Abstract

Yeasts play a crucial role in the winemaking process contributing to the typicity and originality of wines in a region. Therefore, the aim of the present study was to isolate, characterize, and select yeasts from the Geographical Indication “Pozo de Los Algarrobos”, San Juan, Argentina. Yeasts were directly isolated from grapes and at different stages of spontaneous fermentations of Vitis vinifera Viognier and Chardonnay varieties. Molecular and intraspecific identification of Saccharomyces cerevisiae yeasts was conducted using the D1/D2 domain and interdelta, respectively, observing 13 different yeast strains from Viognier and 12 from Chardonnay vinifications. Based on the enological traits assayed, two strains, V22 (Viognier) and C14 (Chardonnay), were selected for further studies. Microvinifications with these yeasts were carried out with Viognier and Chardonnay grape must in 2 L flasks, and the resulting wines were analytically and sensorially evaluated. Overall, strain V22 produced wines with positive and particular sensory properties, associated with fruity and floral aromas, color intensity, sweetness, aromatic persistence, and varietal typicity. Consequently, biomass propagation of V22 was conducted to inoculate pilot- (100 L) and industrial (12,000 L)-scale fermentations. V22 resulted in a correct wine fermentation performance obtaining a final product with distinctive and genuine properties.

1. Introduction

The participation of yeasts in the conversion of grape must into wine has been known for centuries. However, the conscious and controlled use of yeasts in the production of wine began in the late 19th century when the French microbiologist Louis Pasteur discovered that alcoholic fermentation is carried out by living microorganisms: yeasts.

It is widely recognized that the fermentation process occurs naturally in the presence of various yeast species that are found on grape skins and winery equipment [1,2]. The presence and permanence of the different yeast species will mainly depend on their tolerance and adaptation to the various conditions that occur during the process. Among these species, the genus Saccharomyces, particularly Saccharomyces cerevisiae, is able to dominate the fermentation process, due to its high fermentative capacity and ability to tolerate adverse conditions, such as anaerobiosis, nutrient starvation and high acidity, and elevated levels of sugar and ethanol, among others [3].

A very common enological practice is massive inoculation with commercial S. cerevisiae yeasts to ensure the performance of the process and guarantee the quality of the product. However, this practice often leads to a reduction in the diversity of indigenous microbial populations involved in these fermentations [4,5]. Consequently, the use of the same commercial starter cultures for different wines can result in a lack of variation in wine characteristics.

Therefore, one of the main concerns regarding the use of commercial starter cultures is that relying on a limited number of commercial strains to ferment wines of diverse origins and grape varieties reduces the uniqueness of the wine bouquet, a particular trait of the different viticultural regions throughout the world [6].

Over the past three decades, researchers of diverse wine-growing areas have been selecting yeasts specific to each region to use as starter cultures. These region-specific yeasts have been found to be better adapted to the local environmental conditions, enabling them to preserve the distinctive sensory properties and characteristics of regional wines more effectively [7,8,9].

In line with consumer preferences and new trends and technology advances in wine fermentation, the selection of Saccharomyces strains as starter cultures is based on parameters like fermentative power, fermentation kinetics, resistance to ethanol, ability to withstand extreme fermentation temperatures, low assimilable nitrogen requirements, tolerance to SO2, and the overall impact of yeasts on the wine structure and flavor resulting in high-quality and consistent wines [10,11,12,13].

Particularly in Argentina, different wine-growing areas have been recognized by means of a geographical indication (GI). This is a legal system of protection and recognition granted to products with a close relationship between the territory and its natural cultural or human characteristics. The GI designation allows for the identification of products from a specific region that stand out because of their geographic origin, as well as differentiation because of their quality, reputation, and other distinctive characteristics. It is worth mentioning that the study site of the current research has been officially recognized as a Geographical Indication by the National Institute of Viticulture of Argentina (INV) since 2015. This recognition is based on the unique microclimate, soil characteristics, and terroir of the area (Resolution C 30/2015).

Since yeasts play a crucial role in shaping the unique characteristics and quality of the product, examining yeasts from a particular region is of utmost importance. It is also noteworthy that there are currently no existing reports on the isolation, identification, and characterization of S. cerevisiae yeasts for winemaking with Viognier and Chardonnay grapes in Argentina.

In this context, the main goal of the present study was to isolate, characterize, and select indigenous yeasts from the “Pozo de Los Algarrobos”, a GI wine-producing region in the San Juan province in Argentina. The results of our research intend to add value to regional white wines, in addition to assuring a controlled fermentation through massive inoculation with the indigenous yeast.

2. Materials and Methods

2.1. Study Site

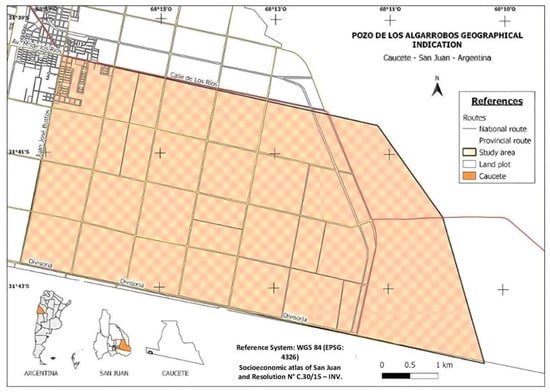

During February 2020, grape samples of the Viognier and Chardonnay varieties were harvested at the farm located in Pozo de Los Algarrobos, in Caucete, San Juan (coordinates: −31°70′27″–68°26′28.9″), at an altitude of 700 m above sea level. The area is characterized by an average annual temperature of 17 °C, annual precipitation below 200 mm, and alluvial soils (Figure 1).

Figure 1.

Pozo de Los Algarrobos, San Juan, Argentina, the winemaking region where Chardonnay and Viognier grapes were harvested.

2.2. Sampling Strategy

Grapevine fruit samples of Vitis vinifera Chardonnay and Viognier varieties were collected randomly from rows and plants of the study site. Healthy and undamaged grapes from each variety were hand-harvested when they were fully ripened. Berries were conserved in hermetically sealed sterile plastic bags and immediately transported to the laboratory, where they were stored at 4 °C.

