Advances in the Synthesis of Carbon Nanomaterials Towards Their Application in Biomedical Engineering and Medicine

Abstract

1. Introduction

2. Synthesis and Medical Applications of Carbon Nanomaterials

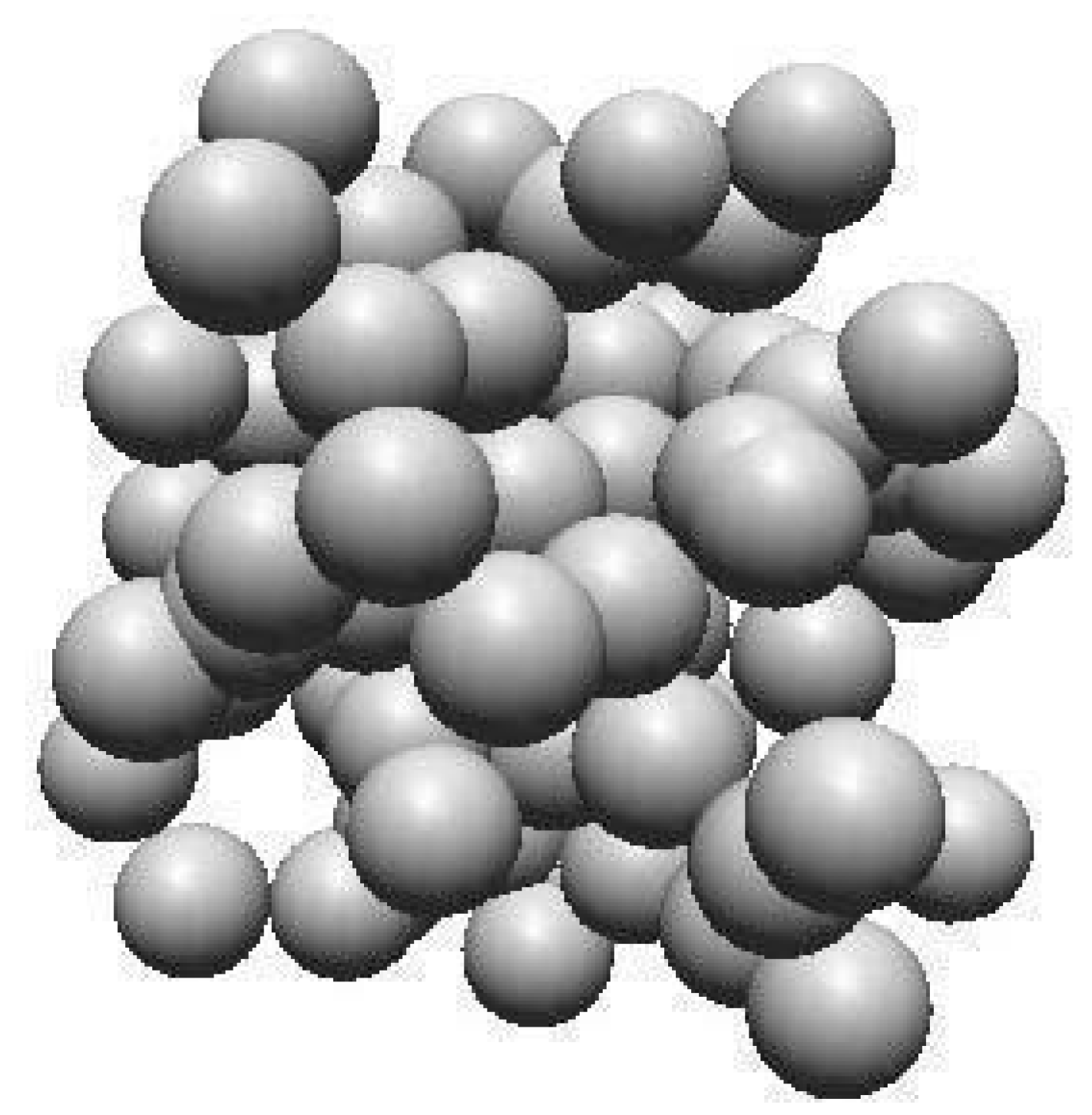

2.1. Amorphous Carbon

2.1.1. Structure of Amorphous Carbon

2.1.2. Synthesis of Amorphous Carbon

2.1.3. Uses of Amorphous Carbon in Medicine

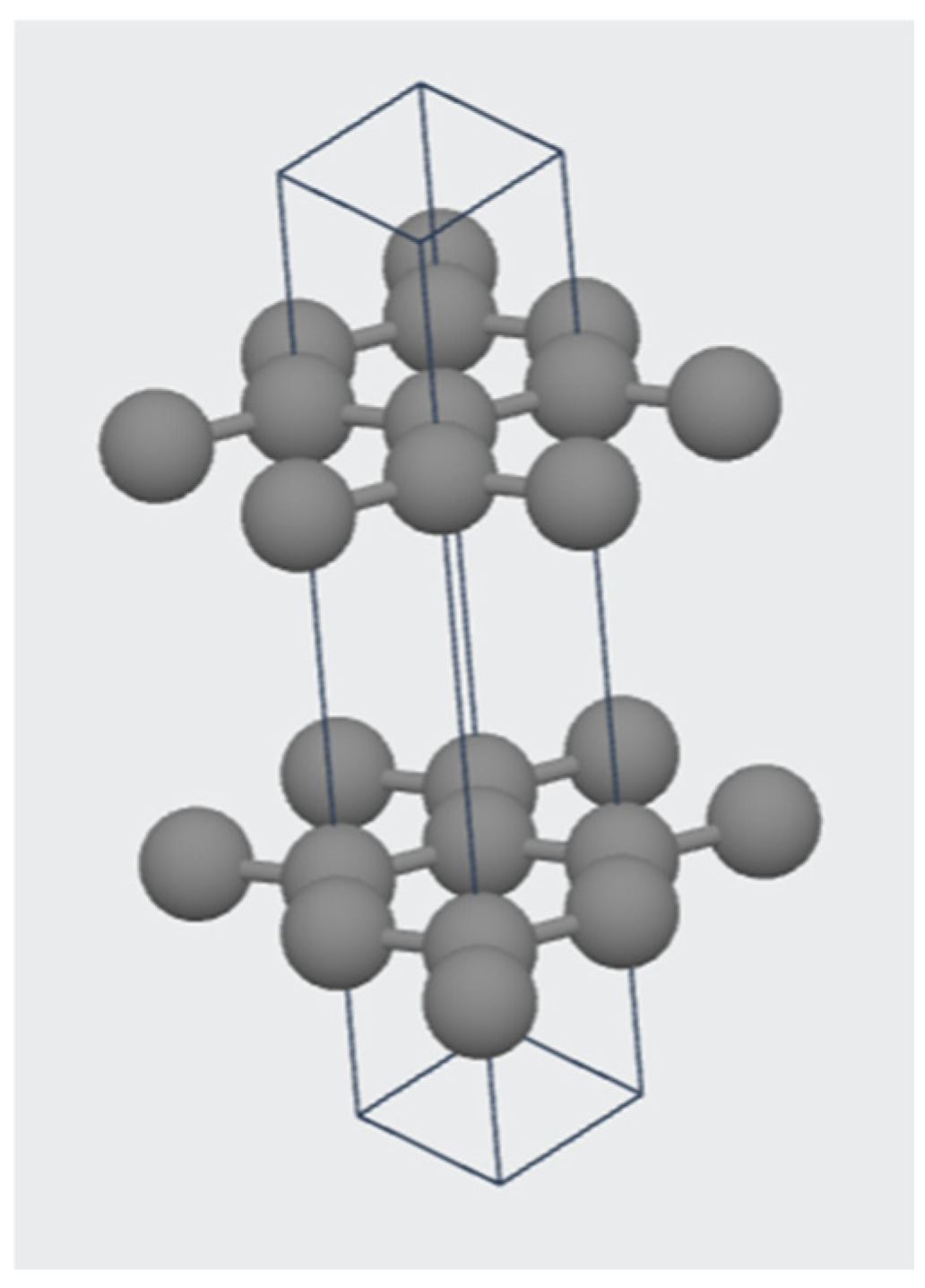

2.2. Graphite

2.2.1. Discovery of Graphite

2.2.2. Structure of Graphite

2.2.3. Synthesis of Graphite

2.2.4. Uses of Graphite in Medicine

2.3. Carbon Nanocones

2.3.1. Discovery of Carbon Nanocones

2.3.2. Structure of Carbon Nanocones

2.3.3. Synthesis of Carbon Nanocones

2.3.4. Uses of Carbon Nanocones in Medicine

2.3.5. Influence of Synthesis Conditions on Biomedical Application

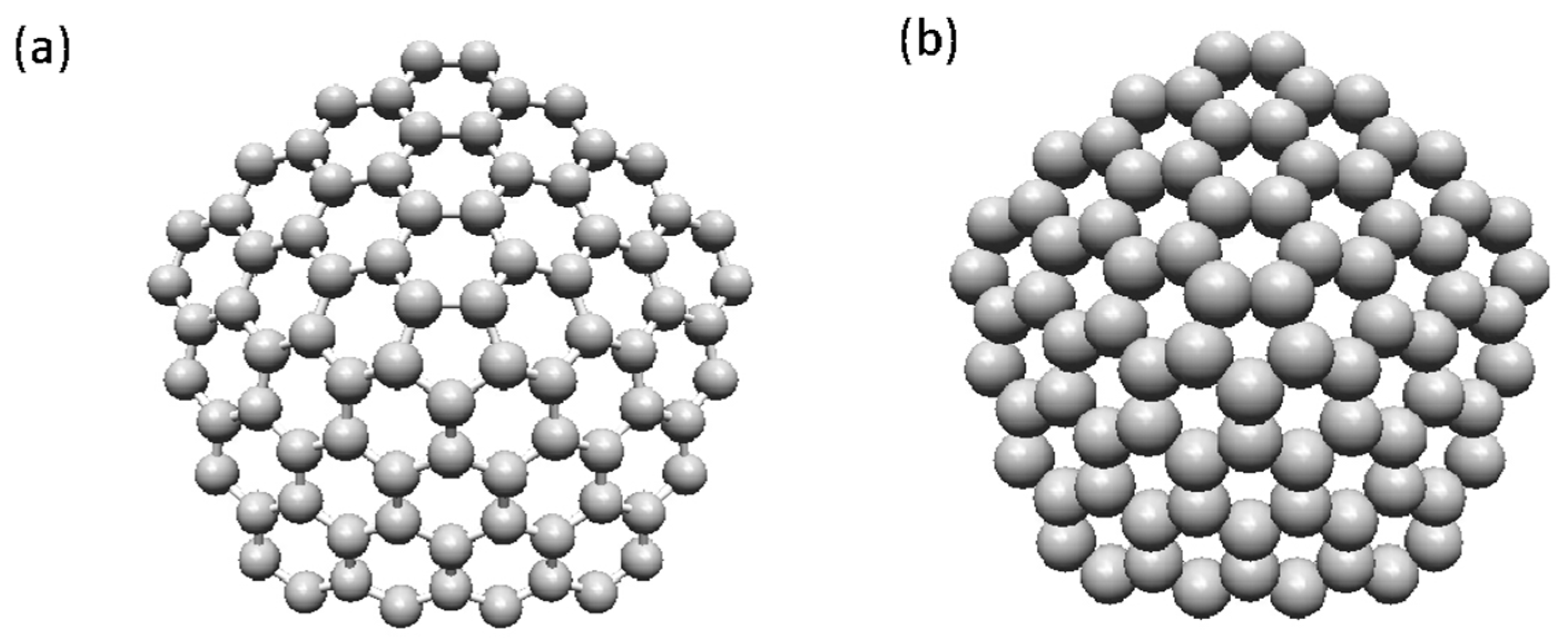

2.4. Fullerene (C60)

2.4.1. Discovery of Fullerene

2.4.2. Structure of Fullerene

2.4.3. Synthesis of Fullerene

2.4.4. Uses of Fullerene in Medicine

2.5. Graphene

2.5.1. Discovery and Structure of Graphene

2.5.2. Synthesis of Graphene

2.5.3. Uses of Graphene in Medicine

2.6. Reduced Graphene/Graphite Oxide (rGO)

2.6.1. Synthesis of Reduced Graphene/Graphite Oxides

2.6.2. Structure of Graphene Oxide

2.6.3. Synthesis of Reduced Graphite Oxide

2.6.4. Uses of Graphite Oxide in Medicine

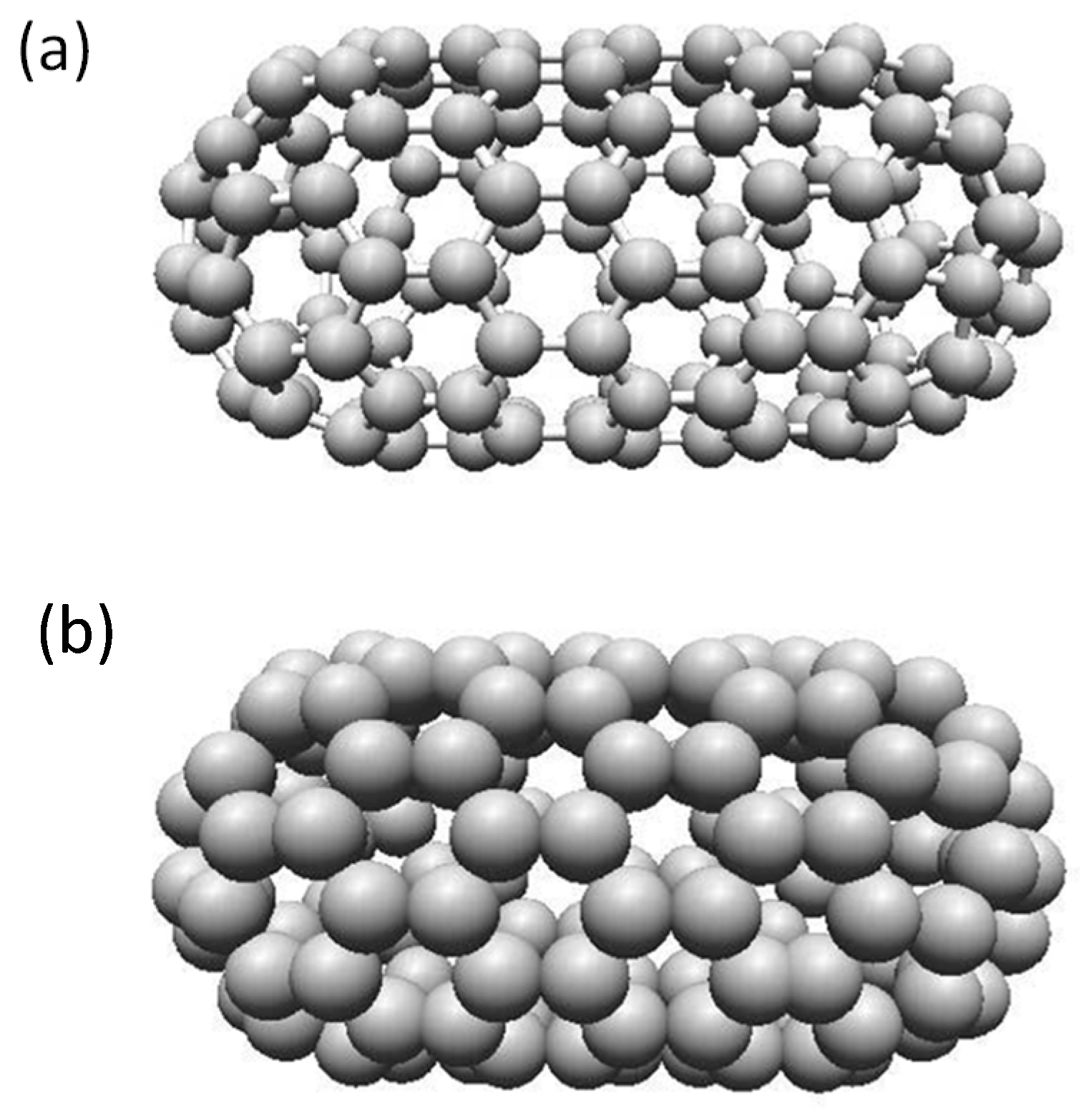

2.7. Single-Walled Carbon Nanotubes (SWCNTs) and Multi-Walled Carbon Nanotubes (MWCNTs)

2.7.1. Discovery of Carbon Nanotubes

2.7.2. Structure of Carbon Nanotubes

2.7.3. Synthesis of Carbon Nanotubes

2.7.4. Uses of Carbon Nanotubes in Medicine

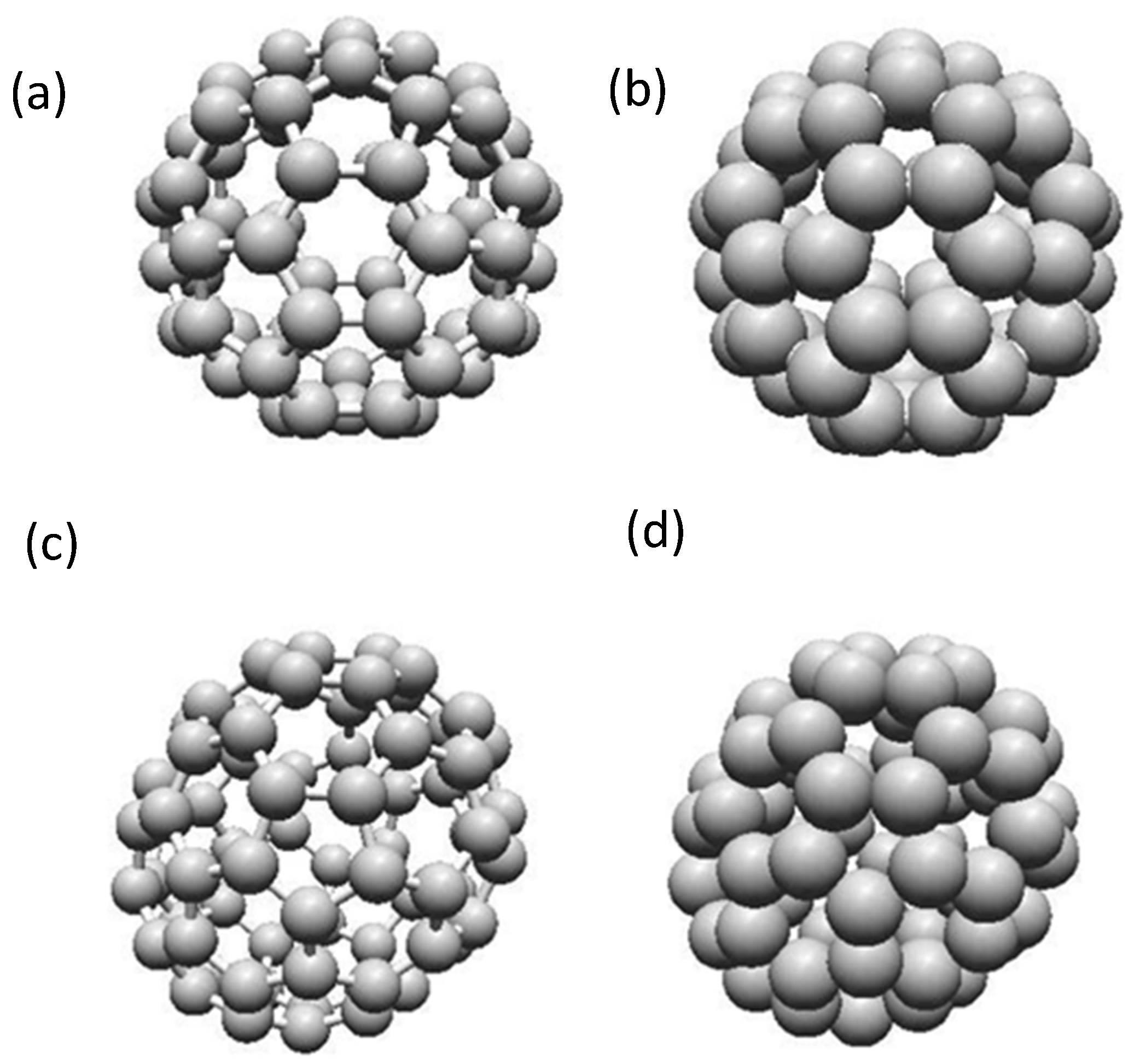

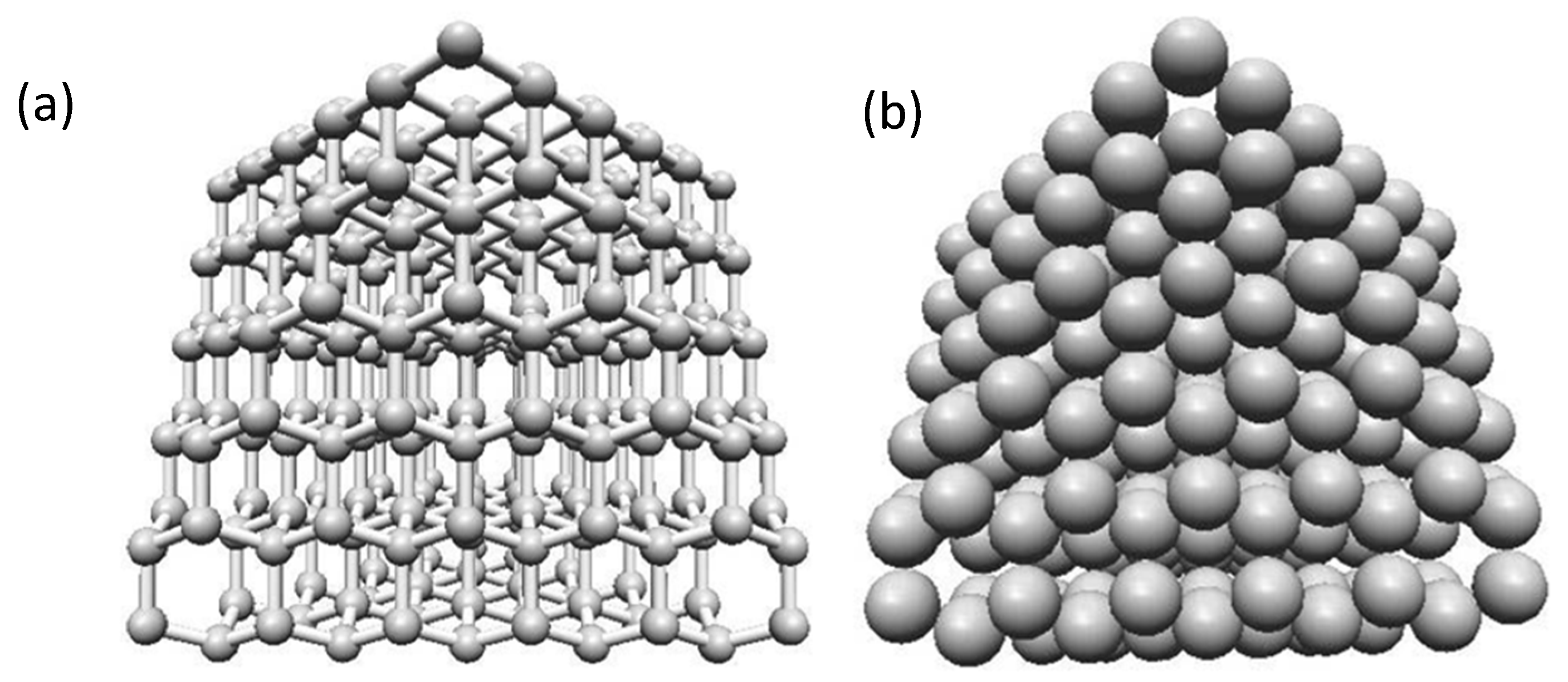

2.8. Nanodiamond

