Abstract

Ethanol, carbon dioxide and glycerol are the major products produced by yeast during wort fermentation but they have little impact on beer and spirit flavour. It is the type and concentration of secondary metabolites that can determine overall beer flavour. These compounds are (but not only) primarily: higher alcohols, esters, carbonyls and sulphur compounds—inorganic and organic. There are a number of factors that can modify the balance of these compounds most of which are discussed in this review paper.

1. Introduction

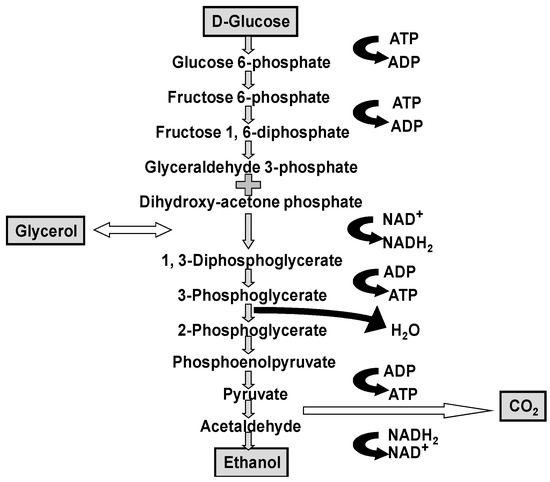

The primary metabolites that occur during the fermentation of either brewer’s or distiller’s wort are ethanol, carbon dioxide and glycerol (Figure 1) [1,2]. Although these metabolites contribute to beer and spirit properties, they have little effect on their flavour characteristics. The flavour and aroma of any beer or spirit is, in large part, determined by secondary metabolic products of the yeast strain employed together with the wort composition and the fermentation conditions used [3,4].

Figure 1.

Formation of ethanol, glycerol and CO2 from glucose by the Embden-Meyerhof-Parnas (EMP) pathway. Two molecules of ethanol and CO2 or glycerol are formed from one molecule of glucose.

This review will consider, in some detail, secondary metabolites produced during wort fermentation most of which (not all) have flavour implications on both beer and distilled spirits (also with a cursory consideration of wine fermentation). However, the text “Brewing and Distilling Yeasts” [5] has recently been completed and contains greater details on this subject.

2. Beer Flavour Production by Yeast

The aroma of beer (and spirits–details later) is the sum of several hundreds of flavour-active compounds produced during every stage of the brewing process [3,4]. The great majority (not all) of these substances are yeast secondary metabolites. They are produced during wort (malt extract) fermentation and consists of fermentation intermediates and by-products (metabolites). Higher alcohols (also called fusel oils), esters, vicinal diketones (VDKs) other carbonyls and sulphur compounds are the key (not all) flavour elements produced by yeast. These compounds (plus malt and hop constituents) determine a beer’s final quality, particularly when it is fresh [6]. Higher alcohols and esters are desirable volatile beer constituents, with a few exceptions [7]. Together with these compounds, yeast wort metabolism contributes to the biosynthesis of these other groups of beer flavour active compounds: organic acids, sulphur compounds (both organic and inorganic) and aldehydes [8,9]. This is an area of yeast activity that is currently termed metabolomics [10]. Metabolomics is the “systematic study of the unique chemical fingerprints that specific cellular processes leave behind”. It is the study of relatively small-molecule metabolite profiles [11]. Many of these small-molecules contribute to beer (and spirit) flavour profiles. Esters (and higher alcohols) are major contributors to beer (and spirit) flavour profile [12] along with a plethora of other metabolites.

Obviously, flavour-active compounds must be maintained within certain limits. Otherwise, a single compound or group of compounds (for example, VDKs) may predominate and prejudice a beer’s flavour balance. Furthermore, flavour compounds such as esters often act in synergy with other compounds to affect beer flavour in concentrations well below their individual threshold values [13,14,15].

Although it is worth repeating that ethanol, carbon dioxide and glycerol are the major products produced by yeast during wort fermentation (Figure 1), they have minimal impact on beer flavour [1]. It is the type and concentration of other metabolites (excretion products), already discussed, which primarily determine beer flavour balance. Yeast strain, malt variety and type, fermentation temperature, adjunct (unmalted cereals and sugar) and percentage in the grist, fermenter design and geometry, wort pH, buffering capacity, wort concentration (gravity), etc., are all influencing factors particularly regarding VDK metabolism [16]. In addition, hop variety and hopping procedures are important factors [17].

Each type of beer has its own unique aroma triggered (but not exclusively) either by the yeast strain employed during the fermentation [18,19,20] or by a plethora of process parameters used during fermentation [21,22,23,24,25,26,27,28,29,30]. Only isoamyl acetate (banana-like aroma) concentration is usually above the threshold level in most lager beers, ales normally have ethyl acetate (solvent-like aroma) and ethyl hexanoate (apple-like aroma) as supplementary flavouring compounds with levels above their taste threshold [29]. However, compounds such as diacetyl and other VDKs (with certain exceptions) should usually be below their flavour threshold values. Diacetyl contributes negatively to a buttery (stale milk) flavour in most beers. Table 1 lists threshold values for the main esters and higher alcohols present in ale and lager beers [4].

Table 1.

Major esters and higher (fusel) alcohols in beer [4].

The biosynthesis and process variables of higher alcohols and esters during wort fermentation have been extensively reviewed by Pires and colleagues [30] and the following discussion has been employed in this publication (with permission) (Table 2). This also includes the effects of maltose concentration (compared to glucose) (Table 3) in a synthetic medium on ester formation [1,30]. Reduced ester formation in wort has also been documented. In addition, material compiled in “An Introduction to Brewery Science and Technology” published by the Institute of Brewing and Distilling has been employed here [1] together with “Whisky: Technology, Production and Marketing” [2]—with permission.

Table 2.

Effects of process variables on beer ester and higher alcohol levels.

Table 3.

Ethyl acetate and isoamyl acetate produced by brewing yeast strains during fermentation of synthetic media [12] a.

3. Higher Alcohols

In flavour terms, the higher alcohols that occur in beer (and many spirits) are: n-propanol, isobutanol, 2-methyl-1-butanol, 3-methyl-1-butanol together with more than 40 further alcohols, have been identified. Regulation of higher alcohol biosynthesis is complex since they either have been produced as by-products of amino acid metabolism or via pyruvate and ethanol produced from carbohydrate metabolism (Figure 1 and Figure 2) [39].

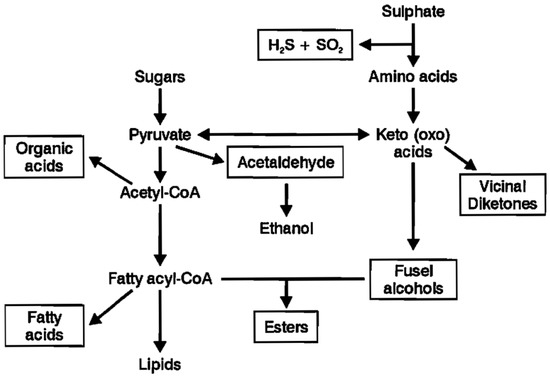

Figure 2.

Major metabolic routes by which brewer’s yeasts synthesize fusel alcohols, esters, sulphur compounds, VDKs, acetaldehydes and ethanol [1].

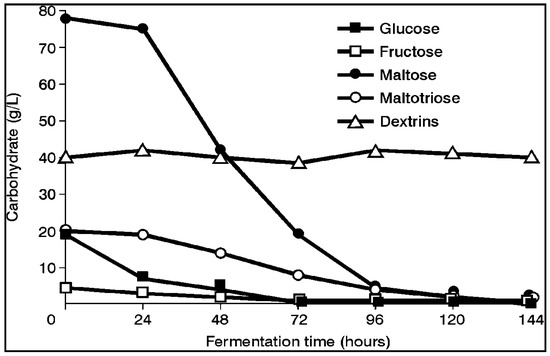

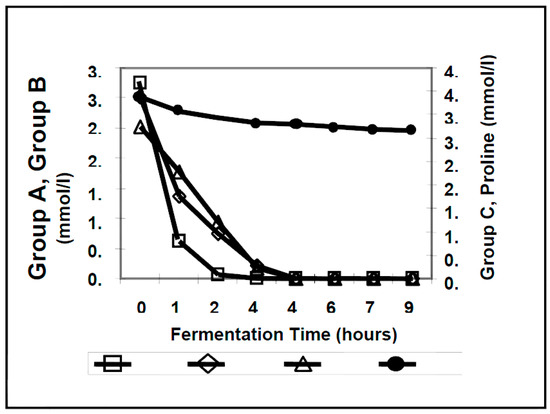

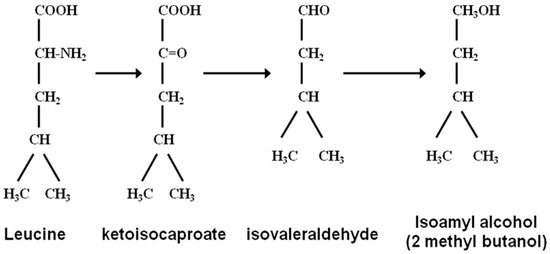

Both brewer’s and distiller’s yeast strains (similar to the five wort sugars (glucose, fructose, sucrose, maltose and maltotriose)—Figure 3) [1] absorb wort’s spectrum of amino acids and small peptides in a distinct order (Figure 4 and Table 4) [40,41] from which they take the amino group (Ehrlich Pathway) so that they can be incorporated into their own structures. What remains from the amino acids are α-keto acids which enter into an irreversible chain reaction that will ultimately form higher alcohols. This metabolic pathway was originally suggested by the German physician Paul Ehrlich (Figure 5) who was intrigued with the structural molecular similarities between amyl alcohol and isoleucine and isoamyl alcohol with leucine (Figure 6 and Figure 7). Ehrlich was awarded the 1908 Nobel Prize in Physiology or Medicine for his contribution to immunology. His observations led to an investigation of the relationship between these amino acids and higher alcohol synthesis. When he supplemented a fermenting medium with these amino acids, increased higher alcohol formation was observed. Ehrlich also proposed that amino acids were enzymatically hydrolyzed to form the corresponding higher alcohol, along with ammonia and carbon dioxide. As ammonia was not detected in the medium, it was assumed that it was incorporated directly into yeast proteins. Subsequently, Neubauer and Fromherz [42] proposed a few intermediate steps to the Ehrlich Pathway, completing a metabolic pathway that is currently accepted. However, a detailed enzymatic chain reaction was demonstrated. Several decades after Ehrlich’s original studies [43] when the enzymatic sequence for the Ehrlich Pathway—transaminase, decarboxylase and alcohol dehydrogenase a detailed metabolic pathway for the Ehrlich Pathway has been elucidated. Although this pathway is the most studied in this context, higher alcohols are also formed during the upstream (anabolic pathway) biosynthesis of amino acids [44,45]. The most important specific pathway in the brewing context is the de novo synthesis of branched-chain amino acids (BCAAs) through the isoleucine-leucine (ILV) pathway (Figure 7) [39,45].

Figure 3.

Uptake order of wort sugars by brewer’s yeast cultures [1].

Figure 4.

Amino acid absorption pattern during wort fermentation [40,41].

