Nanostructured Graphene Oxide-Based Hybrids as Anodes for Lithium-Ion Batteries

Abstract

1. Introduction

- (i)

- Alloying materials such as Si, Ge, Sn, Al, Bi, etc.,

- (ii)

- Conversion materials like transition-metal oxides (MnxOy, NiO, FexOy, CuO, Cu2O, MoO2, etc.), metal sulfides, metal phosphides, and metal nitrides (MxXy; here X = S, P, N),

- (iii)

- Insertion materials, such as carbonaceous compounds (graphite, porous carbon, carbon nanotubes, graphene), TiO2, Li4Ti5O12, etc.

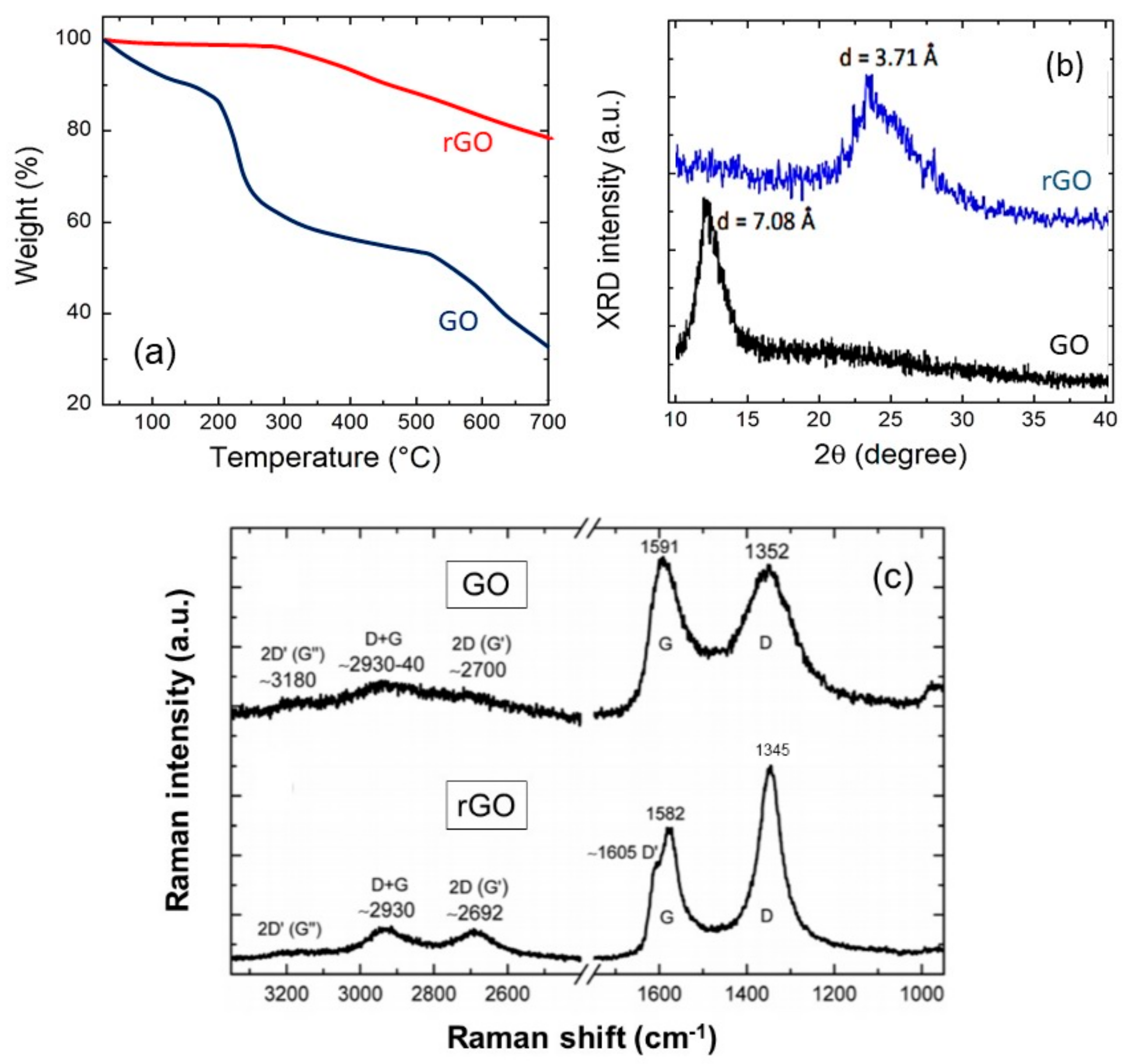

2. Graphene Oxide Materials

2.1. Properties of Graphene Oxides

2.2. Lithiation of rGO

2.3. rGO-Based Composites

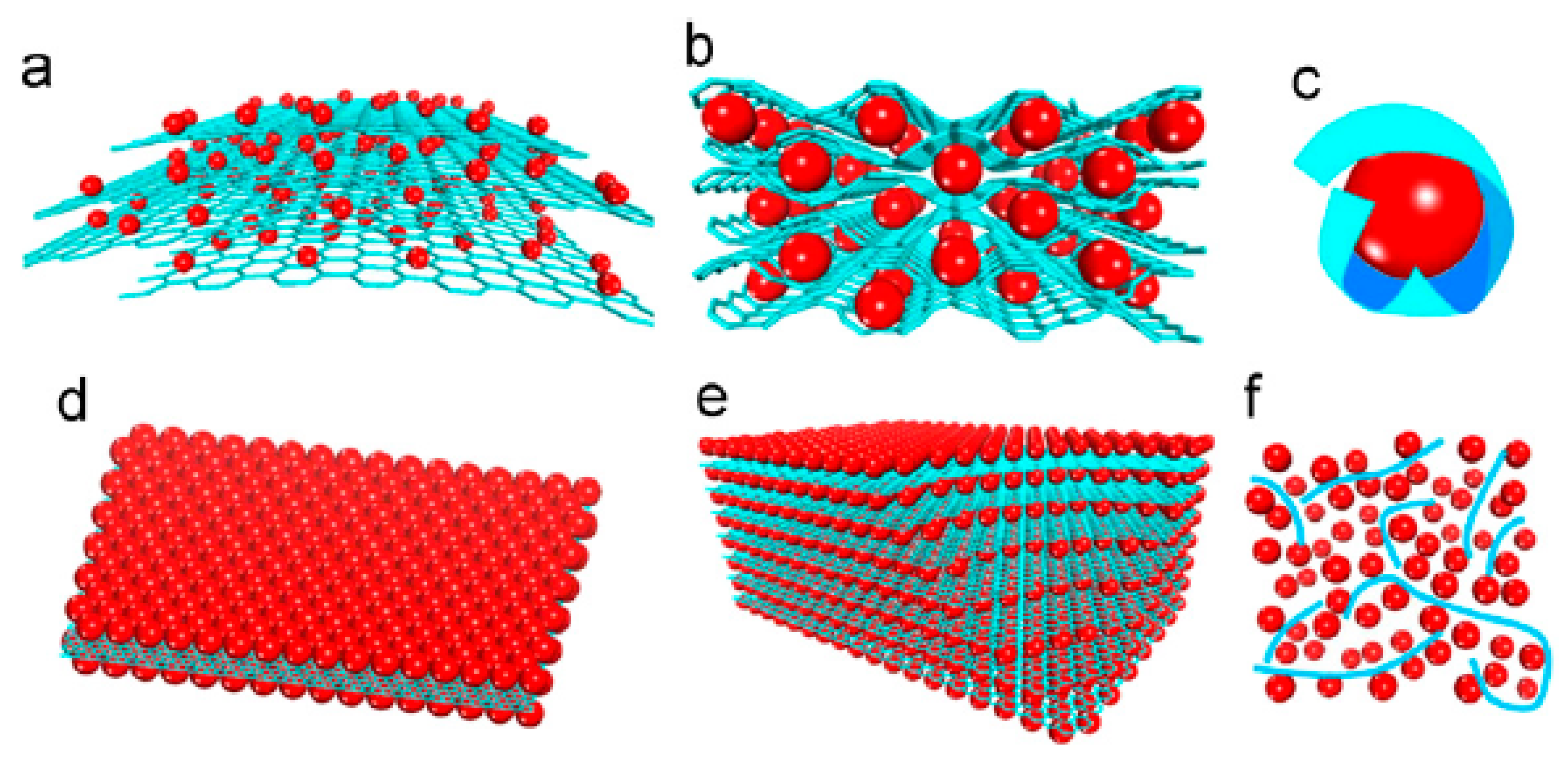

3. Single Element/GO or rGO Composites

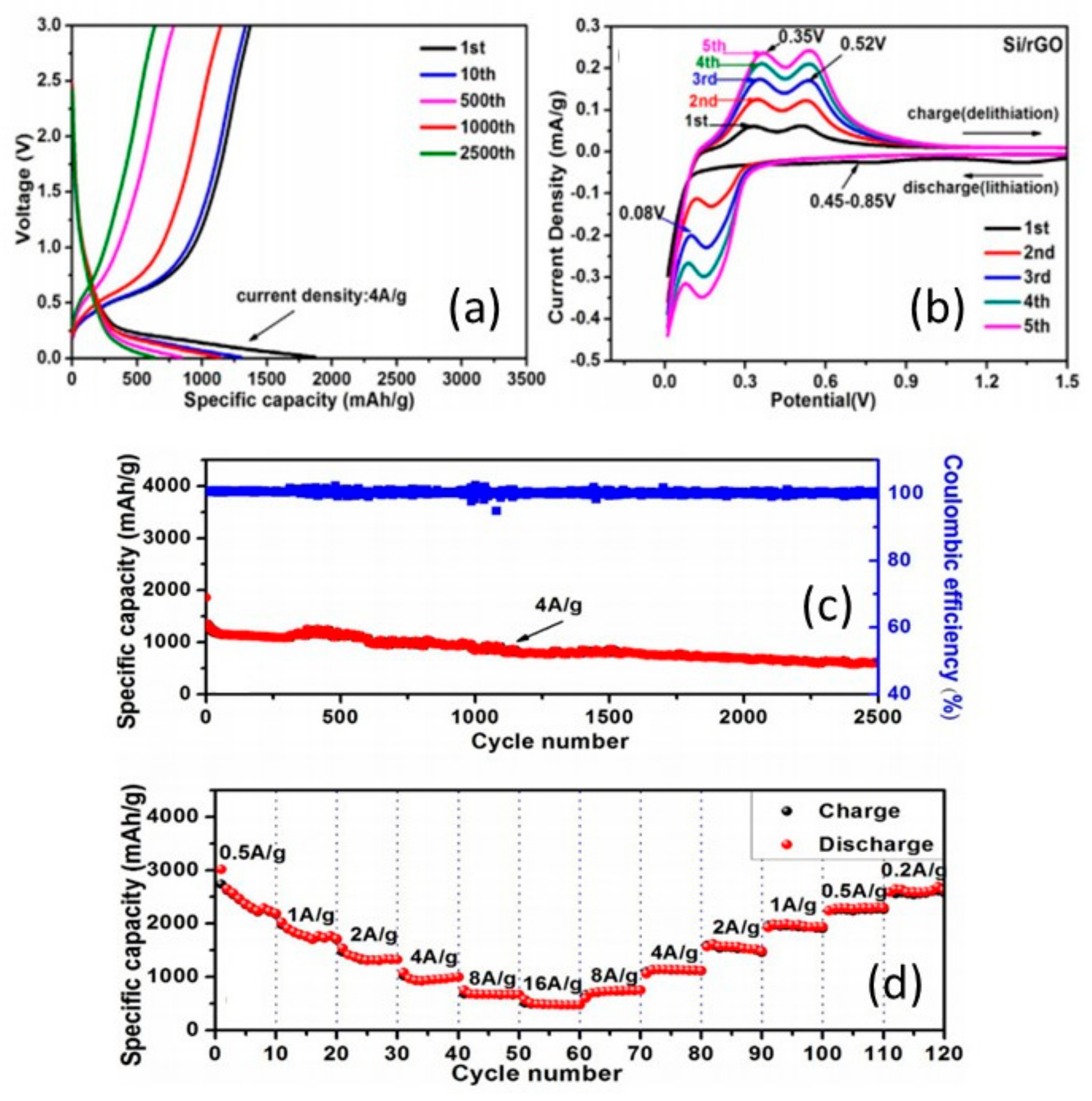

3.1. Silicon

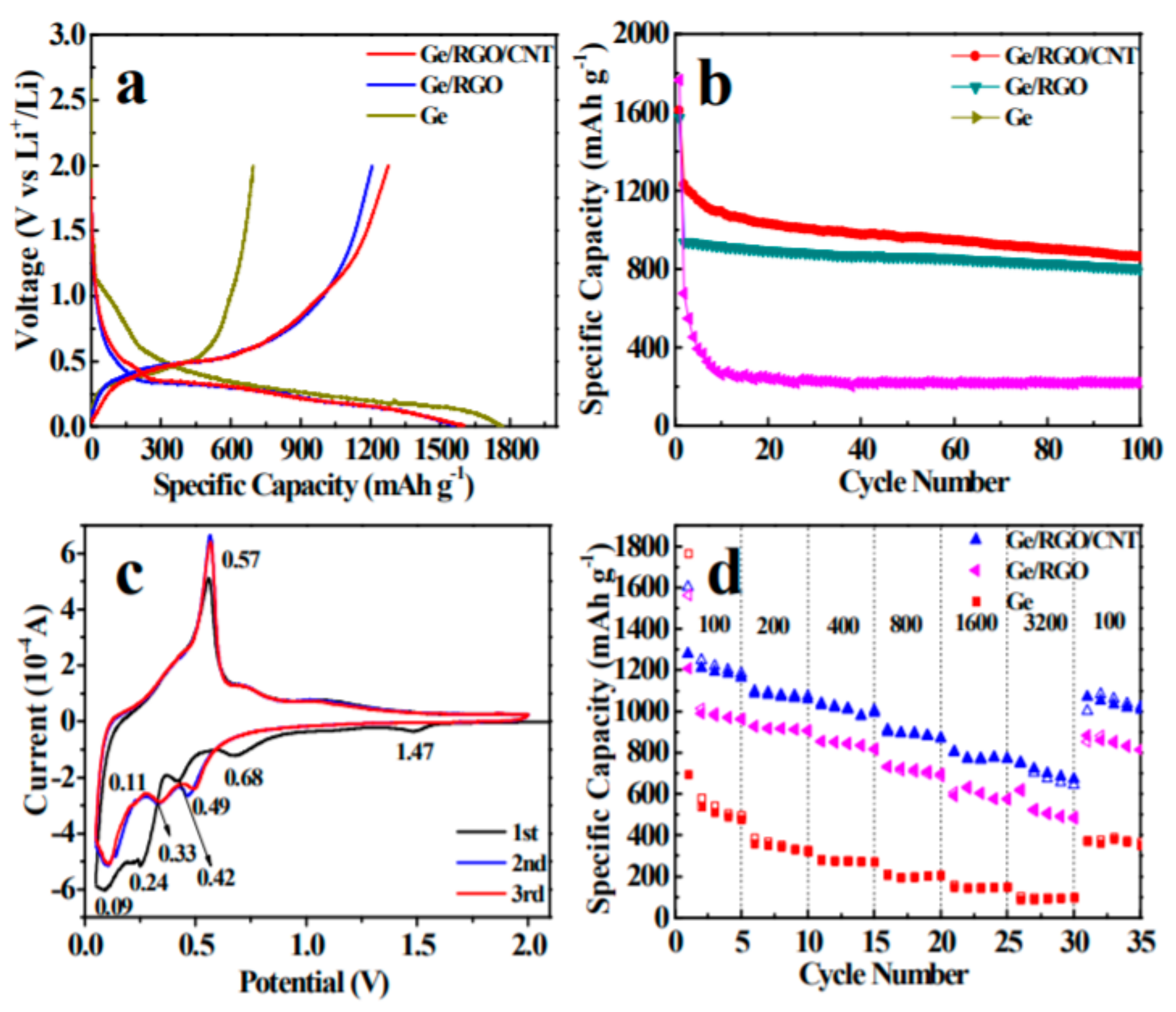

3.2. Germanium

3.3. Tin

4. Metal Oxide/rGO Composites

4.1. Silicon-Based Oxide Composites

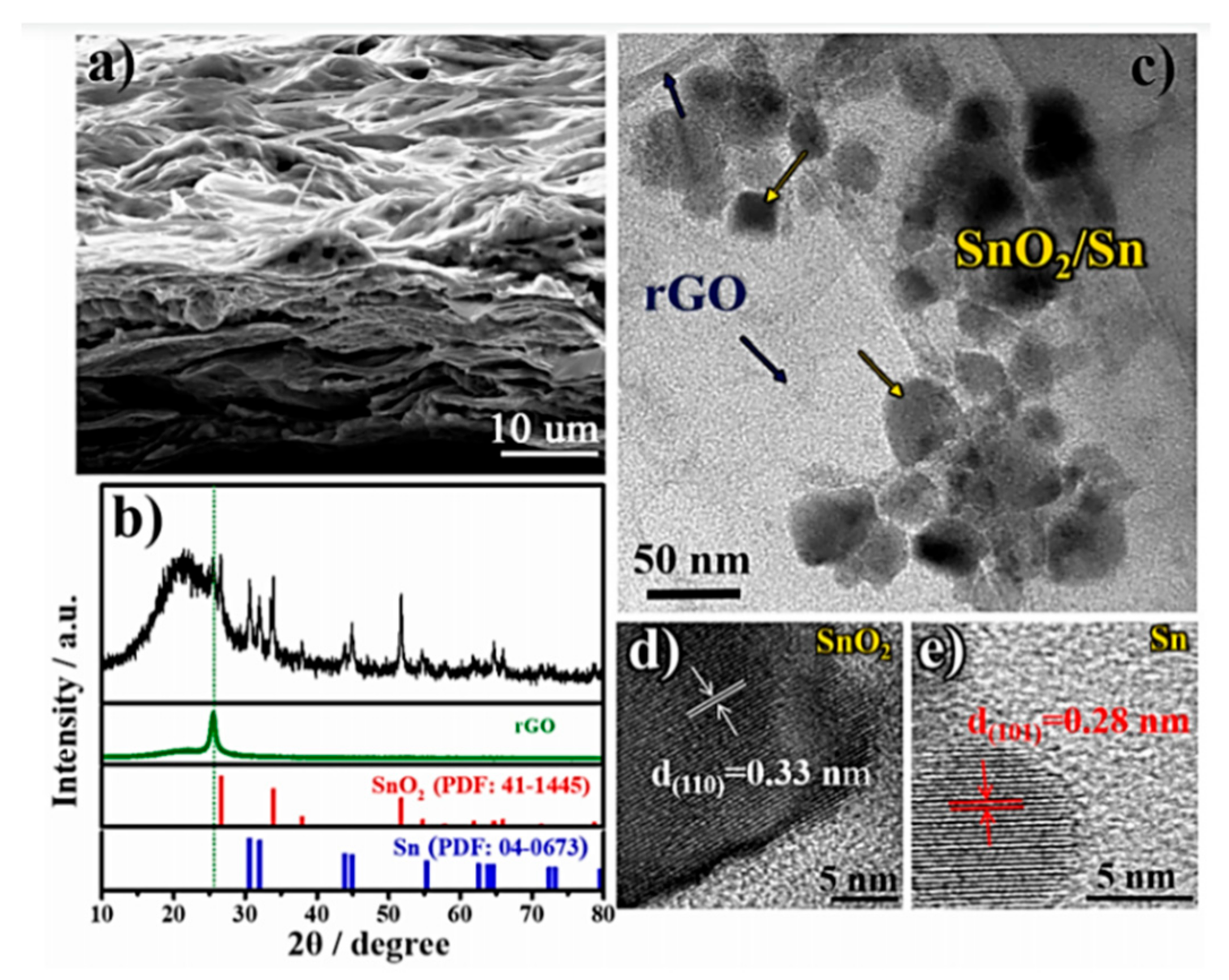

4.2. Tin-Based Oxide Composites

4.3. Manganese-Based Oxide Composites

