How Does Methanogenic Inhibition Affect Large-Scale Waste-to-Energy Anaerobic Digestion Processes? Part 1—Techno-Economic Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Development at Laboratory Scale

2.1.1. Selection and Characterization of Substrates and Inoculum

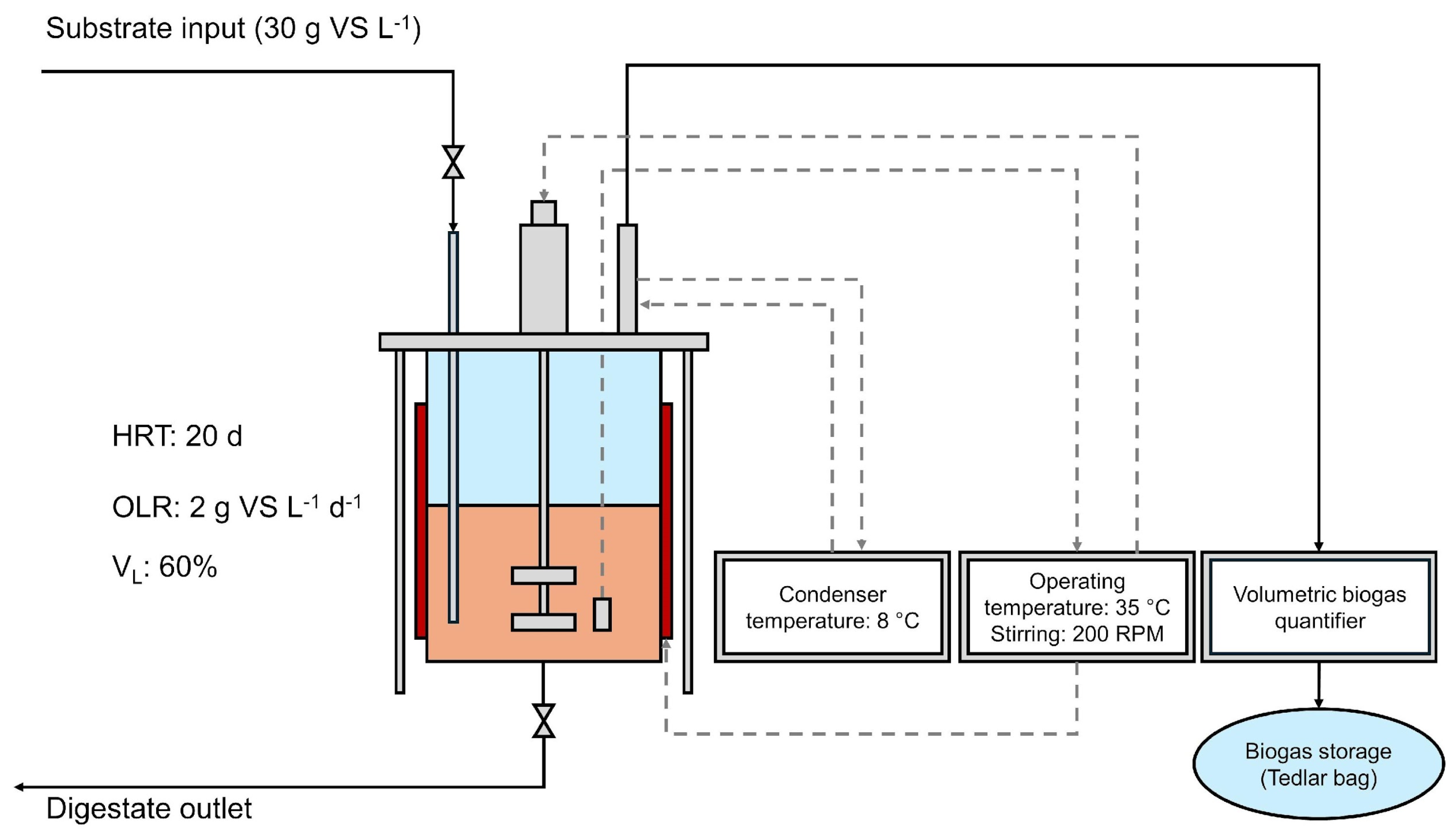

2.1.2. Reaction System

2.1.3. Feeding Scheme for the Scale-Laboratory WtE-AD Process

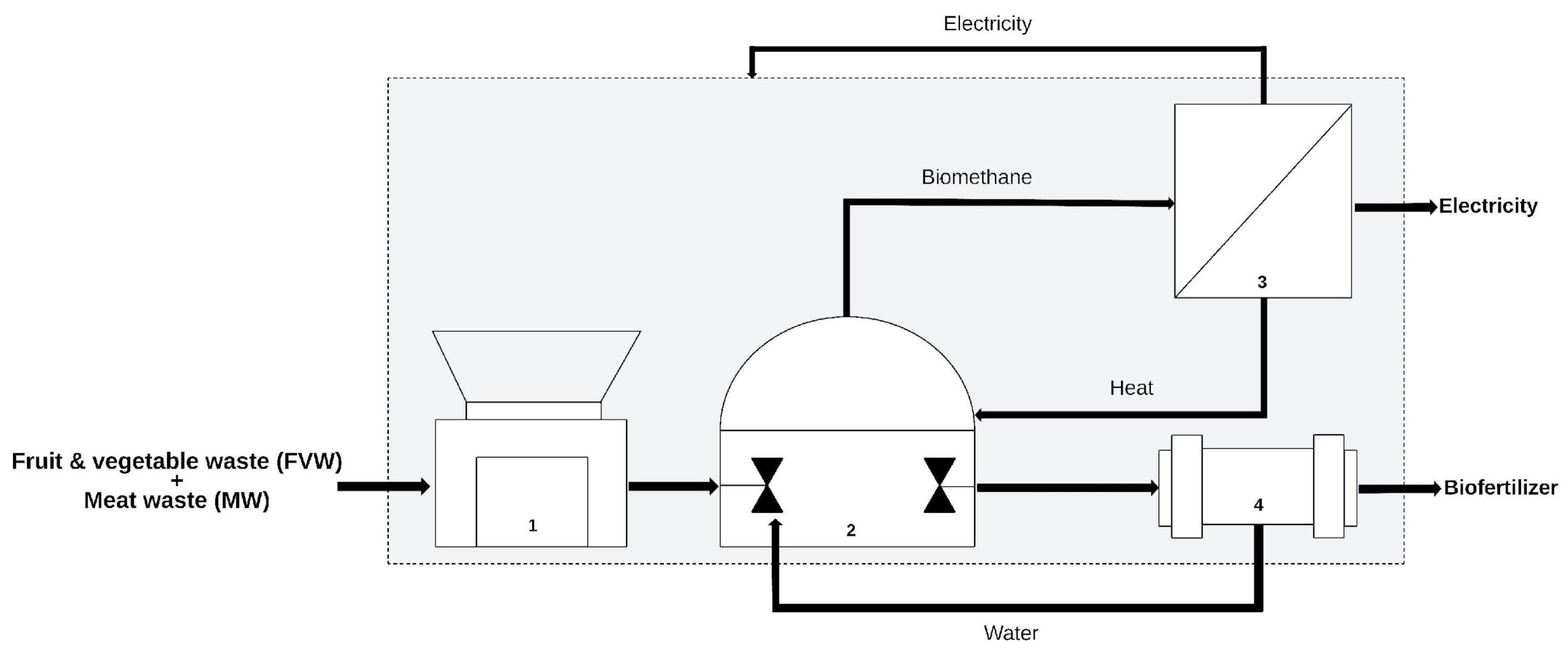

2.2. Conceptualization and Design of the Large-Scale WtE-AD Process

2.3. Economic Evaluation of the WtE-AD Process in a Latin American Context

2.3.1. Investment and O&M Costs

2.3.2. Value-Added Products and Waste Management Fees

2.3.3. Economic Analysis of the Large-Scale WtE-AD Process

2.4. Sensitivity Analysis of Large-Scale WtE-AD Process Effects on Economic Performance

2.5. Analysis of the Economic Impact of the Inhibition Events in a Large-Scale WtE-AD Process

2.6. Sensitivity Analysis of Waste Management Income and Electricity Price for the Large-Scale WtE-AD Process

3. Results and Discussion

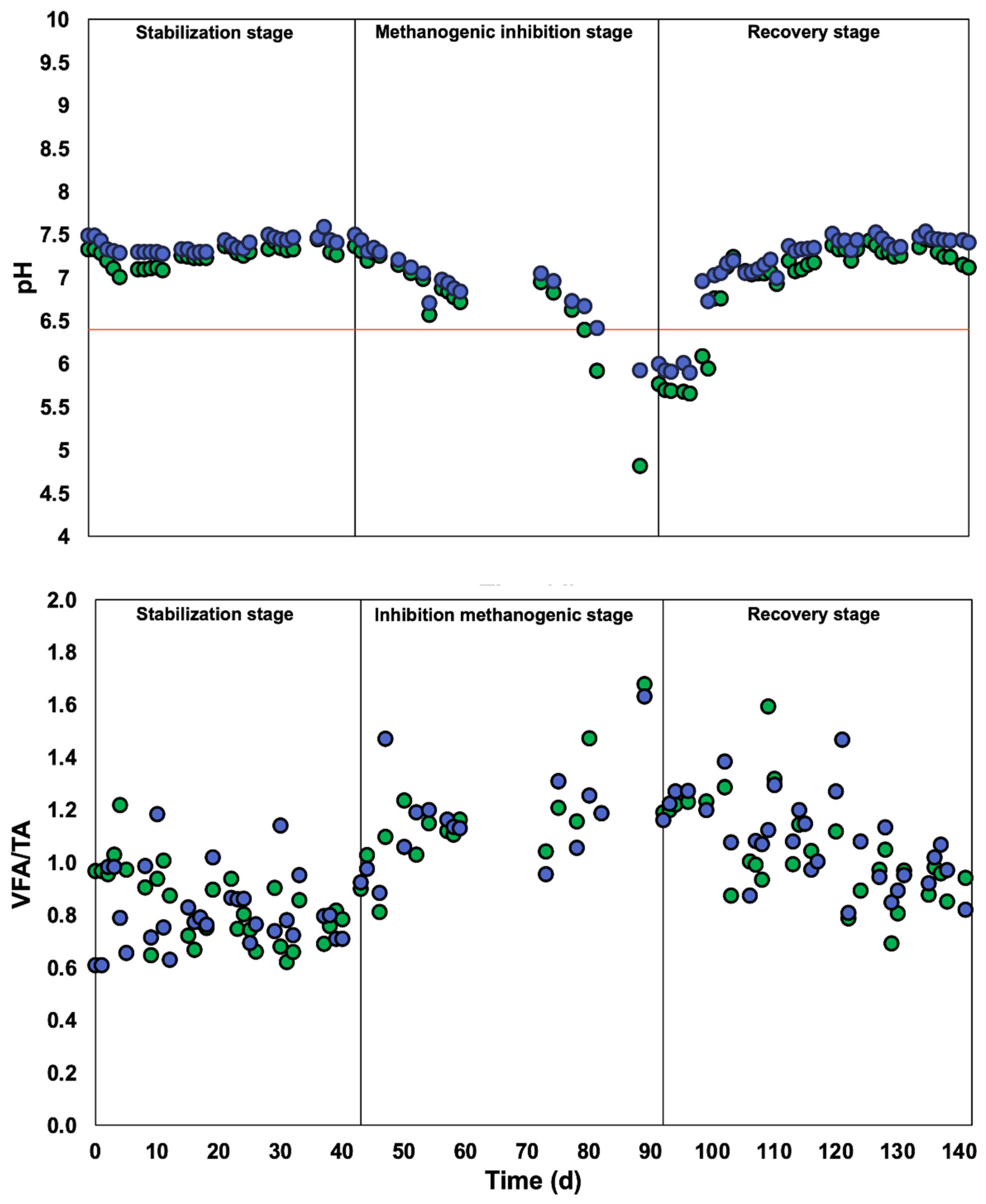

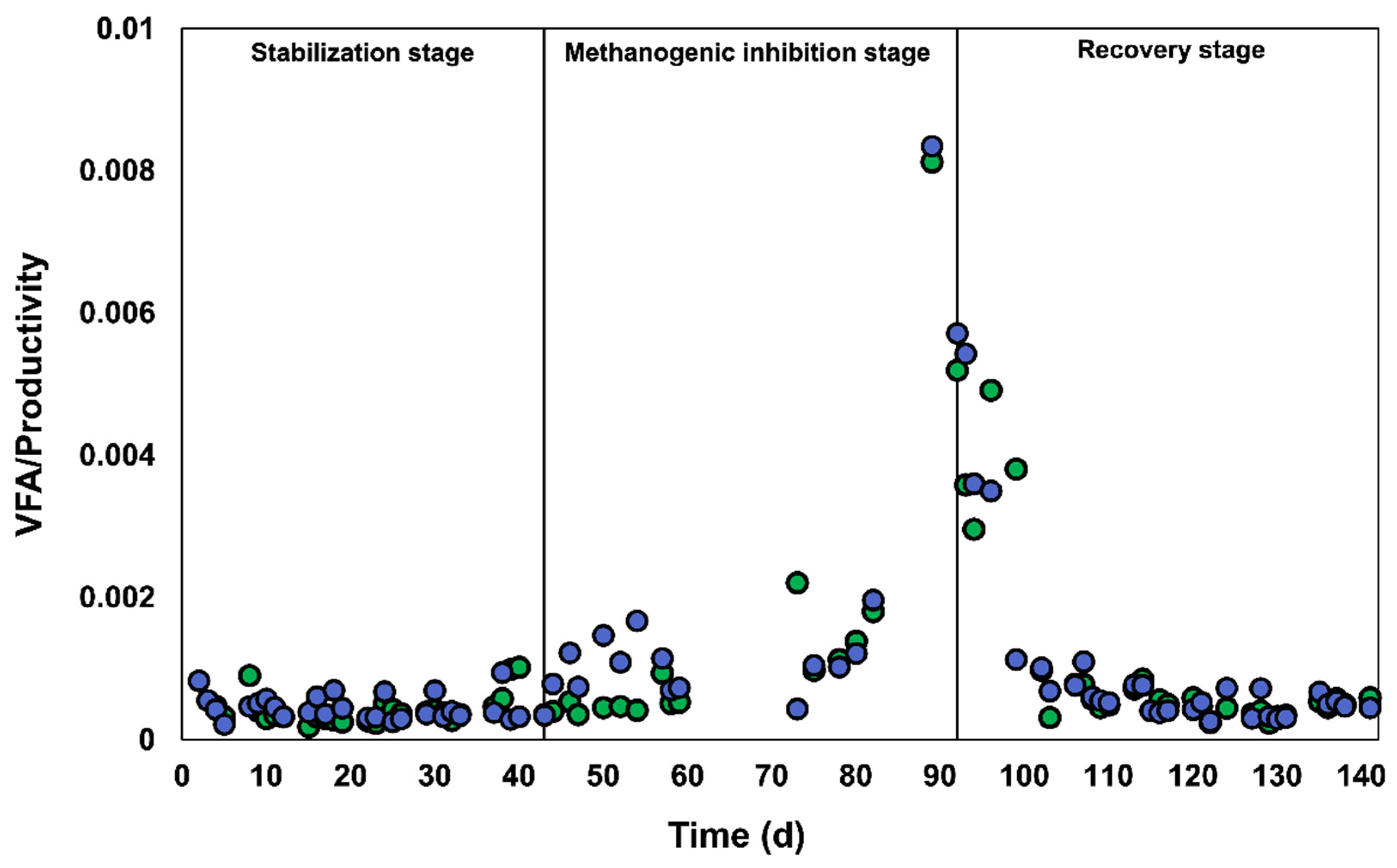

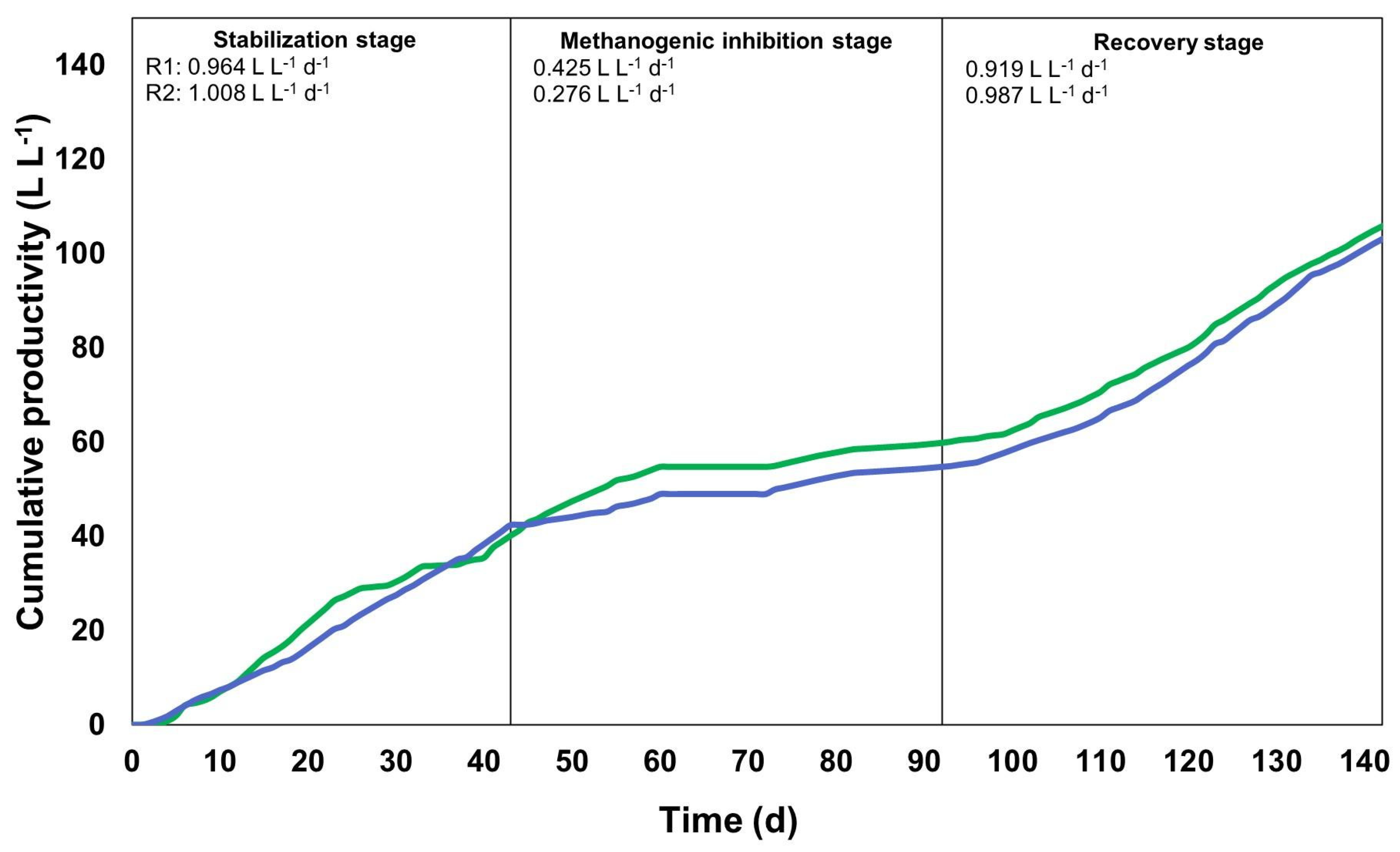

3.1. Performance of Laboratory-Scale Digesters

3.2. Economic Feasibility of the Large-Scale WtE-AD Process Based on Waste Management Capacity

3.3. Impact of Inhibition Events on the Economic Performance of the Large-Scale WtE-AD Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WtE-AD | Waste-to-energy anaerobic digestion |

