Abstract

Waste management and production of clean and affordable energy are two main challenges that our societies face. Food waste (FW), in particular, can be used as a feedstock for the production of ethanol because of its composition which is rich in cellulose, hemicellulose and starch. However, the cost of the necessary enzymes used to convert FW to ethanol remains an obstacle. The on-site production of the necessary enzymes could be a possible solution. In the present study, the multienzyme production by the fungus Fusarium oxysporum F3 under solid state cultivation using different agroindustrial residues was explored. Maximum amylase, glucoamylase, endoglucanase, b-glucosidase, cellobiohydrolase, xylanase, b-xylosidase and total cellulase titers on wheat bran (WB) were 17.8, 0.1, 65.2, 27.4, 3.5, 221.5, 0.7, 0.052 and 1.5 U/g WB respectively. F. oxysporum was used for the hydrolysis of FW and the subsequent ethanol production. To boost ethanol production, mixed F. oxysporum and S. cerevisiae cultures were also used. Bioethanol production by F. oxysporum monoculture reached 16.3 g/L (productivity 0.17 g/L/h), while that of the mixed culture was 20.6 g/L (productivity 1.0 g/L/h). Supplementation of the mixed culture with glucoamylase resulted in 30.3 g/L ethanol with a volumetric productivity of 1.4 g/L/h.

1. Introduction

Food waste has been identified as a big economic, social and environmental problem nowadays. According to the official statistics published by Eurostat, each year, more than 240,000 t of waste is produced in the EU [1]. Bio-waste, the organic fraction of municipal solid waste, i.e., garden, kitchen and food waste, accounts for one third of the total waste and is considered to be a valuable resource that could be used as raw material for the production of high value-added products. This fact is also reflected in the updated Bioeconomy Strategy of the EU. A sustainable bioeconomy can turn bio-waste, residues and discards into valuable resources and can create innovations and incentives to help retailers and consumers cut food waste by 50% by 2030 [2]. However, the use of food by-products and the conversion of food waste is still limited. This is due to current limitations in its quantification along the food supply chain, limited data on its quality and level of homogeneity, and differences in national implementations of the waste legislation [2].

The composition of food waste, as already said, is not stable. It presents significant variations related to the season, the area, and the dietary habits of the population. Despite the inevitable variation in the composition of food waste, it can indisputably be said that it is rich in carbohydrates, proteins, lipids and minerals which make it an ideal raw material for the production of biofuels through microbial conversion [3,4]. The exploitation of food waste for the production of biofuels is also in line with the 2030 Agenda for Sustainable Development set by the UN in 2015 [5]. More precisely, it is directly related to the Sustainable Development Goals: 7. Affordable and Clean Energy, 12. Responsible Consumption and Production and 13. Climate Action. At the EU level, the importance of producing biofuels from bio-waste is reflected in the Renewable Energy Directive 2009/28/EC [6] and the recently adopted recast of the Renewable Energy Directive a.k.a. RED II [7]. The aforementioned legislation defines as advanced biofuels the ‘biofuels that are produced from the feedstocks listed in Part A of Annex IX’ that includes among others, the biomass fraction of municipal solid waste, the biomass fraction of industrial waste as well as bio-waste from households. The directive sets a sub-target of 3.5% for advanced biofuels within the 14% target for renewable energy in transport in 2030. Moreover, those biofuels will continue to count double towards the targets.

From a technical point of view, bioethanol production from lignocellulosic materials is a well- studied process and has been recently reviewed [8]. It includes the following processes: pretreatment, enzymatic hydrolysis, fermentation and ethanol recovery. The pretreatment phase aims at modifying the structural characteristics of the raw material facilitating the enzymes’ access and maximizing sugar monomers production. The enzymatic hydrolysis targets the structural carbohydrates starch, cellulose and hemicellulose. During this step, pentoses and hexoses that can be further used in the fermentation step are liberated. In the subsequent fermentation step, microorganisms metabolize those readily available sugars, producing ethanol, which is subsequently recovered through distillation.

In terms of cost, the most demanding step, which significantly increases the total cost of the production of bioethanol and is identified as a barrier in the further deployment of ethanol production, is enzymatic hydrolysis [9]. A possible solution to this problem is the on-site production of the relevant enzymes instead of using commercially available enzymes [10]. Few organisms are able to produce the necessary enzymes; most of them belong to the species Aspergillus sp., Penicillium sp., Trichoderma sp. Neurospora sp. [11].

