Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock

Abstract

1. Introduction

2. Lignocellulosic Biomass Composition

Wood Composition

3. Second Generation Bioethanol Production

3.1. Pretreatment

3.2. Hydrolysis/Saccharification

3.2.1. Acidic Hydrolysis

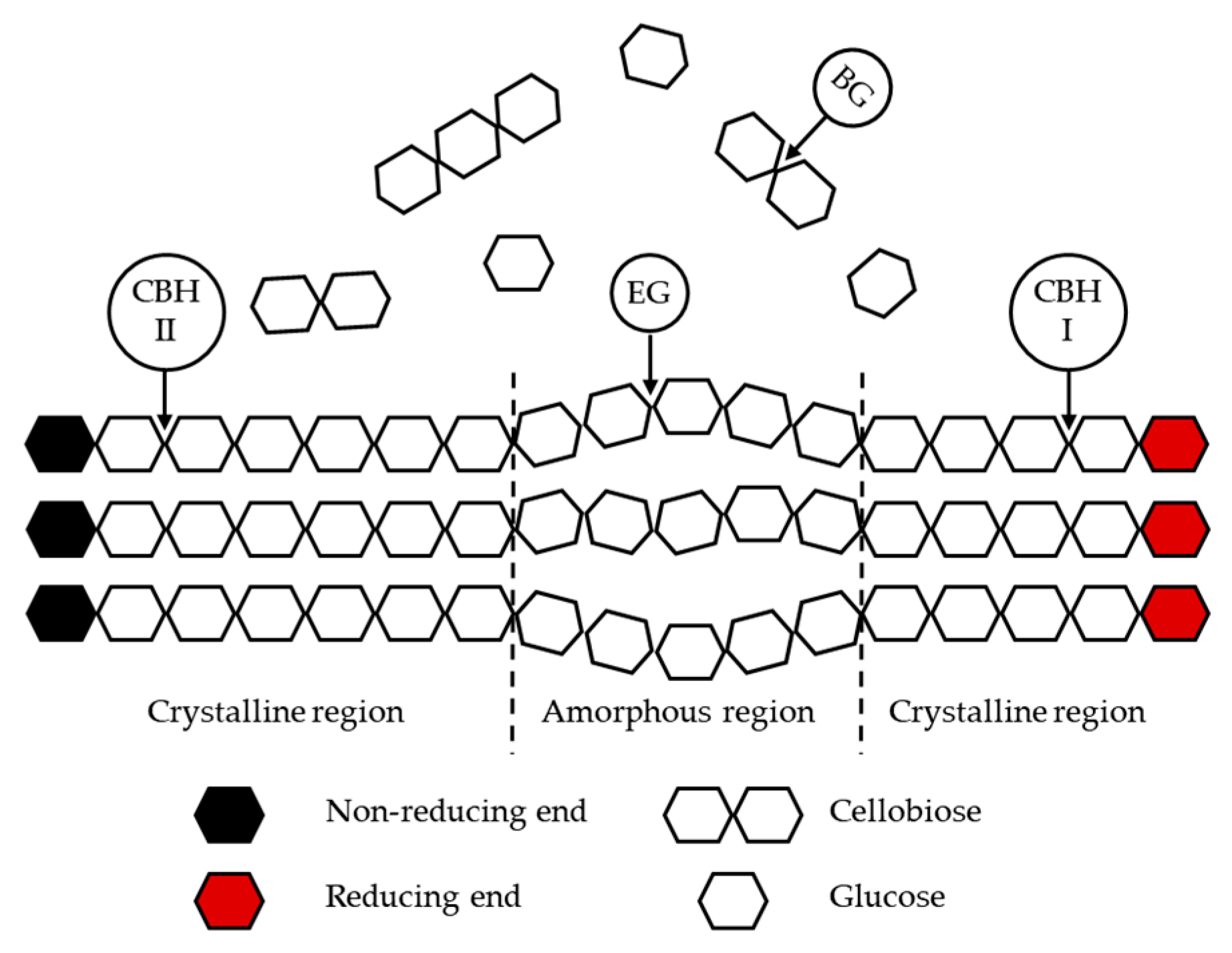

3.2.2. Enzymatic Hydrolysis

3.3. Fermentation

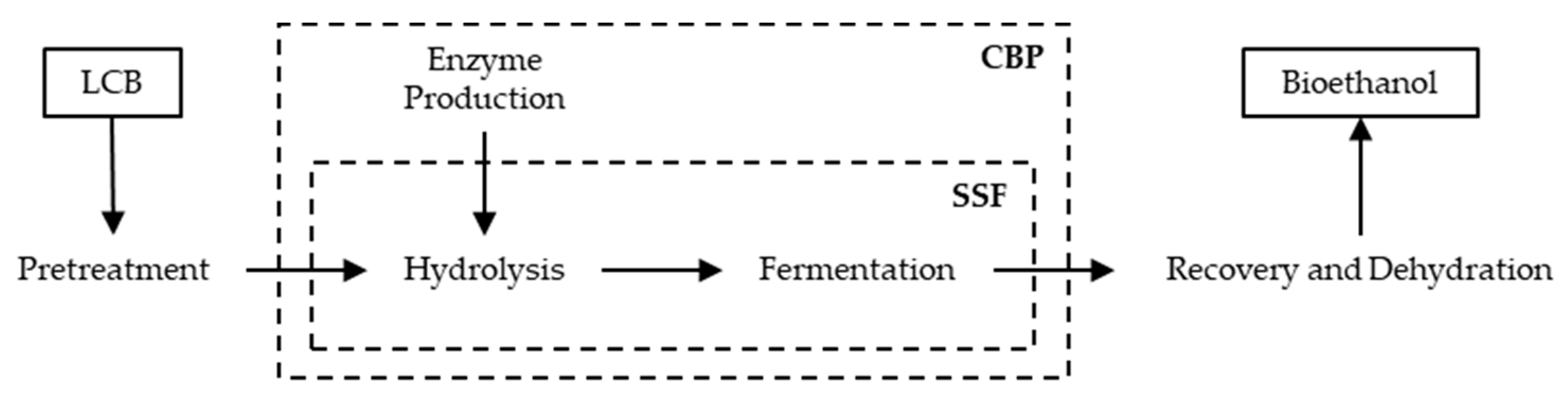

3.3.1. Fermentation Configuration

3.3.2. Ethanologenic Microorganisms

3.4. Recovery and Dehydration

4. Bioethanol Production from Kraft Pulp

4.1. Kraft Pulping

4.2. Bioethanol Production

5. Bioethanol Production from Spent Sulfite Liquor

5.1. Sulfite Pulping

5.2. Bioethanol Production

6. Bioethanol Production from Pulp and Paper Sludge

6.1. Pulp and Paper Mill Sludge

6.2. Bioethanol Production

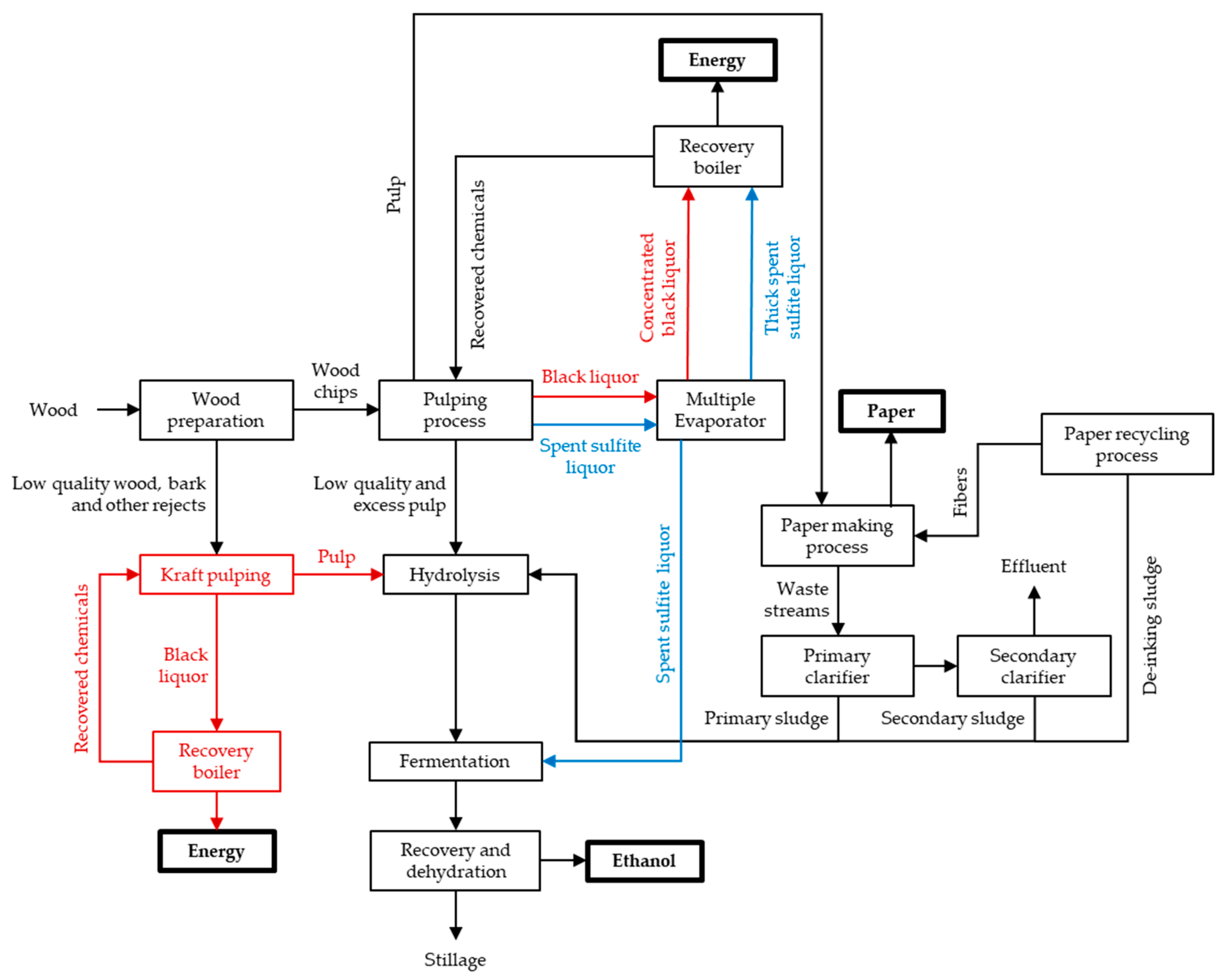

7. Converting Pulp and Paper Mills into Biorefineries

8. Future Prospects

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- REN21. Renewables 2017 Global Status Report; REN21 Secretariat: Paris, France, 2017; pp. 30, 48. ISBN 978-3-9818107-6-9. [Google Scholar]

- Hussain, A.; Arif, S.M.; Aslam, M. Emerging renewable and sustainable energy technologies: State of the art. Renew. Sustain. Energy Rev. 2017, 71, 12–28. [Google Scholar] [CrossRef]

- Du, C.; Zhao, X.; Liu, D.; Lin, C.S.K.; Wilson, K.; Luque, R.; Clark, J. Introduction: An overview of biofuels and production technologies. In Handbook of Biofuels Production Processes and Technologies, 2nd ed.; Lin, C.S.K., Wilson, K., Clark, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; p. 3. ISBN 978-0-08-100455-5. [Google Scholar]

- Liew, W.H.; Hassim, M.H.; Ng, D.K.S. Review of evolution, technology and sustainability assessments of biofuel production. J. Clean. Prod. 2014, 71, 11–29. [Google Scholar] [CrossRef]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Azadi, P.; Malina, R.; Barrett, S.R.H.; Kraft, M. The evolution of the biofuel science. Renew. Sustain. Energy Rev. 2017, 76, 1479–1484. [Google Scholar] [CrossRef]

- Balat, M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Convers. Manag. 2011, 52, 858–875. [Google Scholar] [CrossRef]

- Sebayang, A.H.; Masjuki, H.H.; Ong, H.C.; Dharma, S.; Silitonga, A.S.; Mahlia, T.M.I.; Aditiya, H.B. A perspective on bioethanol production from biomass as alternative fuel for spark ignition engine. RSC Adv. 2016, 6, 14964–14992. [Google Scholar] [CrossRef]

- Sarris, D.; Papanikolaou, S. Biotechnological production of ethanol: Biochemistry, processes and technologies. Eng. Life Sci. 2016, 16, 307–329. [Google Scholar] [CrossRef]

- Maity, S.K. Opportunities, recent trends and challenges of integrated biorefinery: Part II. Renew. Sustain. Energy Rev. 2015, 43, 1446–1466. [Google Scholar] [CrossRef]

- Manochio, C.; Andrade, B.R.; Rodriguez, R.P.; Moraes, B.S. Ethanol from biomass: A comparative overview. Renew. Sustain. Energy Rev. 2017, 80, 743–755. [Google Scholar] [CrossRef]

- Dutta, K.; Daverey, A.; Lin, J.-G. Evolution retrospective for alternative fuels: First to fourth generation. Renew. Energy 2014, 69, 114–122. [Google Scholar] [CrossRef]

- Bastos, R.G. Biofuels from microalgae: Bioethanol. In Energy from Microalgae, 1st ed.; Jacob-Lopes, E., Zepka, L.Q., Queiroz, M.I., Eds.; Springer International Publishing AG: Cham, Switzerland, 2018; p. 229. ISBN 978-3-319-69092-6. [Google Scholar]

- Zabed, H.; Sahu, J.N.; Boyce, A.N.; Faruq, G. Fuel ethanol production from lignocellulosic biomass: An overview on feedstocks and technological approaches. Renew. Sustain. Energy Rev. 2016, 66, 751–774. [Google Scholar] [CrossRef]