Table 4.

Order of wort amino acids and ammonia uptake during fermentation [40,46].

Figure 5.

Paul Ehrlich.

Figure 6.

Ehrlich pathway–relationship between higher (fusel) alcohols and amino acids.

Figure 7.

Anabolic route for the synthesis of fusel oils.

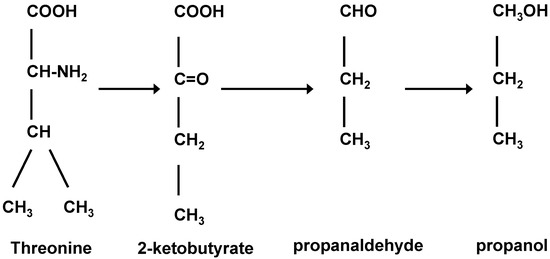

4. Esters

Esters are largely formed during the active phase of primary fermentation by the enzymatic condensation of organic acids with alcohols. Volatile esters in beer are divided into two major groups: the acetate esters and the medium-chain fatty acid (MCFA) ethyl esters. The acetate esters are synthesized from acetic acid (acetate) with ethanol or a higher alcohol (propanol, butanol, etc.) (Figure 8). In the ethyl ester’s family, ethanol will form the alcohol radical and the acid side of the equation is an MCFA [47]. Although dozens of different esters can be formed during the fermentation stage of any beer or spirit [3,48], of major importance as aroma constituents are: ethyl acetate (solvent-like aroma), isoamyl acetate (banana aroma), isobutyl acetate (fruity aroma), phenylethyl acetate (roses and honey aroma), ethyl hexanoate (sweet apple aroma) and ethyl octanoate (sour apple aroma) (further details on Table 1). Esters are synthesized in the yeast cell’s cytoplasm, and they readily leave the cell because they are lipophilic. However, while small-chain acetate esters easily diffuse through the plasma membrane, MCFA ethyl esters may have their passage hindered [49,50,51].

Figure 8.

Production of ethyl acetate during fermentation.

Ester synthesis involves organic acids linked to a coenzyme A module in order to form an acetyl-CoA molecule (Figure 2). Acetyl-CoAs are highly energetic entities, which in the presence of oxygen can be β-oxidized (spliced) into smaller units (acetyl-CoA) in the yeast cell’s mitochondria. This will occur unless the organic acid involved is acetic acid, where it will be converted to acetyl CoA. The great majority of the acetyl-CoA produced by the yeast cell comes from the oxidative decarboxylation of pyruvate (Figure 4). Aerobic conditions inside mitochondria will induce acetyl-CoA to enter the TCA Cycle (Krebs Cycle) to form ATP. In the absence of oxygen, acetyl-CoA will be enzymatically esterified with an alcohol to form acetate esters (Figure 2). Also, MCFA ethyl esters are formed from longer chains of acyl-CoA with ethanol. Figure 3 summarises the major metabolic routes by which brewer’s yeast strains synthesize both higher alcohols and esters.

4.1. Influence of Yeast Strains on Ester Formation

Brewers and distillers have at their disposal a large number of yeast strains from which to produce spirits, ales and lagers. The use of alternative yeast strains offers the prospect of more efficient fermentations, together with diverse characteristics and a variety of beer and spirit flavour characteristics. The characteristics of strain variation have been extensively reported but a basic understanding of the reasons for these differences is still necessary [12]. To illustrate yeast strain diversity, ester production under standard conditions has been extensively studied. Fermentations were conducted in 1 L static fermenters with a 16°Plato all-malt wort at 20 °C (1°Plato ≡ 1004 SG) [12]. When the fermentations were complete, ethyl acetate and isoamyl acetate were determined in the fermented wort samples (Table 5). The results of differences regarding strain variations concerning the production of esters during wort fermentation illustrate strain differentiation between the two brewing and distilling yeast strains of Saccharomyces cerevisiae (ale and distilling) and the two strains of S. pastorianus (lager). Although both the S. cerevisiae and the S. pastorianus genomes have now been sequenced [52,53] and this has enabled an intense study of the genetic control of each species [54,55], an understanding of the reasons for ester production are still largely unclear.

Table 5.

Ethyl acetate and isoamyl acid (mg/L) produced by distillers and brewer’s yeast strains [12].

4.2. Influence of Wort Clarity on Ester Formation

The level of solids carried over as a result of cereal mashing into wort, also solids resulting from grape crushing in the production of must, and their effect on yeast fermentation performance in the production of beer, whisky and wine has been the subject of considerable study [31,32,35,56,57,58].

Wort solids (also called trub) influence:

- The removal of CO2 from solution during fermentation by acting as nucleation sites Removal of CO2 from fermenting wort can occur if no suspended particles are present but it contains a great deal of energy [31].

- Wort solids confer nutritive value to the fermentation medium. The rate of fermentation is more rapid in the presence of insoluble material. Wort solids are generally associated with higher levels of fatty acids [51].

- In some instances, yeast cells are able to attach themselves to wort solids and display enhanced growth because of the nutrient concentration that occurs at the particle’s surface [32,59].

In order to assess the influence of wort clarity on ester formation, a 15°Plato wort, produced in the Heriot Watt University 2hL pilot brewery (Figure 9) and a number of other wort types were fermented in 1 L volume batches employing 2 L tall tubes at 27 °C with a S. cerevisiae distiller’s yeast strain. Carbon dioxide evolution rates during fermentation together with ethyl acetate and isoamyl acetate concentrations at the completion of fermentation were determined. The following wort conditions were studied:

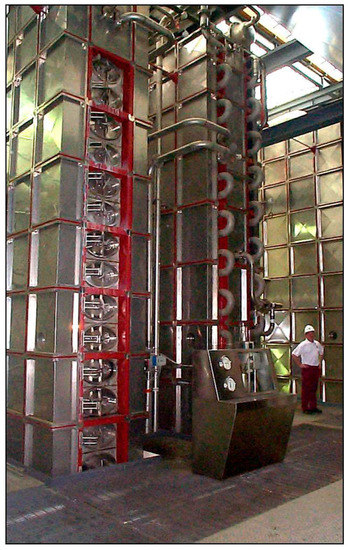

Figure 9.

The 2hL brewing pilot plant at Heriot Watt University, Edinburgh.

- Cloudy wort

- Clear wort

- Clear wort plus 0.2 g/L diatomaceous earth (DE)

- Clear wort plus DE and 5.5 mg/L C16:1 fatty acid

- Clear wort plus 0.2 g/L bentonite.

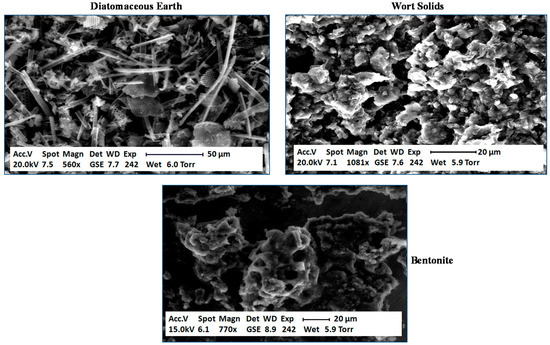

Carbon dioxide concentrations during the fermentation of the wort types have been determined (Table 6) [32]. Cloudy wort, containing trub, and wort containing DE acted as nucleation sites and this increased CO2 evolution out of the wort. Bentonite did not function as a nucleation site with clear wort. Consequently, the CO2 remained in the fermentation medium to a greater extent. Why was there a difference between trub, DE and bentonite? In order to examine each type of particle and obtain data on their surface characteristics, environmental confocal scanning electron microscopy (ESEM) was conducted (Figure 10) [55]. DE consisted of a heterogeneous mix of shapes and sizes of particles. The surface of most of the particles consisted of an extremely porous structure, as would be expected. The micrograph of the cloudy wort solids showed a mix of different structures, again porous in nature. Bentonite demonstrated a more homogenous structure. It did not appear to exhibit the same porous nature as DE or wort solids.

Table 6.

Concentration of CO2 (g/L) present during fermentation of 15°Plato worts [32].

Figure 10.

Environmental scanning electron microscopy (SEM) of different wort solid materials.

Ester levels are also influenced by the wort particle concentration and type. Ethyl acetate and isoamyl acetate concentrations are high in cloudy wort and DE that contained C16:1 fatty acid (Table 7 and Table 8). This reflects the fact that unsaturated fatty acids, that would be absorbed onto wort trub, induced the synthesis of esters [32,35,57,60,61].

Table 7.

Ethyl acetate concentration (mg/L) following 160 h fermentation of different 15°Plato wort types [32].

Table 8.

Isoamyl acetate concentration (mg/L) following 160 h fermentation of different 15°Plato wort types [32].

4.3. Biosynthesis of Acetate Esters

Research on enzymatic synthesis during ester production by yeast dates from the early 1960s [62,63] and the critical enzyme was purified and named alcohol acetyl-transferase (AATase). The most studied and comprehensively characterised enzymes responsible for ester synthesis are AATases I and II, which are encoded by the genes ATFI and ATF2 [64,65,66]. It was also found that lager yeast strains have an additional ATF1 homologous gene–Lg-ATF1 [8,28,47,54,56,59,60,61,65,67] which encodes an AATase very similar to that encoded from the original ATF1 gene. The additional gene expression on lager yeast strains compared to ale strains enhances acetate ester production and ultimately a beer’s aroma profile.

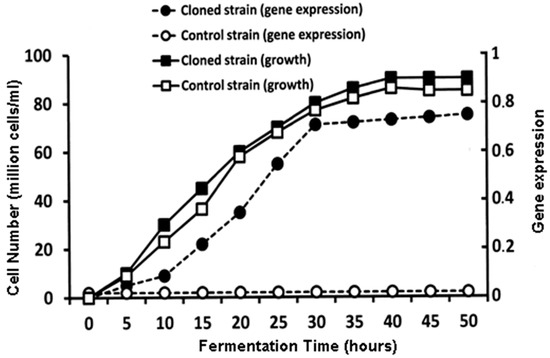

Earlier this decade, a brewer’s yeast strain was designed to increase the ester/higher alcohol ratio by overexpressing ATF1 and decreasing the expression of a gene related to higher alcohol synthesis [56]. Ester production by this genetically modified strain was considerably higher than the parental strain. It has also been shown that the level of ATF genes has an impact on acetate ester production [64,65,67,68]. Overexpression of ATF1 strains may have up to a 180-fold increased isoamyl acetate production and a 30-fold increased ethyl acetate production when compared to wild type yeast strains [67]. Analysis has also revealed that ATF1–encrypted ATTases appear to be responsible for the majority of acetate ester production. When ATF1 and ATF2 were deleted, no acetate esters were formed from alcohols with more than five carbon atoms, such as isoamyl acetate and phenyl ethyl acetate. This means that the formation of the required beer banana aroma (isoamyl acetate) depends on ATF1- and ATF2-encoded enzymes. Subsequently, Saerens and colleagues [22] confirmed that the maximum expression levels of ATF1 and ATF2 are directly correlated to the final concentration of acetate esters. It is possible that there might be more ATTases involved in acetate ester production but currently published knowledge is unclear. Figure 11 illustrates the time course during the production of the major acetate esters with the ATF1 gene cloned into a yeast strain compared to the same yeast strain that does not contain the ATF1 gene [54].

