Carbon Footprint and Uncertainties of Geopolymer Concrete Production: A Comprehensive Life Cycle Assessment (LCA)

Abstract

1. Introduction

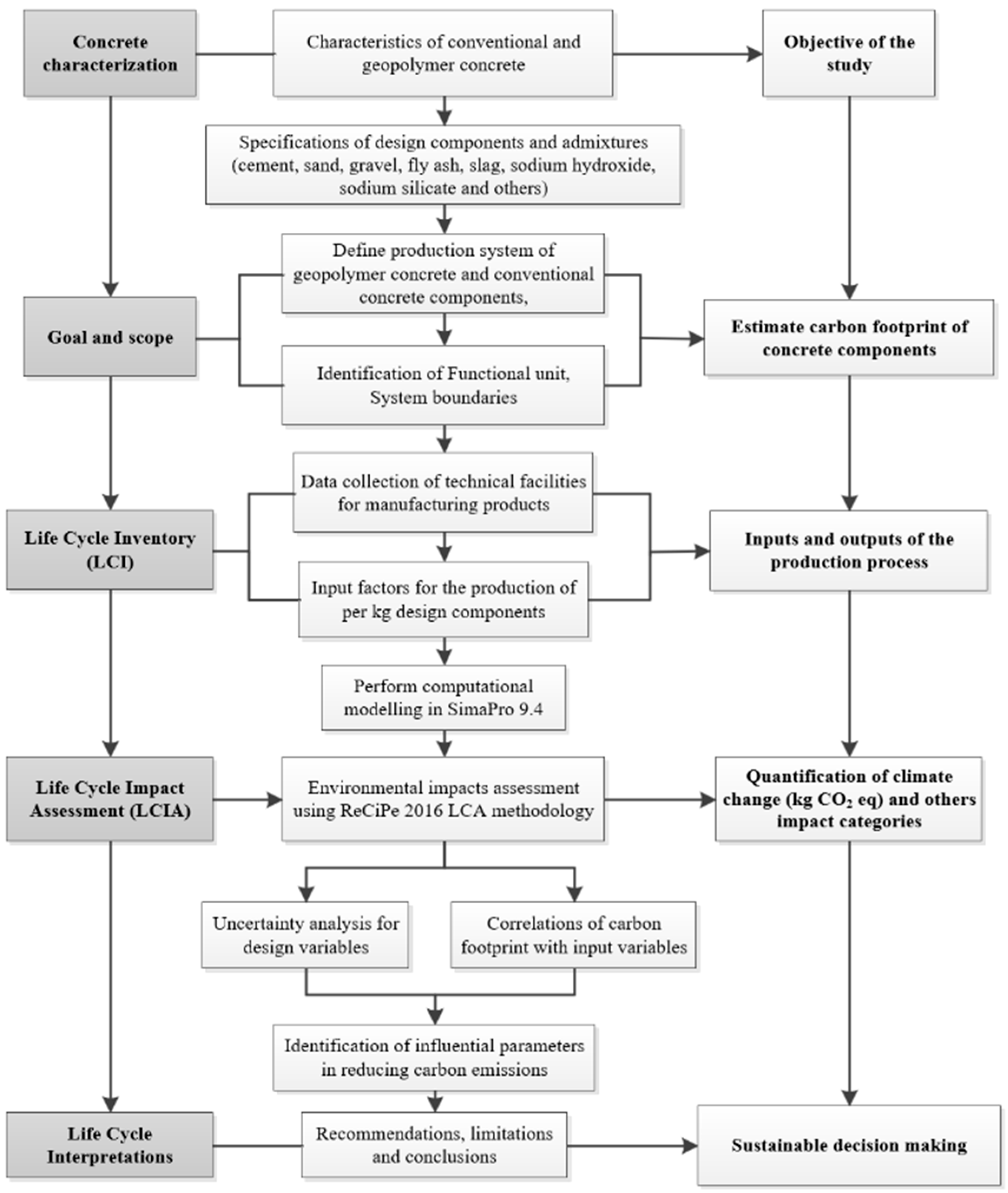

2. Materials and Methods

2.1. Goal and Scope Definition

2.2. Functional Unit and System Boundary

2.3. Life Cycle Inventory

2.4. Sensitivity Analysis

3. Results

3.1. Impact Assessment of Conventional Concrete

3.2. Comparative Assessment of Conventional and Geopolymer Concrete

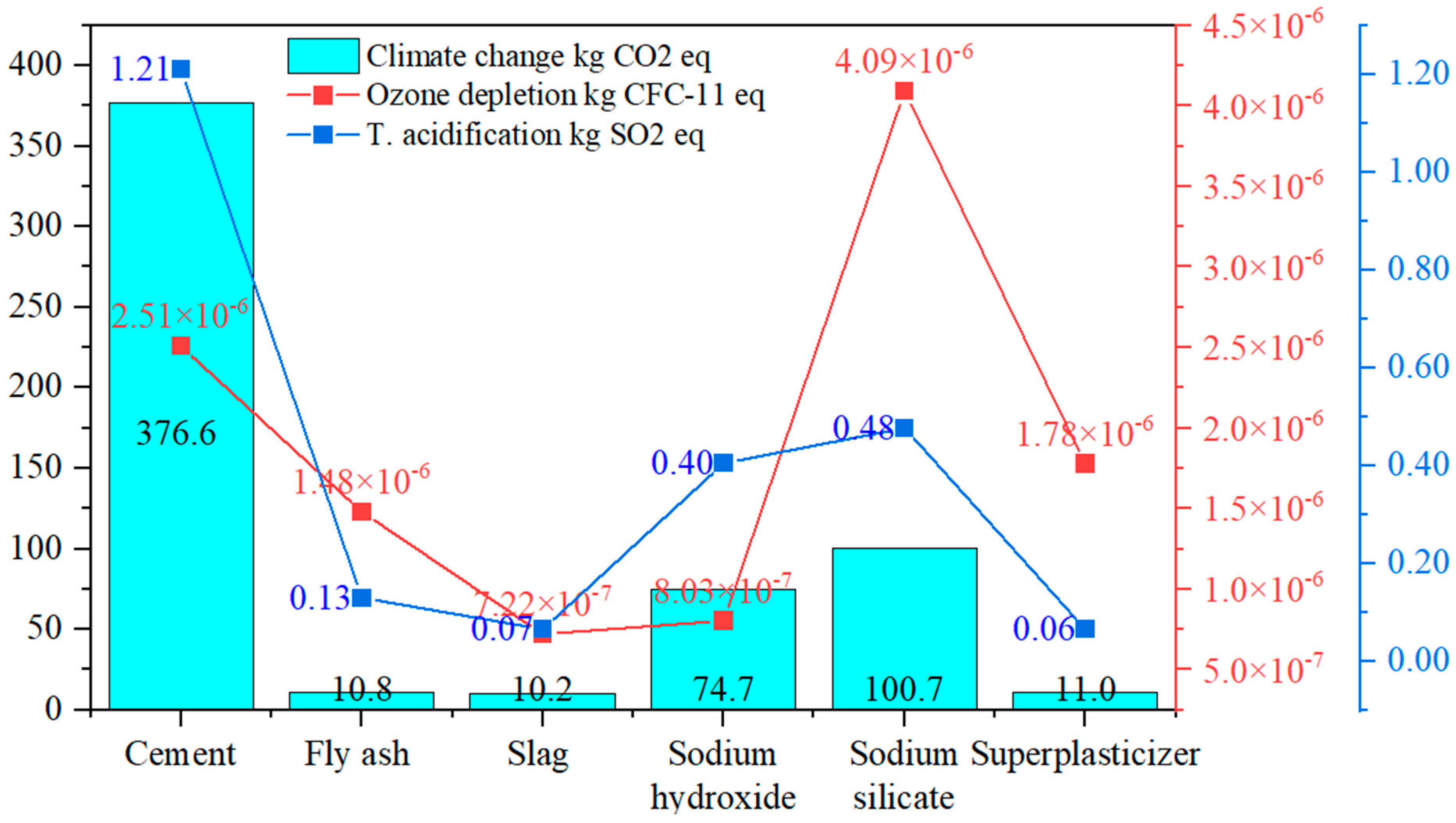

3.3. Impact Categories for Design Components

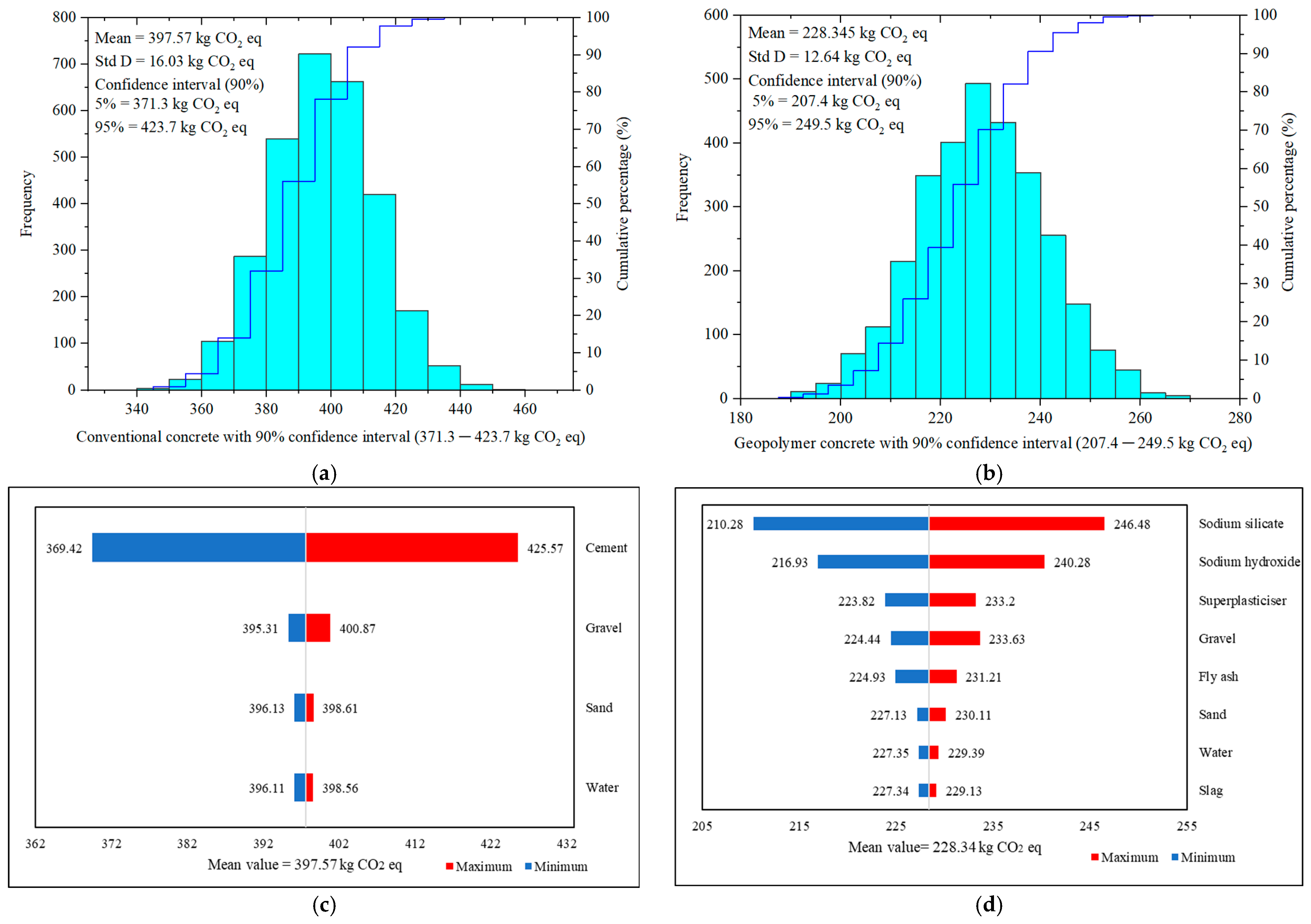

3.4. Ranking of Inputs by Their Effect on the Probabilistic Distribution

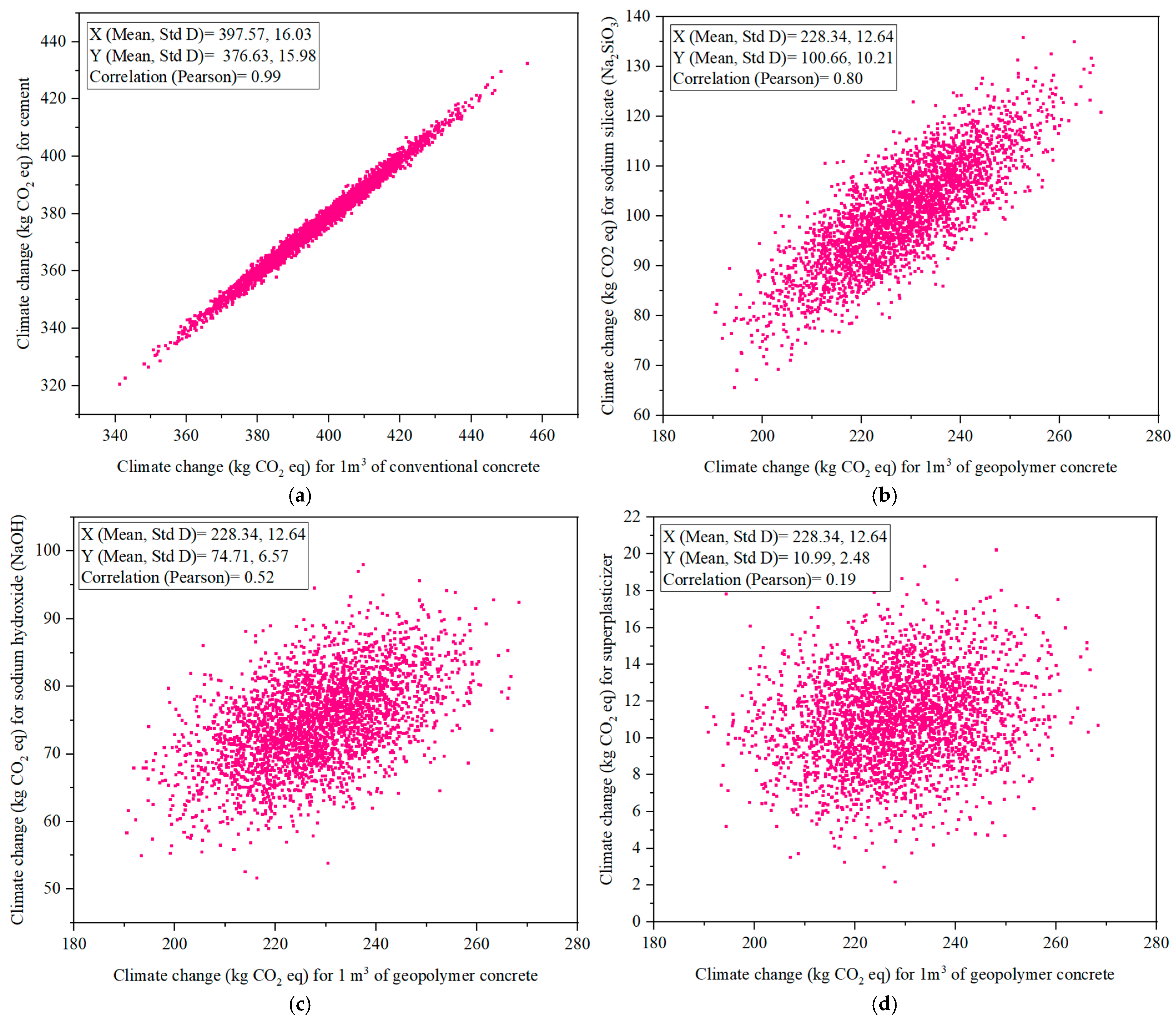

3.5. Correlation Coefficient of the Design Variable with the Carbon Footprint