- Yamakawa, C.K.; Qin, F.; Mussatto, S.I. Advances and opportunities in biomass conversion technologies and biorefineries for the development of a bio-based economy. Biomass Bioenergy 2018, 119, 54–60. [Google Scholar] [CrossRef]

- Erickson, B. A Rising Tide of Cellulosic Ethanol Production. Ind. Biotechnol. 2018, 14, 77–78. [Google Scholar] [CrossRef]

- Phillips, S.; Flach, B.; Lieberz, S.; Lappin, J.; Bolla, S. EU-28 Biofuels Annual: EU Biofuels Annual 2018; USDA: Washington, DC, USA, 2018; pp. 11, 12.

- Berk, C.; Barros, S. Brazil Biofuels Annual 2018; USDA: Washington, DC, USA, 2018; p. 11.

- Bajpai, P. Introduction. In Biotechnology for Pulp and Paper Processing, 1st ed.; Springer: New York, NY, USA, 2012; p. 1. ISBN 978-1-4614-1408-7. [Google Scholar]

- FAO. Yearbook of Forest Products 2015; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017; ISBN 978-92-5-009766-4. [Google Scholar]

- Stoklosa, R.J.; Hodge, D.B. Integration of (hemi)-cellulosic biofuels technologies with chemical pulp production. In Biorefineries: Integrated Biochemical Processes for Liquid Biofuels, 1st ed.; Qureshi, N., Hodge, D., Vertès, A.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; p. 74. ISBN 978-0-444-59498-3. [Google Scholar]

- Koutinas, A.A.; Vlysidis, A.; Pleissner, D.; Kopsahelis, N.; Lopez Garcia, I.; Kookos, I.K.; Papanikolaou, S.; Kwan, T.H.; Lin, C.S.K. Valorization of industrial waste and by-product streams via fermentation for the production of chemicals and biopolymers. Chem. Soc. Rev. 2014, 43, 2587–2627. [Google Scholar] [CrossRef] [PubMed]

- Monrroy, M.; García, J.R.; Mendonça, R.T.; Baeza, J.; Freer, J. Kraft pulping of Eucalyptus globulus as a pretreatment for bioethanol production by simultaneous saccharification and fermentation. J. Chil. Chem. Soc. 2012, 57, 1113–1117. [Google Scholar] [CrossRef]

- Phillips, R.B.; Jameel, H.; Chang, H.M. Integration of pulp and paper technology with bioethanol production. Biotechnol. Biofuels 2013, 6, 13. [Google Scholar] [CrossRef]

- Pereira, S.R.; Portugal-Nunes, D.J.; Evtuguin, D.V.; Serafim, L.S.; Xavier, A.M.R.B. Advances in ethanol production from hardwood spent sulphite liquors. Process. Biochem. 2013, 48, 272–282. [Google Scholar] [CrossRef]

- Schroeder, B.G.; Zanoni, P.R.S.; Magalhães, W.L.E.; Hansel, F.A.; Tavares, L.B.B. Evaluation of biotechnological processes to obtain ethanol from recycled paper sludge. J. Mater. Cycles Waste Manag. 2017, 19, 463–472. [Google Scholar] [CrossRef]

- Dugmore, T.I.J.; Clark, J.H.; Bustamante, J.; Houghton, J.A.; Matharu, A.S. Valorisation of biowastes for the production of green materials using chemical methods. Top. Curr. Chem. 2017, 375. [Google Scholar] [CrossRef]

- Mohan, S.V.; Nikhil, G.N.; Chiranjeevi, P.; Nagendranatha Reddy, C.; Rohit, M.V.; Kumar, A.N.; Sarkar, O. Waste biorefinery models towards sustainable circular bioeconomy: Critical review and future perspectives. Bioresour. Technol. 2016, 215, 2–12. [Google Scholar] [CrossRef]

- IEA Bioenergy. IEA Bioenergy Task42 Biorefining Brochure; IEA Bioenergy: Wageningen, The Netherlands, 2014; pp. 10, 12. [Google Scholar]

- IEA Bioenergy. Newsletter IEA Bioenergy Task42; IEA Bioenergy: Wageningen, The Netherlands, 2017; p. 2. [Google Scholar]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Seidl, P.R.; Goulart, A.K. Pretreatment processes for lignocellulosic biomass conversion to biofuels and bioproducts. Curr. Opin. Green Sustain. Chem. 2016, 2, 48–53. [Google Scholar] [CrossRef]

