobacillus A-53, Lactobacillus A-151, and Leuconostoc A-100) were inoculated in UHT skimmed milk, incubated at 37 °C for 10 h up to a final concentration of 1 × 109 CFU/mL. Standardized raw milk was HTST-pasteurized (72 °C, 15 s) in a stainless-steel benchtop kettle (FJ15, Janschitz GMBH, Austria), rapidly cooled down to inoculation temperature (35 °C), then placed in a sterile stainless-steel container for maintaining its temperature throughout the cheesemaking process. Pasteurized milk was inoculated with 2% v/v of the prepared inoculum, ripened for 45 min, and curdled with double-strength rennet. From this point on, the process was identical to that previously described for RMC.

Both RMC and PMC were sampled at 0, 7, 14, and 21 days of refrigerated storage for performing physicochemical tests. Cheeses for compositional analyses were tested at day 0 and at 21 (for protein and fat analyses only).

2.3. Physicochemical and Compositional Analysis

Cheese yield was calculated as kg of cheese per 100 kg milk. Cheese pH was measured according to the AOAC method 981.12 [23], placing the electrode of a Denver™ B-10 pH meter (Denver Instrument, NY, USA) in contact with the curd or grated cheese upon obtaining a constant reading (about 2 min). The moisture content of cheese samples was determined by vacuum drying (100 °C, 131 mbar vacuum) until constant weight [24]. Water activity was determined using an Aqualab™ Series 3 hygrometer (Decagon, Pullman, WA, USA). Protein and fat contents were determined by the micro-Kjeldahl and Gerber methods, respectively [24].

Free Amino Acids Content

The free amino acid (FAA) content to quantify proteolysis in Adobera cheese (expressed as mmol of FAA per gram of dried cheese) was determined in the citrate-soluble fraction of cheese samples, as described by Ruvalcaba et al. [4]. The color development with Cd-ninhydrin reagent was spectrophotometrically determined at 507 nm [25] using a Multiskan FC™ (Thermo Fisher Scientific, Waltham, MA, USA), and FAA was calculated using a calibration curve prepared with a standard leucine solution. Samples were analyzed in duplicate.

2.4. Texture Profile Analysis of Cheese

Texture profile analysis of cheeses was obtained in a TA.XT Plus™ texturometer (Stable Micro Systems Ltd., Surrey, UK). Cylindrical sections of cheese samples (2.0 cm high, 1.6 cm-diameter) obtained with a borer, were compressed twice at 50% height with a 2.0 cm diameter cylindrical probe at a crosshead speed of 3 mm/s, with a 5 s delay between compressions [4]. Hardness, cohesivity, elasticity, chewiness, and resilience of the samples were calculated using data obtained from the compression graphs (force vs. time) [26].

2.5. Cheese Color

The cheese color surface was measured in duplicate in 4-cm × 5-cm samples from both rind and internal section of cheese samples using a Colorflex EZ™ colorimeter in the Hunter L, a, b color space (L = brightness, a = red-green, b = blue-yellow, HunterLab, Road, Reston, VA, USA), with a D65 illuminant and 10° observer angle [4]. Hue angle values were calculated as the inverse tangent of b*/a* ratio; while chroma values were determined as (a2 + b2)1/2. Whiteness Index (WIJUDD) was calculated as 100 − [(100 − L)2 + (a2) + (b2)]1/2; meanwhile Yellowness Index (YIFC) was determined as 142.86 b/L [26,27]. Finally, to generate the reference color squares, L*, a, and b* scores were processed using a converter tool (http://colormine.org/color-converter, accessed on 28 March 2022) according to the methodology suggested by Sánchez-Feria et al. [28].

2.6. Statistical Analysis

Results were analyzed in SAS™ 9.0 statistical package (SAS Institute Inc., Cary, NC, USA) using the general linear model (GLM) or ANOVA procedures (either one way or two way as applicable) followed by Tukey’s pairwise mean comparisons (p < 0.05). The graphs obtained from FTIR and those corresponding to the texture profile analysis of the cheeses, were processed in the Origin(Pro), version 2022 software (OriginLab Corporation, Northampton, MA, USA). All analyses were carried out in triplicate, except where indicated. Principal component analysis (PCA) was performed using the Statistica software (v.10 Statsoft®, Tulsa, OK, USA) to obtain correlations between attributes of the cheese and their contribution to differentiate between RMCs and PMCs.

3. Results and Discussion

3.1. Strains Selection

Since Adobera cheese is considered a melting cheese, with a low pH and a high content of free amino acids resulting from protein hydrolysis [4], it is desirable to ensure that the strains proposed as starter cultures exhibit good acidifying and proteolytic capabilities [29]. Criteria selection of LAB to be used as a culture to Adobera cheese manufacturing attended to the inclusion of starter and non-starter LAB strains. The first one is recognized by its ability to produce large amounts of lactic acid. At the same time, non-starter LABs participate in producing flavor-related compounds by using residual lactose, lactate, and carbohydrates derived from glycomacropeptide and glycoproteins obtained from caseins and fat globule membranes, respectively, and mainly induce the accumulation of FAA, that act as precursors of other catabolic reactions that result in the production of volatile aroma compounds [30]. However, starter LAB are mainly represented by several species of Streptococcus, Lactococcus, Leuconostoc, and homofermentative lactobacilli; meanwhile, non-starter LAB includes several species of heterofermentative Lactobacillus [31,32]. Under this premise, A Leuconostoc sp. strain and two Lactobacillus sp. strains were selected in this study, from autochthonous Adobera cheese LAB isolates, as a possible combination of starter and non-starter LAB for Adobera cheese manufacturing. Strains were identified as Lactobacillus A-53, Lactobacillus A-151, and Lactococcus A-106.

