Computational Fluid Dynamics Study on Bottom-Hole Multiphase Flow Fields Formed by Polycrystalline Diamond Compact Drill Bits in Foam Drilling

Abstract

1. Introduction

2. Methods

2.1. Theoretical Basis of Numerical Model

2.1.1. Basic Governing Equations of Fluids

- Mass Conservation Equation (Continuity Equation)

- is the velocity component of the velocity vector of a certain point in the coordinate direction;

- is the velocity component of the velocity vector of a certain point in the coordinate direction;

- is the fluid density.

- 2.

- Momentum Conservation Equation

- is velocity vector;

- , , etc. are components of the stress tensor;

- , and are body forces (such as gravity).

- 3.

- Energy Conservation Equation

- is temperature;

- k is heat transfer coefficient;

- ST is the total heat source term, including kinetic energy conversion, viscous dissipation (energy converted to heat due to the viscous action of the fluid) and the work done by gravity on the fluid.

- 4.

- Turbulence Model

- is turbulent kinetic energy dissipation rate constant, ;

- is turbulent kinetic energy dissipation rate constant, ;

- is turbulent kinetic energy Prandtl constant, ;

- is dissipation rate Prandtl constant, ;

- is turbulent kinetic energy caused by viscous forces;

- is the turbulent kinetic energy caused by the influence of buoyancy;

- is the effect of buoyancy on the dissipation rate.

- 5.

- Wall Function Model

- is a dimensionless parameter representing the distance;

- is Karman constant (typically valued at 0.41);

- is the logarithmic law constant (typically valued at 5.0).

2.1.2. Euler–Eulerian Multiphase Flow Model

- and are the densities of the gas and liquid phases, respectively;

- and are the velocities of the gas and liquid phases, respectively;

- is the fluid pressure;

- is the gravitational acceleration;

- and are the stress tensors of the gas and liquid phases, respectively;

- and are the interaction forces between the gas and liquid phases (such as drag force, virtual mass force, lift force, wall lubrication force, and turbulence dissipation force).

2.1.3. Lagrangian Particle Tracking Model

- 1.

- Particle force balance equation

- is the velocity of the particle;

- is the total force acting on the particle, including the drag force, buoyancy due to gravity, and rotational force;

- 2.

- Particle erosion model

- is the particle impact velocity;

- is a dimensionless function related to the impact angle.

2.2. Geometric Modeling and Mesh Generation

2.2.1. Geometric Model

2.2.2. Mesh Generation and Mesh-Independent Analysis

2.2.3. Boundary Conditions

- Inlet conditions: set the foam drilling fluid displacement to 60 L/s, assuming that the air is ideal, the volume fraction is 0.9, and the volume fraction of water is 0.1. The cuttings are made of sandstone and have a density of 2300 kg/m3. It is assumed that the cuttings are incompressible spherical particles.

- Wall conditions: the entire flow field rotates at 120 r/min, and the wall rotates in the opposite direction at the same speed. There is no penetration or slip between the fluid, wall, and rock debris, and the outer wall is smooth.

- Conduct a transient analysis of the bottom-hole flow field, that is, an unsteady-state calculation, and the numerical simulation calculation takes 5 s.

- Outlet conditions: use a pressure outlet; assume the simulated conditions are at a depth of 1800 m in the well. The outlet reference pressure is set to 18 MPa.

- Use rock-breaking simulations to obtain the initial data for the rock cuttings generated by each cutting tooth during the drilling process, including the initial velocity, initial direction (X, Y, Z), and initial mass flow rate of the cuttings. These parameters are then incorporated into the corresponding cutting teeth when establishing the numerical calculation model, serving as one of the initial conditions for the numerical simulation. Due to space limitations, only the rock-breaking simulation results of the blade No. 1 are listed here, as shown in Table 2. Table 3 shows the initial cuttings mass flow rate of each blade.