2.8.1. Discovery of Nanodiamond

2.8.2. Structure of Nanodiamond

2.8.3. Synthesis of Nanodiamond

2.8.4. Uses of Nanodiamond in Medicine

3. Challenges

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeinalipour-Yazdi, C.D.; Pullman, D.P. Quantitative Structure-Property Relationships for Longitudinal, Transverse, and Molecular Static Polarizabilities in Polyynes. J. Phys. Chem. B 2008, 112, 7377–7386. [Google Scholar] [CrossRef] [PubMed]

- Zeinalipour-Yazdi, C.D.; Christofides, C. Linear Correlation between Binding Energy and Young’s Modulus in Graphene Nanoribbons. J. Appl. Phys. 2009, 106, 054318. [Google Scholar] [CrossRef]

- Chen, X.; Tian, F.; Persson, C.; Duan, W.; Chen, N.X. Interlayer interactions in graphites. Sci. Rep. 2013, 3, 3046. [Google Scholar] [CrossRef]

- Melchor, S.; Dobado, J.A. CoNTub: An algorithm for connecting two arbitrary carbon nanotubes. J. Chem. Inf. Comput. Sci. 2004, 44, 1639–1646. [Google Scholar] [CrossRef]

- Akase, Z.; Murakami, Y.; Nakamura, T.; Sergiienko, R.; Shibata, E.; Shindo, D.; Suwa, H. Synthesis of Amorphous Carbon Nanoparticles and Carbon Encapsulated Metal Nanoparticles in Liquid Benzene by an Electric Plasma Discharge in Ultrasonic Cavitation Field. Ultrason. Sonochem. 2006, 13, 6–12. [Google Scholar]

- Falcao, E.; Wudl, F. Carbon Allotropes: Beyond Graphite and Diamond. Chem. Technol. Biotechnol. 2007, 82, 524–541. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Anwar, Z.; Muhammad, B. Exploration of Epoxy Resins, Hardening Systems and Epoxy/Carbon Nanotube Composite Designed for High Performance Materials: A Review. Polym.-Plast. Technol. Eng. 2019, 2019, 312–333. [Google Scholar] [CrossRef]

- Eid, M.E.-S. Polyethylenimine-Functionalized Magnetic Amorphous Carbon Fabricated from Oil Palm Leaves as a Novel Adsorbent for Hg(Ii) from Aqueous Solutions. Egypt. J. Pet. 2018, 27, 1051–1060. [Google Scholar]

