Adjoint-Based High-Fidelity Concurrent Aerodynamic Design Optimization of Wind Turbine

Abstract

:1. Introduction

2. Literature Review

2.1. Low-Fidelity Aerodynamic Design Optimization

2.2. High-Fidelity Gradient-Based Aerodynamic Design Optimization

3. Methodology and Mathematical Modeling

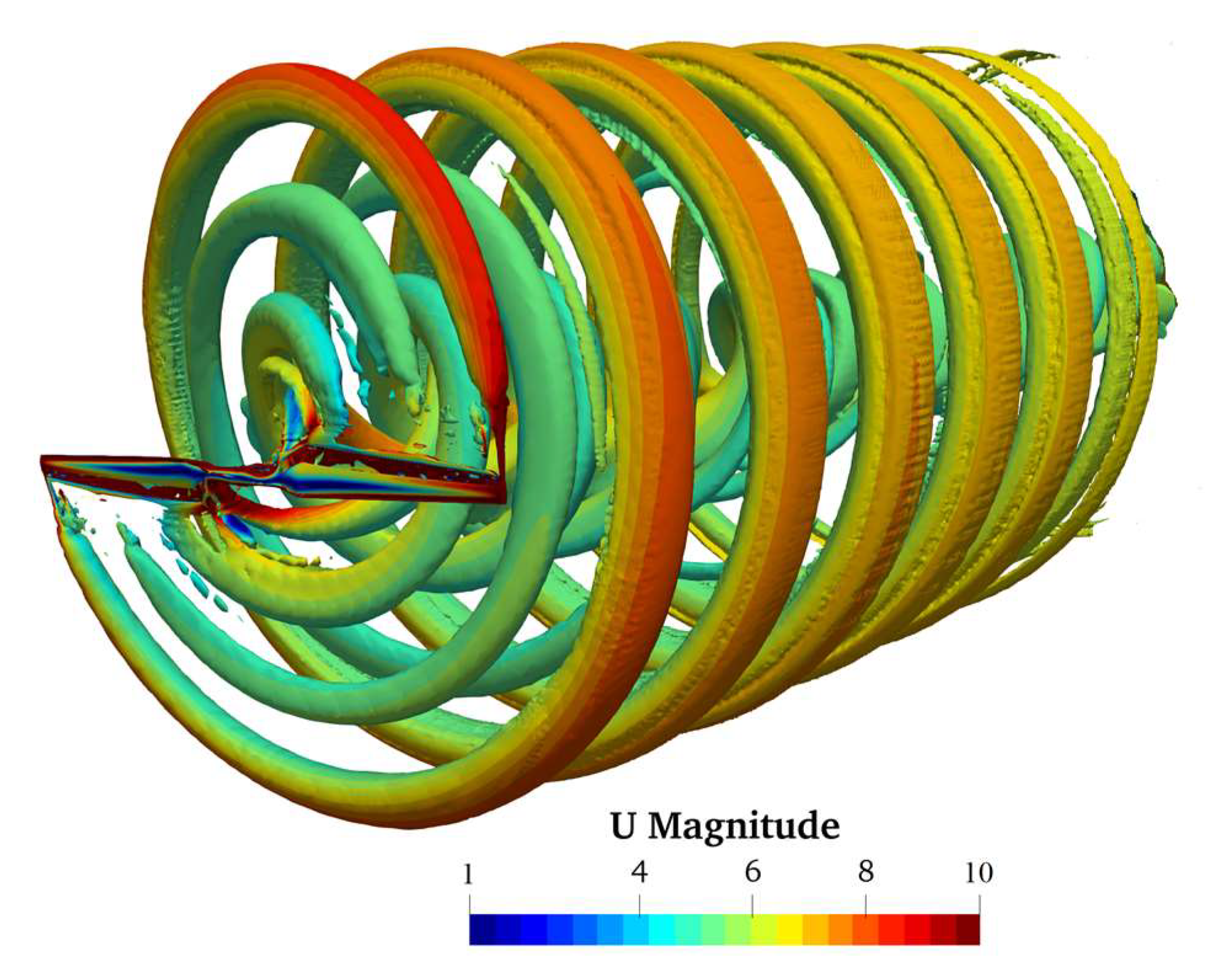

3.1. RANS Formulations and CFD Methods

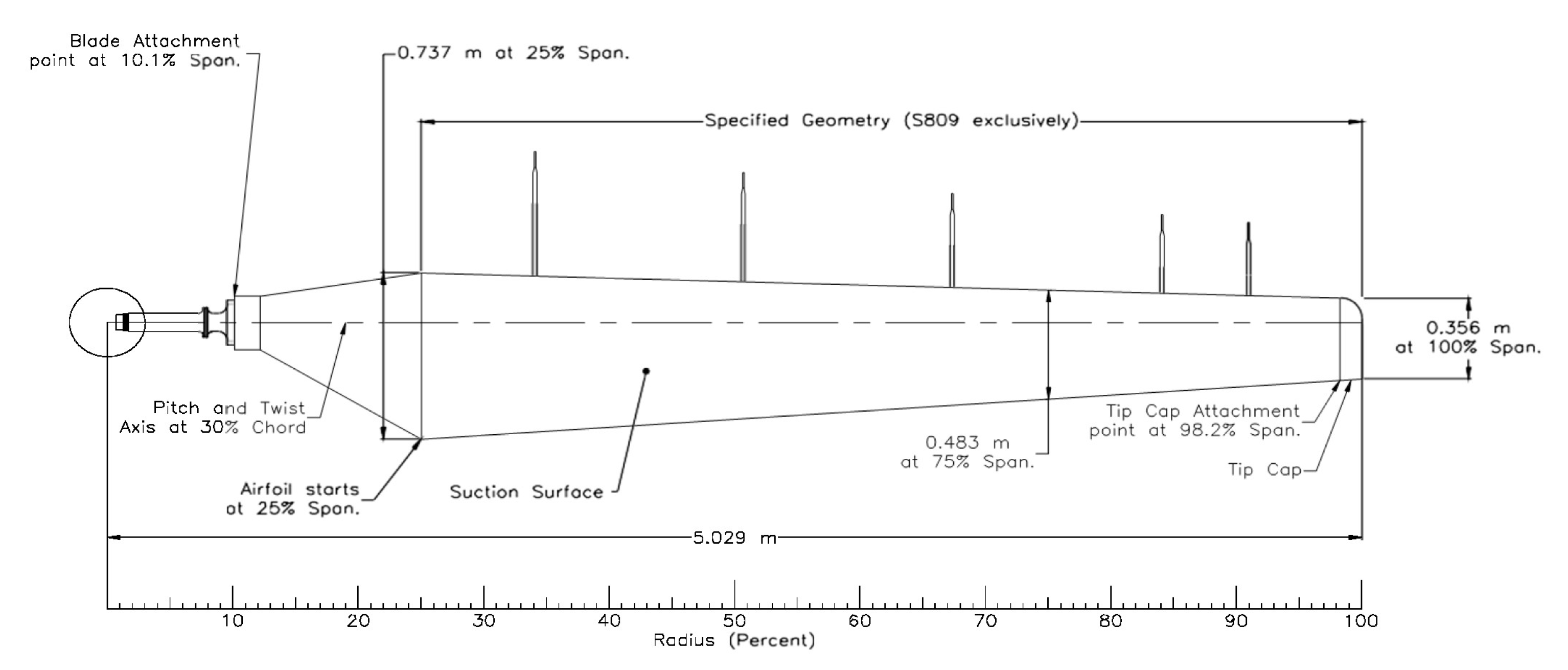

