Formulation of Broiler Chicken Feeds Using Distillers Dried Grains with Solubles

Abstract

1. Introduction

2. Energy and Amino Acid Utilization of DDGS by Poultry

2.1. Energy

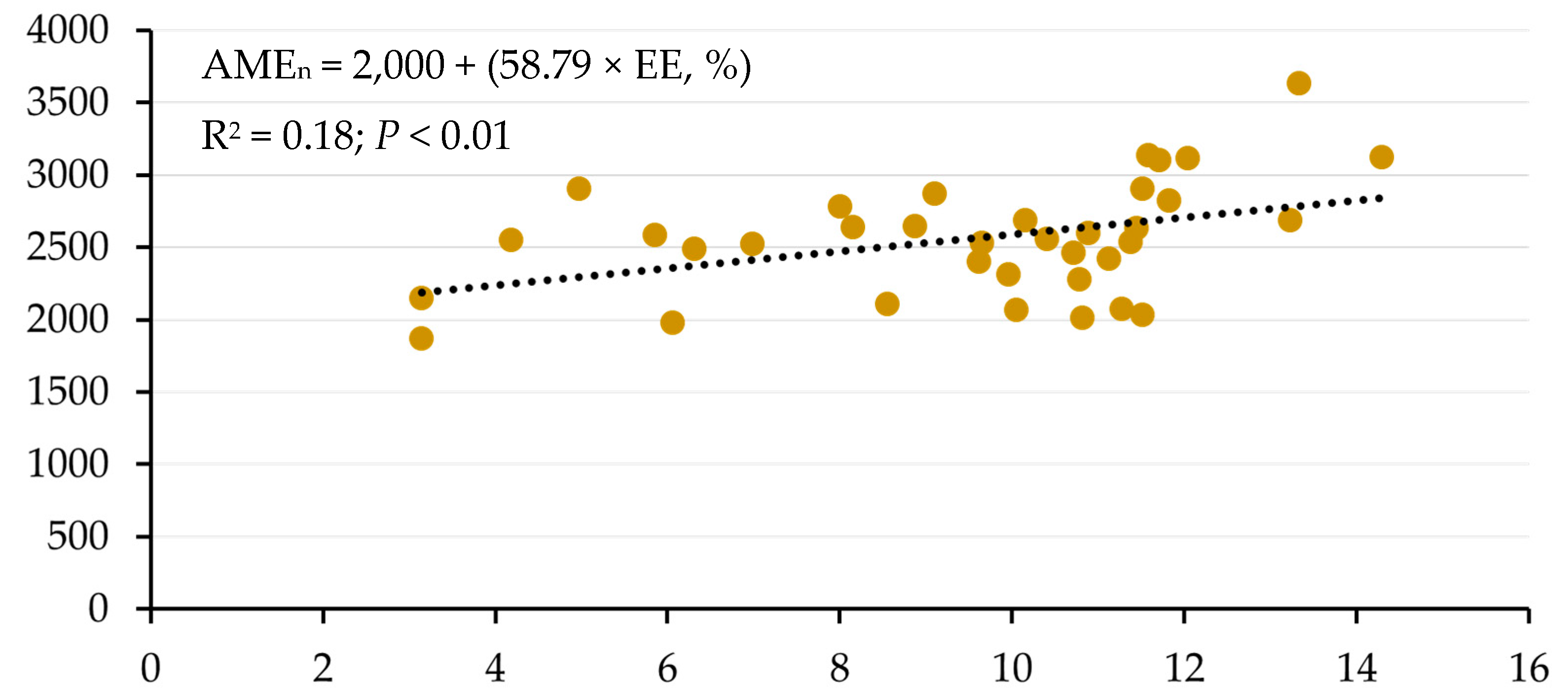

(33.27 × hemicellulose, %); R2 = 0.89, C(p) = −2.57

(0.81 × GE, kcal/kg) − (12.26 × crude protein, %); R2 = 0.87

(89.75 × crude protein, %) + (125.80 × starch, %) − (40.67 × total dietary fiber, %);