The filamentous fungus Fusarium oxysporum could be used both for cellulolytic enzyme production and for ethanol production because of its ability to ferment both hexoses and pentoses [12,13]. The main aim of the present work is, on the one hand, the induction of the metabolic system of F. oxysporum to produce the relevant enzymes by using different raw materials (namely wheat straw, wheat bran, corn cob), and on the other hand, to exploit those enzymes for the hydrolysis of food waste (FW) in order to produce ethanol. Focusing on increasing ethanol production, the addition of a glucoamylase was studied, as well as the use of mixed F. oxysporum and Saccharomyces cerevisiae cultures.

2. Materials and Methods

2.1. Raw Materials, Reagents, Microorganism

The food waste (FW) used in the present study was provided by Professor Gerasimos Lyberatos (Organic Chemical Technology Laboratory, School of Chemical Engineering, National Technical University of Athens), in dry form and with an average particle size of approximately 3 mm. FW were household food wastes from the Municipality of Halandri, Greece. The concept of drying focuses on the dehydration of the material resulting in a significant reduction of its mass and volume, thus facilitating its storage and protecting the readily fermentable sugars by inhibiting microbial activity due to low moisture content.

Wheat straw (WS), wheat bran (WB), and corn cobs (CC) were chopped into particles of less than 3 mm in diameter.

All chemicals were of analytical grade. Commercial glucoamylase (Spirizyme® Fuel) was kindly provided by Novozymes Corporation (Denmark).

The laboratory strain F3 of F. oxysporum, isolated from cumin [14], was used in the present study. The stock culture was maintained on potato-dextrose agar (PDA).

2.2. Chemical Analysis of FW

Moisture, ash, crude fat, crude protein (Kjeldhal method) and total starch content were determined according to standard methods [15]. Pectic polysaccharides were determined according to Phatak et al. [16], while water-soluble materials, cellulose, hemicellulose and acid insoluble lignin content as described by Sluiter et al. [17]. Analysis was carried out in triplicate.

2.3. Pretreatment of FW

Dry FW were pretreated as described elsewhere [18]. Briefly, FW at concentration of 30% w/v was pretreated at 100 °C for 1 h in the presence of 1 g sulfuric acid/100 g of dry FW. Following pH adjustment to 6.0, the pretreated material (the whole slurry) was used in fermentation experiments.

2.4. Media and Growth Conditions for the in Situ Production of Enzymes

Solid-state cultivation (SSC) was carried out in 100-mL Erlenmeyer flasks containing 3.0 g of dry carbon source (WB, WS or CC) moistened with Toyama’s mineral medium (in g·L−1: (NH4)2SO4, 10; KH2PO4, 3; MgSO4·7H2O, 0.5; CaCl2, 0.5) [19]. The initial culture pH was adjusted to 6.0 and the moisture level at 75%. Following heat sterilization (121°C) for 20 min, each flask was inoculated with 1 mL spore suspension (approximately 107 conidia) and incubated at 30 °C under static conditions. Experiments were carried out in duplicate.

2.5. Enzyme Extraction

After suitable periods of time, enzymes were extracted from the SSC with 10-fold (v/w) 50 mM citrate-phosphate buffer pH 6.0 by shaking (250 rpm) at 25 °C for 60 min. The suspended materials and fungal biomass were separated by centrifugation (12,000 x g at 4 °C for 15 min) and the clarified supernatant was used for enzyme activity measurements.

2.6. Enzymatic Hydrolysis of FW

SSC at maximum enzyme production was supplemented with the pretreated FW (SSC to FW ratio, 1/10 w/w) and the appropriate amount of the commercial glucoamylase (Spirizyme® Fuel) in order to achieve 20 and 40 Units of glucoamylase per g starch. Microbial contamination was prevented by the addition of sodium azide (0.02% w/v). Hydrolysis was performed at 50 ± 1 °C in a rotary shaker (250 rpm). Samples were withdrawn periodically, centrifuged (10,000 x g for 10 min), and analyzed for glucose.