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Nuhu, S.; Ladan, S.; Muhammad, A.U.; Cao, A. Effects and control of chemical composition of clinker for cement production. Int. J. Control Sci. Eng. 2020, 10, 16–21. [Google Scholar]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Sustainable energy transition for renewable and low carbon grid electricity generation and supply. Front. Energy Res. 2022, 9, 743114. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Prasittisopin, L. Power plant waste (fly ash, bottom ash, biomass ash) management for promoting circular economy in sustainable construction: Emerging economy context. Smart Sustain. Built Environ. 2024. [Google Scholar] [CrossRef]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Zhang, M.; Deskins, N.A.; Zhang, G.; Cygan, R.T.; Tao, M. Modeling the polymerization process for geopolymer synthesis through reactive molecular dynamics simulations. J. Phys. Chem. C 2018, 122, 6760–6773. [Google Scholar] [CrossRef]

- Arbi, K.; Nedeljkovic, M.; Zuo, Y.; Ye, G. A review on the durability of alkali-activated fly ash/slag systems: Advances, issues, and perspectives. Ind. Eng. Chem. Res. 2016, 55, 5439–5453. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F.; Marvila, M.; Azevedo, A.R.; De Carvalho, J.M.F.; Ribeiro, J.C.L. Application of eco-friendly alternative activators in alkali-activated materials: A review. J. Build. Eng. 2021, 35, 102010. [Google Scholar] [CrossRef]

- Song, Q.; Guo, M.-Z.; Ling, T.-C. A review of elevated-temperature properties of alternative binders: Supplementary cementitious materials and alkali-activated materials. Constr. Build. Mater. 2022, 341, 127894. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, B.; Yu, Q.L.; Brouwers, H.J. Chemistry, design and application of hybrid alkali activated binders. In Cementitious Materials: Composition, Properties, Application; Walter de Gruyter GmbH: Berlin, Germany, 2017; pp. 253–284. [Google Scholar]

- Tushar, Q.; Bhuiyan, M.A.; Zhang, G.; Maqsood, T.; Tasmin, T. Application of a harmonized life cycle assessment method for supplementary cementitious materials in structural concrete. Constr. Build. Mater. 2022, 316, 125850. [Google Scholar] [CrossRef]

- Tushar, Q.; Santos, J.; Zhang, G.; Robert, D.; Giustozzi, F. Recycled used cooking oil (UCO) as a rejuvenator in high content reclaimed asphalt pavement (RAP) mixes: A life cycle assessment (LCA). Sci. Total Environ. 2025, 961, 178376. [Google Scholar] [CrossRef]

- Rafi, S.M.; Ambalal, B.; Rao, B.K.; Baseer, M.A. Analytical study on special concretes with M20 & M25 grades for construction. Int. J. Curr. Eng. Technol. 2014, 2, 338–343. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008. [Google Scholar]

