Fabrication and Supercapacitor Applications of Multiwall Carbon Nanotube Thin Films

Abstract

:1. Introduction

2. Multiwalled Carbon Nanotubes

2.1. Synthesis

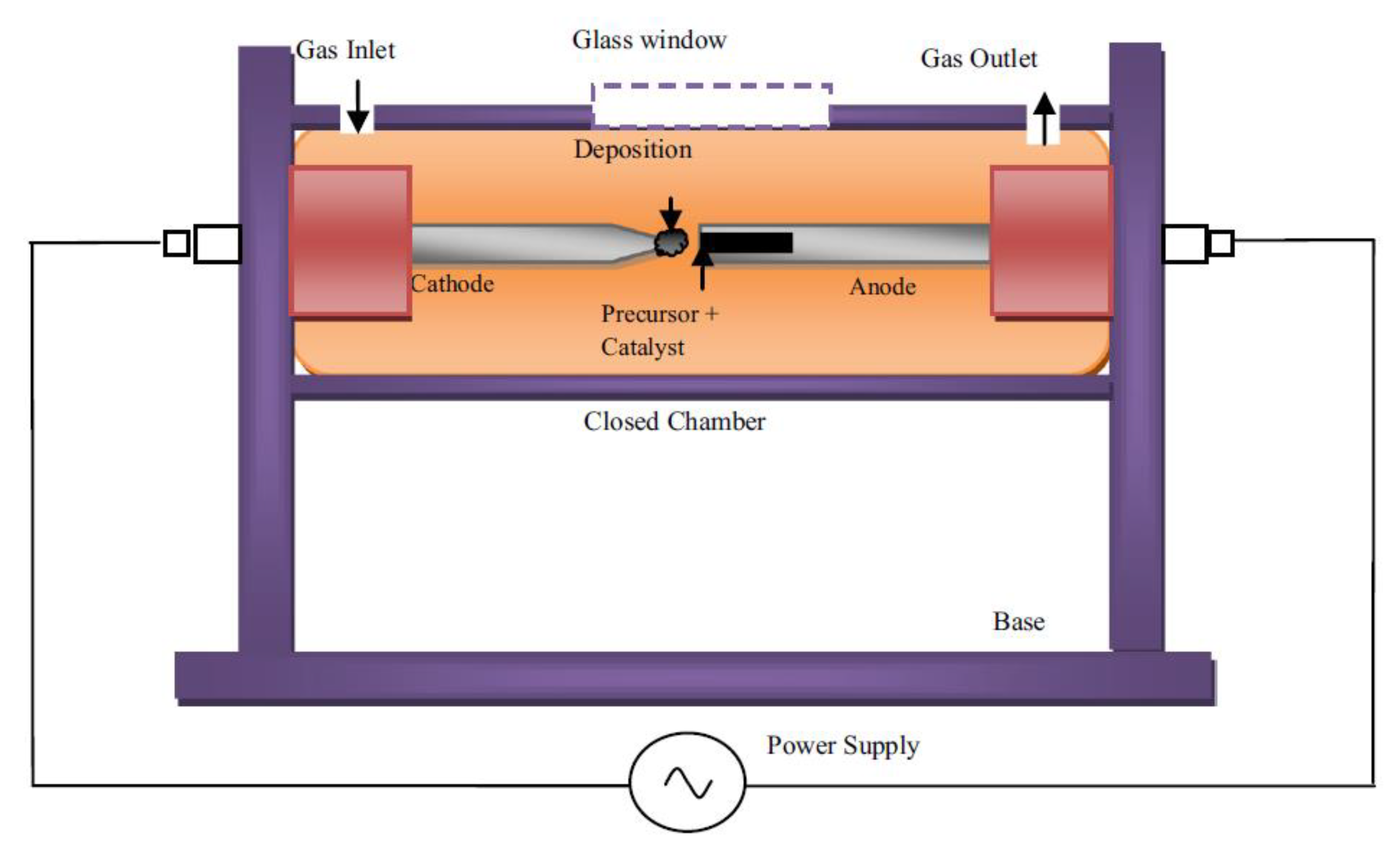

2.1.1. Arc Discharge

2.1.2. Laser Ablation

2.1.3. Chemical Vapor Deposition

2.2. Properties of Individual Nanotubes

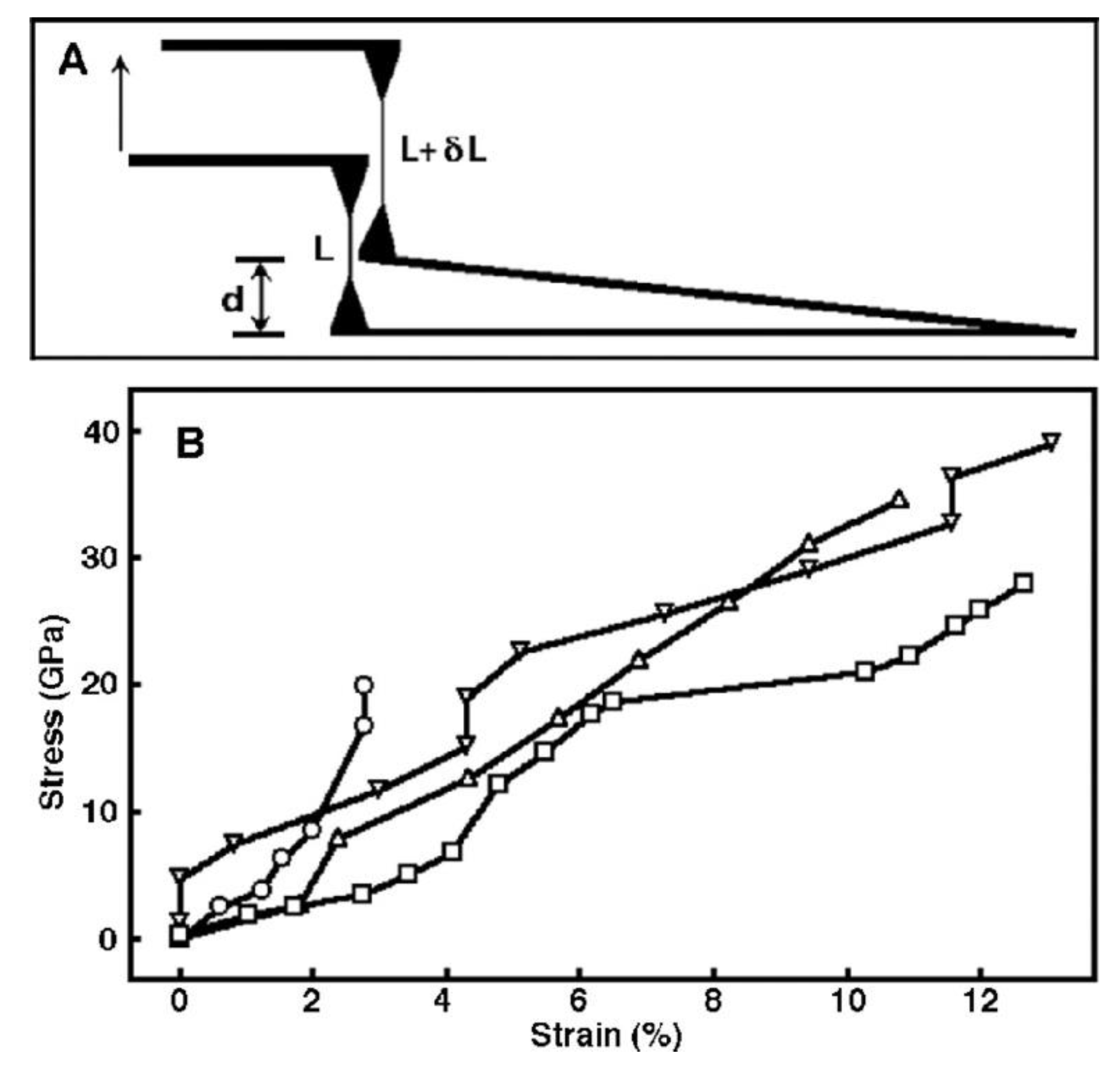

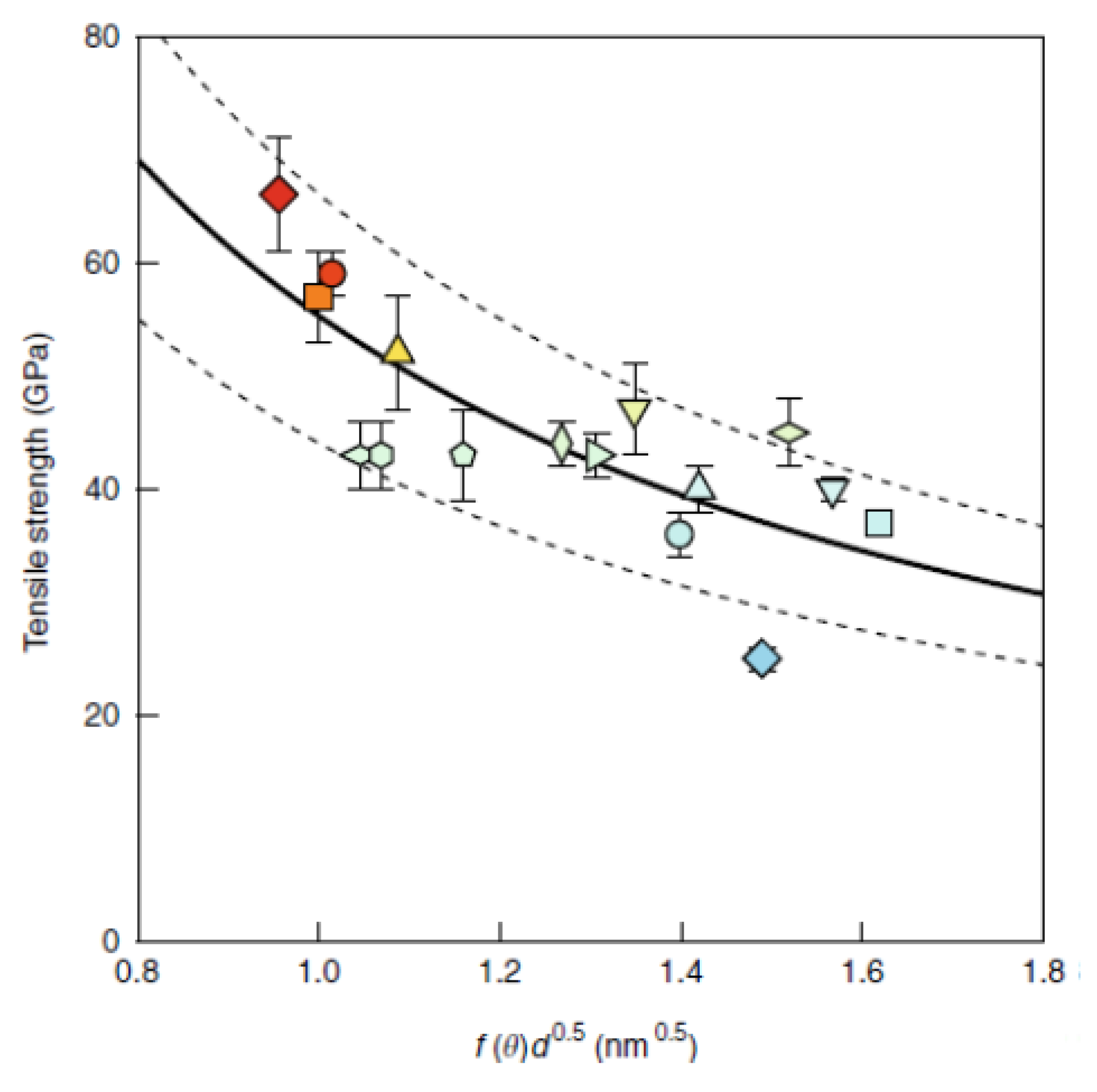

2.2.1. Mechanical Properties

2.2.2. Electrical Properties

3. MWCNT Thin Films

3.1. Fabrication

3.1.1. Direct Growth

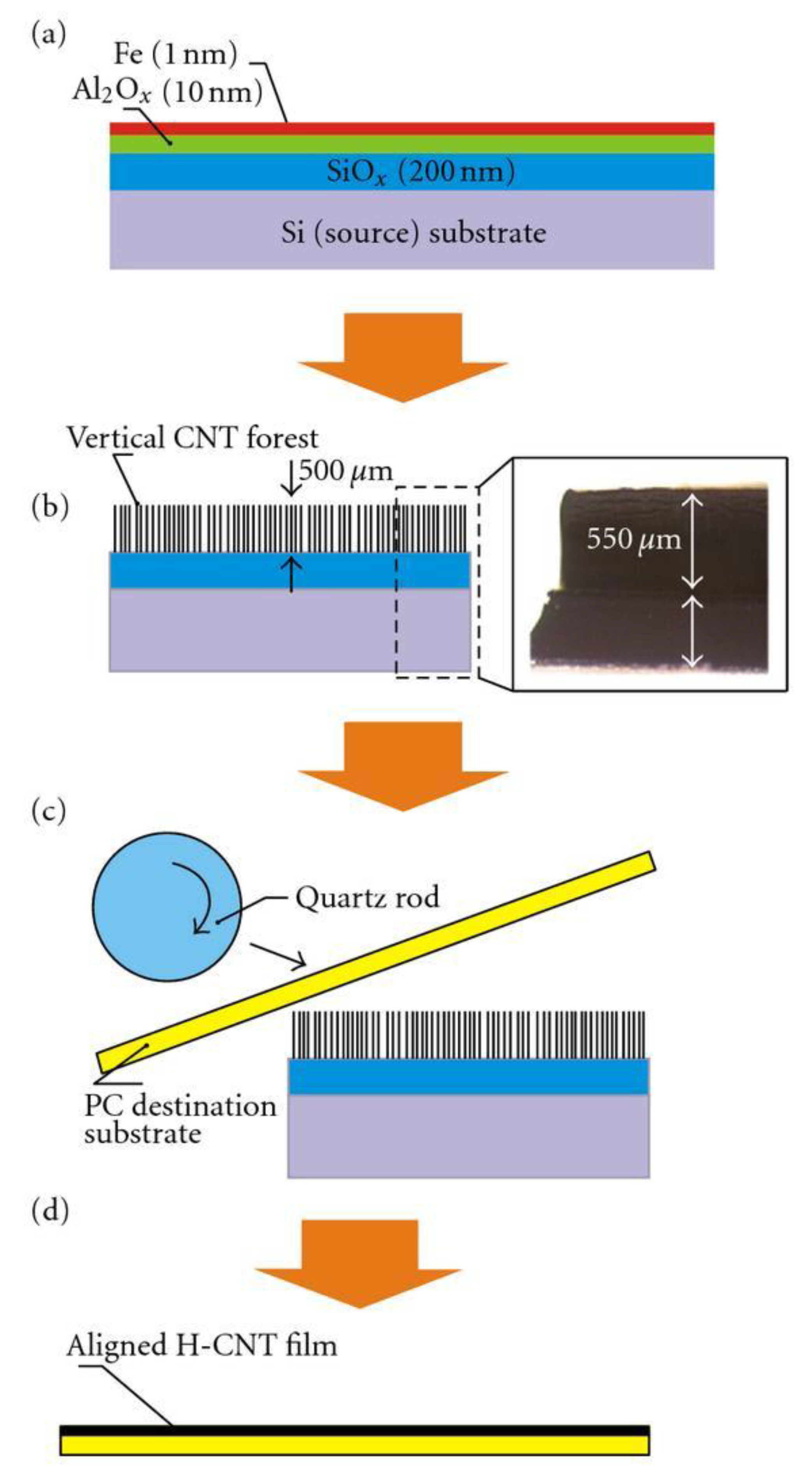

3.1.2. Substrate Transfer

3.1.3. Wet Deposition

3.2. Properties of Multiwalled Nanotube Films

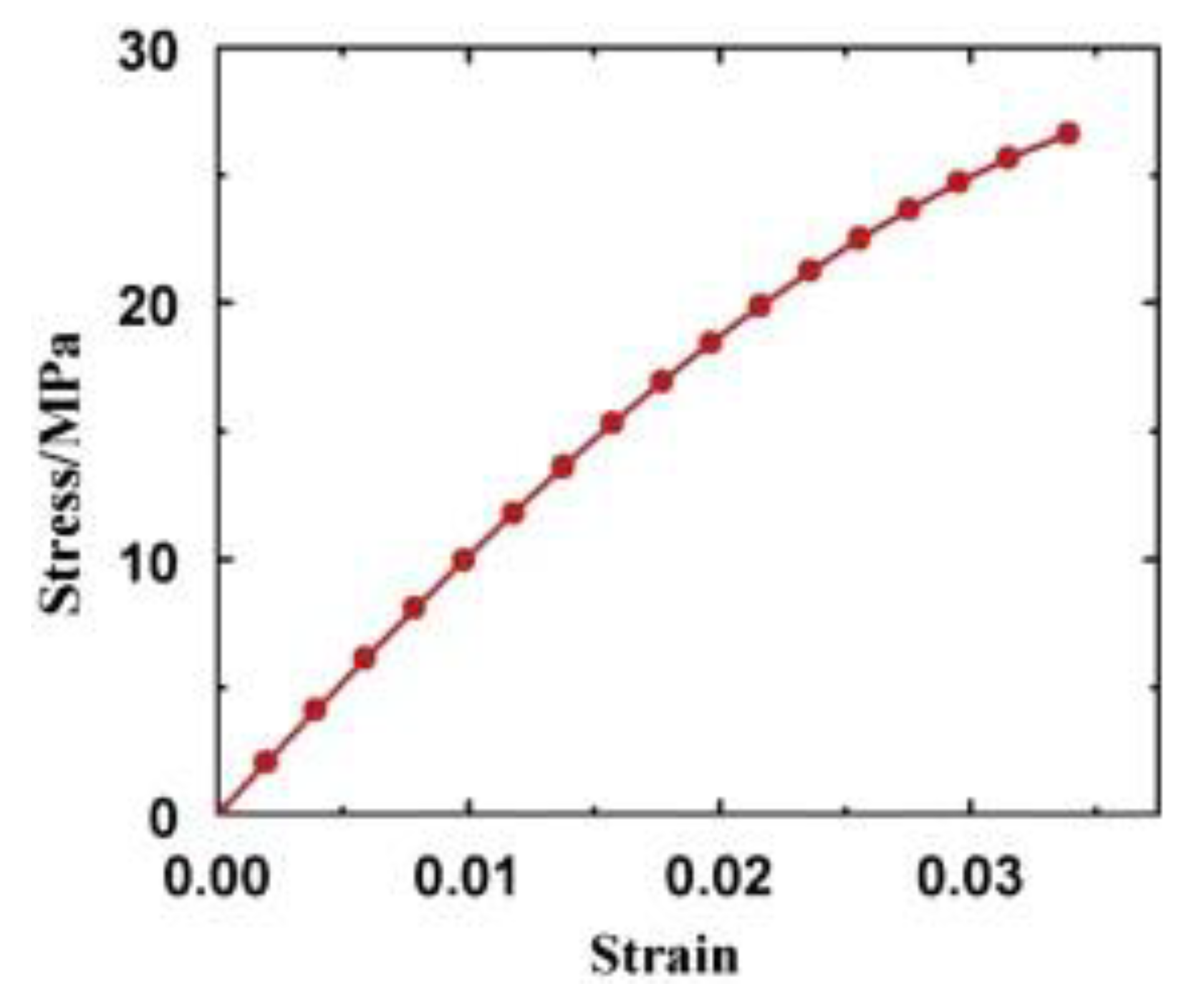

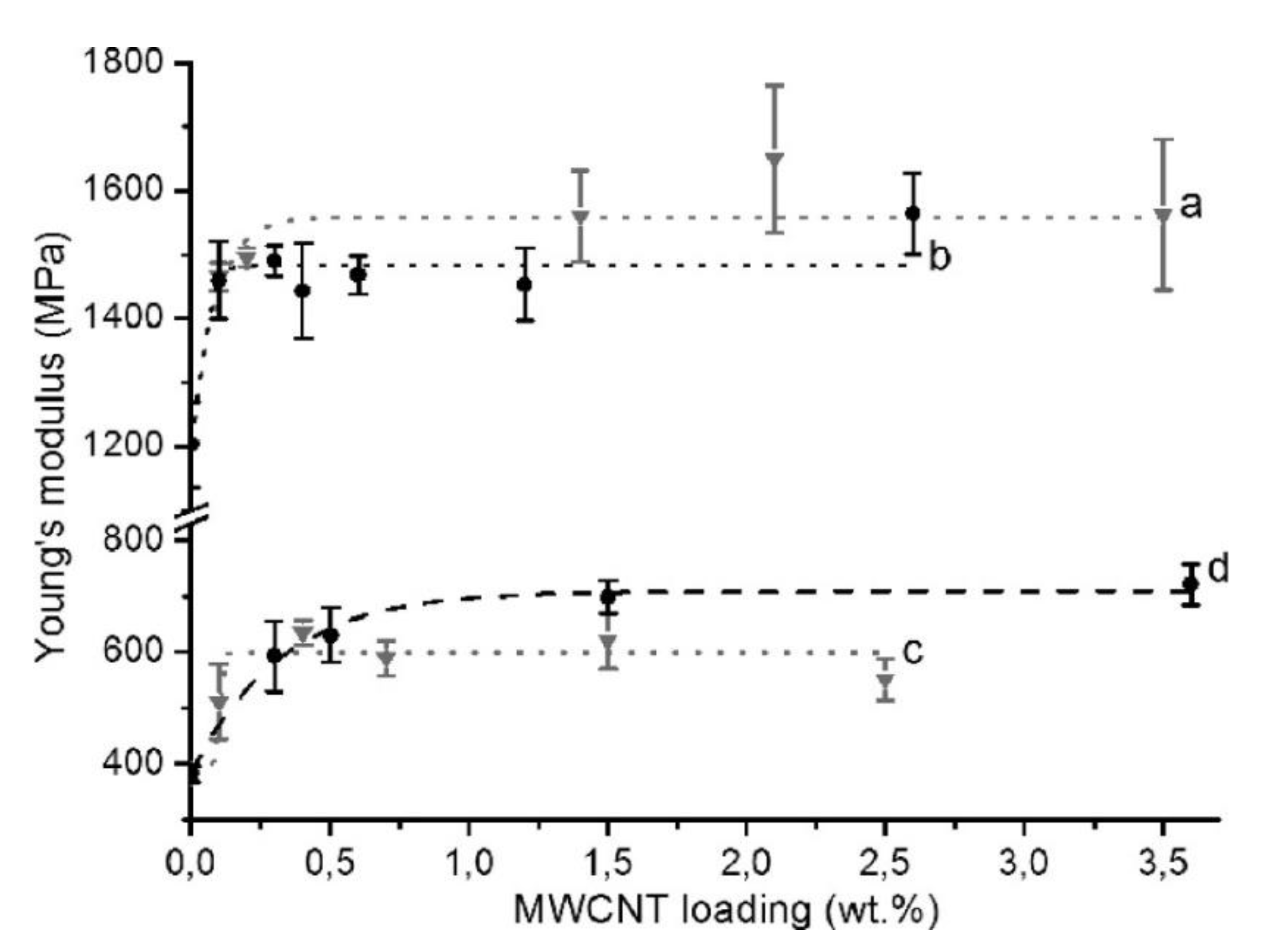

3.2.1. Mechanical Properties

3.2.2. Electrical Properties

3.2.3. Other Properties

4. Multiwall Carbon Nanotube Thin Films for Supercapacitor Applications

4.1. Electrochemical Double-Layer Capacitors

4.2. Compositing Carbon Nanotubes with Conducting Polymer and Metal Oxides

4.3. Other Improvements to the Carbon Capacitor Electrode

4.4. Spin-Coated and Inkjet-Printed MWCNT Capacitor Electrodes

4.4.1. Experimental

Materials

Multiwall Nanotube Ink Dispersion Preparation

Spin Coating

Inkjet Printing

Device Fabrication

Material and Sample Characterization

Computational Simulation of Thin Films

4.4.2. Results and Discussion

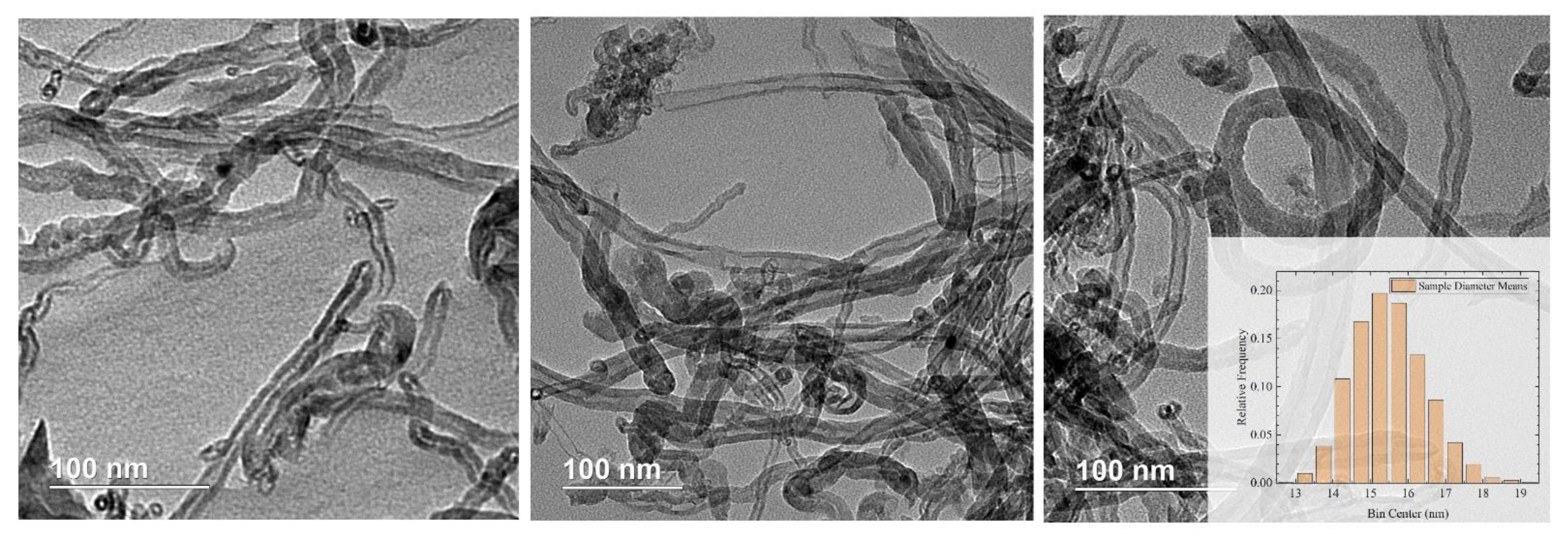

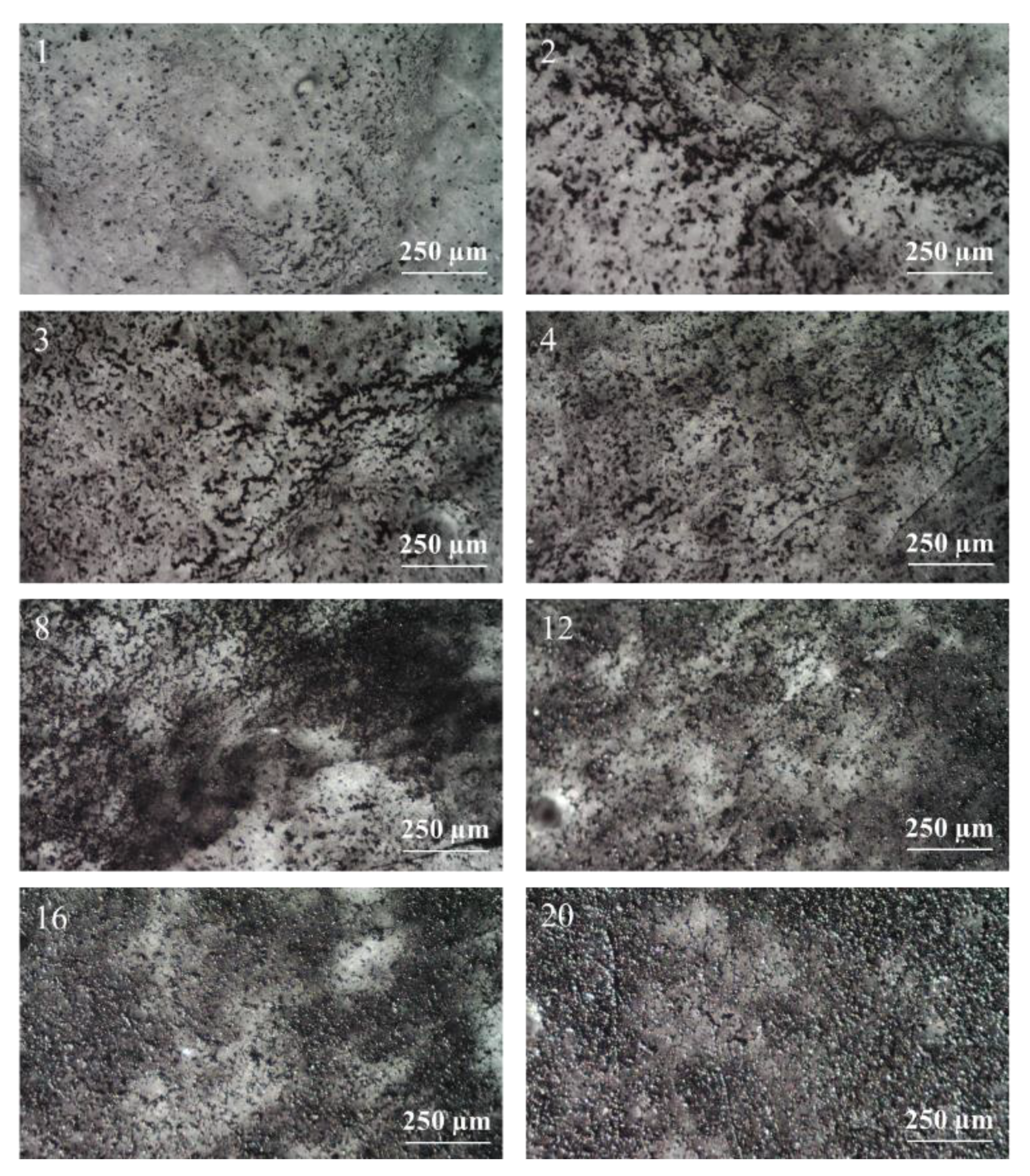

Material Structure and Deposition Morphology

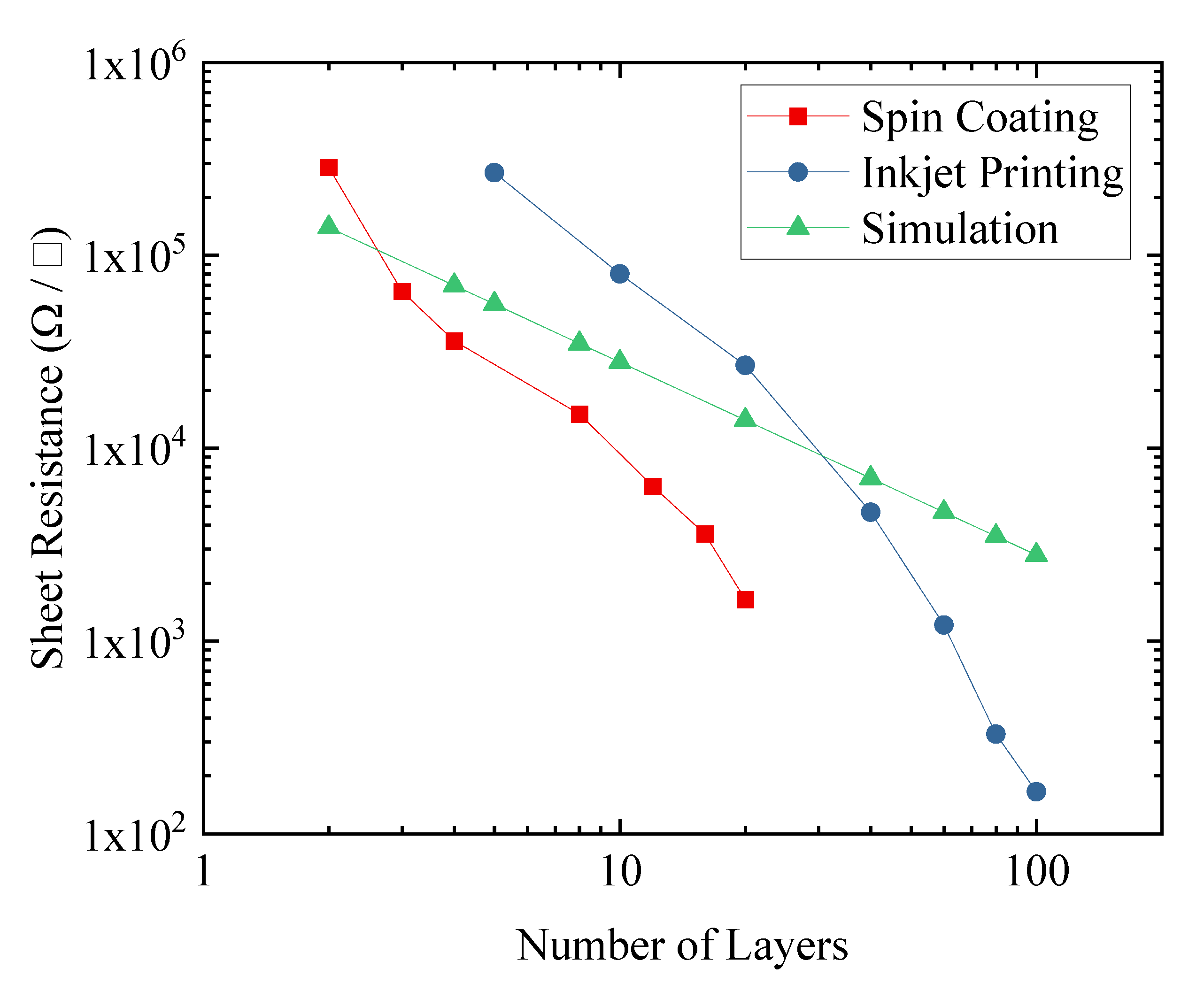

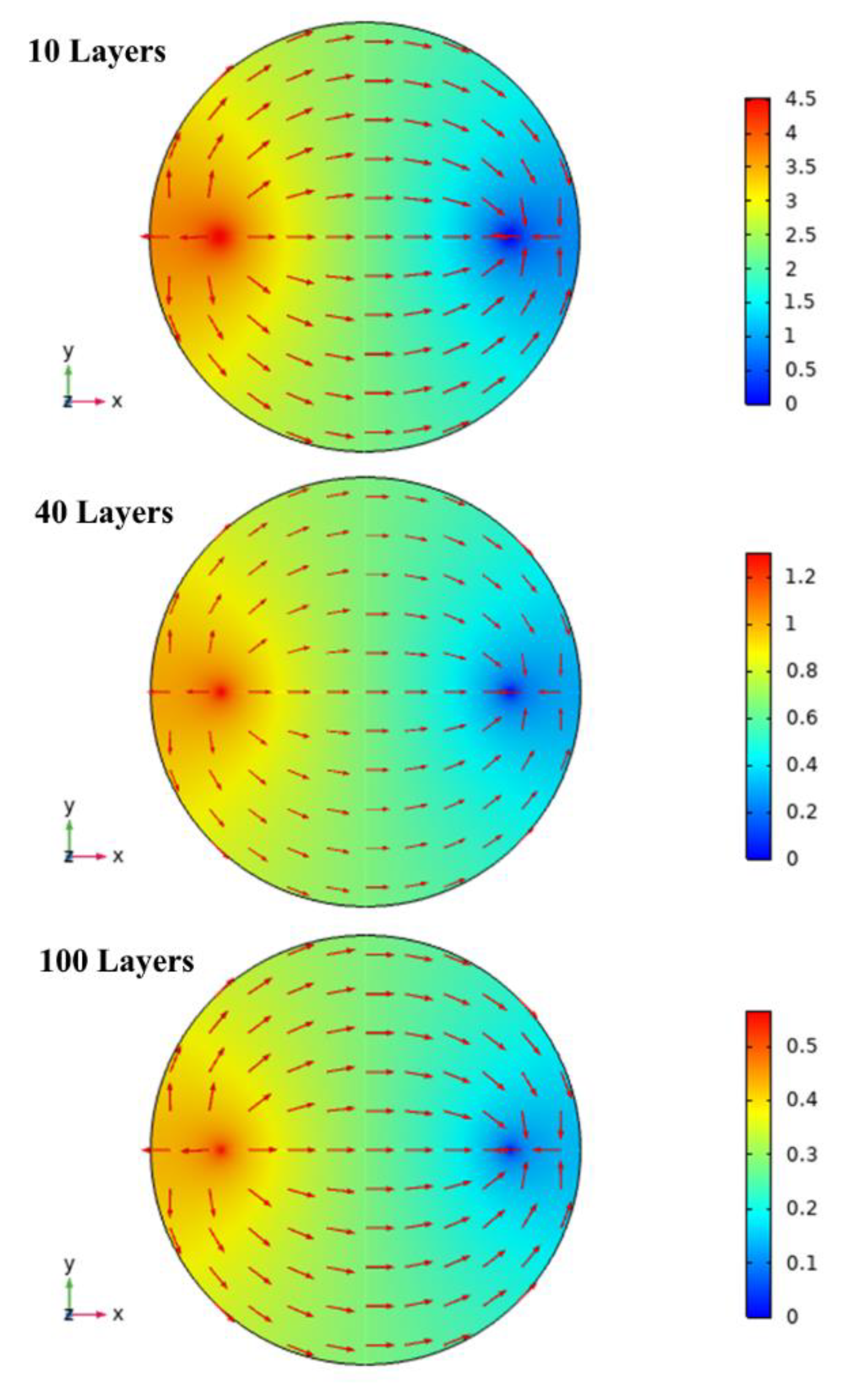

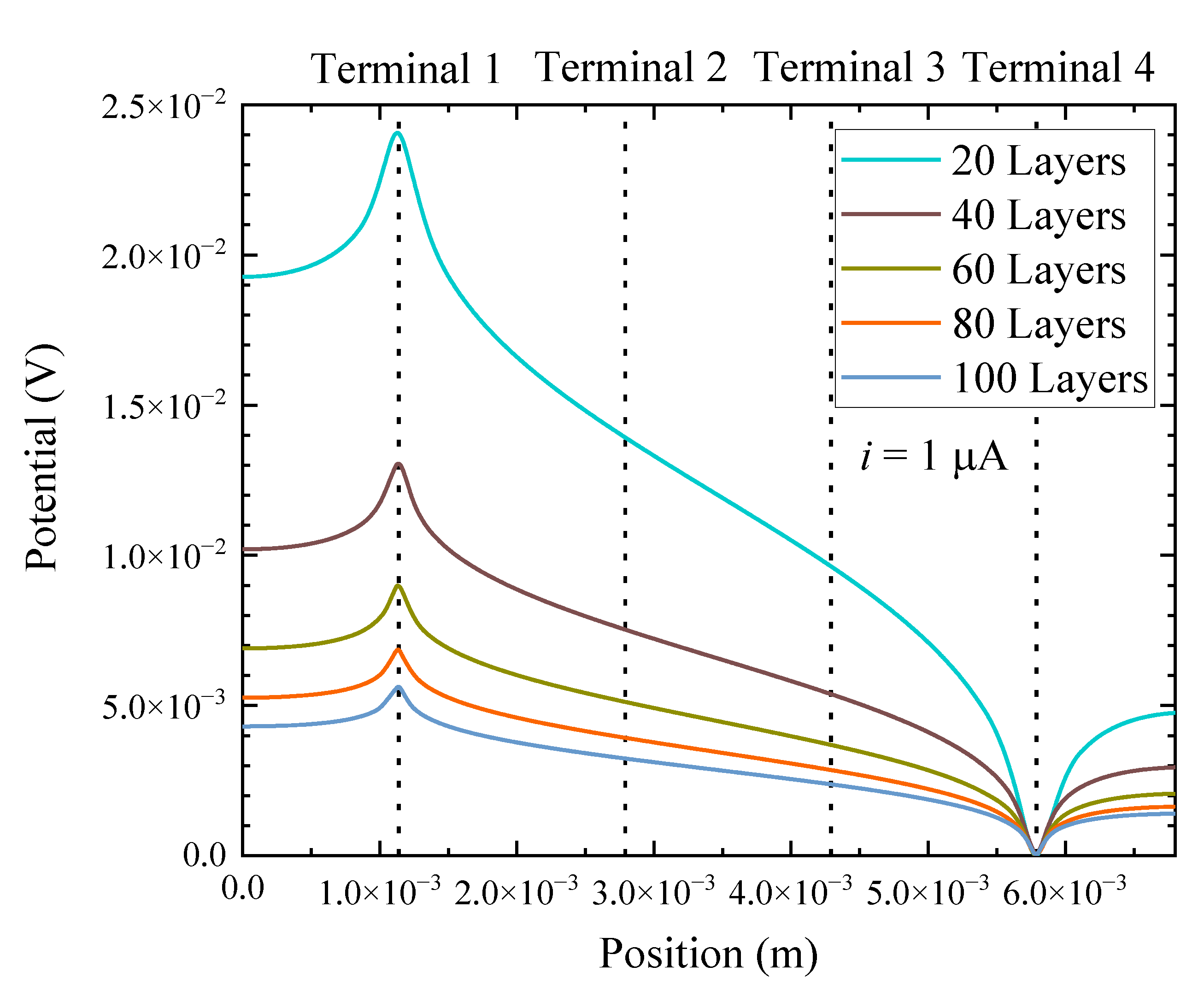

DC Electrical Characterization and Simulation of MWCNT Films

AC Characterization of MWCNT Films

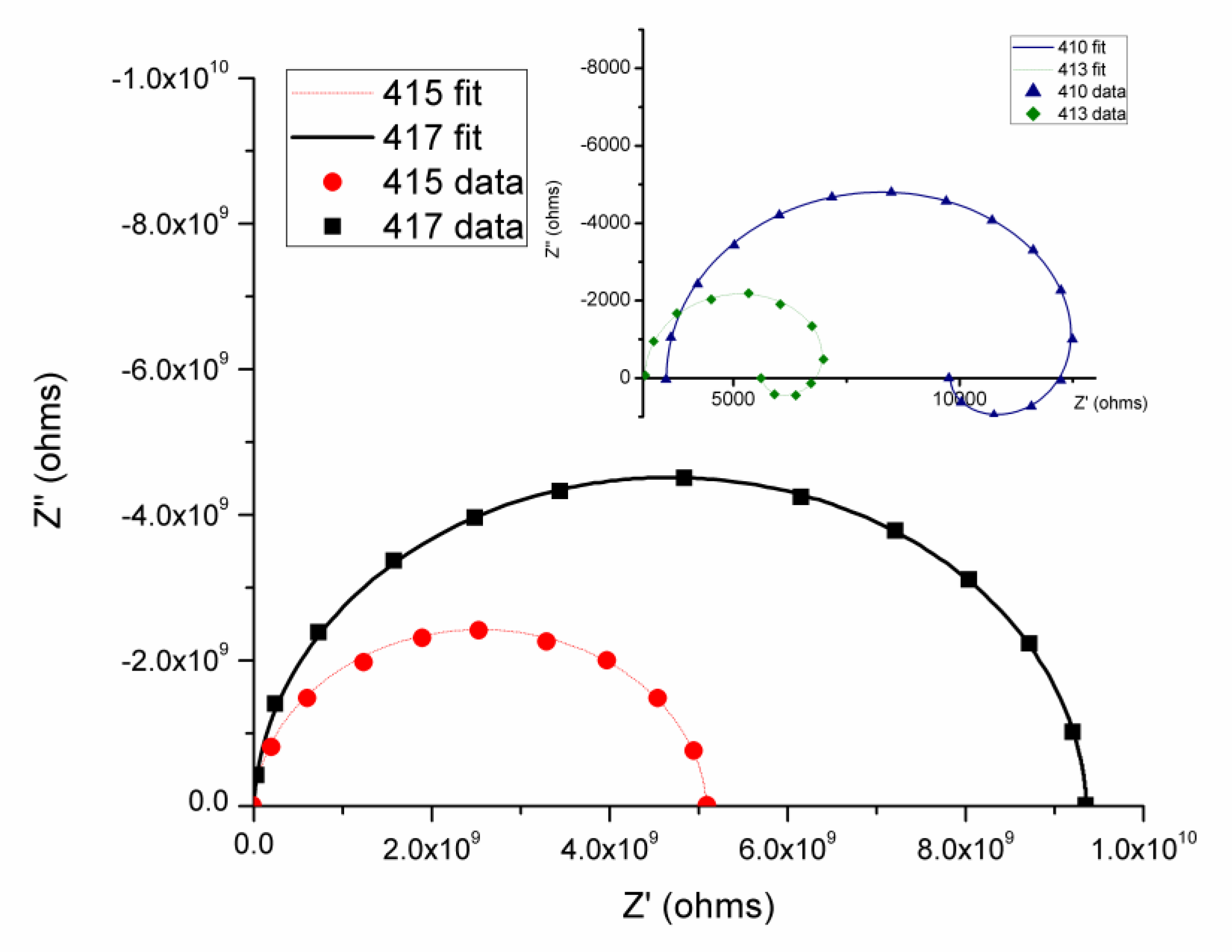

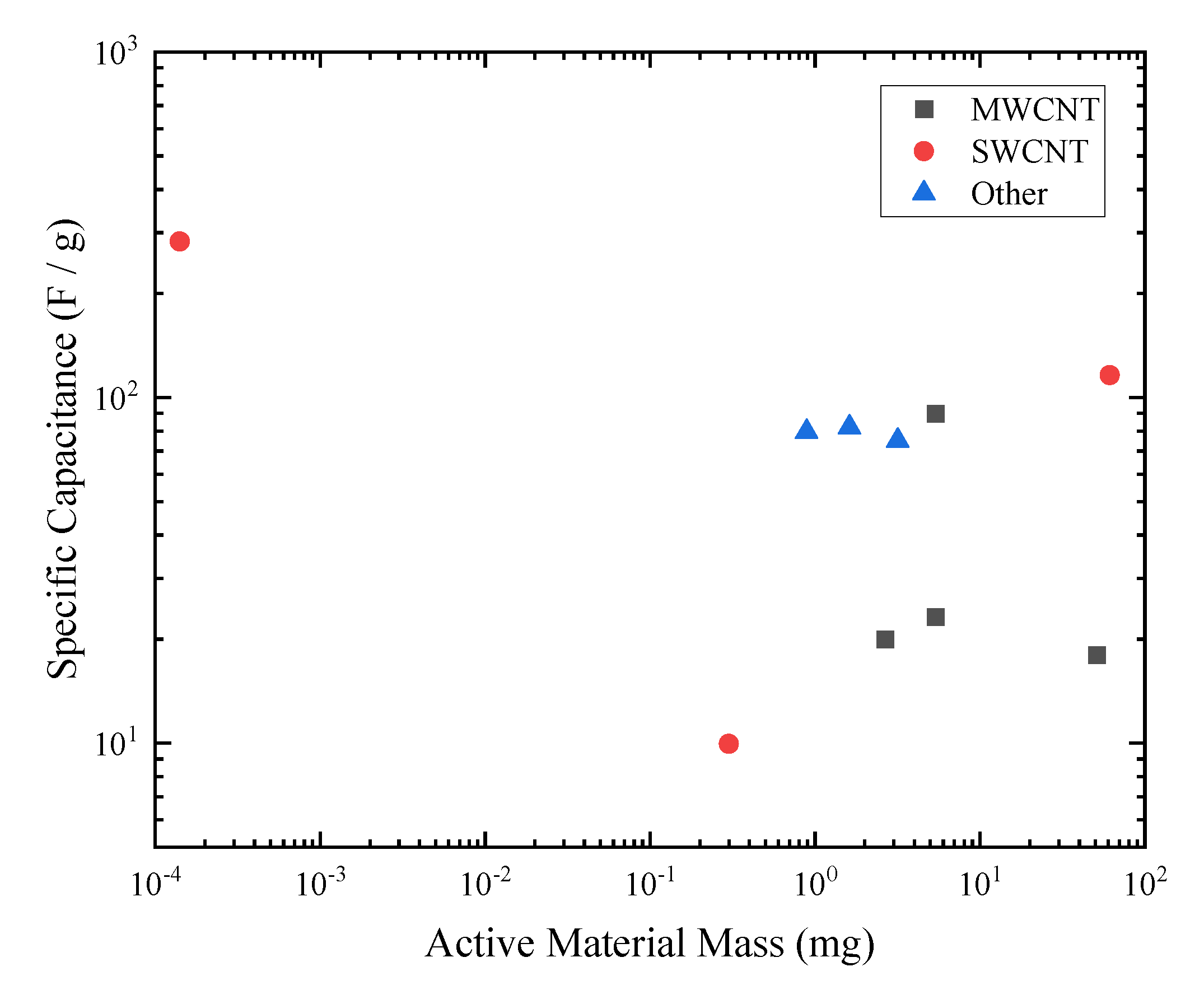

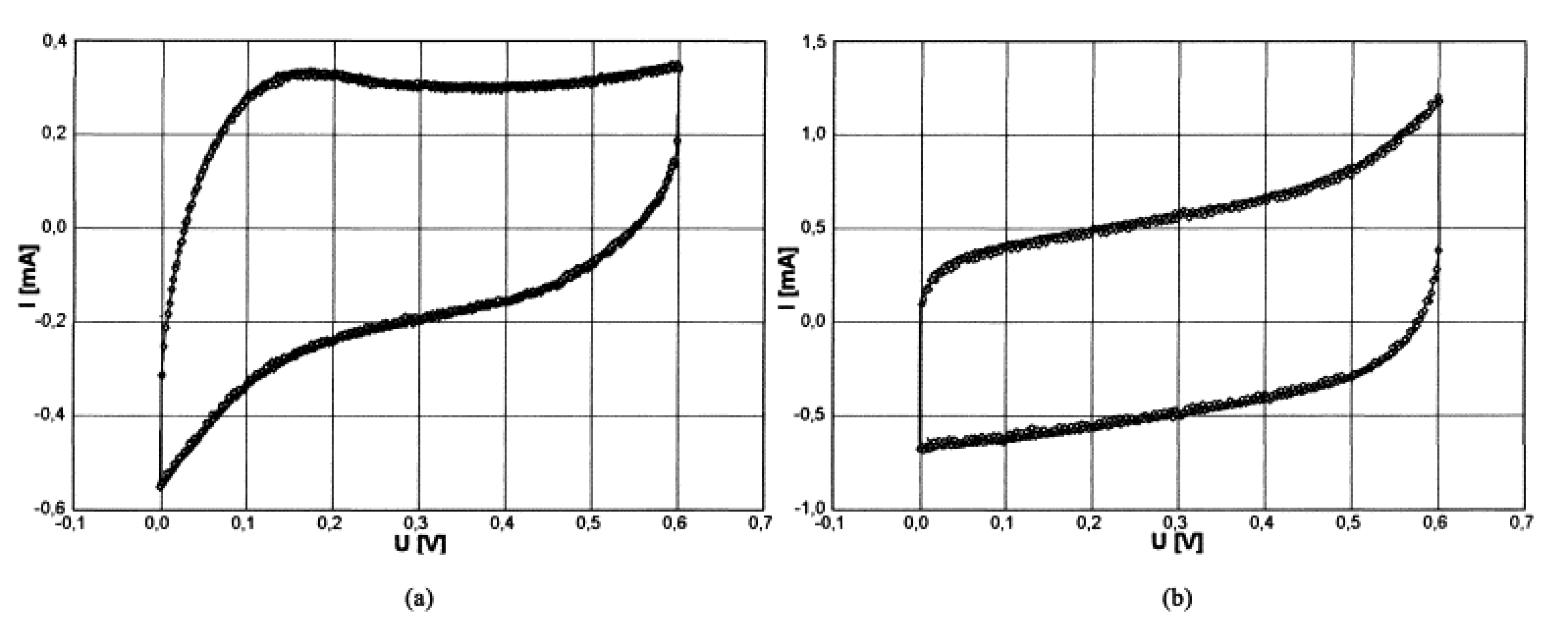

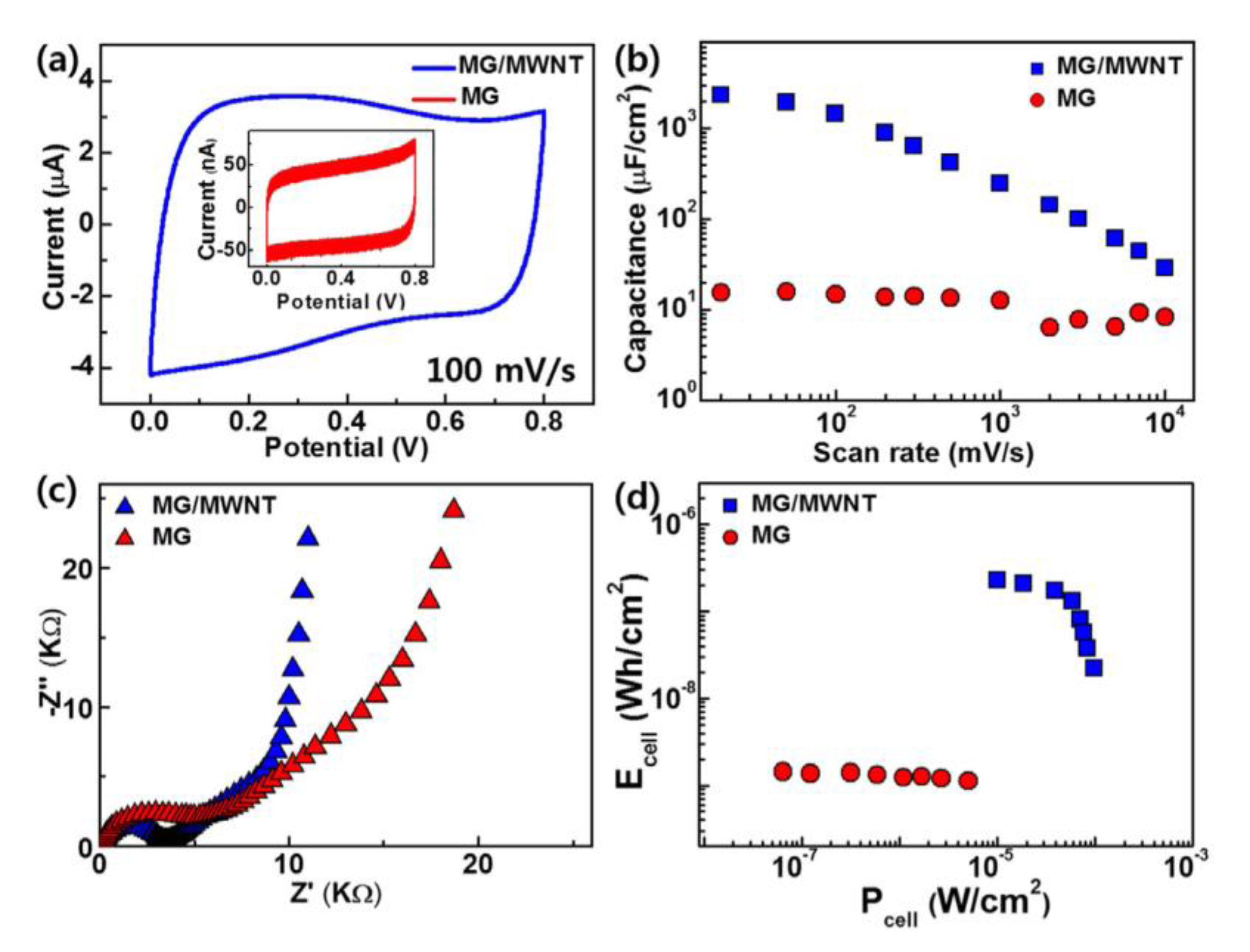

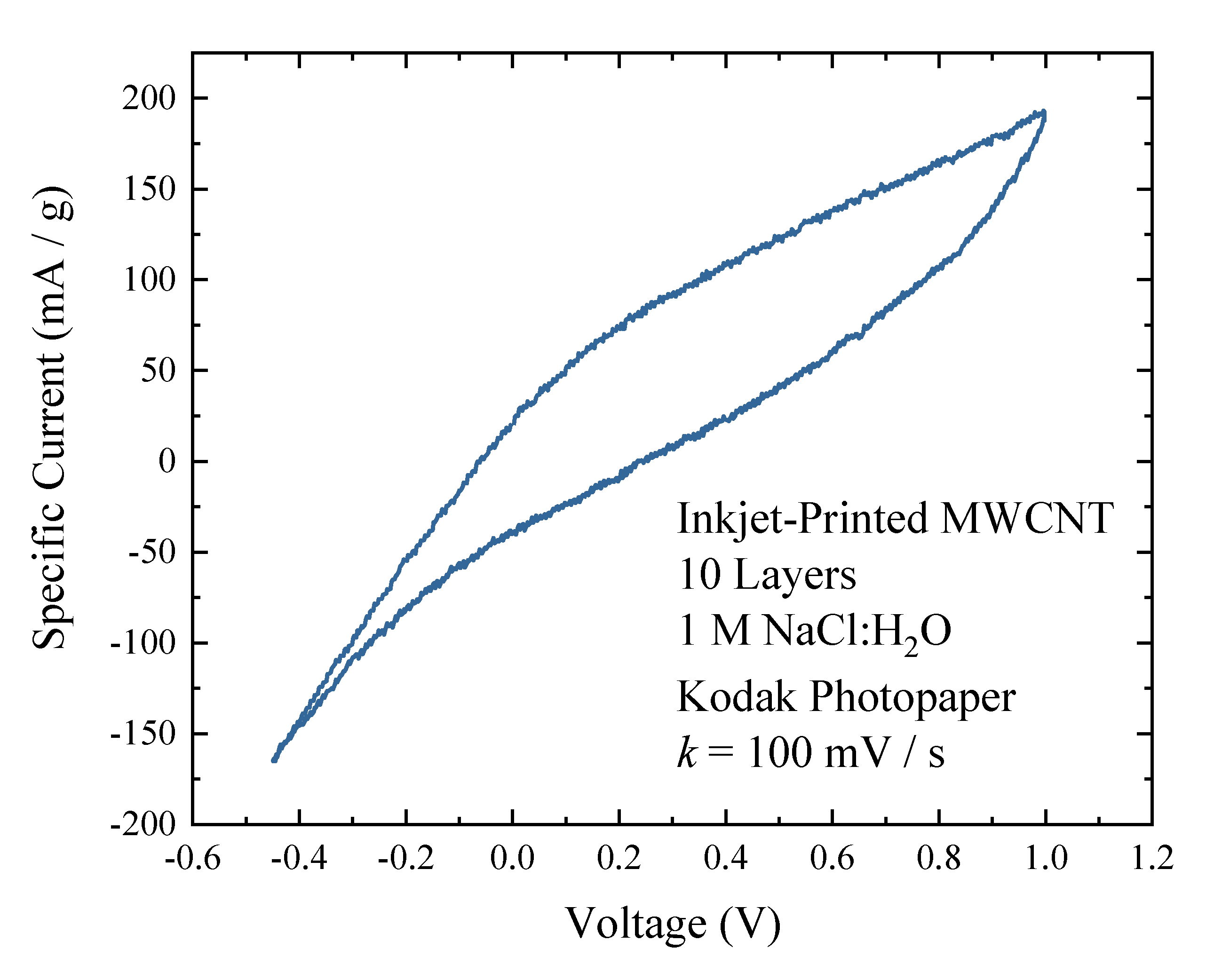

Electrochemical Capacitor

5. Summary and Outlook

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Moisala, A.; Nasibulin, A.G.; Kauppinen, E.I. The role of metal nanoparticles in the catalytic production of single-walled carbon nanotubes—A review. J. Phys. Condens. Matter 2003, 15, S3011–S3035. [Google Scholar] [CrossRef]