| CSTR | Continuous stirred-tank reactor |

| FVW | Fruit and vegetable waste |

| MW | Meat waste |

| CM | Cattle manure |

| FDS | Final disposal sites |

| FW | Food waste |

| GHG | Greenhouse gas |

| VS | Volatile solids |

| VFA | Volatile fatty acids |

| TS | Total solids |

| TA | Total alkalinity |

| IA | Intermediate alkalinity |

| PA | Partial alkalinity |

| HRT | Hydraulic retention time |

| OLR | Organic loading rate |

| AD | Anaerobic digestion |

| CHP | Combined heat and power |

| NPV | Net present value |

| PM | Pig manure |

| SHW | Slaughterhouse waste |

| SL | Sanitary landfills |

| MSW | Municipal solid waste |

| OBW | Organic biological waste |

| OFMSW | Organic fraction of municipal solid waste |

| IE | Inhibition event |

| EW | Early warning |

| VW | Vegetable waste |

| EC | Energy crops |

| SM | Sheep manure |

| WS | Wastewater sludge |

| PS | Pig slurry |

| EG | Elephant grass |

| OW | Organic waste |

| SS | Sewage sludge |

| GS | Grass silage |

| MS | Maize silage |

| CSM | Chicken solid manure |

| NA | Unreported reactor operating regimen |

| WAS | Activated sludge |

References

- UNEP (United Nations Environment Programme). Food Waste Index Report 2021. Nairobi. Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 20 January 2025).

