Utilization of Enhanced Asparagus Waste with Sucrose in Microbial Fuel Cells for Energy Production

Abstract

1. Introduction

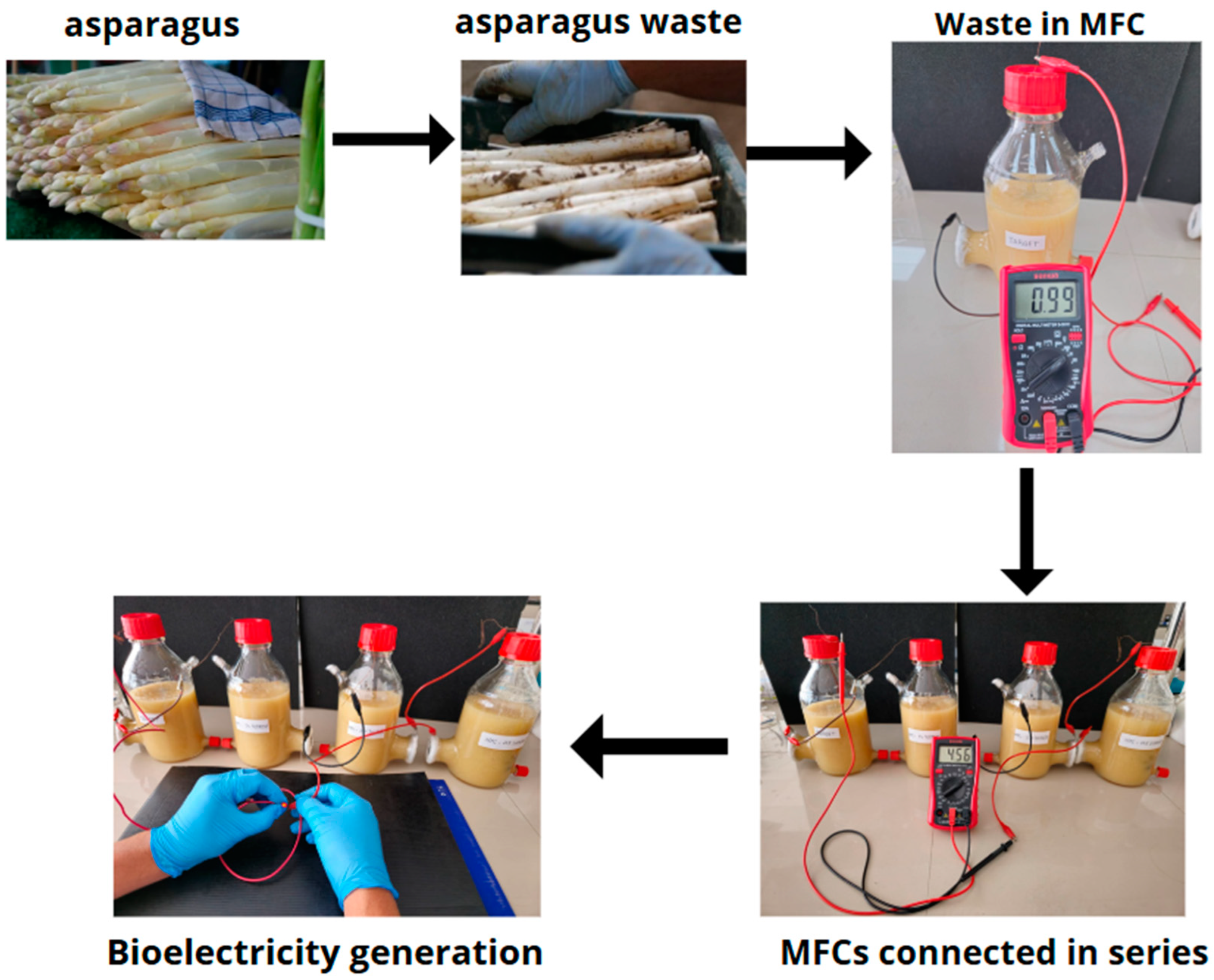