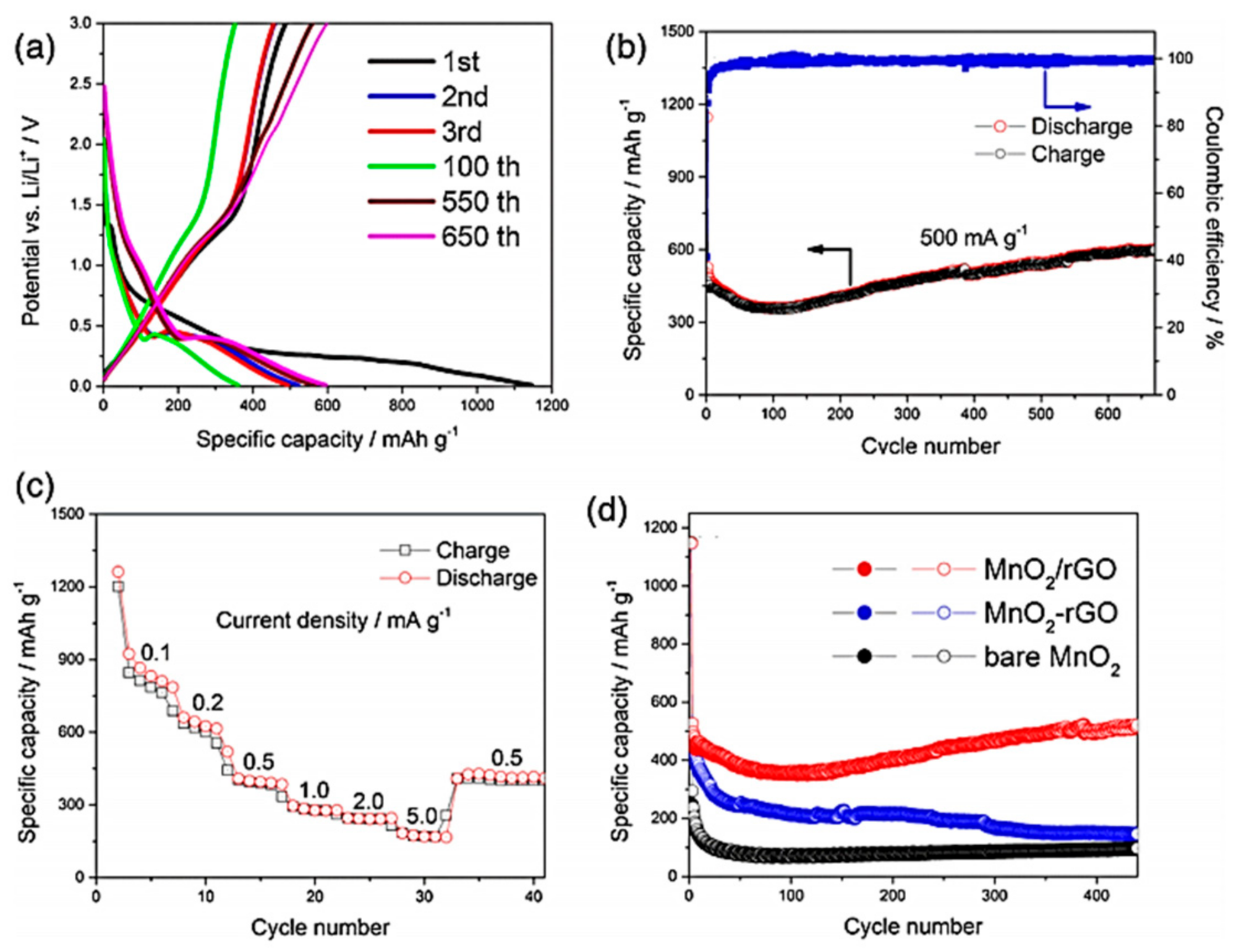

4.3.1. MnO2-Based Composite

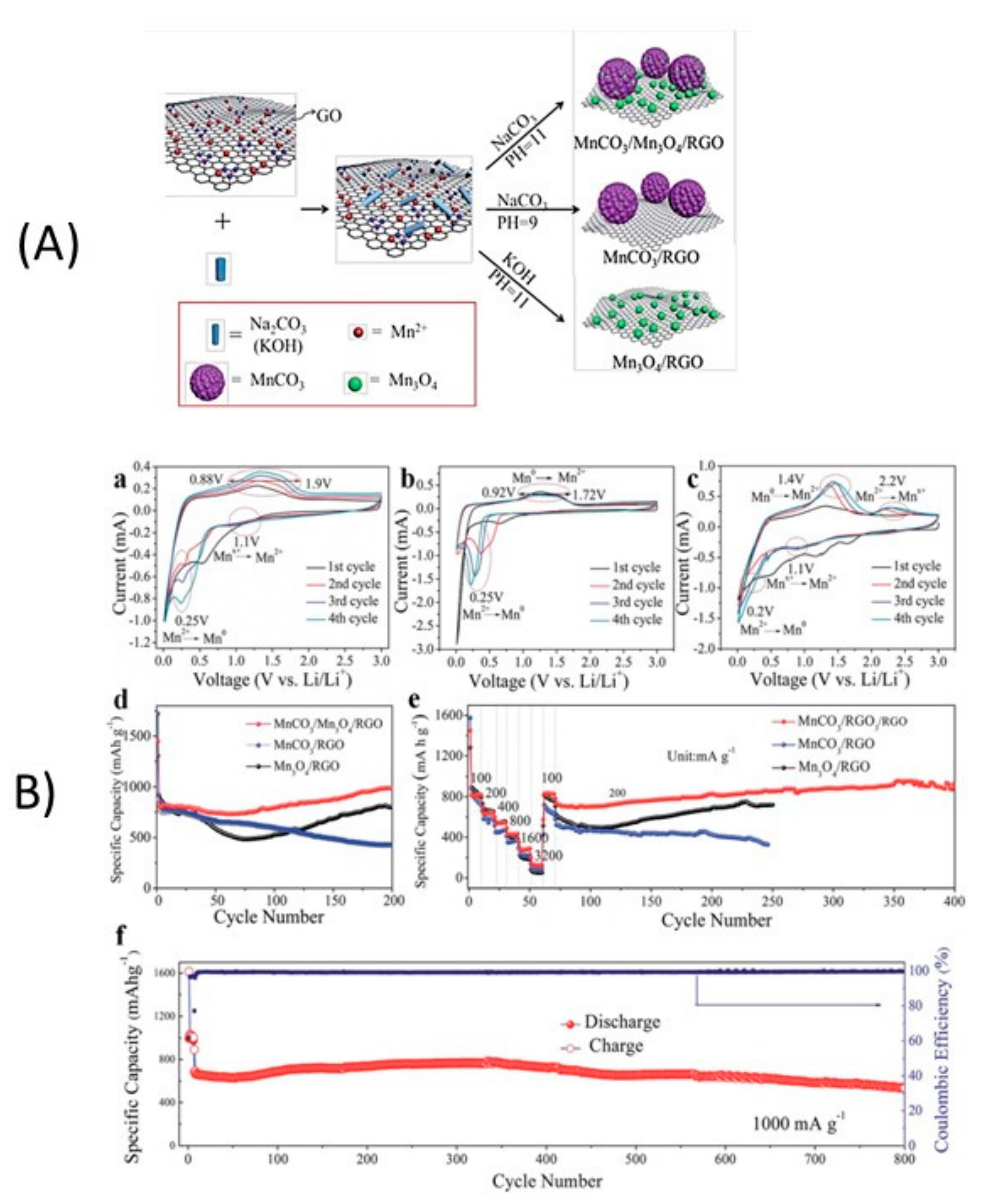

4.3.2. Mn3O4-Based Composite

4.3.3. MnO-Based Composites

4.4. Molybdenum-Based Oxide Composites

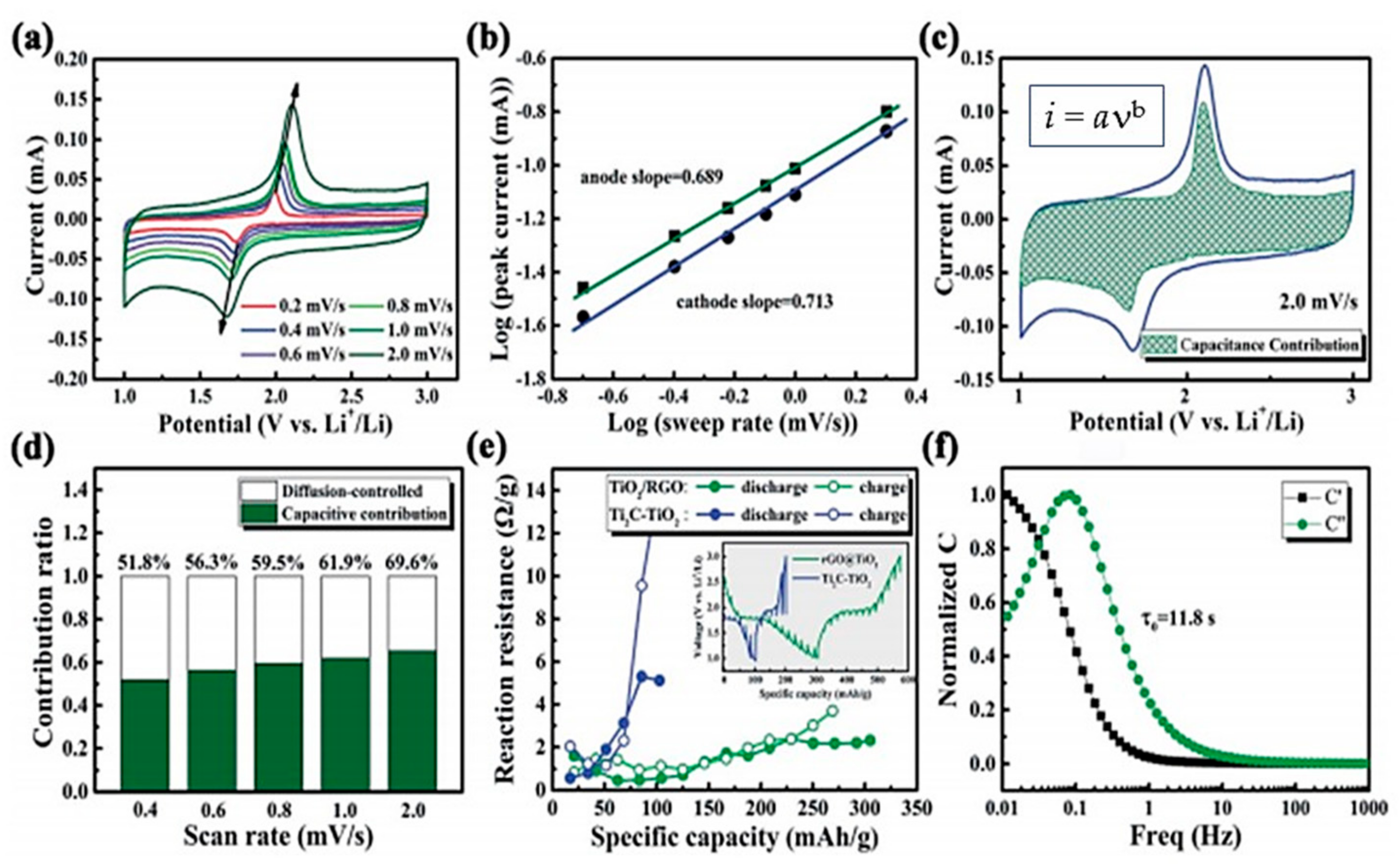

4.5. Titanium-Based Oxide Composites

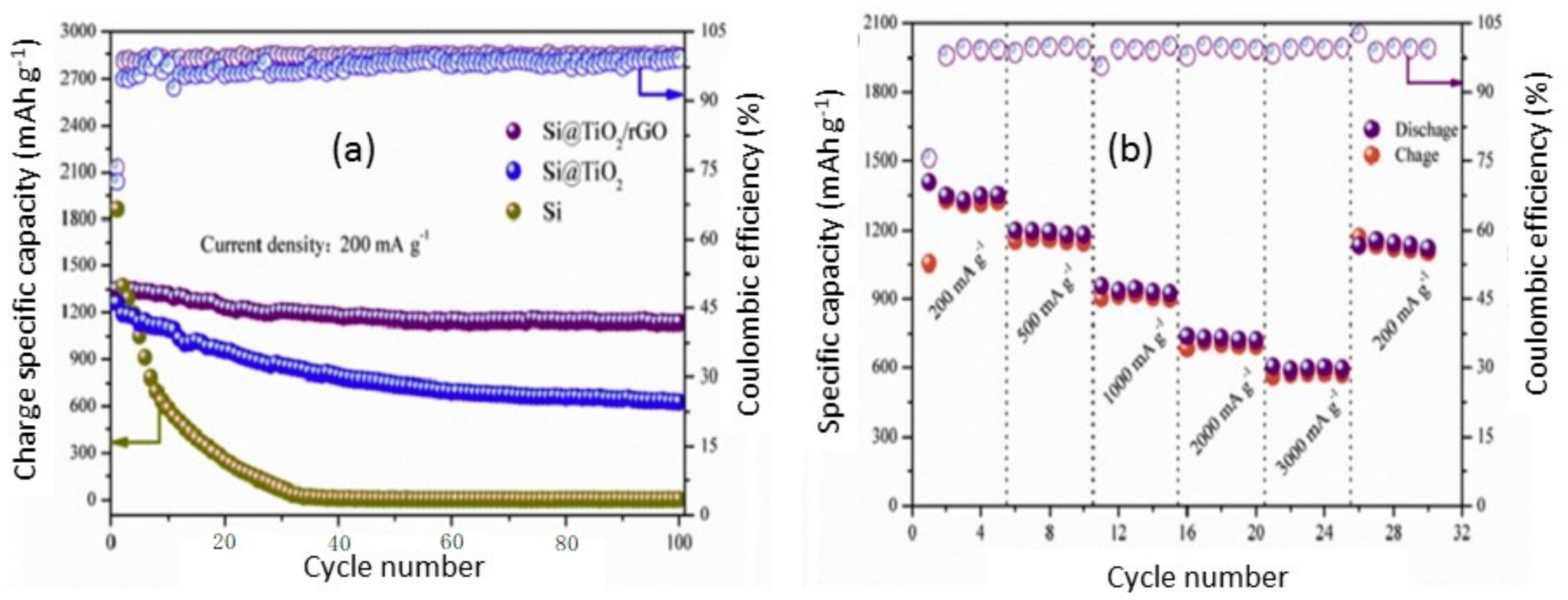

4.5.1. TiO2-Based Composites

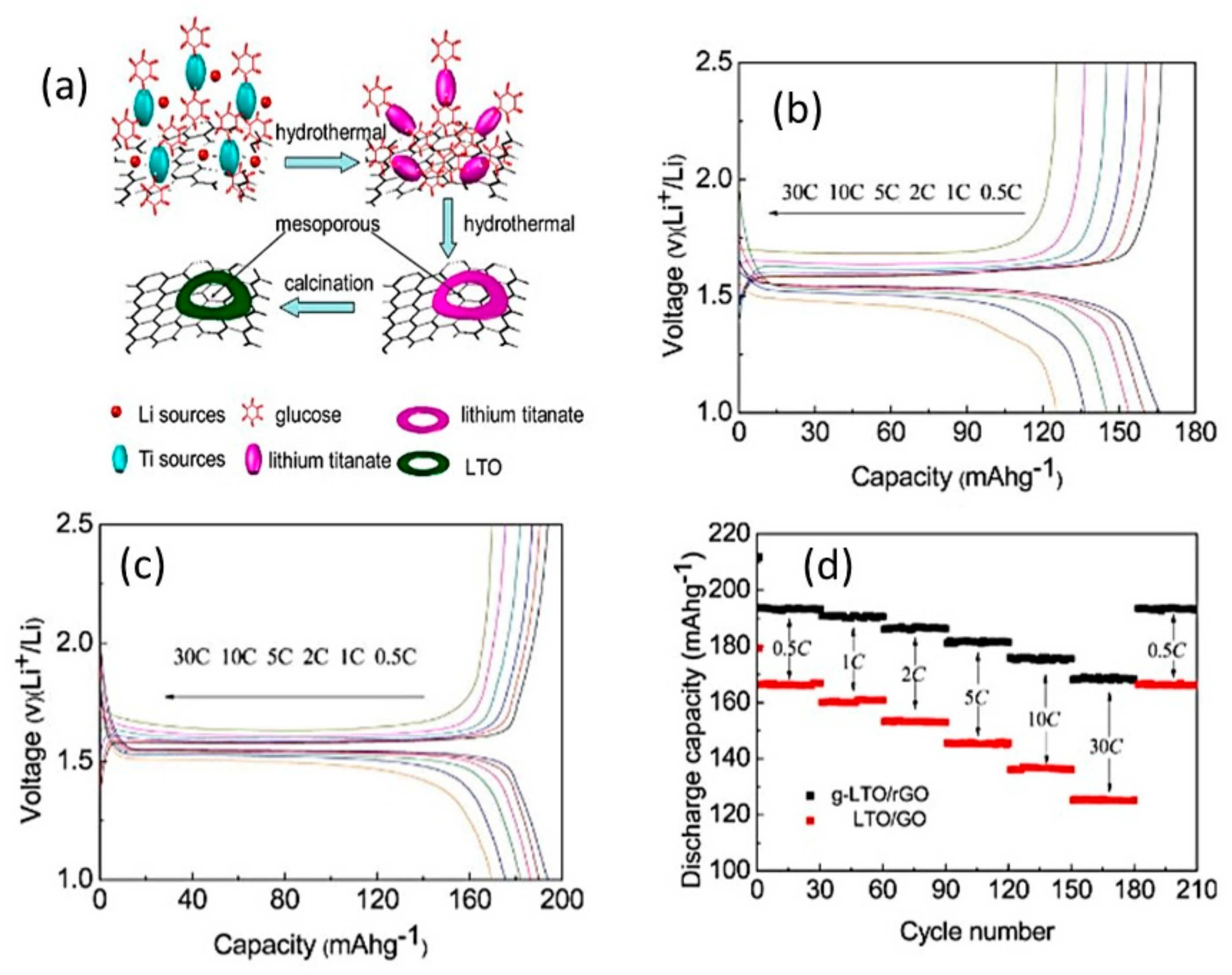

4.5.2. Li4Ti5O12-Based Composites

4.6. Iron-Based Oxide Composites

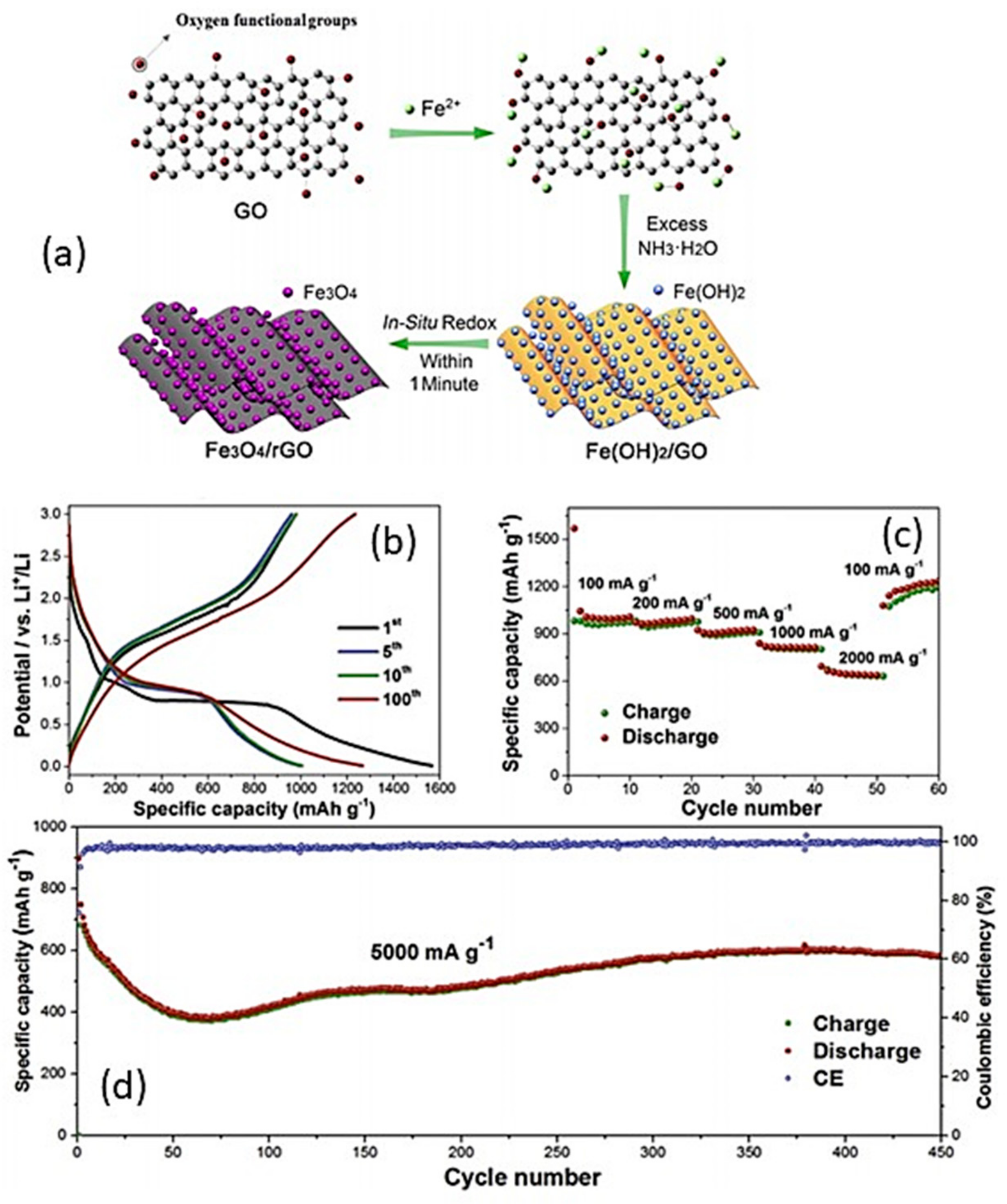

4.6.1. Fe3O4-Based Composites

4.6.2. Fe2O3-Based Composites

4.6.3. FeO-Based Composites

4.7. Vanadium-Based Oxide Composites

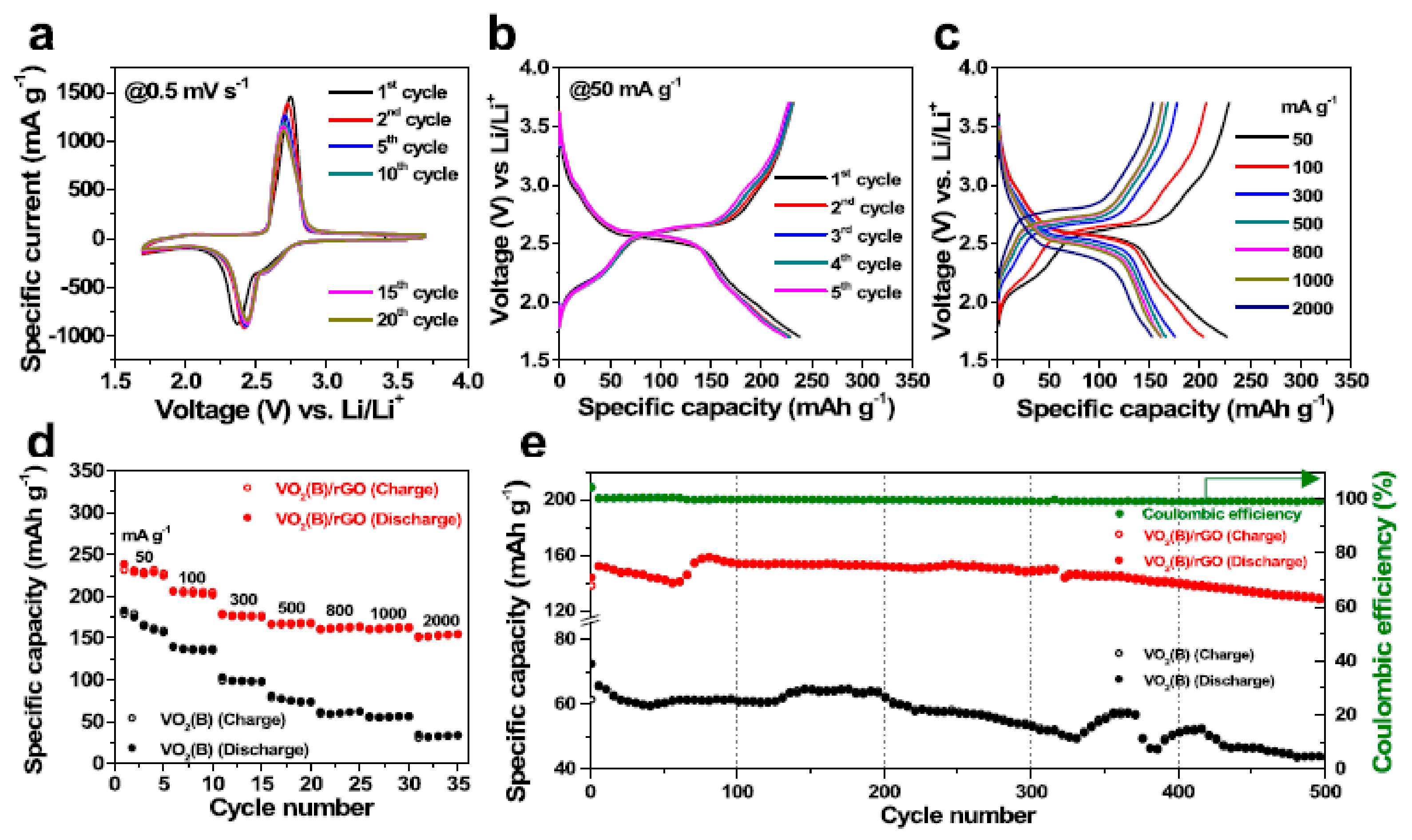

4.7.1. VO2-Based Composites

4.7.2. V2O3-Based Composites

4.7.3. V2O5-Based Composites

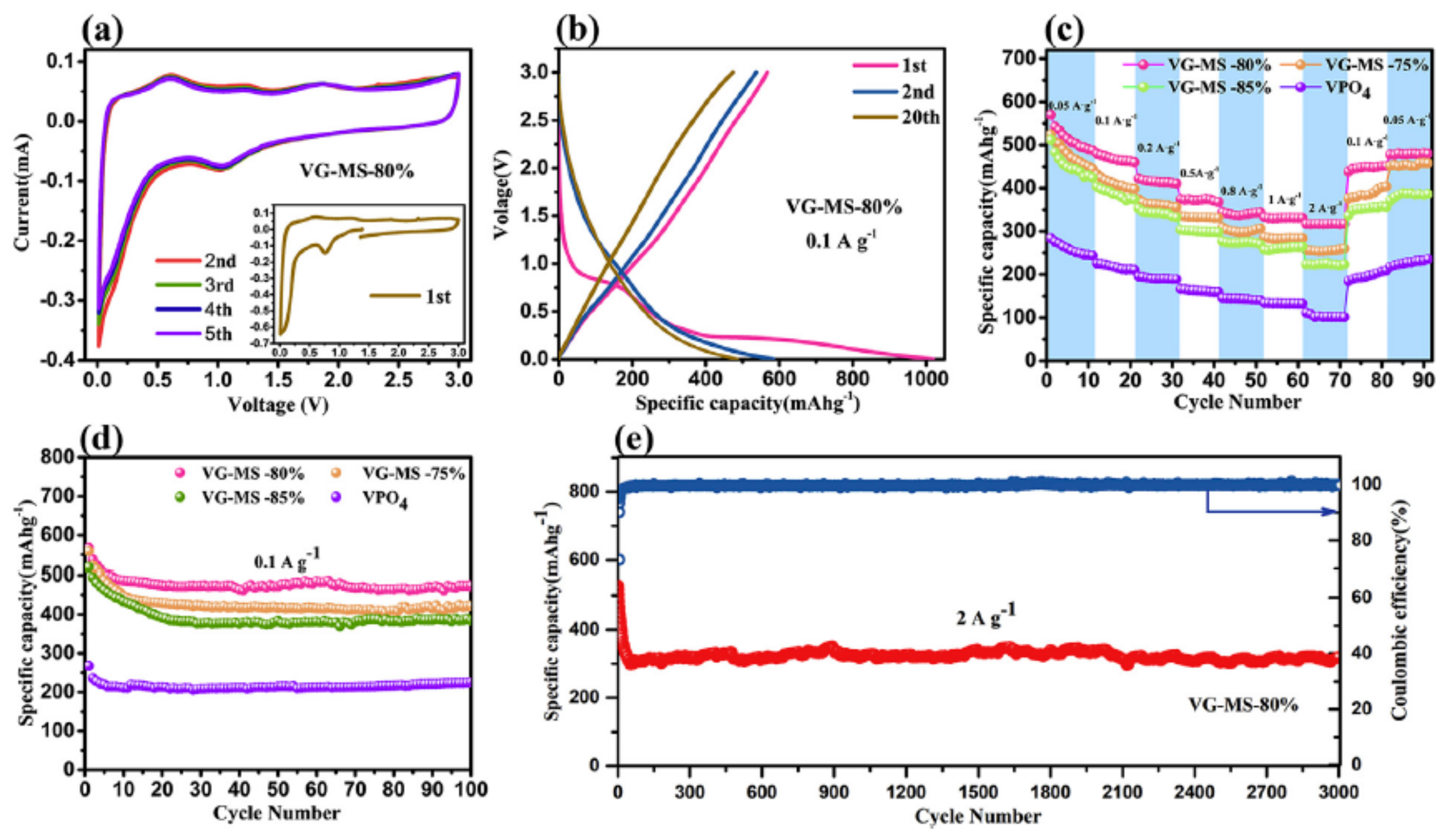

4.7.4. VPO4-Based Composites

4.8. Cobalt-Based Oxide Composites

4.8.1. Co3O4-Based Composites

4.8.2. CoO-Based Composites

4.9. Copper-Based Oxide Composites

4.10. Nickel-Based Oxide Composites

