Abstract

Since European society is experiencing an aggravation of the issue of energy security, the production of renewable energy is becoming increasingly important. The advantages of biofuel—in particular, biogas—and the positive effects of the development of its production are summarized within the framework of the problem statement. It is emphasized that the production of biogas from various renewable raw materials causes economic, ecological, and social effects. The development of biogas production can be especially active in combination with the development of the agricultural sphere. In response to today’s demand, the authors in this research present a model of the correlation between the output of biogas from different types of organic mass and specify the factors affecting it. In particular, a multiple econometric model of the relationship between the output of biogas from different types of organic mass and the content of dry organic matter and the share of possible methane content in organic matter was built; the density of the connection between the factors and the resulting feature was evaluated; the tightness of the general relationship (influence) of independent variables on the dependent variable was checked using the coefficient of determination; and the reliability of the correlation characteristics was estimated using Fisher’s and Student’s tests. As a result, with the use of convincing evidence—in particular, taking into account the potential of the Ukrainian agricultural sector—the feasibility of further development of biogas production in combination with the development of agricultural production is substantiated.

1. Introduction/Literature Review

In today’s conditions, humanity is losing biodiversity on the planet, living in an era of large-scale environmental pollution, desertification, intensification of negative weather phenomena, loss and pollution of fresh water, and loss of forest resources. Stated above are either results of climate change or causes. It is a well-known fact that humanity has until 2030, when climate change will become irreversible. Against the background of such threatening prospects, as well as due to the depletion of fossil fuels, increasing global energy demand, ever-increasing fuel prices, and military conflicts that disrupt the energy balance of nations, humanity is increasingly focusing on alternative energy sources and efficient renewable energy sources.

Accordingly, in order to find an alternative to fossil fuels, as well as to solve the problem of landfilling of organic waste and reduce the negative impact on the environment in general, the world has been developing innovative approaches to bioenergy, biomaterials, and chemical production from organic waste for a long time. One of the key alternatives to fossil fuels is biofuels. Biomass is a potential renewable source for the production of solid, liquid, and gaseous biofuels. In turn, the modernization of existing technologies for the processing of organic waste into biofuels and its use as a substitute for natural gas or automotive fuel is a trendy direction in research in recent decades around the world. It is widely believed that the most viable option for obtaining energy from organic waste is biogas—a renewable gaseous fuel obtained by the decomposition of organic substances, such as food and animal husbandry waste [1,2].

Biogas consists mainly of methane and carbon dioxide. Combustible methane is the main component of biomass (50–85%), which is the main source of energy. It can be used in many ways, including automotive fuel, as well as for heating and electricity generation. In addition, the production of biogas produces a by-product—digestate, which can be used as biofertilizer. Digestate—or as it is also called, natural fertilizer—contains water, nutrients, and organic carbon suitable for soils [3,4,5].

The website of the European Biogas Association states that the use of digestate obtained in the process of biogas production as a biofertilizer helps return organic carbon back to the soil and reduces the need for carbon-laden mineral fertilizers [6].

We consider that information about this fact and everything related to biofuel production should continue to be actively disseminated and promoted both in society as a whole and among the farming environment, especially in developing countries.

It should be noted that the production and use of biogas is not an achievement of today; it has deep roots. It is believed that the first human use of biogas dates back to 3000 BC in the Middle East, when the Assyrians used biogas to heat their baths. In turn, the 17th century chemist Jan Baptist van Helmont discovered that combustible gases can be formed from decomposing organic substances. Van Helmont also first added the word «gas» to the scientific dictionary, derived from the Greek word «chaos». The first large anaerobic fermentation plant was built in 1859 in a leper colony in Bombay [1]. In 1884, Louis Pasteur explored the possibility of obtaining biogas from animal waste and proposed it as a fuel for lighting streetlamps [7]. In general, in the past, biogas was widely used as a source of energy in households in Africa and Asia. Despite the rather primitive design, anaerobic boilers have solved the problems of autonomous energy supply of many households in India, Pakistan, Indochina, and others. Later, biogas became a very important part of the energy source for Western Europe and North America [8].

In today’s conditions, the development of biogas production can produce a number of positive effects never before seen, some of which are as follows. First, it is important for modern humanity that biogas energy production can reduce greenhouse gas emissions. In particular, the fermentation of manure on a biogas plant significantly reduces greenhouse gas emissions. The benefit of reducing greenhouse gas emissions is enhanced by the processing and use of methane (a strong greenhouse gas) that could otherwise be released into the atmosphere due to the decomposition of organic by-products and wastes.