2.7. Conversion of FW into Bioethanol

Food waste was converted into ethanol applying of a two-phases process where enzymes production under SSC was combined with simultaneous saccharification and fermentation (SSF) of FW by the mesophilic fungus F. oxysporum F3 or by a mixed culture of the latter with the yeast S. cerevisiae. Initially F. oxysporum F3 was grown under SSC, as described above for the production of the cellulolytic, hemicellulolytic and amylolytic enzymes. Whole SSC (fungal mycelia and the in situ produced enzymes) was transferred to the pretreated FW (SSC to FW ratio, 1/10 w/w). Fermentation was carried out in a rotary shaker operating at 30 ± 1 °C and 80 rpm in Erlenmeyer flasks provided with special rubber stoppers, which ensured anaerobic conditions and allowed release of produced carbon dioxide.

In the case of mixed microbial culture compressed baker’s yeast (Yiotis, Athens, Greece) corresponding to 15 mg yeast per gram of initial dry FW was added.

2.8. Analytical Methods

Endoglucanase (EG), exoglucanase (EXG), xylanase (XYL), total cellulase (FPU) and amylase (AMYL) activities were assayed on carboxymethyl cellulose, Avicel, birchwood xylan filter paper and starch respectively, as described [18,20]. The activities of β-glucosidase (β-GLU) β-xylosidase (β-XYL) and glucoamylase (GLAMYL) were determined spectrophotometrically using the respective p-nitrophenyl glycosides as substrates [18,20]. All assays were carried out at 50 °C and pH 5.0. Blanks with inactivated enzyme (after boiling for 15 min) were used as a reference.

One unit (U) of enzyme activity was defined as the amount of enzyme liberating 1 μmole of product per min.

Glucose concentration was determined using a commercially available kit (Biosis S.A., Athens, Greece) that employed the Glucose Oxidase–Peroxidase (GOX–PER) method.

Ethanol analysis was conducted in an Aminex HPX-87H (Bio-Rad, 300 x 7.8 mm, particle size 9 μm) chromatography column. Mobile phase was 5 mM H2SO4 in degassed HPLC- water at a flow rate of 0.6 mL/min and column temperature was 40 °C [21].

3. Results and Discussion

3.1. Food Waste Composition

In general, the composition of food waste is complex and includes oil and water, as well as spoiled and leftover foods from kitchen wastes and markets. These substances are mainly composed of soluble sugars, carbohydrate polymers (pectin, starch, cellulose and hemicelluloses), lignin, proteins, lipids and a remaining, smaller inorganic part. High moisture content leads to rapid decomposition of the organic wastes and the production of unpleasant odors, which can attract flies and bugs, which are vectors for various diseases [22]. The feedstock used in the present study was provided in dry form as mentioned above. Compositional analysis of FW is presented in Table 1.

Table 1.

Chemical analysis of dried FW.

The composition of FW, carbohydrates, protein, makes it an excellent feedstock for the production of biofuels and bio-based chemicals through microbial conversion. The polysaccharide content of FW is difficult to be used by ethanol producing microorganisms such as Saccharomyces cerevisiae. Different commercial enzymes (amylase, glucoamylase, carbohydrase, cellulase) have been used to improve the saccharification of FW [23].