R2 = 0.90, R2adj = 0.86, C(p) = 2.58, PRESS = 199,819

(117.8 × crude protein, %) + (149.41 × starch, %) − (18.30 × NDF, %);

R2 = 0.92, R2adj = 0.88, C(p) = 1.35, PRESS = 227,477

(121.08 × ash, %); R2 = 0.70, R2adj = 0.67, C(p) = 0.62

2.2. Amino Acids

3. Influence of DDGS on Live Performance and Processing Characteristics of Broiler Chickens

4. Distillers Corn Oil as a Feed Ingredient for Poultry

5. The Impact of DDGS on Gastrointestinal Health of Poultry

Funding

Conflicts of Interest

References

- Henchion, M.; McCarthy, M.; Resconi, V.C.; Troy, D. Meat consumption: Trends and quality matters. Meat Sci. 2014, 98, 561–568. [Google Scholar] [CrossRef] [PubMed]

- Donohue, M.; (Agri-Stats, Fort Wayne, IN, USA). Personal communication, 2018.

- United States Department of Agriculture Feed Grains Yearbook. Available online: https://www.ers.usda.gov/data-products/feed-grains-database/feed-grains-yearbook-tables.aspx (accessed on 28 June 2018).

- Waldroup, P.W.; Wang, Z.; Coto, C.; Cerrate, S.; Yan, F. Development of a standardized nutrient matrix for corn distillers dried grains with solubles. Int. J. Poult. Sci. 2007, 6, 478–483. [Google Scholar] [CrossRef]

- Świątkiewicz, S.; Koreleski, J. The use of distillers dried grains with solubles (DDGS) in poultry nutrition. Worlds Poult. Sci. J. 2008, 64, 257–266. [Google Scholar] [CrossRef]

- Salim, H.M.; Kruk, Z.A.; Lee, B.D. Nutritive value of corn distillers dried grains with solubles as an ingredient of poultry diets: A review. Worlds Poult. Sci. J. 2010, 66, 411–432. [Google Scholar] [CrossRef]

- Liu, K. Chemical composition of distillers grains, a review. J. Agric. Food Chem. 2011, 59, 1508–1526. [Google Scholar] [CrossRef] [PubMed]

- Shurson, G.C. The Role of Biofuels Coproducts in feeding the world sustainably. Annu. Rev. Anim. Biosci. 2017, 5, 229–254. [Google Scholar] [CrossRef] [PubMed]

- Kong, C.; Adeola, O. Evaluation of amino acid and energy utilization in feedstuff for swine and poultry diets. Asian-Australas. J. Anim. Sci. 2014, 27, 917–925. [Google Scholar] [CrossRef] [PubMed]

- Batal, A.B.; Dale, N.M. True metabolizable energy and amino acid digestibility of distillers dried grains with solubles. J. Appl. Poult. Res. 2006, 15, 89–93. [Google Scholar] [CrossRef]

- Parsons, C.M.; Martinez, C.; Singh, V.; Radhakrishman, S.; Noll, S. Nutritional value of conventional and modified DDGS for poultry. In Proceedings of the Multi-State Poultry Nutrition and Feeding Conference, Indianapolis, IN, USA, 21–23 May 2006. [Google Scholar]

- Fastinger, N.D.; Latshaw, J.D.; Mahan, D.C. Amino acid availability and true metabolizable energy content of corn distillers dried grains with solubles in adult cecectomized roosters. Poult. Sci. 2006, 85, 1212–1216. [Google Scholar] [CrossRef] [PubMed]

- Rochell, S.J.; Kerr, B.J.; Dozier, W.A. Energy determination of corn co-products fed to broiler chicks from 15 to 24 days of age, and use of composition analysis to predict nitrogen-corrected apparent metabolizable energy. Poult. Sci. 2011, 90, 1999–2007. [Google Scholar] [CrossRef] [PubMed]