- Haghighi Mood, S.; Hossein Golfeshan, A.; Tabatabaei, M.; Salehi Jouzani, G.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Silveira, M.H.L.; Morais, A.R.C.; da Costa Lopes, A.M.; Olekszyszen, D.N.; Bogel-Łukasik, R.; Andreaus, J.; Pereira Ramos, L. Current pretreatment technologies for the development of cellulosic ethanol and biorefineries. ChemSusChem 2015, 8, 3366–3390. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Liu, J.; Chang, X.; Chen, D.; Xue, Y.; Liu, P.; Lin, H.; Han, S. A review on the pretreatment of lignocellulose for high-value chemicals. Process Technol. 2017, 160, 196–206. [Google Scholar] [CrossRef]

- Sun, S.; Sun, S.; Cao, X.; Sun, R. The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour. Technol. 2016, 199, 49–58. [Google Scholar] [CrossRef]

- Stevanovic, T. Chemical composition and properties of wood. In Lignocellulosic Fibers and Wood Handbook, 1st ed.; Belgacem, M.N., Pizzi, A., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2016; p. 49. ISBN 978-1-118-77352-9. [Google Scholar]

- Ek, M.; Gellerstedt, G.; Henriksson, G. (Eds.) Pulp and Paper Chemistry and Technology, 1st ed.; De Gruyter: Berlin, Germany, 2009; Volume 1, pp. 1–3, 46, 103, 182, 184, 188. ISBN 978-3-11-021339-3. [Google Scholar]

- Evtuguin, D.V. Sulphite Pulping. In Lignocellulosic Fibers and Wood Handbook, 1st ed.; Belgacem, M.N., Pizzi, A., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 225–229, 233, 239, 240, 243. ISBN 978-1-118-77352-9. [Google Scholar]

- Koch, G. Raw material for pulp. In Handbook of Pulp, 1st ed.; Sixta, H., Ed.; Wiley-VCH: Weinheim, Germany, 2006; Volume 1, pp. 22, 31. ISBN 978-3-527-30999-3. [Google Scholar]

- Lachenal, D. Kraft pulping. In Lignocellulosic Fibers and Wood Handbook, 1st ed.; Belgacem, M.N., Pizzi, A., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 207–209, 213, 215–217. ISBN 978-1-118-77352-9. [Google Scholar]

- Nair, R.B.; Lennartsson, P.R.; Taherzadeh, M.J. Bioethanol production from agricultural and municipal wastes. In Current Developments in Biotechnology and Bioengineering—Solid Waste Management, 1st ed.; Wong, J.W.-C., Tyagi, R.D., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; p. 160. ISBN 978-0-444-63664-5. [Google Scholar]

- Rocha, L.; Raud, M.; Orupõld, K.; Kikas, T. Second-generation bioethanol production: A review of strategies for waste valorisation. Agron. Res. 2017, 15, 830–847. [Google Scholar]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Binod, P.; Pandey, A. Introduction. In Pretreatment of Biomass: Processes and Technologies, 1st ed.; Pandey, A., Negi, S., Binod, P., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 3, 5. ISBN 978-0-12-800080-9. [Google Scholar]

- Bhutto, A.W.; Qureshi, K.; Harijan, K.; Abro, R.; Abbas, T.; Bazmi, A.A.; Karim, S.; Yu, G. Insight into progress in pre-treatment of lignocellulosic biomass. Energy 2017, 122, 724–745. [Google Scholar] [CrossRef]

- Kim, D. Physico-chemical conversion of lignocellulose: Inhibitor effects and detoxification strategies: A mini review. Molecules 2018, 23, 309. [Google Scholar] [CrossRef]

- Jönsson, L.J.; Martín, C. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Ximenes, E.; Kim, Y.; Ladisch, M.R. Biological conversion of plants to fuels and chemicals and the effects of inhibitors. In Aqueous Pretreatment of Plant Biomass for Biological and Chemical Conversion to Fuels and Chemicals: Wyman/Aqueous Pretreatment of Plant Biomass for Biological and Chemical Conversion to Fuels and Chemicals, 1st ed.; Wyman, C.E., Ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2013; p. 49. ISBN 978-0-470-97583-1. [Google Scholar]

- Henriques, T.; Pereira, S.; Serafim, L.; Xavier, A. Two-stage aeration fermentation strategy to improve bioethanol production by Scheffersomyces stipitis. Fermentation 2018, 4, 97. [Google Scholar] [CrossRef]

- Ximenes, E.; Kim, Y.; Mosier, N.; Dien, B.; Ladisch, M. Inhibition of cellulases by phenols. Enzyme Microb. Technol. 2010, 46, 170–176. [Google Scholar] [CrossRef]

- Amarasekara, A.S. (Ed.) Handbook of Cellulosic Ethanol, 1st ed.; Scrivener Publishing: Beverly, MA, USA, 2014; pp. 284–287, 482. ISBN 978-1-118-23300-9. [Google Scholar]

- Haldar, D.; Sen, D.; Gayen, K. A review on the production of fermentable sugars from lignocellulosic biomass through conventional and enzymatic route—A comparison. Int. J. Green Energy 2016, 13, 1232–1253. [Google Scholar] [CrossRef]

- Kuila, A.; Sharma, V.; Garlapati, V.K.; Singh, A.; Roy, L.; Banerjee, R. Present status on enzymatic hydrolysis of lignocellulosic biomass for bioethanol production. In Advances in Biofeedstocks and Biofuels, 1st ed.; Singh, L.K., Chaudhary, G., Eds.; Scrivener Publishing: Beverly, MA, USA, 2016; Volume 1, p. 87. ISBN 978-1-119-11725-4. [Google Scholar]

- Verardi, A.; De Bari, I.; Ricca, E.; Calabrò, V. Hydrolysis of lignocellulosic biomass: Current status of processes and technologies and future perspectives. In Bioethanol, 1st ed.; Lima, M.A.P., Ed.; Intech: Rijeka, Croatia, 2012; p. 100. ISBN 978-953-51-0008-9. [Google Scholar]

- Kennes, D.; Abubackar, H.N.; Diaz, M.; Veiga, M.C.; Kennes, C. Bioethanol production from biomass: Carbohydrate vs. syngas fermentation. J. Chem. Technol. Biotechnol. 2016, 91, 304–317. [Google Scholar] [CrossRef]

- Kamzon, M.A.; Abderafi, S.; Bounahmidi, T. Promising bioethanol processes for developing a biorefinery in the Moroccan sugar industry. Int. J. Hydrog Energy 2016, 41, 20880–20896. [Google Scholar] [CrossRef]

- Gupta, A.; Verma, J.P. Sustainable bio-ethanol production from agro-residues: A review. Renew. Sustain. Energy Rev. 2015, 41, 550–567. [Google Scholar] [CrossRef]

- Dos Santos, L.V.; de Barros Grassi, M.C.; Gallardo, J.C.M.; Pirolla, R.A.S.; Calderón, L.L.; de Carvalho-Netto, O.V.; Parreiras, L.S.; Camargo, E.L.O.; Drezza, A.L.; Missawa, S.K.; et al. Second-generation ethanol: The need is becoming a reality. Ind. Biotechnol. 2016, 12, 40–57. [Google Scholar] [CrossRef]

- Harris, P.V.; Xu, F.; Kreel, N.E.; Kang, C.; Fukuyama, S. New enzyme insights drive advances in commercial ethanol production. Curr. Opin. Chem. Biol. 2014, 19, 162–170. [Google Scholar] [CrossRef]

- Gupta, V.K.; Kubicek, C.P.; Berrin, J.-G.; Wilson, D.W.; Couturier, M.; Berlin, A.; Filho, E.X.F.; Ezeji, T. Fungal enzymes for bio-products from sustainable and waste biomass. Trends Biochem. Sci. 2016, 41, 633–645. [Google Scholar] [CrossRef]

- Volynets, B.; Ein-Mozaffari, F.; Dahman, Y. Biomass processing into ethanol: Pretreatment, enzymatic hydrolysis, fermentation, rheology, and mixing. Green Process. Synth. 2017, 6, 1–22. [Google Scholar] [CrossRef]

- Zhao, X.; Xiong, L.; Zhang, M.; Bai, F. Towards efficient bioethanol production from agricultural and forestry residues: Exploration of unique natural microorganisms in combination with advanced strain engineering. Bioresour. Technol. 2016, 215, 84–91. [Google Scholar] [CrossRef] [PubMed]

- Kubicek, C.P.; Kubicek, E.M. Enzymatic deconstruction of plant biomass by fungal enzymes. Curr. Opin. Chem. Biol. 2016, 35, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Moreira, L.R.S.; Filho, E.X.F. Insights into the mechanism of enzymatic hydrolysis of xylan. Appl. Microbiol. Biotechnol. 2016, 100, 5205–5214. [Google Scholar] [CrossRef] [PubMed]

- Rastogi, M.; Shrivastava, S. Recent advances in second generation bioethanol production: An insight to pretreatment, saccharification and fermentation processes. Renew. Sustain. Energy Rev. 2017, 80, 330–340. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Lennartsson, P.R.; Teichert, O.; Nordholm, H. Bioethanol production processes. In Biofuels Production, 1st ed.; Babu, V., Thapliyal, A., Patel, G.K., Eds.; Scrivener Publishing: Beverly, MA, USA, 2014; pp. 225, 226. ISBN 978-1-118-63450-9. [Google Scholar]