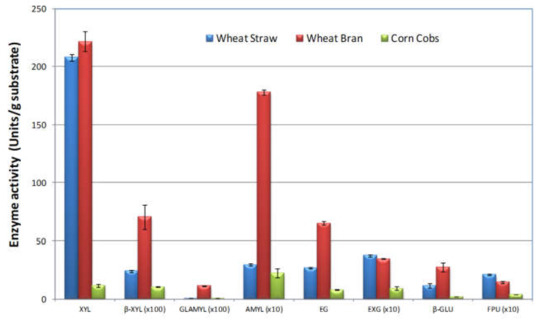

3.2. Multienzyme Production under Solid-State Cultivation

To make the enzymatic hydrolysis of FW more cost-effective, the enzymes should be produced on-site from a cheap feedstock [11]. SSC has several biotechnological advantages such as higher fermentation capacity, higher end-product stability, lower catabolic repression and cost-effective technology [24,25]. SSC is an attractive process for filamentous fungus cultivation because the solid substrates have characteristics similar to the natural habitat of the fungi, resulting in improved growth and secretion of a wide range of enzymes. Selecting the appropriate substrate is an extremely important aspect of SSC, as the solid material will act as a physical support and nutrient source [26]. In the present study three different agroindustrial residues, wheat straw (WS), wheat bran (WB) and corn cobs (CC) were evaluated for the production of cellulolytic, hemicellulolytic and amylolytic enzymes by the mesophilic fungus F. oxysporum F3. Wheat bran (WB), a nutrient-richer intermediate of the wheat processing industry, was the most effective carbon source for multi-enzyme production by F. oxysporum F3 (Figure 1). Implementation of corn cobs (CC) and wheat straw (WS) particles as substrates was associated with lower enzyme titres. Maximum enzyme activities were recorded in the 5th day of fermentation. Amylase activity was found 5- fold higher, than that produced on WS and CC, while traces of glucoamylase was produced on WS and CC. Maximum endoglucanase, b-glucosidase cellobiohydrolase, xylanase and b-xylosidase titers on WB were 65.2, 27.4, 3.5, 221.5, 0.7, 0.052 U/g WB, respectively, while total cellulase activity was 1.5 FPU/g WB.

Figure 1.

Production of cellulolytic, hemicellulolytic and amylolytic enzymes by F. oxysporum F3 grown under solid state cultivation on wheat straw, wheat bran and corn cobs as carbon sources.

For comparison, F. oxysporum F3 grown under SSC on corn stover as carbon source resulted in final endoglucanase, b-glucosidase, cellobiohydrolase, xylanase, b-xylosidase titers of 211, 0.088, 3.9, 1216, 0.052 U/g, respectively [27]. Futhermore, Trichoderma virens grown on alkali-treated WS under SSC produced 123.26 and 348 U/g endoglucase and xylanase, respectively [28].

It is well documented that the type and composition of the carbohydrates present in WB are suitable for induction of cellulases, hemicellulases and amylases from filamentous fungi under SSC [24,25]. Since the target of the present study is the production of a multi-enzyme system capable of hydrolysing the main polysaccharides present in FW, WB was chosen for further experiments.

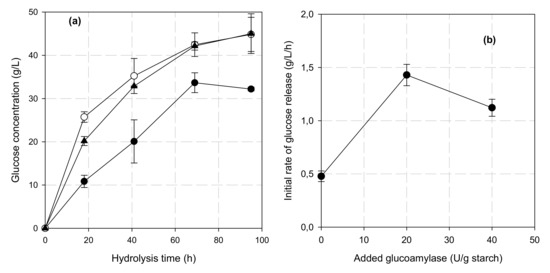

3.3. Hydrolysis of FW by the On-Site Produced Multienzyme System of F. Oxysporum F3

Multienzyme system of F. oxyporum F3 produced under SSC on WB as carbon source was evaluated in FW hydrolysis. Furthermore, due to low glucoamylase titer produced the hydrolysis mixture was supplemented with 20 and 40 Units/g FW. The concentration of glucose increased gradually with time and reached a constant value at 69 h (Figure 2a). Glucose release applying F. oxysporum enzyme system was found 33.7 g/L corresponding to a hydrolysis yield of 47.4% (based on cellulose and starch content of FW). It should be mentioned that glucose release due to pretreatment of FW accounted for 11.2 g/L. Supplementation of hydrolysis mixture with glucoamylase (Spirizyme® Fuel) increased glucose release by approximately 25%.

Figure 2.

(a) Time course of glucose release during FW hydrolysis by F. oxysporum F3 multienzyme system (●), supplemented with 20 (○), 40 (▲) Units/g starch Spirizyme® Fuel. (b) Initial rate of glucose release.

The amount of added glucoamylase affects the initial rate of glucose release (Figure 2b) during hydrolysis. Addition of 20 U/g starch glucoamylase resulted in a 66% improvement in the rate of glucose release while further increase in glucoamylase load did not improve the result.