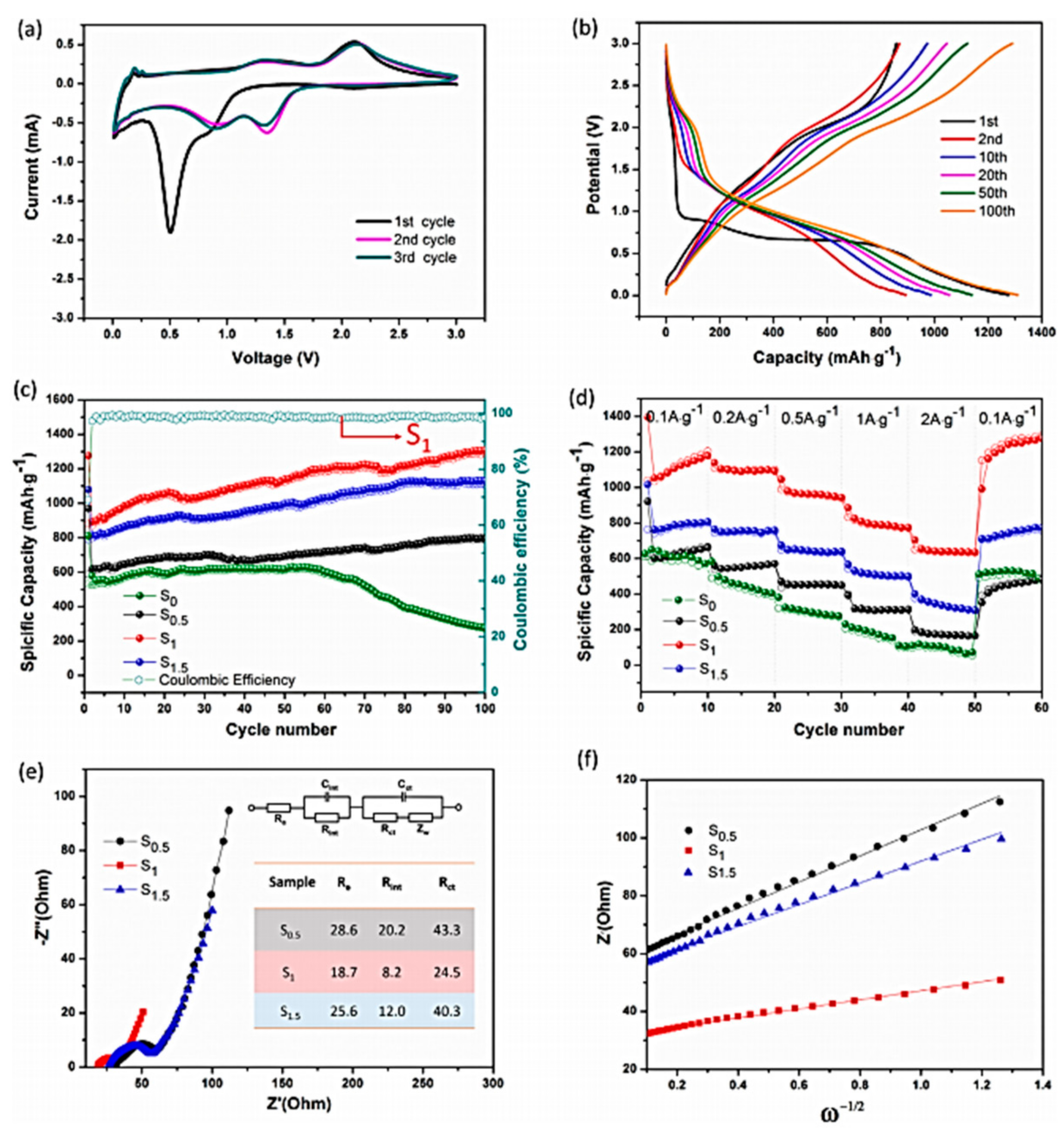

5. Anode Materials for Na-Ion Batteries

6. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Zaghib, K.; Mauger, A.; Julien, C. Rechargeable lithium batteries for energy storage in smart grids. Recharg. Lithium Batter. 2015, 81, 319–351. [Google Scholar]

- Mauger, A.; Armand, M.; Julien, C.M.; Zaghib, K. Challenges and issues facing lithium metal for solid-state rechargeable batteries. J. Power Sources 2017, 353, 333–342. [Google Scholar] [CrossRef]

- Reddy, M.V.; Rao, G.V.S.; Chowdari, B.V.R. Metal oxides and oxysalts as anode materials for Li ion batteries. Chem. Rev. 2013, 113, 5364–5457. [Google Scholar] [CrossRef] [PubMed]

- Ji, L.; Lin, Z.; Alcoutlabi, M.; Zhang, X. Recent developments in nanostructured anode materials for rechargeable lithium-ion batteries. Energy Environ. Sci. 2011, 4, 2682–2699. [Google Scholar] [CrossRef]

- Zhang, W.-J. A review of the electrochemical performance of alloy anodes for lithium-ion batteries. J. Power Sources 2011, 196, 13–24. [Google Scholar] [CrossRef]