Figure 11.

Expression of the ATF1 gene during fermentation. Cells cultured (with shaking) in yeast extract–peptone–glucose medium at 21 °C. Control strain (growth) (□); cloned strain (growth) (●); control strain (gene expression) (○); cloned strain (gene expression) (■) [54].

Pires and colleagues [30] have discussed the importance of acetate esters in alcohol-free beers (AFBs). AFBs can either be produced as a result of physical removal of ethanol from finished beer or control of the biological process involved in beer fermentation [69]. Reduced ethanol affects the retention of volatile aroma-active compounds [18]. A brewing yeast mutant capable of overproducing isoamyl acetate and isoamyl alcohol has been isolated [68]. The sweet banana aroma of the resulting beer could be employed to overcome the undesirable worty off-flavour of AFB [70]. As a consequence, sensory analyses showed that the enhanced level of isoamyl acetate ester had a positive effect on the fruity palate fullness and aroma intensity of the AFB.

4.4. Ester Metabolism during Beer Aging (Maturation)

During beer aging (maturation) following primary fermentation, a beer’s flavour will usually change. This change will usually occur as a result of the yeast culture’s metabolism in a secondary fermenter, cask, keg or bottle [71] or by spontaneous chemical condensation of organic acids with ethanol during beer aging [72,73]. Some esters such as isoamyl acetate are known to be hydrolyzed during beer aging [74]. Chemical hydrolysis and esterification are acid-catalysed [72], but the remaining esterases from yeast autolysis can function in unpasteurized beers [74]. Other ethyl esters such as ethyl nicotinate (medicinal, solvent), ethyl pyruvate (peas, freshly cut grass) and ethyl lactate (fruity, buttery) are also formed during beer aging [73].

5. Carbonyls

Over 200 carbonyl compounds are reported to contribute to the flavour of fresh beer and other alcoholic beverages [1,6]. These compounds influence beer flavour and are produced as a result of yeast metabolism during fermentation. They are various aldehydes (for example, acetaldehyde) and vicinal diketones, notably diacetyl. Also, carbonyl compounds exert a significant influence on beer flavour stability [6]. Excessive concentrations of carbonyl compounds are known to cause stale flavour in beer. The effects of aldehydes on flavour stability are reported to develop grassy notes (propanol, 2-methyl butanol, pentanol and a papery taste trans-2-nonenal, furfural) and a number of novel analytical methods have been developed to develop beer carbonyls [75].

5.1. Acetaldehyde

Quantitatively, acetaldehyde is the carbonyl present in beer at the conclusion of primary fermentation in the highest concentration (10–15 mg/L). It is produced by yeast as a result of the decarboxylation of pyruvate (Figure 1 and Figure 2) and is an intermediate in the metabolic formation of ethanol during glycolysis. It can be present in beer at concentrations above its flavour threshold (approximately 10 mg/L), and it imparts an undesirable “cut grass” or “green apple” character. This carbonyl accumulates during the period of active growth. As with higher alcohols and esters, the extent of acetaldehyde accumulation is determined by the yeast strain employed and the fermentation conditions. Although the yeast strain is of primary importance (details later), elevated wort oxygen concentration, pitching (inoculation rate), wort gravity and fermentation temperatures all influence acetaldehyde accumulation [23]. In addition, premature flocculation of a yeast culture from suspension in fermenting wort [76,77] does not allow the reutilisation of excreted acetaldehyde associated with the later stages of fermentation.

Acetaldehyde has long been known as a product of alcoholic fermentation by yeast (Figure 1 and Figure 2). The concentration of acetaldehyde in various wine musts after fermentations lasting from 5 to 15 days, varied from 20–200 mg/L in the fermented medium. Many years later, a detailed study of acetaldehyde production by S. cerevisiae wine yeasts was conducted [78]. Eighty-six strains were investigated for their ability to produce acetaldehyde in a synthetic fermentation medium and in grape must. Acetaldehyde production characteristics did not differ significantly between the two media, ranging from a few mg/L to 60 mg/L and was found to be a yeast strain characteristic. A 30 °C fermentation temperature increased acetaldehyde production. This study permitted the strains to be assigned into three different phenotypes: low, medium and high acetaldehyde production in S. cerevisiae from both technological and genetic aspects. The low and high phenotypes also differed considerably in the production of acetic acid, acetoin and higher alcohols and can be useful for studying acetaldehyde production in S. cerevisiae.

Acetaldehyde, ethanol and acetate metabolism in S. cerevisiae is complex [79] because several enzymes are involved with a dependence on the cell’s redox balance. The two enzymes ultimately responsible for their metabolic pathways are alcohol dehydrogenase (ADH) and aldehyde dehydrogenase (ALDH), each of which consists of several isoenzymes. The metabolism between ethanol and acetaldehyde is catalysed by aldehyde dehydrogenase [2,5]. In addition, acetaldehyde can be metabolised by oxidation to acetate, with aldehyde dehydrogenases (ALDH) [80,81].

The presence of acetaldehyde is one of the many stress conditions that yeast cells may encounter [79,82]. Several heat-shock proteins (HSP) genes are induced that are also involved in the response to other forms of stress (for example, ethanol) [83]. ALDHs perform an important role during yeast acetaldehyde metabolism when the cells are growing in ethanol. Further addition of acetaldehyde (or ethanol) to wine yeasts induces the expression of some ALD genes and leading to increased ALDH activity. This result is consistent with the need to obtain energy from ethanol during biological aging processes. Also, under certain conditions, acetaldehyde can function as a mutagen with respiratory deficient (petite) mutants as the product [84].

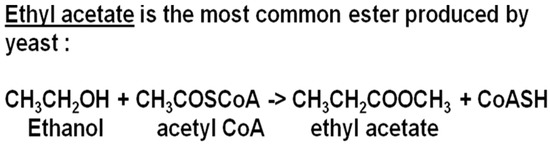

5.2. Vicinal Diketones (VDKs)—Diacetyl and 2,3-Pentanedione

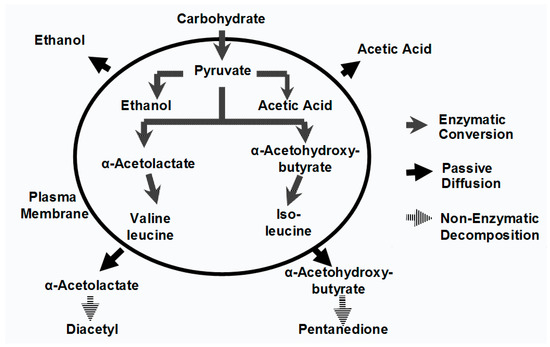

Diacetyl and 2,3-pentanedione are produced during wort fermentation as by-products of specific amino acid synthesis (valine and isoleucine, respectively) by ale and lager yeast strains (Figure 12). Both of these VDKs (especially diacetyl) will have a significant effect on the flavour, aroma and drinkability of beer [85]. Diacetyl imparts a butterscotch-like stale milk flavour to beer with a threshold usually reported to be around 0.1–0.2 mg/L in lagers and 0.1–0.4 mg/L in ale for most tasters [3,4,15,86]. However, diacetyl flavour thresholds as high as 1.7 mg/L [85,86] and 1.4–6.1 mg/L (for ale and lager) [15] have been reported. There is no doubt that the flavour threshold of diacetyl varies with a taster’s geographical background, ethnicity, diet and smoking practices [7]. 2,3-pentanedione has a similar flavour to diacetyl, although often described as more toffee-like but with a higher flavour aroma threshold-1 mg/L. The presence of VDKs above their flavour threshold in beer is generally regarded as a defect because their flavour is undesirable in many styles of beer and can also (not always) indicate microbial contamination. Diacetyl, at detectable concentrations, is acceptable in some beer styles such as Czech Pilsners and some (only some) English ales. Diacetyl metabolism during brewing has been the subject of significant polemic over the years but a comprehensive review, earlier this decade, by Krogerus and Gibson [86] has discussed the history and current situation regarding diacetyl biosynthesis and subsequent metabolism during wort fermentation.

Figure 12.

Formation of diacetyl and 2,3-pentandione.

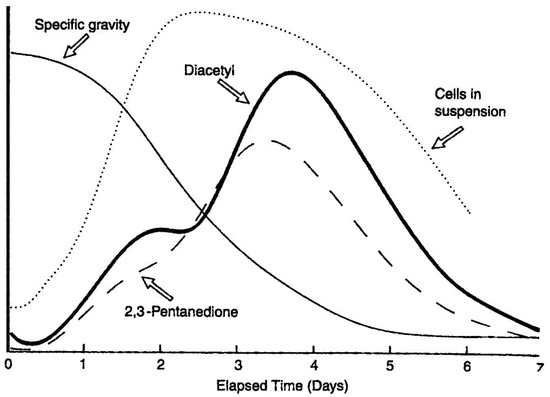

Although microbial contamination can be responsible for diacetyl formation [7,85], yeast metabolism and its management are the major routes and this is why it is discussed in detail here. It has already been discussed that diacetyl and 2,3-pentandione are formed indirectly because of valine and isoleucine biosynthesis. They arise from the spontaneous non-enzymatic oxidative decarboxylation of α-acetohydroxy acids that are intermediates in valine and isoleucine biosynthesis pathways [87] (Figure 12). Valine and isoleucine synthesis occurs in the mitochondria [88]. The reaction between α-acetolactate and 2,3-dihydro-isovalenate is rate-limiting, and thus during fermentation and yeast growth, α-acetolactate is secreted through the cell’s plasma membrane into the wort [89]. Recovery and mechanisms for α-acetolactate secretion are not fully understood, but may involve protecting the yeast from carbonyl stress [90]. The α-acetolactate is then spontaneously decarboxylated, oxidatively or non-oxidatively, forming diacetyl or acetoin respectively, and in both cases releasing carbon dioxide. The non-oxidative decarboxylation of acetoin can be enhanced by heating under anaerobic conditions and by maintaining a low redox wort potential [91]. Diacetyl production is enhanced with increasing valine biosynthesis, which depends on the cell’s access to valine and other amino acids. Fermentation conditions favouring rapid yeast growth give rise to increased diacetyl production if the wort’s free amino nitrogen content is insufficient. The diacetyl and “total diacetyl” concentrations during a typical lager fermentation are depicted in Figure 13. During a typical wort fermentation, the concentration of free diacetyl in wort is usually low whereas α-acetolactate constitutes the majority of the “total diacetyl” [91]. As a result, diacetyl concentrations are often expressed as “total diacetyl” concentrations, that is, the sum of free diacetyl and α-acetolactate (“potential diacetyl”), during analysis in order to highlight the potential diacetyl concentration in fermenting wort.

Figure 13.

Metabolsim of VDKs during wort fermentation. The figure shows the relationship between diacetyl and 2,3-pentanedione, yeast cell growth and specific wort gravity [86].

5.3. Process Conditions and Diacetyl Formation

It has already been discussed (Section 5.2) that diacetyl metabolism is directly linked to valine biosynthesis. Valine intracellular concentration affects the amount of diacetyl generated during fermentation [85]. Valine inhibits acetohydroxyacid synthase (AHAS)–the enzyme responsible for catalysing the formation of α-acetolactate from pyruvate (Figure 12). Consequently, the more valine present in the yeast cell, the less α-acetolactate will be synthesized. As this enzyme is inhibited, less diacetyl will be formed [92].