2.3. Isolation, Purification, and Conservation of Yeasts

Destemmed grapes of each varietal were divided as follows: (Batch 1) Five grape berries were resuspended in physiological solution (0.85% NaCl) and shaken for 15 min at 125 rpm; (Batch 2) grapes inside the collection bags that were manually crushed and the resulting juice was poured into sterilized glass Erlenmeyer flasks (2 L) to conduct spontaneous fermentations. Sampling was carried out at three different moments: the beginning, halfway, and end of fermentation. Aliquots (1 mL) were taken from both batches, and serial dilutions were carried out. These dilutions were subsequently streaked onto Petri dishes with solidified WLN differential medium, supplemented with 0.2 g/L dicloran and 0.5 g/L chloramphenicol, and incubated at 28 ± 1 °C for 5–7 days. This medium allows differentiation between certain yeast species and genera, with S. cerevisiae isolates exhibiting a characteristic morphology [14,15].

A proportional and representative number of Saccharomyces-type colonies was recovered and streaked onto YEPD-Agar medium and subsequently incubated at 28 ± 1 °C for 2–3 days. After confirming the purity of each microbial colony, they were preserved in 30% glycerol at −80 °C.

2.4. Molecular Identification of Saccharomyces cerevisiae Yeasts

Yeasts were grown in 4 mL YEPD broth at 27 ± 1 °C for 24 h. Yeast DNA was extracted according to [16]. DNA concentration and quality were determined after electrophoresis on a 0.7% agarose gel and using spectrophotometry. Identification of the S. cerevisiae species was carried out using sequencing of the D1/D2 domain of the 26S rDNA subunit according to [15]. Identification was considered correct when gene sequences indicated ≥99% identity.

According to the methodology by [17], isolates identified as S. cerevisiae were differentiated at strain level by interdelta PCR analysis and compared with molecular patterns from 8 commercial strains commonly used in the region (VIN 13, Alchemy II, Alchemy IV (Anchor Oenology® (Western Cape, South Africa)); Zymaflore® Xpure, Rx60, VL1, Fx10 (Laffort® (Bordeaux, France)); Lalvin QA23 (Lallemand® (Montreal, QC, Canada)), to ensure isolates did not belong to commercial yeast strains.

Furthermore, during pilot- and industrial-scale vinifications, yeast isolates previously identified as S. cerevisiae in samples taken at the beginning, halfway, and end of the alcoholic fermentation were submitted to intraspecific differentiation to verify the implantation of the starter yeast inoculated.

Thermocycler parameters were as follows: 95 °C for 4 min, followed by 35 cycles at 95 °C for 30 s, 46 °C for 30 s, 72 °C for 45 s, and 72 °C for 10 min. PCR products were separated on 1.2% agarose gels in 1X TBE buffer and stained with 5 μg/mL ethidium bromide. The gel was visualized by UV transillumination.

2.5. Enological Traits of Indigenous Saccharomyces cerevisiae Yeasts

2.5.1. Physiological Characteristics of Enological Interest: Ability to Start the Fermentation at Low Temperature, High Initial Sugar, and Ethanol and Sulfur Dioxide Concentrations

Yeast’s ability to initiate fermentation under high sugar concentration (28 °Bx), ethanol (14% v/v) and sulfur dioxide concentration (200 mg/L), and low temperature (15 °C) was determined according to [12] with modifications. Fermentation assays were performed under static conditions in test tubes with 5 mL of grape must (21 °Bx, 0.1% yeast extract, pH 3.3, except for the high sugar concentration assay). Fermentation assays at high ethanol concentrations (14% v/v) were carried out with the following medium (g/L): fructose 20, glucose 10, and yeast extract 1. An inverted micro tube (Durham tube) was placed in the test tubes to collect the gas produced by the yeasts during the fermentation process. Isolates were inoculated at 1 × 106 cells/mL and incubated at 25 ± 1 °C (except for the low-temperature assay: 15 ± 1 °C). Fermentation ability was monitored daily up to the third day post-inoculation.

2.5.2. Hydrogen Sulfide (H2S) Production

The rotten egg smell, caused by hydrogen sulfide (H2S) presence, is an undesirable compound in wines. To assess the ability of isolates to produce different H2S levels, BD BIGGY agar was used. The yeast strains were spot-inoculated and incubated at 25 ± 1 °C for 48 h. H2S production was evaluated using an arbitrary scale from 1 (white color = no production) to 5 (dark brown = high production) [18]. Commercial yeast strain Vin 13 (Anchor Oenology®, Cape Town, South Africa) was used as control.

2.6. Performance of Selected Native S. cerevisiae Yeasts under Enological Conditions at Laboratory Scale

Laboratory-scale vinifications were carried out using selected yeasts in 2 L glass flasks with 1.7 L of either fresh Viognier or Chardonnay grape must. The characteristics of the initial grape musts are presented in Table 1. The fermentations were conducted at 15 ± 1 °C under static anaerobic conditions. Grape musts were treated with potassium metabisulfite solution to achieve a concentration of 50 mg/L of SO2.

Table 1.

Initial analytical parameters of Chardonnay and Viognier grape must.

All treatments were monitored by measuring the daily weight loss, which corresponds to the release of CO2 until a constant weight was reached. To keep the dissolved oxygen levels constant throughout the process, punching down was carried out every 24 h during the initial days. Commercial yeast strain Vin 13 (Anchor Oenology®), commonly used by wineries in the region for the production of white wines, was used as control. The following parameters were determined: fermentation kinetics (FK = g CO2/day), fermentation power (FP (% v/v) = 100 × 1.3 × (accumulated weight loss (g CO2)/grape must volume (L)) [19,20], fermentation rate (FR = initial sugars − final sugars (g/L)/final ethanol concentration (% v/v)), and fermentative purity (FP = volatile acidity (g/L)/ethanol (% v/v)).

The yeast strain with the highest fermentation performance was subsequently selected for scaling up to pilot and industrial scale.

2.7. Performance of Selected Native S. cerevisiae Yeast Strains at Pilot and Industrial Scale

During the 2023 harvest, Viognier grapes were harvested under the following conditions: 22.8 °Bx, pH 3.67, and total acidity of 4.87; the last two parameters were adjusted with tartaric acid to 3.43 and 6.5, respectively. Fermentations at pilot scale were carried out in 100 L steel tanks, with 80 L of Viognier grape juice loaded into each tank, and at industrial scale in 12,000 L stainless steel tanks equipped with jackets for temperature control, with 9000 L of Viognier grape juice.