3.2. Potential Fermentation Performance of Selected Strains

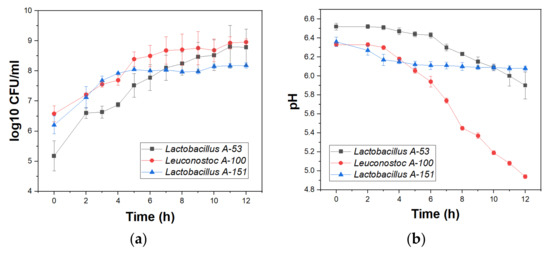

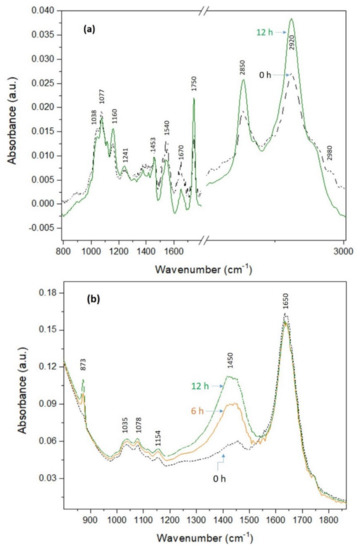

Acidification capacity of each strain, expressed as the pH reduction of single-strain inoculated skim milk maintained at 37 °C and monitored for 12 h (Figure 2a), was assessed. The average final pH was 5.20; although the lower pH was reached by the Leuconostoc strain (4.54), confirming its potential as starter strain, as it has been previously observed [31]. Kinetics, assessed by UV-vis, indicated an average lag time of three hours, followed by six hours of exponential growth (log phase) before reaching the stationary phase, as exemplified in Figure 2b. The potential fermentation performance of single strains inoculated in skim milk was also monitored by FTIR spectroscopy. Lactic acid accumulation during milk acidification was mainly observed by the increase in absorbance at 1730, 1670, 2920, and 2850 cm−1, based on the characteristic signals observed for lactic acid (Exemplified in Figure 3a) [33,34] and was primarily observed when Lactobacillus A-151 and Leuconostoc A-100 were used as inoculum. FTIR has been suitably used to assess proteolytic process involved during storage of milk products [35]. For these reason, proteolysis of single-strain inoculated skim milk was followed by the increase in absorbance values at 873 cm−1, 1035 cm−1, 1078 cm−1, and 1154 cm−1 (corresponding to the amide III region and associated to the free amino acids formation) and by changes in absorbance observed at 1450 cm−1 and 1650 cm−1 (corresponding to the amide I and amide II regions, associated to changes in protein secondary structures) [35]. Changes in absorbance at preselected wavelengths associated with proteolytic behavior were most evident when Lactobacillus strains were used for milk fermentation (exemplified in Figure 3b).

Figure 2.

(a) Growth curve of selected lactic-acid bacteria inoculated in MRS broth. (b) pH reduction of skim milk during fermentation through selected lactic acid bacteria inoculation.

Figure 3.

Evaluation of fermentation performance of selected strains over time by FTIR (a) Leuconostoc A-100 strain (changes at 1730, 1670, 2920, and 2850 cm−1 due to lactic acid accumulation); and (b) Lactobacillus A-53 strain (changes in the amide III region at 873 cm−1, 1035 cm−1, 1078 cm−1, and 1154 cm−1 due to free amino acids formation; and in the amide I and II regions at 1450 cm−1 and 1650 cm−1).

3.3. Cheese Milk Composition and Yield

The average milk composition used to produce RMC and PMC is shown in Table 1. The protein-to-fat ratio (PFR) of cheese milk used for both RMCs and PMCs was adjusted to assess whether differences between treatments were solely associated with the heat treatment of milk or starter culture usage. The average milk pH was 6.5. Average cheese yield (expressed as kg of cheese per 100 kg milk) of RMCs (8.45 ± 1.30) was significantly lower (p < 0.05) than that of PMCs (10.73 ± 1.88).

Table 1.

Average milk composition for RMC and PMC manufacture.

From a technological standpoint, cheese milk’s protein-to-fat ratio (PFR) plays a crucial role in cheese composition and yield; besides, it influences key quality features in cheese, such as texture and color. It is well-known that changes in PFR could affect both cheese fat in dry matter and moisture in nonfat substances [36]. In this context, the PFR of milk used for both RMCs and PMCs was adjusted to relate possible differences in cheeses with the application of heat treatment in milk or with the usage of starter culture. Differences in cheese yield between RMCs and PMCs could be frequently associated with pasteurization inducing structural modifications of whey proteins (mostly β-lactoglobulin denaturation, aggregate formation, and complexation with casein micelles through kappa casein interactions), producing hydrophilic sites that promote higher water retention into the cheese matrix. Diverse authors have reported increases up to 4% in cheese yield associated with milk pasteurization [37,38,39]. Another factor that could modify cheese yield is the acidification rate. PMCs cheeses exhibited increased acidification, expressed as a reduction in pH scores compared to RMCs. A higher acidity rate during cheese making has been associated with more active microorganisms in curd due to a higher initial microbial count or a more active microbial community. A rapid acid development in cheese curd has been shown to promote an accelerated colloidal calcium phosphate loss from the casein micelle during cheese syneresis, which might cause more significant water losses from curd [40].