Valine and isoleucine addition to fermenting wort during the production of diacetyl has found that increased wort valine concentrations significantly reduces the amount of diacetyl produced during fermentation [93]. During fermentation trials with lager yeast strains involve wort with a spectrum of original gravities, free amino nitrogen (FAN) and valine concentrations. It was observed [94] that low levels of valine in wort resulted in the formation of double-peak diacetyl profiles (most likely as a result of valine depletion towards the end of fermentation). However, high concentrations of wort valine resulted in single-peak diacetyl profiles with lower maximum diacetyl levels compared to the wort with low valine concentrations. Wort valine concentrations influence the amount of diacetyl formed but as the wort employed in these studies varied in specific gravity and FAN, no definite conclusions regarding a relationship between wort valine and diacetyl concentrations can occur. Trials with two dried lager yeast strains concluded that diacetyl concentrations in fermenting wort were constant or decreased when valine uptake increased, while diacetyl concentrations increased when valine uptake decreased [95]. Direct supplementation of wort with valine (100–300 mg/L) and consequently greater uptake of valine by yeast, resulted in less diacetyl being formed during fermentation. However, other fermentation parameters such as fermentation rate and yeast growth were unaffected [96]. The same series of fermentation trials showed that when wort FAN levels were reduced, diacetyl production was also decreased. This effect is presumably due to faster absorption of preferred amino acids [40,41,46], resulting in an earlier and enhanced demand for valine and its increased uptake due to less competition for amino acid permease interactions. Increased background levels of initial wort amino acids (maintaining the valine concentration constant) resulting in greater production of diacetyl. The maximum diacetyl concentration during fermentation decreased as the initial wort FAN concentrations were increased from 122 to 144 mg/L. It has also been reported [97] that lower diacetyl production rates and increased valine uptake occurred during the fermentation of 18°Plato adjunct containing wort (FAN content approximately 150–210 mg/L) compared with an all-malt 18°Plato wort (FAN content approximately 300 mg/L). The conflicting diacetyl results are presumably due to differences in valine uptake rate and extent.

Yeast pitching rate and cell density also affects the amount of diacetyl present in wort at the end of fermentation, as it was observed that the diacetyl concentration increases with higher cell pitching rates. Trials with a number of lager yeast strains [25,98] observed over 10-fold increases in beer diacetyl concentrations when the pitching rate was increased several-fold. This can be explained by the fact that more α-acetolactate was produced and fermentation times were shorter as a result of higher pitching rates. This reduced the amount of α-acetolactate being spontaneously decarboxylated to diacetyl outside the cell during active fermentation during the diacetyl rate–limiting step of diacetyl removal (Figure 14). This has led to increased post-fermentation α-acetolactate and eventually diacetyl concentrations. Enhanced diacetyl production occurred with increased wort osmolarity (adjunct with sorbitol-a sugar that is not metabolised by Saccharomyces spp.), most likely as a result of decreased yeast vitality.

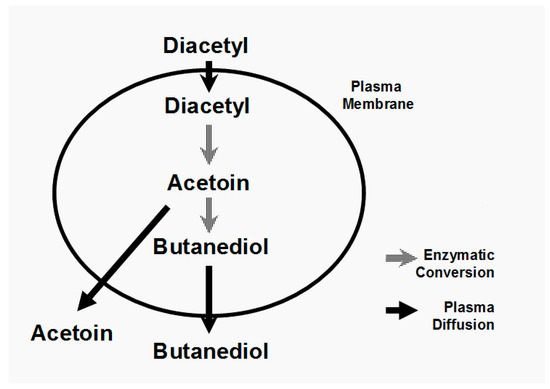

Figure 14.

Reduction of diacetyl to acetoin and 2,3-butanediol.

5.4. Process Conditions and Diacetyl Reduction

The pattern of diacetyl formation (Figure 12) and its subsequent breakdown in relation to yeast growth and gravity during lager fermentation and maturation is shown in Figure 13 and Figure 14. Diacetyl is converted to acetoin and ultimately 2,3-butanediol and 2,3-pentanedione to its corresponding diol. The flavour threshold concentrations of these diols are relatively high-details later. Therefore, the final reductive stages of VDK metabolism are critical to obtain a beer with acceptable organoleptic properties.

Reduction of diacetyl occurs by yeast during the concluding stages of fermentation when active yeast growth is concluded and during maturation. During practical brewing fermentation management, the need to obtain a desired diacetyl specification can be the principal factor which determines when a beer can be moved to its conditioning phase, diluted, filtered and/or centrifuged (depending on the processing procedures). Thus, diacetyl metabolism is a critical determinant of overall vessel residence time, which affects plant utilisation efficiency [99,100,101].

Although the removal of diacetyl during the later stages of brewing fermentation is critical for overall beer quality, this aspect of the process is not as well understood. Also, the formation of this carbonyl requires further study. Diacetyl removal during the closing stages of wort fermentation is usually rapid [102]. It has been suggested that diacetyl reduction to acetoin is not the rate-limiting step. However, the spontaneous decarboxylation of α-acetolactate to diacetyl is rate-limiting. The exact mechanisms of diacetyl uptake by yeast are unknown, but the yeast diacetyl uptake rate into cells, and consequently the diacetyl removal rate, has been shown to be affected by a number of fermentation parameters influencing yeast membrane composition (such as temperature and oxygenation of yeast or wort). Also, such effects will be amplified by the yeast’s flocculation and sedimentation characteristics [101].

Wort pH and the fermentation temperature both influence the amount and rate of diacetyl formed and subsequent reduction as both parameters affect yeast growth rate, the reaction velocity for the spontaneous decarboxylation of α-acetolactate into diacetyl, and the activities of the enzymes responsible for reducing diacetyl to acetoin and 2,3-butanediol [86]. Increased fermentation temperatures results in higher initial diacetyl production rates because of increased yeast growth which reduces the diacetyl to 2,3-butanediol and acetoin rates and also increased oxidative decarboxylation reaction rates of α-acetolactate to diacetyl. This suggests that the rate-limiting conversion of α-acetolactate to diacetyl is expedited at higher temperatures leading to sharper diacetyl concentration peaks during fermentation and consequently faster diacetyl reduction rates [73,85,102].

The increased decarboxylation rate of α-acetolactate to diacetyl at higher temperatures in the presence of yeast can be exploited during the late fermentation stages in a so-called “diacetyl rest” (also called a “free rise” by some brewers), where, temperatures are increased in order to more rapidly decrease wort α-acetolactate concentrations and shorten the maturation period [103]. Bamforth and Kanauchi [104] have reported an optimum pH of 3.5 for an acetoin dehydrogenase isolated from a commercial lager yeast strain, suggesting that diacetyl reduction rates are higher at lower wort pH values towards the end of fermentation. Several publications [91,105,106] have reported increased reaction rates for oxidative decarboxylation of α-acetolactate to diacetyl at lower pH values, which also suggests that the rate-limiting conversion of α-acetolactate to diacetyl is more rapid during more acidic wort conditions. Consequently, the maturation time needed for diacetyl reduction could be reduced at lower pH values as long as the pH within the preferred range is suitable for a palatable beer. Beer is typically in the pH range of 4.0–4.5 but can vary from 3.6 to 5.0 depending on the beer style, raw materials and the brewing process and conditions employed including the yeast strain [1,107].

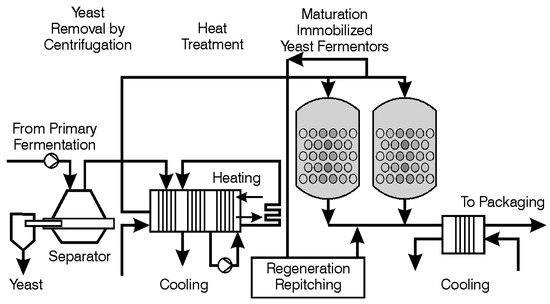

A process has been developed utilising immobilised yeast cells for the accelerated maturation of beer-primarily (but not exclusively) for diacetyl management [108]. The Finnish biotechnology company Cultor, working in association with the Sinebrychoff and Bavaria brewing companies from Finland and the Netherlands respectively and the German engineering company Tuchenhagen, have developed a process utilising immobilised cells for the accelerated maturation of beer. The immobilisation of the yeast cells on the carrier (DEAE cellulose particles—Spezyme®) was accomplished by surface adsorption in a downflow packed bed continuous bioreactor through which a yeast slurry was recirculated. The main advantage of this technology is its high volumetric production with corresponding residence times of only a few hours. The system developed by Cultor and associates is available and has been employed on an industrial scale. Figure 15 depicts a schematic of the Cultor system. In order to achieve rapid diacetyl reduction of immature beer (“green beer”), the remaining freely suspended yeast cells are completely centrifuged out of the primary fermentation and the resulting “clear” beer is subjected to heat treatment (65–90 °C with a holding time of 7–20 min). It is very important to ensure that the dissolved oxygen in this immature beer is kept to a minimum! The non-enzymatic conversion of the α-acetolactate (the diacetyl precursor) to acetoin is enhanced during this step. After cooling, the beer is delivered into the packed bed column containing yeast cells immobilised onto DEAE cellulose particles. In this final stage, the yeast cells complete the conversion of the remaining diacetyl to acetoin and other aspects of flavour maturation also occur (Figure 15).

Figure 15.

Cultor’s two hour continuous maturation system [108].

Because the beer flavour implications of diacetyl (and other VDKs) have been reported since the 1960s [109,110], novel approaches have been ongoing since the 1990s. The enzyme α-acetolactate decarboxylase (ALDC) catalyzes the following reaction without the formation of diacetyl:

α-acetolactate → acetoin + carbon dioxide

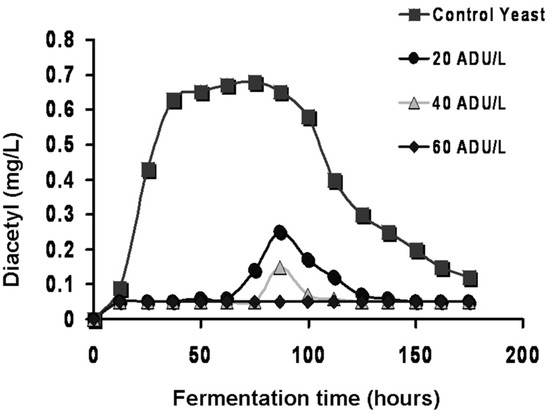

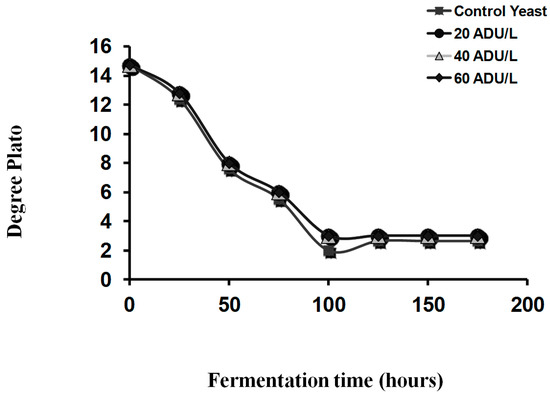

ALDC is not produced by brewer’s yeast strains or any other yeast [111]. However, it is produced by some other bacteria that are generally regarded as safe (GRAS) (for example, the Gram-negative bacterium Acetobacter aceti which converts ethanol to acetic acid during the production of vinegar) [110]. ALDC has been isolated, purified, and added to a brewer’s wort fermentation and the total diacetyl concentration throughout the fermentation cycle determined (Figure 16) [112]. Compared with an untreated control, little diacetyl was produced, and its concentration was inversely related to the concentration of ALDC added to the fermentation. ALDC does not reduce diacetyl levels if it is added once the fermentation has commenced (no one is sure why). In addition, wort fermentation rates with and without added ALDC were similar (Figure 17). It is worthy of note that commercial quantities of ALDC (under the brand name Maturex®) are produced by a genetically modified strain of Bacillus subtilis that has received the genetic coding for ALDC from a strain of B. brevis.