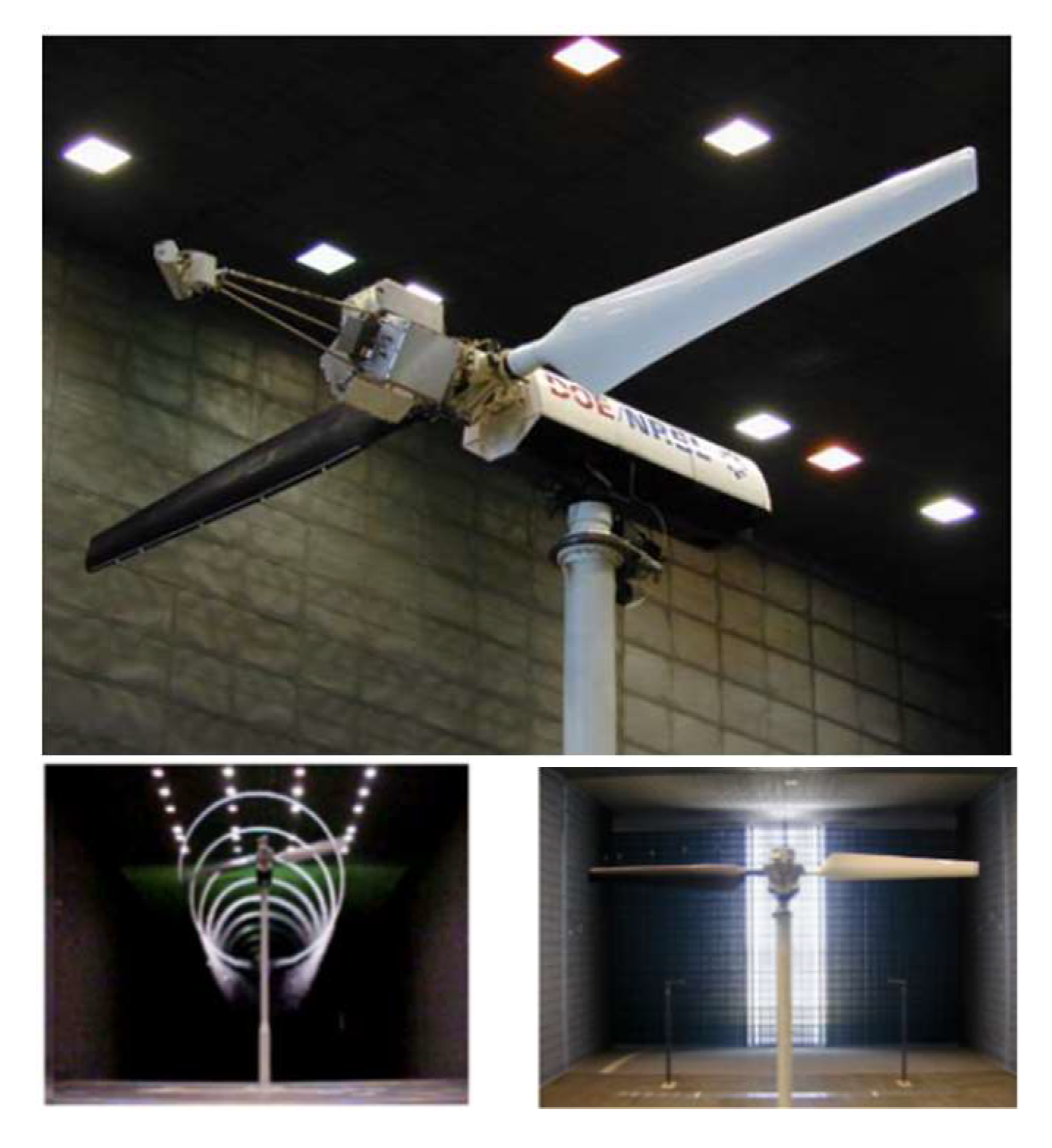

3.1.1. Baseline Geometry

3.1.2. Governing Equations and Boundary Conditions

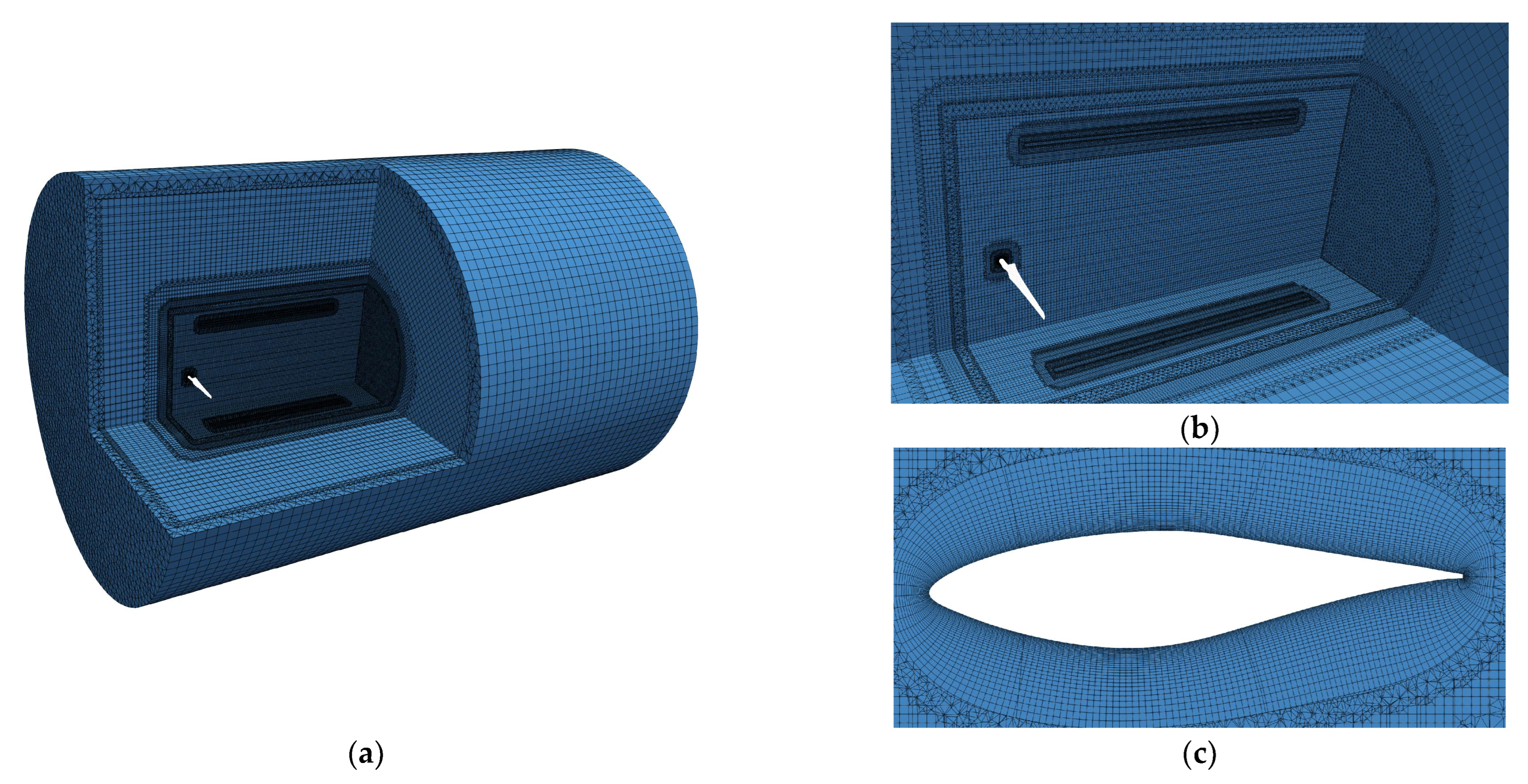

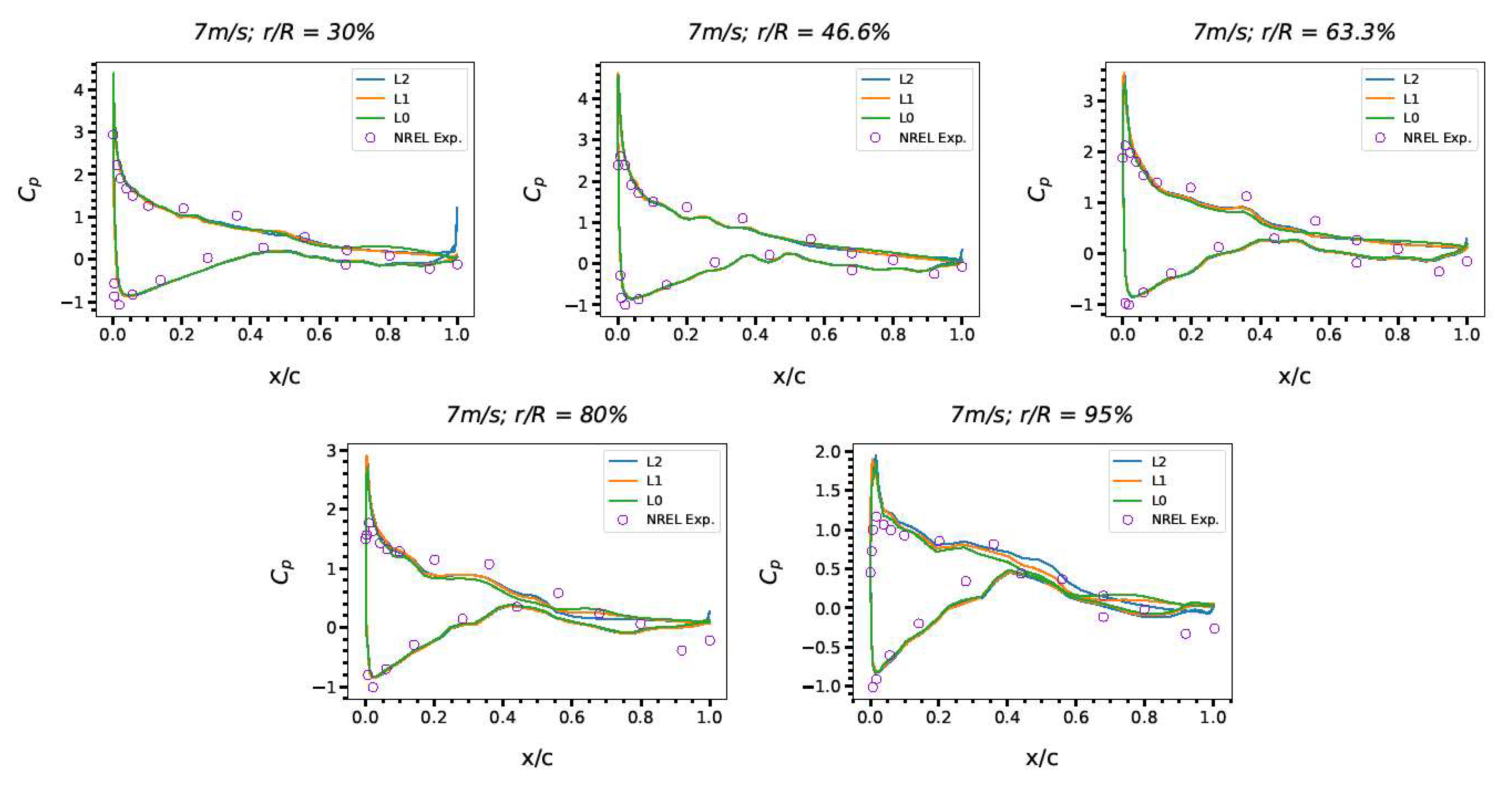