- Siegal, M.P.; Overmyer, D.L.; Provencio, P.P. Precise control of multiwall carbon nanotube diameters using thermal chemical vapor deposition. Appl. Phys. Lett. 2002, 80, 2171–2173. [Google Scholar] [CrossRef]

- Terrones, M. Carbon nanotubes: Synthesis and properties, electronic devices and other emerging applications. Int. Mater. Rev. 2004, 49, 325–377. [Google Scholar] [CrossRef]

- Jilani, A.; Abdel-Wahab, M.S.; Hammad, A.H. Advance Deposition Techniques for Thin Film and Coating. In Modern Technologies for Creating the Thin-film Systems and Coatings; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef] [Green Version]

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Chow, J.; Kopp, R.J.; Portney, P.R. Energy Resources and Global Development. Science 2003, 302, 1528–1531. [Google Scholar] [CrossRef] [Green Version]

- Lehtola, T.; Zahedi, A. Solar energy and wind power supply supported by storage technology: A review. Sustain. Energy Technol. Assess. 2019, 35, 25–31. [Google Scholar] [CrossRef]

- Hall, P.J.; Bain, E. Energy-storage technologies and electricity generation. Energy Policy 2008, 36, 4352–4355. [Google Scholar] [CrossRef] [Green Version]

- Miller, J.R.; Simon, P. MATERIALS SCIENCE: Electrochemical Capacitors for Energy Management. Science 2008, 321, 651–652. [Google Scholar] [CrossRef] [Green Version]

- Qu, D. Studies of the activated carbons used in double-layer supercapacitors. J. Power Sources 2002, 109, 403–411. [Google Scholar] [CrossRef] [Green Version]

- Baddour, C.E.; Briens, C. Carbon Nanotube Synthesis: A Review. Int. J. Chem. React. Eng. 2005, 3. [Google Scholar] [CrossRef]

- Muhlbauer, R.L.; Gerhardt, R.A. A review on the synthesis of carbon nanotube thin films. In Carbon Nanotubes: Synthesis and Properties; Nova Science Publishers: New York, NY, USA, 2012; pp. 107–156. [Google Scholar]

- Rafique, M.M.A.; Iqbal, J. Production of Carbon Nanotubes by Different Routes-A Review. J. Encapsulation Adsorpt. Sci. 2011, 1, 29–34. [Google Scholar] [CrossRef] [Green Version]

- Arora, N.; Sharma, N. Arc discharge synthesis of carbon nanotubes: Comprehensive review. Diam. Relat. Mater. 2014, 50, 135–150. [Google Scholar] [CrossRef]