- Rueda-Avellaneda, J.F.; Rivas-García, P.; Gomez-Gonzalez, R.; Benitez-Bravo, R.; Botello-Álvarez, J.E.; Tututi-Avila, S. Current and prospective situation of municipal solid waste final disposal in Mexico: A spatio-temporal evaluation. Renew. Sustain. Energy Transit. 2021, 1, 100007. [Google Scholar] [CrossRef]

- Albalate-Ramírez, A.; Rueda-Avellaneda, J.; López-Hernández, B.; Alcalá-Rodríguez, M.; García-Balandrán, E.; Evrard, D.; Rivas-García, P. Geographic life cycle assessment of food loss and waste management in Mexico: The reality of distribution and retail centers. Sustain. Prod. Consum. 2024, 48, 289–300. [Google Scholar] [CrossRef]

- Gómez-Puentes, F.J.; Reyes-López, J.A.; López, D.L.; Carreón-Diazconti, C.; Belmonte-Jiménez, S. Geochemical processes controlling the groundwater transport of contaminants released by a dump in an arid region of México. Environ. Earth Sci. 2014, 71, 609–621. [Google Scholar] [CrossRef]

- Capson-Tojo, G.; Rouez, M.; Crest, M.; Steyer, J.P.; Delgenès, J.P.; Escudié, R. Food waste valorization via anaerobic processes: A review. Rev. Environ. Sci. Biotechnol. 2016, 15, 499–547. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G.J.W. Theoretical analysis of biogas potential prediction from agricultural waste. Resour. Technol. 2016, 2, 143–147. [Google Scholar] [CrossRef]

- Al Seadi, T.; Lukehurst, C. Quality Management of Digestate from Biogas Plants Used as Fertilizer. IEA Bioenergy Task 37. 2012. Available online: http://www.iea-biogas.net/files/daten-redaktion/download/publi-task37/digestate_quality_web_new.pdf (accessed on 27 May 2025).