The inoculum concentrations employed in the fermentation trials were 2 × 106 cells/mL. Fermentation kinetics during both pilot- and industrial-scale trials were closely monitored with daily measuring of must density, temperature (°C), and sugar concentration until the juice reached a value below 2 g/L for residual sugars (determined with Fehling’s Test).

2.8. Yeast Inoculum Preparation and Monitoring of the Fermentation Process

The yeast biomass was first grown on multiple YPD agar plates for 48 h and then transferred to YEPD broth and maintained for 24 h at 25 ± 1 °C at 120 rpm. Subsequently, it was pre-adapted at 25 ± 1 °C and 120 rpm for 24 h in 12 °Bx sterile grape must medium, supplemented with 1% yeast extract and 2% peptone.

Microbiological Control

Samples were taken from the grape must before inoculum and SO2 addition (T0) and also at three different stages of the fermentation: initial, halfway, and final. Must aliquots were spread onto Wallerstein Laboratory Nutrient Agar medium (WL, Oxoid, Hampshire, UK), and colony counting was performed after 5 days of incubation at 25 ± 1 °C. Implantation analysis was carried out through interdelta PCR analysis.

2.9. Standard Wine Analysis

Residual reducing sugars (g/L), ethanol (% v/v), titratable acidity (g/L), pH, volatile acidity (g/L), and total and free SO2 (mg/L) in the wines obtained at laboratory, pilot, and industrial scale were analyzed by analytical methods recommended by the OIV (2014).

2.10. Sensory Analysis

2.10.1. Sensory Analysis at Laboratory Scale

Laboratory-scale wines were submitted to sensory analysis 4 months after bottling. A Sensorial Analysis Group consisted of 12 trained panelists from the Professional Council of Enologists of San Juan. ISO 3591 Standard wine glasses [21] were poured with 30 mL wine samples at 16 ± 2 °C. Wines were tasted blindly, and the sample order was randomly assigned.

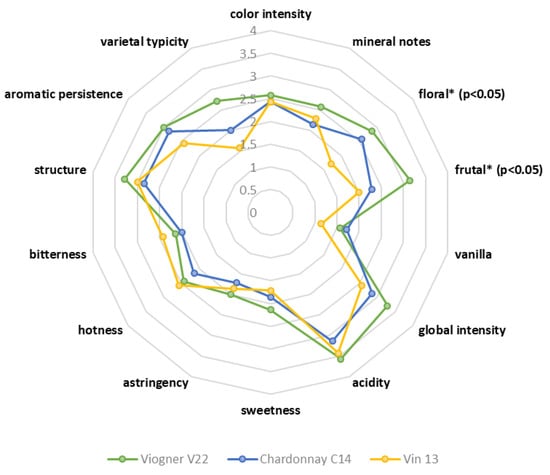

Wines obtained with C14, V22, and Vin 13 (control) yeast strains were tasted. Evaluated sensory properties were classified into three groups in reference to color, aroma, and taste (chromatic, aromatic, and gustatory). Color was evaluated for intensity and clarity. Floral and fruity intensity, mineral notes, and vanilla were the descriptors attributed to aroma. The taste was assessed using the following descriptors: hotness, bitterness, sweetness, acidity, astringency, varietal typicity, global intensity, structure, and aromatic persistence. The intensity of each attribute was assessed using an unstructured scale from 0 to 5, where 0 indicates that the descriptor was not perceived and values between 1 and 5 indicate that the intensity of the descriptors was very low (1) or very high (5). Between tastings, panelists were asked to drink water and eat unsalted crackers to clean their mouths.

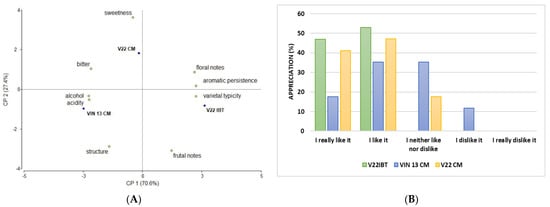

2.10.2. Hedonic Tasting at Pilot and Industrial Scale

The Hedonic test of the wines was carried out by 17 regular wine consumers between 30 and 60 years of age. The following wines were evaluated: V22 IBT (viognier PILOT SCALE with native yeast), Vin 13 CM (viognier INDUSTRIAL SCALE with commercial yeast), and V22 CM (viognier INDUSTRIAL SCALE with native yeast). A constant volume of 30 mL of each wine at 16 ± 2 °C was evaluated, and cold water was used for palate cleansing. Previously, participants were instructed on how to fill out the tasting forms. Only taste and aroma attributes were evaluated: floral and fruity notes, acidity, sweetness, bitterness, structure, alcohol, and aromatic persistence. The intensity of each attribute was assessed using an unstructured scale from 0 to 5, where 0 indicates that the descriptor was not perceived and values between 1 and 5 indicate that the intensity of the descriptors was very low (1) or very high (5). Additionally, the level of eligibility for the evaluated wines was assessed using a five-point hedonic scale (“I really like it”, “I like it”, “I neither like nor dislike it”, “I dislike it”, “I really dislike it”) according to Ref. [22] modified.

2.11. Data Analysis

Each trial for enological characterization of native yeasts was independently conducted in triplicate. The results are presented as the average of three determinations, accompanied by the corresponding standard deviation (±SD). Differences between measurements were evaluated using a one-way analysis of variance (ANOVA). With the exception of the pilot (100 L) and industrial scale (12,000 L), the experiments were not conducted in triplicate. In order to simplify the interpretation of the sensorial analysis at the pilot and industrial scale, principal components analysis (PCA) was applied using the Infostat statistical package (version 2012, Cordoba, Argentina).

3. Results

The main objective of the present study was the selection of indigenous yeasts of the species Saccharomyces cerevisiae for the production of white wines with unique characteristics of a particular geographical indication.

S. cerevisiae strains could not be detected in grape samples of both varieties, Chardonnay and Viognier, resuspended in physiological solution and initial grape must with the techniques applied in this study. However, during the different stages of spontaneous fermentations, 20 S. cerevisiae strains with typical morphology were isolated from Chardonnay grapes and 30 from Viognier grapes.