- Clough, F.J.; Paul, S. Use of Amorphous Carbon as a Gate Insulator for Gaas and Related Compounds. Microelectron. Eng. 2003, 70, 78–82. [Google Scholar]

- Zeinalipour-Yazdi, C.D. A DFT Study of the Interaction of Aspirin, Paracetamol and Caffeine with One Water Molecule. J. Mol. Model. 2022, 28, 285. [Google Scholar] [CrossRef]

- Miriyala, N.; Ouyang, D.; Perrie, Y.; Lowry, D.; Kirby, D.J. Activated Carbon as a Carrier for Amorphous Drug Delivery: Effect of Drug Characteristics and Carrier Wettability. Eur. J. Pharm. Biopharm. 2017, 115, 197–205. [Google Scholar] [CrossRef] [PubMed]

- Alsaab, H.O.; Alharbi, F.D.; Alhibs, A.S.; Alanazi, N.B.; Alshehri, B.Y.; Saleh, M.A.; Alshehri, F.S.; Algarni, M.A.; Almugaiteeb, T.; Uddin, M.N.; et al. PLGA-Based Nanomedicine: History of Advancement and Development in Clinical Applications of Multiple Diseases. Pharmaceutics 2022, 14, 2728. [Google Scholar] [CrossRef] [PubMed]

- Barlow, A.J.; McCulloch, D.G.; McKenzie, D.R.; Murdoch, B.J.; Partridge, J.G.; Raeber, T.J.; Zhao, Z.C. Light-Gated Amorphous Carbon Memristors with Indium-Free Transparent Electrodes. Carbon 2019, 152, 59–65. [Google Scholar]

- Zhang, M.; Xiao, X.; Mao, J.; Lan, Z.; Huang, X.; Lu, Y.; Luo, B.; Liu, M.; Chen, M.; Chen, L. Synergistic Catalysis in Monodispersed Transition Metal Oxide Nanoparticles Anchored on Amorphous Carbon for Excellent Low-Temperature Dehydrogenation of Magnesium Hydride. Mater. Today Energy 2019, 12, 146–154. [Google Scholar] [CrossRef]

- Laue, M. Eine quantitative Prüfung der Theorie für die Interferenzerscheinungen bei Röntgenstrahlen. Annalen der Physik 1913, 346, 989–1002. [Google Scholar] [CrossRef]