- Tsydenova, N.; Morillas, A.V.; Hernández, A.M.; Soria, D.R.; Wilches, C.; Pehlken, A. Feasibility and barriers for anaerobic digestion in Mexico City. Sustainability 2019, 11, 4114. [Google Scholar] [CrossRef]

- Miramontes-Martínez, L.R.; Rivas-García, P.; Briones-Cristerna, R.A.; Abel-Seabra, J.E.; Padilla-Rivera, A.; Botello-Álvarez, J.E.; Alcalá-Rodríguez, M.M.; Levasseur, A. Potential of electricity generation by organic wastes in Latin America: A techno-economic-environmental analysis. Biomass Convers. Biorefinery 2022, 14, 27113–27124. [Google Scholar] [CrossRef]

- Alvarado-Reyna, P.; León, U.A.d.N.; Albalate-Ramírez, A.; García-Balandrán, E.; Escamilla-Alvarado, C.; Galván-Arzola, U.; Miramontes-Martínez, L.; Rivas-García, P. Evaluation of the reaction capacity of early warning indicators to failures in biogas production systems. Rev. Mex. De Ing. Quim. 2024, 23, Bio24313. [Google Scholar] [CrossRef]

- Nielsen, H.B.; Angelidaki, I. Congestion of manure and industrial organic waste at centralized biogas plants: Process imbalances and limitations. Water Sci. Technol. 2008, 58, 1521–1528. [Google Scholar] [CrossRef]

- Albalate-Ramírez, A.; Padilla-Rivera, A.; Rueda-Avellaneda, J.F.; López-Hernández, B.N.; Cano-Gómez, J.J.; Rivas-García, P. Mapping the Sustainability of Waste-to-Energy Processes for Food Loss and Waste in Mexico—Part 1: Energy Feasibility Study. Sustainability 2024, 16, 6111. [Google Scholar] [CrossRef]

- Alibardi, L.; Cossu, R. Composition variability of the organic fraction of municipal solid waste and effects on hydrogen and methane production potentials. Waste Manag. 2015, 36, 147–155. [Google Scholar] [CrossRef]

- Fisgativa, H.; Tremier, A.; Dabert, P. Characterizing the variability of food waste quality: A need for efficient valorization through anaerobic digestion. Waste Manag. 2016, 50, 264–274. [Google Scholar] [CrossRef]

- Xue, S.; Song, J.; Wang, X.; Shang, Z.; Sheng, C.; Li, C.; Zhu, Y.; Liu, J. A systematic comparison of biogas development and related policies between China and Europe and corresponding insights. Renew. Sustain. Energy Rev. 2020, 117, 109474. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Paredes, M.G.; Güereca, L.P. A systematic review of the sustainability assessment of bioenergy: The case of gaseous biofuels. Biomass Bioenergy 2019, 125, 79–94. [Google Scholar] [CrossRef]

- Zheng, L.; Chen, J.; Zhao, M.; Cheng, S.; Wang, L.-P.; Mang, H.-P.; Li, Z. What could China give to and take from other countries in terms of the development of the biogas industry? Sustainability 2020, 12, 1490. [Google Scholar] [CrossRef]

- Yousuf, A.; Khan, M.R.; Pirozzi, D.; Ab Wahid, A. Financial sustainability of biogas technology: Barriers, opportunities, and solutions. Energy Sources 2016, 11, 841–848. [Google Scholar] [CrossRef]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; de Wilde, V.; et al. Towards a standardization of biomethane potential tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef]

- NMX-AA-034-SCFI-2015; Water Analysis—Determination of Solids and Dissolved Salts in Natural Waters, Wastewater, and Treated Wastewater—Test Method. Ministry of Economy: Mexico City, Mexico, 2015. Available online: https://www.gob.mx/cms/uploads/attachment/file/166146/nmx-aa-034-scfi-2015.pdf (accessed on 5 February 2025).

- NMX-AA-036-SCFI-2001; Water Analysis—Determination of Acidity and Alkalinity in Natural Waters, Wastewater, and Treated Wastewater—Test Method. Ministry of Economy: Mexico City, Mexico, 2001. Available online: https://www.gob.mx/cms/uploads/attachment/file/166776/NMX-AA-036-SCFI-2001.pdf (accessed on 5 February 2025).

- Miramontes-Martínez, L.R.; Rivas-García, P.; Albalate-Ramírez, A.; Botello-Álvarez, J.E.; Escamilla-Alvarado, C.; Gomez-Gonzalez, R.; Alcalá-Rodríguez, M.M.; Valencia-Vázquez, R.; Santos-López, I.A. Anaerobic co-digestion of fruit and vegetable waste: Synergy and process stability analysis. J. Air Waste Manag. Assoc. 2021, 71, 620–632. [Google Scholar] [CrossRef]

- Li, D.; Chen, L.; Liu, X.; Mei, Z.; Ren, H.; Cao, Q.; Yan, Z. Instability mechanisms and early warning indicators for mesophilic. Bioresour. Technol. 2017, 245, 90–97. [Google Scholar] [CrossRef]

- Liu, Y.; Whitman, W.B. Metabolic, phylogenetic, and ecological diversity of the methanogenic archaea. In Annals of the New York Academy of Sciences; Blackwell Publishing Inc.: Malden, MA, USA, 2008; pp. 171–189. [Google Scholar] [CrossRef]

- Korai, M.S.; Mahar, R.B.; Uqaili, M.A. The seasonal evolution of fruit, vegetable and yard wastes by mono, co and tri-digestion at Hyderabad, Sindh Pakistan. Waste Manag. 2018, 71, 461–473. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. Predicting the environmental impact of a future nanocellulose production at industrial scale: Application of the life cycle assessment scale-up framework. J. Clean. Prod. 2018, 174, 283–295. [Google Scholar] [CrossRef]

- Scano, E.A.; Asquer, C.; Pistis, A.; Ortu, L.; Demontis, V.; Cocco, D. Biogas from anaerobic digestion of fruit and vegetable wastes: Experimental results on pilot-scale and preliminary performance evaluation of a full-scale power plant. Energy Convers. Manag. 2014, 77, 22–30. [Google Scholar] [CrossRef]

- Tsilemou, K.; Panagiotakopoulos, D. Approximate cost functions for solid waste treatment facilities. Waste Manag. Res. J. Sustain. Circ. Economy. 2006, 24, 310–322. [Google Scholar] [CrossRef]

- Comisión Federal de Electricidad (CFE). Industry-Tariffs: Current Tariff Scheme. Available online: https://app.cfe.mx/Aplicaciones/CCFE/Tarifas/TarifasCREIndustria/Industria.aspx (accessed on 25 May 2025).