It should be noted that the wines obtained through spontaneous fermentations with the isolated yeasts in the present study showed normal analytical parameters.

3.1. Molecular Characterization of the Yeast Isolates

DNA sequence analysis of the D1/D2 domain of the 26S rDNA subunit corroborated that the morphological characteristics of the isolates corresponded to S. cerevisiae.

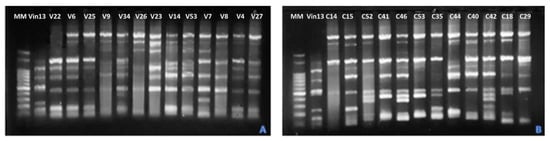

Genomic sequences of 20 and 30 S. cerevisiae strains from Chardonnay and Viognier, respectively, were amplified with δ12 and δ21 primers [17] to reach intraspecific differentiation. The interdelta sequence typing analysis revealed 13 distinct profiles from Viognier, comprising the following groups: I (V3, V4, V5); II (V6, V21, V24); III (V9, V10, V18); IV (V15, V16); V (V25, V26, V28, V29, V30, V40, V42, V44, V45); VI (V7); VII (V8); VIII (V13); IX (V14, V23); X (V22); XI (V27); XII (V33, V35); XIII (V34) (Figure 2A). Regarding S. cerevisiae isolates from Chardonnay, 12 different patterns were found: I (C31, C43, C48, C49, C50, C52); II (C45, C53, C54); III (C35); IV (C40); V (C42); VI (C18, C55); VII (C29); VIII (C15); IX (C41); X (C46); XI (C44); XII (C14) (Figure 2B). It is important to emphasize that several strains presented the same molecular profile. Therefore, before further characterization, a discrimination phase was carried out and only one strain of each profile was selected. Another important fact to mention is that none of the genetic profiles matched the evaluated commercial yeast strain.

Figure 2.

Gel electrophoresis images of DNA fingerprinting using delta 12 and delta 21 primers: (A) Viognier patterns and (B) Chardonnay patterns.

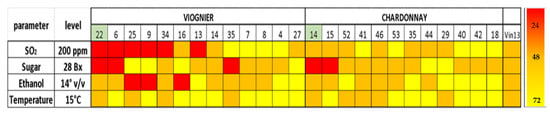

3.2. Physiological Characterization of Enological Interest of Indigenous Yeast Strains

A second differential selection based on important criteria related to winemaking was carried out. All different profiles of S. cerevisiae strains and the commercial yeast strain Vin 13 (control) were physiologically characterized regarding their enological interest. Results are summarized in Figure 3. The results obtained in the second differential stage provided additional information for the selection of the most suitable strains with desirable characteristics for their use in wine production. This allowed for the identification of S. cerevisiae strains that exhibited distinct genetic profiles as well as specific physiological characteristics that could positively affect the final quality of the wine. In order to carry out the yeast selection, assays were evaluated over a period of 3 days, where those strains that began to ferment at 24 h were chosen with priority, followed by 48 h and 72 h, respectively.

Figure 3.

Characterization of indigenous strains isolated from Viognier and Chardonnay grape musts, with colors indicating the onset of fermentation in the trials.

During the assays, it was observed that most strains isolated from Viognier started showing significant results after 24 h, indicating a fast fermentation process, whereas strains isolated from Chardonnay took slightly longer, with a noticeable fermentation progress observed after 48 h.

In the ethanol tolerance assay (14% v/v), it was observed that 50% of the Viognier yeast isolates started fermenting after 24 h, while Chardonnay grape must strains demonstrated a delay in fermentation, starting after 48 h. When evaluating SO2 resistance (200 mg/L), 46.15% of the Viognier isolates initiated fermentation 24 h after inoculation, whereas 58.33% of the Chardonnay strains started fermentation after 48 h. At a high initial sugar concentration (28 °Bx), 23.07% of the Viognier strains started fermentation after 24 h, while 58.33% of the Chardonnay strains initiated fermentation after 48 h. Evaluation of growth capacity at low temperature (15 °C) demonstrated that 30.77% of the Viognier isolates and 41.67% of the Chardonnay isolates began fermentation after 48 h. Finally, the H2S production assay revealed that, according to the scale proposed by [18], yeast strains in the present study exhibited low or medium (corresponding to levels 2 and 3 of the proposed scale) potential for H2S production, with low values of 84.61% and 83.33% for Viognier and Chardonnay, respectively.

V22 and C14 yeast strains registered the highest score during enological characterization. Their genetic profiles did not coincide with other isolates or with commercial yeasts. Both yeasts demonstrated very good technological abilities; they were able to ferment under high initial sugar concentrations (28 °Bx), high alcohol levels (14% v/v), tolerated low temperatures (15 °C), showed strong resistance to high levels of free SO2 (200 mg/L) and produced low H2S concentrations.

3.3. Fermentation Performance of Selected Yeast Strains at Laboratory Scale

At the laboratory scale, fermentations were conducted by inoculation of the selected indigenous yeasts V22 and C14 in their respective grape musts of origin, Viognier and Chardonnay, respectively. The commercial yeast Vin 13 was used as a control.

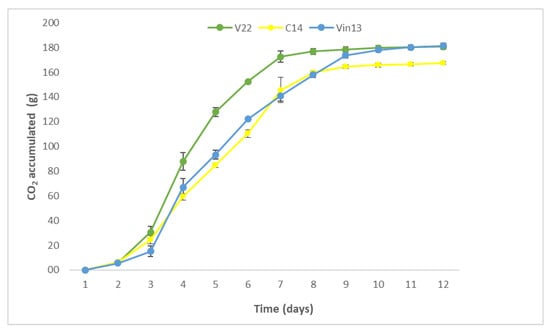

A comparison of the fermentation kinetics among V22, C14, and Vin 13 revealed that V22 had the shortest lag phase of the three strains (Figure 4), indicating a quicker and more efficient onset of fermentation compared to C14 and Vin 13. Conversely, C14 displayed the lowest CO2 production, resulting in a lower ethanol yield than the other two strains. Although the commercial yeast had the longest lag phase, it managed to match the fermentation dynamics of the V22 strain. It is worth mentioning that the fermentations were conducted over a period of 12 days.