3.1.3. Mesh Generation and Mesh Convergence Studies

3.2. Adjoint Equations and Optimization Frameworks Formulation

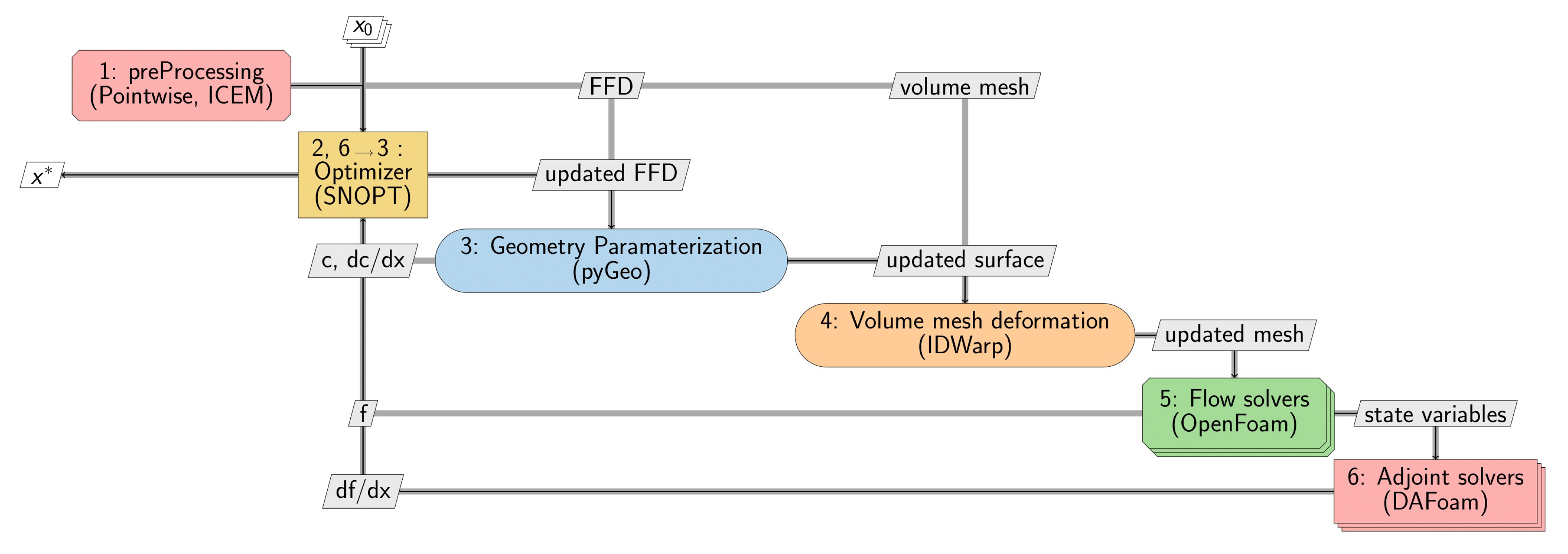

- In step 1 (preProcessing), a volume mesh is produced for the baseline geometry using Pointwise, which will be utilized later, as well as free-form deformation (FFD) points using ICEM, which will be used later in step 3 to morph the design surface (geometric parametrization).