Paolini et al. [9], for example, noted that the main goal of the biogas industry is to reduce fossil fuel consumption to mitigate the effects of global warming, and, in general, biogas can make a significant contribution to reducing greenhouse gas emissions. An additional advantage of biogas technology is the production of organic fertilizers for agricultural crops through the use of digestate [10]. In general, biogas can be developed on a large-scale die to partnerships between the energy and agricultural sectors. Another argument in favor of biogas is that it is an environmentally friendly renewable energy source. The only time when biogas is depleted is when the production of any type of waste is stopped. It is also a free source of energy [11]. It is produced by anaerobic biodegradation of organic substances. To do this, the waste must enter an environment without oxygen. This can happen naturally or as part of an industrial biogas process [12,13,14].

The following also apply:

- -

- Biogas can provide systemic benefits of natural gas (storage, flexibility, high temperature heat) without net carbon emissions. Given the development of a carbon-free economy that humanity is committed to, this is one of the crucial arguments in favor of biogas production.

- -

- Biogas provides a sustainable supply of heat and electricity that can be used by people looking for local, decentralized energy sources, and biogas can be a valuable fuel for cooking in developing countries. In many parts of the world, access to electricity is limited, which makes their way of life more complicated; biogas can provide a good alternative because it is economical to install and possible for both small-scale and large-scale production. Biogas can be used in boilers to produce heat [7,12]. In general, as stated on the website of the World Biogas Association, biogas contributes to the UN Sustainable Development Goal №7: Ensure access to affordable, reliable, sustainable and modern energy for all [15].

- -

- Biogas can play an important role in waste management, increasing overall efficiency of resource use. By converting a number of organic wastes into more valuable products, biogas fits well into the concept of a closed-loop economy. Scholars and practitioners often point out that a constant closed-loop economy can develop largely through the utilization of biomass through the processing of organic waste and, thus, the creation of bioenergy [16,17,18].

- -

- In cases where biogas displaces gas transported or imported over long distances, it also provides energy security benefits.

- -

- Biogas production can help create jobs in rural areas and reduce the amount of time people spend looking for firewood [11,19,20].

The European Biogas Association’s focus on biogas production is a stimulus for rural district development [6]. We consider this aspect to be extremely important for the modern world. In particular, the combination of agricultural activities with renewable energy production using biogas provides three additional benefits: it helps farmers effectively manage their waste and residues, reduces emissions from agriculture, and improves soil quality and biodiversity on agricultural land. In such healthy ecosystems, plants absorb carbon dioxide from the atmosphere, acting as carbon sinks; the digestate used as organic fertilizer returns nutrients to the soil; and methane emissions from livestock enter the controlled environment of the biogas plant, not the atmosphere. Cucui et al. [21] also emphasized that biogas production has a favorable economic effect and can solve waste problems.

The close relationship between agricultural and biogas production is evidenced by the practice of growing cover crops, part of an agronomy system in which an additional second crop is grown before or after the main crop is harvested on the same agricultural land. Cover culture prevents soil erosion and compaction, and promotes the biological, chemical, and physical activity of the soil. As a result, soil quality and fertility are improved, and soils become more resistant to floods and droughts. Cover crops are not ordinary winter crops or pastures, but are sown specifically to protect bare soil in winter and spring after harvesting spring crops. In addition to protecting the soil and its nutrients, cover crops can be of economic importance when used for renewable energy production, such as biogas production.

We fully share the view that bioenergy production from agricultural waste streams and cover crops creates additional business models in the agricultural sector, making agriculture more cost-competitive [6].

In general, in today’s information environment there are a lot of data on the benefits of biogas. In our opinion, the most complete set of them is set out, summarized, systematized, and structured in the 2019 report of the World Biogas Association «Global Potential of Biogas». In particular, in this document, the benefits of biogas production are presented in the following main areas: (1) production of renewable energy; (2) climate change mitigation; (3) contribution to the development of the closed-loop economy; (4) improving air quality in cities, the state of water bodies, and soils; (5) contribution to food security; (6) improving health and sanitation through improved solid waste management; (7) economic development and job creation. Moreover, the report emphasizes that in addition to contributing to the Sustainable Development Goals, the development of organic waste processing in general and biogas production in particular is characterized by the following benefits: (1) the possibility of using diverse and local raw materials; (2) flexibility of scaling—biofuels do not have a minimum scale of realization, and their maximum scale is limited only by the amount of available raw materials; (3) flexible use of biogas—primarily for the production of heat and electricity, as well as fuel for cars; (4) multiple income streams—the source of income can be any main or by-product obtained after waste recycling [22].

Indeed, different types of raw materials are used for biogas production. Scientists and practitioners mostly distinguish four groups of raw materials: crop residues—such as wheat stalks and soybean straw; manure from animals (including cattle, pigs, poultry, and sheep); organic fraction of solid household waste, including industrial waste and sewage sludge [19].