- Meloche, K.J.; Kerr, B.J.; Shurson, G.C.; Dozier, W.A. Apparent metabolizable energy and prediction equations for reduced-oil corn distillers dried grains with solubles in broiler chicks from 10 to 18 days of age. Poult. Sci. 2013, 92, 3176–3183. [Google Scholar] [CrossRef] [PubMed]

- Meloche, K.J.; Kerr, B.J.; Billor, N.; Shurson, G.C.; Dozier, W.A. Validation of prediction equations for apparent metabolizable energy of corn distillers dried grains with solubles in broiler chicks. Poult. Sci. 2014, 93, 1428–1439. [Google Scholar] [CrossRef] [PubMed]

- Adeola, O.; Zhai, H. Metabolizable energy value of dried corn distillers grains and corn distillers grains with solubles for 6-week-old broiler chickens. Poult. Sci. 2012, 91, 712–718. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Y.; Bai, S.P.; Ding, X.M.; Wang, J.P.; Zeng, Q.F.; Su, Z.W.; Xuan, Y.; Zhang, K.Y. Nitrogen-corrected apparent metabolizable energy value of corn distillers dried grains with solubles for laying hens. Anim. Feed Sci. Technol. 2018, 238, 66–72. [Google Scholar] [CrossRef]

- Swiatkiewicz, S.; Swiatkiewicz, M.; Arczewska-Wlosek, A.; Jozefiak, D. Efficacy of feed enzymes in pig and poultry diets containing distillers dried grains with solubles: A review. J. Anim. Physiol. Anim. Nutr. 2016, 100, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Jha, R.; Woyengo, T.A.; Li, J.; Bedford, M.R.; Vasanthan, T.; Zijlstra, R.T. Enzymes enhance degradation of the fiber–starch–protein matrix of distillers dried grains with solubles as revealed by a porcine in vitro fermentation model and microscopy. J. Anim. Sci. 2015, 93, 1039–1051. [Google Scholar] [CrossRef] [PubMed]

- Latorre, J.D.; Hernandez-Velasco, X.; Vicente, J.L.; Wolfenden, R.; Hargis, B.M.; Tellez, G. Effects of the inclusion of a Bacillus direct-fed microbial on performance parameters, bone quality, recovered gut microflora, and intestinal morphology in broilers consuming a grower diet containing corn distillers dried grains with solubles. Poult. Sci. 2017, 96, 2728–2735. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, S.R.; Aoyagi, S.; Han, Y.; Parsons, C.M.; Baker, D.H. Limiting order of amino acids in corn and soybean meal for growth of the chick. Poult. Sci. 1994, 73, 1887–1896. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.J.; Utterback, P.L.; Applegate, T.J.; Parsons, C.M. Comparison of amino acid digestibility of feedstuffs determined with the precision-fed cecectomized rooster assay and the standardized ileal amino acid digestibility assay. Poult. Sci. 2011, 90, 2511–2519. [Google Scholar] [CrossRef] [PubMed]

- Adedokun, S.A.; Jaynes, P.; Payne, R.L.; Applegate, T.J. Standardized ileal amino acid digestibility of corn, corn distillers dried grains with solubles, wheat middlings, and bakery by-products in broilers and laying hens. Poult. Sci. 2015, 94, 2480–2487. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Liu, K. Changes in composition and amino acid profile during dry grind ethanol processing from corn and estimation of yeast contribution toward DDGS proteins. J. Agric. Food Chem. 2010, 58, 3430–3437. [Google Scholar] [CrossRef] [PubMed]

- Almeida, F.N.; Htoo, J.K.; Thomson, J.; Stein, H.H. Amino acid digestibility of heat damaged distillers dried grains with soluble fed to pigs. J. Anim. Sci. Biotechnol. 2013, 4, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Adedokun, S.A.; Adeola, O.; Parsons, C.M.; Lilburn, M.S.; Applegate, T.J. Standardized ileal amino acid digestibility of plant feedstuffs in broiler chickens and turkey poults using a nitrogen-free or casein diet. Poult. Sci. 2008, 87, 2535–2548. [Google Scholar] [CrossRef] [PubMed]