- Goriparti, S.; Miele, E.; De Angelis, F.; Di Fabrizio, E.; Zaccaria, R.P.; Capiglia, C. Review on recent progress of nanostructured anode materials for Li-ion batteries. J. Power Sources 2014, 257, 421–443. [Google Scholar] [CrossRef]

- Hassoun, J.; Scrosati, B. Review—Advances in anode and electrolyte materials for the progress of lithium-ion and beyond lithium-ion batteries. J. Electrochem. Soc. 2015, 162, A2582–A2588. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Z.; Pan, F.; Cui, Y.; Amine, K. High-performance anode materials for rechargeable lithium-ion batteries. Electrochem. Energy Rev. 2018, 1, 35–53. [Google Scholar] [CrossRef]

- Yang, S.; Feng, X.; Ivanovici, S.; Müllen, K. Fabrication of graphene-encapsulated oxide nanoparticles: Towards high-performance anode materials for lithium storage. Angew. Chem. Int. Ed. 2010, 49, 8408–8411. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Y. Graphene-based nanocomposite anodes for lithium-ion batteries. Nanoscale 2014, 6, 11528–11552. [Google Scholar] [CrossRef]

- Mauger, A.; Xie, H.; Julien, C.M. Composite anodes for lithium-ion batteries: Status and trends. AIMS Mater. Sci. 2016, 3, 1054–1106. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Mahmood, N.; Zhang, C.; Yin, H.; Hou, Y. Graphene-based nanocomposites for energy storage and conversion in lithium batteries, supercapacitors and fuel cells. J. Mater. Chem. A 2014, 2, 15–32. [Google Scholar] [CrossRef]

- Han, S.; Wang, J.; Li, S.; Wu, D.; Feng, X. Graphene aerogel supported Fe5(PO4)4(OH)3·2H2O microspheres as high performance cathode for lithium ion batteries. J. Mater. Chem. A 2014, 2, 6174. [Google Scholar] [CrossRef]

- Li, F.; Jiang, X.; Zhao, J.; Zhang, S. Graphene oxide: A promising nanomaterial for energy and environmental applications. Nano Energy 2015, 16, 488–515. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, D.; Yin, Z.; Yan, Q.; Zhang, H. Graphene and graphene-based materials for energy storage applications. Small 2014, 10, 3480–3498. [Google Scholar] [CrossRef]

- Javed, K.; Oolo, M.; Savest, N.; Krumme, A. A review on graphene-based electrospun conductive nanofibers, supercapacitors, anodes and cathodes for lithium-ion batteries. Crit. Rev. Solid State Mater. Sci. 2019, 44, 427–443. [Google Scholar] [CrossRef]

- Chen, D.; Feng, H.; Li, J. Graphene oxide: Preparation, functionalization and electrochemical applications. Chem. Rev. 2012, 112, 6027–6053. [Google Scholar] [CrossRef]

- Kuila, T.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Recent advances in the efficient reduction of graphene oxide and its application as energy storage electrode materials. Nanoscale 2012, 5, 52–71. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Shua, F.; Guo, X.; Xue, D. High performance porous MnO@C composite anode materials for lithium-ion batteries. Electrochim. Acta 2016, 188, 793–800. [Google Scholar] [CrossRef]

- Gao, F.; Qin, S.-H.; Zang, Y.-H.; Gu, J.-F.; Qu, J. Highly efficient formation of Mn3O4-graphene oxide hybrid aerogels for use as the cathode material of high performance lithium ion batteries. New Carbon Mater. 2020, 35, 121–130. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, X.; Yao, K.; Zhang, J.; Liu, Z. A SnO2/graphene composite as a high stability electrode for lithium ion batteries. Carbon 2011, 49, 133–139. [Google Scholar] [CrossRef]

- Deng, Y.; Fang, C.; Chen, G. The developments of SnO2/graphene nanocomposites as anode materials for high performance lithium ion batteries: A review. J. Power Sources 2016, 304, 81–101. [Google Scholar] [CrossRef]

- Sun, Y.; Hu, X.; Luo, W.; Huang, Y. Self-assembled hierarchical MoO2/graphene nanoarchitectures and their application as a high-performance anode material for lithium-ion batteries. ACS Nano 2011, 5, 7100–7107. [Google Scholar] [CrossRef] [PubMed]

- Sennu, P.; Kim, H.S.; An, J.Y.; Aravindan, V.; Lee, Y.-S. Synthesis of 2D/2D structured mesoporous Co3O4 nanosheet/N-doped reduced graphene oxide composites as a highly stable negative electrode for lithium battery applications. Chem. Asian J. 2015, 10, 1776–1783. [Google Scholar] [CrossRef]

- Li, X.; Huang, X.; Liu, D.; Wang, X.; Song, S.; Zhou, L.; Zhang, H. Synthesis of 3D hierarchical Fe3O4/graphene composites with high lithium storage capacity and for controlled drug delivery. J. Phys. Chem. C 2011, 115, 21567–21573. [Google Scholar] [CrossRef]

- Wang, R.; Xu, C.; Du, M.; Sun, J.; Gao, L.; Zhang, P.; Yao, H.; Lin, C. Solvothermal-induced self-assembly of Fe2O3/GS aerogels for high Li-storage and excellent stability. Small 2014, 10, 2260–2269. [Google Scholar] [CrossRef]

- Wu, P.; Wang, H.; Tanga, Y.; Zhou, Y.; Lu, T. Three-dimensional interconnected network of graphene-wrapped porous silicon spheres: In situ magnesiothermic-reduction synthesis and enhanced lithium-storage capabilities. ACS Appl. Mater. Interfaces 2014, 6, 3546–3552. [Google Scholar] [CrossRef]

- Ren, J.-G.; Wu, Q.-H.; Tang, H.; Hong, G.; Zhang, W.; Lee, S.-T. Germanium–graphene composite anode for high-energy lithium batteries with long cycle life. J. Mater. Chem. A 2012, 1, 1821–1826. [Google Scholar] [CrossRef]

- Chockla, A.M.; Panthani, M.G.; Holmberg, V.C.; Hessel, C.M.; Reid, D.K.; Bogart, T.D.; Harris, J.T.; Mullins, C.B.; Korgel, B.A. Electrochemical lithiation of graphene-supported silicon and germanium for rechargeable batteries. J. Phys. Chem. C 2012, 116, 11917–11923. [Google Scholar] [CrossRef]

- Yue, W.; Yang, S.; Liu, Y.; Yang, X. A facile synthesis of mesoporous graphene-tin composites as high-performance anodes for lithium-ion batteries. Mater. Res. Bull. 2013, 48, 1575–1580. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Zhou, G.; Yin, L.-C.; Ren, W.; Li, F.; Cheng, H.-M. Graphene/metal oxide composite electrode materials for energy storage. Nano Energy 2012, 1, 107–131. [Google Scholar] [CrossRef]

- Jana, A.; Scheer, E.; Polarz, S. Synthesis of graphene–transition metal oxide hybrid nanoparticles and their application in various fields. Beilstein J. Nanotechnol. 2017, 8, 688–714. [Google Scholar] [CrossRef]

- Ke, Q.; Wang, J. Graphene-based materials for supercapacitor electrodes—A review. J. Materiomics 2016, 2, 37–54. [Google Scholar] [CrossRef]

- Chee, W.K.; Lim, H.N.; Zainal, Z.; Huang, N.M.; Harrison, I.; Andou, Y. Flexible graphene-based supercapacitors: A review. J. Phys. Chem. C 2016, 120, 4153–4172. [Google Scholar] [CrossRef]

- Park, S.; Ruoff, R.S. Chemical methods for the production of graphenes. Nat. Nanotechnol. 2009, 4, 217–224. [Google Scholar] [CrossRef]

- Brodie, B.C. Sur le poids atomique du graphite. Ann. Chem. Phys. 1860, 59, 466–472. [Google Scholar]

- Becerril, H.A.; Mao, J.; Liu, Z.; Stoltenberg, R.M.; Bao, Z.; Chen, Y. Evaluation of solution-processed reduced graphene oxide films as transparent conductors. ACS Nano 2008, 2, 463–470. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Qiu, X.; Liu, Y.; Wang, L.; Fan, L.-Z. Reverse microemulsion synthesis of nickel-cobalt hexacyanoferrate/reduced graphene oxide nanocomposites for high-performance supercapacitors and sodium ion batteries. Appl. Surf. Sci. 2018, 434, 1285–1292. [Google Scholar] [CrossRef]

- Wang, M.-S.; Song, W.-L.; Fan, L.-Z. Three-dimensional interconnected network of graphene-wrapped silicon/carbon nanofiber hybrids for binder-free anodes in lithium-ion batteries. ChemElectroChem 2015, 2, 1699–1706. [Google Scholar] [CrossRef]

- Si, Y.; Samulski, E.T. Synthesis of water soluble graphene. Nano Lett. 2008, 8, 1679–1682. [Google Scholar] [CrossRef]

- Rao, S.; Upadhyay, J.; Polychronopoulou, K.; Umer, R.; Das, R. Reduced graphene oxide: Effect of reduction on electrical conductivity. J. Compos. Sci. 2018, 2, 25. [Google Scholar] [CrossRef]

- Wang, H.; Tian, H.-W.; Wang, X.-W.; Qiao, L.; Wang, S.-M.; Wang, X.-L.; Zheng, W.-T.; Liu, Y.-C. Electrical conductivity of alkaline-reduced graphene oxide. Chem. Res. Chinese Univ. 2011, 27, 857–861. [Google Scholar]

- Tokarczyk, M.; Kowalski, G.; Witowski, A.; Kozinski, R.; Librant, K.; Aksienionek, M.; Lipińska, L.; Ciepielewski, P. Structural and electronic properties of graphene oxide and reduced graphene oxide papers prepared by high pressure and high temperature treatment. Acta Phys. Pol. A 2014, 126, 1190–1194. [Google Scholar] [CrossRef]

- Marquez, C.; Rodríguez, N.; Ruiz, R.; Gamiz, F. Electrical characterization and conductivity optimization of laser reduced graphene oxide on insulator using point-contact methods. RSC Adv. 2016, 6, 46231–46237. [Google Scholar] [CrossRef]

- Shabir, A.; Sehrawat, P.; Julien, C.M.; Islam, S.S. Reversible synthesis of GO: Role of differential bond structure transformation in fine-tuning photodetector response. Nanotechnology 2020, 32, 045601. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Dikin, D.A.; Stankovich, S.; Zimney, E.J.; Piner, R.D.; Dommett, G.H.B.; Evmenenko, G.; Nguyen, S.T.; Ruoff, R.S. Preparation and characterization of graphene oxide paper. Nat. Cell Biol. 2007, 448, 457–460. [Google Scholar] [CrossRef] [PubMed]

- Chua, C.K.; Pumera, M. Reduction of graphene oxide with substituted borohydrides. J. Mater. Chem. A 2012, 1, 1892–1898. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Ma, G.; Wang, Z.; Liu, K.; Liu, H. Ethylene glycol reduced graphene oxide/polypyrrole composite for supercapacitor. Electrochim. Acta 2013, 88, 519–525. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, H.; Shen, G.; Cheng, P.; Zhang, J.; Guo, S. Reduction of graphene oxide via L-ascorbic acid. Chem. Commun. 2010, 46, 1112–1114. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Wang, K.; Wei, T.; Yan, J.; Song, L.; Shao, B. An environmentally friendly and efficient route for the reduction of graphene oxide by aluminum powder. Carbon 2010, 48, 1686–1689. [Google Scholar] [CrossRef]

- Maddineni, S.B.; Mandal, B.K. Biofabrication of reduction of graphene oxide nanosheets using terminalia Bellirica fruit extract. Current Nanosci. 2016, 12, 94–102. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Y.; Wang, J.; Chan-Park, M.B. Reducing graphene oxide with a modified Birch reaction. RSC Adv. 2015, 5, 11124–11127. [Google Scholar] [CrossRef]

- Li, B.; Cao, H.; Shao, J.; Qu, M. Enhanced anode performances of the Fe3O4–carbon–rGO three dimensional composite in lithium ion batteries. Chem. Commun. 2011, 47, 10374–10376. [Google Scholar] [CrossRef]

- Mei, L.; Xu, C.; Yang, T.; Ma, J.; Chen, L.; Li, Q.; Wang, T. Superior electrochemical performance of ultrasmall SnS2 nanocrystals decorated on flexible RGO in lithium-ion batteries. J. Mater. Chem. A 2013, 1, 8658–8664. [Google Scholar] [CrossRef]

- Patil, S.B.; Nagaraju, G.; Kishore, B.; Nagaraju, G.; Dupont, J.; Nagaraju, G. High capacity MoO3/rGO nanocomposite anode for lithium ion batteries: An intuition into the conversion mechanism of MoO3. New J. Chem. 2018, 42, 18569–18577. [Google Scholar] [CrossRef]

- Paek, S.-M.; Yoo, E.; Honma, I. Enhanced cyclic performance and lithium storage capacity of SnO2/graphene nanoporous electrodes with three-dimensionally delaminated flexible structure. Nano Lett. 2009, 9, 72–75. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Wang, D.-W.; Li, F.; Zhang, L.; Li, N.; Wu, Z.-S.; Wen, L.; Lu, G.Q. (Max); Cheng, H.-M. Graphene-wrapped Fe3O4 anode material with improved reversible capacity and cyclic stability for lithium ion batteries. Chem. Mater. 2010, 22, 5306–5313. [Google Scholar] [CrossRef]

- Ma, C.; Xu, J.; Alvarado, J.; Qu, B.; Somerville, J.; Lee, J.Y.; Meng, Y.S. Investigating the energy storage mechanism of SnS2-rGO composite anode for advanced Na-ion batteries. Chem. Mater. 2015, 27, 5633–5640. [Google Scholar] [CrossRef]

- Zhang, Q.; Karthick, R.; Zhao, X.; Zhang, L.-G.; Shi, Y.; Sun, L.; Su, C.-Y.; Chen, F. Sb nanoparticle decorated rGO as a new anode material in aqueous chloride ion batteries. Nanoscale 2020, 12, 12268–12274. [Google Scholar] [CrossRef]

- Zensich, M.; Jaumann, T.; Morales, G.M.; Giebeler, L.; Barbero, C.; Balach, J. A top-down approach to build Li2S@rGO cathode composites for high-loading lithium–sulfur batteries in carbonate-based electrolyte. Electrochim. Acta 2018, 296, 243–250. [Google Scholar] [CrossRef]

- Abalonyx. Available online: https://www.abalonyx.no/?cat=42023. (accessed on 17 September 2020).

- Kimiagar, S.; Rashidi, N.; Ghadim, E.E. Investigation of the effects of temperature and time on reduction of graphene oxide by microwave hydrothermal reactor. Bull. Mater. Sci. 2015, 38, 1699–1704. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1290. [Google Scholar] [CrossRef]

- Tian, L.; Zhuang, Q.; Yueli, S.; Shigang, S.; Chen, J.; Lu, F.; Sun, S. Mechanism of intercalation and deintercalation of lithium ions in graphene nanosheets. Chin. Sci. Bull. 2011, 56, 3204–3212. [Google Scholar] [CrossRef]

- Datta, D.; Li, J.; Koratkar, N.; Shenoy, V.B. Enhanced lithiation in defective graphene. Carbon 2014, 80, 305–310. [Google Scholar] [CrossRef]

- Lin, K.-H.; Kuo, C.-L. Lithiation mechanisms and lithium storage capacity of reduced graphene oxide nanoribbons: A first-principles study. J. Mater. Chem. A 2017, 5, 4912–4922. [Google Scholar] [CrossRef]

- Pan, D.; Wang, S.; Zhao, B.; Wu, M.; Zhang, H.; Wang, Y.; Jiao, Z. Li Storage properties of disordered graphene nanosheets. Chem. Mater. 2009, 21, 3136–3142. [Google Scholar] [CrossRef]

- Robledo, C.; Otero, M.; Luque, G.L.; Camara, O.; Barraco, D.; Rojas, M.; Leiva, E. First-principles studies of lithium storage in reduced graphite oxide. Electrochim. Acta 2014, 140, 232–237. [Google Scholar] [CrossRef]

- Randviir, E.P.; Banks, C.E. Graphene and Graphene Oxide for Energy Storage; Wiley: Hoboken, NJ, USA, 2017; pp. 725–744. [Google Scholar]

- Kühne, M. Lithium Intercalation in Bilayer Graphene Devices; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2018; pp. 1–92. [Google Scholar]

- Matsuo, Y.; Sasaki, T.; Maruyama, S.; Inamoto, J.; Okamoto, Y.; Tamura, N. Electrochemical intercalation behaviors of lithium ions into graphene-like graphite. J. Electrochem. Soc. 2018, 165, A2409–A2414. [Google Scholar] [CrossRef]

- Ji, K.; Han, J.; Hirata, A.; Fujita, T.; Shen, Y.; Ning, S.; Liu, P.; Kashani, H.; Tian, Y.; Ito, Y.; et al. Lithium intercalation into bilayer graphene. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef]

- Kheirabadi, N.; Shafiekhani, A. Graphene/Li-ion battery. J. Appl. Phys. 2012, 112, 124323. [Google Scholar] [CrossRef]

- Wang, C.; Li, D.; Too, C.O.; Wallace, G.G. Electrochemical properties of graphene paper electrodes used in lithium batteries. Chem. Mater. 2009, 21, 2604–2606. [Google Scholar] [CrossRef]

- Gedela, V.; Puttapati, S.K.; Nagavolu, C.; Srikanth, V.V.S.S. A unique solar radiation exfoliated reduced graphene oxide/polyaniline nanofibers composite electrode material for supercapacitors. Mater. Lett. 2015, 152, 177–180. [Google Scholar] [CrossRef]

- Puttapati, S.K.; Gedela, V.; Srikanth, V.V.S.S.; Reddy, M.V.; Adams, S.; Chowdari, B.V.R. Unique reduced graphene oxide as efficient anode material in Li ion battery. Bull. Mater. Sci. 2018, 41, 53. [Google Scholar] [CrossRef]

- Kim, H.; Seo, D.-H.; Kim, S.-W.; Kim, J.; Kang, K. Highly reversible Co3O4/graphene hybrid anode for lithium rechargeable batteries. Carbon 2011, 49, 326–332. [Google Scholar] [CrossRef]

