Effect of Various Pretreatment Methods on Bioethanol Production from Cotton Stalks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material and Reagents

2.2. Pretreatment of Cotton Stalks

2.2.1. Hydrothermal Treatment

2.2.2. Microwave-Assisted Acid Pretreatment

2.2.3. Alkali Treatment

2.2.4. Organosolv Treatment

2.3. Bioconversion of Pretreated CS to Ethanol

2.4. Analytical Methods

2.5. Calculations

3. Results and Discussion

3.1. Composition of Native and Pretreated CS

3.2. Conversion of Pre-Treated CS to Bioethanol Applying PSSF

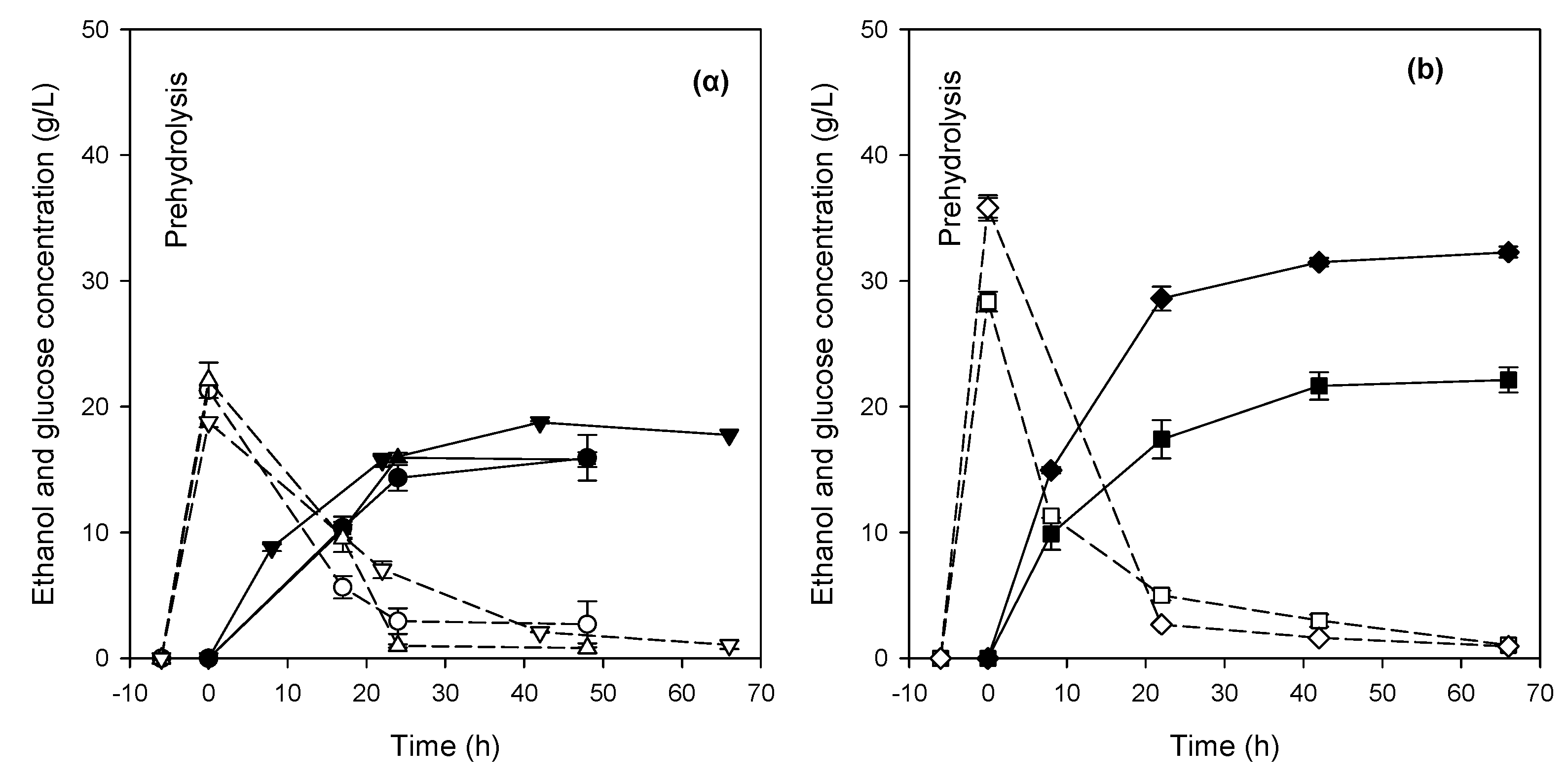

3.3. Effect of Organosolv-Hydrothermally Treated CS Concentration and Pre-Hydrolysis Time on Bioethanol Production

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- De Bhowmick, G.; Sarmaha, A.K.; Sen, R. Lignocellulosic biorefinery as a model for sustainable development of biofuels and value added products. Bioresour. Technol. 2018, 247, 1144–1154. [Google Scholar] [CrossRef] [PubMed]

- Lokko, Y.; Heijde, M.; Schebesta, K.; Scholtès, P.; Van Montagu, M.; Giacca, M. Biotechnology and the bioeconomy-Towards inclusive and sustainable industrial development. New Biotechnol. 2018, 40, 5–10. [Google Scholar] [CrossRef] [PubMed]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Kaur, U.; Oberoi, H.S.; Bhargav, V.K.; Sharma-Shivappa, R.; Dhaliwal, S.S. Ethanol production from alkali- and ozone-treated cotton stalks using thermotolerant Pichia kudriavzevii HOP-1. Ind. Crop Prod. 2012, 37, 219–226. [Google Scholar] [CrossRef]

- Food and Agriculture Organisation of the United Nations (FAO). Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 16 November 2018).

- Keshav, P.K.; Shaik, N.; Koti, S.; Linga, V.R. Bioconversion of alkali delignified cotton stalk using two-stage dilute acid hydrolysis and fermentation of detoxified hydrolysate into ethanol. Ind. Crop Prod. 2018, 91, 323–331. [Google Scholar] [CrossRef]