3.4. Gross Composition

The composition and physicochemical characteristics of experimental Adobera cheeses are shown in Table 2. Dry matter content scores were higher in RMCs than PMCs (p < 0.05) and remained constant through shelf life for both kinds of cheese; besides, residual syneresis was not observed during cheese storage. On the other hand, water activity scores for both types of cheeses (RMC and PMC) were not significantly different (p > 0.05). Protein content did not significantly change for both types of cheese and remained stable during storage (p > 0.05). Meanwhile, fat content did not exhibit significant differences for both types of cheese at day 0, although dry matter decreased in 21-d RMC in comparison with its pasteurized counterpart (p < 0.05).

Table 2.

Gross composition of experimental Adobera cheeses.

Differences in fat content at day-21 could be possibly associated with a reduced ability of RMC curd to retain milk fat, with no differences in moisture or protein retention, as has been previously reported for hard cheeses when microbial coagulants are used [41]. Furthermore, a greater fluctuation was observed for fat scores in RMC samples at day 21. Higher dry matter content in RMCs might be associated with greater water retention in PMCs, mainly due to partial protein denaturation and aggregation, as previously reported [20,42]. Nonetheless, not all studies dealing with the effect of milk pasteurization in cheesemaking have found higher water retention in PMCs and could be associated with the starter culture used, as well as the lack of differences in protein content [43,44,45]. Nonetheless, higher protein contents in cheeses produced with pasteurized milk have been reported in some cases, which was associated with either whey protein retention by casein-whey protein interactions or the type of microorganisms used as starter culture and its related titratable acidity in cheese [39]. In that context, the observed decrease in fat content for RMC also could be related to the lipolytic activity of LAB in cheese, as greater lipolysis in pasteurized milk cheeses inoculated with selected LAB strains has been observed before [45].

3.5. Free Amino Acids

FAA contents as an indicator of proteolysis in experimental Adobera cheeses are shown in Table 3. Significantly (p < 0.05) higher proteolysis scores were observed in RMCs than those of PMCs at all sampling times (+44.8% at day 1; +20.9% at day 21). Although RMCs exhibited the highest FAA accumulation (0.394 mmol/g at 14 and 21 d), FAA changes over time for both types of cheese fitted a straight line (R2 = 0.897 and 0.956 for RMCs and PMCs, respectively); a steeper slope (0.0039) of PMC data than that of RMCs (0.0024) indicates that although the selected starter culture did not produce as much FAA as native lactic acid bacteria in raw milk, if given enough ripening time (or probably by slightly increasing ripening temperature), its proteolytic activity could end up equaling that of RMCs. Proteolysis, mainly expected in aged or acidified cheeses, is desirable for flavor development, and it can be controlled by reducing microbial content in milk or inactivation of selected enzymes by pasteurization [46,47]. Primary and secondary proteolysis occurs in different stages of cheese manufacturing. The first one refers to the breaking of milk caseins, and it could be observed through the electrophoretic profile of milk; meanwhile, secondary proteolysis is measured by an increase of proteins, peptides, and amino acids in the aqueous phase of cheese, which is pursued to enhance the quality and intensity of flavor development [48]. Secondary proteolysis can be measured as an increase in the trichloroacetic acid and phosphotungstic acid-soluble nitrogen fractions [48], as well as the direct quantification of FAA from citrate dispersions and Cd-ninhydrin reagent, which allows to evidence the depth of proteolysis in cheese [49]. FAA accumulation in Adobera experimental cheeses was similar to that observed in Adobera commercial cheese samples [4]. Similar results have been also reported for Pico cheese when raw milk or pasteurized milk added with LAB were used. Authors reported a greater proteolysis level (expressed as an increase of the 12% trichloroacetic acid-soluble fraction in cheese) when raw milk was used, but similar to proteolysis of pasteurized milk cheeses added with some LAB strains included Leunocostoc pseudomesenteroides and Lactococcus lactis, as starter cultures [50]. Extended proteolysis has also been reported in experimental cheese samples when starter culture is added by immersion of cheeses after overnight clothing and whey draining, without changes in pH scores [51]. However, extended proteolysis observed in PMCs in this study could be explained by the metabolic abilities of the strains used as a starter culture. It has been reported that the core microbiota of artisanal Adobera cheese is strongly composed of LAB (starter and non-starter genus) and is mainly represented by genus as Streptococcus, Lactococcus, Lactobacillus, and Leuconostoc [7]. In this context, we selected an acidifier Leuconostoc strain, that we expect would act as a starter culture, and two Lactobacillus strains to serve as non-starter culture during cheese manufacture. The last is supported by the fact that several Lactobacillus species have been considered representative of the proteolytic system of dairy LAB [52], which is essential due to the increase in proteolysis results in flavor development.

Table 3.

Free amino acids content in experimental Adobera cheeses.