- Bragg, W.H.; Bragg, W.L. X Rays and Crystal Structure; G. Bell and Sons, Ltd.: London, UK, 1915.

- Baskin, Y.; Meyer, L. Lattice Constants of Graphite at Low Temperatures. Phys. Rev. 1955, 100, 544. [Google Scholar] [CrossRef]

- Hull, A.W. A New Method of X-Ray Crystal Analysis. Phys. Rev. 1917, 10, 661–696. [Google Scholar] [CrossRef]

- Debye, P.; Scherrer, P. Interference on inordinate orientated particles in x-ray light. III. Phys. Z. 1917, 18, 291–301. [Google Scholar]

- Bernal, J.D. The Structure of Graphite. Proc. Phys. Soc. A 1924, 106, 749–773. [Google Scholar]

- Finch, G.I.; Wilman, H. The Diffraction of Electrons by Graphite. Proc. Roy. Soc. A 1936, 155, 345–365. [Google Scholar]

- Lipson, H.; Stokes, A.R. The Structure of Graphite. Proc. Roy. Soc. A 1942, 181, 101–105. [Google Scholar]

- Lukesh, J.S.; Pauling, L. The Problem of the Graphite Structure. Am. Minerol. 1950, 35, 125. [Google Scholar]

- Pauling, L. The Structure and Properties of Graphite and Boron Nitride. Proc. Natl. Acad. Sci. USA 1966, 56, 1646–1652. [Google Scholar] [CrossRef]

- Laves, F.; Baskin, Y. On the Formation of the Rhombohedral Graphite Modification. Zeit. Krist. 1956, 107, 337–356. [Google Scholar] [CrossRef]

- Zeinalipour-Yazdi, C.D. Electronic Structure and Interlayer Binding Energy of Graphite. Ph.D. Thesis, Northeastern University London, London, UK, 2006. [Google Scholar] [CrossRef]

- Zeinalipour-Yazdi, C.D.; Pullman, D.P. A New Interpretation of the Scanning Tunneling Microscope Image of Graphite. Chem. Phys. 2008, 348, 233–236. [Google Scholar] [CrossRef]

- Zeinalipour-Yazdi, C.D.; Pullman, D.P. Study of Rhombohedral Graphite X-Ray Filter Using the Sphere-in-Contact Model. Chem. Phys. Lett. 2019, 734, 136717. [Google Scholar] [CrossRef]