2.3. Hydraulic Structure Evaluation Method

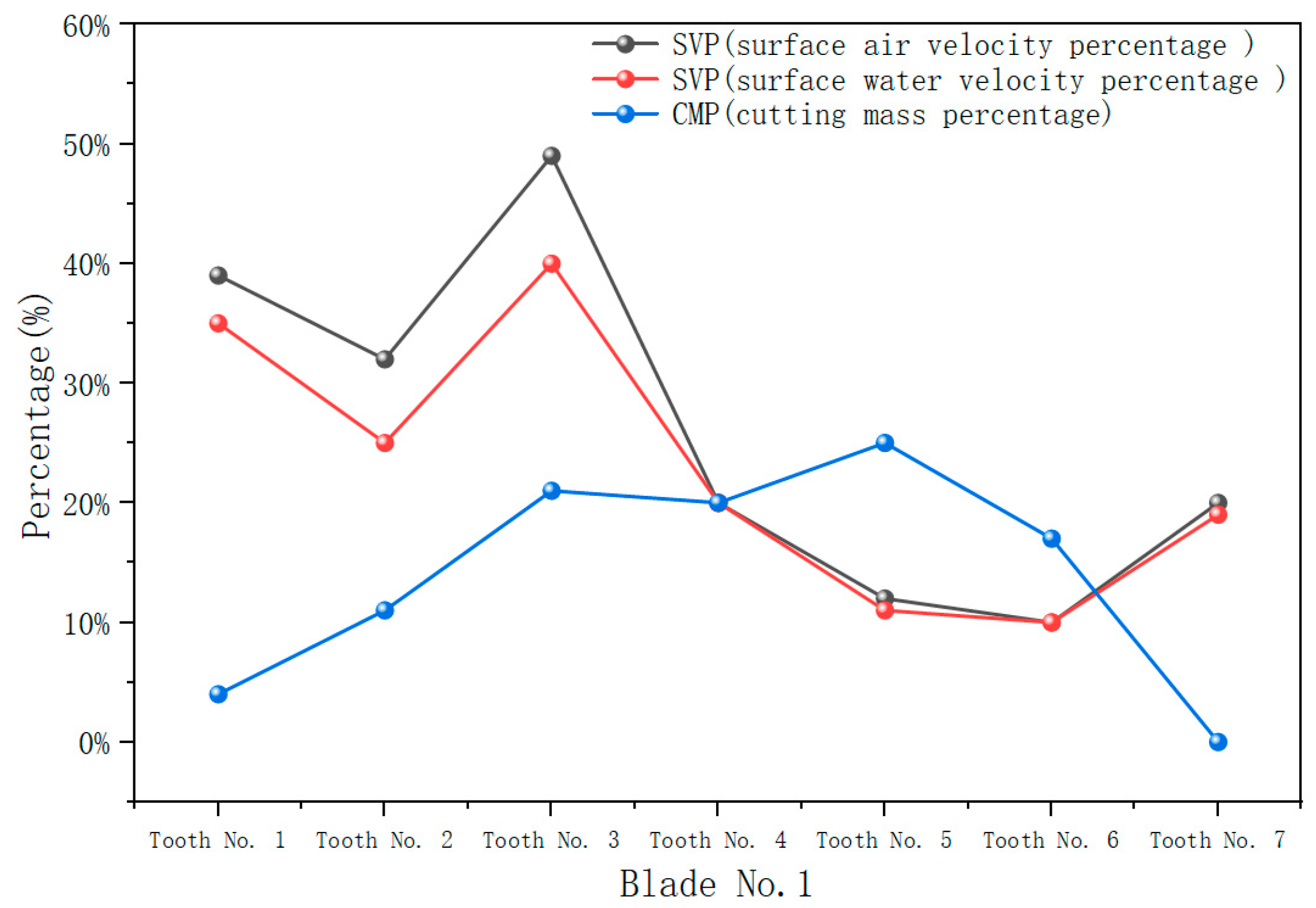

2.3.1. Cutting Tooth Cleaning and Cooling Efficiency Evaluation Method

- is the surface flow velocity of tooth ;

- is the tooth corresponds to the center flow velocity of the nozzle outlet.

- The distribution trends of the two broken lines should be basically the same.

- Generally speaking, on the premise that tooth surface erosion does not occur, cutting teeth with a large cuttings mass flow rate requires a relatively high surface flow velocity to clean and cool the cutting teeth thoroughly. The surface velocity percentage of the main cutting teeth should be higher, while that of the inner bevel teeth with lower cuttings mass flow rate should be lower.

2.3.2. Flow Channel Cutting Matching Evaluation Method

- is the ratio of the cuttings mass flow rate discharged by the -th flow channel to the total cuttings discharged from all flow channels;

- is the ratio of the cuttings mass flow rate generated by the -th blade to the total cuttings generated by all blades.

- If = 1, it signifies an ideal state where the amount of discharged cuttings matches precisely with the amount of generated cuttings, indicating a reasonable distribution of hydraulic energy. When the value of is closer to 1, it means that the cross-flow phenomenon of rock cuttings is less severe, the travelling distance of rock cuttings is shorter, and the possibility of accumulation is smaller, thus reducing the risk of balling in the drill bit.