- Chen, H.; Liu, J.; Chang, X.; Chen, D.; Xue, Y.; Liu, P.; Lin, H.; Han, S. A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Process. Technol. 2017, 160, 196–206. [Google Scholar] [CrossRef]

- Sun, S.; Sun, S.; Cao, X.; Sun, R. The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour. Technol. 2016, 199, 49–58. [Google Scholar] [CrossRef]

- Galbe, M.; Zacchi, G. Pretreatment: The key to efficient utilization of lignocellulosic materials. Biomass Bioenergy 2012, 46, 70–78. [Google Scholar] [CrossRef]

- Mathew, A.K.; Parameshwaran, B.; Sukumaran, R.K.; Pandey, A. An evaluation of dilute acid and ammonia fiber explosion pretreatment for cellulosic ethanol production. Bioresour. Technol. 2016, 199, 13–20. [Google Scholar] [CrossRef]

- Zhuang, X.; Wang, W.; Yu, Q.; Qi, W.; Wang, Q.; Tan, X.; Zhou, G.; Yuan, Z. Liquid hot water pretreatment of lignocellulosic biomass for bioethanol production accompanying with high valuable products. Bioresour. Technol. 2016, 199, 68–75. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Pei, Z.; Wang, D. Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: A review. Bioresour. Technol. 2016, 199, 21–33. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Verma, J.P. Sustainable bio-ethanol production from agro-residues: A review. Renew. Sustain. Energy Rev. 2015, 41, 550–567. [Google Scholar] [CrossRef]

- Koppram, R.; Tomás-Pejó, E.; Xiros, C.; Olsson, L. Lignocellulosic ethanol production at high-gravity: Challenges and perspectives. Trends Biotechnol. 2014, 32, 46–53. [Google Scholar] [CrossRef] [PubMed]

- Modenbach, A.A.; Nokes, S.E. Enzymatic hydrolysis of biomass at high-solids loadings—A review. Biomass Bioenergy 2013, 56, 526–544. [Google Scholar] [CrossRef]

- Hoyer, K.; Galbe, M.; Zacchi, G. The effect of prehydrolysis and improved mixing on high-solids batch simultaneous saccharification and fermentation of spruce to ethanol. Process. Biochem. 2013, 48, 289–293. [Google Scholar] [CrossRef]