The group of plant nutrient residues includes residues after harvesting wheat, corn, rice, and other cereals; and sugar beets, sugar cane, soybeans, and other industrial and oily crops. The group of solid household waste includes food, paper, cardboard, and wood that are not used in other ways (for example, for composting or processing), and some industrial waste from the food industry. Importantly, some industries, such as food, beverages, and chemicals, produce wet waste with a high content of organic substances, which is a suitable raw material for anaerobic digestion. In such industries, biogas production can have the side benefit of cleaning up waste as well as providing heat and electricity on site. The raw material for biogas production is sewage sludge: a semi-solid organic substance extracted in the form of waste gases from municipal treatment plants. In today’s conditions, the largest volumes of biogas are produced from agricultural crops and animal manure.

The development of biogas production in the modern world is quite rapid. Thus, in 2010–2018, due to new directions in biogas use, the volume of biogas production increased by 90% worldwide and further growth is expected, especially based on the use of agricultural crop waste. At the same time, the development of biogas production in the world is uneven, as it depends primarily on the availability of raw materials and on policies that encourage its production and use. A total 90% of world production is accounted for by Europe, China, and the United States. In June 2018, EU institutions agreed on a new Renewable Energy Directive for the next decade, including a legally binding EU-wide target to bring the share of renewable energy to 32% by 2030. Given the above benefits of biogas, it is no exaggeration to say that the biogas sector will contribute to this goal [23].

Considering biogas as the most viable option for obtaining energy from organic waste, it is worth noting that, in fact, there are different technologies to produce biomass, such as gasification (energy conversion performances during the biomass air gasification process under microwave irradiation), pyrolysis (microwave-assisted co-pyrolysis of brown coal and corn stover for oil production), etc. The methane content is significantly varied by many factors [24,25]. These are also promising areas of biomass production, which are increasingly implemented in practice.

It is also worth noting that the biogas sector in Europe, as noted by Vlatka Petravie-Tominac, Nikola Nastav, Mateja Buljubasic, and Bozidar Santek, is quite diverse [26].

In particular, it is well developed in Germany, Denmark, Austria, and Sweden, followed by the Netherlands, France, Spain, Italy, The UK, and Belgium. It is characteristic of the EU countries that they have structured their financial incentives in favor of different types of raw materials depending on national priorities—that is, whether biogas production is considered primarily as a way of processing waste (for example, in the UK, more than 80% of biogas is obtained from landfills and sewage sludge), as a way of obtaining renewable energy (for example, in Germany, 93% of biogas is obtained from agricultural crops and agricultural waste), or their combinations. In other EU countries, different combinations of raw materials are used, depending on the specific circumstances and the availability and prices of certain types of raw materials. For example, Denmark predicts gas networks will use only biogas in 2034. At the same time, a significant part of biogas is produced from corn, beets, and animal manure [27]. Aware of the potential of biogas, France has already invested in the technologies needed to develop it on its territory. As of 31 December 2021, for example, the country counted 365 installations designed to inject biomethane into natural gas networks, with a capacity of 6.4 terawatt-hours (TWh) per year [28].

The war in Ukraine has given renewable gas a new impetus, with the European Commission proposing to ramp up biomethane production to 35 billion cubic meters (bcm) by 2030, up from 3 bcm in 2020. The advantage of renewable gas is that it can be produced within Europe. In fact, the actions of many modern European institutions are aimed at the following: (1) making European energy and climate policy constant, stable, and inclusive, increasing the competitiveness of renewable energy sources at cost; (2) increasing the production and consumption of constant renewable gas in Europe for all energy sectors, including transport, domestic, and industrial use; (3) ensuring cross-border and intersectoral exchange of renewable gases; (4) achieving recognition of additional domestic socio-economic and environmental benefits of renewable gas production; (5) making anaerobic fermentation an integral part of competitive and constant agriculture and waste management [29,30,31,32].

At the same time, the situation with biogas production in different EU countries depends on a number of different factors, such as investment attractiveness (construction of new biogas plants or only modernization of existing ones); guaranteed green tariff price, which is much higher than electricity produced from other sources; national targets; and action plans for renewable energy sources. In addition, with regard to biogas production, each country has its own obstacles that need to be overcome. One such country is Ukraine, a country that is not self-sufficient in terms of energy supply and is characterized by dependence on low-diversified energy imports, which regularly leads to political tensions and is of high socio-economic importance. At the same time, Ukraine is a powerful agrarian state and is a world leader in the production of numerous kinds of agricultural products. Therefore, in today’s Ukrainian society, it is widely believed that the production of agricultural biogas is likely to slow down climate change and increase energy self-sufficiency of the state by replacing or supplementing traditional energy sources [33,34,35].