2. Materials and Methods

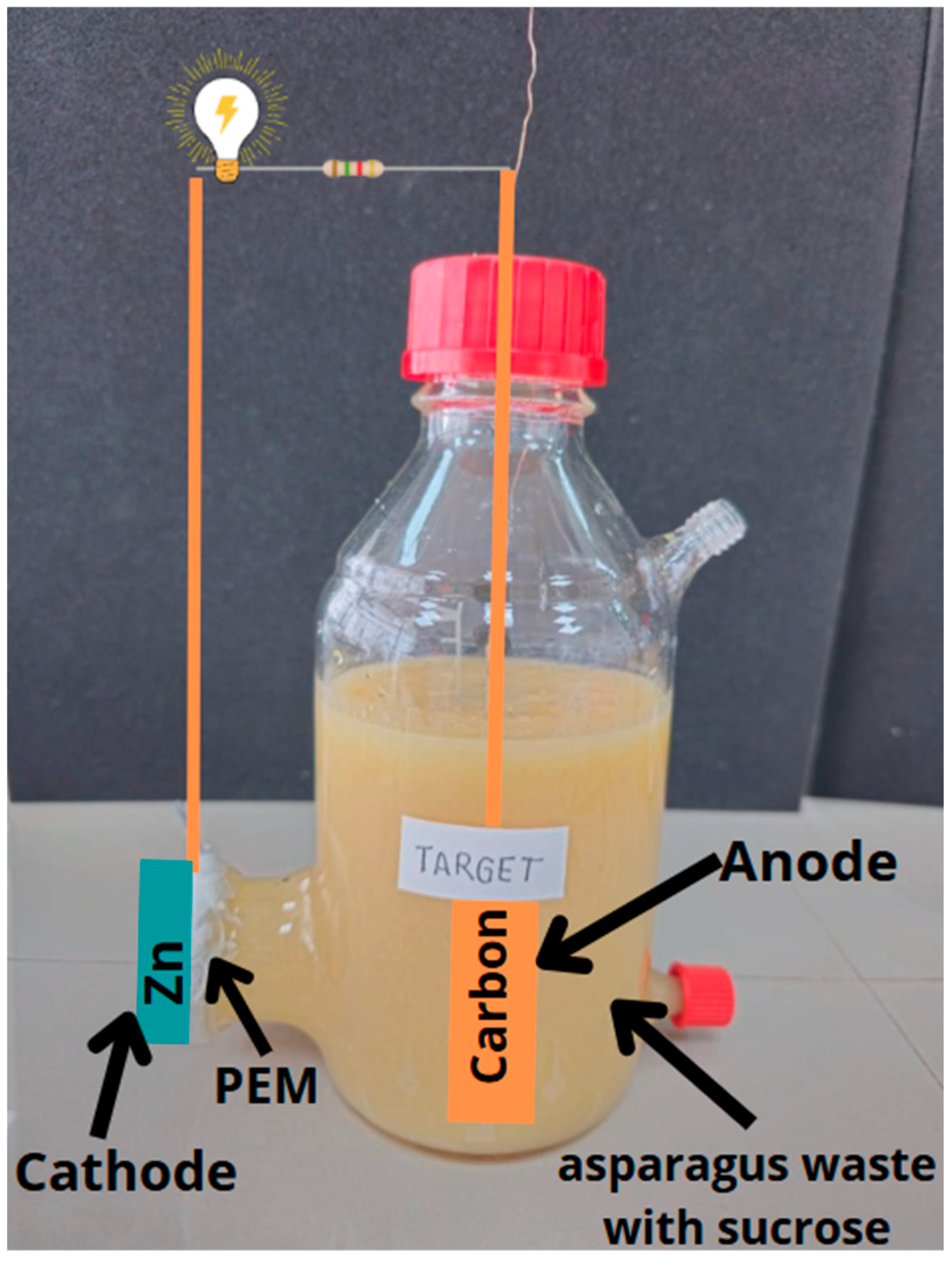

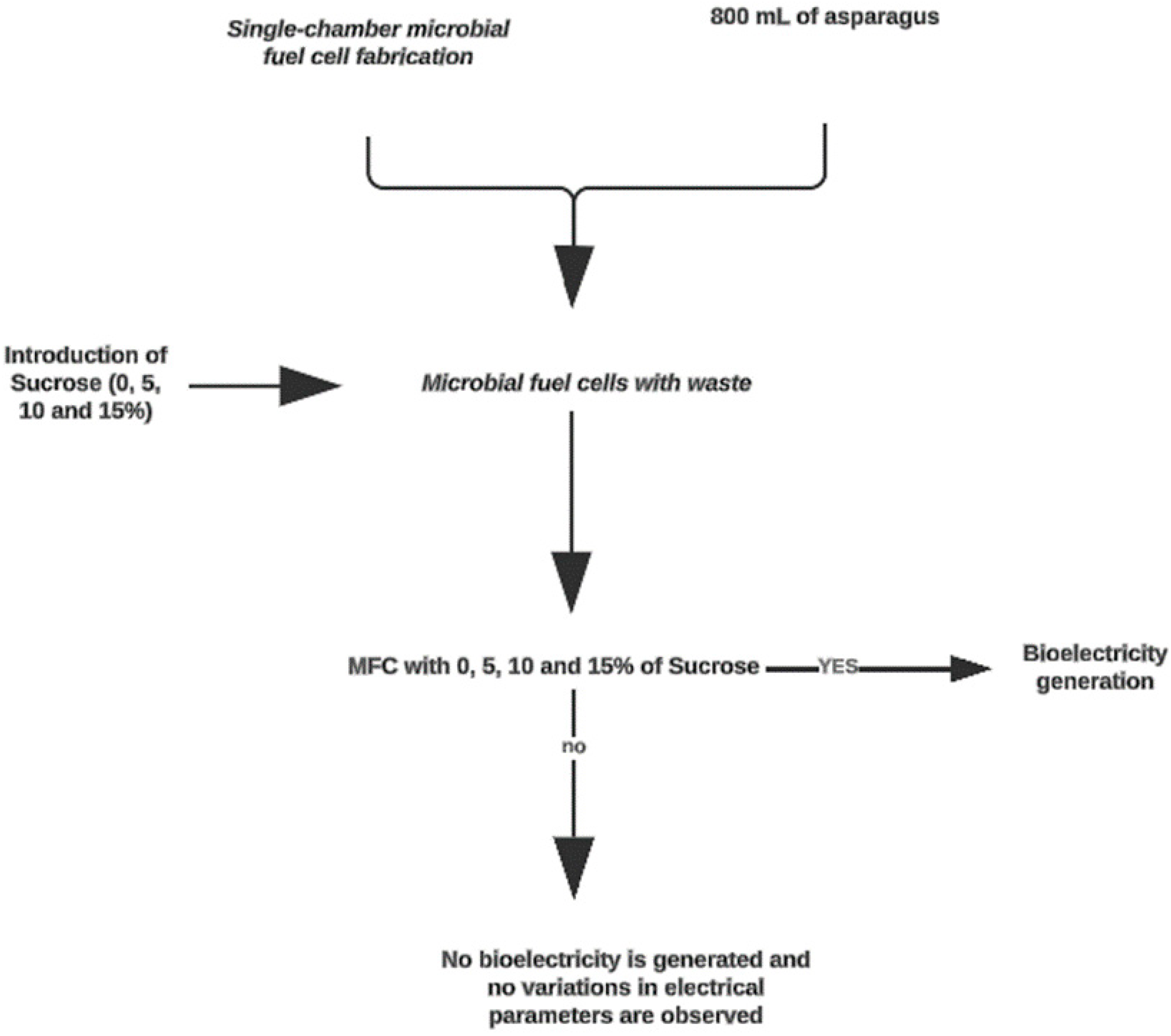

- Manufacturing of the MFC Operationalization

- b.