- Kalogiannis, K.; Stefanidis, S.; Marianou, A.; Michailof, C.; Kalogianni, A.; Lappas, A. Lignocellulosic biomass fractionation as a pretreatment step for production of fuels and green chemicals. Waste Biomass Valoriz. 2015, 6, 781–790. [Google Scholar] [CrossRef]

- Dogaris, I.; Karapati, S.; Mamma, D.; Kalogeris, E.; Kekos, D. Hydrothermal processing and enzymatic hydrolysis of sorghum bagasse for fermentable carbohydrates production. Bioresour. Technol. 2009, 100, 6543–6549. [Google Scholar] [CrossRef]

- Chilari, D.; Dimos, K.; Georgoula, G.; Paschos, T.; Mamma, D.; Louloudi, A.; Papayannakos, N.; Kekos, D. Bioethanol production from alkali-treated cotton stalks at high solids loading applying non-isothermal simultaneous saccharification and fermentation. Waste Biomass Valoriz. 2017, 8, 1919–1929. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Technical Report NREL/TP-510-42618; National Renewable Energy Laboratory: Golden, CO, USA, 2012. Available online: https://www.nrel.gov/docs/gen/fy13/42618.pdf (accessed on 16 November 2018).

- Haykir, N.I.; Bakir, U. Ionic liquid pretreatment allows utilization of high substrate loadings in enzymatic hydrolysis of biomass to produce ethanol from cotton stalks. Ind. Crop Prod. 2013, 51, 408–414. [Google Scholar] [CrossRef]

- Jiang, W.; Chang, S.; Li, H.; Oleskowicz-Popiel, P.; Xu, J. Liquid hot water pretreatment on different parts of cotton stalk to facilitate ethanol production. Bioresour. Technol. 2015, 176, 175–180. [Google Scholar] [CrossRef] [PubMed]

- Agblevor, F.A.; Batz, S.; Trumbo, J. Composition and ethanol production potential of cotton gin residues. In Biotechnology for Fuels and Chemicals. Applied Biochemistry and Biotechnology; Davison, B.H., Lee, J.W., Finkelstein, M., McMillan, J.D., Eds.; Humana Press: Totowa, NJ, USA, 2003; pp. 219–230. [Google Scholar]

- Li, H.; Qu, Y.; Yang, Y.; Chang, S.; Xu, J. Microwave irradiation—A green and efficient way to pretreat biomass. Bioresour. Technol. 2016, 199, 34–41. [Google Scholar] [CrossRef] [PubMed]

- Silverstein, R.A.; Chen, Y.; Sharma-Shivappa, R.R.; Boyette, M.D.; Osborne, J. A comparison of chemical pretreatment methods for improving saccharification of cotton stalks. Bioresour. Technol. 2007, 98, 3000–3011. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Zhou, D.; Wang, Y.; Wei, S.; Yang, W.; Kuang, M.; Ma, L.; Fang, D.; Xu, S.; Du, S. Bioethanol production from cotton stalk: A comparative study of various pretreatments. Fuel 2016, 184, 527–532. [Google Scholar] [CrossRef]

- Du, S.K.; Su, X.; Yang, W.; Wang, Y.; Kuang, M.; Ma, L.; Fang, D.; Zhou, D. Enzymatic saccharification of high pressure assist-alkali pretreated cotton stalk and structural characterization. Carbohydr. Polym. 2016, 140, 279–286. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wei, X.; Zhou, S.; Liu, M.; Tu, Y.; Li, A.; Chen, P.; Wang, Y.; Zhang, X.; Tai, H.; et al. Steam explosion distinctively enhances biomass enzymatic saccharification of cotton stalks by largely reducing cellulose polymerization degree in G. barbadense and G. hirsutum. Bioresour. Technol. 2015, 181, 224–230. [Google Scholar] [CrossRef] [PubMed]

- Gaur, R.; Soam, S.; Sharma, S.; Gupta, R.P.; Bansal, V.R.; Kumar, R.; Tuli, D.K. Bench scale dilute acid pretreatment optimization for producing fermentable sugars from cotton stalk and physicochemical characterization. Ind. Crop Prod. 2016, 83, 104–112. [Google Scholar] [CrossRef]