- Kang, Q.; Appels, L.; Tan, T.; Dewil, R. Bioethanol from lignocellulosic biomass: Current findings determine research priorities. Sci. World J. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- Saini, J.K.; Saini, R.; Tewari, L. Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: Concepts and recent developments. 3 Biotech. 2015, 5, 337–353. [Google Scholar] [CrossRef]

- Paulova, L.; Patakova, P.; Branska, B.; Rychtera, M.; Melzoch, K. Lignocellulosic ethanol: Technology design and its impact on process efficiency. Biotechnol. Adv. 2015, 33, 1091–1107. [Google Scholar] [CrossRef]

- Saggi, S.K.; Dey, P. An overview of simultaneous saccharification and fermentation of starchy and lignocellulosic biomass for bio-ethanol production. Biofuels 2016, 1–13. [Google Scholar] [CrossRef]

- Choudhary, J.; Singh, S.; Nain, L. Thermotolerant fermenting yeasts for simultaneous saccharification fermentation of lignocellulosic biomass. Electron. J. Biotechnol. 2016, 21, 82–92. [Google Scholar] [CrossRef]

- Aditiya, H.B.; Mahlia, T.M.I.; Chong, W.T.; Nur, H.; Sebayang, A.H. Second generation bioethanol production: A critical review. Renew. Sustain. Energy Rev. 2016, 66, 631–653. [Google Scholar] [CrossRef]

- Arora, R.; Behera, S.; Kumar, S. Bioprospecting thermophilic/thermotolerant microbes for production of lignocellulosic ethanol: A future perspective. Renew. Sustain. Energy Rev. 2015, 51, 699–717. [Google Scholar] [CrossRef]

- Limayem, A.; Ricke, S.C. Lignocellulosic biomass for bioethanol production: Current perspectives, potential issues and future prospects. Prog. Energy Combust. Sci. 2012, 38, 449–467. [Google Scholar] [CrossRef]

- Den Haan, R.; van Rensburg, E.; Rose, S.H.; Görgens, J.F.; van Zyl, W.H. Progress and challenges in the engineering of non-cellulolytic microorganisms for consolidated bioprocessing. Curr. Opin. Biotechnol. 2015, 33, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Sun, J.; Chang, J.-S.; Shukla, P. Engineering microbes for direct fermentation of cellulose to bioethanol. Crit. Rev. Biotechnol. 2018, 38, 1089–1105. [Google Scholar] [CrossRef] [PubMed]

- Yanase, H. Ethanol from bacteria. In Bioprocessing of Renewable Resources to Commodity Bioproducts, 1st ed.; Bisaria, V.S., Kondo, A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 184, 185. ISBN 978-1-118-17583-5. [Google Scholar]

- Avanthi, A.; Kumar, S.; Sherpa, K.C.; Banerjee, R. Bioconversion of hemicelluloses of lignocellulosic biomass to ethanol: An attempt to utilize pentose sugars. Biofuels 2017, 8, 431–444. [Google Scholar] [CrossRef]

- Faraco, V. (Ed.) Lignocellulose Conversion: Enzymatic and Microbial Tools for Bioethanol Production, 1st ed.; Springer: Heidelberg, Germany, 2013; pp. 143, 152, 179. ISBN 978-3-642-37860-7. [Google Scholar]

- Sharifyazd, S.; Karimi, K. Effects of fermentation conditions on valuable products of ethanolic fungus Mucor indicus. Electron. J. Biotechnol. 2017, 30, 77–82. [Google Scholar] [CrossRef]

- Nair, R.B.; Lundin, M.; Brandberg, T.; Lennartsson, P.R.; Taherzadeh, M.J. Dilute phosphoric acid pretreatment of wheat bran for enzymatic hydrolysis and subsequent ethanol production by edible fungi Neurospora intermedia. Ind. Crop. Prod. 2015, 69, 314–323. [Google Scholar] [CrossRef]

- Okamoto, K.; Imashiro, K.; Akizawa, Y.; Onimura, A.; Yoneda, M.; Nitta, Y.; Maekawa, N.; Yanase, H. Production of ethanol by the white-rot basidiomycetes Peniophora cinerea and Trametes suaveolens. Biotechnol. Lett. 2010, 32, 909–913. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, K.; Kanawaku, R.; Masumoto, M.; Yanase, H. Efficient xylose fermentation by the brown rot fungus Neolentinus lepideus. Enzyme Microb. Technol. 2012, 50, 96–100. [Google Scholar] [CrossRef]

- Okamoto, K.; Uchii, A.; Kanawaku, R.; Yanase, H. Bioconversion of xylose, hexoses and biomass to ethanol by a new isolate of the white rot basidiomycete Trametes versicolor. Springerplus 2014, 3, 121. [Google Scholar] [CrossRef] [PubMed]

- Horisawa, S.; Ando, H.; Ariga, O.; Sakuma, Y. Direct ethanol production from cellulosic materials by consolidated biological processing using the wood rot fungus Schizophyllum commune. Bioresour. Technol. 2015, 197, 37–41. [Google Scholar] [CrossRef] [PubMed]

- Amore, A.; Faraco, V. Potential of fungi as category I Consolidated BioProcessing organisms for cellulosic ethanol production. Renew. Sustain. Energy Rev. 2012, 16, 3286–3301. [Google Scholar] [CrossRef]

- Maehara, T.; Ichinose, H.; Furukawa, T.; Ogasawara, W.; Takabatake, K.; Kaneko, S. Ethanol production from high cellulose concentration by the basidiomycete fungus Flammulina velutipes. Fungal Biol. 2013, 117, 220–226. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, K.; Nitta, Y.; Maekawa, N.; Yanase, H. Direct ethanol production from starch, wheat bran and rice straw by the white rot fungus Trametes hirsuta. Enzyme Microb. Technol. 2011, 48, 273–277. [Google Scholar] [CrossRef] [PubMed]

- Kamei, I.; Hirota, Y.; Mori, T.; Hirai, H.; Meguro, S.; Kondo, R. Direct ethanol production from cellulosic materials by the hypersaline-tolerant white-rot fungus Phlebia sp. MG-60. Bioresour. Technol. 2012, 112, 137–142. [Google Scholar] [CrossRef]

- Paschos, T.; Xiros, C.; Christakopoulos, P. Ethanol effect on metabolic activity of the ethalogenic fungus Fusarium oxysporum. BMC Biotechnol. 2015, 15. [Google Scholar] [CrossRef] [PubMed]

- Anasontzis, G.E.; Kourtoglou, E.; Villas-Boâs, S.G.; Hatzinikolaou, D.G.; Christakopoulos, P. Metabolic engineering of Fusarium oxysporum to improve its ethanol-producing capability. Front. Microbiol. 2016, 7. [Google Scholar] [CrossRef]

- Galbe, M.; Wallberg, O.; Zacchi, G. Cellulosic bioethanol production. In Separation and Purification Technologies in Biorefineries, 1st ed.; Ramaswamy, S., Huang, H.-J., Ramarao, B.V., Eds.; John Wiley & Sons Inc.: West Sussex, UK, 2013; pp. 490–493. ISBN 978-0-470-97796-5. [Google Scholar]

- Singh, A.; Rangaiah, G.P. Review of technological advances in bioethanol recovery and dehydration. Ind. Eng. Chem. Res. 2017, 56, 5147–5163. [Google Scholar] [CrossRef]

- Heinemann, S.; Blechschmidt, J. Fibrous materials for paper and board manufacture. In Handbook of Paper and Board, 2nd ed.; Holik, H., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; Volume 1, pp. 36–39, 42, 43. ISBN 978-3-527-33184-0. [Google Scholar]

- Buzała, K.; Przybysz, P.; Rosicka-Kaczmarek, J.; Kalinowska, H. Production of glucose-rich enzymatic hydrolysates from cellulosic pulps. Cellulose 2015, 22, 663–674. [Google Scholar] [CrossRef]

- Solihat, N.N.; Fajriutami, T.; Adi, D.T.N.; Fatriasari, W.; Hermiati, E. Reducing sugar production of sweet sorghum bagasse kraft pulp. In Proceedings of the AIP Conference Proceedings; AIP Publishing: Tangerang Banten, Indonesia, 2017; Volume 1803, p. 020012. [Google Scholar]

- Buzała, K.P.; Kalinowska, H.; Przybysz, P.; Małachowska, E. Conversion of various types of lignocellulosic biomass to fermentable sugars using kraft pulping and enzymatic hydrolysis. Wood Sci. Technol. 2017, 51, 873–885. [Google Scholar] [CrossRef]

- Troncoso, E.; Castillo, R.; Valenzuela, R.; Reyes, P.; Freer, J.; Norambuena, M.; RodríGuez, J.; Parra, C. Chemical and microstructural changes in Eucalyptus globulus fibers subjected to four different pretreatments and their influence on the enzymatic hydrolysis. J. Chil. Chem. Soc. 2017, 62, 3442–3446. [Google Scholar] [CrossRef]