- The Materials Project. Materials Data on C by Materials Project; Berkeley, CA, USA. 2020. Available online: https://next-gen.materialsproject.org/materials/mp-48 (accessed on 15 February 2025). [CrossRef]

- Jain, A.; Ong, S.P.; Hautier, G.; Chen, W.; Richards, W.D.; Dacek, S.; Cholia, S.; Gunter, D.; Skinner, D.; Ceder, G.; et al. The Materials Project: A Materials Genome Approach to Accelerating Materials Innovation. APL Mater. 2013, 1, 011002. [Google Scholar] [CrossRef]

- Binnig, G.; Rohrer, H. Scanning Tunneling Microscopy—From Birth to Adolescence. Rev. Mod. Phys. 1987, 59, 615. [Google Scholar] [CrossRef]

- Heo, N.S.; Lee, S.U.; Rethinasabapathy, M.; Lee, E.Z.; Cho, H.-J.; Oh, S.Y.; Choe, S.R.; Kim, Y.; Hong, W.G.; Krishnan, G.; et al. Visible-light-driven dynamic cancer therapy and imaging using graphitic carbon nitride nanoparticles. Mater. Sci. Eng. C 2018, 90, 531–538. [Google Scholar] [CrossRef]

- Zhang, J.-R.; Kan, Y.-S.; Gu, L.-L.; Wang, C.-Y.; Zhang, Y. Graphite Carbon Nitride and Its Composites for Medicine and Health Applications. Chem. Asian J. 2021, 16, 2003. [Google Scholar] [CrossRef]

- Jin, Y.; Sun, Y.; Chen, Y.; Leia, J.; Wei, G. Molecular dynamics simulations reveal the mechanism of graphene oxide nanosheet inhibition of Aβ1–42 peptide aggregation. Phys. Chem. Chem. Phys. 2019, 21, 10981–10991. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Guan, Y.; Chen, Z.; Gao, N.; Ren, J.; Dong, K.; Qu, X. Platinum-coordinated graphitic carbon nitride nanosheet used for targeted inhibition of amyloid β-peptide aggregation. Nano Res. 2016, 9, 2411–2423. [Google Scholar] [CrossRef]

- Ardeshana, B.A.; Jani, U.B.; Patel, A.M.; Joshi, A.Y. Characterizing the Vibration Behavior of Double Walled Carbon Nano Cones for Sensing Applications. Mater. Technol. 2018, 33, 451–466. [Google Scholar] [CrossRef]

- Narjabadifam, A.; Vakili-Tahami, F.; Zehsaz, M. Modal Analysis of Multi-Walled Carbon Nanocones Using Molecular Dynamics Simulation. Comput. Mater. Sci. 2017, 137, 55–66. [Google Scholar] [CrossRef]

- Naess, S.N.; Elgsaeter, A.; Helgesen, G.; Knudsen, K.D. Carbon Nanocones: Wall Structure and Morphology. Sci. Technol. Adv. Mater. 2009, 10, 065002. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Ihsanullah, S.A.; Al-Ansari, T.; Atieh, M.A. A Review of Carbon Nanomaterials’ Synthesis via the Chemical Vapor Deposition (CVD) Method. Materials 2018, 11, 822. [Google Scholar] [CrossRef]

- Shen, P.; Xia, Y. Synthesis-Modification Integration: One-Step Fabrication of Boronic Acid Functionalized Carbon Dots for Fluorescent Blood Sugar Sensing. Anal. Chem. 2014, 86, 5323–5329. [Google Scholar] [CrossRef]

- Ge, M.; Sattler, K. Observation of Fullerene Cones. Chem. Phys. Lett. 1994, 220, 192–196. [Google Scholar] [CrossRef]

- Charlier, J.-C.; Rignanese, G.-M. Electronic Structure of Carbon Nanocones. Phys. Rev. Lett. 2001, 86, 5970–5973. [Google Scholar] [CrossRef]

- El-Barbary, A.A.; Kamel, M.A.; Eid, M.A.; Taha, H.O.; Mohamed, R.A.; Al-Khateeb, M.A. The Surface Reactivity of Pure and Monohydrogenated Nanocones Formed from Graphene Sheets. Graphene 2015, 4, 75–83. [Google Scholar] [CrossRef][Green Version]

- Ansari, R.; Mahmoudinezhad, E. Characterizing the Mechanical Properties of Carbon Nanocones Using an Accurate Spring-Mass Model. Comput. Mater. Sci. 2015, 101, 260–266. [Google Scholar] [CrossRef]

- He, H.; Pham-Huy, L.A.; Dramou, P.; Xiao, D.; Zuo, P.; Pham-Huy, C. Carbon Nanotubes: Applications in Pharmacy and Medicine. Biomed. Res. Int. 2013, 2013, 578290. [Google Scholar] [CrossRef]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. C60: Buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Smalley, R.E. Discovering the Fullerenes, Nobel Lecture. Chemistry 1997, 36, 1594–1601. [Google Scholar] [CrossRef]

- Krätschmer, W.; Lamb, L.D.; Fostiropoulos, K.; Huffman, D.R. Solid C60: A New Form of Carbon. Nature 1990, 347, 354–358. [Google Scholar] [CrossRef]

- Voicu, I.; Armand, X.; Cauchetier, M.; Herlin, N.; Bourcier, S. Laser Synthesis of Fullerenes from Benzene-Oxygen Mixtures. Chem. Phys. Lett. 1996, 256, 261–268. [Google Scholar] [CrossRef]

- Howard, J.B.; McKinnon, J.T.; Makarovsky, Y.; Lafleur, A.L.; Johnson, M.E. Fullerenes C60 and C70 in Flames. Nature 1991, 352, 139–141. [Google Scholar] [CrossRef]

- Bakry, R.; Vallant, R.M.; Najam-ul-Haq, M.; Rainer, M.; Szabo, Z.; Huck, C.W.; Bonn, G.K. Medicinal Applications of Fullerenes. Int. J. Nanomed. 2007, 2, 639–649. [Google Scholar]

- Chen, Z.; Mao, R.; Liu, Y. Fullerenes for Cancer Diagnosis and Therapy: Preparation, Biological and Clinical Perspectives. Curr. Drug Metab. 2012, 13, 1035–1045. [Google Scholar] [CrossRef]

- Somani, R.; Gokhale, M. Fullerenes: Chemistry and It’s Applications. Mini Rev. Org. Chem. 2015, 12, 1–12. [Google Scholar]

- Grushko, Y.S.; Sedov, V.P.; Shilin, V.A. Technology for Manufacture of Pure Fullerenes C60, C70 and a Concentrate of Higher Fullerenes. Russ. J. Appl. Chem. 2007, 80, 448–455. [Google Scholar] [CrossRef]

- Vidal, S.; Marco-Martínez, J.; Filippone, S.; Martín, N. Fullerenes for Catalysis: Metallofullerenes in Hydrogen Transfer Reactions. Chem. Commun. 2017, 53, 4842–4844. [Google Scholar] [CrossRef] [PubMed]

- Lieber, C.M.; Chen, C.-C. Preparation of Fullerenes and Fullerene-Based Materials. Solid. State Phys. 1994, 48, 109–148. [Google Scholar]

- Nimibofa, A.; Newton, E.A.; Cyprain, A.Y.; Donbebe, W. Fullerenes: Synthesis and Applications. J. Mater. Sci. Res. 2018, 7, 22–36. [Google Scholar] [CrossRef]

- Yang, S.; Pettiette, C.; Conceição, J.; Cheshnovsky, O.; Smalley, R. Ups of Buckminsterfullerene and Other Large Clusters of Carbon. Chem. Phys. Lett. 2013, 589, 31–34. [Google Scholar] [CrossRef][Green Version]