3.6. Texture Profile Analysis

Table 4 shows the texture profile of experimental Adobera RMCs and PMCs. Differences in all texture attributes were observed between RMC and PMC (p < 0.05). RMCs were significantly harder and more cohesive, chewable, and resilient but less elastic than PMCs. Cheese texture is a complex parameter, highly influenced by milk pretreatment, product composition, the procedure used, and ripening time and conditions [53]. According to previous reports, compositional and primary TPA attributes of cheese are correlated [54]. For instance, a positive correlation between hardness and fat content has been reported, while the former is negatively correlated to moisture content; meanwhile, cohesiveness is usually positively correlated with moisture content and negatively correlated with fat content in a similar fashion as springiness, although this parameter is also negatively correlated with protein content [54]. Texture profile of RMCs was like that previously reported for artisanal Adobera cheese samples, especially for products obtained during the dry season [4], but are also comparable to those exhibited for other similar cheeses, such as Chihuahua cheese, a Mexican semi-hard, sliceable cheese, manufactured from cow’s milk [53]. However, differences observed between RMC and PMC for texture profiles are similar to those reported with other cheese varieties, such as Oaxaca cheese manufactured using raw milk, which exhibited higher scores for firmness, gumminess, and chewiness in comparison with its counterparts produced from pasteurized milk added with a mesophilic (Lactococcus lactis based) or thermophilic starter culture (Streptococcus based) [55]. In that study, a higher moisture content was observed in pasteurized milk cheeses, which also exhibited higher pH scores [54,55,56]. In this context, higher moisture content as exhibited by PMCs could decrease cheese firmness (the peak force at the first compression cycle), as previously reported [57]. Differences between pasteurized and raw milk cheeses (such as Cheddar and Manchego varieties) have been reported; these have been associated with heat-related beta lactoglobulin-kappa casein complexes, differences in the percentage of degradation of αs-casein, and differences in dry matter content, induced by pasteurization [43]. In order to modulate the texture profile of cheese, some LAB strains could induce an improvement of some texture attributes. This effect has been observed when Lactobacillus acidophilus is used as a probiotic strain in the manufacturing of Tulum cheese (a Turkish ewe’s milk ripened cheese), that favored the highest acidity scores (expressed as ºSH) and texture scores in comparison with Bifidobacterium supplemented cheeses [58].

Table 4.

Texture Profile of experimental Adobera Cheeses.

3.7. Cheese Color

Table 5 shows the color scores of the cheeses within the L*, a*, b* color space. No significant differences (p > 0.05) in cheese brightness (L*) were observed between PMCs and RMCs at day zero. However, a decrease in this parameter over time was observed for RMCs, becoming slightly opaquer than PMCs. On the other hand, for a* and b* values, significant differences (p < 0.05) were observed between the two types of cheese at all sampling times. No significant differences in yellowness and whiteness indexes (Table 5) were observed between RMCs and PMCs and exhibited a more yellowish, ivory color compared to that of PMCs, which appeared to be brighter and whiter. Cheese brightness (L*) has been reported to increase with moisture content and, on the contrary, a higher solids content negatively affects luminosity. Similarly, cold storage seemed to decrease cheese brightness, and this behavior was more evident in raw milk cheeses that became opaquer during the shelf life. Redness, expressed as a* scores, was higher in RMCs and increased during the shelf life of cheese; meanwhile, b* scores were higher at day-0 for RMCs, but at day-21, this parameter was more elevated in PMCs, which means an increase in yellowness of cheese, that has previously been associated to heat treatment [59]. Increasing of a* scores has also been associated with the bacterial strains used as a starter during cheese manufacturing. For instance, when a probiotic mixture, composed of Lactobacillus acidophilus and Bifidobacterium animals, was used for the manufacturing of Tulum cheese, a* scores exhibited a more significant increase than when strains were individually used, probably by oxidation or an increased number of microorganisms, as author hypothesizes [58,60].

Table 5.

Color values for raw milk (RMC) and pasteurized milk (PMC) Adobera cheese samples.

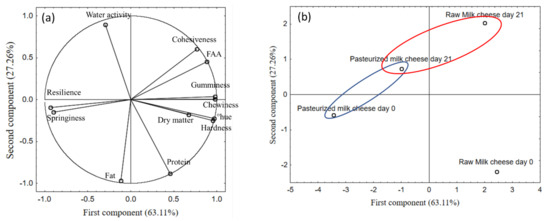

3.8. Principal Component Analysis

Principal component analysis (PCA) was used to assess pattern recognition between attributes and the use of cultured pasteurized milk in Adobera cheesemaking (Figure 4). Two principal components (PC) were enough to explain 90% of the total variance (PC1: 63.11% and PC2: 27.26%). Circle correlations plot (Figure 4a) shows the association that may exist between the different attributes of cheese. Selected attributes of the TPA analysis (hardness, cohesiveness, and chewiness) and color (expressed as °hue) of cheese may be positively correlated to FAA and protein content but less linked to water activity and fat content, since cheeses did not exhibit syneresis or dehydration during storage as usually occurs in ripened cheeses, which induced an increase in the concentration of fat and other components of cheese and, as a consequence, change in instrumental color [61]. Other milk components (including water- and fat-soluble) and changes induced on these by processes affect cheese color are vitamins and carotenoids [59]. Through location graph (Figure 4b), representing the product of PCA performed on the table of average scores, it is possible to infer that PMCs showed different compositional and texture profiles at day 0 post-manufacturing. Textural and color profile of PMCs approached to RMCs at day-21, possibly associated with extended proteolysis in PMCs that transform casein into a more soluble state that induced modification in cheese protein matrix and color, as observed in matured cheeses during ripening process [62,63].

Figure 4.

Representation of principal component analysis (PCA) applied on the average scores table for composition, texture and color of PMC and RMC samples. (a) Correlation circle and (b) two-dimensional graph of principal components for main attributes of cheese.

4. Conclusions

A combination of autochthonous Lactobacillus and Leuconostoc strains shows promising results as a starter culture for pasteurized milk Adobera cheese manufacture. Cheese yield of PMCs increased significantly (about 20%) compared to that of RMCs, probably due to their higher water content (+3.6% at day 1) but no significant changes in protein and fat contents were found between both types of cheese. On the other hand, PMCs were softer, less cohesive, and more elastic than their raw milk counterparts. Cheese whiteness and yellowness indexes did not exhibit significant differences between treatments, although higher hue values in RMCs at all times indicate slight color differences with PMCs. Higher free amino acid accumulation was observed in raw milk cheeses compared to PMCs at all sampling times (+44% at day 1, +20% at day 21), although the faster evolution over time of the latter showed that under the appropriate ripening conditions, its proteolytic activity could end up equaling that of the native microbiota in RMCs. Nonetheless, comprehensive research on additional technological features of the selected microorganisms and a precise definition of their addition rates and ratios are necessary to develop an Adobera cheese starter culture to inoculate pasteurized milk that helps standardizing the cheesemaking process and their quality features while guaranteeing product safety.