- Li, B.; Cao, H.; Shao, J.; Li, G.; Qu, M.; Yin, G. Co3O4@graphene Composites as Anode Materials for High-Performance Lithium Ion Batteries. Inorg. Chem. 2011, 50, 1628–1632. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, X.; Xie, Y.; Yi, N.; Huang, Y.; Chen, Y. Pyrolytic carbon-coated Si nanoparticles on elastic graphene framework as anode materials for high-performance lithium-ion batteries. Carbon 2015, 82, 161–167. [Google Scholar] [CrossRef]

- Ji, J.; Ji, H.; Zhang, L.L.; Zhao, X.; Bai, X.; Fan, X.; Zhang, F.; Ruoff, R.S. Graphene-encapsulated Si on ultrathin-graphite foam as anode for high capacity lithium-ion batteries. Adv. Mater. 2013, 25, 4673–4677. [Google Scholar] [CrossRef] [PubMed]

- Lin, N.; Zhou, J.; Zhu, Y.; Qian, Y. Embedding silicon nanoparticles in graphene based 3D framework by cross-linking reaction for high performance lithium ion batteries. J. Mater. Chem. A 2014, 2, 19604–19608. [Google Scholar] [CrossRef]

- Chang, J.; Huang, X.; Zhou, G.; Cui, S.; Mao, S.; Chen, J. Three-dimensional carbon-coated Si/rGO nanostructures anchored by nickel foam with carbon nanotubes for Li-ion battery applications. Nano Energy 2015, 15, 679–687. [Google Scholar] [CrossRef]

- Wang, B.; Li, X.; Zhang, X.; Luo, B.; Jin, M.; Liang, M.; Dayeh, S.A.; Picraux, S.T.; Zhi, L. Adaptable silicon–carbon nanocables sandwiched between reduced graphene oxide sheets as lithium ion battery anodes. ACS Nano 2013, 7, 1437–1445. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.; Li, B.; Zhang, J.; Lian, F.; Kong, X.; Qu, M. Synthesis and superior anode performance of TiO2@reduced graphene oxide nanocomposites for lithium ion batteries. J. Mater. Chem. 2012, 22, 9759–9766. [Google Scholar] [CrossRef]

- Ji, L.; Zheng, H.; Ismach, A.; Tan, Z.; Xun, S.; Lin, E.; Battaglia, V.; Srinivasan, V.; Zhang, Y. Graphene/Si multilayer structure anodes for advanced half and full lithium-ion cells. Nano Energy 2012, 1, 164–171. [Google Scholar] [CrossRef]

- De Guzman, R.C.; Yang, J.; Cheng, M.M.-C.; Salley, S.O.; Ng, K.Y.S. Effects of graphene and carbon coating modifications on electrochemical performance of silicon nanoparticle/graphene composite anode. J. Power Sources 2014, 246, 335–345. [Google Scholar] [CrossRef]

- Wong, D.P.; Tseng, H.-P.; Chen, Y.-T.; Hwang, B.-J.; Chen, L.-C.; Chen, K.-H. A stable silicon/graphene composite using solvent exchange method as anode material for lithium ion batteries. Carbon 2013, 63, 397–403. [Google Scholar] [CrossRef]

- Xiang, H.; Zhang, K.; Ji, G.; Lee, J.Y.; Zou, C.; Chen, X.; Wu, J. Graphene/nanosized silicon composites for lithium battery anodes with improved cycling stability. Carbon 2011, 49, 1787–1796. [Google Scholar] [CrossRef]

- Lee, J.K.; Smith, K.B.; Hayner, C.M.; Kung, H.H. Silicon nanoparticles–graphene paper composites for Li ion battery anodes. Chem. Commun. 2010, 46, 2025–2027. [Google Scholar] [CrossRef]

- Julien, C.M.; Mauger, A.; Vijh, A.; Zaghib, K. Lithium Batteries: Science and Technology; Springer: Cham, Switzerland, 2016; pp. 323–429. [Google Scholar]

- Chou, S.-L.; Wang, J.-Z.; Choucair, M.; Liu, H.-K.; Stride, J.A.; Dou, S.-X. Enhanced reversible lithium storage in a nanosize silicon/graphene composite. Electrochem. Commun. 2010, 12, 303–306. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, X.; Pan, D. Solutions for the problems of silicon–carbon anode materials for lithium-ion batteries. R. Soc. Open Sci. 2018, 5, 172370. [Google Scholar] [CrossRef] [PubMed]

- Jamaluddin, A.; Umesh, B.; Chen, F.; Chang, J.-K.; Su, C.-Y. Facile synthesis of core–shell structured Si@graphene balls as a high-performance anode for lithium-ion batteries. Nanoscale 2020, 12, 9616–9627. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Zhang, Z.; Chen, H.; Qiao-Bao, Z.; Chen, S.; Yang, Y. On the interface design of Si and multilayer graphene for a high-performance Li-ion battery anode. ACS Appl. Mater. Interfaces 2020, 12, 44840–44849. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Peng, J.; Luo, J.; Li, W.; Wu, Z.; Shi, M.; Li, X.; Li, N.; Chang, B.; Wang, X.; et al. Spherical Gr/Si/GO/C composite as high-performance anode material for lithium-ion batteries. Energy Fuels 2020, 34, 7639–7647. [Google Scholar] [CrossRef]

- Kim, D.; Luo, Y.; Tiwari, A.P.; Hwang, H.M.; Oh, S.; Lee, K.; Lee, H. Highly stable multi-layered silicon-intercalated graphene anodes for lithium-ion batteries. MRS Commun. 2020, 10, 25–31. [Google Scholar] [CrossRef]

- Park, S.-H.; Kim, H.-K.; Ahn, D.-J.; Lee, S.-I.; Roh, K.C.; Kim, K.-B. Self-assembly of Si entrapped graphene architecture for high-performance Li-ion batteries. Electrochem. Commun. 2013, 34, 117–120. [Google Scholar] [CrossRef]

- Ye, Y.-S.; Xie, X.; Rick, J.; Chang, F.-C.; Hwang, B.-J. Improved anode materials for lithium-ion batteries comprise non-covalently bonded graphene and silicon nanoparticles. J. Power Sources 2014, 247, 991–998. [Google Scholar] [CrossRef]

- Li, Q.; Chen, D.; Li, K.; Wang, J.; Zhao, J. Electrostatic self-assembly bmSi@C/rGO composite as anode material for lithium ion battery. Electrochim. Acta 2016, 202, 140–146. [Google Scholar] [CrossRef]

- Liu, L.; Li, X.; Zhang, G.; Zhang, Z.; Fang, C.; Ma, H.; Luo, W.; Liu, Z. Enhanced stability lithium-ion battery based on optimized graphene/Si nanocomposites by templated assembly. ACS Omega 2019, 4, 18195–18202. [Google Scholar] [CrossRef] [PubMed]

- Reddy, A.L.M.; Srivastava, A.; Gowda, S.R.; Gullapalli, H.; Dubey, M.; Ajayan, P.M. Synthesis of nitrogen-doped graphene films for lithium battery application. ACS Nano 2010, 4, 6337–6342. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.; Huang, X.; Zhou, G.; Cui, S.; Hallac, P.B.; Jiang, J.; Hurley, P.T.; Chen, J. Multilayered Si nanoparticle/reduced graphene oxide hybrid as a high-performance lithium-ion battery anode. Adv. Mater. 2013, 26, 758–764. [Google Scholar] [CrossRef] [PubMed]

- Lin, N.; Zhou, J.; Wang, L.; Zhu, Y.; Qian, Y. Polyaniline-assisted synthesis of Si@C/RGO as anode material for rechargeable lithium-ion batteries. ACS Appl. Mater. Interfaces 2014, 7, 409–414. [Google Scholar] [CrossRef]

- Wang, S.; Liao, J.; Wu, M.; Xu, Z.; Gong, F.; Chen, C.; Wang, Y.; Yan, X. High rate and long cycle life of a CNT/rGO/Si nanoparticle composite anode for lithium-ion batteries. Part. Part. Syst. Charact. 2017, 34, 1700141. [Google Scholar] [CrossRef]

- Kumar, K.T.; Reddy, M.J.K.; Sundari, G.S.; Raghu, S.; Kalaivani, R.; Ryu, S.H.; Shanmugharaj, A. Synthesis of graphene-siloxene nanosheet based layered composite materials by tuning its interface chemistry: An efficient anode with overwhelming electrochemical performances for lithium-ion batteries. J. Power Sources 2020, 450, 227618. [Google Scholar] [CrossRef]

- Dai, J.; Liao, J.; He, M.; Yang, M.; Wu, K.; Yao, W. Si@SnS2-reduced graphene oxide composite anodes for high-capacity Li-ion batteries. ChemSusChem 2019, 12, 5092–5098. [Google Scholar] [CrossRef]

- Deng, B.; Xu, R.; Wang, X.; An, L.; Zhao, K.; Cheng, G.J. Roll to roll manufacturing of fast charging, mechanically robust 0D/2D nanolayered Si-graphene anode with well-interfaced and defect engineered structures. Energy Storage Mater. 2019, 22, 450–460. [Google Scholar] [CrossRef]

- Bian, F.; Yu, J.; Song, W.; Huang, H.; Liang, C.; Gan, Y.; Xia, Y.; Zhang, J.; He, X.; Zhang, W. A new magnesium hydride route to synthesize morphology-controlled Si/rGO nanocomposite towards high-performance lithium storage. Electrochim. Acta 2020, 330, 135248. [Google Scholar] [CrossRef]

- Zhaoa, H.; Xuab, X.; Yaoa, Y.; Lic, Y. Si nanoparticles veiled with ultrathin rGO film reduced directly by precoated Ni template: Fabrication and electrochemical performance. Appl. Surf. Sci. 2020, 528, 146993. [Google Scholar] [CrossRef]

- Wu, J.; Qin, X.; Zhang, H.; He, Y.-B.; Li, B.; Ke, L.; Lv, W.; Du, H.; Yang, Q.-H.; Kang, F. Multilayred silicon embedded porous carbon/graphene hybrid as a high performance anode. Carbon 2015, 84, 434–443. [Google Scholar] [CrossRef]

- Majeed, M.K.; Saleem, A.; Ma, X.; Ma, W. Clay-derived mesoporous Si/rGO for anode material of lithium-ion batteries. J. Alloys Compd. 2020, 848, 156590. [Google Scholar] [CrossRef]

- Fang, R.; Xiao, W.; Miao, C.; Mei, P.; Yan, W.; Zhang, Y.; Jiang, Y. Improved lithium storage performance of pomegranate-like Si@NC/rGO composite anodes by facile in-situ nitrogen doped carbon coating and freeze drying processes. J. Alloys Compd. 2020, 834, 155230. [Google Scholar] [CrossRef]

- Zhang, K.; Xia, Y.; Yang, Z.; Fu, R.; Shen, C.; Liu, Z. Structure-preserved 3D porous silicon/reduced graphene oxide materials as anodes for Li-ion batteries. RSC Adv. 2017, 7, 24305–24311. [Google Scholar] [CrossRef]

- Yu, K.; Zhang, H.; Qi, H.; Liang, J.-C.; Liang, C. High performance of porous silicon/carbon/RGO network derived from rice husks as anodes for lithium-ion batteries. New J. Chem. 2018, 42, 19811–19817. [Google Scholar] [CrossRef]

- Chen, S.; Bao, P.; Huang, X.; Sun, B.; Wang, G. Hierarchical 3D mesoporous silicon-graphene nanoarchitectures for lithium ion batteries with superior performance. Nano Res. 2014, 7, 85–94. [Google Scholar] [CrossRef]

- Men, X.; Kong, X.; Yang, X.; Wang, B.; Wang, Y.; Liu, Y.; Yu, L.; Li, H.; Xu, B. Synthesis of a pomegranate shaped reduced graphene oxide stabilized secondary Si nanoparticles composite anode for lithium ion batteries. Int. J. Hydrogen Energy 2020, 45, 29492–29504. [Google Scholar] [CrossRef]

- Benzait, Z.; Yuca, N. Synergistic effect of carbon nanomaterials on a cost-effective coral-like Si/rGO composite for lithium ion battery application. Electrochim. Acta 2020, 339, 135917. [Google Scholar] [CrossRef]

- Tang, X.; Wen, G.; Zhang, Y.; Wang, D.; Song, Y. Novel silicon nanoparticles with nitrogen-doped carbon shell dispersed in nitrogen-doped graphene and CNTs hybrid electrode for lithium ion battery. Appl. Surf. Sci. 2017, 425, 742–749. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, Y.; Li, H. Engineering of a bowl-like Si@rGO architecture for an improved lithium ion battery via synergistic effect. Nanotechnology 2020, 31, 095402. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, Y.; Shen, Z.; Chen, R.; He, X.; Zhang, X.; Zhang, Y.; Wu, K. Sandwich structure of graphene-protected silicon/carbon nanofibers for lithium-ion battery anodes. Electrochim. Acta 2016, 210, 53–60. [Google Scholar] [CrossRef]

- Pan, Q.; Zuo, P.; Lou, S.; Mu, T.; Du, C.; Cheng, X.; Ma, Y.; Gao, Y.; Yin, G. Micro-sized spherical silicon@carbon@graphene prepared by spray drying as anode material for lithium-ion batteries. J. Alloys Compd. 2017, 723, 434–440. [Google Scholar] [CrossRef]

- He, Z.; Wu, X.; Yi, Z.; Wang, X.; Xiang, Y. Silicon/graphene/carbon hierarchical structure nanofibers for high performance lithium ion batteries. Mater. Lett. 2017, 200, 128–131. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kim, Y.-J.; Nam, Y.-S.; Park, S.-H.; Lee, H.; Hyun, Y.; Lee, C.-S. Synthesis and characterization of silicon/reduced graphene oxide composites as anodes for Lithium secondary batteries. J. Nanosci. Nanotechnol. 2018, 18, 5026–5032. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Xiong, L.; Zhu, S.; Zhang, L.; Yang, X. Porous Si/C/reduced graphene oxide microspheres by spray drying as anode for Li-ion batteries. J. Electroanal. Chem. 2017, 797, 16–22. [Google Scholar] [CrossRef]

- Qin, J.; Wu, M.; Feng, T.; Chen, C.; Tu, C.; Li, X.; Duan, C.; Xia, D.; Wang, D. High rate capability and long cycling life of graphene-coated silicon composite anodes for lithium ion batteries. Electrochim. Acta 2017, 256, 259–266. [Google Scholar] [CrossRef]

- Pan, Q.; Zhao, J.; Qu, W.; Liu, R.; Li, N.; Xing, B.; Jiang, S.; Pang, M.; Zhao, L.; Zhang, Y.; et al. Facile synthesis of the 3D framework Si@N-doped C/Reduced graphene oxide composite by polymer network method for highly stable lithium storage. J. Phys. Chem. Solids 2019, 133, 92–99. [Google Scholar] [CrossRef]

- Toçoğlua, U.; Alaf, M.; Akbulut, H. Towards high cycle stability yolk-shell structured silicon/rGO/MWCNT hybrid composites for Li-ion battery negative electrodes. Mater. Chem. Phys. 2020, 240, 122160. [Google Scholar] [CrossRef]

- Xu, H.; Wang, Y.; Chenab, R.; Baiab, Y.; Liab, T.; Jinab, H.; Wanga, J.; Xiaa, H. A green-synthetic spiderweb-like Si@Graphene-oxide anode material with multifunctional citric acid binder for high energy-density Li-ion batteries. Carbon 2020, 157, 330–339. [Google Scholar] [CrossRef]

- Wu, Y.-S.; Yang, C.-C.; Wu, S.; Wu, Z.; Wei, C.; Yang, M.; Lue, S.J. Preparation of ternary hierarchical silicon/reduced graphene oxide/carbon composites as anodes for lithium–ion batteries. J. Alloys Compd. 2019, 793, 433–445. [Google Scholar] [CrossRef]

- Yu, L.; Liu, J.; He, S.; Huang, C.; Gong, Z.; Gan, L.; Long, M. N-doped rGO/C@Si composites using sustainable chitosan as the carbon source for lithium-ion batteries. Appl. Surf. Sci. 2020, 501, 144136. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, Y.; Ma, Z.; Wang, H.; Sly, G.L. Yolk-void-shell Si-C nano-particles with tunable void size for high-performance anode of lithium ion batteries. Nanotechnology 2020. [Google Scholar] [CrossRef] [PubMed]

- Baggetto, L.; Notten, P.H.N. Lithium ion (de)insertion reaction of germanium thin-film electrodes and electrochemical and in-situ XRD study batteries and energy storage. J. Electrochem. Soc. 2009, 156, A169–A175. [Google Scholar] [CrossRef][Green Version]

- Liu, X.; Wu, X.; Chang, B.; Wang, K.-X. Recent progress on germanium-based anodes for lithium ion batteries: Efficient lithiation strategies and mechanisms. Energy Storage Mater. 2020, 30, 146–169. [Google Scholar] [CrossRef]

- Liang, W.; Yang, H.; Fan, F.; Liu, Y.; Liu, X.H.; Huang, J.Y.; Zhu, T.; Zhang, S. Tough germanium nanoparticles under electrochemical cycling. ACS Nano 2013, 7, 3427–3433. [Google Scholar] [CrossRef]

- Panayotov, V.; Panayotova, M.; Chukharev, S. Recent studies on germanium-nanomaterials for LIBs anodes. E3S Web Conf. 2020, 166, 06012. [Google Scholar] [CrossRef]

- Loaiza, L.C.; Montconduit, L.; Seznzc, V. Si and Ge-based anode materials for Li-, Na-, and K-ion batteries: A perspective from structure to electrochemical mechanism. Small 2020, 16, 1905260. [Google Scholar] [CrossRef]

- Xue, D.-J.; Xin, S.; Yan, Y.; Jiang, K.-C.; Yin, Y.-X.; Guo, Y.-G.; Wan, L.-J. Improving the electrode performance of Ge through Ge@C core–shell nanoparticles and graphene networks. J. Am. Chem. Soc. 2012, 134, 2512–2515. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, X.; Zhou, X.; Liu, X.; Liu, Y.; Dai, Z.; Bao, J. Ge nanoparticles encapsulated in nitrogen-doped reduced graphene oxide as an advanced anode material for lithium-ion batteries. J. Phys. Chem. C 2014, 118, 28502–28508. [Google Scholar] [CrossRef]

- Wang, B.; Wen, Z.; Jin, J.; Hong, X.; Zhang, S.; Rui, K. A novel strategy to prepare Ge@C/rGO hybrids as high-rate anode materials for lithium ion batteries. J. Power Sources 2017, 342, 521–528. [Google Scholar] [CrossRef]