- Casadei, N.; Mireille, M.; Guillaume, Y.; André, C. A Humic Acid Stationary Phase for the High Performance Liquid Chromatography Separation of Buckminsterfullerenes: Theoretical and Practical Aspects. Anal. Chim. Acta 2007, 588, 268–273. [Google Scholar] [CrossRef]

- Kroto, W.H. The Stability of the Fullerenes Cn, with N = 24, 28, 32, 36, 50, 60 and 70. Nature 1987, 329, 529–531. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Ruoff, R.S.; Bielawski, C.W. From Conception to Realization: An Historial Account of Graphene and Some Perspectives for Its Future. Angew. Chem. Int. 2010, 49, 9336–9344. [Google Scholar] [CrossRef]

- Cai, M.; Thorpe, D.; Adamson, D.H.; Schniepp, H.C. Methods of Graphite Exfoliation. J. Mater. Chem. 2012, 22, 24992–25000. [Google Scholar] [CrossRef]

- Prekodravac, J.R.; Kepić, D.P.; Colmenares, J.C.; Giannakoudakis, D.A.; Jovanović, S.P. A Comprehensive Review on Selected Graphene Synthesis Methods: From Electrochemical Exfoliation through Rapid Thermal Annealing Towards Biomass Pyrolysis. J. Mater. Chem. C 2021, 9, 6722–6748. [Google Scholar] [CrossRef]

- Yuan, L.; Ge, J.; Peng, X.; Zhang, Q.; Wu, Z.; Jian, Y.; Xiong, X.; Yin, H.; Han, J. A Reliable Way of Mechanical Exfoliation of Large Scale Two Dimensional Materials with High Quality. AIP Adv. 2016, 6, 125201. [Google Scholar] [CrossRef]

- Bharech, S.; Kumar, R. A Review on the Properties and Applications of Graphene. J. Mater. Sci. Mech. Eng. 2015, 2, 70–73. [Google Scholar]

- Neto, A.H.C.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The Electronic Properties of Graphene. Rev. Mod. Phys. 2009, 81, 109. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal Properties of Graphene and Nanostructured Carbon Materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman Spectroscopy as a Versatile Tool for Studying the Properties of Graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Elbahri, M. Graphene Membranes for Water Desalination. NPG Asia Mater. 2017, 9, e417. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Chemical Functionalization of Graphene and Its Applications, Progress in Materials Science. Prog. Mater. Sci. 2012, 57, 1061–1105. [Google Scholar] [CrossRef]

- Georgakilas, V.; Otyepka, M.; Bourlinos, A.B.; Chandra, V.; Kim, N.; Kemp, K.C.; Hobza, P.; Zboril, R.; Kim, K.S. Functionalization of Graphene: Covalent and Non-Covalent Approaches, Derivatives and Applications. Chem. Rev. 2012, 112, 6156–6214. [Google Scholar] [CrossRef]

- Wei, W.; Qu, X. Extraordinary Physical Properties of Functionalized Graphene. Small 2012, 8, 2138–2151. [Google Scholar] [CrossRef]

- Lü, P.; Feng, Y.; Zhang, X.; Li, Y.; Feng, W. Recent Progresses in Application of Functionalized Graphene Sheets. China Technol. Sci. 2010, 53, 2311–2319. [Google Scholar] [CrossRef]

- Abdullaeva, Z.; Kelgenbaeva, Z.; Masayuki, T.; Hirano, M.; Nagaoka, S.; Shirosaki, T. Graphene Sheets with Modified Surface by Sodium Lauryl Sulfate Surfactant for Biomedical Applications. Graphene 2016, 5, 155–165. [Google Scholar] [CrossRef]

- Gadakh, D.; Dashora, P.; Wadhankar, G. A Review Paper on Graphene Coated Fibres. Graphene 2019, 8, 53–74. [Google Scholar] [CrossRef]

- Atif, R.; Inam, F. The Dissimilarities between Graphene and Frame-Like Structures. Graphene 2016, 5, 55–72. [Google Scholar] [CrossRef]

- Randviir, E.P.; Brownson, D.A.C.; Banks, C.E. A Decade of Graphene Research: Production, Applications and Outlook. Today Energy 2014, 17, 426–432. [Google Scholar] [CrossRef]

- Dimitrakopoulos, C.; Avouris, P. Graphene: Synthesis and Applications. Mater. Today Energy 2012, 15, 86–97. [Google Scholar]

- Adetayo, A.; Runsewe, D. Synthesis and Fabrication of Graphene and Graphene Oxide: A Review. Open J. Compos. Mater. 2019, 9, 207–229. [Google Scholar] [CrossRef]

- Reshma, S.C.; Mohanan, P.V. Graphene: A Multifaceted Nanomaterial for Cutting Edge Biomedical Application. Int. J. Med. Nano. Res. 2014, 1, 1–6. [Google Scholar] [CrossRef]

- Cai, X.; Lai, L.; Shen, Z.; Lin, J. Graphene and Graphene-Based Composites as Li-Ion Battery Electrode Materials and Their Application in Fuel Cells. J. Mater. Chem. A 2017, 5, 15423–15446. [Google Scholar] [CrossRef]

- Zare, H.; Ahmadi, S.; Ghasemi, A.; Ghanbari, M.; Rabiee, N.; Bagherzadeh, M.; Karimi, M.; Webster, T.J.; Hamblin, M.R.; Mostafavi, E. Carbon nanotubes: Smart drug/gene delivery carriers. Int. J. Nanomed. 2021, 16, 1681–1706. [Google Scholar] [CrossRef]

- Pumera, M. Graphene in Biosensing. Mater. Today 2011, 14, 308–315. [Google Scholar] [CrossRef]

- Barrejón, M.; Zummo, F.; Mikhalchan, A.; Vilatela, J.J.; Fontanini, M.; Scaini, D.; Ballerini, L.; Prato, M. TEGylated Double-Walled Carbon Nanotubes as Platforms to Engineer Neuronal Networks. ACS Appl. Mater. Interfaces 2023, 15, 77–90. [Google Scholar] [CrossRef] [PubMed]

- Malode, S.J.; Pandiaraj, S.; Alodhayb, A.; Shetti, N.P. Carbon Nanomaterials for Biomedical Applications: Progress and Outlook. ACS Appl. Bio Mater. 2024, 7, 752–777. [Google Scholar] [CrossRef]

- Avouris, P.; Xia, F. Graphene Applications in Electronics and Photonics. In Graphene Fundamentals and Functionality; Cambridge University Press: Cambridge, UK, 2012; Volume 37, pp. 1225–1234. [Google Scholar]

- Yang, H.; Cao, Y.; He, J.; Zhang, Y.; Jin, B.; Sun, J.; Wang, Y.; Zhao, Z. Highly Conductive Free-Standing Reduced Graphene Oxide Thin Films for Fast Photoelectric Devices. Carbon 2017, 115, 561–570. [Google Scholar] [CrossRef]

- Schniepp, H.C.; Li, J.-L.; McAllister, M.J.; Sai, H.; Herrera-Alonso, M.; Adamson, D.H.; Prud’homme, R.K.; Car, R.; Saville, D.A.; Aksay, I.A. Functionalized Single Graphene Sheets Derived from Splitting Graphite Oxide. J. Phys. Chem. B 2006, 110, 8535–8539. [Google Scholar] [CrossRef]

- Gurunathan, S.; Kim, J.-H. Synthesis, toxicity, biocompatibility, and biomedical applications of graphene and graphene-related materials. Int. J. Nanomed. 2016, 11, 1927–1945. [Google Scholar] [CrossRef]

- Cote, L.; Kim, F.; Huang, J. Langmuir−Blodgett Assembly of Graphite Oxide Single Layers. J. Am. Chem. Soc. 2009, 131, 1043–1049. [Google Scholar] [CrossRef]