- Morero, B.; Vicentin, R.; Campanella, E.A. Assessment of biogas production in Argentina from co-digestion of sludge and municipal solid waste. Waste Manag. 2017, 61, 195–205. [Google Scholar] [CrossRef]

- Doychinov, N.; Faircloth, P.; Lonkova, K. Municipal Solid Waste Cost Calculation Technical Guidelines for Low-and Middle-Income Countries. 2024. Available online: www.worldbank.org (accessed on 27 May 2025).

- Income Tax Law (Ley del Impuesto sobre la Renta); Last Amendment Published in the Official Gazette (DOF) on 01-04-2024; Chamber of Deputies of the H. Congress of the Union, Secretariat of Parliamentary Services: Mexico City, Mexico, 2013; Available online: https://www.diputados.gob.mx/LeyesBiblio/pdf/LISR.pdf (accessed on 26 May 2025).

- SAT. Ley de Impuesto al Valor Agregado. 2021. Available online: https://www.diputados.gob.mx/LeyesBiblio/pdf/LIVA.pdf (accessed on 23 May 2025).

- Banco de México. 2025. Available online: https://www.banxico.org.mx/SieInternet/consultarDirectorioInternetAction.do?sector=18&accion=consultarCuadro&idCuadro=CF111&locale=es (accessed on 20 May 2025).

- Ebner, J.H.; Labatut, R.A.; Lodge, J.S.; Williamson, A.A.; Trabold, T.A. Anaerobic co-digestion of commercial food waste and dairy manure: Characterizing biochemical parameters and synergistic effects. Waste Manag. 2016, 52, 286–294. [Google Scholar] [CrossRef] [PubMed]

- Miramontes-Martínez, L.R.; Gomez-Gonzalez, R.; Botello-Álvarez, J.E.; Escamilla-Alvarado, C.; Albalate-Ramírez, A.; Rivas-García, P. Semi-continuous anaerobic co-digestion of vegetable waste and cow manure: A study of process stabilization. Rev. Mex. De Ing. Quim. 2020, 19, 1117–1134. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Holliger, C.; Astals, S.; De Laclos, H.F.; Hafner, S.D.; Koch, K.; Weinrich, S. Towards a standardization of biomethane potential tests: A commentary. Water Sci. Technol. 2021, 83, 247–250. [Google Scholar] [CrossRef]

- Kumar, M.; Ou, Y.L.; Lin, J.G. Co-composting of green waste and food waste at low C/N ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef] [PubMed]

- Garcia, N.H.; Mattioli, A.; Gil, A.; Frison, N.; Battista, F.; Bolzonella, D. Evaluation of the methane potential of different agricultural and food processing substrates for improved biogas production in rural areas. Renew. Sustain. Energy Rev. 2019, 112, 1–10. [Google Scholar] [CrossRef]

- Lindorfer, H.; Corcoba, A.; Vasilieva, V.; Braun, R.; Kirchmayr, R. Doubling the organic loading rate in the co-digestion of energy crops and manure–A full scale case study. Bioresour. Technol. 2008, 99, 1148–1156. [Google Scholar] [CrossRef]

- Ek, A.E.W.; Hallin, S.; Vallin, L.; Schnurer, A.; Karlsson, M. Slaughterhouse Waste Co-Digestion—Experiences from 15 Years of Full-Scale Operation. Proc. World Renew. Energy Congr. 2011, 57, 64–71. [Google Scholar] [CrossRef]

- Akbulut, A. Techno-economic analysis of electricity and heat generation from farm-scale biogas plant: Çiçekdaĝi{dotless} case study. Energy 2012, 44, 381–390. [Google Scholar] [CrossRef]

- Passos, F.; Gutiérrez, R.; Brockmann, D.; Steyer, J.P.; García, J.; Ferrer, I. Microalgae production in wastewater treatment systems, anaerobic digestion and modelling using ADM1. Algal Res. 2015, 10, 55–63. [Google Scholar] [CrossRef]

- Hamawand, I. Anaerobic digestion process and bio-energy in meat industry: A review and a potential. Renew. Sustain. Energy Rev. 2015, 44, 37–51. [Google Scholar] [CrossRef]

- De Vrieze, J.; Saunders, A.M.; He, Y.; Fang, J.; Nielsen, P.H.; Verstraete, W.; Boon, N. Ammonia and temperature determine potential clustering in the anaerobic digestion microbiome. Water Res. 2015, 75, 312–323. [Google Scholar] [CrossRef] [PubMed]

- De Vrieze, J.; Raport, L.; Roume, H.; Vilchez-Vargas, R.; Jáuregui, R.; Pieper, D.H.; Boon, N. The full-scale anaerobic digestion microbiome is represented by specific marker populations. Water Res. 2016, 104, 101–110. [Google Scholar] [CrossRef]

- Gutierrez, E.C.; Xia, A.; Murphy, J.D. Can slurry biogas systems be cost effective without subsidy in Mexico? Renew. Energy 2016, 95, 22–30. [Google Scholar] [CrossRef]

- Ahlberg-Eliasson, K.; Nadeau, E.; Levén, L.; Schnürer, A. Production efficiency of Swedish farm-scale biogas plants. Biomass Bioenergy 2017, 97, 27–37. [Google Scholar] [CrossRef]

- Otuzalti, M.M.; Perendeci, N.A. Modeling of real scale waste activated sludge anaerobic digestion process by Anaerobic Digestion Model 1 (ADM1). Int. J. Green Energy 2018, 15, 454–464. [Google Scholar] [CrossRef]

- Cecchi, F.; Cavinato, C. Smart approaches to food waste final disposal. Int. J. Environ. Res. Public Health 2019, 16, 2860. [Google Scholar] [CrossRef]

- Michailos, S.; Walker, M.; Moody, A.; Poggio, D.; Pourkashanian, M. Biomethane production using an integrated anaerobic digestion, gasification and CO2 biomethanation process in a real waste water treatment plant: A techno-economic assessment. Energy Convers. Manag. 2020, 209, 112663. [Google Scholar] [CrossRef]

- Zhou, L.; Hülsemann, B.; Cui, Z.; Merkle, W.; Sponagel, C.; Zhou, Y.; Guo, J.; Dong, R.; Müller, J.; Oechsner, H. Operating performance of full-scale agricultural biogas plants in germany and china: Results of a year-round monitoring program. Appl. Sci. 2021, 11, 1271. [Google Scholar] [CrossRef]

- Biogas3 Proyect. Sustainable Small-Scale Biogas from Agri-Food Waste for Energy Self-Sufficiency Intelligent Energy Europe Programme. 2020. Available online: http://www.biogas3.eu/esp/index.html (accessed on 26 May 2025).

- Zou, J.; Nie, E.; Lü, F.; Peng, W.; Zhang, H.; He, P. Screening of early warning indicators for full-scale dry anaerobic digestion of household kitchen waste. Environ. Res. 2022, 214, 114136. [Google Scholar] [CrossRef]

- Wu, Y.; Kovalovszki, A.; Pan, J.; Lin, C.; Liu, H.; Duan, N.; Angelidaki, I. Early warning indicators for mesophilic anaerobic digestion of corn stalk: A combined experimental and simulation approach. Biotechnol. Biofuels 2019, 12, 106. [Google Scholar] [CrossRef] [PubMed]

- Vasco-Correa, J.; Khanal, S.; Manandhar, A.; Shah, A. Anaerobic digestion for bioenergy production: Global status, environmental and techno-economic implications, and government policies. Bioresour. Technol. 2017, 247, 1015–1026. [Google Scholar] [CrossRef]

- Gebrezgabher, S.A.; Meuwissen, M.P.M.; Prins, B.A.M.; Oude, A.G.J.M. Economic analysis of anaerobic digestion — A case of Green power biogas plant in The Netherlands. NJAS—Wageningen J. Life Sci. 2010, 57, 109–115. [Google Scholar] [CrossRef]

- Nghiem, L.D.; Wickham, R.; Ohandja, D.G. Enhanced biogas production and performance assessment of a full-scale anaerobic digester with acid phase digestion. Int. Biodeterior. Biodegrad. 2017, 124, 162–168. [Google Scholar] [CrossRef]

- SEMARNAT (Secretaría de Medio Ambiente y Recursos Naturales). Diagnóstico Básico para la Gestión Integral de los Residuos. 2020. Available online: www.gob.mx/semarnat (accessed on 27 May 2025).