Evidence for the development of biogas production in Ukraine being given considerable attention is, for example, the functioning of the Bioenergy Association of Ukraine. In his speeches and publications, the Chairman of the Board emphasizes the need to develop biomethane production, which is in line with the idea of a circular economy, as it converts waste streams, such as agricultural by-products or household waste, into energy while providing recycling of nutrients to agricultural land [35]. In turn, analyst Mostova M., analyzing the current state and prospects of biogas in Ukraine, gave impressive figures: in 2012–2019, in biogas capacity in Ukraine was invested about 140 million euros, and the growth rate of biogas capacity in Ukraine in 2019 was almost 3.5 times higher than in 2018 [36]. As a rule, the production of agricultural biogas is analyzed and evaluated from three main points of view: environmental, economic, and social. Meanwhile, in Ukraine, despite the existing understanding of the importance of biogas use and some efforts by government and business, the growth of total renewable energy production, in particular from biomass, is lagging behind the expected growth. This necessitates constant attention and in-depth research by scientists and practitioners.

The purpose of this publication is to try to model the relationship between the output of biogas from different types of organic mass and to specify the factors that affect it.

2. Materials and Methods

To achieve the research goal, the following general scientific research methods were used: theoretical—analyses that included qualitative and quantitative approaches, generalizations, and explanations; empirical—such as description and experiment, particularly modeling; special economic and mathematical methods—factor and correlation analysis.

The data collection technique used for this study consisted of a thorough search for information through Internet search engines in various sources that are relevant to the research problem. The main source of digital data used in the study were statistical data published in a practical guide for Ukrainian farmers.

With the help of qualitative analysis, relevant research articles indexed in Scopus, Web of Science, Google Scholar, and other databases; statistical data; publications in mass media; and program documents of specialized institutions regarding the development of biogas production were analyzed. A brief overview of the dynamics of biogas production in the modern world and an overview of the current situation at the national and international levels are presented. The arguments in favor of biogas production at this stage of human development are summarized, and attention is focused on the positive effects of using biomass of agricultural origin.

An econometric model was used to model the relationship between biogas output from different types of agricultural crops and the proportion of dry matter in crops within the scope of this study—a logical (usually mathematical) description of what economic theory considers particularly important in the study of a certain problem. The choice of this tool of scientific research is due to the fact that the econometric model is a function or a system of functions that describes the correlation–regression relationship between economic indicators. At the same time, depending on the causal relationships among them, one or more of these indicators is considered a dependent variable and the others an independent variable.

Correlation analysis was applied, which made it possible to solve two main tasks: (1) to describe the dependence of the result characteristic on the factor characteristic using a mathematical equation; (2) to evaluate the closeness or density of the connection between the resulting characteristic and its influencing factors. The relationship between the yield of biogas from various agricultural crops and the proportion of dry matter in crops, as well as the potentially possible production of methane from various agricultural crops, has been established in particular.

3. Results and Discussion

Thus, within the framework of this study, a multiple econometric model of the relationship between biogas yield from different types of organic substance (m3/t)—y and dry organic substance content (kg/t)—x1, and the share of possible methane content in organic substance x2 (m3/t) was built. The initial data were generally accepted indicators of biogas yield and methane content of substrates of plant and animal origin [37,38].

First of all, primary data are calculated, such as the average values of the factor and result characteristic and their dispersion (Table 1 and Table 2).

Table 1.

Estimated data for modeling the relationship between biogas yield and different types of organic mass, source [37,38]; calculations of the authors.

Table 2.

Estimated data for modeling the relationship between biogas yield and different types of organic mass, source [37,38]; calculations of the authors.

The average values are used (Formula (1)) to generalize the signs of the set of significant signs, to compare these signs in different sets, and to study the patterns and development trends of phenomena. Since the individual values of the average sign for each unit of the population are known, simple arithmetic means are calculated.

The study also used the common tool of dispersion, which is the average square of the deviations of all values of the variable sign from its arithmetic mean. This deviation characterizes the average fluctuations of the sign of the totality caused by individual characteristics of the totality from the average value of the sign (Formulas (2) and (3)):

In turn, within the framework of this study, the preconditions of correlation analysis were determined:

- (1)

- The yield of biogas from different types of organic mass really depends on the content of dry organic substance and the share of possible methane content in organic substance;

- (2)

- Variation should be sufficient.

In order to compare the set with different values of average arithmetic and standard deviation, we determined the coefficient of variation—the ratio of the square deviation to the average value of the variable sign (Formula (4)):

Variations of the effective and the second factor sign are very large, with Vy, Vx2 > 50%; the variation of the first factor sign is large, as Vx1 is in the range of 21–50%.