Figure 16.

Effect of α-acetolactate decarboxylase (ALDC) on diacetyl metabolism in fermenting wort [112].

Figure 17.

Effect of α-acetolactate decarboxylase (ALDC) on wort fermentation rate and extent [112].

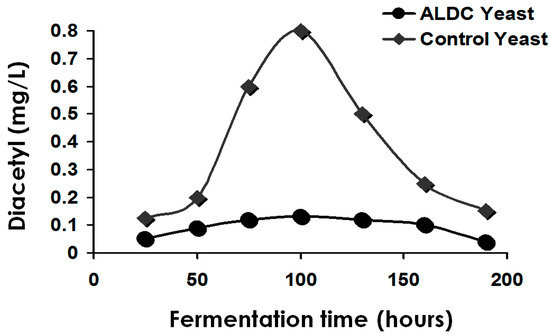

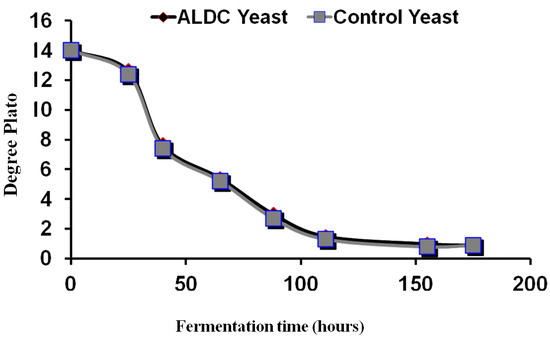

The genetic code for ALDC has been cloned into brewing yeast strains [113]. Wort fermentation trials with the ALDC yeast were conducted and compared with the same uncloned yeast strain as the control. The diacetyl production and reduction profiles were profoundly different when compared with the uncloned control culture (Figure 18). Due to the presence of ALDC, the acetolactate was not spontaneously converted to diacetyl but to acetoin instead. However, acetoin does not exhibit the same flavour impact as the butterscotch/stale milk aroma of diacetyl. The overall fermentation performance of some cloned yeast strains can be adversely affected when compared with the uncloned culture [113] although this was not the case with the ALDC yeast (Figure 19). However, as far as the author is aware, this yeast is not currently being employed for the production of beer on an industrial scale.

Figure 18.

Effect of α-acetolactate decarboxylase (ALDC) in a brewing yeast strain on diacetyl metabolism during wort fermentation [113].

Figure 19.

Effect of α-acetolactate decarboxylase (ALDC) expression in a brewing yeast strain on overall fermentation rate during wort fermentation [113].

6. Sulphur Compounds

Sulphur compounds are secondary metabolic products of yeast strains produced during wort metabolism. Many such compounds make a significant contribution to beer and fresh spirit flavour prior to being matured in oak casks [2]. Although small amounts of sulphur compounds can be acceptable, or even desirable in some beers, in excess they give rise to unpleasant off-flavours and special processes, such as purging with CO2, use of a copper electrode [114] and prolonged maturation times are necessary to remove them [115]. Some of the sulphur compounds present in beer are not directly associated with fermentation and are derived from the brewing raw materials (malt, hops, etc.) employed. However, the concentrations of hydrogen sulphide (rotten egg aroma), sulphur dioxide (burnt match) and thiols (burnt rubber) are largely dependent on yeast metabolism. Failure to manage fermentation properly can result in unacceptably high levels of these compounds in finished beer. In addition, dimethyl sulphide (DMS) and their thioesters are flavour components in beer but they are largely derived from malt and hops not fermentation [17,107].

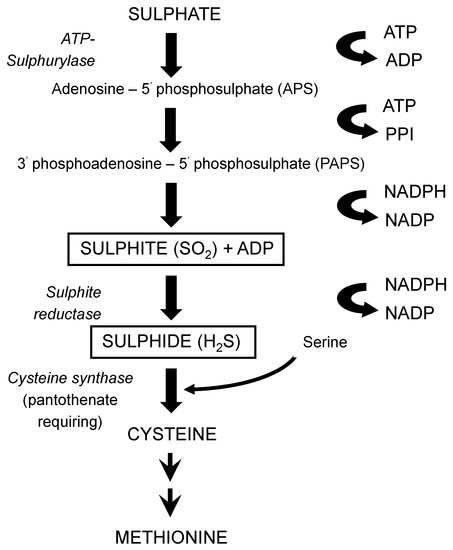

The concentration of hydrogen sulphide and sulphur dioxide [116], produced during fermentation, is primarily determined by the yeast strain employed, also wort composition and fermentation conditions are important factors, particularly where levels of these compounds are abnormally high. Both compounds arise as by-products from the synthesis of the sulphur-containing amino acids cysteine and methionine from sulphate (Figure 20). These syntheses are influenced by wort composition in that the yeast will preferentially assimilate sulphur-containing amino acids such as methionine (Table 4) compared to other amino acids and small peptides [46]. It is only when wort is depleted of amino acids does the biosynthetic route(s) of amino acids come into operation [101].

Figure 20.

Pathway for the synthesis of sulfur-containing amino-acids [1].

The peak of hydrogen sulphide and sulphur dioxide production occurs in the second to the fourth days of fermentation (depending on the yeast strain, the wort gravity and the incubation temperature) [117]. Presumably, by this time, the sulphur-containing amino acids in wort will have been utilised. Yeast growth during wort fermentation is approximately synchronous with cell division occurring at the same time and hydrogen sulphide evolution seems to occur in a number of peaks which correspond to the growth phase of the yeast culture just prior to the onset of budding [118].

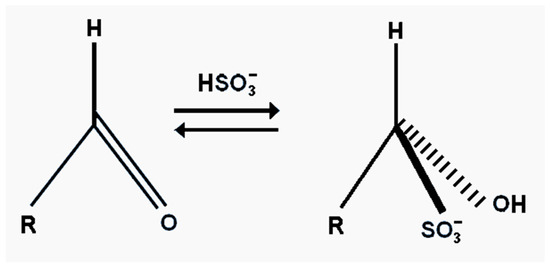

The formation of excessive levels of hydrogen sulphide and sulphur dioxide during fermentation is associated with conditions that restrict yeast growth. In this regard, the provision of adequate oxygen to wort at the time of pitching is a critical factor. Since both hydrogen sulphide and sulphur dioxide are volatile metabolites, it follows that vigorous fermentation will enhance their removal as a result of carbon dioxide purging [118]. The type and geometry of the fermentation vessel is also influential. Sulphur dioxide, as well as contributing to beer flavour (burnt match), has a number of other functions in beer (and other alcoholic beverages). It can act as an antimicrobial agent, an antioxidant [6,72,115] and it retards the development of the beer staling characteristics. Bisulphite’s antimicrobial activity can only occur at concentrations in excess of 50 mg/L which is well above the permitted limit in beer by most countries (in the United States it is 10 mg/L, Canada less than 10 mg/L and the United Kingdom 25 mg/L). Due to the adverse effects of oxygen on the flavour stability of finished beer, some brewers (not all) add bisulphites or other antioxidants, such as ascorbic acid (vitamin C), to beer prior to packaging in order to provide protection against oxygen pickup. However, because of bisulphite’s allergenic properties its use is questionable and is decreasing.

The effectiveness of bisulphite, besides its antioxidant properties, is also its ability to bind carbonyl compounds into flavour neutral complexes [119]. This can improve beer flavour stability. The efficiency of bisulphite binding to carbonyl compounds does vary. The reaction is reversible, so that an excess of bisulphite will increase the yield of the flavour inactive adjuvant (Figure 21). The addition of bisulphites to fresh beer minimizes increases in acetaldehyde concentrations during aging. In addition, when added to stale beer, bisulphite lowers the concentration of free aldehyde and affects the removal of the cardboard flavour [119]. Over time, the bisulphite will be oxidized, by oxygen in the beer, to sulphate, thus increasing the concentration of free aldehydes [120]. Studies at the Carlsberg Research Centre in Copenhagen have developed a genetically manipulated yeast strain that hyper-produces sulphur dioxide. Results would indicate that beer produced with this yeast strain has enhanced flavour stability [121]. More recently, the development of a S. cerevisiae mutant which produces higher levels of sulphur dioxide and glutathione but a lower level of hydrogen sulphide, with improved beer flavour stability, has been reported [44]. This mutant has been developed by nongenetic engineering means employing ultra violet (UV) mutagenesis together with specific plate screening methods. The antioxidising ability of the mutant was significantly improved and will be safe for production use.

Figure 21.

Binding of bisulphite to carbonyls.

The process of maturation (aging or lagering) is complex (one aspect—the management of VDK—has already been discussed here). Maturation also manages the levels of unwanted sulphur compounds (for example, H2S, SO2 and thiols) during primary fermentation. The reduction of unwanted volatile sulphur compounds (inorganic and organic) occurs principally during secondary fermentation (lagering). For this purpose, some yeast must be present during secondary fermentation. The yeast employed for this role is usually (not always) the same yeast strain as that used for primary fermentation. Sometimes (rarely these days), a speciality lagering yeast strain is employed [115] and the conditions that the yeast encounters during maturation are different to those during primary fermentation-lower pH, higher alcohol, carbon dioxide concentrations, CO2 pressure, reduced osmotic pressure and lower temperature, etc. Copper ions in fermented wort have a positive effect on the reduction of these sulphur compounds [114,122]. The positive effects of copper in this regard can also be illustrated by its importance in the distilling industry [2].

The use of copper in the construction of pot and continuous stills for malt and grain whisky distillation respectively (Figure 22 and Figure 23) [2] is invaluable for the removal of unwanted sulphur compounds. The expanding application of stainless steel for the manufacture of brewing equipment, replacing copper, has reduced beer copper concentrations in many breweries since WWII. Copper ions can precipitate hydrogen sulphide (and other sulphur-containing compounds) as insoluble copper sulphide. The resultant CuS can subsequently be removed by filtration of the maturing beer or adsorbed by the filter bed. The traditional use of copper vessels, pipes, and plates during wort and beer production does not permit precise copper ion addition. Consequently, deliberate and careful treatment of beer with copper is advisable. Copper electrolysis of maturing beer is a potential alternative [114]. It should be noted that Cu2+ ions can have a negative effect on beer flavour stability. For example, Irwin and his colleagues reported [123] that the rate of beer staling increased in the presence of small amounts of copper ions. As a transition metal ion, copper catalyzes the activation of molecular oxygen, which in turn can oxidize primary alcohols to beer-staling aldehydes. Nevertheless, the application of a copper electrode during maturation cannot be ignored. In a typical application [114], a copper electrolysis system reduced H2S levels in beer from 4 μg/L to undetectable levels and beer copper levels increased from 32 to 68 μg/L (Table 9). Many years ago, in an attempt to reduce maturation times, copper sulphate was added to boiling wort or to the initial stages of fermentation to remove compounds such as copper sulphide [122]. Although copper’s negative effect on beer flavour stability was unknown at the time, copper sulphate addition to wort has not been employed during the brewing process for many years!