- Obtaining samples used as a substrate.

- c.

- Obtaining Physicochemical Parameters of the MFCs

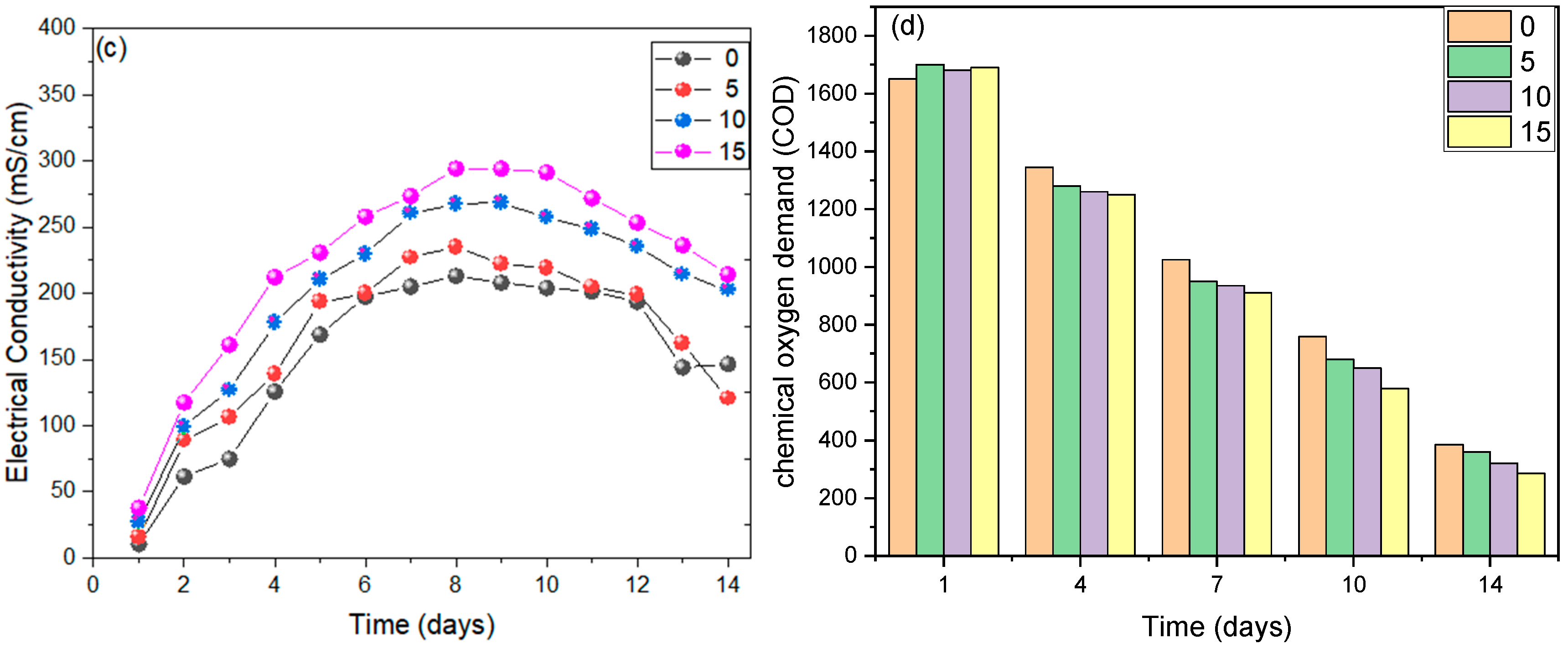

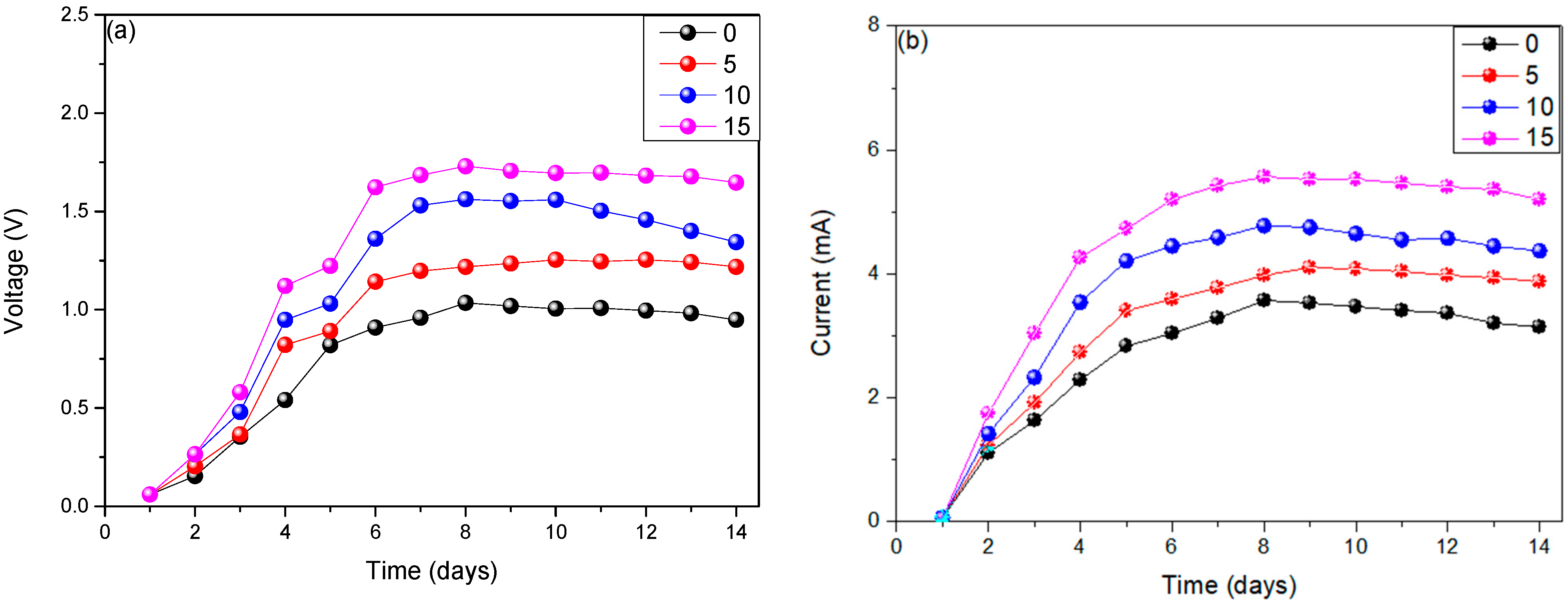

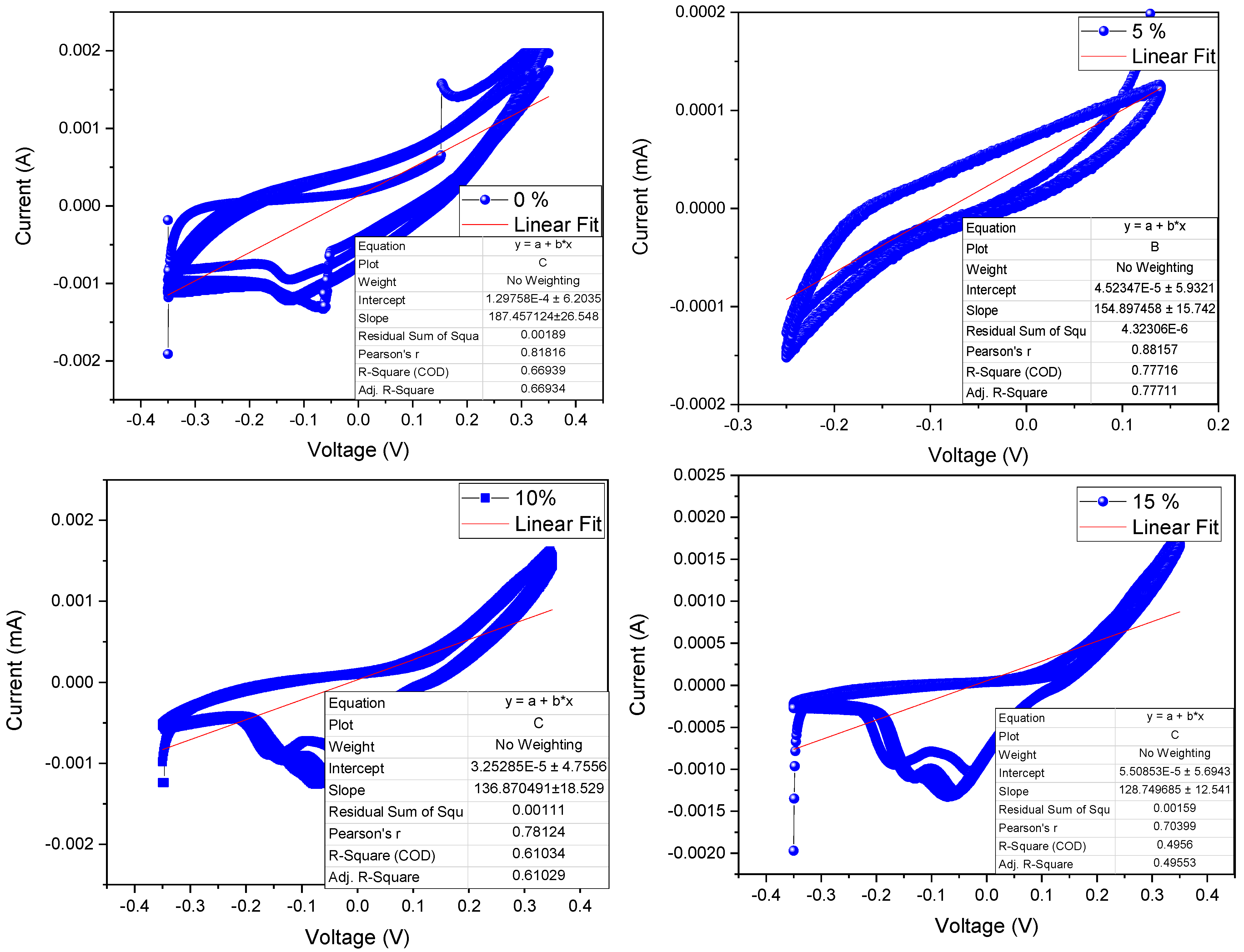

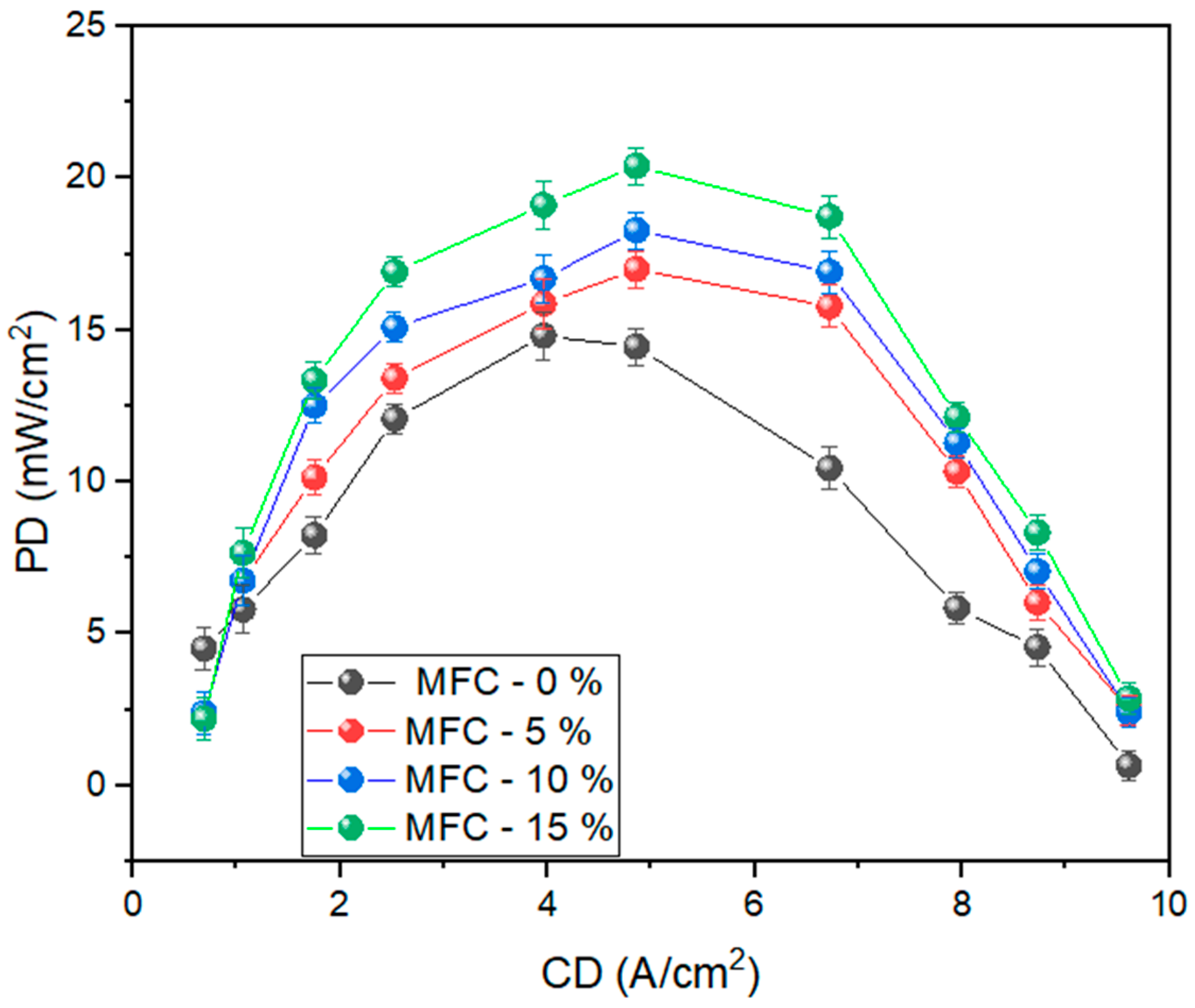

3. Result and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Esparza, I.; Jiménez-Moreno, N.; Bimbela, F.; Ancín-Azpilicueta, C.; Gandía, L.M. Fruit and vegetable waste management: Conventional and emerging approaches. J. Environ. Manag. 2020, 265, 110510. [Google Scholar]

- Suri, S.; Singh, A.; Nema, P.K. Current applications of citrus fruit processing waste: A scientific outlook. Appl. Food Res. 2022, 2, 100050. [Google Scholar]

- Russo, C.; Maugeri, A.; Lombardo, G.E.; Musumeci, L.; Barreca, D.; Rapisarda, A.; Cirmi, S.; Navarra, M. The second life of Citrus fruit waste: A valuable source of bioactive compounds. Molecules 2021, 26, 5991. [Google Scholar] [CrossRef] [PubMed]

- Vama, L.; Cherekar, M.N. Production, extraction and uses of eco-enzyme using citrus fruit waste: Wealth from waste. Asian J. Microbiol. Biotechnol. Environ. Sci. 2020, 22, 346–351. [Google Scholar]