- Wang, B.; Jin, J.; Hong, X.; Gu, S.; Guo, J.; Wen, Z. Facile synthesis of the sandwich-structured germanium/reduced graphene oxide hybrid: An advanced anode material for high-performance lithium ion batteries. J. Mater. Chem. A 2017, 5, 13430–13438. [Google Scholar] [CrossRef]

- Fang, S.; Shen, L.; Zheng, H.; Zhang, X. Ge–graphene–carbon nanotube composite anode for high performance lithium-ion batteries. J. Mater. Chem. A 2014, 3, 1498–1503. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, L.; Shen, X.; Ji, Z.; Yuan, A.; Xu, K.; Shah, S.A. In-situ synthesis of Ge/reduced graphene oxide composites as ultrahigh rate anode for lithium-ion battery. J. Alloys Compd. 2019, 801, 90–98. [Google Scholar] [CrossRef]

- Zhao, M.; Zhao, D.-L.; Yang, H.-X.; Han, X.-Y.; Duan, Y.-J.; Tian, X.-M.; Meng, W.-J. Graphene-supported cubic hollow carbon shell-coated germanium particles as high-performance anode for lithium-ion batteries. Ceram. Int. 2019, 45, 13210–13218. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, Y.; Zhang, X.; Liang, X.; Zhang, F.; Wang, L.; Li, Y.; Feng, Y.; Feng, W. Few-layer methyl-terminated germanene–graphene nanocomposite with high capacity for stable lithium storage. Carbon 2020, 161, 287–298. [Google Scholar] [CrossRef]

- Meng, W.-J.; Zhao, M.; Yang, H.-X.; Wu, Y.-Q.; Pu, H.; Gao, R.-Z.; Yang, Y.; Zhao, D.-L. Synthesis of CuGeO3/reduced graphene oxide nanocomposite by hydrothermal reduction for high performance Li-ion battery anodes. Ceram. Int. 2020, 46, 9249–9255. [Google Scholar] [CrossRef]

- Wen, C.J.; Huggins, R.A. Thermodynamic study of the lithium-tin system. J. Electrochem. Soc. 1981, 128, 1181–1187. [Google Scholar] [CrossRef]

- Winter, M.; Besenhard, J.O. Electrochemical lithiation of tin and tin-based intermetallics and composites. Electrochim. Acta 1999, 45, 31–50. [Google Scholar] [CrossRef]

- Park, C.-M.; Kim, J.-H.; Kim, H.; Sohn, H.-J. Li-alloy based anode materials for Li secondary batteries. Chem. Soc. Rev. 2010, 39, 3115–3141. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, Z.S.; Jiang, W.; Wang, Y.; Pan, Y.; Lu, C. Mechanical properties of Li–Sn alloys for Li-ion battery anodes: A first-principles perspective. AIP Adv. 2016, 6, 015107. [Google Scholar] [CrossRef]

- Li, H. Nano-alloy anode for lithium ion batteries. Solid State Ionics 2002, 148, 247–258. [Google Scholar] [CrossRef]

- Wang, B.; Luo, B.; Li, X.; Zhi, L. The dimensionality of Sn anodes in Li-ion batteries. Mater. Today 2012, 15, 544–552. [Google Scholar] [CrossRef]

- Wang, G.; Wang, B.; Wang, X.; Park, J.; Dou, S.; Ahn, H.; Kim, K. Sn/graphene nanocomposite with 3D architecture for enhanced reversible lithium storage in lithium ion batteries. J. Mater. Chem. 2009, 19, 8378–8384. [Google Scholar] [CrossRef]

- Luo, B.; Wang, B.; Liang, M.; Ning, J.; Li, X.; Zhi, L. Reduced graphene oxide-mediated growth of uniform tin-core/carbon-sheath coaxial nanocables with enhanced lithium ion storage properties. Adv. Mater. 2012, 24, 1405–1409. [Google Scholar] [CrossRef]

- Wang, H.; Xing, Z.; Hu, Z.; Zhang, Y.; Hu, Y.; Sun, Y.; Ju, Z.; Zhuang, Q. Sn-based submicron-particles encapsulated in porous reduced graphene oxide network: Advanced anodes for high-rate and long life potassium-ion batteries. Appl. Mater. Today 2019, 15, 58–66. [Google Scholar] [CrossRef]

- Botas, C.; Carriazo, D.; Singh, G.; Rojo, T. Sn—And SnO2–graphene flexible foams suitable as binder-free anodes for lithium ion batteries. J. Mater. Chem. A 2015, 3, 13402–13410. [Google Scholar] [CrossRef]

- Soler-Piña, F.J.; Hernández-Rentero, C.; Caballero, A.; Morales, J.; Rodríguez-Castellón, E.; Canales-Vázquez, J. Highly graphitized carbon nanosheets with embedded Ni nanocrystals as anode for Li-ion batteries. Nano Res. 2020, 13, 86–94. [Google Scholar] [CrossRef]

- Dashairya, L.; Das, D.; Saha, P. Electrophoretic deposition of antimony/reduced graphite oxide hybrid nanostructure: A stable anode for lithium-ion batteries. Mater. Today Commun. 2020, 24, 101189. [Google Scholar] [CrossRef]

- Yang, J.; Takeda, Y.; Imanishi, N.; Capiglia, C.; Xie, J.Y.; Yamamoto, O. SiOx-based anodes for secondary lithium batteries. Solid State Ion. 2002, 152-153, 125–129. [Google Scholar] [CrossRef]

- Chang, W.-S.; Park, C.-M.; Kim, J.-H.; Kim, Y.-U.; Jeong, G.; Sohn, H.-J. Quartz (SiO2): A new energy storage anode material for Li-ion batteries. Energy Environ. Sci. 2012, 5, 6895–6899. [Google Scholar] [CrossRef]

- Yamada, Y.; Iriyama, Y.; Abe, T.; Ogumi, Z. Kinetics of electrochemical insertion and extraction of lithium ion at SiO. J. Electrochem. Soc. 2010, 157, A26. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, H.; Chen, Y.; Li, N.; Li, Y.; Liu, L. SiO2@SnO2/graphene composite with a coating and hierarchical structure as high performance anode material for lithium ion battery. J. Alloys Compd. 2016, 677, 237–244. [Google Scholar] [CrossRef]

- Zhao, Y.; Zheng, L.; Wu, H.; Chen, H.; Su, L.; Wang, L.; Wang, Y.; Ren, M. Co2SiO4/SiO2/RGO nanosheets: Boosting the lithium storage capability of tetravalent Si by using highly-dispersed Co element. Electrochim. Acta 2018, 282, 609–617. [Google Scholar] [CrossRef]

- Hu, Z.; Cui, H.; Li, J.; Lei, G.; Li, Z. Constructing three-dimensional Li-transport channels within the Fe3O4@SiO2@RGO composite to improve its electrochemical performance in Li-ion batteries. Ceram. Int. 2020, 46, 18868–18877. [Google Scholar] [CrossRef]

- Haeri, S.; Ramezanzadeh, B.; Asghari, M. A novel fabrication of a high performance SiO2-graphene oxide (GO) nanohybrids: Characterization of thermal properties of epoxy nanocomposites filled with SiO2-GO nanohybrids. J. Colloid Interface Sci. 2017, 493, 111–122. [Google Scholar] [CrossRef] [PubMed]

- Kasimayan, U.; Nadarajan, A.; Singaravelu, C.M.; Pan, G.-T.; Kandasamy, J.; Yang, T.C.-K.; Lin, J.-H. In-situ DRIFT investigation of photocatalytic reduction and oxidation properties of SiO2@α-Fe2O3 core-shell decorated RGO nanocomposite. Sci. Rep. 2020, 10, 1–13. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, P.; Hou, Z.; Zhang, X.; Li, C. One-step synthesis of SiOx@graphene composite material by a hydrothermal method lithium-ion batteries anodes. Energy Fuels 2020, 34, 3895–3900. [Google Scholar] [CrossRef]

- Huang, J.; Fam, D.; He, Q.; Chen, H.; Zhan, D.; Faulkner, S.H.; Nimmo, M.; Tok, A.I.Y. The mechanism of graphene oxide as a growth template for complete reduced graphene oxide coverage on an SiO2 substrate. J. Mater. Chem. C 2014, 2, 109–114. [Google Scholar] [CrossRef]

- Liang, X.; Liu, S.; Song, X.; Zhu, Y.; Jiang, S. Layer-by-layer self-assembled graphene oxide/silica microsphere composites as stationary phase for high performance liquid chromatography. Analyst 2012, 137, 5237–5244. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, F.R.; Zhu, W.X.; Su, D.; Sang, Z.Y.; Yan, X.; Li, S.; Liang, J.; Dou, S.X. A multifunctional hierarchical porous SiO2/GO membrane for high efficiency oil/water separation and dye removal. Carbon 2020, 160, 88–97. [Google Scholar] [CrossRef]

- Guo, C.; Wang, D.; Liu, T.; Zhu, J.X.; Lang, X. A three dimensional SiOx/C@RGO nanocomposite as a high energy anode material for lithium-ion batteries. J. Mater. Chem. A 2014, 2, 3521–3527. [Google Scholar] [CrossRef]

- Guo, X. Reduced Graphene oxide -coated 3D interconnected SiO2 Nanoparticles with Enhanced Lithium Storage Performance. Int. J. Electrochem. Sci. 2018, 13, 5645–5653. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, J.; Lin, S.; Khan, S.; Huang, J.; Liu, S.; Chen, Z.; Wu, D.; Fu, R. Synthesis of SiOx/C composite nanosheets as high-rate and stable anode materials for lithium-ion batteries. ACS Appl. Energy Mater. 2020, 3, 3562–3568. [Google Scholar] [CrossRef]

- Idota, Y.; Kubota, T.; Matsufuji, A.; Maekawa, Y.; Miyasaka, T. Tin-based amorphous oxide: A high-capacity lithium-ion-storage material. Science 1997, 276, 1395–1397. [Google Scholar] [CrossRef]

- Zoller, F.; Böhm, D.; Bein, T.; Fattakhova-Rohlfing, D. Tin oxide based nanomaterials and their application as anodes in lithium-ion batteries and beyond. ChemSusChem 2019, 12, 4140–4159. [Google Scholar] [CrossRef]

- Li, Y.; Lv, X.; Lu, J.; Li, J. Preparation of SnO2-nanocrystal/graphene-nanosheets composites and their lithium storage ability. J. Phys. Chem. C 2010, 114, 21770–21774. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, G.; Song, J.; Jiang, Y.; Zhuang, H.; Liu, P.; Fang, T. Bivalent tin ion assisted reduction for preparing graphene/SnO2 composite with good cyclic performance and lithium storage capacity. Electrochim. Acta 2011, 56, 7340–7346. [Google Scholar] [CrossRef]

- Lian, P.; Zhu, X.; Liang, S.; Li, Z.; Yang, W.; Wang, H. High reversible capacity of SnO2/graphene nanocomposite as an anode material for lithium-ion batteries. Electrochim. Acta 2011, 56, 4532–4539. [Google Scholar] [CrossRef]

- Huang, X.; Zhou, X.; Zhou, L.; Qian, K.; Wang, Y.; Liu, Z.; Yu, C. A facile one-step solvothermal synthesis of SnO2/graphene nanocomposite and its application as an anode material for lithium-ion batteries. ChemPhysChem 2010, 12, 278–281. [Google Scholar] [CrossRef]

- Xie, J.; Liu, S.Y.; Chen, X.F.; Zhang, Y.X.; Song, W.T.; Cao, G.S.; Zhu, T.J.; Zhao, X.B. Nanocrystal-SnO2-loaded graphene with improved Li-storage properties prepared by a facile one-pot hydrothermal route. Int. J. Electrochem. Sci. 2011, 6, 5539–5549. [Google Scholar]

- Lim, S.P.; Huang, N.M.; Lim, H.N. Solvothermal synthesis of SnO2/graphene nanocomposites for supercapacitor application. Cream. Int. 2013, 39, 6647–6655. [Google Scholar] [CrossRef]

- Ding, S.; Luan, D.; Boey, F.Y.C.; Chen, J.S.; Lou, X.W.D. SnO2 nanosheets grown on graphene sheets with enhanced lithium storage properties. Chem. Commun. 2011, 47, 7155–7157. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Huang, K.; Qi, X.; Li, H.; Yang, L.; Zhong, J. Free-standing SnO2 nanoparticles@graphene hybrid paper for advanced lithium-ion batteries. Ceram. Int. 2014, 40, 6891–6897. [Google Scholar] [CrossRef]

- Cui, D.; Zheng, Z.; Peng, X.; Li, T.; Sun, T.; Yuan, L. Fluorine-doped SnO2 nanoparticles anchored on reduced graphene oxide as a high-performance lithium ion battery anode. J. Power Sources 2017, 362, 20–26. [Google Scholar] [CrossRef]

- Wang, H.; Pan, Q.; Wu, Q.; Zhang, X.; Huang, Y.-G.; Lushington, A.; Li, Q.; Sun, X. Ultrasmall MoS2 embedded in carbon nanosheets-coated Sn/SnOx as anode material for high-rate and long life Li-ion batteries. J. Mater. Chem. A 2017, 5, 4576–4582. [Google Scholar] [CrossRef]

- Tang, J.; Yang, J.; Zhou, L.; Xie, J.; Chen, G.; Zhou, X. Layer-by-layer self-assembly of a sandwich-like graphene wrapped SnOx@graphene composite as an anode material for lithium ion batteries. J. Mater. Chem. A 2014, 2, 6292–6295. [Google Scholar] [CrossRef]

- Cai, D.; Yang, T.; Liu, B.; Wang, D.; Liu, Y.; Wang, L.; Li, Q.; Wang, T. A nanocomposite of tin dioxide octahedral nanocrystals exposed to high-energy facets anchored onto graphene sheets for high performance lithium-ion batteries. J. Mater. Chem. A 2014, 2, 13990. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, D.; Wang, J.; Han, S.; Lv, L.; Zhang, F.; Feng, X. Amphiphilic polymer promoted assembly of macroporous graphene/SnO2 frameworks with tunable porosity for high-performance lithium storage. Small 2014, 10, 2226–2232. [Google Scholar] [CrossRef]

- Zhou, X.; Wan, L.-J.; Guo, Y.-G. Binding SnO2 Nanocrystals in nitrogen-doped graphene sheets as anode materials for lithium-ion batteries. Adv. Mater. 2013, 25, 2152–2157. [Google Scholar] [CrossRef]

- Hu, X.; Zeng, G.; Chen, J.; Lu, C.; Wen, Z. 3D graphene network encapsulating SnO2 hollow spheres as a high-performance anode material for lithium-ion batteries. J. Mater. Chem. A 2017, 5, 4535–4542. [Google Scholar] [CrossRef]

- Wang, S.; Shi, L.; Chen, G.; Ba, C.; Wang, Z.; Zhu, J.; Zhao, Y.; Zhang, M.; Yuan, S. In situ synthesis of tungsten-doped SnO2 and graphene nanocomposites for high-performance anode materials of lithium-ion batteries. ACS Appl. Mater. Interfaces 2017, 9, 17163–17171. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Li, X.; Wang, J.; Ynag, J.; Geng, D.; Li, R.; Cai, M.; Sham, T.-K.; Sun, X. defect-rich crystalline SnO2 immobilized on graphene nanosheets with enhanced cycle performance for Li ion batteries. J. Phys. Chem. C 2012, 116, 22149–22156. [Google Scholar] [CrossRef]

- Shao, Q.; Tang, J.; Sun, Y.; Li, J.; Zhang, K.; Yuan, J.; Zhu, D.-M.; Qin, L.-C. Unique interconnected graphene/SnO2 nanoparticle spherical multilayers for lithium-ion battery applications. Nanoscale 2017, 9, 4439–4444. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Xu, P.; Ni, Y.; Geng, H.; Zheng, G.; Dong, B.; Jiao, Z. In situ chemical synthesis of SnO2/reduced graphene oxide nanocomposites as anode materials for lithium-ion batteries. J. Mater. Res. 2014, 29, 617–624. [Google Scholar] [CrossRef]

- Chen, L.; Ma, X.; Wang, M.; Chen, C.; Ge, X. Hierarchical porous SnO2/reduced graphene oxide composites for high-performance lithium-ion battery anodes. Electrochim. Acta 2016, 215, 42–49. [Google Scholar] [CrossRef]

- Hou, C.-C.; Brahma, S.; Weng, S.-C.; Chang, C.-C.; Huang, J.-L. Facile, low temperature synthesis of SnO2/reduced graphene oxide nanocomposite as anode material for lithium-ion batteries. Appl. Surf. Sci. 2017, 413, 160–168. [Google Scholar] [CrossRef]

- Tan, Q.; Kong, Z.; Chen, X.; Zhang, L.; Hu, X.; Mu, M.; Sun, H.; Shao, X.; Guan, X.; Gao, M.; et al. Synthesis of SnO2/graphene composite anode materials for lithium-ion batteries. Appl. Surf. Sci. 2019, 485, 314–322. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, N.; Wang, X.; Yang, C.; Cheng, H.; Zhao, H. SnO2 nanoparticles anchored on graphene oxide as advanced anode materials for high-performance lithium-ion batteries. Front. Mater. Sci. 2019, 13, 186–192. [Google Scholar] [CrossRef]

- Jiang, W.; Zhao, X.; Ma, Z.S.; Lin, J.; Lu, C. SnO2/reduced graphene oxide nanocomposite as anode material for lithium-ion batteries with enhanced cyclability. J. Nanosci. Nanotechnol. 2016, 16, 4136–4140. [Google Scholar] [CrossRef]

- Jiang, S.; Huang, R.; Zhu, W.; Li, X.; Zhao, Y.; Gao, Z.; Gao, L.; Zhao, J. Free-standing SnO2@rGO hybrid via the anti-solvent-assisted precipitation for superior lithium storage performance. Front. Chem. 2019, 7, 878. [Google Scholar] [CrossRef]

- Wu, Y.-Z.; Brahma, S.; Weng, S.-C.; Chang, C.-C.; Huang, J.-L. Reduced graphene oxide (RGO)-SnOx (x = 0,1,2) nanocomposite as high performance anode material for lithium-ion batteries. J. Alloys Compd. 2020, 818, 152889. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Zhang, S.; Liang, S.; Liang, X.; Huang, H.; Zhou, W.; Guo, J. Facile synthesis of iron-doped SnO2/reduced graphene oxide composite as high-performance anode material for lithium-ion batteries. J. Alloys Compd. 2018, 748, 1013–1021. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, Z.; Ding, S.; Chen, C.; Zhang, M. Enhanced electrochemical properties of SnO2–graphene–carbon nanofibers tuned by phosphoric acid for potassium storage. Nanotechnology 2018, 29, 375702. [Google Scholar] [CrossRef] [PubMed]