- If ≠ 1, it indicates that the hydraulic energy distribution is unreasonable, resulting in more or less cuttings discharged from some flow channels than the initial cuttings generated on the corresponding blade. This indicates that a certain extent of cuttings cross-flow phenomenon has occurred between the flow channels, and some cuttings have been moved to other flow channels by drilling fluid, which increases the movement time and movement path of cuttings at the bottom of the well, making it impossible for cuttings to be discharged from the bottom of the well in time. Therefore, when designing the hydraulic structure of the PDC drill bit, the cross-flow of cuttings between the flow channels should be minimized or avoided, and the hydraulic structure of the drill bit should be optimized by properly adjusting the position of the nozzle or the injection angle.

2.3.3. Drill Bit Body Erosion Evaluation Method

3. Results

3.1. Bottom-Hole Flow Velocity

3.2. Cutting Tooth Ceaning and Cooling Efficiency Results

3.3. Matching Results of Flow Channel Cutting Removal Volume

3.4. Blade Surface Erosion Results

- Severe Erosion: The most severe erosion was observed on the No. 3 tooth of the No. 2 secondary blade, which exhibited the highest total erosion rate among all the cutting teeth. It may cause erosion damage to the cutting tooth surface and cutting tooth base in this area. Once an erosion pit is formed, the fluid will undergo a more violent vortex phenomenon, aggravating the erosion of the tooth surface and tooth base, which may eventually lead to tooth loss or tooth breakage.

- Moderate Erosion: The cutting teeth’ surface at each blade’s crown has also been eroded, which may affect the rock-breaking efficiency of PDC cutting teeth. Moderate erosion was seen on the No. 3 and No. 4 teeth of the No. 5 main blade, the No. 3 tooth of the No. 1 blade, the No. 3 tooth of the No. 3 blade, the No. 3 tooth of the No. 4 blade, and the No. 3 tooth of the No. 6 blade.

- Erosion Distribution: The erosion patterns suggest that certain cutting teeth are more susceptible to erosion. The distribution of erosion suggests a strong correlation with the flow dynamics and the placement of nozzles on the drill bit. High-velocity jets impacting specific cutting teeth likely contribute to the observed erosion patterns. The data highlights the need for optimized nozzle placement and angle and protective measures for more vulnerable teeth to enhance the durability of the PDC drill bit.

4. Discussion

5. Conclusions

6. Future Work Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hirasaki, G.J.; Lawson, J.B. Mechanisms of Foam Flow in Porous Media: Apparent Viscosity in Smooth Capillaries. Soc. Pet. Eng. J. 1985, 25, 176–190. [Google Scholar] [CrossRef]

- Nguyen, Q.P.; Currie, P.K.; Zitha, P.L.J. Motion of Foam Films in Diverging–Converging Channels. J. Colloid Interface Sci. 2004, 271, 473–484. [Google Scholar] [CrossRef] [PubMed]

- Wendorff, C.L.; Ainley, B.R. Massive Hydraulic Fracturing of High-Temperature Wells with Stable Frac Foams. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 4–7 October 1981. [Google Scholar]

- Li, Q.; Zhang, K.; Zhou, Q.; Ling, X.; Liu, B.; Wang, Y. Analysis of the Influence of Cutting Depth on the Ultra-High-Speed Rock Breaking Mechanism of PDC Cutters. Pet. Mach. 2022, 50, 1–8. [Google Scholar]

- Wang, J.; Zou, D.; Yang, G.; He, R.; Chen, X. Interaction Model between PDC Cutting Teeth and Rocks. J. China Univ. Pet. (Ed. Nat. Sci.) 2014, 38, 104–109. [Google Scholar]

- Xu, A. Analysis of the Rock-Breaking Load Law of PDC Drill Bit Cutting Teeth. Explor. Eng. (Rock Soil Drill. Eng.) 2006, 7, 59–61. [Google Scholar]

- Luo, W. Analysis of Cuttings from PDC Drill Bits at Different Wear Stages under Different Drilling Parameters. China New Technol. New Prod. 2010, 13, 126. [Google Scholar]

- Huang, Z.; Shan, D.; Li, Q.; Tan, J.; Yang, M.; Liu, S. Numerical Simulation Study on Bottom Hole Flow Field of Down-the-Hole Drill Bit. Pet. Mach. 2006, 8, 11–18. [Google Scholar]