- Sganzerla, W.G.; Buller, L.S.; Mussatto, S.I.; Forster-Carneiro, T. Techno-economic assessment of bioenergy and fertilizer production by anaerobic digestion of brewer’s spent grains in a biorefinery concept. J. Clean. Prod. 2021, 297, 126600. [Google Scholar] [CrossRef]

- Pablo-Romero, M.P.; Sánchez-Braza, A.; Salvador-Ponce, J. An overview of feed-in tariffs, premiums and tenders to promote electricity from biogas in the EU-28. Renew. Sustain. Energy Rev. 2017, 73, 1366–1379. [Google Scholar] [CrossRef]

- Lukehurst, C.; Bywater, A. Exploring the Viability of Small Scale Anaerobic Digesters in Livestock Farming. 2015. Available online: https://www.ieabioenergy.com/wp-content/uploads/2015/12/Small_Scale_RZ_web2.pdf (accessed on 20 May 2025).

- Tradings Economics. 2025. Available online: https://es.tradingeconomics.com/italy/indicators (accessed on 27 May 2025).

- Kassem, N.; Sills, D.; Posmanik, R.; Blair, C.; Tester, J.W. Combining anaerobic digestion and hydrothermal liquefaction in the conversion of dairy waste into energy: A techno economic model for New York state. Waste Manag. 2020, 103, 228–239. [Google Scholar] [CrossRef] [PubMed]

- New York State Energy Research and Development Authority (NYSERDA). 2024 New York Clean Energy Industry Report Overview; NYSERDA: Albany, NY, USA, 2024. Available online: https://nyserda.ny.gov/clean-energy-jobs (accessed on 30 May 2025).

- Xu, J.; Akhtar, M.; Haris, M.; Muhammad, S.; Abban, O.J.; Taghizadeh-Hesary, F. Energy crisis, firm profitability, and productivity: An emerging economy perspective. Energy Strategy Rev. 2022, 41, 100849. [Google Scholar] [CrossRef]

| Parameter | Value | Unit | Ref. |

|---|---|---|---|

| Reference year | 2025 | ||

| WtE-AD process lifetime | 25 | y | |

| Income tax | 35 | % | [33] |

| Inflation 1 | 4.54 | % y−1 | [34] |

| Revenue generated from the sale of: | |||

| Organic waste management | 33 | USD t−1 | [31] |

| Electricity | 0.05 | USD kWh−1 | [29] |

| Biofertilizer 2 | 129 | USD t−1 | [30] |

| Parameter | Unit | FVW | MW | SHW | Inoculum | Quality Criteria 1 | |||

|---|---|---|---|---|---|---|---|---|---|

| This Study | Ref [22] | This Study | Ref [22] | This Study | Ref [36] | ||||

| Methanogenic activity | mL CH4 g VS−1 | 349 | 340 to 395 | ||||||

| TS | % | 11.37 ± 1.04 | 10.89 | 37.23 | 11.81 | 10.28 | 4.248 | ||

| VS | % of TS | 91.98 ± 3.81 | 92.87 | 90.88 | 95.14 | 62.63 | 76.02 | ||

| Ash | % of TS | 8.02 ± 3.81 | 7.14 | 9.12 | 4.86 | 37.37 | 23.98 | ||

| TA | mg CaCO3 L−1 | 673.33 ± 49.06 | 1610 | 380 | 550 | >3000 | |||

| IA | mg CaCO3 L−1 | 131.25 ± 53.60 | 300 | 43.3 | |||||

| PA | mg CaCO3 L−1 | 950 | 53.3 | ||||||

| IA/PA | 0.316 | 0.813 | |||||||

| VFA | mg L−1 | 1445 ± 676.01 | 672 | 420 | <1000 | ||||

| VFA/TA | 2.16 ± 1.01 | 0.417 | 1.105 | ||||||

| pH | 4.63 ± 0.54 | 4.51 | 8.07 | 6.94 | 8.04 | 8.47 | 7.0 to 8.5 | ||

| Reactor Operating Regime (Volume in m3) | Temperature (°C) | Substrate | Biogas Productivity (L L−1 d−1) | OLR (g VS L−1 d−1) | HRT (d) | Ref. |