- Cadek, M.; Murphy, R.; McCarthy, B.; Drury, A.; Lahr, B.; Barklie, R.; Panhuis, M.I.H.; Coleman, J.; Blau, W. Optimisation of the arc-discharge production of multi-walled carbon nanotubes. Carbon 2002, 40, 923–928. [Google Scholar] [CrossRef]

- Zhao, T. Gas and pressure effects on the synthesis of amorphous carbon nanotubes. Chin. Sci. Bull. 2004, 49, 2569–2571. [Google Scholar] [CrossRef]

- Kim, H.H.; Kim, H.J. Preparation of carbon nanotubes by DC arc discharge process under reduced pressure in an air atmosphere. Mater. Sci. Eng. B 2006, 133, 241–244. [Google Scholar] [CrossRef]

- Bagiante, S.; Scalese, S.; Scuderi, V.; D’Urso, L.; Messina, E.; Compagnini, G.; Privitera, V. Role of the growth parameters on the structural order of MWCNTs produced by arc discharge in liquid nitrogen. Phys. Status Solidi (B) 2010, 247, 884–887. [Google Scholar] [CrossRef]

- Wienecke, M.; Bunescu, M.-C.; Deistung, K.; Fedtke, P.; Borchartd, E. MWCNT coatings obtained by thermal CVD using ethanol decomposition. Carbon 2006, 44, 718–723. [Google Scholar] [CrossRef]

- Rahmandoust, M.; Öchsner, A. Buckling Behaviour and Natural Frequency of Zigzag and Armchair Single-Walled Carbon Nanotubes. J. Nano Res. 2012, 16, 153–160. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’Ko, Y. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Treacy, M.M.J.; Ebbesen, T.W.; Gibson, J.M. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sammalkorpi, M.; Krasheninnikov, A.; Kuronen, A.; Nordlund, K.; Kaski, K. Mechanical properties of carbon nanotubes with vacancies and related defects. Phys. Rev. B 2004, 70, 245416. [Google Scholar] [CrossRef] [Green Version]

- Mielke, S.L.; Troya, D.; Zhang, S.; Li, J.-L.; Xiao, S.; Car, R.; Ruoff, R.S.; Schatz, G.C.; Belytschko, T. The role of vacancy defects and holes in the fracture of carbon nanotubes. Chem. Phys. Lett. 2004, 390, 413–420. [Google Scholar] [CrossRef]

- Salvetat, J.-P.; Bonard, J.-M.; Thomson, N.; Kulik, A.; Forró, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Takakura, A.; Beppu, K.; Nishihara, T.; Fukui, A.; Kozeki, T.; Namazu, T.; Miyauchi, Y.; Itami, K. Strength of carbon nanotubes depends on their chemical structures. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Charlier, J.-C.; Issi, J.-P. Electronic structure and quantum transport in carbon nanotubes. Appl. Phys. A 1998, 67, 79–87. [Google Scholar] [CrossRef]