Figure 4.

Fermentation kinetics of V22, C14, and Vin 13 yeast strains carried out at laboratory-scale vinifications using Viognier and Chardonnay musts.

Final values for ethanol, residual reducing sugar and free SO2 concentrations, total acidity, pH, and micro fermentation parameters are shown in Table 2. All wines are fermented until dryness (residual sugar < 1.8 g/L).

Table 2.

General analytical parameters of wines obtained to laboratory scale.

The final amounts of ethanol revealed that C14 was the lowest ethanol producer (17.7 g/L sugar/ethanol conversion rate), which is corroborated by its fermentative power. It is important to mention that the fermentative yield of V22 and Vin 13 did not show significant differences and consumed less sugar (15.5 and 15.18 g/L, respectively) to produce 1% v/v ethanol compared with C14.

Regarding volatile acidity, the values found are acceptable according to current legislation. The fermentative purity and volatile acidity showed significant differences among the three fermentations. Strain C14 registered the highest volatile acidity production (0.33 ± 0.01 g/L), and the volatile acidity produced by Vin 13 was higher than that produced by S. cerevisiae V22 (Table 2).

Total acidity and pH are fundamental parameters during the fermentation of grape must; they have gained significant importance in winemaking because of their crucial role in various aspects of the process. Both parameters are closely related to yeast fermentative activity, cell growth, fermentative kinetics, and the production of metabolites that contribute to the sensory characteristics of wines. In our study, special attention was given to the correction of the acidity and pH of the must prior to the fermentation process, adjusting them to commonly used values. This allowed us to maintain optimal conditions for yeast development and ensure proper fermentation and production of high-quality wine.

Sensorial Analysis of Lab-Scale Wines

Figure 5 shows the sensorial analyses carried out with a professional panel of the wines obtained on a lab scale. In Viognier wine fermented with S. cerevisiae V22, it can be observed that overall, structure, varietal typicity, floral and frutal notes, and global intensity stood out as positive attributes and carried more weight in the evaluation. Viognier fermented with commercial S. cerevisiae Vin13 was associated with a hot mouthfeel; this could be associated with the higher alcohol content obtained in this wine. The wine obtained with the C14 yeast was not highlighted for any of the attributes analyzed by the panel.

Figure 5.

The diagram shows the sensory analysis conducted on the wines obtained on a laboratory scale. Viognier with V22 yeast, Chardonnay with C14 yeast, and Chardonnay obtained with commercial yeast Vin 13. (* indicates significant difference).

3.4. Fermentative Performance of the Selected Indigenous Yeast Strain (V22) at Pilot and Industrial Scale

The indigenous yeast strain selected based on the results of laboratory-scale vinifications (V22) was inoculated as a starter culture for both pilot-scale (100 L) and industrial-scale (12,000 L) fermentations. Monitoring of the yeast population was conducted by sampling at the initial, middle, and final stages of the fermentation process. During the pilot-scale experiment, a single morphology was observed from halfway through the fermentation. Molecular analysis using interdelta PCR confirmed that this morphology corresponded to strain V22, indicating successful implantation of the yeast in the reactor at this scale.

Regarding wine production at an industrial scale, both morphological and molecular analyses from halfway through the fermentation process supported a predominance of over 80% of the selected V22 yeast. This result also confirms a high degree of implantation of this strain at an industrial scale.

After completion of the fermentations, several analyses were carried out with the final product, and the values are shown in Table 3.

Table 3.

Analytical data and parameters of the wines at two production scales: pilot and industrial scale.

Both wines showed very low levels of reducing sugars, which indicates that the fermentation was successful, and it also means that almost all sugars present in the must were converted into alcohol. Furthermore, the levels of total and volatile acidity were within an acceptable range, contributing to the quality and stability of the wine.

Analysis of Hedonic Tasting

Principal component analysis (PCA) was performed in order to characterize the sensorial attributes of the wines. The wine tasters analyzed nine sensorial attributes (Figure 6A). PC1 explains 70.6% of the total variability, while PC2 only explains 27.4%. The attributes that best described the first component (with their respective eigenvector values indicated in parenthesis) were aromatic persistence and varietal typicity (0.39), and alcohol and acidity (−0.039). These attributes allowed a clear separation of V22 IBT (pilot scale) from V22 CM and Vin 13 CM (industrial scale). PC2 was described by attributes such as fruity (0.63) and sweetness (−0.54). This component shows a separation between V22 CM and Vin 13 CM (both industrial-scale fermentation). Wines fermented with S. cerevisiae V22 at pilot scale (V22 IBT) appeared to be mainly defined by floral notes, varietal typicity, and aromatic persistence. Contrarily, wines produced with S. cerevisiae Vin 13 (industrial scale) were related to attributes like alcohol, acidity, and bitterness. Sweetness was related to wine fermented with S. cerevisiae V22 at an industrial scale. In order to test the consumer preference and acceptability of the three wines assayed, a hedonic scaling method was conducted with a panel consisting of 17 people. According to the results of the preference, wines elaborated with V22 IBT and V22 CM were “very much liked” by the majority of the judges. At the same time, 11.7% of the panelists disliked the wine made with Vin 13 CM, whereas 35.9% neither liked nor disliked the wine (Figure 6B).

Figure 6.

(A) Principal component analysis (PCA) of sensory attributes obtained from tasting by a trained panel, and (B) results of the preference analysis obtained from the hedonic tasting of wines on a pilot and industrial scale.

4. Discussion

Fermentation with indigenous yeasts that are adapted to their environment and to the characteristics of the local grape must unites two concepts, natural fermentation and process control, thus increasing the possibility of obtaining a personalized product with characteristics unique to each winegrowing region [23].