The homogeneity of the totality was checked using the Tao-criterion (τ) (Formula (5)):

Since all τ < 3, the totality is defined as homogeneous.

The next step is to describe the relationship between the effective sign and the factors with the help of the matrix regression equation (Formula (6)):

Values of unknown parameters a0, a1, a2 were determined based on the method of least squares (Formula (7))

and based on the nest equation (Formula (8))

Thus, based on the method of least squares, the following system of normal equations (Formula (9)) was obtained:

The next step is to substitute the values of the unknowns into the system of equations and obtain its solution (Formula (10)):

II—I, III—II →

II—I →

Therefore, the values of unknown parameters were obtained (Formula (11)):

According to Formula (11), a0—free member of the regression, which has no economic interpretation but contains everything that is not taken into account in the created dependence; a1,2—regression coefficients that characterize the proportion of the factor’s influence on the result.

Thus, we obtained the regression equation of the following formula (Formula (12)):

The correctness of the regression equation was checked by the following regularity (Formula (13)):

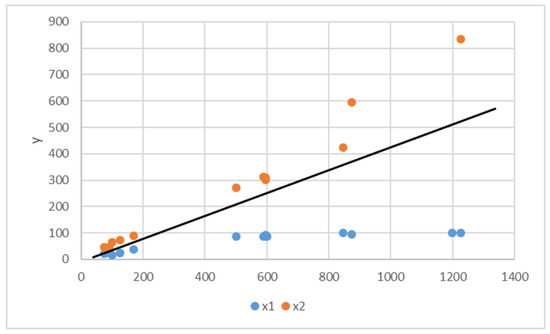

Based on the regression equation (Figure 1), we can calculate the coefficient of elasticity Ei (Formula (14)), which shows by what percentage the value of the resultant trait will change when the factor trait changes by 1%.

Figure 1.

Direct regression equitation on the scatter diagram.

Linear correlation analysis is about determining the closeness or density of the relationship between factors and performance. The closeness of the relationship in the correlation analysis is characterized by the correlation coefficient. Accordingly, the density of the relationship between the factors was estimated using simple correlation coefficients (Formula (15)), partial correlation coefficients (Formula (16)), and multiple correlation coefficients (Formula (17)).

Simple correlation coefficients (15):

Partial correlation coefficients (16):

Multiple correlation coefficients (17):

To determine the extent to which the constructed econometric model is consistent with the empirical information on the basis of which it was constructed, the coefficient of determination, namely, multiple, was used (Formula (18)):

Partial was also used (Formula (19)):

The correctness of the calculation of partial coefficients of determination is checked by regularity (Formula (20)):

In turn, the multiple factor was checked for materiality. To do this, we formed a null hypothesis H0: R2 = 0 (insignificant) and hypothesis Ha: R2 ≠ 0 (significant). For checking H0, F-criteria (Fisher’s) was used (Formula (21)):

Ftabular = F0.05 =Ftabular < Fcalculated

The significance of partial regression coefficients was assessed using t-criteria (Student’s) for the first coefficient (Formula (22)),

and for the second coefficient (Formula (23)),

To assess the degree of influence of factors on the result, in addition to the correlation coefficient, we calculated it using the multiple correlation index (Formula (24)):

4. Conclusions

Thus, as a result of building a multiple econometric model of the dependence of biogas yield from different types of agricultural crops on the proportion of dry substance in these crops, and the potential production of methane from them, we obtained the regression equation of the following type:

In the regression equation, a1 = 0.33, which means that when the share of dry matter in crops increases by 1 kg/t, the biogas yield will increase by 0.33 m2/t; a2 = 1.13 m3/t means that when the share of methane in biogas increases by 1 m3/t, the biogas yield will increase by 1.13 m3/t.

Since, a1 and a2 are greater than zero, the relationship between the effective sign and the factors influencing it is direct. From this, the coefficient of elasticity E1 = 0.43 means that with an increase in the share of dry substance in agricultural crops of 1%, the yield of biogas will increase by 0.43%; E2 = 0.67 means that with an increase in the share of methane in biogas of 1%, the yield of biogas will increase by 0.67%.

Estimation of the density of the relationship between the factors and the effective sign showed the following results:

- (1)

- Simple correlation coefficients

Ryx1 = 0.899 (strong, positive, direct connection) characterizes the indirect impact on biogas yield not only of the dry substance content of the agricultural crop (kg/t), but also to some extent the impact of the potential share of methane production in the agricultural crop (m3/t);

Ryx2 = 0.983 (strong, positive, direct connection) characterizes the unclean impact on biogas yield not only of the potential share of methane production from agricultural crops (m3/t), but also to some extent the impact of dry substance content in the crop (kg/t);

Rx1x2 = 0.820 (strong, positive, direct relationship) characterizes the closeness of the relationship between the factors influencing the proportion of dry substance in agricultural crops (x1) and potentially possible production of methane from the crop (x2) on the effective basis of biogas output (y).