- Harutyunyan, A.R.; Chen, G.; Paroyan, T.M.; Pigos, E.M.; Kuznetsov, O.A.; Hewparakrama, K.; Kim, S.M.; Zakharov, D.; Stach, E.A.; Sumanasekera, G.U. Preferential Growth of Single-Walled Carbon Nanotubes with Metallic Conductivity. Science 2009, 36, 116–120. [Google Scholar] [CrossRef] [Green Version]

- Ding, L.; Tselev, A.; Wang, J.; Yuan, D.; Chu, H.; McNicholas, T.P.; Li, Y.; Liu, J. Selective Growth of Well-Aligned Semiconducting Single-Walled Carbon Nanotubes. Nano Lett. 2009, 9, 800–805. [Google Scholar] [CrossRef]

- Langer, L.; Stockman, L.; Heremans, J.P.; Bayot, V.; Olk, C.H.; Van Haesendonck, C.; Bruynseraede, Y.; Issi, J.-P. Electrical resistance of a carbon nanotube bundle. J. Mater. Res. 1994, 9, 927–932. [Google Scholar] [CrossRef]

- Cole, M.; Hiralal, P.; Ying, K.; Li, C.; Zhang, Y.; Teo, K.; Ferrari, A.; Milne, W. Dry-Transfer of Aligned Multiwalled Carbon Nanotubes for Flexible Transparent Thin Films. J. Nanomater. 2012, 2012, 1–8. [Google Scholar] [CrossRef]

- Honda, Y.; Haramoto, T.; Takeshige, M.; Shiozaki, H.; Kitamura, T.; Ishikawa, M. Aligned MWCNT Sheet Electrodes Prepared by Transfer Methodology Providing High-Power Capacitor Performance. Electrochem. Solid-State Lett. 2007, 10, A106–A110. [Google Scholar] [CrossRef]

- Shin, J.-H.; Shin, D.-W.; Patole, S.P.; Lee, J.H.; Park, S.M.; Yoo, J.B. Smooth, transparent, conducting and flexible SWCNT films by filtration–wet transfer processes. J. Phys. D Appl. Phys. 2009, 42, 045305. [Google Scholar] [CrossRef]

- Brinker, C.; Frye, G.; Hurd, A.; Ashley, C. Fundamentals of sol-gel dip coating. Thin Solid Films 1991, 201, 97–108. [Google Scholar] [CrossRef]

- Scriven, L.E. Physics and Applications of DIP Coating and Spin Coating. MRS Proc. 1988, 121, 717. [Google Scholar] [CrossRef]

- Sahu, N.; Parija, B.; Panigrahi, S. Fundamental understanding and modeling of spin coating process: A review. Indian J. Phys. 2009, 83, 493–502. [Google Scholar] [CrossRef] [Green Version]