- Ray, A.; Dubey, K.K.; Marathe, S.J.; Singhal, R. Supercritical fluid extraction of bioactives from fruit waste and its therapeutic potential. Food Biosci. 2023, 52, 102418. [Google Scholar]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Sustainable energy transition for renewable and low carbon grid electricity generation and supply. Front. Energy Res. 2022, 9, 743114. [Google Scholar]

- Obileke, K.; Onyeaka, H.; Meyer, E.L.; Nwokolo, N. Microbial fuel cells, a renewable energy technology for bio-electricity generation: A mini-review. Electrochem. Commun. 2021, 125, 107003. [Google Scholar]

- Shen, D.; Duley, W.W.; Peng, P.; Xiao, M.; Feng, J.; Liu, L.; Zou, Z.; Zhou, Y.N. Moisture-enabled electricity generation: From physics and materials to self-powered applications. Adv. Mater. 2020, 32, 2003722. [Google Scholar]

- Huang, Y.; Cheng, H.; Qu, L. Emerging materials for water-enabled electricity generation. ACS Mater. Lett. 2021, 3, 193–209. [Google Scholar]

- Wątróbski, J.; Bączkiewicz, A.; Król, R.; Sałabun, W. Green electricity generation assessment using the CODAS-COMET method. Ecol. Indic. 2022, 143, 109391. [Google Scholar]

- Meylani, V.; Surahman, E.; Fudholi, A.; Almalki, W.H.; Ilyas, N.; Sayyed, R.Z. Biodiversity in microbial fuel cells: Review of a promising technology for wastewater treatment. J. Environ. Chem. Eng. 2023, 11, 109503. [Google Scholar]

- Sun, F.; Chen, J.; Tang, M.; Yang, Y. Recent research progress, challenges and future directions of sediment microbial fuel cell: A comprehensive review. Int. J. Hydrogen Energy 2024, 50, 870–886. [Google Scholar]

- Sonawane, A.V.; Rikame, S.; Sonawane, S.H.; Gaikwad, M.; Bhanvase, B.; Sonawane, S.S.; Mungray, A.K.; Gaikwad, R. A review of microbial fuel cell and its diversification in the development of green energy technology. Chemosphere 2024, 350, 141127. [Google Scholar]

- Sharma, M.; Sharma, S.; Alkhanjaf, A.A.M.; Arora, N.K.; Saxena, B.; Umar, A.; Ibrahim, A.A.; Akhtar, M.S.; Mahajan, A.; Negi, S.; et al. Microbial fuel cells for azo dye degradation: A perspective review. J. Ind. Eng. Chem. 2024, 142, 45–67. [Google Scholar]