- (2)

- Partial correlation coefficients

Ryx1 × x2 = 0.881 (strong, positive, direct relationship)—characterizes the value of the net impact of dry substance content in agricultural crops (kg/t) on the yield of biogas from different crops, provided that the factor of the potential share of methane production from the crop (m3/t) is eliminated;

Ryx2 × x1 = 0.980 (strong, positive, direct connection) characterizes the value of the net impact of the potential share of methane production from agricultural crops (m3/t) on the yield of biogas from different crops, provided that the factor of dry substance content in agricultural crops (kg/t) is eliminated.

- (3)

- Multiple correlation coefficients

Ryx1x2 = 0.966 (strong, positive, direct relationship) characterizes the density (tightness) of the relationship between the biogas output from different agricultural crops and the proportion of dry substance in crops, and the potential for methane production from different agricultural crops.

Checking the closeness of the general relationship (influence) of independent variables on the dependent variable using the coefficient of determination obtained the following results:

- (1)

- Multiple

Dyx1x2 = 99.24% means that the variation in biogas yield from different types of agricultural crops by 99.24% depends on two factors: x1 (share of dry substance in crops) and x2 (potentially possible production of methane from agricultural crops), and 0.76% due to the impact of unaccounted random factors.

- (2)

- Partial coefficients of determination

dyx1 = 25.44% means that the variation in biogas yield from different types of agricultural crops by 25.44% depends on the factor x1 (share of dry substance in agricultural crops), provided that the factor x2 (potentially possible production of methane from agricultural crops) is eliminated;

dyx2 = 73.80% means that the variation of biogas yield from different types of agricultural crops by 73.80% depends on factor x2 (potentially possible production of methane from agricultural crops), provided that factor x1 (share of dry substance in agricultural crops) is eliminated.

Fisher’s (F) and Student’s (t) criteria were used to assess the reliability of correlation characteristics.

As a result of checking the multiple correlation coefficient for materiality using Fisher’s F-criteria, its following value was obtained FR2 = 854.3, which is greater than its tabular value Ftabular = F0.05 (2;15) = 3.68. This means that we reject the null hypothesis and accept the alternative (H0: R2 ≠ 0)—the multiple correlation coefficient is significant.

As a result of estimating the significance of partial regression coefficients using Student’s t-criteria, the following results were obtained: ta1 = 17.83, which is greater than its tabular value ttabular = t0.05 (2;21) = 2.13. This means that we reject the null hypothesis and accept the alternative (H0: ta1≠0)—partial regression coefficient ta1 is significant. ta2 = 47.28, which is greater than its tabular value ttabular = t0.05 (2;21) = 2.13. This means that we reject the null hypothesis and accept the alternative (H0: ta2≠0)—partial regression coefficient ta2 is significant.

To estimate the relationship between the effective sign and its factors, a multiple correlation index of 0.966 was calculated. This means that the link between biogas output from different agricultural crops and the proportion of dry substance in crops, and the potential for methane production from different agricultural crops, is strong and functional, as η = 0.966 → 0.

Therefore, we consider the results of the study as an argument in favor of further development of biogas production in Ukraine from various types of organic biomass produced by the agricultural sector in order to strengthen energy security. This issue is especially relevant in modern military cataclysms, threats to the energy security of many countries, and the accession of the Ukrainian energy system to the European one. The results of the study are also relevant for other countries where they have issues in the transition of bioenergy.

Author Contributions

Conceptualization, N.T. and T.M.; methodology, N.T. and V.N.; validation, N.G., O.T. and O.N.; formal analysis, T.M. and V.N.; writing—original draft preparation, N.T. and N.G.; writing—review and editing, T.M. and V.N.; visualization, O.T. and O.N.; supervision, N.G. and O.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- What Is Biogas and Why Is It Important? Howden Group. 2022. Available online: https://www.howden.com/en-gb/articles/renewables/what-is-biogas (accessed on 22 October 2022).

- Lusiana, L.; Sasongko, N.A.; Kuntjoro, Y.D.; Fakhruddin, M.; Widrian, A.F.; Siregar, A.M.; Vidura, A. Biogas efficiency from cow dung waste in strengthening energy security during the COVID-19 pandemic through a dynamic modeling system. IOP Conf. Ser. Earth Environ. Sci. 2021, 926, 12085. [Google Scholar] [CrossRef]

- Pooja, G.; Goldy, S.; Shivali, S.; Lakhveer, S.; Virendra, K.V. Biogas production from waste: Technical overview, progress, and challenges. Sustain. Des. Ind. Appl. Mitig. GHG Emiss. 2020, 2020, 89–104. [Google Scholar] [CrossRef]

- You Matter. Biogas Definition: What Is Biogas Production? What Are Its Stages? 2020. Available online: https://youmatter.world/en/definition/definitions-biogas-definition-what-is-biogas/ (accessed on 22 October 2022).