- Da Silva, A.R.G.; Errico, M.; Rong, B.-G. Techno-economic analysis of organosolv pretreatment process from lignocellulosic biomass. Clean Technol. Environ. Policy 2018, 20, 1401–1412. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin Valorization: Improving Lignin Processing in the Biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- McIntosh, S.; Vancov, T.; Palmer, J.; Morris, S. Ethanol production from cotton gin trash using optimised dilute acid pretreatment and whole slurry fermentation processes. Bioresour. Technol. 2014, 173, 42–51. [Google Scholar] [CrossRef]

- Lu, X.; Zheng, X.; Li, X.; Zhao, J. Adsorption and mechanism of cellulase enzymes onto lignin isolated from corn stover pretreated with liquid hot water. Biotechnol. Biofuels 2016, 9, 118. [Google Scholar] [CrossRef] [PubMed]

- Berlin, A.; Balakshin, M.; Gilkes, N.; Kadla, J.; Maximenko, V.; Kubo, S.; Saddler, J. Inhibition of cellulase, xylanase and beta-glucosidase activities by softwood lignin preparations. J. Biotechnol. 2006, 125, 198–209. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Kosa, M.; Sun, Q. Fermentation to bioethanol/biobutanol. In Materials for Biofuels; Ragauskas, A., Ed.; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2014; pp. 155–189. [Google Scholar]

- Gladis, A.; Bondesson, P.-Μ.; Galbe, M.; Zacchi, G. Influence of different SSF conditions on ethanol production from corn stover at high solids loadings. Energy Sci. Eng. 2015, 3, 481–489. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Lu, J.; Zhao, J.; Qu, Y. Characteristics of corn stover pretreated with liquid hot water and fed-batch semi-simultaneous saccharification and fermentation for bioethanol production. PLoS ONE 2014, 9, e95455. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Zhao, X.; Li, W.-C.; Zhu, J.-Q.; Liu, L.; Li, B.-Z.; Yuan, Y.-J. Process analysis and optimization of simultaneous saccharification and co-fermentation of ethylenediamine-pretreated corn stover for ethanol production. Biotechnol. Biofuels 2018, 11, 118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Plácido, J.; Imam, T.; Capareda, S. Evaluation of ligninolytic enzymes, ultrasonication and liquid hot water as pretreatments for bioethanol production from cotton gin trash. Bioresour. Technol. 2013, 139, 203–208. [Google Scholar] [CrossRef] [PubMed]

| Component | Content (g/100 g of Pretreated CS) | ||||

|---|---|---|---|---|---|

| Microwave-Assisted Acid a | Hydrothermal b | Alkali c | Organosolv d | Organosolv-Hydrothermal e | |

| Cellulose | 48.6 ± 0.3 | 47.3 ± 2.1 | 55.3 ± 1.5 | 77.0 ± 0.7 | 79.6 ± 0.2 |

| Hemicellulose | 9.6 ± 0.8 | 3.9 ± 0.1 | 21.2 ± 0.7 | 1.4 ± 0.3 | 0.4 ± 0.1 |

| Lignin Klason | 38.3 ± 1.5 | 39.1 ±1.3 | 22.2 ± 1.0 | 9.7 ± 0.6 | 10.4 ± 0.5 |

| Acid Soluble Lignin | 2.3 ± 0.0 | 1.7 ± 0.0 | 1.1 ± 0.0 | 1.1 ± 0.1 | 0.8 ± 0.0 |

| Total lignin | 40.6 ± 1.6 | 40.8 ± 1.3 | 23.3 ± 1.0 | 10.8 ± 0.7 | 11.2 ± 0.5 |

| Pretreatment Method (Pretreatment Conditions) | Ethanol (g/L) | Ethanol Yield (g/100 g Pretreated CS) | Theoretical Ethanol Yield (%) 1 | Ethanol Productivity (g/L/h) |

|---|---|---|---|---|

| Alkali treatment (10% w/w NaOH, 121 °C, 30 min) | 15.9 ± 0.7 | 10.6 ± 0.5 | 33.9 ± 1.5 | 0.33 ± 0.02 |

| Microwave-assisted acid pretreatment (210 °C, 10 min, 2%, w/w sulfuric acid) | 15.9 ± 1.8 | 10.6 ± 1.2 | 38.5 ± 1.3 | 0.33 ± 0.02 |