- Roy, H.; Rahman, T.U.; Tasnim, N.; Arju, J.; Rafid, M.M.; Islam, M.R.; Pervez, M.N.; Cai, Y.; Naddeo, V.; Islam, M.S. Microbial fuel cell construction features and application for sustainable wastewater treatment. Membranes 2023, 13, 490. [Google Scholar] [CrossRef]

- Ahmad, A. Conventional vegetable waste: A potential source for the high performance of benthic microbial fuel cells. Biomass Convers. Biorefin. 2024, 14, 24641–24653. [Google Scholar]

- Din, M.I.; Iqbal, M.; Hussain, Z.; Khalid, R. Bioelectricity generation from waste potatoes using single chambered microbial fuel cell. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 12596–12606. [Google Scholar]

- Yaakop, A.S.; Ahmad, A.; Hussain, F.; Oh, S.E.; Alshammari, M.B.; Chauhan, R. Domestic Organic Waste: A Potential Source to Produce the Energy via a Single-Chamber Microbial Fuel Cell. Int. J. Chem. Eng. 2023, 2023, 2425735. [Google Scholar]

- Kohli, D.; Champawat, P.S.; Mudgal, V.D. Asparagus (Asparagus racemosus L.) roots: Nutritional profile, medicinal profile, preservation, and value addition. J. Sci. Food Agric. 2023, 103, 2239–2250. [Google Scholar]

- Guo, Q.; Wang, N.; Liu, H.; Li, Z.; Lu, L.; Wang, C. The bioactive compounds and biological functions of Asparagus officinalis L.—A review. J. Funct. Foods 2020, 65, 103727. [Google Scholar]

- Drost, D. Asparagus breeding: Future research needs for sustainable production. Front. Plant Sci. 2023, 14, 1148312. [Google Scholar] [CrossRef]

- Moreno-Pinel, R.; Castro-López, P.; Die-Ramón, J.V.; Gil-Ligero, J. Asparagus (Asparagus officinalis L.) breeding. In Advances in Plant Breeding Strategies: Vegetable Crops: Volume 9: Fruits and Young Shoots; Springer International Publishing: Cham, Switzerland, 2021; pp. 425–469. [Google Scholar]

- Hong, W.; Ma, Z.; Ye, B.; Yu, G.; Tang, T.; Zheng, M. Detection of green asparagus in complex environments based on the improved YOLOv5 algorithm. Sensors 2023, 23, 1562. [Google Scholar] [CrossRef] [PubMed]

- Segundo, R.F.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Otiniano, N.M.; Soto-Deza, N.; Rojas-Villacorta, W.; De La Cruz-Cerquin, M. The Potential Use of Pseudomonas stutzeri as a Biocatalyst for the Removal of Heavy Metals and the Generation of Bioelectricity. Fermentation 2024, 10, 113. [Google Scholar] [CrossRef]

- La Cruz-Noriega, D.; Nazario-Naveda, R.; Benites, S.M.; Rojas-Flores, S.; Delfín-Narciso, D.; Rojas-Villacorta, W.; Diaz, F. Potential use of mango waste and microalgae Spirulina sp. for bioelectricity generation. J. Environ. Res. Eng. Manag. 2022, 78, 129–136. [Google Scholar]

- Halim, M.A.; Rahman, M.O.; Ibrahim, M.; Kundu, R.; Biswas, B.K. Effect of Anolyte pH on the Performance of a Dual-Chambered Microbial Fuel Cell Operated with Different Biomass Feed. J. Chem. 2021, 2021, 5465680. [Google Scholar] [CrossRef]

- Li, X.; Lu, Y.; Luo, H.; Liu, G.; Torres, C.I.; Zhang, R. Effect of pH on bacterial distributions within cathodic biofilm of the microbial fuel cell with maltodextrin as the substrate. Chemosphere 2021, 265, 129088. [Google Scholar] [PubMed]

- Aliyu, A.; Musa, H.A.; Fardami, A.Y. Isolation and Identification of Bacteria Associated With Bioelectricity Generation From Fruit Wastes and Gutter Sludge Using Microbial Fuel Cells (MFC) In Kano Metropolis, Kano State, Nigeria. Niger. J. Sci. Eng. Infrastruct. 2024, 2. [Google Scholar]

- Kumar, A.; Deshmukh, R.K.; Gaikwad, K.K. Quality preservation in banana fruits packed in pine needle and halloysite nanotube-based ethylene gas scavenging paper during storage. Biomass Convers. Biorefin. 2024, 14, 6311–6320. [Google Scholar] [CrossRef]

- Niju, S.; Elakkiya, E. Synthetic alkali soluble lignin supplementation to sucrose-rich wastewater fed mfc. IWRA (India) J. (Half Yrly. Tech. J. Indian Geogr. Comm. IWRA) 2020, 9, 18–21. [Google Scholar]

- Pushkar, P.; Mungray, A.K. Exploring the use of 3 dimensional low-cost sugar-urea carbon foam electrode in the benthic microbial fuel cell. Renew. Energy 2020, 147, 2032–2042. [Google Scholar] [CrossRef]

- Niu, T.; Zhu, H.; Shutes, B.; He, C. Gaseous carbon and nitrogen emissions from microbial fuel cell-constructed wetlands with different carbon sources: Microbiota-driven mechanisms. J. Clean. Prod. 2024, 435, 140404. [Google Scholar] [CrossRef]

- Córdova-Bautista, Y.; Ramírez-Morales, E.; Pérez-Hernández, B.; Ojeda-Morales, M.E.; López-Lázaro, J.S.; Martínez-Pereyra, G. Electricity production and bioremediation from synthetic sugar industry wastewater by using microbial isolate in microbial fuel cell. Sugar Tech 2020, 22, 820–829. [Google Scholar] [CrossRef]