- Derby, B. Inkjet Printing of Functional and Structural Materials: Fluid Property Requirements, Feature Stability, and Resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- MacLeod, D. Wire-Wound Rod Coating. In Coatings Technology Handbook, 3rd ed.; Taylor and Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Mistler, R.; Twiname, E.R. The Tape Casting Process. In Tape Casting: Theory and Practice; The American Ceramic Society: Westerville, OH, USA, 2000; pp. 83–186. [Google Scholar]

- Shin, P.; Sung, J.; Lee, M.H. Control of droplet formation for low viscosity fluid by double waveforms applied to a piezoelectric inkjet nozzle. Microelectron. Reliab. 2011, 51, 797–804. [Google Scholar] [CrossRef]

- Sánchez, M.; Rincón, M. Sensor response of sol–gel multiwalled carbon nanotubes-TiO2 composites deposited by screen-printing and dip-coating techniques. Sens. Actuators B Chem. 2009, 140, 17–23. [Google Scholar] [CrossRef]

- Choi, J.; Park, E.J.; Park, D.W.; Shim, S.E. MWCNT–OH adsorbed electrospun nylon 6,6 nanofibers chemiresistor and their application in low molecular weight alcohol vapours sensing. Synth. Met. 2010, 160, 2664–2669. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.; Hamzah, E.; Dias, G.J.; Saud, S.; Yaghoubidoust, F.; Hadisi, Z. Fabrication and characterisation of novel ZnO/MWCNT duplex coating deposited on Mg alloy by PVD coupled with dip-coating techniques. J. Alloys Compd. 2017, 728, 159–168. [Google Scholar] [CrossRef]

- Abrishamchian, A.; Hooshmand, T.; Mohammadi, M.; Najafi, F. Preparation and characterization of multi-walled carbon nanotube/hydroxyapatite nanocomposite film dip coated on Ti–6Al–4V by sol–gel method for biomedical applications: An in vitro study. Mater. Sci. Eng. C 2013, 33, 2002–2010. [Google Scholar] [CrossRef] [PubMed]

- Raut, S.S.; Sankapal, B.R. Comparative studies on MWCNTs, Fe2O3 and Fe2O3/MWCNTs thin films towards supercapacitor application. New J. Chem. 2016, 40, 2619–2627. [Google Scholar] [CrossRef]

- Karade, S.S.; Sankapal, B.R. Room temperature PEDOT: PSS encapsulated MWCNTs thin film for electrochemical supercapacitor. J. Electroanal. Chem. 2016, 771, 80–86. [Google Scholar] [CrossRef]

- Kalaivani, A.; Narayanan, S.S. Cadmium Selenide Quantum Dots—MWCNTs Nanocomposite Modified Electrode for the Determination of Epinephrine. Adv. Mater. Res. 2014, 938, 176–181. [Google Scholar] [CrossRef]