Author Contributions

Conceptualization, J.M.R.-G., R.J.D.-M. and H.R.-E.; methodology, J.M.R.-G., R.J.D.-M. and H.R.-E.; formal analysis, J.M.R.-G., H.R.-E. and L.M.A.-E.; investigation, J.M.R.-G.; writing—original draft preparation, J.M.R.-G., R.I.A.-G., Z.V. and M.D.M.-R.; review and editing, H.R.-E., R.J.D.-M. and J.M.R.-G.; supervision, H.R.-E. and R.J.D.-M.; funding acquisition, R.J.D.-M. and H.R.-E. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Instituto Politécnico Nacional through the research and postgraduate secretariat (Grant SIP-IPN 20220963).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data present in this study are available on reasonable request from the corresponding author.

Acknowledgments

Special thanks to the staff and students of the Food Engineering Laboratory at BUAP for their support in complementary cheese analyses.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Villegas-de Gante, A.; Cervantes-Escoto, F.; Cesín-Vargas, A.; Espinosa-Ortega, A.; Hernández-Montes, A.; Santos-Moreno, A.; Martínez-Campos, A. Atlas de Los Quesos Mexicanos Genuinos, 1st ed.; Colegio de Postgraduados: Texcoco, Mexico, 2014. [Google Scholar]

- González-Córdova, A.F.; Yescas, C.; Ortiz-Estrada, Á.M.; de la Rosa-Alcaraz, M.d.l.Á.; Hernández-Mendoza, A.; Vallejo-Cordoba, B. Invited Review: Artisanal Mexican Cheeses. J. Dairy Sci. 2016, 99, 3250–3262. [Google Scholar] [CrossRef] [PubMed]

- Centeno-Rodríguez, M.A.C.; Gutiérrez-Cárdenas, M.G.; Jaime-Patlán, M.; Meza-Plaza, E.F.; Montecillos-Ramírez, K.E.; Rojas-Salinas, W.B.; Ozuna, C. Genuine Mexican Cheeses: Technological Processes and Manufacturing Parameters. Agro Product. 2020, 13, 9–15. [Google Scholar] [CrossRef]

- Ruvalcaba-Gómez, J.M.; Ruiz-Espinosa, H.; Arteaga-Garibay, R.I.; Rojas-López, M.; Amador-Espejo, G.G.; Anaya-Esparza, L.M.; Delgado-Macuil, R.J. Texture, Physicochemical and Sensory Properties of Artisanal Adobera Cheese from Los Altos de Jalisco, a Genuine Mexican Cheese. Int. J. Dairy Technol. 2020, 73, 411–420. [Google Scholar] [CrossRef]

- Agudelo-López, M.A.; Cervantes-Escoto, F.; Cesín-Vargas, A.; Palacios-Rangel, M.I.; Espinoza-Ortega, A. Impact of Collective Trademarks in Mexican Artisanal Cheesemakers. Cienc. Tecnol. Agropecu. 2021, 22, e-1603. [Google Scholar] [CrossRef]

- Vázquez-Velázquez, R.; Salvador-Figueroa, M.; Adriano-Anaya, L.; DeGyves–Córdova, G.; Vázquez-Ovando, A. Use of Starter Culture of Native Lactic Acid Bacteria for Producing an Artisanal Mexican Cheese Safe and Sensory Acceptable. CYTA J. Food 2018, 16, 460–468. [Google Scholar] [CrossRef]

- Ruvalcaba-Gómez, J.M.; Delgado-Macuil, R.J.; Zelaya-Molina, L.X.; Maya-Lucas, O.; Ruesga-Gutiérrez, E.; Anaya-Esparza, L.M.; Villagrán-de la Mora, Z.; López-de la Mora, D.A.; Arteaga-Garibay, R.I. Bacterial Succession through the Artisanal Process and Seasonal Effects Defining Bacterial Communities of Raw-Milk Adobera Cheese Revealed by High Throughput DNA Sequencing. Microorganisms 2020, 9, 24. [Google Scholar] [CrossRef] [PubMed]

- Montes de Oca-Flores, E.; Cruz-Flores, M.A.; Espinoza-Ortega, A. Physicochemical and Microbiological Evaluation of Traditional Queso Molido (Ground Cheese) during Maturation. Agro Product. 2021, 14, 149–153. [Google Scholar] [CrossRef]

- De la Rosa-Alcaraz, M.d.l.Á.; Ortiz-Estrada, Á.M.; Heredia-Castro, P.Y.; Hernández-Mendoza, A.; Reyes-Díaz, R.; Vallejo-Cordoba, B.; González-Córdova, A.F. Poro de Tabasco Cheese: Chemical Composition and Microbiological Quality during Its Artisanal Manufacturing Process. J. Dairy Sci. 2020, 103, 3025–3037. [Google Scholar] [CrossRef]

- Adame-Gómez, R.; Muñoz-Barrios, S.; Castro-Alarcón, N.; Leyva-Vázquez, M.-A.; Toribio-Jiménez, J.; Ramírez-Peralta, A. Prevalence of the Strains of Bacillus Cereus Group in Artisanal Mexican Cheese. Foodborne Pathog. Dis. 2020, 17, 8–14. [Google Scholar] [CrossRef]