- Ali, B. Evaluation of Alkali-Activated Mortar Incorporating Combined and Uncombined Fly Ash and GGBS Enhanced with Nano Alumina. Civ. Eng. J. 2024, 10, 902–914. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A. Fly ash-slag interaction during alkaline activation: Influence of activators on phase assemblage and microstructure formation. Constr. Build. Mater. 2016, 122, 594–606. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Olonade, K.A.; Esenogho, E.; Lawan, M.M. Proposed simplified methodological approach for designing geopolymer concrete mixtures. Sci. Rep. 2024, 14, 15191. [Google Scholar] [CrossRef]

- Wardhono, A. Comparison study of class F and class C fly ashes as cement replacement material on strength development of non-cement mortar. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Woszuk, A.; Bandura, L.; Franus, W. Fly ash as low cost and environmentally friendly filler and its effect on the properties of mix asphalt. J. Clean. Prod. 2019, 235, 493–502. [Google Scholar] [CrossRef]

- Cheah, C.B.; Tiong, L.L.; Ng, E.P.; Oo, C.W. The engineering performance of concrete containing high volume of ground granulated blast furnace slag and pulverized fly ash with polycarboxylate-based superplasticizer. Constr. Build. Mater. 2019, 202, 909–921. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Ghafoor, M.T.; Khan, Q.S.; Qazi, A.U.; Sheikh, M.N.; Hadi, M. Influence of alkaline activators on the mechanical properties of fly ash based geopolymer concrete cured at ambient temperature. Constr. Build. Mater. 2021, 273, 121752. [Google Scholar] [CrossRef]

- Hameed, A.; Rasool, A.M.; Ibrahim, Y.E.; Afzal, M.F.U.D.; Qazi, A.U.; Hameed, I. Utilization of fly ash as a viscosity-modifying agent to produce cost-effective, self-compacting concrete: A sustainable solution. Sustainability 2022, 14, 11559. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A.; Gobinath, R. Role of recycling fine materials as filler for improving performance of concrete-a review. Aust. J. Civ. Eng. 2019, 17, 85–95. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Tan, E.C.; Tu, Q.; Martins, A.A.; Yao, Y.; Sunol, A.; Smith, R.L. Uncertainty in inventories for life cycle assessment: State-of-the-art, challenges, and new technologies. Environ. Prog. Sustain. Energy 2025, e14644. [Google Scholar] [CrossRef]

- Weidema, B.; Wenzel, H.; Petersen, C.; Hansen, K. The product, functional unit and reference flows in LCA. Environ. News 2004, 70, 1–46. [Google Scholar]

- Tushar, Q.; Zhang, G.; Giustozzi, F.; Bhuiyan, M.A.; Hou, L.; Navaratnam, S. An integrated financial and environmental evaluation framework to optimize residential photovoltaic solar systems in Australia from recession uncertainties. J. Environ. Manag. 2023, 346, 119002. [Google Scholar] [CrossRef]

- Tait, M.W.; Cheung, W.M. A comparative cradle-to-gate life cycle assessment of three concrete mix designs. Int. J. Life Cycle Assess. 2016, 21, 847–860. [Google Scholar] [CrossRef]

- Ahmed, B.; Rana, M.M.; Nguyen, H.T. Life cycle assessment of construction materials: Cradle-to-Gate and Cradle-to-Grave approach. J. Sustain. Constr. Eng. Proj. Manag 2019, 2, 1–9. [Google Scholar]

- Grant, T. AusLCI Database Manual; Australian Life Cycle Assessment Society (ALCAS): Melbourne, Australia, 2016. [Google Scholar]

- Grant, T.; Eady, S.; Cruypenninck, H.; Simmons, A. AusLCI Methodology for Developing Life Cycle Inventory for Australian Agriculture; Lifecycles: Melbourne, Australia, 2019. [Google Scholar]

- Pehlken, A.; Decker, A.; Kottowski, C.; Kirchner, A.; Thoben, K.-D. Energy efficiency in processing of natural raw materials under consideration of uncertainties. J. Clean. Prod. 2015, 106, 351–363. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Georgiadis, S.; Fantke, P. Uncertainty management and sensitivity analysis. In Life Cycle Assessment: Theory and Practice; Springer: Cham, Switzerland, 2017; pp. 271–321. [Google Scholar]

- Paxton, P.; Curran, P.J.; Bollen, K.A.; Kirby, J.; Chen, F. Monte Carlo experiments: Design and implementation. Struct. Equ. Model. 2001, 8, 287–312. [Google Scholar] [CrossRef]