- Du, C.; Yeh, J.; Pan, N. High power density supercapacitors using locally aligned carbon nanotube electrodes. Nanotechnology 2005, 16, 350–353. [Google Scholar] [CrossRef]

- Niu, C.; Sichel, E.K.; Hoch, R.; Moy, D.; Tennent, H. Supercapacitors using carbon nanotubes films by electrophoretic deposition. Appl. Phys. Lett. 2006, 160, 1480–1482. [Google Scholar] [CrossRef]

- Sanli, A.; Benchirouf, A.; Ramalingame, R.; Palaniyappan, S.; Sharma, R.; Muller, C.; Kanoun, O. Characterization of the dielectric properties of multiwalled carbon nanotubes (MWCNTs)/PEDOT:PSS nanocomposites. In Proceedings of the 2014 IEEE 11th International Multi-Conference on Systems, Signals Devices (SSD14), Barcelona, Spain, 11–14 February 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Wu, B.; Li, X.; An, D.; Zhao, S.; Wang, Y. Electro-casting aligned MWCNTs/polystyrene composite membranes for enhanced gas separation performance. J. Membr. Sci. 2014, 462, 62–68. [Google Scholar] [CrossRef]

- Peng, S.; Wu, Y.; Zhu, P.; Thavasi, V.; Mhaisalkar, S.G.; Ramakrishna, S. Facile fabrication of polypyrrole/functionalized multiwalled carbon nanotubes composite as counter electrodes in low-cost dye-sensitized solar cells. J. Photochem. Photobiol. A Chem. 2011, 223, 97–102. [Google Scholar] [CrossRef]

- Munkhbayar, B.; Hwang, S.; Kim, J.; Bae, K.; Ji, M.; Chung, H.; Jeong, H. Photovoltaic performance of dye-sensitized solar cells with various MWCNT counter electrode structures produced by different coating methods. Electrochim. Acta 2012, 80, 100–107. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Jia, C.; Mou, J.; Zhu, L. Highly efficient dye-sensitized solar cell with a novel nanohybrid film of Cu2ZnSnS4-MWCNTs as counter electrode. Appl. Surf. Sci. 2017, 422, 591–596. [Google Scholar] [CrossRef]

- Zhou, J.; Lubineau, G. Improving Electrical Conductivity in Polycarbonate Nanocomposites Using Highly Conductive PEDOT/PSS Coated MWCNTs. ACS Appl. Mater. Interfaces 2013, 5, 6189–6200. [Google Scholar] [CrossRef] [PubMed]

- Kordas, K.; Mustonen, T.; Toth, G.; Jantunen, H.; Lajunen, M.; Soldano, C.; Talapatra, S.; Kar, S.; Vajtai, R.; Ajayan, P.M. Inkjet Printing of Electrically Conductive Patterns of Carbon Nanotubes. Small 2006, 2, 1021–1025. [Google Scholar] [CrossRef] [PubMed]

- Song, J.-W.; Kim, J.; Yoon, Y.-H.; Choi, B.-S.; Kim, J.-H.; Han, C.-S. Inkjet printing of single-walled carbon nanotubes and electrical characterization of the line pattern. Nanotechnology 2008, 19, 095702. [Google Scholar] [CrossRef] [PubMed]

- Small, W.R.; Panhuis, M.I.H. Inkjet Printing of Transparent, Electrically Conducting Single-Walled Carbon-Nanotube Composites. Small 2007, 3, 1500–1503. [Google Scholar] [CrossRef]

- Muhlbauer, R.L.; Joshi, S.; Gerhardt, R. The effect of substrate pore size on the network interconnectivity and electrical properties of dropcasted multiwalled carbon nanotube thin films. J. Mater. Res. 2013, 28, 1617–1624. [Google Scholar] [CrossRef]

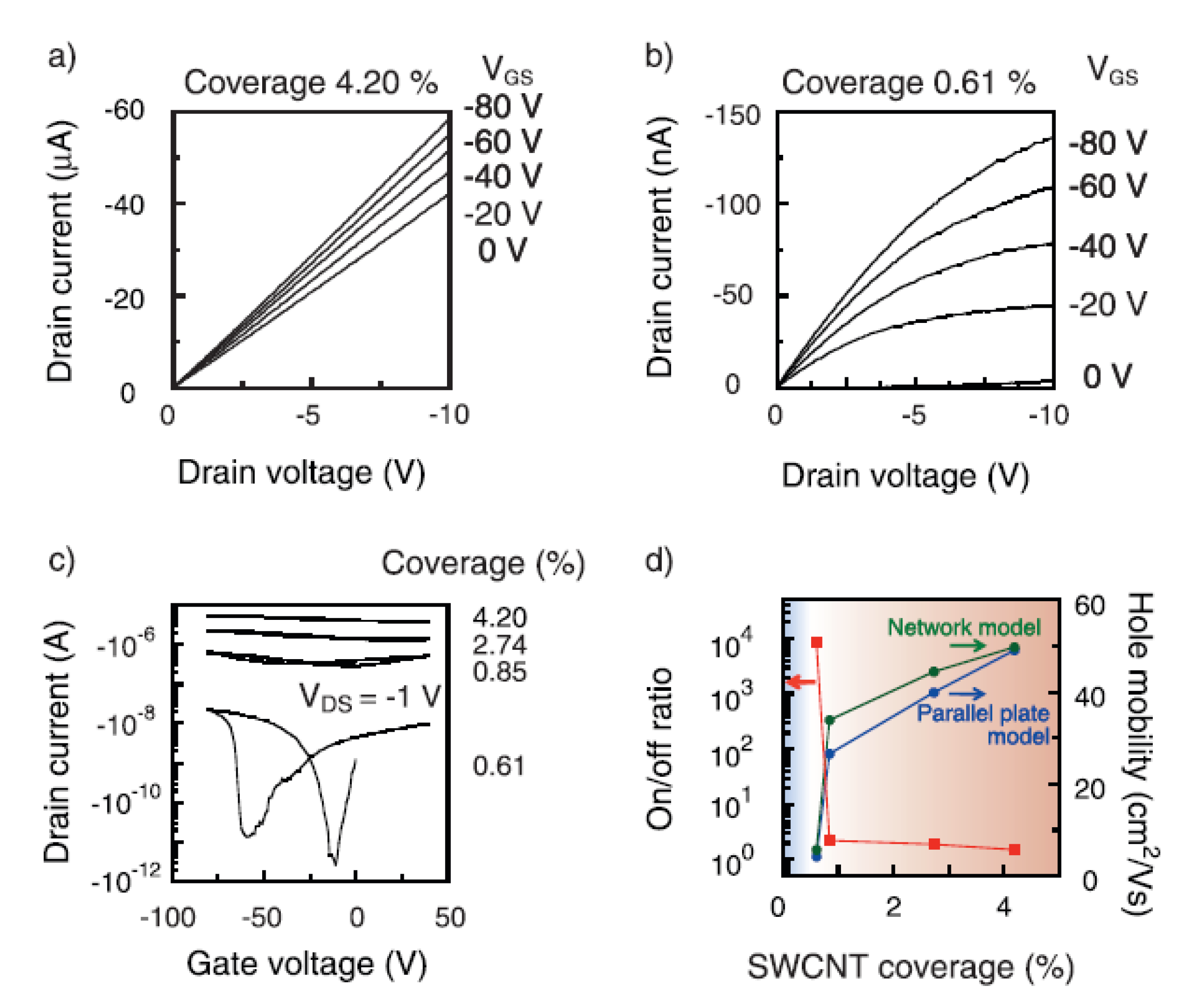

- Okimoto, H.; Takenobu, T.; Yanagi, K.; Miyata, Y.; Shimotani, H.; Kataura, H.; Iwasa, Y. Tunable Carbon Nanotube Thin-Film Transistors Produced Exclusively via Inkjet Printing. Adv. Mater. 2010, 22, 3981–3986. [Google Scholar] [CrossRef]

- Mustonen, T.; Mäklin, J.; Kordas, K.; Halonen, N.; Toth, G.; Saukko, S.; Vähäkangas, J.; Jantunen, H.; Kar, S.; Ajayan, P.M.; et al. Controlled Ohmic and nonlinear electrical transport in inkjet-printed single-wall carbon nanotube films. Phys. Rev. B 2008, 77. [Google Scholar] [CrossRef]

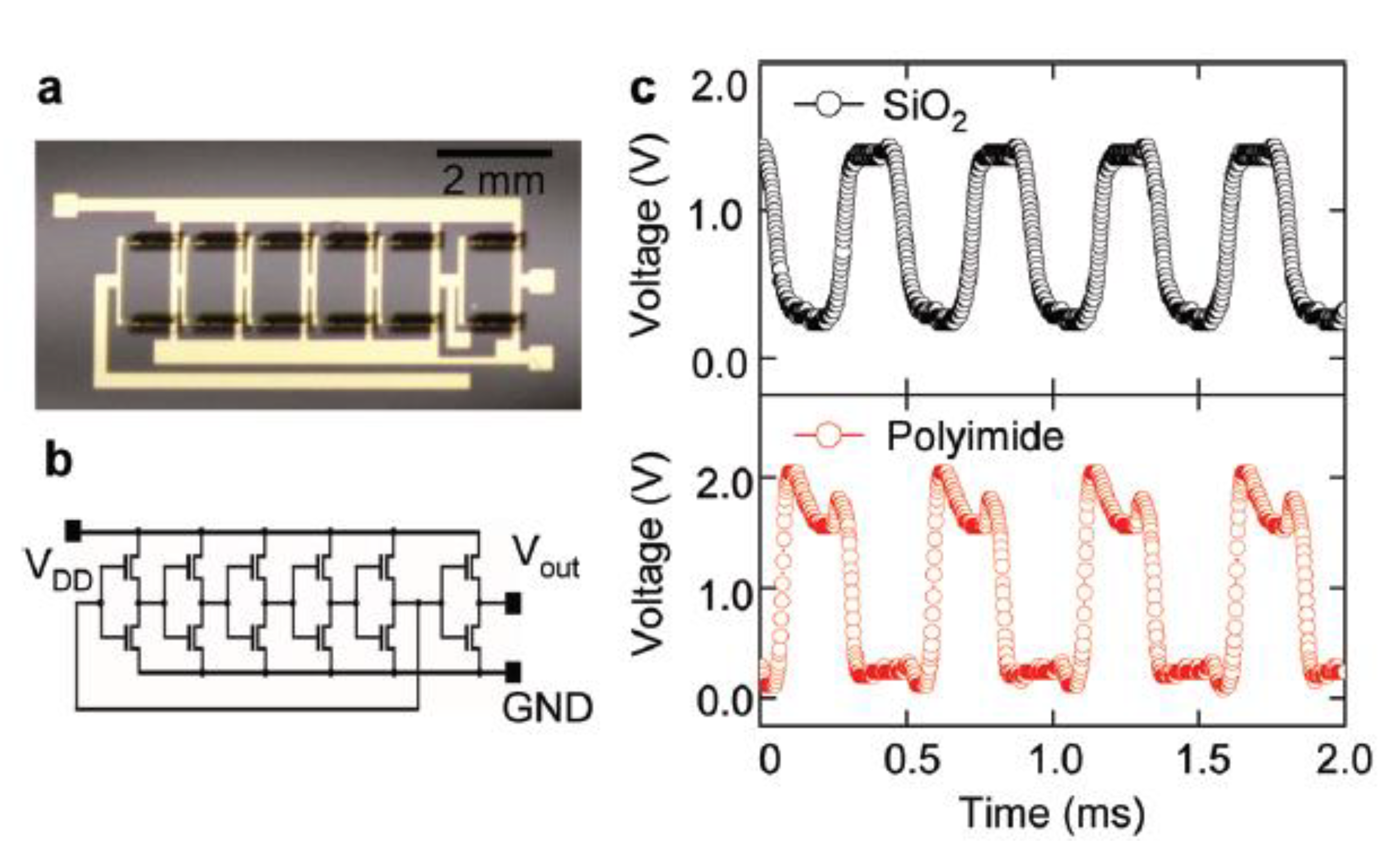

- Kim, B.; Jang, S.; Geier, M.L.; Prabhumirashi, P.L.; Hersam, M.C.; Dodabalapur, A. High-Speed, Inkjet-Printed Carbon Nanotube/Zinc Tin Oxide Hybrid Complementary Ring Oscillators. Nano Lett. 2014, 14, 3683–3687. [Google Scholar] [CrossRef]

- Ha, M.; Xia, Y.; Green, A.; Zhang, W.; Renn, M.J.; Kim, C.H.; Hersam, M.C.; Frisbie, C.D. Printed, Sub-3V Digital Circuits on Plastic from Aqueous Carbon Nanotube Inks. ACS Nano 2010, 4, 4388–4395. [Google Scholar] [CrossRef]

- Khan, S.; Dahiya, R.; Tinku, S.; Lorenzelli, L. Conformable tactile sensing using screen printed P(VDF-TrFE) and MWCNT-PDMS composites. Sensors 2014, 862–865. [Google Scholar] [CrossRef]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Bendable piezoresistive sensors by screen printing MWCNT/PDMS composites on flexible substrates. In Proceedings of the 2014 10th Conference on Ph.D. Research in Microelectronics and Electronics (PRIME), Grenoble, France, 30 June–3 July 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Khan, S.; Dang, W.; Lorenzelli, L.; Dahiya, R. Flexible Pressure Sensors Based on Screen-Printed P(VDF-TrFE) and P(VDF-TrFE)/MWCNTs. IEEE Trans. Semicond. Manuf. 2015, 28, 486–493. [Google Scholar] [CrossRef]

- Viswanathan, S.; Rani, C.; Anand, A.V.; Ho, J.-A.A. Disposable electrochemical immunosensor for carcinoembryonic antigen using ferrocene liposomes and MWCNT screen-printed electrode. Biosens. Bioelectron. 2009, 24, 1984–1989. [Google Scholar] [CrossRef]

- Viswanathan, S.; Rani, C.; Ho, A. Electrochemical immunosensor for multiplexed detection of food-borne pathogens using nanocrystal bioconjugates and MWCNT screen-printed electrode. Talanta 2012, 94, 315–319. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Portet, C.; Yushin, G.; Gogotsi, Y. Electrochemical performance of carbon onions, nanodiamonds, carbon black and multiwalled nanotubes in electrical double layer capacitors. Carbon 2007, 45, 2511–2518. [Google Scholar] [CrossRef]