3.4. Bioethanol Production by Mixed Microbial Culture of F. Oxysporum F3 with the Yeast S. Cerevisiae

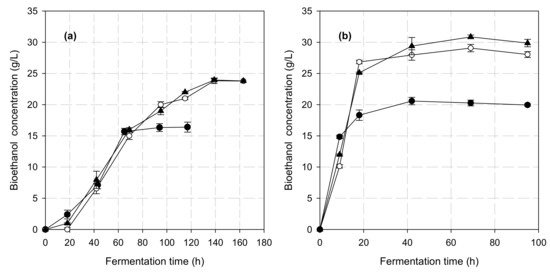

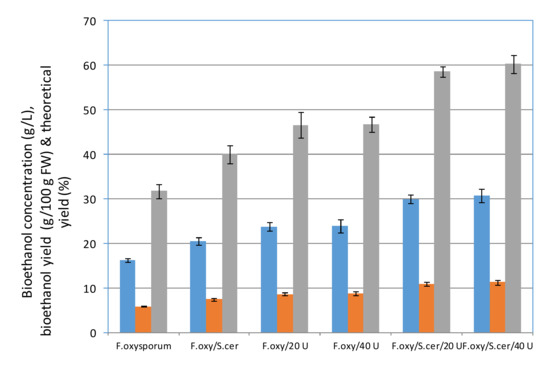

The processes generally used in bioethanol production are simultaneous saccharification and fermentation (SSF) and separate hydrolysis and fermentation (SHF). Performing hydrolysis and fermentation in a single step, the SSF process, has several advantages over SHF. In SSF, end-product inhibition of b-glucosidase is avoided, and the need for separate reactors is eliminated [29]. In the present study FW were converted to bioethanol applying SSF process in batch mode. Ethanol production from FW by mono-culture of F. oxysporum F3 reached 16.3 g/L after 94 h of fermentation (Figure 3a) corresponding to 31.8% of the maximum theoretical based on the soluble fraction and the carbohydrate content (cellulose, starch and hemicellulose) of FW (Figure 4).

Figure 3.

Bioethanol production from FW by (a) mono-culture of F. oxysporum F3 (●), supplemented with 20 (○) and 40 (▲) Units/g starch Spirizyme® Fuel; and (b) mixed microbial culture of F. oxysporum F3 with the yeast S. cerevisiae (●), supplemented with 20 (○) and 40 (▲) Units/g starch Spirizyme® Fuel.

Figure 4.

Maximum values of bioethanol production (g/L) (■), bioethanol yield (g/100 g FW) (■), theoretical yield (%) (■).

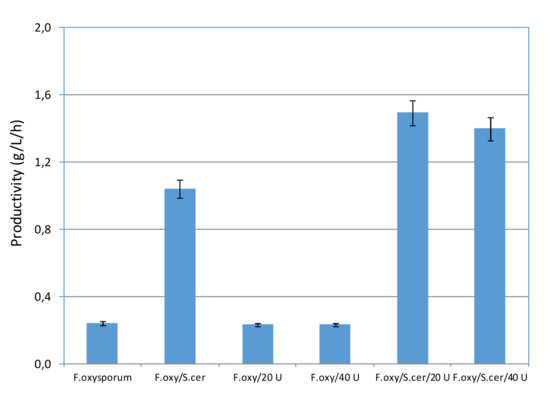

When the fermentation medium was supplemented with 20 U/g starch glucoamylase, ethanol titer was 23.9 g/L (corresponding to 46.8.0% of the maximum theoretical). Increase in glucoamylase supplementation did not improve bioethanol production (Figure 3a). Maximum ethanol production was recorded at 139 h of fermentation, and no further increase in ethanol concentration was found when fermentation was extended to 163 h. Bioethanol volumetric productivities were in the range of 0.17 to 0.23 g/L/h (Figure 5).

Figure 5.

Bioethanol volumetric productivities.

To improve the sugar assimilation rate, mixed culture of F. oxysporum F3 with the yeast S. cerevisiae were applied with the same bioconversion setup. The results are presented in Figure 3b. As can be seen, ethanol concentration at 18 h of process was about 18.3 g/L in the mixed culture of F. oxysporum F3 with S. cerevisiae approximately 7.5 times higher than the corresponding value achieved with the mono-culture of F. oxysporum F3. Fermentation was completed after 42 h using mixed microbial culture and ethanol production reached 20.6 g/L (corresponding to 40.1% of the maximum theoretical) (Figure 4). Ethanol concentrations of about 26.8 and 25.1 g/L were reached at 18 h when the mixed cultures were supplemented with 20 and 40 U/g starch of glucoamylase, while the corresponding values in mono-cultures were in the range of 1 g/L. Maximum ethanol production of 29.9 and 30.8 g/L was achieved at 69 h (Figure 3b). At the end of all fermentations, glucose concentration in the fermentation broth was lower than 2.0 g/L. Volumetric productivities ranged from 1.0 g/L/h (mixed microbial culture) to 1.5 g/L/h (mixed microbial culture supplemented with 20 U/g glucoamylase) (Figure 5).