- Tushar, Q.; Bhuiyan, M.; Zhang, G.; Sandanayake, M. Correlation of Building Parameters with Energy Reduction. In Proceedings of the 2018 5th Asia-Pacific World Congress on Computer Science and Engineering (APWC on CSE), Nadi, Fiji, 10–12 December 2018; pp. 116–120. [Google Scholar]

- Lewis, A. Comparative Assessment of the Environmental Footprint of Infant Formula Packaging Containers: A Cradle-to-Gate Plus End-of-Life LCA Using Full and Streamlined Software. Master’ Thesis, Michigan State University, East Lansing, MI, USA, 2023. [Google Scholar]

- Spreafico, C.; Landi, D.; Russo, D. A new method of patent analysis to support prospective life cycle assessment of eco-design solutions. Sustain. Prod. Consum. 2023, 38, 241–251. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.D.; Hollander, A.; Zijp, M.; Van Zelm, R. ReCiPe 2016: A harmonized life cycle impact assessment method at midpoint and endpoint level Report I: Characterization. RIVM Rep. 2016, 22, 138–147. [Google Scholar]

- Chen, G.; Zheng, D.-P.; Chen, Y.-W.; Lin, J.-X.; Lao, W.-J.; Guo, Y.-C.; Chen, Z.-B.; Lan, X.-W. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A.; Andrews-Phaedonos, F. Field applications of geopolymer concrete: A measure towards reducing carbon dioxide emission. Concr. Aust. 2013, 39, 34–44. [Google Scholar]

- Das, S.; Saha, P.; Jena, S.P.; Panda, P. Geopolymer concrete: Sustainable green concrete for reduced greenhouse gas emission–A review. Mater. Today Proc. 2022, 60, 62–71. [Google Scholar] [CrossRef]

- Zannerni, G.M.; Fattah, K.P.; Al-Tamimi, A.K. Ambient-cured geopolymer concrete with single alkali activator. Sustain. Mater. Technol. 2020, 23, e00131. [Google Scholar] [CrossRef]

- Raza, M.H.; Khan, M.; Zhong, R.Y. Investigating the impact of alkaline activator on the sustainability potential of geopolymer and alternative hybrid materials. Mater. Today Sustain. 2024, 26, 100742. [Google Scholar] [CrossRef]

- Obilor, E.I.; Amadi, E.C. Test for significance of Pearson’s correlation coefficient. Int. J. Innov. Math. Stat. Energy Policies 2018, 6, 11–23. [Google Scholar]

| No | Design Components | Density (kg/m3) | Quantity (kg) | Percentage of Total Mass (%) |