- Huang, C.; He, J.; Min, D.; Lai, C.; Yong, Q. Understanding the nonproductive enzyme adsorption and physicochemical properties of residual lignins in moso bamboo pretreated with sulfuric acid and Kraft pulping. Appl. Biochem. Biotechnol. 2016, 180, 1508–1523. [Google Scholar] [CrossRef] [PubMed]

- Novozhilov, E.V.; Sinel’nikov, I.G.; Aksenov, A.S.; Chukhchin, D.G.; Tyshkunova, I.V.; Rozhkova, A.M.; Osipov, D.O.; Zorov, I.N.; Sinitsyn, A.P. Biocatalytic conversion of kraft pulp using cellulase complex of Penicillium verruculosum. Catal. Ind. 2016, 8, 95–100. [Google Scholar] [CrossRef]

- Kawaguchi, H.; Katsuyama, Y.; Danyao, D.; Kahar, P.; Nakamura-Tsuruta, S.; Teramura, H.; Wakai, K.; Yoshihara, K.; Minami, H.; Ogino, C.; et al. Caffeic acid production by simultaneous saccharification and fermentation of kraft pulp using recombinant Escherichia coli. Appl. Microbiol. Biotechnol. 2017, 101, 5279–5290. [Google Scholar] [CrossRef] [PubMed]

- Kawaguchi, H.; Uematsu, K.; Ogino, C.; Teramura, H.; Niimi-Nakamura, S.; Tsuge, Y.; Hasunuma, T.; Oinuma, K.-I.; Takaya, N.; Kondo, A. Simultaneous saccharification and fermentation of kraft pulp by recombinant Escherichia coli for phenyllactic acid production. Biochem. Eng. J. 2014, 88, 188–194. [Google Scholar] [CrossRef]

- Hama, S.; Mizuno, S.; Kihara, M.; Tanaka, T.; Ogino, C.; Noda, H.; Kondo, A. Production of d-lactic acid from hardwood pulp by mechanical milling followed by simultaneous saccharification and fermentation using metabolically engineered Lactobacillus plantarum. Bioresour. Technol. 2015, 187, 167–172. [Google Scholar] [CrossRef] [PubMed]

- Ko, C.-H.; Wang, Y.-N.; Chang, F.-C.; Chen, J.-J.; Chen, W.-H.; Hwang, W.-S. Potentials of lignocellulosic bioethanols produced from hardwood in Taiwan. Energy 2012, 44, 329–334. [Google Scholar] [CrossRef]

- Buzała, K.P.; Kalinowska, H.; Małachowska, E.; Przybysz, P. The utility of selected kraft hardwood and softwood pulps for fuel ethanol production. Ind. Crop. Prod. 2017, 108, 824–830. [Google Scholar] [CrossRef]

- Wistara, N.J.; Pelawi, R.; Fatriasari, W. The effect of lignin content and freeness of pulp on the bioethanol productivity of Jabon wood. Waste Biomass Valorization 2016, 7, 1141–1146. [Google Scholar] [CrossRef]

- Edgardo, A.; Carolina, P.; Manuel, R.; Juanita, F.; Baeza, J. Selection of thermotolerant yeast strains Saccharomyces cerevisiae for bioethanol production. Enzyme Microb. Technol. 2008, 43, 120–123. [Google Scholar] [CrossRef]

- Bauer, N.A.; Gibbons, W.R. Saccharification versus simultaneous saccharification and fermentation of kraft pulp. Biol. Eng. 2012, 5, 48–55. [Google Scholar] [CrossRef]

- Amoah, J.; Ishizue, N.; Ishizaki, M.; Yasuda, M.; Takahashi, K.; Ninomiya, K.; Yamada, R.; Kondo, A.; Ogino, C. Development and evaluation of consolidated bioprocessing yeast for ethanol production from ionic liquid-pretreated bagasse. Bioresour. Technol. 2017, 245, 1413–1420. [Google Scholar] [CrossRef] [PubMed]

- Sixta, H.; Potthast, A.; Krotschek, A.W. Chemical pulping processes. In Handbook of Pulp, 1st ed.; Sixta, H., Ed.; Wiley-VCH: Weinheim, Germany, 2006; Volume 1, pp. 392, 393, 407, 418, 419. ISBN 978-3-527-30999-3. [Google Scholar]

- Sjöström, E. Wood Chemistry: Fundamentals and Applications, 2nd ed.; Academic Press: San Diego, CA, USA, 1993; pp. 137, 138, 158, 238, 240, 244. ISBN 978-0-12-647481-7. [Google Scholar]

- Portugal-Nunes, D.; Sànchez i Nogué, V.; Pereira, S.R.; Craveiro, S.C.; Calado, A.J.; Xavier, A.M. Effect of cell immobilization and pH on Scheffersomyces stipitis growth and fermentation capacity in rich and inhibitory media. Bioresour. Bioprocess. 2015, 2. [Google Scholar] [CrossRef]

- Nigam, J.N. Ethanol production from hardwood spent sulfite liquor using an adapted strain of Pichia stipitis. J. Ind. Microbiol. Biotechnol. 2001, 26, 145–150. [Google Scholar] [CrossRef] [PubMed]

- Rueda, C.; Calvo, P.A.; Moncalián, G.; Ruiz, G.; Coz, A. Biorefinery options to valorize the spent liquor from sulfite pulping. J. Chem. Technol. Biotechnol. 2015, 90, 2218–2226. [Google Scholar] [CrossRef]

- Rueda, C.; Marinova, M.; Paris, J.; Ruiz, G.; Coz, A. Technoeconomic assessment of different biorefinery approaches for a spent sulfite liquor. J. Chem. Technol. Biotechnol. 2016, 91, 2646–2653. [Google Scholar] [CrossRef]

- Queirós, D.; Rossetti, S.; Serafim, L.S. PHA production by mixed cultures: A way to valorize wastes from pulp industry. Bioresour. Technol. 2014, 157, 197–205. [Google Scholar] [CrossRef]

- Queirós, D.; Fonseca, A.; Lemos, P.C.; Serafim, L.S. Long-term operation of a two-stage polyhydroxyalkanoates production process from hardwood sulphite spent liquor. J. Chem. Technol. Biotechnol. 2016, 91, 2480–2487. [Google Scholar] [CrossRef]

- Queirós, D.; Sousa, R.; Pereira, S.; Serafim, L.S. Valorization of a pulp industry by-product through the production of short-chain organic acids. Fermentation 2017, 3, 20. [Google Scholar] [CrossRef]

- Figueira, D.; Cavalheiro, J.; Ferreira, B. Purification of polymer-grade fumaric acid from fermented spent sulfite liquor. Fermentation 2017, 3, 13. [Google Scholar] [CrossRef]

- Linden, T.; Hahn-Higerdal, B. Fermentation of lignocellulose hydrolysates with yeasts and xylose isomerase. Enzyme Microb. Technol. 1989, 11, 337–353. [Google Scholar] [CrossRef]

- Safi, B.F.; Rouleau, D.; Mayer, R.C.; Desrochers, M. Fermentation kinetics of spent sulfite liquor by Saccharomyces cerevisiae. Biotechnol. Bioeng. 1986, 28, 944–951. [Google Scholar] [CrossRef] [PubMed]

- Mandenius, C.F. Controlling fermentation of lignocellulose hydrolysates in a continuous hollow-fiber reactor using biosensors. Biotechnol. Bioeng. 1988, 32, 123–129. [Google Scholar] [CrossRef] [PubMed]

- Björling, T.; Lindman, B. Evaluation of xylose-fermenting yeasts for ethanol production from spent sulfite liquor. Enzyme Microb. Technol. 1989, 11, 240–246. [Google Scholar] [CrossRef]

- Yu, S.; Wayman, M.; Parekh, S.K. Fermentation to ethanol of pentose-containing spent sulphite liquor. Biotechnol. Bioeng. 1987, 29, 1144–1150. [Google Scholar] [CrossRef] [PubMed]

- Olsson, L.; Hahn-Hägerdal, B. Fermentative performance of bacteria and yeasts in lignocellulose hydrolysates. Process. Biochem. 1993, 28, 249–257. [Google Scholar] [CrossRef]

- Lawford, H.G.; Rousseau, J.D. Production of ethanol from pulp mill hardwood and softwood spent sulfite liquors by genetically engineered E. coli. Appl. Biochem. Biotechnol. 1993, 39–40, 667–685. [Google Scholar] [CrossRef]

- Marko-Varga, G.; Buttler, T.; Gorton, L.; Olsson, L.; Durand, G.; Barceló, D. Qualitative and quantitative carbohydrate analysis of fermentation substrates and broths by liquid chromatographic techniques. J. Chromatogr. A 1994, 665, 317–332. [Google Scholar] [CrossRef]

- Mohandas, D.V.; Whelan, D.R.; Panchal, C.J. Development of xylose-fermenting yeasts for ethanol production at high acetic acid concentrations. Appl. Biochem. Biotechnol. 1995, 51–52, 307–318. [Google Scholar] [CrossRef]

- Schneider, H. Selective removal of acetic acid from hardwood-spent sulfite liquor using a mutant yeast. Enzyme Microb. Technol. 1996, 19, 94–98. [Google Scholar] [CrossRef]