It is widely recognized that S. cerevisiae yeasts are the main protagonists during alcohol fermentation. However, according to our results and in concordance with other studies, this yeast species is rarely detected or found at very low proportions in the vineyard, especially on healthy berries [24,25]. Saccharomyces yeasts are adapted to the characteristics of the grape must and can grow under those conditions, which allows them to become the dominant species and complete the alcohol fermentation. It is common for different strains of the same species to coexist in the same place and show diverse adaptations. In the case of winemaking, multiple S. cerevisiae strains have been identified in grape musts and wines, and it has been shown that these strains can have different characteristics regarding fermentation, production of aromatic compounds, and tolerance to stress factors such as sugar, ethanol, and sulfur dioxide. These differences can affect the quality of the final wine, and many of these features are being studied to improve winemaking processes [26]. Despite the small number of isolates in the present study (50), our findings confirm that the winemaking region represents a reservoir of indigenous yeasts, with 13 strains reported for the Viognier varietal and 12 for the Chardonnay varietal, each with a different and peculiar genotypic and phenotypic profile. It is quite interesting that despite the fact that wineries in the region have been conducting fermentations with commercial yeasts for quite some time, none of the most commonly used yeasts were detected in the present study. Therefore, Pozo de Los Algarrobos could be considered a geographic indication in Argentina with relevant biodiversity because 25 different strains could be isolated from only two grape varieties studied.

Particularly, yeast adaptation to different stress conditions such as ethanol, SO2, temperature, sugar concentration, and kinetic performance is considered crucial to the selection of strains used in winemaking [13].

Ethanol production during alcohol fermentation is unfailing, but the amount of ethanol produced and the ability of yeast strains to tolerate high ethanol concentrations are variable and strain-dependent. Some strains have a higher ethanol tolerance and may be able to successfully complete the fermentation process even under high ethanol concentrations, while other strains are more susceptible to the effects of ethanol and may not be able to properly complete the process. This can affect the quality of the final wine and is an important factor to consider during the selection of yeast strains in winemaking. Evaluation of the ability of yeast strains to initiate the fermentation process at high ethanol concentration is also important. This situation arises during stuck fermentations, and it is crucial that the same yeast strain can be used to restart the process. As detailed in the Section 3, the different strains assessed were all able to initiate fermentation in a medium with 14% v/v ethanol.

It is important to highlight that all strains resisted the maximum dose of free SO2 according to Resolution N° C. 143/94 from the National Institute of Viticulture of Argentina (INV). This trait may give these strains a certain advantage over other wild yeasts present in the environment at the beginning of the fermentation process.

The ability of yeasts to grow at high sugar concentrations present in musts is a highly relevant characteristic in areas with a hot desert climate, like that in the Pozo de Los Algarrobos area. The must sugar content in such regions can be higher than 24 °Bx [27]. It is worth noting that several isolates from Viognier must demonstrated resistance to high sugar concentration in the present study and initiated fermentation after 24 h, whereas the commercial control strain started fermentation after 48 h.

According to [28], the fermentation of white wine must benefited from an optimal temperature range between 12 °C and 18 °C. Within this temperature range, the development of floral and fruity aromas of the wines was favored. During low-temperature fermentations, specific biochemical pathways are activated, which involve yeast proteins related to the primary aromas of flowers and fruits. These series of metabolic reactions generate higher alcohols that are responsible for the formation of key aromatic compounds such as phenyl ethanol and its acetates. As these metabolic pathways are not expressed in the same way at higher temperatures, they result in significant differences in the aromatic profile of the wines [29]. Therefore, the present research paper especially focused on the evaluation of the possibility of rapidly initiating fermentation at low temperatures. The expectation is to get early implantation in the medium and provide a high aromatic complexity, and distinctive flavor and structure, all important features to be considered in the production of white wines [30]. It is well known that indigenous strains have a higher level of implantation than commercial strains; hence, they compete more effectively against the yeast microbiota naturally present in the grape must [6]. The yeasts selected in this study, V22 and C14, exhibited the best oenological characteristics and were among the strains that fermented most rapidly in the various trials conducted, including high concentrations of sugars, ethanol, and SO2, as well as at low temperatures. However, for their selection in winemaking, yeasts should not only show desirable fermentation characteristics but also be able to impart distinctive and positive characteristics to the wine.

It is widely known that the same grape must subjected to different yeast strains can generate different wines. Both commercial and indigenous yeasts play a role in modulating the aroma of wine. This modulation depends on the yeast species, strain, and inoculum size.

Yeasts can contribute to the wine quality through the formation of both primary and secondary metabolism compounds [31]. The results obtained in the present study have demonstrated the impact of indigenous Saccharomyces yeasts on the aromatic composition of the wine. Particularly, during the sensory analysis conducted with the laboratory-scale wine, the V22 strain stood out because of its aromatic persistence, fruity and floral intensity, and varietal typicity. This led to the selection of V22 over C14, because the latter one did not receive a favorable sensory evaluation.

The influence of Saccharomyces on the composition of wine has been extensively evaluated at a laboratory scale. However, few studies have been conducted on a larger scale such as pilot or industrial scale [32]. Pilot-scale validation is particularly important as it allows a better simulation of large-scale conditions and production, thus evaluating yeast performance in real-life situations. This helps ensure the quality and consistency of the produced wine. Yeast validation at both laboratory and pilot scales (100 L) was carried out by [32]. These authors found that their lab-scale fermentations were unable to mimic pilot- or industrial-scale fermenters. In contrast, in our study, strain V22 demonstrated consistent behavior both at the laboratory and pilot scale, and the elaborated wines exhibited identical sensory attributes, such as structure, varietal typicity, floral and fruity notes, as well as uniform overall intensity. However, at the industrial scale, the behavior of V22 was different, which could be due to the technological capacity. In wineries (industrial scale), the size and volume of the fermenter can affect yeast development and behavior like transcriptome-related issues [33], yeast cell-to-cell interactions and cell-to-cell communication [34], and different stress factors, among others. Furthermore, the difference between the pilot and industrial scale can depend on the implantation level. At a larger scale (industrial), V22 managed an implantation of 80% compared with 100% at the pilot scale.

Although the behavior of V22 at the pilot scale was not repeated at the industrial scale, it is important to mention that the wines produced by the selected yeast strain both at the pilot and industrial scale were better accepted by consumers than the wine produced with the commercial control yeast.

In general terms, the wine industry is constantly seeking innovation to diversify production processes in order to better meet consumers’ needs. To date, there exist very few studies on indigenous Saccharomyces yeasts obtained from Chardonnay and Viognier grapes. Moreover, few studies have been conducted regarding upscaling from laboratory scale to industrial scale. Through a detailed study of the molecular and physiological characteristics of the yeast strain, proper preparation of the initial inoculum, and careful monitoring of the fermentation, it is possible to bridge the gap between laboratory and industrial scales.