- Zoller, F.; Peters, K.; Zehetmaier, P.M.; Zeller, P.; Dçblinger, M.; Bein, T.; Sofer, Z.; Fattakhova-Rohlfing, D. Making ultrafast high-capacity anodes for lithium-ion batteries via antimony doping of nanosized tin oxide/graphene composites. Adv. Funct. Mater. 2018, 28, 1706529. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, L.; Jiang, S.; Li, G.; Huang, Y.; Geng, J. Fluorine-doped SnO2@graphene porous composite for high capacity lithium-ion batteries. Chem. Mater. 2015, 27, 4594–4603. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Zheng, Z.; Li, T.; Tong, Z.; Ai, C. Fluorine-doped SnO2/reduced graphene oxide-artificial graphite hybrids as lithium-ion battery anodes with stable capacity. Ionics 2020, 26, 2835–2843. [Google Scholar] [CrossRef]

- Dong, W.; Xu, J.; Wang, C.; Lu, Y.; Liu, X.; Wang, X.; Yuan, X.; Wang, Z.; Lin, T.; Sui, M.; et al. A robust and conductive black tin oxide nanostructure makes efficient lithium-ion batteries possible. Adv. Mater. 2017, 29, 1700136. [Google Scholar] [CrossRef]

- Dou, P.; Cao, Z.; Wang, C.; Zheng, J.; Xu, X. Multilayer Zn-doped SnO2 hollow nanospheres encapsulated in covalently interconnected three-dimensional graphene foams for high performance lithium-ion batteries. Chem. Eng. J. 2017, 320, 405–415. [Google Scholar] [CrossRef]

- Kokubu, T.; Oaki, Y.; Hosono, E.; Zhou, H.; Imai, H. Biomimetic solid-solution precursors of metal carbonate for nanostructured metal oxides: MnO/Co and MnO-CoO nanostructures and their electrochemical properties. Adv. Funct. Mater. 2011, 21, 3673–3680. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, S.; Wang, H.; Wang, X.; Zhang, X.; Jin, G. A novel solvothermal synthesis of Mn3O4/graphene composites for supercapacitors. Electrochim. Acta 2013, 90, 210–218. [Google Scholar] [CrossRef]

- Qiu, Y.; Xu, G.-L.; Yan, K.; Sun, H.; Xiao, J.; Yang, S.; Sun, S.; Jin, L.; Deng, H. Morphology-conserved transformation: Synthesis of hierarchical mesoporous nanostructures of Mn2O3 and the nanostructural effects on Li-ion insertion/deinsertion properties. J. Mater. Chem. 2011, 21, 6346–6353. [Google Scholar] [CrossRef]

- Li, L.; Raji, A.-R.O.; Tour, J.M. Graphene-wrapped MnO2-graphene nanoribbons as anode materials for high-performance lithium ion batteries. Adv. Mater. 2013, 25, 6298–6302. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, T.; Golikand, A.N.; Mashhadizadeh, M.H.; Aghazadeh, M. Facile synthesis of α-MnO2 one-dimensional (1D) nanostructure and energy storage ability studies. J. Solid State Chem. 2012, 190, 202–207. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, D.; Li, Y.; Wu, Z.; Zhuo, R.; Li, S.; Feng, J.; Wang, J.; Yan, P.; Geng, Z. Manganese dioxide nanosheet arrays grown on graphene oxide as an advanced electrode material for supercapacitors. Electrochim. Acta 2014, 117, 528–533. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, G.; Huang, J.; Nan, J.; Zhen, S.; Wang, Y.; Li, A. Hollow MnO2 spheres/porous reduced graphene oxide as a cathode host for high-performance lithium-sulfur batteries. J. Solid State Chem. 2020, 286, 121297. [Google Scholar] [CrossRef]

- Majid, S.R. Green synthesis of in situ electrodeposited rGO/MnO2 nanocomposite for high energy density supercapacitors. Sci. Rep. 2015, 5, 16195. [Google Scholar] [CrossRef]

- Sawangphruk, M.; Srimuk, P.; Chiochan, P.; Krittayavathananon, A.; Luanwuthi, S.; Limtrakul, J. High-performance supercapacitor of manganese oxide/reduced graphene oxide nanocomposite coated on flexible carbon fiber paper. Carbon 2013, 60, 109–116. [Google Scholar] [CrossRef]

- Gund, G.S.; Dubal, D.P.; Patil, B.H.; Shinde, S.S.; Lokhande, C.D. Enhanced activity of chemically synthesized hybrid graphene oxide/Mn3O4 composite for high performance supercapacitors. Electrochim. Acta 2013, 92, 205–215. [Google Scholar] [CrossRef]

- Wang, L.; Wang, D.-L. Preparation and electrochemical characterization of MnOOH nanowire–graphene oxide. Electrochim. Acta 2011, 56, 5010–5015. [Google Scholar] [CrossRef]

- Chen, T.; Zhiu, Y.; Zhang, J.; Cao, Y. Two-dimensional MnO2/reduced graphene oxide nanosheet as a high-capacity and high-rate cathode materials for lithium-ion batteries. Int. J. Electrochem. Sci. 2018, 13, 8575–8588. [Google Scholar] [CrossRef]

- Lee, S.-W.; Lee, C.-W.; Yoon, S.-B.; Kim, M.-S.; Jeong, J.H.; Nam, K.-W.; Roh, K.C.; Kim, K.-B. Superior electrochemical properties of manganese dioxide/reduced graphene oxide nanocomposites as anode materials for high-performance lithium ion batteries. J. Power Sources 2016, 312, 207–215. [Google Scholar] [CrossRef]

- Devi, P.; Bansod, B.; Kaur, M.; Bagchi, S.; Nayak, M.K. Co-electrodeposited rGO/MnO2 nanohybrid for arsenite detection in water by stripping voltammetry. Sensors Actuators B Chem. 2016, 237, 652–659. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, H.; Ruan, H.; Su, Y.; Hu, R.; Tian, L.; Hu, Z.; Li, J. Fabrication of β-MnO2/rGO composite and its electrochemical properties. Int. J. Electrochem. Sci. 2016, 11, 10815–10826. [Google Scholar] [CrossRef]

- Liu, H. Preparation of (MnO2/RGO)/Li7La3Zr2O12/LiCoO2 Solid State Lithium Ion Batteries and Theirs Electrochemical Performance. Int. J. Electrochem. Sci. 2017, 12, 11479–11486. [Google Scholar] [CrossRef]

- Ali, G.A.; Yusoff, M.; Algarni, H.; Chong, K.F. One-step electrosynthesis of MnO2/rGO nanocomposite and its enhanced electrochemical performance. Ceram. Int. 2018, 44, 7799–7807. [Google Scholar] [CrossRef]

- Liu, H.D.; Hu, Z.L.; Su, Y.Y.; Ruan, H.B.; Hu, R.; Zhang, L. MnO2 nanorods/3D-rGO composite as high performance anode materials for Li-ion batteries. Appl. Surf. Sci. 2017, 392, 777–784. [Google Scholar] [CrossRef]

- Cao, Y.; Lin, X.; Zhang, C.; Yang, C.; Zhang, Q.; Hu, W.; Zheng, M.; Dong, Q. MnO2 nanoflakes anchored on reduced graphene oxide nanosheets as high performance anode materials for lithium-ion batteries. RSC Adv. 2014, 4, 30150–30155. [Google Scholar] [CrossRef]

- Chae, C.; Kim, K.W.; Yun, Y.J.; Lee, D.; Moon, J.; Choi, Y.; Lee, S.S.; Choi, S.; Jeong, S. Polyethylenimine-mediated electrostatic assembly of MnO2 nanorods on graphene oxides for use as anodes in lithium-ion batteries. ACS Appl. Mater. Interfaces 2016, 8, 11499–11506. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Zhu, Z.; Wong, K.; Mi, R.; Mei, J.; Lau, W. A green hydrothermal approach for the preparation of graphene/α-MnO2 3D network as anode for lithium ion battery. Electrochim. Acta 2013, 108, 465–471. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, T. Reduced graphene oxide anchored with MnO2 nanorods as anode for high rate and long cycle Lithium ion batteries. Electrochim. Acta 2016, 201, 165–171. [Google Scholar] [CrossRef]

- Li, Y.; Ye, D.; Liu, W.; Shi, B.; Guo, R.; Pei, H.; Xie, J. A three-dimensional core-shell nanostructured composite of polypyrrole wrapped MnO2/reduced graphene oxide/carbon nanotube for high performance lithium ion batteries. J. Colloid Interface Sci. 2017, 493, 241–248. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhao, Y.; Liu, Z.; Yang, L.; Zhang, J.; Wang, M.; Che, R. Flexible graphene-wrapped carbon nanotube/graphene@MnO2 3D multilevel porous film for high-performance lithium-ion batteries. Small 2018, 14, 1801007. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; Yun, Y.J.; Kim, K.W.; Chae, C.; Jeong, S.; Kang, Y.; Choi, S.-Y.; Lee, S.S.; Choi, S. Superior lithium storage performance using sequentially stacked MnO2/reduced graphene oxide composite electrodes. ChemSusChem 2015, 8, 1484–1491. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ye, D.; Shi, B.; Liu, W.; Guo, R.; Pei, H.; Xie, J. Free-standing reduced graphene oxide/MnO2–reduced graphene oxide–carbon nanotube nanocomposite flexible membrane as an anode for improving lithium-ion batteries. Phys. Chem. Chem. Phys. 2017, 19, 7498–7505. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xu, X.; Xia, F.; Bu, L.; Qiu, H.; Chen, M.; Zhang, L.; Gao, J. Electrochemically active MnO2/RGO nanocomposites using Mn powder as the reducing agent of GO and the MnO2 precursor. Electrochim. Acta 2014, 130, 305–313. [Google Scholar] [CrossRef]

- Han, G.; Liu, Y.; Zhang, L.; Kan, E.; Zhang, S.; Tang, J.; Tang, W. MnO2 nanorods intercalating graphene oxide/polyaniline ternary composites for robust high-performance supercapacitors. Sci. Rep. 2015, 4, 4824. [Google Scholar] [CrossRef]

- Chan, P.Y.; Rusi, R.; Majid, S. RGO-wrapped MnO2 composite electrode for supercapacitor application. Solid State Ionics 2014, 262, 226–229. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, H.; Chen, P.; Nie, L.H.; Li, C.-H.; Li, S.K. Self-assembled three-dimensional hierarchical graphene hybrid hydrogels with ultrathin β-MnO2 nanobelts for high performance supercapacitors. J. Mater. Chem. A 2015, 3, 1540–1548. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, J.W.; Wu, X.D.; Han, Q.F.; Wang, X. Graphene oxide-MnO2 nanocomposites for supercapacitors. ACS Nano 2010, 4, 2822–2830. [Google Scholar] [CrossRef]

- Lu, L.; Xu, S.; An, J.; Yan, S. Electrochemical performance of CNTs/RGO/MnO2 composite material for supercapacitor. Nanomater. Nanotechnol. 2016, 6, 1–7. [Google Scholar] [CrossRef]

- Hareesh, K.; Shateesh, B.; Joshi, R.P.; Williams, J.F.; Phase, D.M.; Haram, S.K.; Dhole, S.D. Ultra high stable supercapacitance performance of conducting polymer coated MnO2 nanorods/rGO nanocomposites. RSC Adv. 2017, 7, 20027–20036. [Google Scholar] [CrossRef]

- Seredych, M.; Bandosz, T.J. Evaluation of GO/MnO2 composites as supercapacitors in neutral electrolytes: Role of graphite oxide oxidation level. J. Mater. Chem. 2012, 22, 23525–23533. [Google Scholar] [CrossRef]

- Pang, M.; Long, G.; Jiang, S.; Ji, Y.; Han, W.; Wang, B.; Liu, X.; Xi, Y. Rapid synthesis of graphene/amorphous α-MnO2 composite with enhanced electrochemical performance for electrochemical capacitor. Mater. Sci. Eng. B 2015, 194, 41–47. [Google Scholar] [CrossRef]

- Miniach, E.; Śliwak, A.; Moyseowicz, A.; Fernández-Garcia, L.; González, Z.; Granda, M.; Menendez, R.; Gryglewicz, G. MnO2/thermally reduced graphene oxide composites for high-voltage asymmetric supercapacitors. Electrochim. Acta 2017, 240, 53–62. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Cao, J.; Liu, Y.; Ouyang, J.-H.; Jia, D.; Zhou, Y. Flexible and solid-state asymmetric supercapacitor based on ternary graphene/MnO2/carbon black hybrid film with high power performance. Electrochim. Acta 2015, 182, 861–870. [Google Scholar] [CrossRef]

- Zardkhoshoui, A.M.; Davarani, S.S.H. Flexible asymmetric supercapacitors based on CuO@MnO2-rGO and MoS2-rGO with ultrahigh energy density. J. Electroanal. Chem. 2018, 827, 221–229. [Google Scholar] [CrossRef]

- Wang, K.; Li, L.; Xue, W.; Zhou, S.; Lan, Y.; Zhang, H.; Sui, Z. Electrodeposition synthesis of PANI/MnO2/graphene composite materials and its electrochemical performance. Int. J. Electrochem. Sci. 2017, 12, 8306–8314. [Google Scholar]

- Dong, W.; Meng, L.; Hong, X.; Liu, S.; Shen, D.; Xia, Y.; Yang, S. MnO2/rGO/CNTs framework as a sulfur host for high-performance Li-S batteries. Molecules 2020, 25, 1989. [Google Scholar] [CrossRef]

- Jie, G.; Michael, A.L.; Hector, D.A. Sponge like nanosized Mn3O4 as a high-capacity anode material for rechargeable lithium batteries. Chem. Mater. 2011, 23, 3223–3227. [Google Scholar]

- Su, Q.; Wang, S.; Du, G.; Xu, B.; Ma, S.; Shang, L. Microstructure evolution and conversion mechanism of Mn3O4 under electrochemical cyclings. J. Phys. Chem. C 2018, 122, 2475–2480. [Google Scholar] [CrossRef]

- Wang, H.; Cui, L.-F.; Yang, Y.; Casalongue, H.S.; Robinson, J.T.; Liang, Y.; Cui, Y.; Dai, H. Mn3O4−graphene hybrid as a high-capacity anode material for lithium-ion batteries. J. Am. Chem. Soc. 2010, 132, 13978–13980. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Guo, L.; Shi, W.; Zou, X.; Xiang, B.; Xing, S. Rapid production of Mn3O4/rGO as an efficient electrode material for supercapacitor by flame plasma. Materials 2018, 11, 881. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y. Coprecipitated 3D nanostructured graphene oxide-Mn3O4 hybrid as anode for lithium-ion batteries. J. Mater. Res. 2015, 30, 484–492. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Fulari, A.; Ghodake, G.; Kim, D.; Lohar, G.M. Performance of chemically synthesized Mn3O4/rGO nanocomposite for electrochemical supercapacitor: A cost-effective high-performance electrode. Nanotechnology 2020, 31, 415403. [Google Scholar] [CrossRef]

- Wang, L.; Ouyang, Y.; Jiao, X.; Xia, X.; Lei, W.; Hao, Q. Polyaniline-assisted growth of MnO2 ultrathin nanosheets on graphene and porous graphene for asymmetric supercapacitor with enhanced energy density. Chem. Eng. J. 2018, 334, 1–9. [Google Scholar] [CrossRef]

- Liu, M.; Shi, M.; Lu, W.; Zhu, D.; Li, L.; Gan, L. Core–shell reduced graphene oxide/MnOx@carbon hollow nanospheres for high performance supercapacitor electrodes. Chem. Eng. J. 2017, 313, 518–526. [Google Scholar] [CrossRef]

- Wang, Y.; Lai, W.H.; Wang, N. A reduced graphene oxide/mixed-valent manganese oxides composite electrode for tailorable and surface mountable supercapacitors with high capacitance and super-long life. Energy Environ. Sci. 2017, 10, 941–949. [Google Scholar] [CrossRef]

- Seong, C.-Y.; Park, S.-K.; Bae, Y.; Yoo, S.; Piao, Y. An acid-treated reduced graphene oxide/Mn3O4 nanorod nanocomposite as an enhanced anode material for lithium ion batteries. RSC Adv. 2017, 7, 37502–37507. [Google Scholar] [CrossRef]

- Wang, J.; Guan, C.; Feng, G.; Ke, Q.; Huang, X.; Wang, J. Flexible asymmetric supercapacitor based on structure-optimized Mn3O4/reduced Graphene oxide nanohybrid paper with high energy and power density. Adv. Funct. Mater. 2015, 25, 7291–7299. [Google Scholar] [CrossRef]

- Gu, Y.; Wu, J.; Wang, X.; Liu, W.; Yan, S. Producing symbiotic reduced graphene oxide/Mn3O4 nanocoposites directly from converting graphite for high-performance supercapacitor electrodes. ACS Omega 2020, 5, 18975–18986. [Google Scholar] [CrossRef]

- Li, Y.; Gai, T.; Shao, L.; Tang, H.; Li, R.; Yang, S.; Wang, S.; Wu, Q.; Ren, Y. Synthesis of sandwich-like Mn3O4@reduced graphene oxide nano-composites via modified Hummers’ method and its application as uranyl adsorbents. Heliyon 2019, 5, e01972. [Google Scholar] [CrossRef] [PubMed]

- Raj, B.G.S.; Ramprasad, R.N.R.; Asiri, A.M.; Wu, J.J.; Anandan, S. Ultrasound assisted synthesis of Mn3O4 nanoparticles anchored graphene nanosheets for supercapacitor applications. Electrochim. Acta 2015, 156, 127–137. [Google Scholar] [CrossRef]

- Park, G.; Bartolome, L.; Lee, K.G.; Lee, S.J.; Kim, D.H.; Park, T.J. One-step sonochemical synthesis of a graphene oxide-manganese oxide nanocomposite for catalytic glycolysis of polu(ethylene terephthalate). Nanoscale 2012, 4, 3879–3885. [Google Scholar] [CrossRef] [PubMed]