It is evident that mixed microbial culture decreases significantly the time needed for the fermentation to be completed therefore increasing volumetric productivity. Mixed cultures of mesophilic fungi, such as F. oxysporum F3 and N. crassa, with the yeast S. cerevisiae, have been successfully implemented for the bioconversion of sweet sorghum and sweet sorghum baggasse to bioethanol [30,31]. Table 2 summarizes results obtained from the bioconversion of different kinds of FW.

Table 2.

Production of bioethanol from FW applying different processes.

Bioethanol production of the present sudy was 30.8 g/L which is higher than that reported by Matsakas and Christakopoulos [33] using the on-site produced cellulolytic enzymes from the thermophillic fungus Myceliophthora thermophila. On the other hand, Kiran and Liu [37] achieved much higher ethanol production (58.0 g/L) using the multienzyme system produced on-site by the fugus Aspergillus awamori. Wang et al. [36] used response surface methodology to optimize the conditions of SSF for ethanol production from kitchen garbage. Maximum ethanol concentration of 33.0g/L was reported with the optimum conditions of time of 67.60 h, pH= 4.18 and T = 35 °C using glucoamylase in the saccharification step. Kitchen wastes were treated with a mixture of amylolytic and cellulolytic enzymes, the hydrolyzate was converted to bioethanol using commercial dry baker’s yeast, and resulted in 23.3 g/L bioethanol production [35].

Bioethanol volumetric productivities ranged from 0.33 to 1.8 g/L/h and that of the present study is among the higher (Table 2). It is evident that the variability in FW content from region to region, the substrate concentration, the type and dosage of used enzymes and processes applied affect bioethanol production.

Enzyme cost still remains high, and this is identified as a major challenge in the deployment of lignocellulosic ethanol [9]. If the necessary enzymes could be efficiently produced on-site, the cost could be significantly reduced. A recent study has estimated that this cellulase cost can be reduced, from 0.78 to 0.58 $/gallon, by shifting from the off-site to the on-site approach of cellulase production [38].

4. Conclusions

In the present study, the feasibility of producing bioethanol from FW applying the on-site produced multienzyme system was demonstrated. The mesophilic fungus F. oxysporum F3 grown under SSC in wheat bran as carbon source produced a mixture of hydrolytic enzymes capable of hydrolyzing the polysaccharides in FW. Mixed-microbial cultures of F. oxysporum with the yeast S. cerevisiae increased bioethanol volumetric productivity compared to mono-culture of the fungus. Bioethanol production increased by approximately 23% when the mixed microbial culture was supplemented with commercial glucoamylase. The results of the study demonstrated that non-commercial enzyme products obtained from fungi could be an efficient alternative to commercial preparations in technologies which use elevated substrate loadings or where an accurate loading is impossible due to practical limitations.

Author Contributions

Conceptualization, A.K., D.K. and D.M.; Methodology, A.K. and D.M.; Investigation, G.P., A.G., S.K.; Writing—Original Draft Preparation, D.M.; Writing—Review & Editing, all authors. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding

Acknowledgments

The authors would like to thank Gerasimos Lyberatos of Organic Chemical Technology Laboratory, School of Chemical Engineering, National Technical University of Athens for providing the dry FW. The authors would also like to thank Novozymes Corporation for generously providing the cellulose enzyme samples.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Eurostat. Municipal Waste by Waste Operations; Eurostat: Brussels, Belgium, 2017. [Google Scholar]

- European Commission. A sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment—Updated Bioeconomy Strategy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Patel, A.; Hrůzová, K.; Rova, U.; Christakopoulos, P.; Matsakas, L. Sustainable biorefinery concept for biofuel production through holistic volarization of food waste. Bioresour. Technol. 2019, 294, 122247. [Google Scholar] [CrossRef] [PubMed]

- Carmona-Cabello, M.; García, I.L.; Sáez-Bastante, J.; Pinzi, S.; Koutinas, A.A.; Dorado, M.P. Food waste from restaurant sector—Characterization for biorefinery approach. Bioresour. Technol. 2020, 301, 122779. [Google Scholar] [CrossRef] [PubMed]