- Dozier, W.A.; Perryman, K.R.; Hess, J.B. Apparent ileal amino acid digestibility of reduced-oil distillers dried grains with solubles fed to broilers from 23 to 31 days of age. Poult. Sci. 2015, 94, 379–383. [Google Scholar] [CrossRef] [PubMed]

- Guney, A.C.; Shim, M.Y.; Batal, A.B.; Dale, N.M.; Pesti, G.M. Effect of feeding low-oil distillers dried grains with solubles on the performance of broilers. Poult. Sci. 2013, 92, 2070–2076. [Google Scholar] [CrossRef] [PubMed]

- Cortes-Cuevas, A.; Ramirez-Estrada, S.; Arce-Menocal, J.; Avila-Gonzalez, E.; Lopez-Coello, C. Effect of feeding low-oil DDGS to laying hens and broiler chickens on performance and egg yolk and skin pigmentation. Braz. J. Poult. Sci. 2015, 17, 247–254. [Google Scholar] [CrossRef]

- Kim, E.J.; Purswell, J.L.; Branton, S.L. Effects of increasing inclusion rates of a low fat distillers dried grains with solubles in finishing broiler diets. Int. J. Poult. Sci. 2016, 15, 182–187. [Google Scholar] [CrossRef]

- Dozier, W.A.; Hess, J.B. Growth and meat yield responses of Hubbard × Cobb 500 male broilers fed diets formulated with distillers dried grains with solubles varying in ether extract content and inclusion rate from 1 to 33 days of age. J. Appl. Poult. Res. 2015, 24, 436–450. [Google Scholar] [CrossRef]

- Dozier, W.A.; McCafferty, K.M.; Hess, J.B. Growth and meat yield responses of Ross × Ross 708 male broilers fed diets formulated with distillers dried grains with solubles varying in ether extract content and inclusion rate from 1 to 49 days of age. J. Appl. Poult. Res. 2017, 26, 23–37. [Google Scholar] [CrossRef]

- Kerr, B.J.; Dozier, W.A.; Shurson, G.C. Lipid digestibility and energy content of distillers’ corn oil in swine and poultry. J. Anim. Sci. 2016, 94, 2900–2908. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.J.; Purswell, J.L.; Davis, J.D.; Loar, R.E.; Karges, K. Live production and carcass characteristics of broilers fed a blend of poultry fat and corn oil derived from distillers dried grains with solubles. Poult. Sci. 2013, 92, 2732–2736. [Google Scholar] [CrossRef] [PubMed]

- Viguie, M.; Livingston, K.A.; Malheiros, R.; Ferket, P.R. Effect of corn distillers solubles oil on broiler chicken skin pigmentation and plasma carotenoid content. Poult. Sci. 2016, 95 (E-Suppl. 1), 13. [Google Scholar]

- Rinttilä, T.; Apajalahti, J. Intestinal microbiota and metabolites—Implications for broiler chicken health and performance. J. Appl. Poult Res. 2013, 22, 647–658. [Google Scholar] [CrossRef]

- Shurson, G.C. Yeast and yeast derivatives in feed additives and ingredients: Sources, characteristics, animal responses, and quantification methods. Anim. Feed Sci. Technol. 2017, 235, 60–76. [Google Scholar] [CrossRef]

- Vohra, A.; Syal, P.; Madan, A. Probiotic yeasts in livestock sector. Anim. Feed Sci. Technol. 2016, 219, 31–47. [Google Scholar] [CrossRef]

- Jaworski, N.W.; Owusu-Asiedu, A.; Walsh, M.C.; McCann, J.C.; Loor, J.J.; Stein, H.H. Effects of a 3 strain Bacillus-based direct-fed microbial and dietary fiber concentration on growth performance and expression of genes related to absorption and metabolism of volatile fatty acids in weanling pigs. J. Anim. Sci. 2017, 95, 308–319. [Google Scholar] [CrossRef] [PubMed]