|---|---|---|---|---|---|---|

| CSTR (2000) | 39 | PM | 1.5 | 2.11 | [41] | |

| CSTR (2000) | 39 | PM and EC | 2.91 | 4.25 | ||

| CSTR (7400) | 38 | SHW | 4.08 | 45 to 55 | [42] | |

| Lagoon-type (2713) | CM | 1.05 | 2.51 | 33 | [43] | |

| CSTR (2713) | 40 | CM and SM | 1.28 | 2.51 | 33 | |

| CSTR (2000) | 37 | Microalgae and EC | 0.12 | 0.70 | 20 | [44] |

| CSTR (2400) | CM and EC | 1.99 | [45] | |||

| CSTR (4000) | MSW | <2.5 | [46] | |||

| CSTR (4000) | MSW | 4 to 5.5 | ||||

| CSTR (1500) | Maize and manure | 5.6 | ||||

| CSTR (1500) | Maize and manure | 5.6 | ||||

| CSTR (1000) | SHW | 7.5 | ||||

| CSTR (1000) | SHW | 7.5 | ||||

| CSTR (2500) | Maize and manure | 4.8 | ||||

| CSTR (3600) | Manure, OBW, EC, and SHW | 1.5 | ||||

| CSTR (3600) | Manure, OBW, EC, and SHW | 2 | ||||

| CSTR (3150) | OFMSW | 5.5 to 7 | ||||

| CSTR (3150) | OFMSW | 2.5 to 4 | ||||

| CSTR (3450) | OFMSW | 2.5 to 4 | ||||

| CSTR (1200) | Maize and manure | 10 to 12 | ||||

| CSTR (1200) | Maize and manure | 10 to 12 | ||||

| CSTR (1200) | Maize and manure | 10 to 12 | ||||

| CSTR (1200) | Maize and manure | <2.5 | ||||

| CSTR (1000) | Maize, fats, and fruits | 5.7 | ||||

| CSTR (3255) | Sludge and manure | 2.7 | ||||

| CSTR (4000) | WS | 2 | ||||

| CSTR (4000) | WS | 2 | ||||

| CSTR (4000) | WS | 2 | ||||

| CSTR (1200) | Maize and manure | 1.1 | ||||

| CSTR (1200) | Maize and manure | 1.1 | ||||

| CSTR (1250) | Manure | 4.1 | ||||

| CSTR (2000) | Maize and manure | 7.4 | ||||

| CSTR (2000) | Maize and manure | 7.4 | ||||

| CSTR (3000) | Maize and manure | 5.7 | ||||

| CSTR (3200) | Maize and manure | 2.1 | ||||

| CSTR (1500) | OBW | 2.8 | ||||

| CSTR (1500) | OBW | 2.8 | ||||

| CSTR (1500) | OBW | 2.8 | ||||

| CSTR (1500) | OBW | 6.4 | ||||

| CSTR (3000) | 37 | EC and OBW | 3.9 | 40 | [47] | |

| CSTR (2500) | 37 | EC and OBW | 6.35 | 60 | ||

| CSTR (3500) | 37 | Manure and OBW | 7.88 | 45 | ||

| CSTR (3000) | 37 | EC, manure, and OBW | 9.2 | 40 to 50 | ||

| Lagoon (1344) | PS and EG | 1.72 | 2.28 | 30 | [48] | |

| Lagoon (2330) | PS and EG | 1.41 | 2.63 | 41 | ||

| Lagoon (5450) | PS and EG | 0.5 | 0.94 | 41 | ||

| NA (570) | 37 | CM | 0.56 | 2.30 | 32 | [49] |

| NA (2100) | 38 | CM and OW | 0.74 | 2.20 | 34 | |

| NA (600) | 38 | CM | 0.88 | 2.30 | 34 | |

| NA (300) | 38 | CM | 0.61 | 1.90 | 38 | |

| NA (261) | 37 | CM | 0.54 | 2.00 | 33 | |

| NA (1780) | 38 | CM and OW | 0.91 | 2.30 | 32 | |

| NA (610) | 37 | CM | 0.52 | 1.70 | 45 | |

| NA (1206) | 37 | CM | 0.62 | 2.20 | 34 | |

| NA (405) | 37 | CM | 0.37 | 1.30 | 55 | |

| NA (680) | 38 | CM | 0.75 | 2.10 | 35 | |

| NA (800) | 38 | CM and OW | 0.73 | 1.70 | 29 | |

| NA (1000) | 38 | CM and OW | 1.12 | 2.50 | 31 | |

| NA (1170) | 39 | CM and OW | 0.67 | 3.20 | 23 | |

| NA (478) | 37 | CM and OW | 1.38 | 2.20 | 60 | |

| NA (2700) | 36 | CM and OW | 0.57 | 1.50 | 36 | |

| NA (550) | 37 | PM | 0.65 | 2.00 | 25 | |

| NA (1500) | 36 | PM | 0.32 | 1.20 | 32 | |

| NA (520) | 40 | PM | 0.61 | 1.80 | 38 | |

| NA (2435) | 38 | PM and OW | 0.63 | 1.20 | 47 | |

| NA (1000) | 38 | PM and OW | 0.62 | 1.40 | 45 | |

| NA (2440) | 38 | PM and OW | 0.46 | 1.00 | 46 | |

| NA (3240) | 55 | PM and OW | 0.91 | 1.20 | 63 | |

| NA (1120) | 37 | PM and OW | 0.58 | 1.20 | 55 | |

| NA (515) | 52 | PM and OW | 0.63 | 1.50 | 29 | |

| NA (950) | 40 | PM and OW | 0.73 | 2.10 | 39 | |

| NA (370) | 38 | PM and OW | 0.87 | 2.70 | 23 | |

| NA (1680) | 38 | PM and OW | 0.91 | 2.60 | 30 | |

| CSTR (36,000) | 35 to 37 | SS | 0.44 | 1.35 | 22.5 | [50] |

| NA (2200) | 35.7 | Sludge and OFMSW | 0.35 | 0.87 | 25 to 30 | [51] |

| NA (10,000) | 35 to 37 | Sludge and OFMSW | 0.72 | 1.38 | 30 to 40 | |

| CSTR (16,000) | 39 | SS | 1.28 | [52] | ||

| CSTR (1500) | CM, manure, and GS | 0.821 | 2.31 | [53] | ||

| CSTR (1880) | CM, manure, MS, and GS | 1.411 | 4.05 | |||

| CSTR (847) | CSM, CM, manure, MS, and GS | 0.491 | 2.10 | |||

| USBR (1400) | CSM | 0.171 | 0.78 | |||

| CSTR (1800) | CSM and CM | 0.181 | 0.91 | |||

| CSTR (320) | PM | 0.171 | 1.55 | |||

| NA (22) | Agri-food waste | 1.29 | 2.16 | 61 | [54] | |

| NA (285) | Agri-food waste | 1.16 | 2.18 | 57 | ||

| NA (2159) | Agri-food waste | 1.05 | 2.15 | 42 | ||

| NA (699) | Agri-food waste | 1.34 | 1.80 | 51 | ||

| NA (1261) | Agri-food waste | 1.16 | 2.17 | 52 | ||

| NA (905) | Agri-food waste | 1.72 | 2.17 | 53 | ||

| NA (149) | Agri-food waste | 2.28 | 4.37 | 55 | ||

| NA (486) | Agri-food waste | 1.52 | 2.18 | 42 | ||

| NA (478) | Agri-food waste | 1.78 | 2.04 | 20 | ||

| NA (2993) | Agri-food waste | 0.73 | 2.18 | 35 | ||

| NA (121) | Agri-food waste | 0.73 | 2.18 | 35 | ||

| NA (549) | Agri-food waste | 0.75 | 2.10 | 20 | ||

| NA (242) | Agri-food waste | 0.80 | 2.18 | 41 | ||

| NA (102) | Agri-food waste | 1.97 | 4.37 | 38 | ||

| NA (1568) | Agri-food waste | 0.74 | 2.18 | 47 | ||

| NA (138) | Agri-food waste | 1.77 | 2.16 | 51 | ||

| NA (84) | Agri-food waste | 0.70 | 2.17 | 50 | ||

| NA (122) | Agri-food waste | 2.21 | 2.18 | 62 | ||

| NA (1218) | Agri-food waste | 1.98 | 2.18 | 55 | ||

| NA (1328) | Agri-food waste | 0.92 | 2.16 | 51 | ||

| NA (241) | Agri-food waste | 0.87 | 2.18 | 47 |

| Specific Methane Production (mL CH4 g VS−1) | R1 | R2 | Average |

|---|---|---|---|

| Stable stage (day 42) | 506.4 | 535.8 | 521.1 ± 21 |

| Methanogenic inhibition stage (day 92) | 71.4 | 63.6 | 67.5 ± 6 |

| Recovery stage (day 142) | 371.4 | 400.8 | 386.1 ± 21 |

| Treatment Capacity (t d−1) | Capital Costs (Million USD) | O&M Costs (Million USD y−1) | Total Revenue (Million USD) | NPV (Million USD) |

|---|---|---|---|---|

| 33 | 8.67 | 0.63 | −0.57 | −1.87 |

| 40 | 9.98 | 0.71 | 1.62 | −1.27 |

| 50 | 11.74 | 0.81 | 5.13 | −0.25 |

| 60 | 13.41 | 0.90 | 8.96 | 0.92 |

| 70 | 15.01 | 0.99 | 13.05 | 2.19 |

| 80 | 16.54 | 1.07 | 17.26 | 3.52 |

| 90 | 18.03 | 1.14 | 21.54 | 4.87 |

| 100 | 19.46 | 1.22 | 25.89 | 6.23 |

| 125 | 22.90 | 1.39 | 37.00 | 9.67 |

| 150 | 26.16 | 1.54 | 48.50 | 13.21 |

| 200 | 32.26 | 1.83 | 72.52 | 20.72 |

| IE over the 25-Year Time Horizon | Electricity Production (MWh y−1) | Amount of Organic Waste Managed (t d−1) |

|---|---|---|

| Zero | 10,516 | 60 |

| One | 9983 | 59 |

| Two | 9463 | 58 |

| Three | 8798 | 56 |

| Five | 7811 | 54 |

| Seven | 6892 | 52 |

| Ten | 5490 | 48 |

| Treatment Capacity (t d−1) | NPV (Million USD) of the Large-Scale WtE-AD Process Under Different IE | ||||||