5. Conclusions

In conclusion, indigenous strain V22 was selected for its fermentative capabilities, rendering it an optimal choice for successful vinification. Additionally, wines produced across all three vinification scales exhibited distinctive characteristics compared to those made with the commercial strain. Numerous studies have examined the positive effect of indigenous yeasts in the winemaking process, both from an organoleptic point of view and in terms of territorial differentiation of the final product. However, bridging the gap between science and industry remains a great challenge. Further research, like the present study, is needed to determine the feasibility of using selected indigenous strains in industrial processes. Our results indicate that the use of the selected indigenous strain V22 yields a profile significantly different, highlighting the need to evaluate the potential of the selected yeasts in different types of white grapes to understand their impact on the flavor of the wines. Additionally, it is important to note that there are no inherently superior or inferior yeasts, but rather different criteria for acceptance by consumers and adherence to modern trends. Understanding the demands of the wine market is crucial in determining which yeast will be more suitable for a certain wine production. Expanding knowledge in the microbiological field opens up a range of possibilities in both the industrial and commercial sectors. While the current definition of genuine wine does not take into account the origin of the yeast used in the fermentation process, our research group believes that all resources employed, including fermentation yeasts, should be characteristic of the specific region. This approach would further enhance the authenticity and uniqueness of the wine.

Author Contributions

Conceptualization, D.B.P., M.V.M. and Y.P.M.; methodology, D.B.P., M.V.M., S.V.C. and Y.P.M.; software, M.V.M. and M.F.V.; formal analysis, F.V. and Y.P.M.; investigation, D.B.P.; writing—original draft preparation, D.B.P., M.V.M. and Y.P.M.; writing—review and editing, D.B.P., M.V.M., M.F.V., F.V. and Y.P.M.; supervision, Y.P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This article was financially supported by Universidad Nacional de San Juan-SECITI Gobierno de San Juan: PDTS UNSJ project (Res. 1054/18-R; SIGEVA CODE 80020170400077SJ).

Institutional Review Board Statement

This article does not contain studies with human participants or animals performed by any of the authors.

Informed Consent Statement

Informed consent was obtained from all individual participants included in the study.

Data Availability Statement

All the data are provided in this manuscript.

Acknowledgments

We are especially grateful to the institutions to which we belong to Universidad Nacional de San Juan (UNSJ) and Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET). Likewise, the authors would like to thank “Bodega y Viñedos Casa Montes” and, particularly, their oenologists Pedro Pellegrina and Matias Blanco for their active participation in this work and their always good disposition. Furthermore, it is important to highlight the participation of the members of the “Consejo de Enólogos de San Juan” in the wine tasting at the laboratory scale.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mercado, L.; Dalcero, A.; Masuelli, R.; Combina, M. Diversity of Saccharomyces strains on grapes and winery surfaces: Analysis of their contribution to fermentative flora of Malbec wine from Mendoza (Argentina) during two consecutive years. Food microbiol. 2007, 24, 403–412. [Google Scholar] [CrossRef] [PubMed]

- Zott, K.; Miot-Sertier, C.; Claisse, O.; Lonvaud-Funel, A.; Masneuf-Pomarede, I. Dynamics and diversity of non-Saccharomyces yeasts during the early stages in winemaking. Int. J. Food Microbiol. 2008, 125, 197–203. [Google Scholar] [CrossRef]

- Gonzalez, R.; Morales, P. Truth in wine yeast. Microbiol. Biotechnol. 2022, 15, 1339–1356. [Google Scholar] [CrossRef]

- Csoma, H.; Zakany, N.; Capece, A.; Romano, P.; Sipiczkia, M. Biological diversity of Saccharomyces yeasts from spontaneously fermented wines in four wine-growing regions: Comparative genotypic and phenotypic analysis. Int. J. Food Microbiol. 2010, 140, 239–248. [Google Scholar] [CrossRef]

- Di Maio, S.; Polizzotto, G.; Di Gangi, E.; Foresta, G.; Genna, G.; Verzera, A. Biodiversity of indigenous Saccharomyces populations from old wineries of south- eastern Sicily (Italy): Preservation and economic potential. PLoS ONE 2012, 7, e30428. [Google Scholar] [CrossRef] [PubMed]

- Capece, A.; Pietrafesa, R.; Siesto, G.; Romaniello, R.; Condelli, N.; Romano, P. Selected Indigenous Saccharomyces cerevisiae Strains as Profitable Strategy to Preserve Typical Traits of Primitivo Wine. Fermentation 2019, 5, 87. [Google Scholar] [CrossRef]

- Capece, A.; Romaniello, R.; Siesto, G.; Romano, P. Diversity of Saccharomyces cerevisiae yeasts associated to spontaneously fermenting grapes from an Italian “heroic vine-growing area”. Food Microbiol. 2012, 31, 159–166. [Google Scholar] [CrossRef]

- Alvarez-Pérez, J.; Alvarez-Rodriguez, M.; Campo, E.; Saenz de Miera, L.; Ferreira, V.; Hernandez-Orte, P.; Garzón-Jimeno, E.; Coque, J. Selection of Saccharomyces cerevisiae strains applied to the production of Prieto Picudo Rosé wines with a different aromatic profile. S. Afr. J. Enol. Vitic. 2014, 35, 2. [Google Scholar] [CrossRef]

- Feng, L.; Jia, H.; Wang, J.; Qin, Y.; Liu, Y.; Song, Y. Selection of indigenous Saccharomyces cerevisiae strains for winemaking in Northwest China. Am. J. Enol. Vitic. 2019, 70, 115–126. [Google Scholar] [CrossRef]

- Pretorius, I.S. Tailoring wine yeast for the new millennium: Novel approaches to the ancient art of winemaking. Yeast 2000, 16, 675–729. [Google Scholar] [CrossRef]

- Suárez-Lepe, J.A.; Morata, A. New Trends in Yeast Selection for Winemaking. Trends Food Sci. Technol. 2012, 23, 39–50. [Google Scholar] [CrossRef]