- In step 2, the optimizer (SNOPT) is provided with a collection of baseline design variables. The design variables will be updated and passed along to the geometry parameterization module (pyGeo).

- Step 3 accepts the updated design variables and FFD points created in the pre-processing phase, executes the deformation for the design surface, and then sends it to the mesh deformation module (IDWarp) for mesh deformation. In addition, pyGeo computes the values of geometric constraints and their derivatives with respect to the design variables.

- In step 4, IDWarp deforms the volume mesh in accordance with the modified design surface and delivers the deformed volume mesh to the flow simulation module.

- In step 5, CFD tools (OpenFoam) are used in the flow simulation module to calculate the state variables in process 5 and send them to the adjoint solver.

- In step 6, the total derivatives of the objective function of the design variables are computed and sent to the optimizer.

- In the end, SNOPT obtains the values and derivatives of the objective functions and constraints, executes the SQP computation, and returns a collection of updated design variables to pyGeo.

- The above procedures are repeated until convergence is obtained.

3.3. Geometric Parameterization and Mesh Deformation

3.4. Design Optimization Algorithm

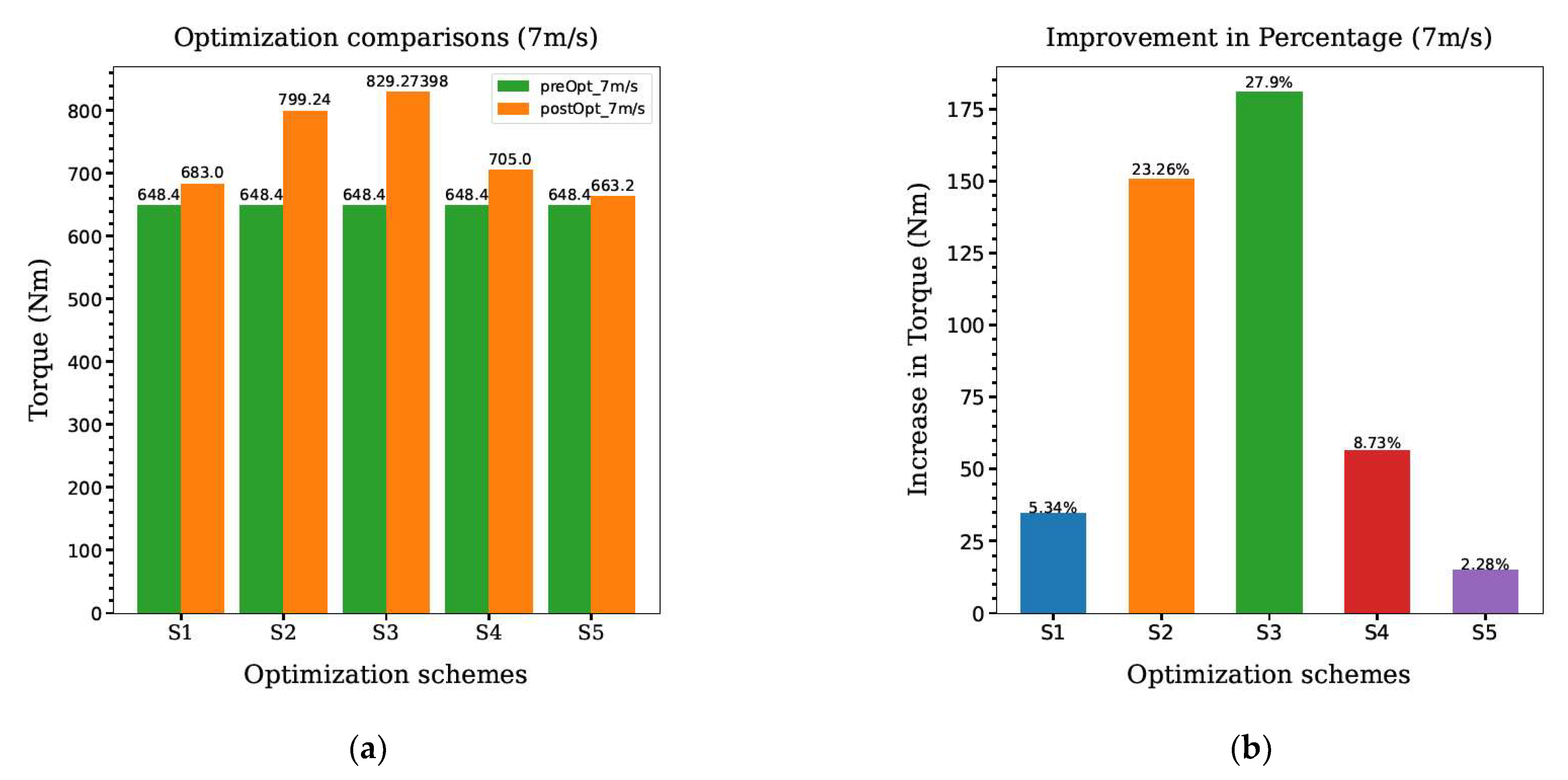

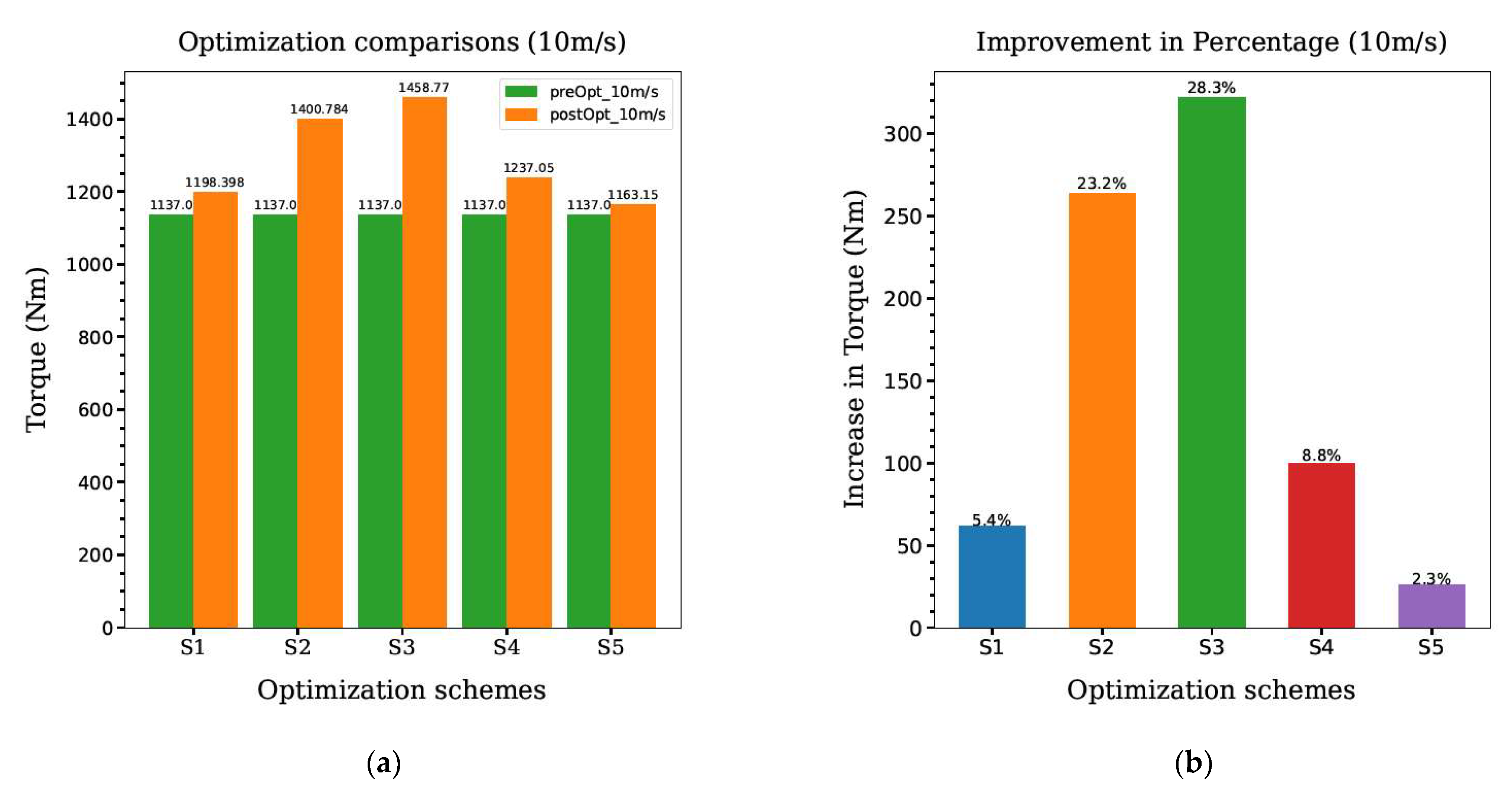

- Optimization scheme S1: pitch optimization with pitch angle as a single design variable.