- Palmqvist, E.; Galbe, M.; Hahn-Hägerdal, B. Evaluation of cell recycling in continuous fermentation of enzymatic hydrolysates of spruce with Saccharomyces cerevisiae and on-line monitoring of glucose and ethanol. Appl. Microbiol. Biotechnol. 1998, 50, 545–551. [Google Scholar] [CrossRef] [PubMed]

- Harner, N.K.; Bajwa, P.K.; Formusa, P.A.; Austin, G.D.; Habash, M.B.; Trevors, J.T.; Chan, C.-K.; Ho, C.-Y.; Lee, H. Determinants of tolerance to inhibitors in hardwood spent sulfite liquor in genome shuffled Pachysolen tannophilus strains. Antonie Van Leeuwenhoek 2015, 108, 811–834. [Google Scholar] [CrossRef] [PubMed]

- Pereira, S.R.; Sànchez i Nogué, V.; Frazão, C.J.R.; Serafim, L.S.; Gorwa-Grauslund, M.F.; Xavier, A.M.R.B. Adaptation of Scheffersomyces stipitis to hardwood spent sulfite liquor by evolutionary engineering. Biotechnol. Biofuels 2015, 8. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, S.; Tanifuji, K.; Shiell, K.; Fatehi, P.; Jahan, M.S.; Ohi, H.; Ni, Y. Removal of acetic acid from spent sulfite liquor using anion exchange resin for effective xylose fermentation with Pichia stipitis. Bioresources 2013, 8. [Google Scholar] [CrossRef]

- Pereira, S.R.; Ivanuša, Š.; Evtuguin, D.V.; Serafim, L.S.; Xavier, A.M.R.B. Biological treatment of eucalypt spent sulphite liquors: A way to boost the production of second generation bioethanol. Bioresour. Technol. 2012, 103, 131–135. [Google Scholar] [CrossRef] [PubMed]

- Pinel, D.; D’Aoust, F.; del Cardayre, S.B.; Bajwa, P.K.; Lee, H.; Martin, V.J.J. Saccharomyces cerevisiae genome shuffling through recursive population mating leads to improved tolerance to spent sulfite liquor. Appl. Environ. Microbiol. 2011, 77, 4736–4743. [Google Scholar] [CrossRef] [PubMed]

- Bajwa, P.K.; Pinel, D.; Martin, V.J.J.; Trevors, J.T.; Lee, H. Strain improvement of the pentose-fermenting yeast Pichia stipitis by genome shuffling. J. Microbiol. Methods 2010, 81, 179–186. [Google Scholar] [CrossRef]

- Xavier, A.M.R.B.; Correia, M.F.; Pereira, S.R.; Evtuguin, D.V. Second-generation bioethanol from eucalypt sulphite spent liquor. Bioresour. Technol. 2010, 101, 2755–2761. [Google Scholar] [CrossRef]

- Bajwa, P.K.; Shireen, T.; D’Aoust, F.; Pinel, D.; Martin, V.J.J.; Trevors, J.T.; Lee, H. Mutants of the pentose-fermenting yeast Pichia stipitis with improved tolerance to inhibitors in hardwood spent sulfite liquor. Biotechnol. Bioeng. 2009, 104, 892–900. [Google Scholar] [CrossRef]

- Johansson, E.; Xiros, C.; Larsson, C. Fermentation performance and physiology of two strains of Saccharomyces cerevisiae during growth in high gravity spruce hydrolysate and spent sulphite liquor. BMC Biotechnol. 2014, 14, 47. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Olsson, L. Characterization and fermentation of side streams from sulfite pulping. Process. Biochem. 2014, 49, 1231–1237. [Google Scholar] [CrossRef]

- Tanifuji, K.; Takahashi, S.; Shiell, K.; Jahan, S.M.; Ni, Y.; Ohi, H. Improvement of ethanol fermentation from oligosaccharides in spent sulfite liquor with Pichia stipitis by combined calcium oxide and ion exchange resin treatments. Bioresources 2013, 8. [Google Scholar] [CrossRef]

- Johansson, E.; Brandberg, T.; Larsson, C. Influence of cultivation procedure for Saccharomyces cerevisiae used as pitching agent in industrial spent sulphite liquor fermentations. J. Ind. Microbiol. Biotechnol. 2011, 38, 1787–1792. [Google Scholar] [CrossRef] [PubMed]

- Novy, V.; Krahulec, S.; Longus, K.; Klimacek, M.; Nidetzky, B. Co-fermentation of hexose and pentose sugars in a spent sulfite liquor matrix with genetically modified Saccharomyces cerevisiae. Bioresour. Technol. 2013, 130, 439–448. [Google Scholar] [CrossRef] [PubMed]

- Keating, J.D.; Robinson, J.; Cotta, M.A.; Saddler, J.N.; Mansfield, S.D. An ethanologenic yeast exhibiting unusual metabolism in the fermentation of lignocellulosic hexose sugars. J. Ind. Microbiol. Biotechnol. 2004, 31, 235–244. [Google Scholar] [CrossRef] [PubMed]

- Keating, J.D.; Panganiban, C.; Mansfield, S.D. Tolerance and adaptation of ethanologenic yeasts to lignocellulosic inhibitory compounds. Biotechnol. Bioeng. 2006, 93, 1196–1206. [Google Scholar] [CrossRef]

- Helle, S.S.; Murray, A.; Lam, J.; Cameron, D.R.; Duff, S.J. Xylose fermentation by genetically modified Saccharomyces cerevisiae 259ST in spent sulfite liquor. Bioresour. Technol. 2004, 92, 163–171. [Google Scholar] [CrossRef]

- Fernandes, D.L.A.; Pereira, S.R.; Serafim, L.S.; Evtuguin, D.V.; Xavier, A.M.R.B. Second generation bioethanol from lignocellulosics: Processing of hardwood sulphite spent liquor. In Bioethanol, 1st ed.; Intech: Rijeka, Croatia, 2012; pp. 133, 134. ISBN 978-953-51-0008-9. [Google Scholar]

- Fernandes, D.L.A.; Silva, C.M.; Xavier, A.M.R.B.; Evtuguin, D.V. Fractionation of sulphite spent liquor for biochemical processing using ion exchange resins. J. Biotechnol. 2012, 162, 415–421. [Google Scholar] [CrossRef]

- Das, T.K.; Jain, A.K. Pollution prevention advances in pulp and paper processing. Environ. Prog. 2001, 20, 87–92. [Google Scholar] [CrossRef]

- Faubert, P.; Barnabé, S.; Bouchard, S.; Côté, R.; Villeneuve, C. Pulp and paper mill sludge management practices: What are the challenges to assess the impacts on greenhouse gas emissions? Resour. Conserv. Recycl. 2016, 108, 107–133. [Google Scholar] [CrossRef]

- Gottumukkala, L.D.; Haigh, K.; Collard, F.-X.; van Rensburg, E.; Görgens, J. Opportunities and prospects of biorefinery-based valorisation of pulp and paper sludge. Bioresour. Technol. 2016, 215, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Boshoff, S.; Gottumukkala, L.D.; van Rensburg, E.; Görgens, J. Paper sludge (PS) to bioethanol: Evaluation of virgin and recycle mill sludge for low enzyme, high-solids fermentation. Bioresour. Technol. 2016, 203, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Kuokkanen, T.; Nurmesniemi, H.; Pöykiö, R.; Kujala, K.; Kaakinen, J.; Kuokkanen, M. Chemical and leaching properties of paper mill sludge. Chem. Speciat. Bioavailab. 2008, 20, 111–122. [Google Scholar] [CrossRef]

- Meyer, T.; Edwards, E.A. Anaerobic digestion of pulp and paper mill wastewater and sludge. Water Res. 2014, 65, 321–349. [Google Scholar] [CrossRef] [PubMed]

- Monte, M.C.; Fuente, E.; Blanco, A.; Negro, C. Waste management from pulp and paper production in the European Union. Waste Manag. 2009, 29, 293–308. [Google Scholar] [CrossRef] [PubMed]

- Mendes, C.V.T.; Rocha, J.M.; dos, S.; de Menezes, F.F.; Carvalho, M.; da, G.V.S. Batch and fed-batch simultaneous saccharification and fermentation of primary sludge from pulp and paper mills. Environ. Technol. 2017, 38, 1498–1506. [Google Scholar] [CrossRef]

- Gogoi, H.; Nirosha, V.; Jayakumar, A.; Prabhu, K.; Maitra, M.; Panjanathan, R. Paper mill sludge as a renewable substrate for the production of acetone-butanol-ethanol using Clostridium sporogenes NCIM 2337. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 39–44. [Google Scholar] [CrossRef]

- Guan, W.; Shi, S.; Tu, M.; Lee, Y.Y. Acetone–butanol–ethanol production from Kraft paper mill sludge by simultaneous saccharification and fermentation. Bioresour. Technol. 2016, 200, 713–721. [Google Scholar] [CrossRef]

- Moreau, A.; Montplaisir, D.; Sparling, R.; Barnabé, S. Hydrogen, ethanol and cellulase production from pulp and paper primary sludge by fermentation with Clostridium thermocellum. Biomass Bioenergy 2015, 72, 256–262. [Google Scholar] [CrossRef]