- González Ariceaga, C.C.; Afzal, M.I.; Umer, M.; Abbas, S.; Ahmad, H.; Sajjad, M.; Parvaiz, F.; Imdad, K.; Imran, M.; Maan, A.A.; et al. Physicochemical, Sensorial and Microbiological Characterization of PoroCheese, an Artisanal Mexican Cheese Made from Raw Milk. Foods 2019, 8, 509. [Google Scholar] [CrossRef]

- Escobar-Zepeda, A.; Sanchez-Flores, A.; Quirasco Baruch, M. Metagenomic Analysis of a Mexican Ripened Cheese Reveals a Unique Complex Microbiota. Food Microbiol. 2016, 57, 116–127. [Google Scholar] [CrossRef] [PubMed]

- Aldrete-Tapia, A.; Escobar-Ramírez, M.C.; Tamplin, M.L.; Hernández-Iturriaga, M. High-Throughput Sequencing of Microbial Communities in Poro Cheese, an Artisanal Mexican Cheese. Food Microbiol. 2014, 44, 136–141. [Google Scholar] [CrossRef] [PubMed]

- Cervantes-Escoto, F.; Villegas-de Gante, A.; Cesín-Vargas, A. Caracterización de La Cadena Agroindustrial Del Queso Adobera de Los Altos de Jalisco, México. In Proceedings of the 1er Simposio de Los Quesos Mexicanos Genuinos, Texcoco, Mexico State, Mexico, 18 May 2016. [Google Scholar]

- Ruvalcaba-Gómez, J.M.; Arteaga-Garibay, R.I.; Delgado-Macuil, R.J.; Villaseñor-González, F.; Montes-Oceguera, L. Exploración Del Perfil de Inocuidad Microbiológica de Queso Adobera Elaborado Artesanalmente. In Investigaciones en Ciencia e Inocuidad de Alimentos; Orozco-Hernández, L.O., Garay-Martínez, L.E., Torres-Vitela, M.R., Eds.; Universidad de Guadalajara: Guadalajara, Jalisco, México, 2017; Volume 1, pp. 738–741. [Google Scholar]

- Torres-Vitela, M.R.; Mendoza-Bernardo, M.; Castro-Rosas, J.; Gomez-Aldapa, C.A.; Garay-Martinez, L.E.; Navarro-Hidalgo, V.; Villarruel-López, A. Incidence of Salmonella, Listeria monocytogenes, Escherichia coli O157:H7, and Staphylococcal Enterotoxin in Two Types of Mexican Fresh Cheeses. J. Food Prot. 2012, 75, 79–84. [Google Scholar] [CrossRef]

- Havelaar, A.; Grace, D.; Wu, F. Foodborne Diseases from Dairy Products in Developing Countries: Hazards and Health Implications. In Proceedings of the 2019 Annual Meeting of the American Dairy Science Association, Cincinnati, OH, USA, 23–26 June 2019. [Google Scholar]

- Licitra, G.; Caccamo, M.; Lortal, S. Artisanal Products Made With Raw Milk. In Raw Milk; Elsevier: Amsterdam, The Netherlands, 2019; pp. 175–221. [Google Scholar]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Fundamentals of Cheese Science; Springer US: Boston, MA, USA, 2017. [Google Scholar]

- Tarhan, Ö.; Kaya, A. Investigation of the Compositional and Structural Changes in the Proteins of Cow Milk When Processed to Cheese. LWT 2021, 151, 112102. [Google Scholar] [CrossRef]

- Scatassa, M.L.; Gaglio, R.; Cardamone, C.; Macaluso, G.; Arcuri, L.; Todaro, M.; Mancuso, I. Anti-Listeria Activity of Lactic Acid Bacteria in Two Traditional Sicilian Cheeses. Ital. J. Food Saf. 2017, 6, PMC5337783. [Google Scholar] [CrossRef][Green Version]

- Murugesan, S.; Reyes-Mata, M.P.; Nirmalkar, K.; Chavez-Carbajal, A.; Juárez-Hernández, J.I.; Torres-Gómez, R.E.; Piña Escobedo, A.; Maya, O.; Hoyo-Vadillo, C.; Ramos-Ramírez, E.G.; et al. Profiling of bacterial and fungal communities of Mexican cheeses by high throughput DNA sequencing. Food Res. Int. 2018, 113, 371–381. [Google Scholar] [CrossRef]

- Association of Officiating Analytical Chemists (AOAC). Official Method of Analysis, 18th ed.; Association of Officiating Analytical Chemists (AOAC): Washington, DC, USA, 2005. [Google Scholar]

- Wehr, H.; Frank, J.F. Standard Methods for the Examination of Dairy Products, 17th ed.; American Public Health Association: Washington, DC, USA, 2004. [Google Scholar]

- Wick, C.; Nienaber, U.; Anggraeni, O.; Shellhammer, T.H.; Courtney, P.D. Texture, Proteolysis and Viable Lactic Acid Bacteria in Commercial Cheddar Cheeses Treated with High Pressure. J. Dairy Res. 2004, 71, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.S.; Al-Attabi, Z.H.; Al-Habsi, N.; Al-Khusaibi, M. Measurement of Instrumental Texture Profile Analysis (TPA) of Foods. In Techniques to Measure Food Safety and Quality; Springer International Publishing: Cham, Switzerland, 2021; pp. 427–465. [Google Scholar]