- Markoulidis, F.; Lei, C.; Lekakou, C.; Figgemeier, E.; Duff, D.; Khalil, S.; Martorana, B.; Cannavaro, I. High-performance Supercapacitor cells with Activated Carbon/MWNT nanocomposite electrodes. IOP Conf. Ser. Mater. Sci. Eng. 2012, 40, 012021. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.J.; Yao, X.F.; Wang, D. Experimental investigation on mechanical properties of CNT film using digital speckle correlation method. Opt. Lasers Eng. 2012, 50, 1575–1581. [Google Scholar] [CrossRef]

- Xu, X.; Thwe, M.M.; Shearwood, C.; Liao, K. Mechanical properties and interfacial characteristics of carbon-nanotube-reinforced epoxy thin films. Appl. Phys. Lett. 2002, 81, 2833–2835. [Google Scholar] [CrossRef]

- Koval’Chuk, A.A.; Shevchenko, V.G.; Shchegolikhin, A.N.; Nedorezova, P.M.; Klyamkina, A.N.; Aladyshev, A.M. Effect of Carbon Nanotube Functionalization on the Structural and Mechanical Properties of Polypropylene/MWCNT Composites. Macromolecules 2008, 41, 7536–7542. [Google Scholar] [CrossRef]

- Sun, F.; Cha, H.-R.; Bae, K.; Hong, S.; Kim, J.-M.; Kim, S.H.; Lee, J.; Lee, D. Mechanical properties of multilayered chitosan/CNT nanocomposite films. Mater. Sci. Eng. A 2011, 528, 6636–6641. [Google Scholar] [CrossRef]

- Lau, C.H.; Cervini, R.; Clarke, S.R.; Markovic, M.G.; Matisons, J.G.; Hawkins, S.C.; Huynh, C.P.; Simon, G.P. The effect of functionalization on structure and electrical conductivity of multi-walled carbon nanotubes. J. Nanoparticle Res. 2008, 10, 77–88. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, K.; Han, K.; Yoo, K.; Kim, J. Enhanced optical and electrical properties of PEDOT: PSS films by the addition of MWCNT-sorbitol. Synth. Met. 2009, 159, 1701–1704. [Google Scholar] [CrossRef]

- Ram, R.; Rahaman, M.; Khastgir, D. Electrical properties of polyvinylidene fluoride (PVDF)/multi-walled carbon nanotube (MWCNT) semi-transparent composites: Modelling of DC conductivity. Compos. Part A Appl. Sci. Manuf. 2015, 69, 30–39. [Google Scholar] [CrossRef]

- Chen, M.; Tao, T.; Zhang, L.; Gao, W.; Li, C. Highly conductive and stretchable polymer composites based on graphene/MWCNT network. Chem. Commun. 2013, 49, 1612–1614. [Google Scholar] [CrossRef]

- Kim, K.-S.; Park, S.-J. Effect of silver doped MWCNTs on the electrical properties of conductive MWCNTs/PMMA thin films. Synth. Met. 2010, 160, 123–126. [Google Scholar] [CrossRef]

- Fernandez-d’Arlas, B.; Khan, U.; Rueda, L.; Martin, L.; Ramos, J.A.; Coleman, J.N.; Gozalez, M.L.; Valea, A.; Mondragon, I.; Corcuera, M.A.; et al. Study of the mechanical, electrical and morphological properties of PU/MWCNT composites obtained by two different processing routes. Compos. Sci. Technol. 2012, 72, 235–242. [Google Scholar] [CrossRef]

- Staudinger, U.; Thoma, P.; Lüttich, F.; Janke, A.; Kobsch, O.; Gordan, O.; Pötschke, P.; Voit, B.; Zahn, D.R. Properties of thin layers of electrically conductive polymer/MWCNT composites prepared by spray coating. Compos. Sci. Technol. 2017, 138, 134–143. [Google Scholar] [CrossRef]

- Jung, D.; Kim, D.; Lee, K.H.; Overzet, L.J.; Lee, G.S. Transparent film heaters using multi-walled carbon nanotube sheets. Sens. Actuators A Phys. 2013, 199, 176–180. [Google Scholar] [CrossRef]

- Saw, L.; Mariatti, M.; Azura, A.; Azizan, A.; Kim, J. Transparent, electrically conductive, and flexible films made from multiwalled carbon nanotube/epoxy composites. Compos. Part B Eng. 2012, 43, 2973–2979. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Gao, C.; Zhang, J.; Sun, H. Influence of MWCNTs Doping on the Structure and Properties of PEDOT:PSS Films. Int. J. Photoenergy 2009, 2009, 1–5. [Google Scholar] [CrossRef]

- Hone, J.; Llaguno, M.; Nemes, N.M.; Johnson, A.T.; Fischer, J.E.; Walters, D.A.; Casavant, M.J.; Schmidt, J.; Smalley, R.E. Electrical and thermal transport properties of magnetically aligned single wall carbon nanotube films. Appl. Phys. Lett. 2000, 77, 666–668. [Google Scholar] [CrossRef]

- Yang, K.; Gu, M.; Guo, Y.; Pan, X.; Mu, G. Effects of carbon nanotube functionalization on the mechanical and thermal properties of epoxy composites. Carbon 2009, 47, 1723–1737. [Google Scholar] [CrossRef]

- Pradhan, N.R.; Duan, H.; Liang, J.; Iannacchione, G. The specific heat and effective thermal conductivity of composites containing single-wall and multi-wall carbon nanotubes. Nanotechnology 2009, 20, 245705. [Google Scholar] [CrossRef] [PubMed]

- Antiohos, D.; Romano, M.; Chen, J.; Razal, J.M. Carbon nanotubes for energy applications. In Syntheses and Applications of Carbon Nanotubes and Their Composites; IntechOpen: London, UK, 2013. [Google Scholar] [CrossRef] [Green Version]

- Bu, F.; Zhou, W.; Xu, Y.; Du, Y.; Guan, C.; Huang, W. Recent developments of advanced micro-supercapacitors: Design, fabrication and applications. NPJ Flex. Electron. 2020, 4, 1–16. [Google Scholar] [CrossRef]

- Jurewicz, K.; Babeł, K.; Pietrzak, R.; Delpeux, S.; Wachowska, H. Capacitance properties of multi-walled carbon nanotubes modified by activation and ammoxidation. Carbon 2006, 44, 2368–2375. [Google Scholar] [CrossRef]

- Frackowiak, E.; Metenier, K.; Bertagna, V.; Beguin, F. Supercapacitor electrodes from multiwalled carbon nanotubes. Appl. Phys. Lett. 2000, 77, 2421–2423. [Google Scholar] [CrossRef]

- Frackowiak, E.; Jurewicz, K.; Szostak, K.; Delpeux, S.; Béguin, F. Nanotubular materials as electrodes for supercapacitors. Fuel Process. Technol. 2002, 77–78, 213–219. [Google Scholar] [CrossRef]

- Hu, S.; Rajamani, R.; Yu, X. Flexible solid-state paper based carbon nanotube supercapacitor. Appl. Phys. Lett. 2012, 100, 104103. [Google Scholar] [CrossRef]

- Hu, L.; Wu, H.; Cui, Y. Printed energy storage devices by integration of electrodes and separators into single sheets of paper. Appl. Phys. Lett. 2010, 96, 183502. [Google Scholar] [CrossRef]

- Liu, C.-Y.; Bard, A.J.; Wudl, F.; Weitz, I.; Heath, J.R. Electrochemical Characterization of Films of Single-Walled Carbon Nanotubes and Their Possible Application in Supercapacitors. Electrochem. Solid-State Lett. 1999, 2, 577–578. [Google Scholar] [CrossRef]

- Diederich, L.; Barborini, E.; Piseri, P.; Podestà, A.; Milani, P.; Schneuwly, A.; Gallay, R. Supercapacitors based on nanostructured carbon electrodes grown by cluster-beam deposition. Appl. Phys. Lett. 1999, 75, 2662–2664. [Google Scholar] [CrossRef]

- Le, L.T.; Ervin, M.H.; Qiu, H.; Fuchs, B.E.; Lee, W.Y. Graphene supercapacitor electrodes fabricated by inkjet printing and thermal reduction of graphene oxide. Electrochem. Commun. 2011, 13, 355–358. [Google Scholar] [CrossRef]

- Xu, Y.; Hennig, I.; Freyberg, D.; Strudwick, A.J.; Schwab, M.G.; Weitz, T.; Cha, K.C.-P. Inkjet-printed energy storage device using graphene/polyaniline inks. J. Power Sources 2014, 248, 483–488. [Google Scholar] [CrossRef]

- Sharma, P.; Bhatti, T. A review on electrochemical double-layer capacitors. Energy Convers. Manag. 2010, 51, 2901–2912. [Google Scholar] [CrossRef]

- Libich, J.; Máca, J.; Vondrák, J.; Čech, O.; Sedlaříková, M. Supercapacitors: Properties and applications. J. Energy Storage 2018, 17, 224–227. [Google Scholar] [CrossRef]

- Kisza, A. The capacitance of the diffuse layer of electric double layer of electrodes in molten salts. Electrochim. Acta 2005, 51, 2315–2321. [Google Scholar] [CrossRef]

- An, K.H.; Kim, W.S.; Park, Y.S.; Choi, Y.C.; Lee, S.M.; Chung, D.C.; Bae, D.J.; Lim, S.C.; Lee, Y.H. Supercapacitors Using Single-Walled Carbon Nanotube Electrodes. Adv. Mater. 2001, 13, 497–500. [Google Scholar] [CrossRef]

- Li, C.; Wang, D.; Liang, T.; Wang, X.; Ji, L. A study of activated carbon nanotubes as double-layer capacitors electrode materials. Mater. Lett. 2004, 58, 3774–3777. [Google Scholar] [CrossRef]

- Chen, J.; Li, W.; Wang, D.; Yang, S.; Wen, J.; Ren, Z. Electrochemical characterization of carbon nanotubes as electrode in electrochemical double-layer capacitors. Carbon 2002, 40, 1193–1197. [Google Scholar] [CrossRef]

- Markoulidis, F.; Lei, C.; Lekakou, C.; Duff, D.; Khalil, S.; Martorana, B.; Cannavaro, I. A method to increase the energy density of supercapacitor cells by the addition of multiwall carbon nanotubes into activated carbon electrodes. Carbon 2014, 68, 58–66. [Google Scholar] [CrossRef]

- Conway, B.; Birss, V.; Wojtowicz, J. The role and utilization of pseudocapacitance for energy storage by supercapacitors. J. Power Sources 1997, 66, 1–14. [Google Scholar] [CrossRef]

- Frackowiak, E.; Jurewicz, K.; Delpeux, S.; Beguin, F. Nanotubular materials for supercapacitors. J. Power Sources 2001, 97–98, 822–825. [Google Scholar] [CrossRef]

- Kong, L.-B.; Zhang, J.; An, J.-J.; Luo, Y.-C.; Kang, L. MWNTs/PANI composite materials prepared by in-situ chemical oxidative polymerization for supercapacitor electrode. J. Mater. Sci. 2008, 43, 3664–3669. [Google Scholar] [CrossRef]

- Gao, B.; Hao, L.; Fu, Q.; Su, L.; Yuan, C.; Zhang, X. Hydrothermal synthesis and electrochemical capacitance of RuO2·xH2O loaded on benzenesulfonic functionalized MWCNTs. Electrochim. Acta 2010, 55, 3681–3686. [Google Scholar] [CrossRef]

- Rakhi, R.; Alshareef, H. Enhancement of the energy storage properties of supercapacitors using graphene nanosheets dispersed with metal oxide-loaded carbon nanotubes. J. Power Sources 2011, 196, 8858–8865. [Google Scholar] [CrossRef]

- Zhi, M.; Xiang, C.; Li, J.; Li, M.; Wu, N. Nanostructured carbon–metal oxide composite electrodes for supercapacitors: A review. Nanoscale 2013, 5, 72–88. [Google Scholar] [CrossRef]

- Terasawa, N.; Mukai, K.; Yamato, K.; Asaka, K. Superior performance of non-activated multi-walled carbon nanotube polymer actuator containing ruthenium oxide over a single-walled carbon nanotube. Carbon 2012, 50, 1888–1896. [Google Scholar] [CrossRef]

- Lewandowski, A.; Galiński, M. Practical and theoretical limits for electrochemical double-layer capacitors. J. Power Sources 2007, 173, 822–828. [Google Scholar] [CrossRef]

- Du, C.; Yeh, J.; Pan, N. High power density supercapacitors electrodes of carbon nanotube films by electrophoretic deposition. Nanotechnology 2006, 17, 5314–5318. [Google Scholar] [CrossRef]

- Ma, R.; Liang, J.; Wei, B.; Zhang, B.; Xu, C.; Wu, D. Study of electrochemical capacitors utilizing carbon nanotube electrodes. J. Power Sources 1999, 84, 126–129. [Google Scholar] [CrossRef]

- Yun, J.; Kim, D.; Lee, G.; Ha, J.S. All-solid-state flexible micro-supercapacitor arrays with patterned graphene/MWNT electrodes. Carbon 2014, 79, 156–164. [Google Scholar] [CrossRef]

- Geng, X.; Li, F.; Wang, D.-W.; Cheng, H.-M. The influence of pretreatment on multi-wall carbon nanotubes for electrochemical capacitors. Carbon 2013, 60, 564. [Google Scholar] [CrossRef]

- Sham, M.L.; Li, J.; Ma, P.C.; Kim, J.-K. Cleaning and Functionalization of Polymer Surfaces and Nanoscale Carbon Fillers by UV/Ozone Treatment: A Review. J. Compos. Mater. 2009, 43, 1537–1564. [Google Scholar] [CrossRef]

- Tsao, C.W.; Hromada, L.; Liu, J.; Kumar, P.; DeVoe, D. Low temperature bonding of PMMA and COC microfluidic substrates using UV/ozone surface treatment. Lab Chip 2007, 7, 499–505. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Chen, K.; Peng, C.; Gerhardt, R.A. Highly conductive paper fabricated with multiwalled carbon nanotubes and poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) by unidirectional drying. J. Mater. Sci. 2011, 46, 6648–6655. [Google Scholar] [CrossRef]