|---|---|---|---|---|---|---|---|

| Zero | One | Two | Three | Five | Seven | Ten | |

| 60 | 0.92 | 0.55 | 0.20 | −0.25 | −0.92 | −1.53 | −2.44 |

| 70 | 2.19 | 1.78 | 1.25 | 0.86 | −0.02 | −0.82 | −1.87 |

| 80 | 3.52 | 2.94 | 2.51 | 1.94 | 0.97 | 0.07 | −1.22 |

| 90 | 4.87 | 4.27 | 3.67 | 3.21 | 2.02 | 0.92 | −0.51 |

| 100 | 6.23 | 5.60 | 4.98 | 4.37 | 3.13 | 1.93 | 0.27 |

| 125 | 9.67 | 8.99 | 8.18 | 7.51 | 6.02 | 4.57 | 2.39 |

| 200 | 20.72 | 19.47 | 18.25 | 17.06 | 14.73 | 12.55 | 9.43 |

| Fee | Unit | Substrate | Country | Ref. |

|---|---|---|---|---|

| 65 | USD t−1 | CM | [57] | |

| 67 | FW | |||

| 49 to 58 | MSW | |||

| 11.5 | PM | Netherlands | [58] | |

| 14 | Poultry manure | Netherlands | ||

| 86 | EUR t−1 | WAS y FW | Italy | [59] |

| 75 | OFMSW, WAS, and others | Italy | ||

| 70 | WAS and FW | Italy | ||

| 17 to 30 | CM and dairy waste | Germany | ||

| 30 | FW | Germany | ||

| 33 | USD t−1 | FVW and MW | Mexico | This study |

| Waste Management Income (USD t−1) | NPV (Million USD) of the Large-Scale WtE-AD Process Under Different IE | ||||||

|---|---|---|---|---|---|---|---|

| Zero | One | Two | Three | Five | Seven | Ten | |

| 33 | 0.92 | 0.55 | 0.20 | −0.25 | −0.92 | −1.53 | −2.44 |

| 34 | 1.20 | 0.83 | 0.47 | 0.01 | −0.66 | −1.28 | −2.22 |

| 36 | 1.76 | 1.39 | 1.02 | 0.54 | −0.15 | −0.79 | −1.76 |

| 38 | 2.32 | 1.94 | 1.56 | 1.07 | 0.35 | −0.3 | −1.31 |

| 40 | 2.86 | 2.48 | 2.11 | 1.59 | 0.86 | 0.19 | −0.86 |

| 42 | 3.38 | 3.01 | 2.63 | 2.11 | 1.37 | 0.60 | −0.41 |

| 44 | 3.89 | 3.51 | 3.14 | 2.62 | 1.88 | 1.17 | 0.04 |

| 99.5 1 | 16.32 | 15.78 | 15.24 | 14.38 | 13.34 | 12.35 | 10.60 |

| Price | Unit | Country | Electrical Capacity of the WtE-AD Process (kW) | Ref. |

|---|---|---|---|---|

| 0.060 1 | USD kWh−1 | Brazil | [61] | |

| 0.190 1 | EUR kWh−1 | Croatia | 300 to 400 | [62] |

| 0.165 1 | 400 to 1000 | |||

| 0.160 1 | 1000 to 2000 | |||

| 0.150 1 | 2000 to 5000 | |||

| 0.097 1 | France | <150 | ||

| 0.081 1 | >2000 | |||

| 0.097 1 | Hungary | <150 | ||

| 0.081 1 | >2000 | |||

| 0.147 1 | Luxembourg | <150 | ||

| 0.137 1 | 150 to 300 | |||

| 0.127 1 | 300 to 500 | |||

| 0.117 1 | 500 to 2500 | |||

| 0.088 1 | UK | <250 | ||

| 0.082 1 | 250 to 500 | |||

| 0.084 1 | <500 | |||

| 0.101 1 | GBP kWh−1 | UK | <250 | [63] |

| 0.195 1 | EUR kWh−1 | Austria | <250 | |

| 0.056 1 | Denmark | |||

| 0.118 to 0.211 1 | France | |||

| 0.237 1 | Germany | <75 | ||

| 0.150 1 | Irland | <500 | ||

| 0.280 1 | CHF kWh−1 | Switzerland | <50 | |

| 0.150 1 | EUR kWh−1 | Netherlands | ||

| 0.084 2 | UK | [64] | ||

| 0.089 2 | Germany | |||

| 0.067 2 | France | |||

| 0.080 2 | Spain | |||

| 0.125 2 | Italy | |||

| 0.060 2 | NY, USA | [65] | ||

| 0.088 2 | NY, USA | [66] | ||

| 0.050 2 | USD kWh−1 | Mexico | [29] |

| Electricity Scenario | NPV (Million USD) of the Large-Scale WtE-AD Process Under Different IE | ||||||

|---|---|---|---|---|---|---|---|

| Zero | One | Two | Three | Five | Seven | Ten | |

| Mexico | 0.92 | 0.55 | 0.2 | −0.25 | −0.92 | −1.53 | −2.44 |

| New York, USA | 5.34 | 4.84 | 4.33 | 3.67 | 2.64 | 1.64 | 0.08 |

| Mexico 1 | 7.13 | 6.56 | 5.99 | 5.26 | 4.16 | 3.06 | 1.27 |

| Italy | 9.29 | 8.6 | 7.93 | 7.07 | 5.8 | 4.61 | 2.66 |

| Germany | 21.23 | 19.94 | 18.68 | 17.06 | 14.67 | 12.45 | 9.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz-Castro, D.E.; García-Balandrán, E.E.; Albalate-Ramírez, A.; Escamilla-Alvarado, C.; Sinagawa-García, S.R.; Rivas-García, P.; Miramontes-Martínez, L.R. How Does Methanogenic Inhibition Affect Large-Scale Waste-to-Energy Anaerobic Digestion Processes? Part 1—Techno-Economic Analysis. Fermentation 2025, 11, 510. https://doi.org/10.3390/fermentation11090510

Díaz-Castro DE, García-Balandrán EE, Albalate-Ramírez A, Escamilla-Alvarado C, Sinagawa-García SR, Rivas-García P, Miramontes-Martínez LR. How Does Methanogenic Inhibition Affect Large-Scale Waste-to-Energy Anaerobic Digestion Processes? Part 1—Techno-Economic Analysis. Fermentation. 2025; 11(9):510. https://doi.org/10.3390/fermentation11090510

Chicago/Turabian StyleDíaz-Castro, Denisse Estefanía, Ever Efraín García-Balandrán, Alonso Albalate-Ramírez, Carlos Escamilla-Alvarado, Sugey Ramona Sinagawa-García, Pasiano Rivas-García, and Luis Ramiro Miramontes-Martínez. 2025. "How Does Methanogenic Inhibition Affect Large-Scale Waste-to-Energy Anaerobic Digestion Processes? Part 1—Techno-Economic Analysis" Fermentation 11, no. 9: 510. https://doi.org/10.3390/fermentation11090510

APA StyleDíaz-Castro, D. E., García-Balandrán, E. E., Albalate-Ramírez, A., Escamilla-Alvarado, C., Sinagawa-García, S. R., Rivas-García, P., & Miramontes-Martínez, L. R. (2025). How Does Methanogenic Inhibition Affect Large-Scale Waste-to-Energy Anaerobic Digestion Processes? Part 1—Techno-Economic Analysis. Fermentation, 11(9), 510. https://doi.org/10.3390/fermentation11090510