- Hirschler, R. Whiteness, Yellowness, and Browning in Food Colorimetry. A Critical Review. In Color in Food. Technological and Psychophysical Aspects; Luis Caivano, J., del Pilar Buera, M., Eds.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Boca Raton, FL, USA, 2012; pp. 93–104. [Google Scholar]

- Sánchez-Feria, C.; Salinas Moreno, Y.; Ybarra-Moncada, M.D.C.; González-Hernández, V.A.; Machuca-Sánchez, M.L. Effect of the Dehydration Method of Hibiscus Sabdariffa L. Calyces on the Quality of Their Aqueous Extracts. Emir. J. Food Agric. 2021, 33, 159–170. [Google Scholar]

- Engels, W.; Dusterhoft, E.-M.; Huppertz, T. Starter Cultures for Cheese Manufacture. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Settanni, L.; Moschetti, G. Non-starter lactic acid bacteria used to improve cheese quality and provide health benefits. Food Microbiol. 2010, 27, 691–697. [Google Scholar] [CrossRef]

- Gobbetti, M.; Di Cagno, R.; Calasso, M.; Neviani, E.; Fox, P.F.; De Angelis, M. Drivers that establish and assembly the lactic acid bacteria biota in cheeses. Trends Food Sci. Technol. 2018, 78, 244–254. [Google Scholar] [CrossRef]

- Nieto-Arribas, P.; Seseña, S.; Poveda, J.M.; Palop, L.; Cabezas, L. Genotypic and technological characterization of Leuconostoc isolates to be used as adjunct starters in Manchego cheese manufacture. Food Microbiol. 2010, 27, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Paucean, A.; Vodnar, D.-C.; Socaci, S.-A.; Socaciu, C. Carbohydrate Metabolic Conversions to Lactic Acid and Volatile Derivatives, as Influenced by Lactobacillus plantarum ATCC 8014 and Lactobacillus casei ATCC 393 Efficiency during in Vitro and Sourdough Fermentation. Eur. Food Res. Technol. 2013, 237, 679–689. [Google Scholar] [CrossRef]

- Păucean, A.; Vodnar, D.C.; Mureșan, V.; Fetea, F.; Ranga, F.; Man, S.M.; Muste, S.; Socaciu, C. Monitoring Lactic Acid Concentrations by Infrared Spectroscopy: A New Developed Method for Lactobacillus Fermenting Media with Potential Food Applications. Acta Aliment. 2017, 46, 420–427. [Google Scholar] [CrossRef]

- Ranvir, S.; Sharma, R.; Gandhi, K.; Upadhyay, N.; Mann, B. Assessment of Proteolysis in Ultra-high Temperature Milk Using Attenuated Total Reflectance–Fourier Transform Infrared Spectroscopy. Int. J. Dairy Technol. 2020, 73, 366–375. [Google Scholar] [CrossRef]

- Guinee, T.P.; Mulholland, E.O.; Kelly, J.; Callaghan, D.J.O. Effect of Protein-to-Fat Ratio of Milk on the Composition, Manufacturing Efficiency, and Yield of Cheddar Cheese. J. Dairy Sci. 2007, 90, 110–123. [Google Scholar] [CrossRef]

- Ali, F.; Wang, Z.-X. Effect of Pasteurization on the Enzymatic Cross-Linking of Milk Proteins by Microbial Transglutaminase in View of Milk Fat Globule Membrane Isolation. Food Biosci. 2021, 43, 101100. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Chronakis, I.S. Crosslinking of Milk Proteins by Microbial Transglutaminase: Utilization in Functional Yogurt Products. Food Chem. 2018, 245, 620–632. [Google Scholar] [CrossRef]

- Morales-Celaya, M.F.; Lobato-Calleros, C.; Alvarez-Ramirez, J.; Vernon-Carter, E.J. Effect of Milk Pasteurization and Acidification Method on the Chemical Composition and Microstructure of a Mexican Pasta Filata Cheese. LWT-Food Sci. Technol. 2012, 45, 132–141. [Google Scholar] [CrossRef]

- Lucey, J.A. Cheese|Rennet-Induced Coagulation of Milk. In Encyclopedia of Dairy Sciences; Elsevier: Amsterdam, The Netherlands, 2011; pp. 579–584. [Google Scholar]

- D’Incecco, P.; Hogenboom, J.A.; Rosi, V.; Cabassi, G.; Pellegrino, L. Effects of Microbial Coagulants from Rhyzomucor Miehei on Composition, Sensory and Textural Characteristics of Long-Ripened Hard Cheeses. Food Chem. 2022, 370, 131043. [Google Scholar] [CrossRef]

- Guinee, T.P. Effect of High-Temperature Treatment of Milk and Whey Protein Denaturation on the Properties of Rennet–Curd Cheese: A Review. Int. Dairy J. 2021, 121, 105095. [Google Scholar] [CrossRef]

- Pappa, E.C.; Kondyli, E.; Samelis, J. Microbiological and Biochemical Characteristics of Kashkaval Cheese Produced Using Pasteurised or Raw Milk. Int. Dairy J. 2019, 89, 60–67. [Google Scholar] [CrossRef]

- Buffa, M.N.; Trujillo, A.J.; Pavia, M.; Guamis, B. Changes in Textural, Microstructural, and Colour Characteristics during Ripening of Cheeses Made from Raw, Pasteurized or High-Pressure-Treated Goats’ Milk. Int. Dairy J. 2001, 11, 927–934. [Google Scholar] [CrossRef]

- Hickey, D.K.; Kilcawley, K.N.; Beresford, T.P.; Wilkinson, M.G. Lipolysis in Cheddar Cheese Made from Raw, Thermized, and Pasteurized Milks. J. Dairy Sci. 2007, 90, 47–56. [Google Scholar] [CrossRef]