- Energypedia. Advantages and Disadvantages of Biogas. 2021. Available online: https://energypedia.info/wiki/Advantages_and_Disadvantages_of_Biogas (accessed on 22 October 2022).

- European Biogas Association. About Biogas and Biomethane. 2022. Available online: https://www.europeanbiogas.eu/about-us/vision-mission/ (accessed on 22 October 2022).

- Korbag, I.; Salma, M.; Hanan, B.; Mousay, A. Recent Advances of Biogas Production and Future Perspective. Biogas: Recent Advances and Integrated Approaches; IntechOpen: London, UK, 2020; pp. 1–41. [Google Scholar] [CrossRef]

- Damyanova, S.; Beschkov, V. Biorefinery Concepts, Energy and Products; Beschkov, V., Ed.; BoD—Books on Demand: Norderstedt, Germany, 2020. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, P.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Health Part A Toxic/Hazard. Subst. Environ. Eng. 2018, 53, 899–906. [Google Scholar] [CrossRef] [PubMed]

- Garcia, A. Techno-Economic Feasibility Study of a Small-Scale Biogas Plant for Treating Market Waste in the City of El Alto. Available online: http://www.diva-portal.org/smash/get/diva2:741758/FULLTEXT01.pdf (accessed on 22 October 2022).

- Shireen, B.; Payal, D. A Review: Advantages and Disadvantages of Biogas. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 890–893. Available online: https://www.irjet.net/archives/V4/i10/IRJET-V4I10155.pdf (accessed on 22 October 2022).

- Raveendran, S.; Parameswaran, B.; Ashok, P.; Snehalata, A.; Yumin, D.; Mukeshm, K.A. Biofuel Production From Biomass: Toward Sustainable Development. Waste Treat. Process. Energy Gener. 2019, 2019, 79–92. [Google Scholar] [CrossRef]

- Mirzoieva, T.; Tkach, N. Economic and production aspects of biomass processing in the energy component. Bioeco. Agrar. Bus. 2019, 10, 85–96. [Google Scholar] [CrossRef]

- Tkach, N.; Mirzoieva, T. Justification of economic performance of processing of grain crops in biogas. Bioecon. Agrar. Bus. 2021, 12, 5–17. [Google Scholar] [CrossRef]

- Biogas’ Contribution to the un Sustainable Development Goals, World Biogas Association. 2022. Available online: https://www.worldbiogasassociation.org/goals/energy-security (accessed on 22 October 2022).

- Abanades, S.; Abbaspour, H.; Ahmadi, A.; Das, B.; Ehyaei, M.; Esmaeilion, F.; El Haj Assad, M.; Hajilounezhad, T.; Jamali, D.H.; Hmida, A.; et al. A critical review of biogas production and usage with legislations framework across the globe. Int. J. Environ. Sci. Technol. 2021, 19, 3377–3400. [Google Scholar] [CrossRef]

- Fagerstrom, A.; Al Seadi, T.; Rasi, S.; Briseid, T. The Role of Anaerobic Digestion and Biogas in the Circular Economy; Murphy, J.D., Ed.; IEA Bioenergy Task: Paris, France, 2018; Volume 8, Available online: https://www.ieabioenergy.com/wp-content/uploads/2018/08/anaerobic-digestion_web_END.pdf (accessed on 22 October 2022).

- Tagne, R.; Dong, X.; Anagho, S.G.; Kaiser, S.; Ulgiati, S. Technologies, challenges and perspectives of biogas production within an agricultural context. The case of China and Africa. Environ. Dev. Sustain. 2021, 23, 14799–14826. [Google Scholar] [CrossRef]

- Outlook for Biogas and Prospects for Organic Growth, World Energy Outlook Special Report. 2020. Available online: https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth/an-introduction-to-biogas-and-biomethane (accessed on 22 October 2022).

- Anggraeni, A.; Sahfitri, A.; Hassan, F.; Octavian, A.; Pudjiatmoko, S. Biogas Utilization as Renewable Energy to Achieve National Energy Security (Study of Wonolelo Village, Bantul, Yogyakarta). In Proceedings of the 3rd International Conference of Integrated Intellectual Community, Bantul, Yogyakarta, 27 May 2018. [Google Scholar] [CrossRef]

- Sarika, J. Global Potential of Biogasm. World Biogas Associ. 2019. Available online: https://www.worldbiogasassociation.org/wp-content/uploads/2019/07/WBA-globalreport-56ppa4_digital.pdf (accessed on 22 October 2022).