- Wells, M.; Marvel, T.; Beuershausen, C. Bit Balling Mitigation in PDC Bit Design. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Jakarta, Indonesia, 25–27 August 2008. [Google Scholar]

- Moslemi, A.A.; Rahmani, R.; Graham, R.; Ivie, B. Hydraulic Design of Shale DrillBit Using an Integrated Numerical and Experimental Approach. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March 2015. [Google Scholar]

- Gerbaud, L.; Menand, S.; Sellami, H. PDC Bits: All Comes from the Cutter/Rock Interaction. In Proceedings of the IADC/SPE Drilling Conference, Miami, FL, USA, 21–23 February 2006. [Google Scholar]

- Rahmani, R.; Smith, J.R.; Taleghani, A.D. Analytical Modeling of PDC Single Cutter-Rock Interaction Under Confining Pressure. In Proceedings of the 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012. [Google Scholar]

- Jiang, X.; Duan, L.; Liu, Z. Experimental Study on Erosion Wear of Mud on WC-Based Matrix Material of Drill Bit. Coal Geol. Explor. 2007, 4, 77–80. [Google Scholar]

- Xing, X.; Xu, Y.; Yang, Y.; Wang, G. Study on Erosion Characteristics of Particle Impact Drilling Bit Internal Flow Channel. Pet. Mach. 2015, 43, 39–43. [Google Scholar]

- Zhao, J.; Zhang, G.; Xu, Y.; Wang, R.; Zhou, W.; Yang, D. Experimental and Theoretical Evaluation of Solid Particle Erosion in an Internal Flow Passage within a Drilling Bit. J. Pet. Sci. Eng. 2018, 160, 582–596. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, G.; Xu, Y.; Wang, R.; Zhou, W.; Han, L. Wear of WC-Based Matrix Material of Drill Bit Internal Flow Channel under Solid-Liquid Two-Phase Flow Particle Erosion. J. Cent. South Univ. (Nat. Sci. Ed.) 2018, 49, 1228–1236. [Google Scholar]

- Wang, Y.; Zhang, S.; Wang, W.; Lv, L. Numerical Simulation and Simulation of PDC Drill Bit under Rotating Flow Field. Yunnan Chem. Ind. 2019, 46, 174–175. [Google Scholar]

- Wu, Z.; Wang, Y.; Pan, Y.; Wang, W.; Lv, L. Comparative Study on Numerical Simulation of Rotating Flow Field and Non-Rotating Flow Field of PDC Drill Bit. Oilfield Mach. 2020, 49, 10–15. [Google Scholar]

- Guo, B.; Miska, S.; Hareland, G. A Simple Approach to Determination of Bottom Hole Pressure in Directional Foam Drilling. ASME Drill. Technol. Symp. 2005, 65, 329–338. [Google Scholar]

- Zhai, Y.; Wang, Z.; Zhang, T. Experimental study on the annular cuttings migration rules in the horizontal section of aerated underbalanced drilling. Sci. Technol. Technol. Eng. 2016, 25, 8–11. [Google Scholar]

- Ming, Y.; Lan, Q.; Li, H.; Liu, Z.; Bu, F. Research and field testing of high temperature resistant foam drilling fluid in deep wells. Pet. Drill. Tech. 2018, 46, 47–53. [Google Scholar]

- Guo, L. Two-Phase and Multiphase Flow Dynamics; Xi’an Jiaotong University Press: Xi’an, China, 2002; pp. 23–26. [Google Scholar]

- Li, J.; Bian, C.; Liu, Z.; Hou, H. Study on Flow Field Characteristics of Rotary Cutting PDC Bit Based on DPM Model. Pet. Mach. 2021, 49, 24–32. [Google Scholar]

- Pu, G. ANSYS Workbench Basic Tutorials and Detailed Examples, 2nd ed.; China Water Conservancy and Hydropower Press: Shanghai, China, 2013; pp. 48–56. [Google Scholar]

- Burns, A.D.; Frank, T.; Hamill, I.; Shi, J.M. The favre averaged drag model for turbulent dispersion in Eulerian multi-phase flows. J. Fluid Mech. 2004, 392, 67–93. [Google Scholar]

- Wang, F. Principles and Applications of CFD Software for Computational Fluid Dynamics Analysis; Tsinghua University Press: Beijing, China, 2004; pp. 5–8. [Google Scholar]

- Kalitzin, G.; Medic, G.; Iaccarino, G.; Durbin, P. Near-wall behavior of RANS turbulence models and implications for wall functions. J. Comput. Phys. 2005, 204, 265–291. [Google Scholar] [CrossRef]