Figure 22.

A typical pot still employed for the batch distillation of malt whisky.

Figure 23.

Coffey still employed for the continuous distillation of grain whisky.

Table 9.

Content of hydrogen sulfide (H2S) and copper in maturing beer samples [113].

7. Summary

The aroma of beer and many spirits is largely (not totally) dependent on a plethora of secondary metabolites produced by yeast [1,2,5,6]. They are produced during wort fermentation and consist of fermentation intermediates and/or by-products. Higher alcohols (also called fusel oils), esters, vicinal diketones (VDKs) other carbonyls (such as acetaldehyde) and sulphur compounds (inorganic and organic) are key elements produced by yeast. These constituent compounds determine a beer’s final quality, particularly when it is fresh. Although ethanol, carbon dioxide and glycerol are the primary metabolic products produced by yeast during wort fermentation they have little impact on the final beer flavour, although they do influence its overall character [3,4]. It is the type and concentration of secondary metabolites (excretion products) that primarily determines beer flavour balance. There are many factors that can modify this balance including: the yeast strain, malt variety, fermentation temperature, adjunct type (unmalted cereals) and level, fermenter design and geometry, wort pH and clarity, media buffering capacity, wort gravity, etc.

Acknowledgments

The author is grateful to Anne Anstruther for her help and support during the preparation of this review manuscript.

Conflicts of Interest

The author declares no conflict of interest.

References

- Stewart, G.G.; Russell, I. An Introduction to Brewing Science and Technology: Series III: Brewer’s Yeast, 2nd ed.; Institute of Brewing and Distilling: London, UK, 2009. [Google Scholar]

- Russell, I.; Stewart, G.G. Whisky: Technology, Production and Marketing; Elsevier: Boston, MA, USA, 2014. [Google Scholar]

- Meilgaard, M. Flavour chemistry of beer. Part I flavour interaction between principal volatiles. MBAA Tech. Q. 1975, 12, 107–117. [Google Scholar]

- Meilgaard, M. Flavour chemistry of beer. Part II flavour and threshold of 235 aroma volatiles. MBAA Tech. Q. 1975, 12, 151–168. [Google Scholar]

- Stewart, G.G. Brewing and Distilling Yeasts; Springer: Berlin, Germany, 2017; in press; ISBN 876-3-319-69126. [Google Scholar]

- Bamforth, C.W. 125th Anniversary Review: The non-biological instability of beer. J. Inst. Brew. 2011, 117, 488–497. [Google Scholar] [CrossRef]

- Inoue, T. Diacetyl in Fermented Foods and Beverages; American Society of Brewing Chemists: St Paul, MN, USA, 2008. [Google Scholar]

- Molina, A.M.; Swiegers, J.H.; Varela, C.; Pretorius, I.S.; Agosin, E. Influence of wine fermentation temperature on the synthesis of yeast-derived volatile aroma compounds. Appl. Microbiol. Biotechnol. 2007, 77, 675–687. [Google Scholar] [CrossRef] [PubMed]

- Ekberg, J.; Rautio, J.; Mattinen, L.; Vidgren, V.; Londesborough, J.; Gibson, B.R. Adaptive evolution of the lager brewing yeast Saccharomyces pastorianus for improved growth under hyperosmotic conditions and its influence on fermentation performance. FEMS Yeast Res. 2013, 13, 335–349. [Google Scholar] [CrossRef] [PubMed]

- Nicholson, J.K.; Lindon, J.C. Systems biology: Metabonomics. Nature 2008, 455, 1054–1056. [Google Scholar] [CrossRef] [PubMed]

- Daviss, B. Growing pains for metabolomics. Scientist 2005, 19, 25–28. [Google Scholar]

- Stewart, G.G. Esters—The most important group of flavour-active compounds in alcoholic beverages. In Distilled Spirits. Production, Technology and Innovation; Bryce, J.H., Piggott, J.R., Stewart, G.G., Eds.; Nottingham University Press: Nottingham, UK, 2008; pp. 243–250. [Google Scholar]

- Culver, K.W.; Labow, M.A. Genomics. In Genetics. Macmillan Science Library; Robinson, R., Ed.; Macmillan Reference: New York, NY, USA, 2002. [Google Scholar]

- Smart, K.A. Brewing yeast genomes and genome-wide expression and proteome profiling during fermentation. Yeast 2007, 24, 993–1013. [Google Scholar] [CrossRef] [PubMed]

- Kluba, R.; de Banchs, N.; Fraga, A.; Jansen, G.; Langstaff, S.; Meilgaard, M.; Nonaka, R.; Thompson, S.; Verhagen, L.; Word, K.; Crumplen, R. Sensory threshold determination of added substances in beer. J. Am. Soc. Brew. Chem. 1993, 51, 181–183. [Google Scholar]

- Boulton, C.; Box, W. Formation and disappearance of diacetyl during lager fermentation. In Brewing Yeast Fermentation Performance; Smart, K., Ed.; Blackwell Science: Oxford, UK, 2003; pp. 183–195. [Google Scholar]

- Roberts, T.; Falconer, F. Hops. In Handbook of Brewing, 3rd ed.; Stewart, G.G., Anstruther, A., Russell, I., Eds.; Taylor and Francis: Boca Raton, FL, USA, 2018; pp. 148–224. [Google Scholar]

- Peddie, H.A.B. Ester formation in brewery fermentations. J. Inst. Brew. 1990, 96, 327–331. [Google Scholar] [CrossRef]

- Ramos-Jeunehomme, C.; Laub, R.; Masschelein, C.A. Why is ester formation in brewery fermentations yeast strain dependent? Proc. Congr. Eur. Brew. Conv. 1991, 23, 257–264. [Google Scholar]

- Rossouw, D.; Naes, T.; Bauer, F.F. Linking gene regulation and the exo-metabolome: A comparative transcriptomics approach to identify genes that impact on the production of volatile aroma compounds in yeast. BMC Genom. 2008, 9, 530. [Google Scholar] [CrossRef] [PubMed]

- Lodolo, E.J.; Kock, J.L.; Axcell, B.C.; Brooks, M. The yeast Saccharomyces cerevisiae—The main character in beer brewing. FEMS Yeast Res. 2008, 8, 1018–1036. [Google Scholar] [CrossRef] [PubMed]

- Saerens, S.M.; Delvaux, F.; Verstrepen, K.J.; Van Dijck, P.; Thevelein, J.M. Delvaux, Parameters affecting ethyl ester production by Saccharomyces cerevisiae during fermentation. Appl. Environ. Microbiol. 2008, 74, 454–461. [Google Scholar] [CrossRef] [PubMed]

- Saerens, S.M.; Verbelen, P.J.; Vanbeneden, N.; Thevelein, J.M.; Delvaux, F.R. Monitoring the influence of high-gravity brewing and fermentation temperature on flavour formation by analysis of gene expression levels in brewing yeast. Appl. Microbiol. Biotechnol. 2008, 80, 1039–1051. [Google Scholar] [CrossRef] [PubMed]

- Bravi, E.; Perretti, G.; Buzzini, P.; Della Sera, R.; Fantozzi, P. Technological steps and yeast biomass as factors affecting the lipid content of beer during the brewing process. J. Agric. Food Chem. 2009, 57, 6279–6284. [Google Scholar] [CrossRef] [PubMed]

- Verbelen, P.; Dekoninck, T.; Saerens, S.; van Mulders, S.; Thevelein, J.; Delvaux, F. Impact of pitching rate on yeast fermentation performance and beer flavour. Appl. Microbiol. Biotechnol. 2009, 82, 155–167. [Google Scholar] [CrossRef] [PubMed]

- Blasco, L.; Vinas, M.; Villa, T.G. Proteins influencing foam formation in wine and beer: The role of yeast. Int. Microbiol. 2011, 14, 61–71. [Google Scholar] [PubMed]

- Berner, T.S.; Arneborg, N. The role of lager beer yeast in oxidative stability of model beer. Lett. Appl. Microbiol. 2012, 54, 225–232. [Google Scholar] [CrossRef] [PubMed]

- Dekoninck, T.; Verbelen, P.J.; Delvaux, F.; Van Mulders, S.E.; Delvaux, F. The importance of wort composition for yeast metabolism during accelerated brewery fermentations. J. Am. Soc. Brew. Chem. 2012, 70, 195–204. [Google Scholar] [CrossRef]

- Hiralal, L.; Olaniran, A.O.; Pillay, B. Aroma-active ester profile of ale beer produced under different fermentation and nutritional conditions. J. Biosci. Bioeng. 2013, 117, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Pires, E.J.; Teixeira, J.A.; Brányik, T.; Vicente, A.A. Yeast: The soul of beer’s aroma-a review of flavour-active esters and higher alcohols produced by the brewing yeast. Appl. Microbiol. Biotechnol. 2014, 98, 1937–1949. [Google Scholar] [CrossRef] [PubMed]

- Merritt, N.R. The effect of suspended solids on the fermentation of distiller’s malt wort. J. Inst. Brew. 1967, 73, 484–488. [Google Scholar] [CrossRef]

- Stewart, G.G.; Martin, S.A. Wort clarity: Effects on fermentation. MBAA Tech. Q. 2004, 41, 18–26. [Google Scholar]

- Kucharczyk, K.; Tuszyński, T. The effect of pitching rate on fermentation, maturation and flavour compounds of beer produced on an industrial scale. J. Inst. Brew. 2015, 121, 349–355. [Google Scholar] [CrossRef]

- Landaud, S.; Lieben, P.; Picque, D. Quantitative analysis of diacetyl, pentanedione and their precursors during beer fermentation by an accurate gc/ms method. J. Inst. Brew. 1998, 104, 93–99. [Google Scholar] [CrossRef]

- Stewart, G.G. The influence of high gravity wort on the stress characteristics of brewer’s yeast and related strains. Cerevisia 2007, 32, 37–48. [Google Scholar]

- Younis, O.S.; Stewart, G.G. Sugar uptake and subsequent ester and alcohol production in Saccharomyces cerevisiae. J. Inst. Brew. 1998, 104, 255–264. [Google Scholar] [CrossRef]

- Younis, O.S.; Stewart, G.G. The effect of malt wort, very high gravity malt wort and very high gravity adjunct wort on volatile production in Saccharomyces cerevisiae. J. Am. Soc. Brew. Chem. 1999, 52, 38–45. [Google Scholar]

- Klug, L.; Daum, G. Yeast lipid metabolism at a glance. FEMS Yeast Res. 2014, 14, 369–388. [Google Scholar] [CrossRef] [PubMed]