- Cucui, G.; Ionescu, C.A.; Goldbach, I.R.; Coman, M.D.; Marin, E. Quantifying the Economic Effects of Biogas Installations for Organic Waste from Agro-Industrial Sector. Sustainability 2018, 10, 2582. [Google Scholar] [CrossRef]

- European Biogas Association. Biogas Trends for This Year. 2022. Available online: https://www.europeanbiogas.eu/biogas-trends-for-this-year/ (accessed on 22 October 2022).

- Ke, C.; Shi, C.; Zhang, Y.; Guang, M.; Li, B. Energy conversion performances during biomass air gasification process under microwave irradiation. Int. J. Hydrogen. Energy 2022, 47, 31833–31842. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, L.; Liu, S.; Zhou, N.; Ding, K.; Peng, P.; Anderson, E.; Addy, M.; Cheng, Y.; Liu, Y.; et al. Microwave-assisted co-pyrolysis of brown coal and corn stover for oil production. Bioresour. Technol. 2018, 259, 461–464. [Google Scholar] [CrossRef]

- Petravic-Tominac, V.; Nastav, N.; Buljubasic, M.; Santek, B. Current state of biogas production in Croatia. Energy Sustain. Soc. 2020, 10, 8. [Google Scholar] [CrossRef]

- Brooks, C. Denmark Predicts Gas Networks Will Use Only Biogas in 2034. 2022. Available online: https://cleanenergynews.ihsmarkit.com/research-analysis/denmark-predicts-gas-networks-will-use-only-biogas-in-2034.html (accessed on 22 October 2022).

- Europe Rediscovers Biogas in Search for Energy Independence, EURACTIV France. 2022. Available online: https://www.euractiv.com/section/energy/news/europe-rediscovers-biogas-in-search-for-energy-independence/ (accessed on 22 October 2022).

- In the Legislative Period 2019–2024 the Eba Will Call for a Common European, European Biogas Association. 2022. Available online: https://www.diva-portal.org/smash/get/diva2:1635090/FULLTEXT01.pdf (accessed on 22 October 2022).

- Gustafsson, M.; Anderberg, S. Biogas policies and production development in Europe: A comparative analysis of eight countries. Biofuels 2022, 2022, 931–944. [Google Scholar] [CrossRef]

- Perspectives for Biogas in Europe. The Oxford Institute for Energy Studies. 2012. Available online: https://a9w7k6q9.stackpathcdn.com/wpcms/wp-content/uploads/2012/12/NG-70.pdf (accessed on 22 October 2022).

- Einarsson, R.; Persson, M.; Lantz, M.; Berndes, G.; Cederberg, C.; Toren, J. Estimating the eu Biogas Potential from Manure and Crop Residues—A Spatial Analysis. The Swedish Knowledge Centre for Renewable Transportation Fuels. 2015. Available online: https://f3centre.se/app/uploads/f3_2015-07_einarsson_et_al_final_160107.pdf (accessed on 22 October 2022).

- Wąs, A.; Sulewski, P.; Gerasymchuk, G.; Stepasyuk, S.; Krupin, K.; Titenko, Z.; Pogodzińska, K. The Potential of Ukrainian Agriculture’s Biomass to Generate Renewable Energy in the Context of Climate and Political Challenges—The Case of the Kyiv Region. Energies 2022, 18, 6547. [Google Scholar] [CrossRef]

- Kurbatova, T. Economic benefits from production of biogas based on animal waste within energy co-operatives in Ukraine. Int. J. Sustain. Energy Plan. Manag. 2018, 18, 69–80. [Google Scholar] [CrossRef]

- Geletukha, G. Biomethan—Renewable Gas Which Will Save the Planet. Green Deal. 2021. Available online: https://interfax.com.ua/news/greendeal/742601.html (accessed on 22 October 2022).

- Mostova, M. The Field of Biogas in Ukraine: Great Prospects and Reality. 2020. Available online: https://energytransition.in.ua/sfera-biohazu-v-ukraini-velyki-perspektyvy-ta-real-nist/ (accessed on 22 October 2022).

- Sidorchuk, O. Raw Materials for Biogas Production or What Is the Best Way to Harvest Energy. Practical Guide for Farmers “AgroExpert”, Section Economics, Series of Articles Biogas—Energy Independence of Ukraine. 2020, Volume 4. Available online: https://agrobiogas.com.ua/raw-materials-for-biogas-production-or-what-best-way-to-harvest-energy/ (accessed on 22 October 2022).

- Raw Materials for Biogas. AgroBiogas 2020. Available online: https://agrobiogas.com.ua/raw-material-for-biogas/ (accessed on 22 October 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).