- Uddin, N.M.; Capaldi, F.M.; Farouk, B. Molecular dynamics simulations of carbon nanotube dispersions in water: Effects of nanotube length, diameter, chirality and surfactant structures. Comput. Mater. Sci. 2012, 53, 133–144. [Google Scholar] [CrossRef]

- Chen, P.; Chen, H.; Qiu, J.; Zhou, C. Inkjet printing of single-walled carbon nanotube/RuO2 nanowire supercapacitors on cloth fabrics and flexible substrates. Nano Res. 2010, 3, 594–603. [Google Scholar] [CrossRef] [Green Version]

- Singjai, P.; Changsarn, S.; Thongtem, S. Electrical resistivity of bulk multi-walled carbon nanotubes synthesized by an infusion chemical vapor deposition method. Mater. Sci. Eng. A 2007, 443, 42–46. [Google Scholar] [CrossRef]

- Safadi, B.; Andrews, R.; Grulke, E.A. Multiwalled carbon nanotube polymer composites: Synthesis and characterization of thin films. J. Appl. Polym. Sci. 2002, 84, 2660–2669. [Google Scholar] [CrossRef]

- Castillo, F.Y.; Socher, R.; Krause, B.; Headrick, R.; Grady, B.P.; Prada-Silvy, R.; Pötschke, P. Electrical, mechanical, and glass transition behavior of polycarbonate-based nanocomposites with different multi-walled carbon nanotubes. Polymer 2011, 52, 3835–3845. [Google Scholar] [CrossRef]

- Lee, A.; Sudau, K.; Ahn, K.H.; Lee, S.J.; Willenbacher, N. Optimization of Experimental Parameters to Suppress Nozzle Clogging in Inkjet Printing. Ind. Eng. Chem. Res. 2012, 51, 13195–13204. [Google Scholar] [CrossRef]

- Ju, L.; Zhang, W.; Wang, X.; Hu, J.; Zhang, Y. Aggregation kinetics of SDBS-dispersed carbon nanotubes in different aqueous suspensions. Colloids Surf. A Physicochem. Eng. Asp. 2012, 409, 159–166. [Google Scholar] [CrossRef]

- Lin, L.; Peng, H.; Ding, G. Dispersion stability of multi-walled carbon nanotubes in refrigerant with addition of surfactant. Appl. Therm. Eng. 2015, 91, 163–171. [Google Scholar] [CrossRef]

- Zhang, H.; Gerhardt, R.A. AAMC Conference Presentation Given by Prof. Gerhardt in Miami, December 2016 Which Includes Data from Mulhbauer. Ph.D. Thesis. 2014. Available online: smartech-gatech.edu (accessed on 5 September 2021).

- Lacy, F. Developing a theoretical relationship between electrical resistivity, temperature, and film thickness for conductors. Nanoscale Res. Lett. 2011, 6, 636. [Google Scholar] [CrossRef] [Green Version]

- Karoui, A. Aluminum Ultra Thin Film Grown by Physical Vapor Deposition for Solar Cell Electric Nanocontacts. ECS Trans. 2011, 41, 21–28. [Google Scholar] [CrossRef]

- Patil, S.S.; Bhat, T.S.; Teli, A.M.; Beknalkar, S.A.; Dhavale, S.B.; Faras, M.M.; Karanjkar, M.M.; Patil, P.S. Hybrid solid state supercapacitors (HSSC’s) for high energy & power density: An overview. Eng. Sci. 2020. [Google Scholar] [CrossRef]

- Du, C.; Pan, N. Supercapacitors using carbon nanotubes films by electrophoretic deposition. J. Power Sources 2006, 160, 1487–1494. [Google Scholar] [CrossRef]

- Hughes, M.; Shaffer, M.S.P.; Renouf, A.C.; Singh, C.; Chen, G.Z.; Fray, D.J.; Windle, A.H. Electrochemical Capacitance of Nanocomposite Films Formed by Coating Aligned Arrays of Carbon Nanotubes with Polypyrrole. Adv. Mater. 2002, 14, 382–385. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.; Wang, D.; Yang, S.; Li, W.; Wen, J.; Ren, Z. Electrochemical synthesis of polypyrrole films over each of well-aligned carbon nanotubes. Synth. Met. 2001, 125, 289–294. [Google Scholar] [CrossRef]

- Hughes, M.; Chen, G.; Shaffer, M.S.P.; Fray, D.J.; Windle, A.H. Electrochemical Capacitance of a Nanoporous Composite of Carbon Nanotubes and Polypyrrole. Chem. Mater. 2002, 14, 1610–1613. [Google Scholar] [CrossRef]

- Barisci, J.N.; Wallace, G.; Baughman, R.H. Electrochemical studies of single-wall carbon nanotubes in aqueous solutions. J. Electroanal. Chem. 2000, 488, 92–98. [Google Scholar] [CrossRef]

- An, K.H.; Jeon, K.K.; Heo, J.K.; Lim, S.C.; Bae, D.J.; Lee, Y.H. High-Capacitance Supercapacitor Using a Nanocomposite Electrode of Single-Walled Carbon Nanotube and Polypyrrole. J. Electrochem. Soc. 2002, 149, A1058–A1062. [Google Scholar] [CrossRef]

- Wang, W.; Guo, S.; Penchev, M.; Ruiz, I.; Bozhilov, K.N.; Yan, D.; Ozkan, M.; Ozkan, C.S. Three dimensional few layer graphene and carbon nanotube foam architectures for high fidelity supercapacitors. Nano Energy 2012, 2, 294–303. [Google Scholar] [CrossRef]

| Fabrication Technique | Description | Schematic | Applications |

|---|---|---|---|

| Dip coating | Substrate extracted from dispersion Thin film formed by evaporation and gravitational draining |  | Chemical sensing [43,44] Corrosion resistance [45] Biomedical [46] Supercapacitors [47,48] |

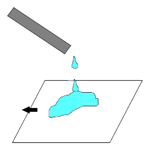

| Drop casting/Drying | Dispersion droplet placed on substrate Droplet optionally moved across substrate Evaporation removes solvent |  | Chemical sensing [49] Supercapacitors [50,51] Electrically conductive films [52] Gas separation [53] Photovoltaics [54] |

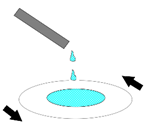

| Spin coating | Dispersion dropped onto rotating substrate Shearing force from rotation spreads dispersion over surface Evaporation removes solvent |  | Transparent films Photovoltaics [55,56] Electromagnetic shielding [57] |

| Inkjet printing | Electrical potential applied across piezoelectric nozzle, ejecting droplets on substrate Evaporation removes solvent |  | Electrically conductive films [58,59,60,61] Transistor devices [62,63,64,65] |

| Screen printing | Ink squeezed through open areas of a screen Ink is deposited on substrate Evaporation removes solvent |  | Piezoresistive pressure sensors [66,67,68] Bio sensing [69,70] Chemical sensing [43] Photovoltaics [55] |

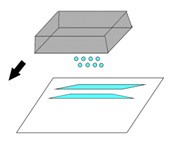

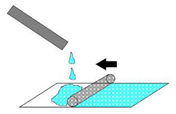

| Meyer rod coating | Slurry is cast behind threaded rod Rod is translated without rotation over substrate |  | Supercapacitors [71,72] |

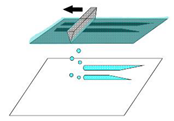

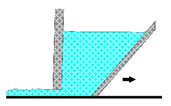

| Doctor blading | Slurry is cast in front of blade or in a reservoir Doctor blade is drawn over substrate Thickness of film is related to distance between blade and carrier |  | Supercapacitors |

| Active Material | Additives | Deposition Process | Active Material Details | Substrate Material/Surface Treatments | Post-Proessing | Electrolyte | Specific Capacitance [F/g] | Ref. |

|---|---|---|---|---|---|---|---|---|

| MWCNT | SDBS (surf.) | Spin coating/Inkjet printing | Spin coating: 400 μg (25 μg/layer, 8 layers) Inkjet printing: 60 μg (6.0 μg/layer, 10 layers) | Photo paper/UV ozone | N/A | 1 M NaCl in H2O | 0.02 | Current Work |

| MWCNT (acet. decomp.) | PVDF (bind.); acetylene black (cond.) | Pressing | 3.4–8.5 mg (85 wt% MWCNT, 4–10 mg total electrode mass) | Stainless steel | N/A | 6 M KOH | 4–135 | [93] |

| MWCNT (CCVD) | PTFE (bind.); carbon black (cond.) | Lamination | 51 mg (85 wt% active material, 15 mg/cm2, 4 cm2) | Aluminum/polyurethane paint (cond.) | N/A | 1.5 M NEt4BF4 in acetonitrile | 18 | [71] |

| MWCNT | PVDF (bind.); acetylene black (cond.) Activation with KOH | Pressing | 1.7–17 mg (85 wt% active material, 2–20 mg total) | Gold | N/A | 1 M H2SO4 | 90 | [94] |

| MWCNT | Mg(NO3)2 (EPD electrolyte) | Electrophoretic deposition | 0.8 cm × 0.8 cm (electrode area) | Nickel foil | Ar/H2 gas treatment | 6 N KOH | 21 | [135] |

| MWCNT | N/A | Colloid deposition and evaporation | 2.67 mg (26.7 mg/mL, 0.1 mL) | Nickel foil | Drying at room temperature | 6 M KOH | 20 | [50] |

| MWCNT | Nitric acid treatment | Drying | 25 μm (thickness), 800 mg/mL (MWCNT density) | N/A | Drying; thermally cross-linking | 38 wt% H2SO4 | 102 | [51] |

| MWCNT | Phenolic resin (PF) (bind.), nitric acid treatment | Molding | 1 g/cm3 (bulk density) | Graphite | Carbonization; Immersion in sulfuric/nitric acid | 38 wt% H2SO4 | 15–25 | [109] |

| MWCNT (aligned) | PPy (polymerization on MWCNTs) | Direct growth via pyrolysis of toluene and ferrocene | 100 μm (aligned MWCNT length); 0.16 cm2 (electrode area) | Gold-coated Mylar | N/A | 0.5 M KCl | 2.55 [F/cm2] | [136] |

| MWCNT/PPy | PPy (polymerization on MWCNTs) | Direct growth with Ni catalyst | 8–10 μm (aligned MWCNT length) | Titanium | Soaking in distilled water; bubbling in nitrogen (eliminate oxygen) | 0.1 M LiClO4 | N/A | [137] |

| MWCNT (in-plane aligned)/PPy | PPy (polymerization on MWCNTs) | MWCNT solution as polymerization | 0.2–2.5 μm (MWCNT length); 60 wt% MWCNTs | Graphite | N/A | 0.5 M KCl | 192 | [138] |

| SWCNT | Sulfuric acid/nitric acid treatment | Dip coating | 61.2 mg (by weighing) | Non-woven cotton paper | Drying at room temperature | PVA/phosphoric acid (solid) | 116 | [95] |

| SWCNT | SDBS (surf.) | Inkjet printing | 300 μg (0.3 mg/cm2, 1 cm2) | Newspaper; Kodak photo paper/PVDF coating | N/A | 1 M LiPF6 in EC: DEC | 3–33 | [96] |

| SWCNT | PVDC (bind.); THF (solv.) | Pressing | 150 μm (thickness of pellet), 750 mg/mL (SWCNT density) | Nickel foil/foam; Polishing | N/A | 38 wt% H2SO4 | 180 | [96] |

| SWCNT | SDS (surf.) | Suspension deposition and evaporation | 141 ng (by QCM) | Platinum | Heating in oven | 0.1 M TBAPF6 | 283 | [97] |

| SWCNT | N/A | Dip coating | 0.85 mg/cm2 | NTP | N/A | 3 M NaCl | 37.3 | [139] |

| SWCNT/PPy | PPy(polymerization on SWCNTs), PTFE (bind.), super P (cond.) | Pressing | 250 μm (electrode thickness) | Nickel foam | Vacuum drying | 7.5 M KOH | 265 | [140] |

| Activated Carbon (AC)/MWNT | PVDA or PVA (bind.) | Film application | 120 μm (thickness of AC/MWNT) | Aluminum foil | N/A | 1 M TEABF4 | 120 | [72] |

| Nanostructured Carbon | N/A | Cluster beam deposition | 3.17 mg (1 g/cm3 density, 6 cm × 6 cm × 0.8 μm) | Aluminum | N/A | Quartenary ammonium salt in PC | 75 | [98] |

| Graphene | N/A | Inkjet printing | 890 μg (8.9 μg/layer, 100 layers) | Titanium foil | Reduction of GO in flowing N2 | 1 M H2SO4 | 48–132 | [99] |

| Graphene/MWNT | Functionalized with nitric/sulfuric acid | Spray coating of MWCNTs onto CVD-grown graphene | 500 nm (thickness of MWNT film) | Polyethylene terephthalate (PET) | N/A | PVA-H3PO4 (gel) | 2.54 [mF/cm2] | [110] |

| Graphene/MWNT foam | Activation with KOH | Foam grown via one-step ambient pressure CVD | Nickel foam | Cooling to room temperature | 6 M KOH | 286 | [141] | |

| Graphene/PANI | SDBS (surf.) | Inkjet printing | 1.62 mg (800 × 800 array, 13 μm separation, 1.5 mg/cm2) 5 layers | Quartz; carbon fabric | N/A | 1 M H2SO4 | 82 | [100] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, K.; Gerhardt, R.A. Fabrication and Supercapacitor Applications of Multiwall Carbon Nanotube Thin Films. C 2021, 7, 70. https://doi.org/10.3390/c7040070

Jiang K, Gerhardt RA. Fabrication and Supercapacitor Applications of Multiwall Carbon Nanotube Thin Films. C. 2021; 7(4):70. https://doi.org/10.3390/c7040070

Chicago/Turabian StyleJiang, Kyle, and Rosario A. Gerhardt. 2021. "Fabrication and Supercapacitor Applications of Multiwall Carbon Nanotube Thin Films" C 7, no. 4: 70. https://doi.org/10.3390/c7040070

APA StyleJiang, K., & Gerhardt, R. A. (2021). Fabrication and Supercapacitor Applications of Multiwall Carbon Nanotube Thin Films. C, 7(4), 70. https://doi.org/10.3390/c7040070