- Wu, S.; Shi, T.; Zhang, L. Preparation and Properties of Amine-Functionalized Reduced Graphene Oxide/Waterborne Polyurethane Nanocomposites. High Perform. Polym. 2015, 28, 453–465. [Google Scholar] [CrossRef]

- Marcano, D.; Kosynkin, D.; Berlin, J.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.; Lu, W.; Tour, J. Improved Synthesis of Graphene Oxide. ACS Nano 2010, 4, 4806–4814, Erratum in ACS Nano 2018, 12, 2078–2078. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H. The Reduction of Graphene Oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Dideikin, A.; Vul’, A. Graphene Oxide and Derivatives: The Place in Graphene Family. Front. Phys. 2019, 6, 1–13. [Google Scholar] [CrossRef]

- Gómez-Navarro, C.; Meyer, J.; Sundaram, R.; Chuvilin, A.; Kurasch, S.; Burghard, M.; Kern, K.; Kaiser, U. Atomic Structure of Reduced Graphene Oxide. Nano Lett. 2010, 10, 1144–1148. [Google Scholar] [CrossRef] [PubMed]

- Hidayah, N.; Liu, W.; Lai, C.; Noriman, N.; Khe, C.; Hashim, U.; Lee, H. Comparison on Graphite, Graphene Oxide and Reduced Graphene Oxide: Synthesis and Characterization. AIP Conf. Proc. 2017, 1892, 150002. [Google Scholar]

- Smith, A.; LaChance, A.; Zeng, S.; Liu, B.; Sun, L. Synthesis, Properties, and Applications of Graphene Oxide/Reduced Graphene Oxide and Their Nanocomposites. Nano Mater. Sci. 2019, 1, 31–47. [Google Scholar] [CrossRef]

- Iijima, S. Helical Microtubules of Graphitic Carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Radushkevich, L.V.; Lukyanovich, V.M. The Structure of Carbon Forming in Thermal Decomposition of Carbon Monoxide on an Iron Catalyst. Russ. J. Phys. Chem. 1952, 26, 88–95. [Google Scholar]

- Iijima, S.; Ichihashi, T. Single-Shell Carbon Nanotubes of 1-Nm Diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Bethune, D.S.; Kiang, C.H.; de Vries, M.S.; Gorman, G.; Savoy, R.; Vazquez, J.; Beyers, R. Cobalt-Catalysed Growth of Carbon Nanotubes with Single-Atomic-Layer Walls. Nature 1993, 363, 605–660.607. [Google Scholar] [CrossRef]

- Monthioux, M.; Kuznetsov, V. Who Should Be Given the Credit for the Discovery of Carbon Nanotubes? Carbon 2006, 44, 1621–1623. [Google Scholar] [CrossRef]

- Venkataraman, A.; Amadi, E.V.; Chen, Y.; Papadopoulos, C. Carbon Nanotube Assembly and Integration for Applications. Nanoscale Res. Lett. 2019, 14, 1–47. [Google Scholar] [CrossRef]

- Anzar, N.; Hasan, R.; Tyagi, M.; Yadav, N.; Narang, J. Carbon Nanotube-a Review on Synthesis, Properties and Plethora of Applications in the Field of Biomedical Science. Sens. Int. 2020, 1, 100003. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Mahalingam, P.; Karthik, M. Large Scale Synthesis of Carbon Nanotubes. J. Chem. 2008, 6, 1–12. [Google Scholar] [CrossRef]

- Deshpande, P.; Mahendru, A. A Review of Single Wall Carbon Nanotube: Structure and Preparation. Int. J. Sci. Technol. Res. 2018, 7, 132–134. [Google Scholar]

- Sun, D.L.; Hong, R.Y.; Liu, J.Y.; Wang, F.; Wang, Y.F. Preparation of Carbon Nanomaterials Using Two-Group Arc Discharge Plasma. Chem. Eng. J. 2016, 303, 217–230. [Google Scholar] [CrossRef]

- Zhu, X.; Xie, Y.; Zhang, Y.; Huang, H.; Huang, S.; Hou, L.; Zhang, H.; Li, Z.; Shi, J.; Zhang, Z. Thermo-Sensitive Liposomes Loaded with Doxorubicin and Lysine Modified Single-Walled Carbon Nanotubes as Tumor-Targeting Drug Delivery System. J. Biomater. Appl. 2014, 29, 769–779. [Google Scholar] [CrossRef]

- Burke, A.; Ding, X.; Singh, R.; Kraft, R.A.; Levi-Polyachenko, N.; Rylander, M.N.; Szot, C.; Buchanan, C.; Whitney, J.; Fisher, J.; et al. Long-term survival following a single treatment of kidney tumors with multiwalled carbon nanotubes and near-infrared radiation. Proc. Natl. Acad. Sci. USA 2009, 106, 12897–12902. [Google Scholar] [CrossRef]

- Danilenko, V.V. On the History of the Discovery of Nanodiamond Synthesis. Phys. Solid. State 2004, 46, 595–599. [Google Scholar] [CrossRef]

- Narayan, J.; Bhaumik, A. Research Update: Direct Conversion of Amorphous Carbon into Diamond at Ambient Pressures and Temperatures in Air. APL Mater. 2015, 3, 100702. [Google Scholar] [CrossRef]

- Xu, J.; Chow, E.K.-H. Biomedical Applications of Nanodiamonds: From Drug-Delivery to Diagnostics. SLAS Technol. 2023, 28, 214–222. [Google Scholar] [CrossRef]

- Moosa, A.A.; Abed, M.S. Graphene preparation and graphite exfoliation. Turk. J. Chem. 2021, 45, 493–519. [Google Scholar] [CrossRef]

- Rimkute, G.; Gudaitis, M.; Barkauskas, J.; Zarkov, A.; Niaura, G.; Gaidukevic, J. Synthesis and Characterization of Graphite Intercalation Compounds with Sulfuric Acid. Crystals 2022, 12, 421. [Google Scholar] [CrossRef]

- Jayasena, B.; Subbiah, S. A Novel Mechanical Cleavage Method for Synthesizing Few-Layer Graphenes. Nanoscale Res. Lett. 2011, 6, 95. [Google Scholar] [CrossRef] [PubMed]

- Naik, V.; Zantye, P.; Gunjal, D.; Gore, A.; Anbhule, P.; Kowshik, M.; Bhosale, S.V.; Kolekar, G. Nitrogen-Doped Carbon Dots via Hydrothermal Synthesis: Naked Eye Fluorescent Sensor for Dopamine and Used for Multicolor Cell Imaging. ACS Appl. Bio Mater. 2019, 2, 2069–2077. [Google Scholar] [CrossRef]

- Naief, M.F.; Mohammed, S.N.; Mayouf, H.J.; Mohammed, A.M. A review of the role of carbon nanotubes for cancer treatment based on photothermal and photodynamic therapy techniques. J. Organomet. Chem. 2023, 999, 122819. [Google Scholar] [CrossRef]

| Category | Function | Key Benefits | Challenges | Ref. |

|---|---|---|---|---|

| Therapeutics | Drug delivery, phototherapy, gene delivery | High drug-load capacity via large surface area; targeted delivery through functional groups (carboxyl, amine, folate, antibodies); NIR-triggered heat and ROS for cancer ablation; π–π interactions protect genetic material; pegylation improves tumor targeting | Potential cytotoxicity; accumulation in organs; immune activation; limited clinical translation. | Reshma et al. [81], Adetayo et al. [80], Atif et al. [77], Zare et al. [83] |

| Diagnostics | Biosensing, real-time disease detection | Rapid electron transfer; high conductivity and sensitivity; detects low-concentration biomarkers; DNA-functionalized graphene for disease-specific detection | Sensor stability over time; biofouling; reproducibility; complex fabrication and miniaturization. | Randviir et al. [78], Atif et al. [77], Wei & Qu [73], Pumera [84] |