- Li, W.; Yang, H.; Liu, S. Simulation Study on Flow Field Characteristics of PDC Bit Rotating Nozzle. Oilfield Mach. 2023, 52, 26–32. [Google Scholar]

- Chen, Z.; Wang, M.; Li, X.; Shi, H.; Fan, Y.; He, W. Numerical simulation research and field test of bottom hole flow field of PDC drill bit. Drill. Prod. Technol. 2023, 46, 85–93. [Google Scholar]

- Bitter, J.G. A Study of Erosion Phenomena Part I. Wear 1963, 6, 5–21. [Google Scholar] [CrossRef]

- Bitter, J.G. A Study of Erosion Phenomena Part II. Wear 1963, 6, 169–190. [Google Scholar] [CrossRef]

- Liu, X. Numerical Simulation of Erosion Wear in Spiral Axial Flow Mixed Transportation Pump Inlet Pipeline; China University of Petroleum (Beijing): Beijing, China, 2018. [Google Scholar]

- Tilly, G. A Two-Stage Mechanism of Ductile Erosion. Wear 1973, 23, 87–96. [Google Scholar] [CrossRef]

- Yang, Y.; Qin, C.; Kuang, Y. Numerical Simulation and Comparison of Static and Rotating Flow Fields of PDC Drill Bits. Drill. Prod. Technol. 2015, 38, 82–85. [Google Scholar]

- Shen, Y.; Liu, J.; Cheng, X. Application of Foam Drilling Technology in Kenya OW904 Ultra-High-Temperature Geothermal Well. J. Chongqing Univ. Sci. Technol. (Nat. Sci. Ed.) 2009, 11, 16–32. [Google Scholar]

| Mesh Scheme | Minimum Mesh Size (mm) | Cutting Tooth Velocity (m/s) |

|---|---|---|

| Coarse Mesh | 3 | 14.712 |

| Medium Mesh | 1.5 | 15.267 |

| Fine Mesh | 1 | 15.324 |

| Cutting Parameters | Tooth No. 1 | Tooth No. 2 | Tooth No. 3 | Tooth No. 4 | Tooth No. 5 | Tooth No. 6 | Tooth No. 7 |

|---|---|---|---|---|---|---|---|

| Cuttings Mass Flow Rate (kg/s) | 0.004 | 0.014 | 0.025 | 0.024 | 0.028 | 0.018 | 0.001 |

| initial velocity (m/s) | 0.107 | 0.35 | 0.592 | 0.851 | 1.096 | 1.249 | 1.281 |

| direction of movement (X) | 0.016 | 0.005 | 0.038 | −0.169 | −0.609 | −0.882 | −0.902 |

| direction of movement (Y) | 0.326 | 0.344 | 0.365 | 0.241 | 0.004 | −0.149 | −0.086 |

| direction of movement (Z) | −0.909 | −0.901 | −0.883 | −0.904 | −0.716 | −0.287 | 0.002 |

| Blade Number | Blade No. 1 | Blade No. 2 | Blade No. 3 | Blade No. 4 | Blade No. 5 | Blade No. 6 |

|---|---|---|---|---|---|---|

| Cuttings Mass Flow Rate (kg/s) | 0.114 | 0.069 | 0.101 | 0.081 | 0.108 | 0.071 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Honra, J. Computational Fluid Dynamics Study on Bottom-Hole Multiphase Flow Fields Formed by Polycrystalline Diamond Compact Drill Bits in Foam Drilling. Fluids 2024, 9, 211. https://doi.org/10.3390/fluids9090211

Wei L, Honra J. Computational Fluid Dynamics Study on Bottom-Hole Multiphase Flow Fields Formed by Polycrystalline Diamond Compact Drill Bits in Foam Drilling. Fluids. 2024; 9(9):211. https://doi.org/10.3390/fluids9090211

Chicago/Turabian StyleWei, Lihong, and Jaime Honra. 2024. "Computational Fluid Dynamics Study on Bottom-Hole Multiphase Flow Fields Formed by Polycrystalline Diamond Compact Drill Bits in Foam Drilling" Fluids 9, no. 9: 211. https://doi.org/10.3390/fluids9090211

APA StyleWei, L., & Honra, J. (2024). Computational Fluid Dynamics Study on Bottom-Hole Multiphase Flow Fields Formed by Polycrystalline Diamond Compact Drill Bits in Foam Drilling. Fluids, 9(9), 211. https://doi.org/10.3390/fluids9090211