- Wang, W.; Kang, L.; Lee, Y.Y. Production of cellulase from Kraft paper mill sludge by Trichoderma Reesei Rut C-30. Appl. Biochem. Biotechnol. 2010, 161, 382–394. [Google Scholar] [CrossRef] [PubMed]

- Kolbl, S.; Forte-Tavčer, P.; Stres, B. Potential for valorization of dehydrated paper pulp sludge for biogas production: Addition of selected hydrolytic enzymes in semi-continuous anaerobic digestion assays. Energy 2017, 126, 326–334. [Google Scholar] [CrossRef]

- Steffen, F.; Janzon, R.; Wenig, F.; Saake, B. Valorization of waste streams from deinked pulp mills through anaerobic digestion of deinking sludge. Bioresources 2017, 12. [Google Scholar] [CrossRef]

- Ridout, A.; Boshoff, S.; Haigh, K.; Carrier, M.; Van, E.; Görgens, J. Valorisation of paper waste sludge via fermentation and pyrolysis. Cellul. Chem. Technol. 2016, 50, 439–442. [Google Scholar]

- Reckamp, J.M.; Garrido, R.A.; Satrio, J.A. Selective pyrolysis of paper mill sludge by using pretreatment processes to enhance the quality of bio-oil and biochar products. Biomass Bioenergy 2014, 71, 235–244. [Google Scholar] [CrossRef]

- Jain, S.; Chouhan, S.; Chavan, K.J.; Singh, P.; Tiwari, A. Bioethanol production from waste paper sludge as a fermentation substrate by using xylose fermenting yeast. Minerva Biotecnol. 2016, 28, 7. [Google Scholar]

- Gurram, R.N.; Al-Shannag, M.; Lecher, N.J.; Duncan, S.M.; Singsaas, E.L.; Alkasrawi, M. Bioconversion of paper mill sludge to bioethanol in the presence of accelerants or hydrogen peroxide pretreatment. Bioresour. Technol. 2015, 192, 529–539. [Google Scholar] [CrossRef]

- Mendes, C.V.T.; Rocha, J.M.S.; Carvalho, M.G.V.S. Valorization of residual streams from pulp and paper mills: Pretreatment and bioconversion of primary sludge to bioethanol. Ind. Eng. Chem. Res. 2014, 53, 19398–19404. [Google Scholar] [CrossRef]

- Marques, S.; Alves, L.; Roseiro, J.C.; Gírio, F.M. Conversion of recycled paper sludge to ethanol by SHF and SSF using Pichia stipitis. Biomass Bioenergy 2008, 32, 400–406. [Google Scholar] [CrossRef]

- Mendes, C.V.T.; Cruz, C.H.G.; Reis, D.F.N.; Carvalho, M.G.V.S.; Rocha, J.M.S. Integrated bioconversion of pulp and paper primary sludge to second generation bioethanol using Saccharomyces cerevisiae ATCC 26602. Bioresour. Technol. 2016, 220, 161–167. [Google Scholar] [CrossRef]

- Peng, L.; Chen, Y. Conversion of paper sludge to ethanol by separate hydrolysis and fermentation (SHF) using Saccharomyces cerevisiae. Biomass Bioenergy 2011, 35, 1600–1606. [Google Scholar] [CrossRef]

- Pelli, P.; Haapala, A.; Pykäläinen, J. Services in the forest-based bioeconomy—Analysis of European strategies. Scand. J. For. Res. 2017, 32, 559–567. [Google Scholar] [CrossRef]

- Wu, S.; Chang, H.; Phillips, R.; Jameel, H. Techno-economic analysis of the optimum softwood lignin content for the production of bioethanol in a repurposed Kraft mill. Bioresources 2014, 9. [Google Scholar] [CrossRef]

- Fornell, R.; Berntsson, T. Process integration study of a kraft pulp mill converted to an ethanol production plant—Part A: Potential for heat integration of thermal separation units. Appl. Therm. Eng. 2012, 35, 81–90. [Google Scholar] [CrossRef]

- Fornell, R.; Berntsson, T.; Åsblad, A. Process integration study of a kraft pulp mill converted to an ethanol production plant—Part B: Techno-economic analysis. Appl. Therm. Eng. 2012, 42, 179–190. [Google Scholar] [CrossRef]

- Petersen, A.M.; Daful, A.G.; Görgens, J.F. Technical, economic, and greenhouse gas reduction potential of combined ethanol fermentation and biofuel gasification-synthesis at sulphite pulping mills. Energy Fuels 2016, 30, 7387–7399. [Google Scholar] [CrossRef]

- Petersen, A.M.; Haigh, K.; Görgens, J.F. Techno-economics of integrating bioethanol production from spent sulfite liquor for reduction of greenhouse gas emissions from sulfite pulping mills. Biotechnol. Biofuels 2014, 7. [Google Scholar] [CrossRef]

- Fan, Z.; Lynd, L.R. Conversion of paper sludge to ethanol, II: Process design and economic analysis. Bioprocess. Biosyst. Eng. 2007, 30, 35–45. [Google Scholar] [CrossRef]

- Aksoy, B.; Cullinan, H.; Webster, D.; Gue, K.; Sukumaran, S.; Eden, M.; Sammons, N. Woody biomass and mill waste utilization opportunities in Alabama: Transportation cost minimization, optimum facility location, economic feasibility, and impact. Environ. Prog. Sustain. Energy 2011, 30, 720–732. [Google Scholar] [CrossRef]

- Machani, M.; Nourelfath, M.; D’Amours, S. A mathematically-based framework for evaluating the technical and economic potential of integrating bioenergy production within pulp and paper mills. Biomass Bioenergy 2014, 63, 126–139. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.G.; Littlewood, J.; Cheng, H.B. Co-production of biorefinery products from kraft paper sludge and agricultural residues: Opportunities and challenges. Green Chem. 2014, 16, 1527. [Google Scholar] [CrossRef]

- Chen, H.; Venditti, R.; Gonzalez, R.; Phillips, R.; Jameel, H.; Park, S. Economic evaluation of the conversion of industrial paper sludge to ethanol. Energy Econ. 2014, 44, 281–290. [Google Scholar] [CrossRef]

- Robus, C.L.L.; Gottumukkala, L.D.; van Rensburg, E.; Görgens, J.F. Feasible process development and techno-economic evaluation of paper sludge to bioethanol conversion: South African paper mills scenario. Renew. Energy 2016, 92, 333–345. [Google Scholar] [CrossRef]

- Sebastião, D.; Gonçalves, M.S.; Marques, S.; Fonseca, C.; Gírio, F.; Oliveira, A.C.; Matos, C.T. Life cycle assessment of advanced bioethanol production from pulp and paper sludge. Bioresour. Technol. 2016, 208, 100–109. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y. Development and application of co-culture for ethanol production by co-fermentation of glucose and xylose: A systematic review. J. Ind. Microbiol. Biotechnol. 2011, 38, 581–597. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; He, J.; Chang, H.; Jameel, H.; Yong, Q. Coproduction of ethanol and lignosulfonate from moso bamboo residues by fermentation and sulfomethylation. Waste Biomass Valorization 2017, 8, 965–974. [Google Scholar] [CrossRef]

- Mendes, C.V.T.; Carvalho, M.G.V.S.; Baptista, C.M.S.G.; Rocha, J.M.S.; Soares, B.I.G.; Sousa, G.D.A. Valorisation of hardwood hemicelluloses in the kraft pulping process by using an integrated biorefinery concept. Food Bioprod. Process. 2009, 87, 197–207. [Google Scholar] [CrossRef]

- Mendes, C.V.T.; Rocha, J.M.S.; Soares, B.I.G.; Sousa, G.D.A.; Carvalho, M.G.V.S. Extraction of hemicelluloses prior to kraft cooking: A step for an integrated biorefinery in the pulp mill. O Pap. 2011, 72, 79–83. [Google Scholar]

- Guigou, M.D.; Cebreiros, F.; Cabrera, M.N.; Ferrari, M.D.; Lareo, C. Bioethanol production from Eucalyptus grandis hemicellulose recovered before kraft pulping using an integrated biorefinery concept. Biomass Convers. Biorefinery 2017, 7, 191–197. [Google Scholar] [CrossRef]

- Boucher, J.; Chirat, C.; Lachenal, D. Extraction of hemicelluloses from wood in a pulp biorefinery, and subsequent fermentation into ethanol. Energy Convers. Manag. 2014, 88, 1120–1126. [Google Scholar] [CrossRef]

- Cabrera, M.N.; Arrosbide, M.F.; Franzoni, P.; Cassella, N. Integrated forest biorefineries: Green liquor extraction in eucalyptus wood prior to kraft pulping. Biomass Convers. Biorefinery 2016, 6, 465–474. [Google Scholar] [CrossRef]

- Martin-Sampedro, R.; Eugenio, M.E.; Moreno, J.A.; Revilla, E.; Villar, J.C. Integration of a kraft pulping mill into a forest biorefinery: Pre-extraction of hemicellulose by steam explosion versus steam treatment. Bioresour. Technol. 2014, 153, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.-J.; Ramaswamy, S.; Al-Dajani, W.W.; Tschirner, U. Process modeling and analysis of pulp mill-based integrated biorefinery with hemicellulose pre-extraction for ethanol production: A comparative study. Bioresour. Technol. 2010, 101, 624–631. [Google Scholar] [CrossRef] [PubMed]