- UN. Transforming Our World: The 2030 Agenda for Sustainable Development, A/Res/70/1; United Nations: New York, NY, USA, 2015. [Google Scholar]

- European Parliament and Council of the European Union. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC; European Parliament and Council of the European Union: Brussels, Belgium, 2009. [Google Scholar]

- European Parliament and Council of the European Union. Directive 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast); European Parliament and Council of the European Union: Brussels, Belgium, 2018. [Google Scholar]

- Barampouti, E.M.; Mai, S.; Malamis, D.; Moustakas, K.; Loizidou, M. Liquid biofuels from the organic fraction of municipal solid waste: A review. Renew. Sustain. Energy Rev. 2019, 110, 298–314. [Google Scholar] [CrossRef]

- Padella, M.; O’Connell, A.; Prussi, M. What is still limiting the deployment of cellulosic ethanol? Analysis of the Current Status of the Sector. Appl. Sci. 2019, 9, 4523. [Google Scholar] [CrossRef]

- Wan, Y.K.; Sadhukhan, J.; Ng, D.K.S. Techno-economic evaluations for feasibility of sago-based biorefinery, Part 2: Integrated bioethanol production and energy systems. Chem. Eng. Res. Des. 2016, 107, 102–116. [Google Scholar] [CrossRef]

- Siqueira, J.G.W.; Rodrigues, C.; Vandenberghe, L.P.D.S.; Woiciechowski, A.L.; Soccol, C.R. Current advances in on-site cellulase production and application on lignocellulosic biomass conversion to biofuels: A review. Biomass Bioenerg 2020, 132, 105419. [Google Scholar] [CrossRef]

- Da Rosa-Garzon, N.G.; Laure, H.J.; Rosa, J.C.; Cabral, H. Fusarium oxysporum cultured with complex nitrogen sources can degrade agricultural residues: Evidence from analysis of secreted enzymes and intracellular proteome. Renew. Energ. 2019, 133, 941–950. [Google Scholar] [CrossRef]

- Sharma, S.; Kuila, A.; Sharma, V. Enzymatic hydrolysis of thermochemically pretreated biomass using a mixture of cellulolytic enzymes produced from different fungal sources. Clean Technol. Environ. 2017, 19, 1577–1584. [Google Scholar] [CrossRef]

- Christakopoulos, P.; Macris, B.J.; Kekos, D. Direct fermentation of cellulose to ethanol by Fusarium oxysporum. Enzyme Microb. Technol. 1989, 11, 236–239. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 15th ed.; AOAC Inc.: Rockville, MD, USA, 1990. [Google Scholar]

- Phatak, L.; Chang, K.C.; Brown, G. Isolation and characterization of pectin in sugar-beet pulp. J. Food Sci. 1988, 53, 830–833. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Technical Report NREL/TP-510-42618; National Renewable Energy Laboratory: Golden, CO, USA, 2012. Available online: https://www.nrel.gov/docs/gen/fy13/42618.pdf (accessed on 8 January 2020).

- Loizidou, M.; Alamanou, D.G.; Sotiropoulos, A.; Lytras, C.; Mamma, D.; Malamis, D.; Kekos, D. Pilot scale system of two horizontal rotating bioreactors for bioethanol production from household food waste at high solid concentrations. Waste Biomass Valorization 2017, 8, 1709–1719. [Google Scholar] [CrossRef]

- Toyama, N.; Ogawa, K. Cellulase production by Trichoderma viride in solid and submerged culture conditions. In Proceedings of the Symposium for the Bioconversion of Cellulosic Substances into Energy, Chemicals and Microbial Protein, New Delhi, India, 21–23 February 1977; Ghose, T.K., Ed.; IIT: New Delhi, India, 1978; pp. 325–327. [Google Scholar]

- Dogaris, I.; Vakontios, G.; Kalogeris, E.; Mamma, D.; Kekos, D. Induction of cellulases and hemicellulases from Neurospora crassa under solid-state cultivation for bioconversion of sorghum bagasse into ethanol. Ind. Crop. Prod. 2009, 29, 404–411. [Google Scholar] [CrossRef]