- Grappin, R.; Beuvier, E. Possible Implications of Milk Pasteurization on the Manufacture and Sensory Quality of Ripened Cheese. Int. Dairy J. 1997, 7, 751–761. [Google Scholar] [CrossRef]

- Hougaard, A.B.; Ardö, Y.; Ipsen, R.H. Cheese Made from Instant Infusion Pasteurized Milk: Rennet Coagulation, Cheese Composition, Texture and Ripening. Int. Dairy J. 2010, 20, 449–458. [Google Scholar] [CrossRef]

- Rank, T.C.; Grappin, R.; Olson, N.F. Secondary Proteolysis of Cheese during Ripening: A Review. J. Dairy Sci. 1985, 68, 801–805. [Google Scholar] [CrossRef]

- Folkertsma, B.; Fox, P.F. Use of the Cd-Ninhydrin Reagent to Assess Proteolysis in Cheese during Ripening. J. Dairy Res. 1992, 59, 217–224. [Google Scholar] [CrossRef]

- De Aguiar e Câmara, S.P.; Maduro Dias, C.; Rocha, L.; Dapkevicius, A.; Duarte Rosa, H.J.; de Borba, A.E.S.; Silveira, M.d.G.; Malcata, F.X.; de Lurdes Enes Dapkevicius, M. Assessment of Autochthonous Lactic Acid Bacteria as Starter Cultures for Improved Manufacture of Pico Cheese Using a Cheese Model. Int. Dairy J. 2022, 128, 105294. [Google Scholar] [CrossRef]

- Öründü, S.; Tarakçı, Z. Effects of Different Starter Culture Applications Pre- and Post-Scalding on the Biochemical and Sensory Properties of Pasta Filata Type Cheeses. LWT 2021, 136, 110288. [Google Scholar] [CrossRef]

- Kok, J.; de Vos, W.M. The Proteolytic System of Lactic Acid Bacteria. In Genetics and Biotechnology of Lactic Acid Bacteria; Springer Netherlands: Dordrecht, The Netherlands, 1994; pp. 169–210. [Google Scholar]

- Sánchez-Gamboa, C.; Hicks-Pérez, L.; Gutiérrez-Méndez, N.; Heredia, N.; García, S.; Nevárez-Moorillón, G. Microbiological Changes during Ripening of Chihuahua Cheese Manufactured with Raw Milk and Its Seasonal Variations. Foods 2018, 7, 153. [Google Scholar] [CrossRef]

- Álvarez, S.; Rodríguez, V.; Ruiz, M.E.; Fresno, M. Correlaciones de Textura y Color Instrumental Con La Composición Química de Quesos de Cabra Canarios. Arch. Zootec. 2007, 56, 663–666. [Google Scholar]

- Sandoval-Copado, J.; Orozco-Villafuerte, J.; Pedrero-Fuehrer, D.; Colín-Cruz, M.A. Sensory Profile Development of Oaxaca Cheese and Relationship with Physicochemical Parameters. J. Dairy Sci. 2016, 99, 7075–7084. [Google Scholar] [CrossRef] [PubMed]

- Creamer, L.K.; Olson, N.F. Rheological Evaluation of Maturing Cheddar Cheese. J. Food Sci. 1982, 47, 631–636. [Google Scholar] [CrossRef]

- Golin Bueno Costa, R.; Caiafa Junior, A.; Gomes da Cruz, A.; Sobral, D.; Gonçalves Costa Júnior, L.C.; Jacinto de Paula, J.C.; Magalhães Machado Moreira, G.; Martins Teodoro, V.A. Effect of Partial Replacement of Sodium Chloride with Potassium Chloride on the Characteristics of Minas Padrão Cheese. Int. Dairy J. 2019, 91, 48–54. [Google Scholar] [CrossRef]

- Tomar, O. The Effects of Probiotic Cultures on the Organic Acid Content, Texture Profile and Sensory Attributes of Tulum Cheese. Int. J. Dairy Technol. 2019, 72, 218–228. [Google Scholar] [CrossRef]

- Sert, D.; Akin, N.; Aktumsek, A. Lipolysis in Tulum Cheese Produced from Raw and Pasteurized Goats’ Milk during Ripening. Small Rumin. Res. 2014, 121, 351–360. [Google Scholar] [CrossRef]

- Khanal, B.K.S.; Bhandari, B.; Prakash, S.; Liu, D.; Zhou, P.; Bansal, N. Modifying Textural and Microstructural Properties of Low Fat Cheddar Cheese Using Sodium Alginate. Food Hydrocoll. 2018, 83, 97–108. [Google Scholar] [CrossRef]

- Diezhandino, I.; Fernández, D.; Sacristán, N.; Combarros-Fuertes, P.; Prieto, B.; Fresno, J.M. Rheological, Textural, Colour and Sensory Characteristics of a Spanish Blue Cheese (Valdeón Cheese). LWT-Food Sci. Technol. 2016, 65, 1118–1125. [Google Scholar] [CrossRef]

- Chudy, S.; Bilska, A.; Kowalski, R.; Teichert, J. Colour of Milk and Milk Products in CIE L*a*b* Space. Med. Weter 2020, 76, 77–81. [Google Scholar] [CrossRef]

- Milovanovic, B.; Djekic, I.; Miocinovic, J.; Djordjevic, V.; Lorenzo, J.M.; Barba, F.J.; Mörlein, D.; Tomasevic, I. What Is the Color of Milk and Dairy Products and How Is It Measured? Foods 2020, 9, 1629. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).