- Ayhan, I.A.; Meduri, P.; Oh, H.; Bhimanapati, G.R.; Li, Q.; Yang, G.; Robinson, J.A.; Wang, Q. Effect of Mn3O4 nanoparticle composition and distribution on graphene as a potential hybrid anode material for lithium-ion batteries. RSC Adv. 2016, 6, 33022–33030. [Google Scholar] [CrossRef]

- Park, S.-H.; Lee, W.-J. Hierarchically mesoporous CuO/carbon nanofiber coaxial shell-core nanowires for lithium ion batteries. Sci. Rep. 2015, 5, 9754. [Google Scholar] [CrossRef] [PubMed]

- Rosaiah, P.; Zhu, J.; Shaik, D.P.M.D.; Hussain, O.M.; Qiu, Y.; Zhao, L. Reduced graphene oxide/Mn3O4 nanocomposite electrodes with enhanced electrochemical performance for energy storage applications. J. Electroanal. Chem. 2017, 794, 78–85. [Google Scholar] [CrossRef]

- Nithya, C.; Vishnuprakash, P.; Gopukumar, S. A Mn3O4 nanospheres@rGO architecture with capacitive effects on high potassium storage capability. Nanoscale Adv. 2019, 1, 4347–4358. [Google Scholar] [CrossRef]

- Nam, I.; Kim, N.D.; Kim, G.-P.; Park, J.; Yi, J. One step preparation of Mn3O4/graphene composites for use as an anode in Li ion batteries. J. Power Sources 2013, 244, 56–62. [Google Scholar] [CrossRef]

- Luo, Y.; Fan, S.; Hao, N.; Zhong, S.; Liu, W. An ultrasound-assisted approach to synthesize Mn3O4/RGO hybrids with high capability for lithium ion batteries. Dalton Trans. 2014, 43, 15317–15320. [Google Scholar] [CrossRef]

- Li, S.; Yu, L.-L.; Shi, Y.-T.; Fan, J.; Li, R.-B.; Fan, G.-D.; Xu, W.-L.; Zhao, J.-T. Greatly Enhanced Faradic Capacities of 3D Porous Mn3O4/G Composites as Lithium-Ion Anodes and Supercapacitors by C–O–Mn Bonding. ACS Appl. Mater. Interfaces 2019, 11, 10178–10188. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.; Qin, L.-C.; Wen, G.; Pan, H.; Zhang, Y.; Tian, N.; Zhou, Y.; Huang, X. MnCO3/Mn3O4/reduced graphene oxide ternary anode materials for lithium-ion batteries: Facile green synthesis and enhanced electrochemical performance. J. Mater. Chem. A 2017, 5, 17001–17011. [Google Scholar] [CrossRef]

- Shah, H.U.; Wang, F.; Javed, M.S.; Shaheen, N.; Saleem, M.; Li, Y. Hydrothermal synthesis of reduced graphene oxide – Mn3O4 nanocomposite as an efficient electrode material for supercapacitors. Ceram. Int. 2018, 44, 3580–3584. [Google Scholar] [CrossRef]

- Varghese, S.P.; Babu, B.; Prasannachandran, R.; Antony, R.; Shaijumon, M.M. Enhanced electrochemical properties of Mn3O4/graphene nanocomposite as efficient anode material for lithium ion batteries. J. Alloys Compd. 2019, 780, 588–596. [Google Scholar] [CrossRef]

- Petnikota, S.; Srikanth, V.V.S.S.; Nithyadharseni, P.; Reddy, M.V.; Adams, S.; Chowdari, B.V.R. Sustainable graphenothermal reduction chemistry to obtain MnO nanonetwork supported exfoliated graphene oxide composite and its electrochemical characteristics. ACS Sustain. Chem. Eng. 2015, 3, 3205–3213. [Google Scholar] [CrossRef]

- Yuan, T.; Xu, B.; Sun, W.; Xiang, B.; Li, Y.; Yan, M.; Xu, B.; Dou, S. Ever-Increasing Pseudocapacitance in RGO-MnO-RGO Sandwich Nanostructures for Ultrahigh-Rate Lithium Storage. Adv. Funct. Mater. 2016, 26, 2198–2206. [Google Scholar] [CrossRef]

- Cheng, F.; Zhou, X.; Yang, J.; Sun, A.; Wang, H.; Tang, J. MnO nanoparticles sandwiched within 3D graphene-based hierarchical architecture for efficient lithium storage. Inorg. Chem. 2019, 58, 3329–3337. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.; Liu, Z.; Zhao, H.; Liu, H.; Zhang, Y. Bottom-up construction of reduced-graphene-oxide-anchored MnO with an nitrogen-doped carbon coating for synergistically improving lithium-ion storage. Inorg. Chem. 2018, 57, 13693–13701. [Google Scholar] [CrossRef]

- Hsieh, C.-T.; Lin, C.-Y.; Lin, J.-Y. High reversibility of Li intercalation and de-intercalation in MnO-attached graphene anodes for Li-ion batteries. Electrochim. Acta 2011, 56, 8861–8867. [Google Scholar] [CrossRef]

- Zhang, K.; Han, P.; Gu, L.; Zhang, L.; Liu, Z.; Kong, Q.; Zhang, C.; Dong, S.; Zhang, Z.; Yao, J.; et al. Synthesis of nitrogen-doped MnO/graphene nanosheets hybrid material for lithium ion batteries. ACS Appl. Mater. Interfaces 2012, 4, 658–664. [Google Scholar] [CrossRef]

- Qiu, D.; Ma, L.; Zheng, M.; Lin, Z.; Zhao, B.; Wen, Z.; Hu, Z.; Pu, L.; Shi, Y. MnO nanoparticles anchored on graphene nanosheets via in situ carbothermal reduction as high-performance anode materials for lithium-ion batteries. Mater. Lett. 2012, 84, 9–12. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Xie, J.; Zheng, Y.-X.; Cao, G.-S.; Zhu, T.-J.; Zhao, X. Nanocrystal manganese oxide (Mn3O4, MnO) anchored on graphite nanosheet with improved electrochemical Li-storage properties. Electrochim. Acta 2012, 66, 271–278. [Google Scholar] [CrossRef]

- Mai, Y.; Zhang, D.; Qiao, Y.; Gu, C.; Wang, X.; Tu, J. MnO/reduced graphene oxide sheet hybrid as an anode for Li-ion batteries with enhanced lithium storage performance. J. Power Sources 2012, 216, 201–207. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, L.; Song, H.; Chen, X.; Zhou, J. Enhanced electrochemical performance of MnO nanowire/graphene composite during cycling as the anode material for lithium-ion batteries. Nano Energy 2014, 10, 172–180. [Google Scholar] [CrossRef]

- Wu, T.; Tu, F.; Liu, S.; Zhuang, S.; Jin, G.; Pan, C. MnO nanorods on graphene as an anode material for high capacity lithium ion batteries. J. Mater. Sci. 2013, 49, 1861–1867. [Google Scholar] [CrossRef]

- Zang, J.; Qian, H.; Wei, Z.; Cao, Y.; Zheng, M.; Dong, Q. Reduced graphene oxide supported MnO nanoparticles with excellent lithium storage performance. Electrochim. Acta 2014, 118, 112–117. [Google Scholar] [CrossRef]

- Jiang, X.; Zhu, X.; Liu, X.; Xiao, L.; Ai, X.; Yang, H.; Cao, Y. Nanospherical-like manganese monoxide/reduced graphene oxide composite Synthesized by rlectron beam radiation as anode Material for high-performance lithium-ion batteries. Electrochim. Acta 2016, 196, 431–439. [Google Scholar] [CrossRef]

- Auborn, J.J.; Barberio, Y.L. Lithium intercalation cells without metallic lithium: MoO2/LiCoO2 and WO2/LiCoO2. J. Electrochem. Soc. 1987, 134, 638–640. [Google Scholar] [CrossRef]

- Rogers, D.B.; Shannon, R.D.; Sleight, A.W.; Gillson, J.L. Crystal chemistry of metal dioxides with rutile-related structures. Inorg. Chem. 1969, 8, 841–849. [Google Scholar] [CrossRef]

- Shi, Y.; Guo, B.; Corr, S.A.; Shi, Q.; Hu, Y.-S.; Heier, K.R.; Chen, L.; Seshadri, R.; Stucky, G.D. Ordered mesoporous metallic MoO2 materials with highly reversible lithium storage capacity. Nano Lett. 2009, 9, 4215–4220. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Z. A new approach to synthesize MoO2@C for high-rate lithium ion batteries. J. Mater. Chem. A 2015, 3, 21314–21320. [Google Scholar] [CrossRef]

- Sen, U.K.; Shaligram, A.; Mitra, S. Intercalation anode material for lithium ion battery based on molybdenum dioxide. ACS Appl. Mater. Interfaces 2014, 6, 14311–14319. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.-J.; Wu, T.-H.; Wang, K.-X.; Wu, X.-Y.; Chen, X.-T.; Jiang, Y.-M.; Wei, X.; Chen, J.-S. Uniform hierarchical MoO2/carbon spheres with high cycling performance for lithium ion batteries. J. Mater. Chem. A 2013, 1, 12038–12043. [Google Scholar] [CrossRef]

- Petnikota, S.; Teo, K.W.; Chen, L.; Sim, A.; Marka, S.K.; Reddy, M.V.; Srikanth, V.V.S.S.; Adams, S.; Chowdari, B. Exfoliated graphene oxide/MoO2 composites as anode materials in Lithium-ion batteries: An insight into intercalation of Li and conversion mechanism of MoO2. ACS Appl. Mater. Interfaces 2016, 8, 10884–10896. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Yin, F.; Uchaker, E.; Chen, W.; Zhang, M.; Zhou, J.; Qi, Y.; Cao, G. Facile and green preparation for the formation of MoO2-GO composites as anode material for lithium-ion batteries. J. Phys. Chem. C 2014, 118, 24890–24897. [Google Scholar] [CrossRef]

- Qian, Y.; Lu, S.; Gao, F. Preparation of MoO2/graphene composite as electrode material for supercapacitors. J. Mater. Sci. 2011, 46, 3517–3522. [Google Scholar] [CrossRef]

- Huang, J.; Xu, Z.; Cao, L.; Zhang, Q.; Ouyang, H.; Li, J. Tailoring MoO2/graphene oxide nanostructures for stable, high-density sodium-ion battery anodes. Energy Technol. 2015, 3, 1108–1114. [Google Scholar] [CrossRef]

- Tang, W.; Peng, C.X.; Nai, C.T.; Su, J.; Liu, Y.P.; Reddy, M.V.V.; Lin, M.; Loh, K.P. Ultrahigh capacity due to multi-electron conversion reaction in reduced graphene oxide-wrapped MoO2 porous nanobelts. Small 2015, 11, 2446–2453. [Google Scholar] [CrossRef]

- Zhu, Y.; Xu, X.; Chen, G.; Zhong, Y.; Cai, R.; Li, L.; Shao, Z. Surfactant-free self-assembly of reduced graphite oxide-MoO2 nanobelt composites used as electrode for lithium-ion batteries. Electrochim. Acta 2016, 211, 972–981. [Google Scholar] [CrossRef]

- Ju, P.; Zhu, Z.; Shao, X.; Wang, S.; Zhao, C.; Qian, X.; Zhao, C. 3D walnut-shaped TiO2/RGO/MoO2@Mo electrode exhibiting extraordinary supercapacitor performance. J. Mater. Chem. A 2017, 5, 18777–18785. [Google Scholar] [CrossRef]

- Hwang, J.; Yoon, D.; Kweon, B.; Chang, W.; Kim, J. A simple, one-pot synthesis of molybdenum oxide-reduced graphene oxide composites in supercritical methanol and their electrochemical performance. RSC Adv. 2016, 6, 108298–108309. [Google Scholar] [CrossRef]

- Xu, Z.; Yao, K.; Fu, H.; Shen, X.; Duan, X.; Cao, L.; Huang, J.; Wang, H. Constructing MoO2 porous architectures using graphene oxide flexible supports for lithium io battery anodes. Glob. Chall. 2017, 1, 7. [Google Scholar] [CrossRef]

- Wang, S.; Liu, B.; Zhi, G.; Xu, G.; Wang, Q.; Zhang, J. 2D layered mesoporous MoO2/rGO composites for high performance anode materials in lithium-ion battery. Microporous Mesoporous Mater. 2017, 246, 14–23. [Google Scholar] [CrossRef]

- Chen, X.; Liu, R.; Zeng, L.; Huang, X.; Fang, Y.; Liu, J.; Xu, Y.; Chen, Q.; Wei, M.; Qian, Q. Preparation of hierarchical MoO2@RGO composite and its application for high rate performance lithium-ion batteries. Mater. Lett. 2018, 212, 198–201. [Google Scholar] [CrossRef]

- Li, F.; Li, L.; Wang, W.; Gao, J. A new facile approach to prepare reduced graphene oxide and MoO2/reduced graphene oxide as electrode materials for oxygen reduction reactions. J. Colloid Interface Sci. 2018, 519, 194–202. [Google Scholar] [CrossRef]

- Liu, C.-L.; Luo, S.-H.; Huang, H.-B.; Zhai, Y.-C.; Wang, Z.-W. Direct growth of MoO2/reduced graphene oxide hollow sphere composites as advanced anode materials for potassium-ion batteries. ChemSusChem 2019, 12, 873–880. [Google Scholar] [CrossRef]

- Li, M.; Zhu, Y.; Ji, X.; Cheng, S. Facile synthesis of MoO2/Mo-GO with high initial columbic efficiency and enhanced lithiation ability. Mater. Lett. 2019, 254, 332–335. [Google Scholar] [CrossRef]

- Devina, W.; Hwang, J.; Kim, J. Synthesis of MoO2/Mo2C/rGO composite in supercritical fluid and its enhanced cycling stability in Li-ion batteries. Chem. Eng. J. 2018, 345, 1–12. [Google Scholar] [CrossRef]

- Zhang, R.; Tang, Z.; Wang, H.; Sun, D.; Tang, Y.; Xie, Z. The fabrication of hierarchical MoO2@MoS2/rGO composite as high reversible anode material for lithium ion batteries. Electrochim. Acta 2020, 364, 136996. [Google Scholar] [CrossRef]

- Xia, F.; Hu, X.; Sun, Y.; Luo, W.; Han, J. Layer-by-layer assembled MoO2–graphene thin film as a high-capacity and binder-free anode for lithium-ion batteries. Nanoscale 2012, 4, 4707. [Google Scholar] [CrossRef]

- Xu, Y.; Yi, R.; Yuan, B.; Wu, X.; Dunwell, M.; Lin, Q.; Fei, L.; Deng, S.; Andersen, P.; Wang, D.; et al. High capacity MoO2/graphite oxide composite anode for lithium-ion batteries. J. Phys. Chem. Lett. 2012, 3, 309–314. [Google Scholar] [CrossRef]

- Tang, Q.; Shan, Z.; Wang, L.; Qin, X. MoO2–graphene nanocomposite as anode material for lithium-ion batteries. Electrochim. Acta 2012, 79, 148–153. [Google Scholar] [CrossRef]

- Seng, K.H.; Du, G.D.; Li, L.; Chen, Z.X.; Liu, H.K.; Guo, Z. Facile synthesis of graphene–molybdenum dioxide and its lithium storage properties. J. Mater. Chem. 2012, 22, 16072. [Google Scholar] [CrossRef][Green Version]

- Guo, L.; Wang, Y. Standing carbon-coated molybdenum dioxide nanosheets on graphene: Morphology evolution and lithium ion storage properties. J. Mater. Chem. A 2015, 3, 4706–4715. [Google Scholar] [CrossRef]

- Bhaskar, A.; Deepa, M.; Rao, T.; Varadaraju, U. Enhanced nanoscale conduction capability of a MoO2/graphene composite for high performance anodes in lithium ion batteries. J. Power Sources 2012, 216, 169–178. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, Y.; Wang, J.; Sun, L.; Cao, M. Facile fabrication of molybdenum dioxide/nitrogen-doped graphene hybrid as high performance anode material for lithium ion batteries. J. Power Sources 2015, 274, 142–148. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, H. One-dimensional architecture with reduced graphene oxide supporting ultrathin MoO2 nanosheets as high performance anodes for lithium-ion batteries. Nanotechnology 2019, 30, 315602. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Luo, J.; Hu, X.; Wang, X.; Liang, J.-C.; Yu, K. Fabrication of TiO2 hollow nanostructures and their application in lithium ion batteries. J. Alloys Compd. 2015, 651, 685–689. [Google Scholar] [CrossRef]

- Zhang, X.; Kumar, P.S.; Aravindan, V.; Liu, H.H.; Sundaramurthy, J.; Mhaisalkar, S.G.; Duong, H.M.; Ramakrishna, S.; Madhavi, S. Electrospun TiO2-graphene composite nanofibers as a highly durable insertion anode for lithium ion batteries. J. Phys. Chem. C 2012, 116, 14780–14788. [Google Scholar] [CrossRef]

- El-Deen, S.S.; Hashem, A.M.; Ghany, A.E.A.; Indris, S.; Ehrenberg, H.; Mauger, A.; Julien, C.M. Anatase TiO2 nanoparticles for lithium-ion batteries. Ionics 2018, 24, 2925–2934. [Google Scholar] [CrossRef]

- Wu, F.; Wang, Z.; Li, X.; Guo, H. Simple preparation of petal-like TiO2 nanosheets as anode materials for lithium-ion batteries. Ceram. Int. 2014, 40, 16805–16810. [Google Scholar] [CrossRef]

- Kucinskis, G.; Bajars, G.; Kleperis, J. Graphene in lithium ion battery cathode materials: A review. J. Power Sources 2013, 240, 66–79. [Google Scholar] [CrossRef]

- Li, B.; Yuan, Z.; Xu, Y.; Liu, J. N-doped graphene as an efficient electrocatalyst for lithium-thionyl chloride batteries. Appl. Catal. A Gen. 2016, 523, 241–246. [Google Scholar] [CrossRef]

- Zhen, M.; Zhu, X.; Zhang, X.; Zhou, Z.; Liu, L. Reduced graphene oxide-supported TiO2 fiber bundles with mesostructures as anode materials for lithium-ion batteries. Chem. A Eur. J. 2015, 21, 14454–14459. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Ma, R.; Du, N.; Ren, J.; Wong, T.; Li, Y.Y.; Lee, S.T. Growth of TiO2 nanorod arrays on reduced graphene oxide with enhanced lithium-ion storage. J. Mater. Chem. 2012, 22, 19061–19066. [Google Scholar] [CrossRef]