- Hazelwood, L.A.; Daran, J.M.; van Maris, A.J.A.; Pronk, J.T.; Dickinson, J.R. The Ehrlich Pathway for fusel oil production: A century of research on Saccharomyces cerevisiae metabolism. Appl. Environ. Microbiol. 2008, 74, 2259–2266. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.; Pierce, J. Absorption of amino acids from wort by yeasts. J. Inst. Brew. 1964, 70, 307–315. [Google Scholar] [CrossRef]

- Lekkas, C.; Hill, A.E.; Taidi, B.; Hodgson, J.; Stewart, G.G. The role of small peptides in brewing fermentation. J. Inst. Brew. 2009, 115, 3–29. [Google Scholar] [CrossRef]

- Neubauer, O.; Fromherz, K. Über den Abbau der Aminosäuren bei der Hefegärung.—De Gruyter. Hoppe-Seyler’s Z. Physiol. Chem. 1911, 70, 326–350. [Google Scholar] [CrossRef]

- Ehrlich, F. Über die Bedingungen der Fuselölbildung und über ihren Zusammenhang mit dem Eiweissaufbau der Hefe. Ber. Dtsch. Chem. Ges. 1907, 40, 1027–1047. [Google Scholar] [CrossRef]

- Chen, Y.; Siewers, V.; Nielsen, J. Profiling of cytosolic and peroxisomal acetyl-CoA metabolism in Saccharomyces cerevisiae. PLoS ONE 2012, 7, e42475. [Google Scholar] [CrossRef] [PubMed]

- Dickinson, J.R.; Norte, V. A study of branched-chain amino acid aminotransferase and isolation of mutations affecting the catabolism of branched-chain amino acids in Saccharomyces cerevisiae. FEBS Lett. 1993, 326, 29–32. [Google Scholar] [CrossRef]

- Lekkas, C.; Stewart, G.G.; Hill, A.; Taidi, B.; Hodgson, J. Elucidation of the role of nitrogenous wort components in wort fermentation. J. Inst. Brew. 2007, 113, 183–191. [Google Scholar] [CrossRef]

- Malcorps, P.; Dufour, J.P. Short-chain and medium-chain aliphatic-ester synthesis in Saccharomyces cerevisiae. Eur. J. Biochem. 1992, 210, 1015–1022. [Google Scholar] [CrossRef] [PubMed]

- Engan, S. Beer composition: Volatile substances. In Brewing Science; Pollock, J., Ed.; Academic Press: London, UK, 1981; Volume 2, pp. 7–67. [Google Scholar]

- Nykänen, L.; Nykänen, I. Production of esters by different yeast strains in sugar fermentations. J. Inst. Brew. 1977, 83, 30–31. [Google Scholar] [CrossRef]

- Nykanen, L.; Nykanen, I.; Suomalainen, H. Distribution of esters produced during sugar fermentation between the yeast cell and the medium. J. Inst. Brew. 1977, 83, 32–34. [Google Scholar] [CrossRef]

- Dufour, J.-P.; Malcorps, P. Ester synthesis during fermentation: Enzymes characterization and modulation mechanism. In The Institute of Brewing; Campbell, I., Priest, F.G., Eds.; The Institute of Brewing: Aviemore, UK, 1994; pp. 137–151. [Google Scholar]

- Goffeau, A.; Barrell, B.G.; Bussey, H.; Davis, R.W.; Dujon, B.; Feldmann, H.; Galibert, F.; Hoheisel, J.D.; Jacq, C.; Johnston, M.; et al. Life with 6000 genes. Yeast 1996, 274, 546–567. [Google Scholar] [CrossRef]

- Krogerus, K.; Magalhães, F.; Vidgren, V.; Gibson, B.R. New lager strains generated by interspecific hybridization. J. Ind. Microbiol. Biotechnol. 2015, 42, 769–778. [Google Scholar] [CrossRef] [PubMed]

- Lyness, C.A.; Steele, G.M.; Stewart, G.G. Investigating ester metabolism: Characterisation of the ATF1 gene in Saccharomyces cerevisiae. J. Am. Soc. Brew. Chem. 1997, 55, 141–146. [Google Scholar]

- Ancin, H.; Roysam, B.; Dufresne, T.E.; Chestnut, M.M.; Ridder, G.M.; Szarowski, D.H.; Turner, J.N. Advances in automated 3D image analyses of cell populations imaged by confocal microscopy. Cytometry 1996, 25, 221–234. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Liu, Y.L.; Qi, Y.N.; Zhang, J.W.; Dai, L.H.; Lin, X.; Xiao, D.G. Increased esters and decreased alcohols production by brewer’s yeast strains. Eur. Food Res. Technol. 2013, 236, 1009–1014. [Google Scholar] [CrossRef]

- O’Connor-Cox, E.S.C.; Lodolo, E.J.; Steyn, G.J.; Axcell, B.C. High-gravity wort clarity and its effect on brewing yeast performance. MBAA Tech. Q. 1996, 33, 20–29. [Google Scholar]

- Thomas, C.; Hynes, S.H.; Ingledew, W.M. Effects of particulate materials and osmoprotectants on very high gravity ethanolic fermentation by Saccharomyces cerevisiae. Appl. Environ. Microbiol. 1994, 60, 1519–1524. [Google Scholar] [PubMed]

- Yonezawa, T.; Stewart, G.G. Monitoring and controlling whisky fermentation. In Distilled Spirits. Tradition and Innovation; Bryce, J.H., Stewart, G.G., Eds.; Nottinghan University Press: Nottingham, UK, 2004; pp. 103–111. [Google Scholar]

- Äyräpää, T.; Lindström, I. Influence of long-chain fatty acids on the formation of esters by brewer’s yeast. Proc. Congr. Eur. Brew. Conv. 1973, 14, 271–283. [Google Scholar]

- O’Connor-Cox, E.S.C.; Lodolo, E.J.; Axcell, B.C. Mitochondrial relevance to yeast fermentative performance: A review. J. Inst. Brew. 1996, 102, 19–25. [Google Scholar] [CrossRef]

- Fujii, T.; Nagasawa, N.; Iwamatsu, A.; Bogaki, T.; Tamai, Y.; Hamachi, M. Molecular cloning, sequence analysis and expression of the yeast alcohol acetyltransferase gene. Appl. Environ. Microbiol. 1994, 60, 2786–2792. [Google Scholar] [PubMed]

- Nordström, K. Formation of ethyl acetate in fermentation with brewer’s yeast. J. Inst. Brew. 1962, 67, 173–181. [Google Scholar] [CrossRef]

- Nagasawa, N.; Bogaki, T.; Iwamatsu, A.; Hamachi, M.; Kumagai, C. Cloning and nucleotide sequence of the alcohol acetyltransferase II gene (ATF2) from Saccharomyces cerevisiae Kyokai No 7. Biosci. Biotechnol. Biochem. 1998, 62, 1852–1857. [Google Scholar] [CrossRef] [PubMed]

- Yoshimoto, H.; Fujiwara, D.; Momma, T.; Ito, C.; Sone, H.; Kaneko, Y.; Tamai, Y. Characterization of the ATF1 and Lg-ATF1 genes encoding alcohol acetyltransferase in the bottom fermenting yeast Saccharomyces pastorianus. J. Ferment. Bioeng. 1998, 86, 15–20. [Google Scholar] [CrossRef]

- Fujii, T.; Yoshimoto, H.; Nagasawa, N.; Bogaki, T.; Tamai, Y.; Hamachi, M. Nucleotide sequence of alcohol acetyltransferase genes from lager brewing yeast. Saccharomyces carlsbergensis. Yeast 1996, 12, 593–598. [Google Scholar] [CrossRef]

- Verstrepen, K.J.; Van Laere, S.D.M.; Vanderhaegen, B.M.P.; Derdelinckx, G.; Dufour, J.P.; Pretorius, I.S.; Winderickx, J.; Thevelein, J.M.; Delvaux, F.R. Expression levels of the yeast alcohol acetyltransferase genes ATF1,Lg-ATF1, and ATF2 control the formation of a broad range of volatile esters. Appl. Environ. Microbiol. 2003, 69, 5228–5237. [Google Scholar] [CrossRef] [PubMed]

- Strejc, J.; Siříšťová, L.; Karabín, M.; Almeida e Silva, J.B.; Brányik, T. Production of alcohol-free beer with elevated amounts of flavouring compounds using lager yeast mutants. J. Inst. Brew. 2013, 119, 149–155. [Google Scholar] [CrossRef]

- Brányik, T.; Silva, D.P.; Baszczyňski, M.; Lehnert, R.; João, B.; Almeida e Silva, R.J.B. A review of methods of low alcohol and alcohol-free beer production. J. Food Eng. 2012, 108, 493–506. [Google Scholar] [CrossRef]

- Fujii, T.; Yoshimoto, H.; Tamai, T. Acetate ester production by Saccharomyces cerevisiae lacking the ATF1 gene encoding the alcohol acetyltransferase. J. Ferment Bioeng. 1996, 81, 538–542. [Google Scholar] [CrossRef]

- Vanderhaegen, V.; Neven, H.; Coghe, S.; Verstrepen, K.J.; Verachtert, H.; Derdelinckx, G. Evolution of chemical and sensory properties during aging of top-fermented beer. J. Agric. Food Chem. 2003, 51, 6782–6790. [Google Scholar] [CrossRef] [PubMed]

- Vanderhaegen, V.; Neven, H.; Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- Saison, D.; De Schutter, D.P.; Uyttenhove, B.; Delvaux, F.; Delvaux, F.R. Contribution of staling compounds to the aged flavour of lager beer by studying their flavour thresholds. Food Chem. 2009, 114, 1206–1215. [Google Scholar] [CrossRef]

- Neven, H.; Delvaux, F.; Derdelinck, G. Flavor evaluation of top fermented beers. MBAA Tech. Q. 1997, 34, 115–118. [Google Scholar]

- Saison, D.; De Schutter, D.P.; Delvaux, F.; Delvaux, F.R. Determination of carbonyl compounds in beer by derivatisation and headspace solid-phase microextraction in combination with gas chromatography and mass spectrometry. J. Chromatogr. A 2009, 1216, 5061–5068. [Google Scholar] [CrossRef] [PubMed]

- Lake, J.C.; Speers, R.A. A discussion of malt-induced premature yeast flocculation. MBAA Tech. Q. 2008, 4, 253–262. [Google Scholar]

- Lake, J.C.; Speers, R.A.; Porter, A.V.; Gill, T.A. Miniaturizing the fermentation assay: Effects of fermentor size and fermentation kinetics on detection of premature yeast flocculation. J. Am. Soc. Brew. Chem. 2008, 66, 94–102. [Google Scholar]

- Romano, P.; Suzzi, G.; Turbanti, L.; Polsinelli, M. Acetaldehyde production in Saccharomyces cerevisiae wine yeasts. FEMS Microbiol. Lett. 1994, 118, 213–218. [Google Scholar] [CrossRef] [PubMed]

- Aranda, A.; del Olmo, M. Response to acetaldehyde stress in the yeast Saccharomyces cerevisiae involves a strain-dependent regulation of several ALD genes and is mediated by the general stress response pathway. Yeast 2003, 20, 747–759. [Google Scholar] [CrossRef] [PubMed]