- Huang, X.; Duan, C.; Duan, W.; Sun, F.; Cui, H.; Zhang, S.; Chen, X. Role of electrode materials on performance and microbial characteristics in the constructed wetland coupled microbial fuel cell (CW-MFC): A review. J. Clean. Prod. 2021, 301, 126951. [Google Scholar] [CrossRef]

- Li, C.; Luo, M.; Zhou, S.; He, H.; Cao, J.; Luo, J. Comparison analysis on simultaneous decolorization of Congo red and electricity generation in microbial fuel cell (MFC) with l-threonine-/conductive polymer-modified anodes. Environ. Sci. Pollut. Res. 2021, 28, 4262–4275. [Google Scholar] [CrossRef]

- Rincón-Catalán, N.I.; Cruz-Salomón, A.; Sebastian, P.J.; Pérez-Fabiel, S.; Hernández-Cruz, M.D.C.; Sánchez-Albores, R.M.; Hernández-Méndez, J.M.E.; Domínguez-Espinosa, M.E.; Esquinca-Avilés, H.A.; Ríos-Valdovinos, E.I.; et al. Banana waste-to-energy valorization by microbial fuel cell coupled with anaerobic digestion. Processes 2022, 10, 1552. [Google Scholar] [CrossRef]

- Zafar, H.; Peleato, N.; Roberts, D. Bioaugmentation with Bacillus subtilis and Cellulomonas fimi to enhance the biodegradation of complex carbohydrates in MFC-fed fruit waste. Biomass Bioenergy 2023, 174, 106843. [Google Scholar] [CrossRef]

- Akinwumi, O.D.; Dada, E.O.; Agarry, S.E.; Aremu, M.O.; Agbede, O.O.; Alade, A.O.; Aworanti, O.A.; Alao, A.I. Effects of retention time, pH, temperature and type of fruit wastes on the bioelectricity generation performance of microbial fuel cell during the biotreatment of pharmaceutical wastewater: Experimental study, optimization and modelling. Environ. Process. 2024, 11, 51. [Google Scholar] [CrossRef]

- Rokhim, D.A.; Vitarisma, I.Y.; Sumari, S.; Utomo, Y.; Asrori, M.R. Optimizing Household Wastes (Rice, Vegetables, and Fruit) as an Environmentally Friendly Electricity Generator. J. Renew. Mater. 2024, 12, 275–284. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Daud, N.N.M.; Hussin, M.H.; Ibrahim, M.N.M.; Al-Sadoon, M.K.; Abdulrahman, R.M.I. Role of dragon fruit waste (DFW) in microbial fuel cell to treat metal-polluted wastewater with electricity generation. Int. J. Environ. Sci. Technol. 2024, 1–12. [Google Scholar] [CrossRef]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Benites, S.M.; Delfín-Narciso, D.; Luis, A.-S.; Díaz, F.; Luis, C.-C.; Moises, G.C. Electric Current Generation by Increasing Sucrose in Papaya Waste in Microbial Fuel Cells. Molecules 2022, 27, 5198. [Google Scholar] [CrossRef]

- Sreelekshmy, B.R.; Basheer, R.; Sivaraman, S.; Vasudevan, V.; Elias, L.; Shibli, S.M.A. Sustainable electric power generation from live anaerobic digestion of sugar industry effluents using microbial fuel cells. J. Mater. Chem. A 2020, 8, 6041–6056. [Google Scholar]

- Segundo, R.F.; Magaly, D.L.C.N.; Benites, S.M.; Daniel, D.N.; Angelats-Silva, L.; Díaz, F.; Luis, C.C.; Fernanda, S.P. Increase in electrical parameters using sucrose in tomato waste. Fermentation 2022, 8, 335. [Google Scholar] [CrossRef]

- Tariq, M.; Wang, J.; Bhatti, Z.A.; Bilal, M.; Malik, A.J.; Akhter, M.S.; Mahmood, Q.; Hussain, S.; Ghfar, A.; Al-Anazy, M.M.; et al. Bioenergy potential of albumin, acetic acid, sucrose, and blood in microbial fuel cells treating synthetic wastewater. Processes 2021, 9, 1289. [Google Scholar] [CrossRef]

- Bose, D.; Bhattacharya, R.; Gopinath, M.; Vijay, P.; Krishnakumar, B. Bioelectricity production and bioremediation from sugarcane industry wastewater using microbial fuel cells with activated carbon cathodes. Results Eng. 2023, 18, 101052. [Google Scholar]

- Kinyua, A.; Mbugua, J.K.; Mbui, D.N.; Kithure, J.; Michira, I.; Wandiga, S.O. Voltage Recovery from Pesticides Doped Tomatoes, Cabbages and Loam Soil Inoculated with Rumen Waste: Microbial Fuel Cells. Int. J. Sci. Res. Sci. Eng. Technol. 2022, 9, 172–180. [Google Scholar]

- Sakr, E.A.; Khater, D.Z.; Kheiralla, Z.M.; El-khatib, K.M. Statistical optimization of waste molasses-based exopolysaccharides and self-sustainable bioelectricity production for dual chamber microbial fuel cell by Bacillus piscis. Microb. Cell Factories 2023, 22, 202. [Google Scholar]

- Verma, M.; Singh, V.; Mishra, V. Bioelectricity generation by using cellulosic waste and spent engine oil in a concentric photobioreactor-microbial fuel cell. J. Environ. Chem. Eng. 2023, 11, 110566. [Google Scholar]

- Aleid, G.M.; Alshammari, A.S.; Alomari, A.D.; Sa’ad Abdullahi, S.; Mohammad RE, A.; Abdulrahman, R.M.I. Degradation of metal ions with electricity generation by using fruit waste as an organic substrate in the microbial fuel cell. Int. J. Chem. Eng. 2023, 2023, 1334279. [Google Scholar]