|---|---|---|---|---|

| Conventional concrete | ||||

| 1 | Cement | 1440 | 418 | 15.05% |

| 2 | Fine aggregate (sand) | 1600 | 688 | 24.77% |

| 3 | Coarse aggregate (gravel) | 1700 | 1462 | 52.64% |

| 4 | Water | 1000 | 209 | 7.52% |

| Total mass | 2777 | 100% | ||

| Geopolymer concrete | ||||

| 1 | Fly ash (Class F) | 1050 | 389 | 12.56% |

| 2 | Slag (GGBFS) | 1100 | 167 | 5.39% |

| 3 | Fine aggregate (sand) | 1600 | 688 | 22.22% |

| 4 | Coarse aggregate (gravel) | 1700 | 1462 | 47.23% |

| 5 | Water | 1000 | 229 | 7.39% |

| 6 | Sodium hydroxide (NaOH) | 480 | 41 | 1.32% (12 M solution) |

| 7 | Sodium silicate (Na2SiO3) | 1400 | 111 | 3.58 % |

| 8 | Superplasticizer | 1130 | 8.34 | 1.5% of the binder |

| Total mass | 3087 | 100% | ||

| Inputs for Emissions Factors | Quantity | Unit |

|---|---|---|

| Ordinary Portland Cement (OPC) | 1 kg | Kilogram |

| Limestone-milled | 1.4 kg | Kilogram |

| Transport truck—28 t fleet | 0.429 tkm | Ton–kilometer |

| Electricity—low voltage | 0.633 MJ | Megajoule |

| Energy from coal | 1.34 MJ | Megajoule |

| Energy from natural gas | 2.54 MJ | Megajoule |

| Gravel, crushed at the mine | 1 kg | Kilogram |

| Diesel is burned in the machine | 0.0161 MJ | Megajoule |

| Building hall—steel construction | 3 × 10−6 m2 | Square meter |

| Electricity—medium voltage | 0.0332 MJ | Megajoule |

| Heat—light fuel oil | 0.00492 MJ | Megajoule |

| Sand, at mine | 1 kg | Kilogram |

| Energy from diesel | 0.025 MJ | Megajoule |

| Energy from natural gas | 0.018 MJ | Megajoule |

| Fly ash from the stove | 1 kg | Kilogram |

| Transport lorry—20-to-28 ton | 0.0683 tkm | Ton–kilometer |

| Natural gas is burned in a furnace | 0.05 MJ | Megajoule |

| Low-voltage electricity at grid | 0.000606 MJ | Megajoule |

| Ground granulated blast furnace slag | 1 kg | Kilogram |

| Aluminum primary ingot | 0.000566 kg | Kilogram |

| Steel unalloyed market | 0.00386 kg | Kilogram |

| Sinter iron market | 0.0174 kg | Kilogram |

| Electricity—medium voltage | 0.0393 MJ | Megajoule |

| Sodium hydroxide 12 M (membrane cell) | 1 kg | Kilogram |

| Sodium chloride—powder | 0.854 kg | Kilogram |

| Electricity—medium voltage | 6.13 MJ | Megajoule |

| Sodium silicate (furnace process) | 1 kg | Kilogram |

| Soda powder | 0.403 kg | Kilogram |

| Electricity—medium voltage | 0.551 MJ | Megajoule |

| Heat—heavy fuel oil in the furnace | 2.25 MJ | Megajoule |

| Heat—natural gas | 2.22 MJ | Megajoule |

| Superplasticizer | 1 kg | Kilogram |

| Chemical (organic) | 0.649 kg | Kilogram |

| Sodium hydroxide without water | 0.125 kg | Kilogram |

| Electricity—medium voltage | 2.05 MJ | Megajoule |

| Water use | 1 kg | Kilogram |

| Electricity—low voltage | 0.00313 MJ | Megajoule |

| Ozone—liquid at plant | 3.33 × 10−6 kg | Kilogram |

| Water works | 1.19 × 10−11 p | Process |

| Design Components | Impact Unit | Statistical Indicators for Per Unit (kg) | 95% Confidence Interval | ||||

|---|---|---|---|---|---|---|---|

| Mean | Median | SD | CV (%) | 2.5% | 97.5% | ||

| Cement | kg CO2 eq | 0.9010 | 0.8969 | 0.0382 | 4.2441 | 0.8324 | 0.9839 |

| Sand | kg CO2 eq | 0.0031 | 0.0031 | 0.0003 | 10.3986 | 0.0025 | 0.0038 |

| Gravel | kg CO2 eq | 0.0127 | 0.0127 | 0.0011 | 8.9070 | 0.0107 | 0.0150 |

| Water | kg CO2 eq | 0.0010 | 0.0009 | 0.0003 | 31.8765 | 0.0005 | 0.0017 |

| Fly ash | kg CO2 eq | 0.0277 | 0.0275 | 0.0033 | 11.7802 | 0.0222 | 0.0354 |

| Slag | kg CO2 eq | 0.0613 | 0.0610 | 0.0045 | 7.3772 | 0.0540 | 0.0714 |

| NaOH | kg CO2 eq | 1.8224 | 1.8170 | 0.1603 | 8.7956 | 1.5120 | 2.1630 |

| Na2SiO3 | kg CO2 eq | 0.9068 | 0.8894 | 0.0921 | 10.1559 | 0.7806 | 1.1589 |

| Superplasticiser | kg CO2 eq | 1.3178 | 1.2711 | 0.2976 | 22.5871 | 0.8601 | 2.0422 |

| Impact Category | Unit | Cement | Sand | Gravel | Water | Total |

|---|---|---|---|---|---|---|

| Climate change | kg CO2 eq | 376.637 | 2.146 | 18.587 | 0.202 | 397.570 |

| Ozone. D | kg CFC-11 eq | 2.5 × 10−6 | 2.3 × 10−10 | 4.7 × 10−7 | 1.0 × 10−9 | 3.0 × 10−6 |

| T. acidification | kg SO2 eq | 1.214 | 0.013 | 0.108 | 0.001 | 1.335 |

| F. eutrophication | kg P eq | 1.2 × 10−3 | 4.2 × 10−7 | 3.3 × 10−4 | 2.7 × 10−6 | 1.5 × 10−3 |

| M. eutrophication | kg N eq | 4.3 × 10−2 | 8.0 × 10−4 | 3.1 × 10−3 | 2.4 × 10−5 | 4.7 × 10−2 |

| Human toxicity | kg 1,4-DB eq | 8.089 | 0.810 | 0.920 | 0.011 | 9.830 |

| Photochem. OF | kg NMVOC | 1.163 | 0.022 | 0.078 | 0.001 | 1.263 |

| Particulate. MF | kg PM10 eq | 4.4 × 10−1 | 4.8 × 10−3 | 3.7 × 10−2 | 3.2 × 10−4 | 4.8 × 10−1 |

| T. ecotoxicity | kg 1,4-DB eq | 3.1 × 10−3 | 2.5 × 10−6 | 6.5 × 10−4 | 1.2 × 10−5 | 3.7 × 10−3 |