- Mestre Furlani, M.; Maturano, Y.; Combina, M.; Mercado, L.; Toro, M.E.; Vazquez, F. Selection of non-Saccharomyces yeasts to be used in grape musts with high alcoholic potential: A strategy to obtain wines with reduced ethanol content. FEMS Yeast Res. 2017, 17, fox010. [Google Scholar] [CrossRef] [PubMed]

- Morera, G.; de Ovalles, S.; Gonzalez-Pombo, P. Prospection of indigenous yeasts from Uruguayan Tannat vineyards for oenological applications. Int. Microbiol. 2022, 25, 733–744. [Google Scholar] [CrossRef] [PubMed]

- Pallmann, C.; Brown, J.; Olineka, T.; Cocolin, L.; Mills, D.; Bisson, L. Use of WL Medium to profile native Flora fermentations. Am. J. Enol. Vitic. 2001, 52, 198–203. [Google Scholar] [CrossRef]

- Maturano, Y.P.; Mestre, M.V.; Esteve-Zarzoso, B.; Nally, M.C.; Lerena, M.C.; Toro, M.E.; Vazquez, F.; Combina, M. Yeast population dynamics during prefermentative cold soak of Cabernet Sauvignon and Malbec wines. Int. J. Food Microbiol. 2015, 199, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, C.S.; Winston, F.A. A ten-minute preparation from yeast effiently releases autonomous plasmids for transformation of Escherichia coli. Gene 1987, 57, 267–272. [Google Scholar] [CrossRef] [PubMed]

- Legras, J.; Karst, F. Optimisation of interdelta analysis for Saccharomyces cerevisiae strain characterization. FEMS Microbiol. Lett. 2003, 221, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Mendes-Ferreira, A.; Mendes-Faia, A.; Leão, C. Survey of hydrogen sulphide production by wine yeasts. J. Food Prot. 2002, 65, 1033–1037. [Google Scholar] [CrossRef] [PubMed]

- Ciani, M.; Rosini, G. The determination of alcohol capacity of wine making yeast strain. Annali della Facolta di Agraria Universita degli Studi di Perugia 1987, 41, 753–762. [Google Scholar]

- Ciani, M.; Maccarelli, F. Oenological properties of non-Saccharomyces yeasts associated with wine-making. World J. Microbiol. Biotechnol. 1997, 14, 199–203. [Google Scholar] [CrossRef]

- ISO NORM 3591; Sensory Analysis—Apparatus—Wine-tasting glass. International Organization for Standardizaction: Geneva, Switzerland, 1977.

- Lawless, H.; Heymann, H. Descriptive analysis. Sens. Eval. Food Princ. Pract. 1988, 227–257. [Google Scholar] [CrossRef] [PubMed]

- Vazquez, F.; Nally, M.C.; Maturano, Y.P.; Toro, M.E. Selección de cepas de levaduras autóctonas para vinificación. El Vino Su Industria 2004, XVII, 32–39. [Google Scholar]

- Mortimer, R.; Polsinelli, M. On the origins of wine yeast. Res. Microbiol. 1999, 150, 199–204. [Google Scholar] [CrossRef] [PubMed]

- Viel, A.; Legras, J.; Nadai, C.; Carlot, M.; Lombardi, A.; Crespan, M.; Migliaro, D.; Giacomini, A.; Corich, V. The geographic distribution of Saccharomyces cerevisiae isolates within three italian neighboring winemaking regions reveals strong differences in yeast abundance, genetic diversity and industrial strain dissemination. Front. Microbiol. 2017, 8, 1595. [Google Scholar] [CrossRef] [PubMed]

- Mercado, L.; Sturm, M.; Rojo, M.; Ciklic, I.; Martínez, C.; Combina, M. Biodiversity of Saccharomyces cerevisiae populations in Malbec vineyards from the “Zona Alta del Río Mendoza” region in Argentina. Int. J. Food Microbiol. 2011, 151, 319–326. [Google Scholar] [CrossRef] [PubMed]

- Jordão, A.; Vilela, A.; Cosme, F. From Sugar of Grape to Alcohol of Wine: Sensorial Impact of Alcohol in Wine. Beverages 2015, 1, 292–310. [Google Scholar] [CrossRef]

- Varela, C.; Sengler, F.; Solomon, M.; Curtin, C. Volatile flavour profile of reduced alcohol wines fermented with the non-conventional yeast species Metschnikowia pulcherrima and Saccharomyces uvarum. Food Chem. 2016, 209, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Bernal, E.; Deery, M.; Rodríguez, M.; Cantoral, J.; Howard, J.; Feret, R.; Natera, R.; Lilley, K.; Fernández-Acero, F. Analysis of temperature-mediated changes in the wine yeast Saccharomyces bayanus var uvarum. An oenological study of how the protein content influences wine quality. Proteomics 2016, 16, 576–592. [Google Scholar] [CrossRef] [PubMed]

- Parpinello, G.; Ricci, A.; Folegatti, B.; Patrignani, F.; Lanciotti, R.; Versari, A. Unraveling the potential of cryotolerant Saccharomyces eubayanus in Chardonnay white wine production. LWT-Food Sci. Tecnol. 2020, 134, 110183. [Google Scholar] [CrossRef]

- Romano, P.; Braschi, G.; Siesto, G.; Patrignani, F.; Lanciotti, R. Role of yeasts on the sensory component of wines. Foods 2022, 11, 1921. [Google Scholar] [CrossRef]

- Gottardi, D.; Siesto, G.; Bevilacqua, A.; Patrignani, F.; Campaniello, D.; Speranza, B.; Lanciotti, R.; Capece, A.; Romano, P. Pilot scale evaluation of wild Saccharomyces cerevisiae strains in aglianico. Fermentation 2023, 9, 245. [Google Scholar] [CrossRef]

- Rossouw, D.; Du Toit, M.; Bauer, F. The impact of co-inoculation with Oenococcus oeni on the trancriptome of Saccharomyces cerevisiae and on the flavour-active metabolite profiles during fermentation in synthetic must. Food Microbial. 2012, 29, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Avbelj, A.; Zupan, J.; Raspor, P. Quorum-sensing in yeast and its potential in wine making. Microbiol. Biotechnol. 2016, 100, 7841–7852. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).