| Regenerative Medicine | Tissue scaffolds, neural and bone repair | Supports cell adhesion, proliferation, and differentiation; mimics extracellular matrix; enhanced biocompatibility via poly-L-lysine and other coatings | Mechanical mismatch with tissues; long-term degradation behavior unclear; limited in vivo validation. | Gadakh et al. [76], Reshma et al. [81], Barrejón et al. [85], Malode et al. [86] |

| Protective Coatings | Implant and antimicrobial coatings | Corrosion and wear resistance; antimicrobial action via metabolic inhibition; prevents infection on medical implants; SDS-modified graphene enhances antibacterial activity | Durability under physiological conditions; risk of delamination; regulatory hurdles for implant use. | Abdullaeva et al. [75], Gadakh et al. [76], El-Barbary et al. [43], Barlow et al. [13] |

| Wearables & Devices | Flexible sensors, implantable devices | High flexibility and strength; real-time monitoring support; electrical conductivity for bioelectronics; epitaxial graphene enables integration into medical hardware | Signal drift over time; interfacing with biological tissue; long-term biocompatibility of circuitry. | Avouris et al. [87], Atif et al. [77], Yang et al. [88], Barrejón et al. [85] |

| Energy Systems | LIBs in medical devices | Improved lithium storage; structural resilience; reduced internal resistance; stable, compact power for implants; graphene composites with silicon/metal oxides enhance battery life | Thermal safety concerns; degradation under biological exposure; battery encapsulation for implants. | Cai et al. [82], Yuan et al. [65], Bharech & Kumar [66], Cai et al. [82] |

| Functionalization & Synthesis | Graphene modification methods | Functional groups (ether, thiocarbonyl, sulfoxide, carboxyl, hydroxyl, carbonyl); enhanced dispersion, targeting, and biocompatibility; Techniques: CVD, solvothermal with SDS, Hummers’ method, chemical reduction | Residual synthesis byproducts; batch-to-batch variation; scale-up challenges for biomedical-grade purity. | Abdullaeva et al. [75], Gadakh et al. [76], Avouris et al. [87], Adetayo et al. [80] |

| CNT Type & Wall Structure | Electronic Type | Synthesis Methods | Functionalization | Biomedical Applications (with Challenges) | TRL | Example Studies |

|---|---|---|---|---|---|---|

| SWCNT (Single cylinder) | Semiconducting or metallic (chirality-dependent) | CVD, laser ablation | Mainly exohedral | Biosensors and imaging probes; challenges include toxicity at high doses and purification difficulty. | 3–5 | Zhu et al. [109], He et al. [45] |

| DWCNT (Two concentric tubes) | Typically semiconducting core, metallic shell | CVD (esp. CCVD) | Both endo- and exohedral | Drug delivery and theranostics; synthesis complexity and biocompatibility vary with surface treatment. | 3–4 | Malode et al. [86], Barrejón et al. [85] |

| MWCNT (Items with more than 2 (i.e., 3 to 50+) cylinders) | Semi-metallic | Arc discharge, CVD | Exohedral | Used in tissue scaffolds and drug carriers; tend to agglomerate and exhibit batch inconsistency. | 4–6 | Burke et al. [110], Zare et al. [83], Heo et al. [32] |

| CNT Solids (Aggregated CNTs in yarns, films, etc.) | Mixed depending on base CNTs | CVD + post-processing | Surface coating | Applied in supercapacitors and mechanical biosensors; limited solubility and processing challenges remain. | 5–6 | Anzar et al. [105], Yang et al. [88], Venkataraman et al. [104] |

| Synthesis Method | Key Features | Cost | Scalability | Purity (% Target Material) | Medical Relevance | Challenges | Example Studies |

|---|---|---|---|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Produces high-quality CNTs and graphene with precise control over properties | High (~USD 200–USD 500/g) | Moderate | High (~90–98%) | Ideal for biosensors and neural interfaces where high material quality is critical | High cost; requires precise control | Smith et al. [98], Iijima et al. [99], Manawi et al. [39] |

| Pyrolysis of Hydrocarbons | Thermal decomposition of gases (e.g., methane) to produce amorphous carbon | Low (~USD 50–USD 100/g) | High | Moderate (~70–90%) | Cost-effective for coatings, drug-delivery systems, and composite materials | Impurities; limited structure control | Sahoo et al. [93], Moosa et al. [114], Sun et al. [108] |

| Laser Ablation | High-intensity lasers vaporize graphite for high-purity graphene/nanotubes | Very High (~USD 1000+/g) | Low | Very High (~95–99%) | Advanced uses: imaging agents, sensors, prosthetics | High cost; low scalability for industrial use | Rimkute et al. [115], Deshpande et al. [107], Karthikeyan et al. [106] |

| Scotch Tape Technique | Mechanical exfoliation of graphite for research-scale graphene | Very Low (negligible) | Very Low | Very High (~99.9%) | Research tool for biosensing and early experimental applications | Labor-intensive; impractical for scaling | Yuan et al. [65], Neto et al. [67], Prekodravac et al. [11], Bharech et al. [66] |

| Graphite Intercalation | Inserts molecules (e.g., acids) to create GO from graphite layers | Moderate (~USD 100–USD 300/g) | Low to Moderate | Moderate to High (~80–95%) | Enables GO for coatings, composites, and functionalized drug delivery | Chemical hazards and byproducts | Rimkute et al. [115], Moosa et al. [114], Hidayah et al. [97] |

| Electric Arc Discharge (ARC) | Graphite electrodes arc discharge to create CNTs and fullerenes | Moderate (~USD 100–USD 300/g) | Low | High (~85–95%) | High-quality CNTs for imaging and diagnostics; currently research-stage | Energy-intensive; low scalability | Karthikeyan et al. [106], Manawi et al. [39] |

| Laser Vaporization | Laser vaporization of graphite targets to form nanomaterials | Very High (~USD 1000+/g) | Low | Very High (~95–98%) | Ideal for devices requiring exact structural purity (e.g., implants) | Expensive; not suited for large-scale production | Iijima et al. [101], Bethune et al. [102], Monthioux et al. [103] |

| Solar Energy Focusing | Concentrates sunlight to form nanomaterials sustainably | Low (~USD 50–USD 100/g) | Low to Moderate | Moderate (~70–85%) | Eco-friendly method for drug-delivery carriers and composites | Limited structure control; sunlight dependency | Hidayah et al. [97], Jayasena et al. [116] |

| Laser-Induced Melting | Laser restructuring of carbon to form novel biomedical nanostructures | High (~USD 300–USD 800/g) | Low | High (~90–99%) | Creates optical imaging agents and precision nanomaterials | Advanced equipment and expertise required | Naik et al. [117], Heo et al. [32], Shen et al. [40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elahi, N.; Zeinalipour-Yazdi, C.D. Advances in the Synthesis of Carbon Nanomaterials Towards Their Application in Biomedical Engineering and Medicine. C 2025, 11, 35. https://doi.org/10.3390/c11020035

Elahi N, Zeinalipour-Yazdi CD. Advances in the Synthesis of Carbon Nanomaterials Towards Their Application in Biomedical Engineering and Medicine. C. 2025; 11(2):35. https://doi.org/10.3390/c11020035

Chicago/Turabian StyleElahi, Numair, and Constantinos D. Zeinalipour-Yazdi. 2025. "Advances in the Synthesis of Carbon Nanomaterials Towards Their Application in Biomedical Engineering and Medicine" C 11, no. 2: 35. https://doi.org/10.3390/c11020035

APA StyleElahi, N., & Zeinalipour-Yazdi, C. D. (2025). Advances in the Synthesis of Carbon Nanomaterials Towards Their Application in Biomedical Engineering and Medicine. C, 11(2), 35. https://doi.org/10.3390/c11020035