| Hydrothermolysis (175 °C, 2 h, N2) | 18.8 ± 0.3 | 12.5 ± 0.3 | 54.6 ± 1.3 | 0.45 ± 0.04 |

| Organosolv | 22.1 ± 0.2 | 14.8 ± 0.1 | 33.8 ± 0.4 | 0.52 ± 0.01 |

| Organosolv and hydrothermal treatment (175 °C, 2 h, N2) | 32.3 ± 2.2 | 21.5 ± 1.5 | 47.6 ± 2.7 | 0.49 ± 0.05 |

| Type of Pretreatment | Fermenting Microorganism | Solids Loading (%, w/v) | Type of Process | Ethanol Conc. (g/L) | Productivity (g/L/h) | Reference |

|---|---|---|---|---|---|---|

| Alkaline (4% w/v NaOH, 121 °C/15psi for 60 min) | Pichia kudriavzevii HOP-1 | 10.0 | PSSF (12 h) 1 | 19.48 | 0.41 | [4] |

| Ozone treatment (ozone concentration of 45 mg/L and flow rate of 0.37 L/min for 150 min) | P. kudriavzevii HOP-1 | 10.0 | SHF | 10.96 | 0.46 | [4] |

| Dilute acid (0.8% v/v (1.5% w/v), H2SO4 at 180 °C for 12 min) | S. cerevisiae Thermosacc® Dry | 10.0 | SSF | 12.88 | 0.13 | [33] |

| Liquid Hot Water (severity factor: 4.34) | Dry yeast | 8.0 | PSSF (24 h) 1 | 14.0 | 0.12 | [23] |

| Alkaline (3% NaOH at room temperature for 24 h). Two-stage acid hydrolysis of cellulose | S. cerevisiae VS3 and Pichia stipitis NCIM-3498 | 10.0 3 | - | 11.64 | 0.24 | [6] |

| High pressure-assisted alkali pretreatment (HPAP) (3.0% NaOH, 121 °C, 130 kPa for 40 min) | S. cerevisiae | 2.0 2 | SHF | 3.32 | 0.07 | [27] |

| Ionic Liquids (EMIMAc) (150 °C for 30 min) | S. cerevisiae NRRL Y-132 | 15.0 2 | SHF | 22.9 | 1.92 | [22] |

| Ultrasonication and hot water and ligninolytic enzymes pretreatment | S. cerevisiae Ethanol Red | 10.0 2 | SHF | 5.5 | 0.08 | [40] |

| Organosolv and hydrothermal treatment | Dry yeast | 20.0 | PSSF (14 h) 1 | 47.0 | 1.57 | Present study |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dimos, K.; Paschos, T.; Louloudi, A.; Kalogiannis, K.G.; Lappas, A.A.; Papayannakos, N.; Kekos, D.; Mamma, D. Effect of Various Pretreatment Methods on Bioethanol Production from Cotton Stalks. Fermentation 2019, 5, 5. https://doi.org/10.3390/fermentation5010005

Dimos K, Paschos T, Louloudi A, Kalogiannis KG, Lappas AA, Papayannakos N, Kekos D, Mamma D. Effect of Various Pretreatment Methods on Bioethanol Production from Cotton Stalks. Fermentation. 2019; 5(1):5. https://doi.org/10.3390/fermentation5010005

Chicago/Turabian StyleDimos, Konstantinos, Thomas Paschos, Argiro Louloudi, Konstantinos G. Kalogiannis, Angelos A. Lappas, Nikolaos Papayannakos, Dimitris Kekos, and Diomi Mamma. 2019. "Effect of Various Pretreatment Methods on Bioethanol Production from Cotton Stalks" Fermentation 5, no. 1: 5. https://doi.org/10.3390/fermentation5010005

APA StyleDimos, K., Paschos, T., Louloudi, A., Kalogiannis, K. G., Lappas, A. A., Papayannakos, N., Kekos, D., & Mamma, D. (2019). Effect of Various Pretreatment Methods on Bioethanol Production from Cotton Stalks. Fermentation, 5(1), 5. https://doi.org/10.3390/fermentation5010005