- Khodaparastasgarabad, N.; Sonawane, J.M.; Baghernavehsi, H.; Gong, L.; Liu, L.; Greener, J. Microfluidic membraneless microbial fuel cells: New protocols for record power densities. Lab A Chip 2023, 23, 4201–4212. [Google Scholar]

- Liu, Y.; Ren, T.; Su, Z.; Li, C. Nanoflower-like MoS2 anchored on electrospun carbon nanofiber-interpenetrated reduced graphene oxide as a microbial fuel cell anode achieving high power density. J. Mater. Chem. A 2023, 11, 10371–10383. [Google Scholar]

- Sayed, E.T.; Rezk, H.; Abdelkareem, M.A.; Olabi, A.G. Artificial neural network based modelling and optimization of microalgae microbial fuel cell. Int. J. Hydrogen Energy 2024, 52, 1015–1025. [Google Scholar]

- García-Villagómez, A.D.; Galindo-de-la-Rosa, J.; Dector, A.; Álvarez, A.; Rodríguez-Morales, J.A.; Olivares-Ramírez, J.M.; Arjona, N.; Chávez-Ramírez, A.U.; Vallejo-Becerra, V. Immobilization of Saccharomyces cerevisiae for application in paper-based microfluidic fuel cell. Int. J. Hydrogen Energy 2023, 48, 5301–5312. [Google Scholar]

- Bhattacharya, R.; Bose, D.; Yadav, J.; Sharma, B.; Sangli, E.; Patel, A.; Mukherjee, A.; Singh, A.A. Bioremediation and bioelectricity from Himalayan rock soil in sediment-microbial fuel cell using carbon rich substrates. Fuel 2023, 341, 127019. [Google Scholar]

- Sonu, K.; Sogani, M.; Syed, Z.; Maheshwari, K.; Rajvanshi, J.; Sengupta, N. Effectiveness of a Biofertilizer in the Treatment of Carpet Industry Dye Wastewater in an Earthen Pot–Coupled Plant Microbial Fuel Cell. J. Hazard. Toxic Radioact. Waste 2025, 29, 04024050. [Google Scholar]

- Rathinavel, N.; Veleeswaran, A.; Rathinam, Y.; Alagarsamy, A. Turning Waste into Watt: Usage of natural biomass activated carbon-based anode and septic tank wastewater for Microbial Fuel Cell (MFC) based electricity generation. Carbon Trends 2025, 19, 100461. [Google Scholar]

- Plakar, G.P.Z.; Kovo, A.S.; Oguzie, K.L.; Oguzie, E.E. Valorization of mixed blackwater/agricultural wastes for bioelectricity and biohydrogen production: A microbial treatment pathway. Heliyon 2025, 11, e41126. [Google Scholar] [PubMed]

- Rojas-Flores, S.; Nazario-Naveda, R.; Benites, S.M.; Gallozzo-Cardenas, M.; Delfín-Narciso, D.; Díaz, F. Use of pineapple waste as fuel in microbial fuel cell for the generation of bioelectricity. Molecules 2022, 27, 7389. [Google Scholar] [CrossRef]

- Rahman, W.; Yusup, S.; Mohammad, S.N.A. Screening of fruit waste as substrate for microbial fuel cell (MFC). In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2021; Volume 2332. [Google Scholar]

- Sarangi, P.K.; Singh, A.K.; Srivastava, R.K.; Gupta, V.K. Recent progress and future perspectives for zero agriculture waste technologies: Pineapple waste as a case study. Sustainability 2023, 15, 3575. [Google Scholar] [CrossRef]

| Substrate | Maximum Voltage (V) | Power Density (mW/cm2) | Current Density (A/cm2) | Internal Resistance (Ω) | Ref. |

|---|---|---|---|---|---|

| Asparagus waste with 15% sucrose | 1.729 | 20.196 | 5.574 | 128.749 | This study |

| Potato waste | 1.12 | N/A | 12.45 | N/A | [17] |

| Household waste | 0.110 | 0.1047 | 21.84 | 117 | [18] |

| Fruit waste (mixture) | 0.710 | 0.53 | 12.59 | 88 | [59] |

| Pineapple waste | 0.99 ± 0.03 | 513.99 ± 6.54 | 6.123 | 865.845 ± 4.726 | [60] |

| Tomato waste | 0.568 | 0.720 | 6.762 | 200 | [46] |

| Mango waste | 0.845 ± 0.314 | 657.958 ± 21.114 | 4.484 | 205.056 ± 25 | [25] |

| Banana waste | 0.286 | 41.3 | 0.286 | 580.99 | [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segundo, R.-F.; Luis, C.-C.; De La Cruz-Noriega, M.; Otiniano, N.M.; Cardenas, M.M.G. Utilization of Enhanced Asparagus Waste with Sucrose in Microbial Fuel Cells for Energy Production. Fermentation 2025, 11, 260. https://doi.org/10.3390/fermentation11050260

Segundo R-F, Luis C-C, De La Cruz-Noriega M, Otiniano NM, Cardenas MMG. Utilization of Enhanced Asparagus Waste with Sucrose in Microbial Fuel Cells for Energy Production. Fermentation. 2025; 11(5):260. https://doi.org/10.3390/fermentation11050260

Chicago/Turabian StyleSegundo, Rojas-Flores, Cabanillas-Chirinos Luis, Magaly De La Cruz-Noriega, Nélida Milly Otiniano, and Moisés M. Gallozzo Cardenas. 2025. "Utilization of Enhanced Asparagus Waste with Sucrose in Microbial Fuel Cells for Energy Production" Fermentation 11, no. 5: 260. https://doi.org/10.3390/fermentation11050260

APA StyleSegundo, R.-F., Luis, C.-C., De La Cruz-Noriega, M., Otiniano, N. M., & Cardenas, M. M. G. (2025). Utilization of Enhanced Asparagus Waste with Sucrose in Microbial Fuel Cells for Energy Production. Fermentation, 11(5), 260. https://doi.org/10.3390/fermentation11050260