- Alamanou, D.G.; Malamis, D.; Mamma, D.; Kekos, D. Bioethanol from dried household food waste applying non-isothermal simultaneous saccharification and fermentation at high substrate concentration. Waste Biomass Valorization 2015, 6, 353–361. [Google Scholar] [CrossRef]

- Yazid, N.A.; Barrena, R.; Komilis, D.; Sánchez, A. Solid-State Fermentation as a Novel Paradigm for Organic Waste Valorization: A Review. Sustainability 2017, 9, 224. [Google Scholar] [CrossRef]

- Kiran, E.U.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Bioconversion of food waste to energy: A review. Fuel 2014, 134, 389–399. [Google Scholar] [CrossRef]

- Behera, S.S.; Ray, R.C. Solid state fermentation for production of microbial cellulases: Recent advances and improvement strategies. Int. J. Biol. Macromol. 2016, 86, 656–669. [Google Scholar] [CrossRef]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial wastes and their utilization using solid state fermentation: A review. Bioresour. Bioprocess. 2018, 5, 1. [Google Scholar] [CrossRef]

- De Castro, R.J.S.; Sato, H.H. Enzyme Production by Solid State Fermentation: General Aspects and an Analysis of the Physicochemical Characteristics of Substrates for Agro-industrial Wastes Valorization. Waste Biomass Valorization 2015, 6, 1085–1093. [Google Scholar] [CrossRef]

- Panagiotou, G.; Kekos, D.; Macris, B.J.; Christakopoulos, P. Production of cellulolytic and xylanolytic enzymes by Fusarium oxysporum grown on corn stover in solid state fermentation. Ind. Crop. Prod. 2003, 18, 37–45. [Google Scholar] [CrossRef]

- El-Shishtawy, R.M.; Mohamed, S.A.; Asiri, A.M.; Gomaa, A.A.; Ibrahim, I.H.; Al-Talhi, H.A. Saccharification and hydrolytic enzyme production of alkali pre-treated wheat bran by Trichoderma virens under solid state fermentation. BMC Biotechnol. 2015, 15, 37. [Google Scholar] [CrossRef]

- Gupta, A.; Verma, J.P. Sustainable bio-ethanol production from agro-residues: A review. Renew. Sustain. Energy Rev. 2015, 41, 550–567. [Google Scholar] [CrossRef]

- Mamma, D.; Koullas, D.; Fountoukidis, G.; Kekos, D.; Macris, B.J.; Koukios, E. Bioethanol from Sweet Sorghum: Simultaneous saccharification and fermentation of carbohydrates by a mixed microbial culture. Process Biochem. 1996, 31, 377–381. [Google Scholar] [CrossRef]

- Dogaris, I.; Gkounta, O.; Mamma, D.; Kekos, D. Bioconversion of dilute-acid pretreated sorghum bagasse to ethanol by Neurospora crassa. Appl. Microbiol. Biot. 2012, 95, 541–550. [Google Scholar] [CrossRef] [PubMed]

- Walker, K.; Vadlani, P.; Madl, R.; Ugorowski, P.; Hohn, K.L. Ethanol Fermentation from Food Processing Waste. Environ. Prog. Sustain. 2013, 32, 1280–1283. [Google Scholar] [CrossRef]

- Matsakas, L.; Christakopoulos, P. Ethanol Production from Enzymatically Treated Dried Food Waste Using Enzymes Produced On-Site. Sustainability 2015, 7, 1446–1458. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, J.C.; Pak, D. Feasibility of producing ethanol from food waste. Waste Manag. 2011, 31, 2121–2125. [Google Scholar] [CrossRef]

- Cekmecelioglu, D.; Uncu, O.N. Kinetic modeling of enzymatic hydrolysis of pretreated kitchen wastes for enhancing bioethanol production. Waste Manag. 2013, 33, 735–739. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, H.; Xu, W.; Gong, L.; Zhang, W.; Zou, D. Ethanol production from kitchen garbage using response surface methodology. Biochem. Eng. J. 2008, 39, 604–610. [Google Scholar] [CrossRef]

- Kiran, E.U.; Liu, Y. Bioethanol production from mixed food waste by an effective enzymatic pretreatment. Fuel 2015, 159, 463–469. [Google Scholar] [CrossRef]

- Johnson, E. Integrated enzyme production lowers the cost of cellulosic ethanol. Biofuels Bioprod. Biorefin. 2016, 10, 164–174. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).