- Lutstorf, U.; Megnet, R. Multiple forms of alcohol dehydrogenase in S. cerevisiae. I. Physiological control of ADH-2 and properties of ADH-2 and ADH-4. Arch. Biochem. Biophys. 1968, 126, 933–944. [Google Scholar] [CrossRef]

- Beier, D.R.; Sledziewski, A.; Young, E.T. Deletion analysis identifies a region, upstream of the ADH2 gene of S. cerevisiae, which is required for ADR1-mediated derepression. Mol. Cell. Biol. 1985, 5, 1743–1749. [Google Scholar] [CrossRef] [PubMed]

- Aranda, A.; Querol, A.; del Olmo, M. Correlation between acetaldehyde and ethanol resistance and expression of HSP genes in yeast strains isolated during the biological ageing of sherry wines. Arch. Microbiol. 2002, 177, 304–312. [Google Scholar] [CrossRef] [PubMed]

- Piper, P.W.; Talreja, K.; Panaretou, B.; Moradas-Ferreira, P.; Byrne, K.; Praekelt, U.M.; Meacock, P.; Recnacq, M.; Boucherie, H. Induction of major heat-shock proteins of Saccharomyces cerevisiae, including plasma membrane Hsp30, by ethanol levels above a critical threshold. Microbiology 1994, 140, 3031–3038. [Google Scholar] [CrossRef] [PubMed]

- Ernandes, J.R.; Williams, J.W.; Russell, I.; Stewart, G.G. Respiratory deficiency in brewing yeast strains—effects on fermentation, flocculation, and beer flavor components. J. Am. Soc. Brew. Chem. 1993, 51, 16–20. [Google Scholar]

- Wainwright, T. Diacetyl—A review. J. Inst. Brew. 1973, 79, 451–470. [Google Scholar] [CrossRef]

- Krogerus, K.; Gibson, B.R. 125th Anniversary Review: Diacetyl and its control during brewery fermentation. J. Inst. Brew. 2013, 119, 86–97. [Google Scholar]

- Radhakrishnan, A.N.; Wagner, R.P.; Snell, E.E. Biosynthesis of valine and isoleucine III α-keto-β-hydroxy acid reductase and α-hydroxy-β-keto acid reductoisomerase. J. Biol. Chem. 1960, 235, 2232–2242. [Google Scholar]

- Ryan, E.D.; Kohlhaw, G.B. Subcellular localization of isoleucine-valine biosynthetic enzymes in yeast. J. Bacteriol. 1974, 120, 631–637. [Google Scholar] [PubMed]

- Dillemans, M.; Goossens, E.; Goffin, O.; Masschelein, C. The amplification effect of the ILV5 gene on the production of vicinal diketones in Saccharomyces cerevisiae. J. Am. Soc. Brew. Chem. 1987, 45, 81–84. [Google Scholar]

- Van Bergen, B.; Strasser, R.; Cyr, N.; Sheppard, J.D.; Jardim, A. α,β-dicarbonyl reduction by Saccharomyces D-arabinose dehydrogenase. Biochim. Biophys. Acta (BBA) 2006, 1760, 1636–1645. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, K.; Kusaka, K.; Takahashi, T.; Sato, K. Method for the simultaneous assay of diacetyl and acetoin in the presence of α-acetolactate: Application in determining the kinetic parameters for the decomposition of α-acetolactate. J. Biosci. Bioeng. 2005, 99, 502–507. [Google Scholar] [CrossRef] [PubMed]

- Landaud, S.; Latrille, E.; Corrieu, G. Top pressure and temperature control the fusel alcohol/ester ratio through yeast growth in beer fermentation. J. Inst. Brew. 2001, 107, 107–117. [Google Scholar] [CrossRef]

- Nakatani, K.; Takahashi, T.; Nagami, K.; Kumada, J. Kinetic study of vicinal diketones in brewing II: Theoretical aspect for the formation of total vicinal diketones. MBAA Tech. Q. 1984, 21, 175–183. [Google Scholar]

- Petersen, E.; Margaritis, A.; Stewart, R.; Pilkington, P.; Mensour, N. The effects of wort valine concentration on the total diacetyl profile and levels late in batch fermentations with brewing yeast Saccharomyces carlsbergensis. J. Am. Soc. Brew. Chem. 2004, 62, 131–139. [Google Scholar]

- Cyr, N.; Blanchette, M.; Price, S.; Sheppard, J. Vicinal diketone production and amino acid uptake by two active dry lager yeasts during beer fermentation. J. Am. Soc. Brew. Chem. 2007, 65, 138–144. [Google Scholar]

- Pugh, T.; Maurer, J.; Pringle, A. The impact of wort nitrogen limitation on yeast fermentation performance and diacetyl. MBAA Tech. Q. 1997, 34, 185–189. [Google Scholar]

- Verbelen, P.J.; Dekoninck, T.M.; Van Mulders, S.E.; Saerens, S.M.; Delvaux, F.; Delvaux, F.R. Stability of high cell density brewery fermentations during serial repitching. Biotechnol. Lett. 2009, 31, 1729–1737. [Google Scholar] [CrossRef] [PubMed]

- Inoue, T. A review of the diacetyl control technology. In Proceedings of the 22nd Convention of the Institute Brewing, Australia, and New Zealand Section, Melbourne, Australia, 1–6 March 1992; pp. 109–113. [Google Scholar]

- Stewart, G.G. Saccharomyces. In Encyclopedia of Food Microbiology, 2nd ed.; Catt, C., Tortorello, M.-L., Eds.; Elsevier: Oxford, UK, 2014; pp. 297–315. [Google Scholar]

- Stewart, G.G. Brewing Intensification; American Society for Brewing Chemists: St. Paul, MN, USA, 2014. [Google Scholar]

- Stewart, G.G.; Maskell, D.L.; Speers, A. Brewing fundamentals—fermentation. MBAA Tech. Q. 2016, 53, 2–22. [Google Scholar]

- Garcia, A.; Garcia, L.; Diaz, M. Modelling of diacetyl production during beer fermentation. J. Inst. Brew. 1994, 100, 179–183. [Google Scholar] [CrossRef]

- Quain, D.; Smith, I. The long and short of maturation. Brew. Guard 2009, 138, 56–61. [Google Scholar]

- Bamforth, C.W.; Kanauchi, M. Enzymology of vicinal diketone reduction in brewer’s yeast. J. Inst. Brew. 2004, 110, 83–93. [Google Scholar] [CrossRef]

- Inoue, T.; Yamamoto, Y. Diacetyl and beer fermentation-the effect of pH on the spontaneous conversion of a-acetolactate to diacetyl. Rep. Res. Lab. Kirin Brew. Co. Ltd. 1970, 13, 79. [Google Scholar]

- Rondags, E.; Germain, P.; Marc, I. Quantification of extracellular α-acetolactate oxidative decarboxylation in diacetyl production by an α-acetolactate overproducing strain of Lactococcus. lactis sp. lactis bv. Diacetylactis. Biotechnol. Lett. 1999, 21, 303–307. [Google Scholar] [CrossRef]

- Stewart, G.G. Biochemistry of brewing. In Biochemisty of Foods; Eskin, N.A.M., Shandi, N., Eds.; Elsevier: Oxford, UK, 2012; pp. 291–318. [Google Scholar]

- Pajunen, E. Immobilised yeast lager beer maturation: DEAE-cellulose at Sinebrychoff. Proc. Eur. Brew. Conv. 1995, 24, 23–34. [Google Scholar]

- Inoue, T.; Masuyama, K.; Yamamoto, Y.; Okada, K. Mechanism of diacetyl formation in beer. Part. 1 Presence of material X and its chemistry. Rep. Res. Lab. Kirin Brew. Co. Ltd. 1968, 11, 13–16. [Google Scholar]

- Inoue, T.; Masuyama, K.; Yamamoto, Y.; Okada, K. Mechanism of diacetyl formation in beer. Part. 2 Identification of material X with α-acetolactate. Rep. Res. Lab. Kirin Brew. Co. Ltd. 1968, 11, 9–12. [Google Scholar]

- Godtfredsen, S.E.; Ottesen, M. Maturation of beer with α-acetolactate decarboxylase. Carlsberg Res. Commun. 1982, 47, 93–102. [Google Scholar] [CrossRef]

- Suihko, M.-L.; Penttila, M.; Sone, H.; Home, S.; Blomqvist, K.; Tanaka, J.; Inoue, T.; Knowles, J. Pilot brewing with α-acetolactate decarboxylase active yeasts. In Proceedings of the 22nd Congress European Brewery Convention, Zurich, Switzerland, 20–25 May 1989; IRL Press: Oxford, UK, 1989; pp. 483–490. [Google Scholar]

- Yamano, S.; Tomizuka, K.; Sone, H.; Imura, M.; Takeuchi, S.; Inoue, T. Brewing performance of a brewer’s yeast having α-acetolactate decarboxylase from Acetobacter. aceti spp. xylinum in brewer’s yeast. J. Biotechnol. 1995, 39, 21–26. [Google Scholar]

- Pfisterer, E.; Richardson, I.; Soti, A. Control of hydrogen sulfide in beer with a copper electrolysis system. MBAA Tech. Q. 2004, 41, 50–52. [Google Scholar]

- Munroe, J.H. Fermentation. In Handbook of Brewing, 2nd ed.; Priest, F.G., Stewart, G.G., Eds.; Taylor & Francis: Boca Raton, FL, USA, 2006; pp. 487–524. [Google Scholar]

- Samp, E.J.; Sedin, D. Important aspects of controlling sulfur dioxide in brewing. MBAA Tech. Q. 2017, 54, 60–71. [Google Scholar]

- Duan, W.; Roddick, F.; Higgins, V.; Rogers, P. A parallel analysis of H2S and SO2 formation by brewing yeast in response to sulfur-containing amino acids and ammonium ions. J. Am. Soc. Brew. Chem. 2004, 62, 35–41. [Google Scholar]

- Ogata, T. Hydrogen sulphide production by bottom-fermenting yeast is related to nitrogen starvation signalling. J. Inst. Brew. 2013, 119, 228–236. [Google Scholar] [CrossRef]

- Barker, R.L.; Gracey, D.E.F.; Irwin, A.J.; Pipasts, P.; Leiska, E. Liberation of staling aldehydes during storage of beer. J. Inst. Brew. 1983, 89, 411–415. [Google Scholar] [CrossRef]

- Narziss, L. Centenary Review. Technological factors of flavour stability. J. Inst. Brew. 1986, 92, 346–353. [Google Scholar] [CrossRef]

- Hansen, J.; Kielland-Brandt, M.C. Inactivation of MET2 in brewer’s yeast increases the level of sulfite in beer. J. Biotechnol. 1996, 50, 75–87. [Google Scholar] [CrossRef]

- Boulton, C.; Quain, D. Biochemistry of Fermentation (Chapter 3) in Brewing Yeast & Fermentation; Blackwell Science Ltd.: Oxford, UK, 2001; pp. 69–142. [Google Scholar]

- Irwin, A.J.; Barker, R.L.; Pipasts, P. The role of copper, oxygen, and polyphenols in beer flavor instability. J. Am. Soc. Brew. Chem. 1991, 49, 140–149. [Google Scholar]

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).