| F. ecotoxicity | kg 1,4-DB eq | 4.1 × 10−2 | 6.7 × 10−3 | 6.7 × 10−3 | 4.1 × 10−4 | 5.5 × 10−2 |

| M. ecotoxicity | kg 1,4-DB eq | 6.3 × 10−2 | 6.7 × 10−3 | 9.7 × 10−3 | 1.2 × 10−4 | 8.0 × 10−2 |

| Ionizing radiation | kBq U235 eq | 9.0 × 10−3 | 3.9 × 10−6 | 6.4 × 10−3 | 1.8 × 10−5 | 1.5 × 10−2 |

| Agricultural. LO | m2a | 1.761 | 0.001 | 0.575 | 0.051 | 2.388 |

| Urban. LO | m2a | 3.399 | 0.001 | 1.270 | 0.011 | 4.681 |

| Natural land. T | m2 | 9.3 × 10−3 | 2.9 × 10−6 | 2.2 × 10−2 | 1.8 × 10−5 | 3.1 × 10−2 |

| Water depletion | m3 | 7.683 | 1.376 | 2.061 | 0.237 | 11.357 |

| Metal depletion | kg Fe eq | 5.226 | 0.001 | 1.825 | 0.007 | 7.059 |

| Fossil depletion | kg oil eq | 65.844 | 0.793 | 5.053 | 0.050 | 71.740 |

| Design Components | Statistical Indicators (kg CO2 eq) | 95% Confidence Interval | ||||||

|---|---|---|---|---|---|---|---|---|

| Quantity | Mean | Median | SD | CV | 2.5% | 97.5% | ||

| 1 | Cement | 418 | 376.637 | 374.914 | 15.985 | 4.264 | 347.962 | 411.265 |

| 2 | Sand | 688 | 2.146 | 2.139 | 0.223 | 10.433 | 1.727 | 2.647 |

| 3 | Gravel | 1462 | 18.587 | 18.506 | 1.655 | 8.946 | 15.600 | 21.958 |

| 4 | Water | 209 | 0.202 | 0.192 | 0.064 | 33.511 | 0.108 | 0.359 |

| Conventional concrete (Output) | 397.570 | 395.750 | 16.03 | 4.031 | 365.9 | 428.5 | ||

| 1 | Fly ash | 389 | 10.780 | 10.682 | 1.270 | 11.888 | 8.652 | 13.788 |

| 2 | Slag | 167 | 10.243 | 10.181 | 0.756 | 7.423 | 9.013 | 11.925 |

| 3 | Sand | 688 | 2.146 | 2.139 | 0.223 | 10.433 | 1.727 | 2.647 |

| 4 | Gravel | 1462 | 18.587 | 18.506 | 1.655 | 8.946 | 15.600 | 21.958 |

| 5 | Water | 229 | 0.221 | 0.210 | 0.070 | 33.511 | 0.119 | 0.394 |

| 6 | NaOH | 41 | 74.718 | 74.498 | 6.572 | 8.822 | 61.994 | 88.681 |

| 7 | Na2SiO3 | 111 | 100.66 | 98.73 | 10.22 | 10.15 | 86.65 | 128.64 |

| 8 | Superplasticizer | 8.34 | 10.990 | 10.601 | 2.482 | 23.417 | 7.173 | 17.032 |

| Geopolymer concrete (Output) | 228.34 | 228.21 | 12.64 | 5.535 | 203.3 | 253.2 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tushar, Q.; Bhuiyan, M.A.; Abunada, Z.; Lemckert, C.; Giustozzi, F. Carbon Footprint and Uncertainties of Geopolymer Concrete Production: A Comprehensive Life Cycle Assessment (LCA). C 2025, 11, 55. https://doi.org/10.3390/c11030055

Tushar Q, Bhuiyan MA, Abunada Z, Lemckert C, Giustozzi F. Carbon Footprint and Uncertainties of Geopolymer Concrete Production: A Comprehensive Life Cycle Assessment (LCA). C. 2025; 11(3):55. https://doi.org/10.3390/c11030055

Chicago/Turabian StyleTushar, Quddus, Muhammed A. Bhuiyan, Ziyad Abunada, Charles Lemckert, and Filippo Giustozzi. 2025. "Carbon Footprint and Uncertainties of Geopolymer Concrete Production: A Comprehensive Life Cycle Assessment (LCA)" C 11, no. 3: 55. https://doi.org/10.3390/c11030055

APA StyleTushar, Q., Bhuiyan, M. A., Abunada, Z., Lemckert, C., & Giustozzi, F. (2025). Carbon Footprint and Uncertainties of Geopolymer Concrete Production: A Comprehensive Life Cycle Assessment (LCA). C, 11(3), 55. https://doi.org/10.3390/c11030055