- Perez, V.G.; Jacobs, C.M.; Barnes, J.; Jenkins, M.C.; Kuhlenschmidt, M.S.; Fahey, G.C.; Parsons, C.M.; Pettigrew, J.E. Effect of corn distillers dried grains with solubles and Eimeria acervulina infection on growth performance and the intestinal microbiota of young chicks. Poult. Sci. 2011, 90, 958–964. [Google Scholar] [CrossRef] [PubMed]

- Abudabos, A.M.; Al-Atiyat, R.M.; Albatshan, H.A.; Aljassim, R.; Aljumaah, M.R.; Alkhulaifi, M.M.; Stanley, D.M. Effects of concentration of corn distillers dried grains with solubles and enzyme supplementation on cecal microbiota and performance in broiler chickens. Appl. Microbiol. Biotechnol. 2017, 101, 7017–7026. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, M.; Rogiewicz, A.; McMillan, E.; Rodriguez-Lecompte, J.C.; Patterson, R.; Slominski, B.A. Effect of yeast-derived products and distillers dried grains with solubles (DDGS) on growth performance and local innate immune response of broiler chickens challenged with Clostridium perfringens. Avian Pathol. 2016, 45, 334–345. [Google Scholar] [CrossRef] [PubMed]

| Item, % Dry Matter Unless Noted Otherwise | Rochell et al. [13] | Meloche et al. [14] | Meloche et al. [15] | Adeola and Zhai [16] | Weighted Mean | |||

|---|---|---|---|---|---|---|---|---|

| n = 6 | n = 15 | n = 15 | n = 1 | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | ||

| Dry matter | 89.72 | 2.15 | 89.07 | 1.55 | 89.32 | 0.93 | 92.10 | 89.36 |

| Crude protein | 30.32 | 2.35 | 30.28 | 2.01 | 31.33 | 1.70 | 28.70 | 30.67 |

| Ether extract | 9.81 | 2.80 | 9.47 | 2.65 | 9.45 | 2.63 | 10.10 | 9.54 |

| Total dietary fiber | 34.99 | 2.48 | 33.33 | 2.36 | 31.22 | 2.24 | NR | 32.73 |

| Neutral detergent fiber | 37.78 | 6.63 | 35.72 | 6.14 | 35.14 | 3.94 | 24.83 | 35.52 |

| Acid detergent fiber | 11.74 | 2.37 | 11.86 | 2.21 | 10.49 | 1.87 | 8.45 | 11.19 |

| Crude fiber | 7.67 | 0.53 | NR | NR | 9.19 | 0.81 | 5.93 | 8.63 |

| Starch | 4.81 | 1.63 | 2.27 | 1.06 | 5.19 | 1.87 | NR | 3.91 |

| Ash | 4.68 | 0.41 | 4.90 | 0.30 | 5.17 | 0.38 | NR | 4.98 |

| Gross energy, kcal/kg | 5287 | 114 | 4998 | 108 | 5063 | 121 | 4762 | 5065 |

| AMEn, kcal/kg | 2764 | 363 | 2309 | 260 | 2676 | 272 | 2688 | 2563 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rochell, S.J. Formulation of Broiler Chicken Feeds Using Distillers Dried Grains with Solubles. Fermentation 2018, 4, 64. https://doi.org/10.3390/fermentation4030064

Rochell SJ. Formulation of Broiler Chicken Feeds Using Distillers Dried Grains with Solubles. Fermentation. 2018; 4(3):64. https://doi.org/10.3390/fermentation4030064

Chicago/Turabian StyleRochell, Samuel J. 2018. "Formulation of Broiler Chicken Feeds Using Distillers Dried Grains with Solubles" Fermentation 4, no. 3: 64. https://doi.org/10.3390/fermentation4030064

APA StyleRochell, S. J. (2018). Formulation of Broiler Chicken Feeds Using Distillers Dried Grains with Solubles. Fermentation, 4(3), 64. https://doi.org/10.3390/fermentation4030064