- Moshkelani, M.; Marinova, M.; Perrier, M.; Paris, J. The forest biorefinery and its implementation in the pulp and paper industry: Energy overview. Appl. Therm. Eng. 2013, 50, 1427–1436. [Google Scholar] [CrossRef]

- Lundberg, V.; Axelsson, E.; Mahmoudkhani, M.; Berntsson, T. Process integration of near-neutral hemicellulose extraction in a Scandinavian kraft pulp mill—Consequences for the steam and Na/S balances. Appl. Therm. Eng. 2012, 43, 42–50. [Google Scholar] [CrossRef]

- Kemppainen, K.; Ranta, L.; Sipilä, E.; Östman, A.; Vehmaanperä, J.; Puranen, T.; Langfelder, K.; Hannula, J.; Kallioinen, A.; Siika-aho, M.; et al. Ethanol and biogas production from waste fibre and fibre sludge—The FibreEtOH concept. Biomass Bioenergy 2012, 46, 60–69. [Google Scholar] [CrossRef]

- Rødsrud, G.; Lersch, M.; Sjöde, A. History and future of world’s most advanced biorefinery in operation. Biomass Bioenergy 2012, 46, 46–59. [Google Scholar] [CrossRef]

- Modahl, I.S.; Brekke, A.; Valente, C. Environmental assessment of chemical products from a Norwegian biorefinery. J. Clean. Prod. 2015, 94, 247–259. [Google Scholar] [CrossRef]

| Compound | Chemical Composition (%) | |

|---|---|---|

| Softwood | Hardwood | |

| Cellulose | 40–44 | 45–50 |

| Hemicelluloses | 25–29 | 25–35 |

| Lignin | 26–31 | 18–24 |

| Hydrolysis | Concentrated Acid | Diluted Acid | Enzymatic |

|---|---|---|---|

| Hydrolysis agent | 30–70% H2SO4/HCl | 2–5% H2SO4/HCl | Cellulases and hemicellulases |

| Advantages | Low temperature High sugar yield | Low acid consumption | Mild conditions No inhibitors formation High sugar yield |

| Disadvantages | Large amounts of acids Equipment corrosion Environmental and cost issues | High temperature Formation of inhibitors Low sugar yield | High cost Slow reactions |

| Feedstock | Config | Microorganism | [EtOH] (g·L−1) | Prodvol (g·L−1·h−1) | Yethanol (g g dw−1) | Ref. |

| E. globulus | SSF | S. cerevisiae IR2T9 a | 30–38 | NA | 0.168–0.202 b | [23] |

| E. globulus | SSF | S. cerevisiae D5A | 5.67 | 0.033 | 0.042 b | [105] |

| A. confusa | 5.88 | 0.035 | 0.045 b | |||

| Populus trichocarpa | SHF | S. cerevisiae wild-type | NA | NA | 0.12 b | [106] |

| Populus maximowiczi | NA | NA | 0.11 b | |||

| Populus tremula | NA | NA | 0.14 b | |||

| Betula pendula | NA | NA | 0.13 b | |||

| Fagus sylvatica | NA | NA | 0.13 b | |||

| Pinus sylvestrii | NA | NA | 0.02 b | |||

| Pinus sylvestriib | NA | NA | 0.20 b | |||

| Jabon wood | SSF | NA | NA | 0.022–0.129 c | [107] | |

| Feedstock | Config | Microorganism | [EtOH] (g·L−1) | Prodvol (g·L−1·h−1) | Yethanol (% theoret.) | Ref. |

| Pinus radiatad | SSF | S. cerevisiae IR2-9a a | 28 | 0.388 | 62 | [108] |

| NS | SSF | S. cerevisiae NRRL Y-2034 | 14.24–17.90 | 0.15–0.25 | 68.33–85.90 | [109] |

| C. molischiana ATCC 2516 | 12.51–18.21 | 0.19–0.24 | 60.00–87.38 | |||

| NS | CBP | S. cerevisiae MT8-1 e | 0.71 | 0.010 | 41.2 | [110] |

| Feedstock | Detox. | Microrganism | [EtOH] (g·L−1) | Prodvol (g·L−1·h−1) | Yethanol (g·g−1) | Ref. |

|---|---|---|---|---|---|---|

| Hardwood | ||||||

| E. globulus | Biological a | S. stipitis NRRL-7124 b | NA | 0.028 ± 0.005 | 0.26 ± 0.06 | [113] |

| NS | No | P. tannophilus GHW301 c | 7.4–8.5 | NA | NA | [132] |

| E. globulus | No | S. stipitis NRRL-7124 | 1.76 | 0.02 | 0.13 | [133] |

| S. stipitis C4 isolate d | 4.60 | 0.05 | 0.16 | |||

| E. globulus | No | S. stipitis C4 isolate d | 12.2 | 0.04 | 0.39 | [50] |

| NS | CaO + Anion exchange | S. stipitis CBS6054 | 10.6 | 0.441 | NA | [134] |

| E. globulus | Biological a | S. stipitis NRRL-7124 | 2.4 | 0.086 | 0.24 | [135] |

| NS | No | S. cerevisiae R57 c | NA | NA | 0.41 | [136] |

| NS | No | S. stipitis GS301 c and GS302 c | 1.8 | NA | NA | [137] |

| E. globulus | Ion exchange | S. stipitis NRRL-7124 | 8.1 | 1.22 | 0.49 | [138] |

| Softwood | ||||||

| Spruce | No | S. cerevisiae Thermosacc e | 9 | 0.41 | 0.25 | [140] |

| S. cerevisiae CCUG 53310 f | 11 | 0.5 | 0.31 | |||

| NS | No | S. cerevisiae Red Star | NA | 0.00–0.19 | NA | [141] |

| NS | CaO + Ion exchange | S. stipitis CBS6054 | 1.3 | 0.054 | NA | [142] |

| NS | No | S. cerevisiae CCUG 53310 f | 10.05 ± 0.09 | 0.838 ± 0.008 | NA | [143] |

| Hardwood + Softwood | ||||||

| Spruce + Beech | No | S. cerevisiae IBB10B05 g | NA | NA | 0.31–0.44 | [144] |

| Type of PPMS | Fermentation | Microorganism | [EtOH] (g·L−1) | Prodvol (g·L−1·h−1) | Yethanol (%) | Ref. |

|---|---|---|---|---|---|---|

| Recycled paper sludge | Batch/SHF | S. cerevisiae PE-2 | 5.6–6.3 | 0.47–0.52 | 67.9–76.8 | [26] |

| Primary sludge | Batch/SSF | S. cerevisiae | 22.7 | 0.94 | 80.6 | [157] |

| K. marxianus NCYC 1426 | 20.7 | 0.86 | 73.7 | |||

| Fed-batch/SSF | S. cerevisiae (baker yeast) | 40.7 | 0.52 | 32.4 | ||

| K. marxianus NCYC 1426 | 24.2 | 0.31 | 18.8 | |||

| Virgin pulp sludge | Fed-batch/SSF | S. cerevisiae MH1000 | 34.2 | 0.230 | 66.9 | [153] |

| Corrugated recycled paper sludge | 45.5 | 0.448 | 78.2 | |||

| Primary sludge | Batch/SSF | S.cerevisiae ATCC 26602 | 41.7–41.9 | 0.78–0.80 | 48.9–49.4 | [170] |

| Fed-batch/SSF | 33.3–39.7 | 0.43–0.52 | 39.1–46.4 | |||

| Primary sludge a | Batch/SHF | FermPro™ | 25–30 | 1.73–3.28 | 94.5–95.7 | [167] |

| Primary sludge b | Batch/SHF | S. cerevisiae (baker yeast) | 8.3 | 0.16 | 64.7 | [168] |

| P. stipitis DSM 3651 | 10.5 | 0.20 | 76.5 | |||

| Primary sludge c | Batch/SHF | S. cerevisiae (baker yeast) | 7.1 | 0.14 | 0.32 | [168] |

| P. stipitis DSM 3651 | 8.5 | 0.16 | 62.7 | |||

| Primary sludge | Batch/SHF | S. cerevisiae GIM-2 | 9.5 | 0.59 | 66.5 | [171] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Branco, R.H.R.; Serafim, L.S.; Xavier, A.M.R.B. Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock. Fermentation 2019, 5, 4. https://doi.org/10.3390/fermentation5010004

Branco RHR, Serafim LS, Xavier AMRB. Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock. Fermentation. 2019; 5(1):4. https://doi.org/10.3390/fermentation5010004

Chicago/Turabian StyleBranco, Rita H. R., Luísa S. Serafim, and Ana M. R. B. Xavier. 2019. "Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock" Fermentation 5, no. 1: 4. https://doi.org/10.3390/fermentation5010004

APA StyleBranco, R. H. R., Serafim, L. S., & Xavier, A. M. R. B. (2019). Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock. Fermentation, 5(1), 4. https://doi.org/10.3390/fermentation5010004