- Optimization scheme S2: shape and twist optimization with 120 shapes in the y direction and 6 twist angles as design variables (126 in total).

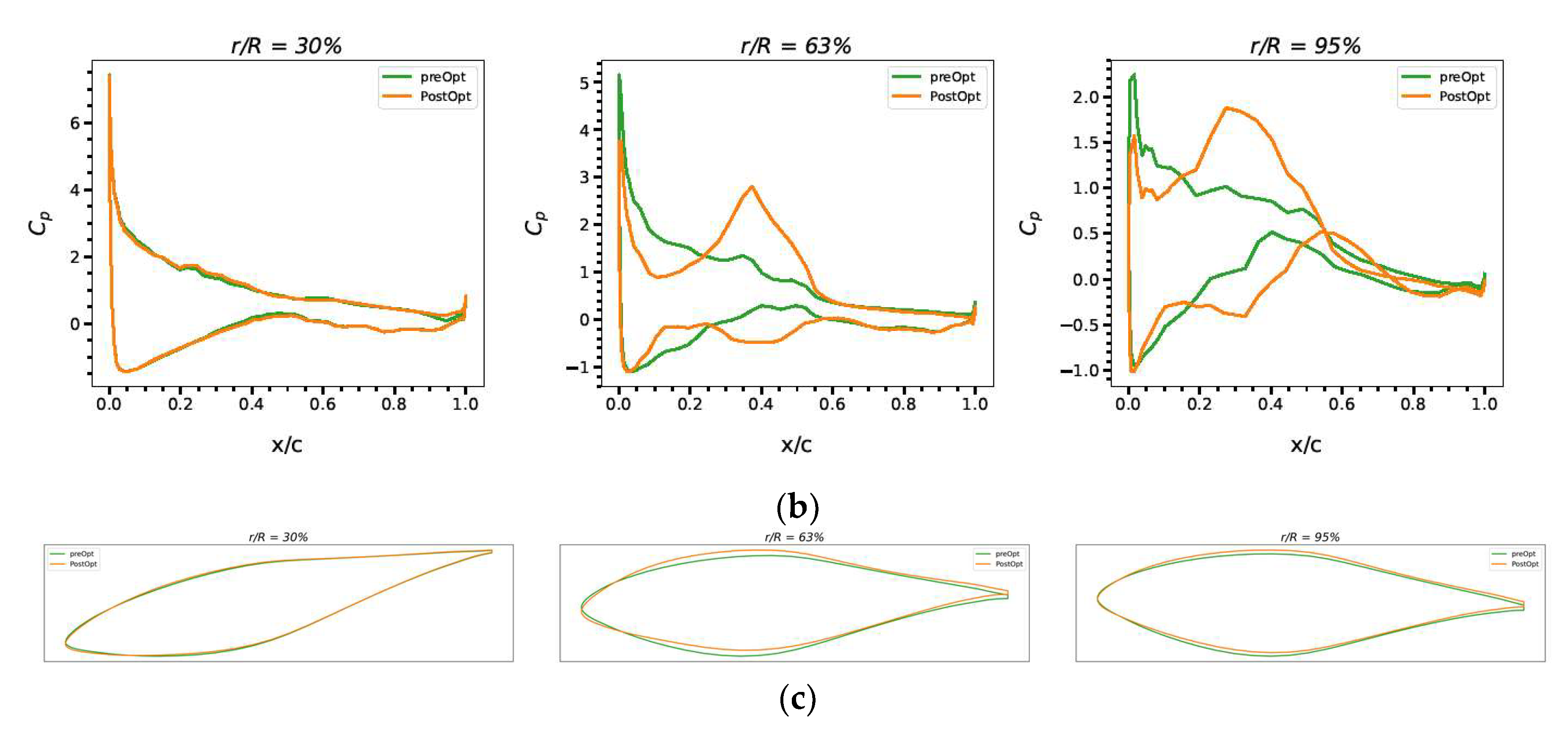

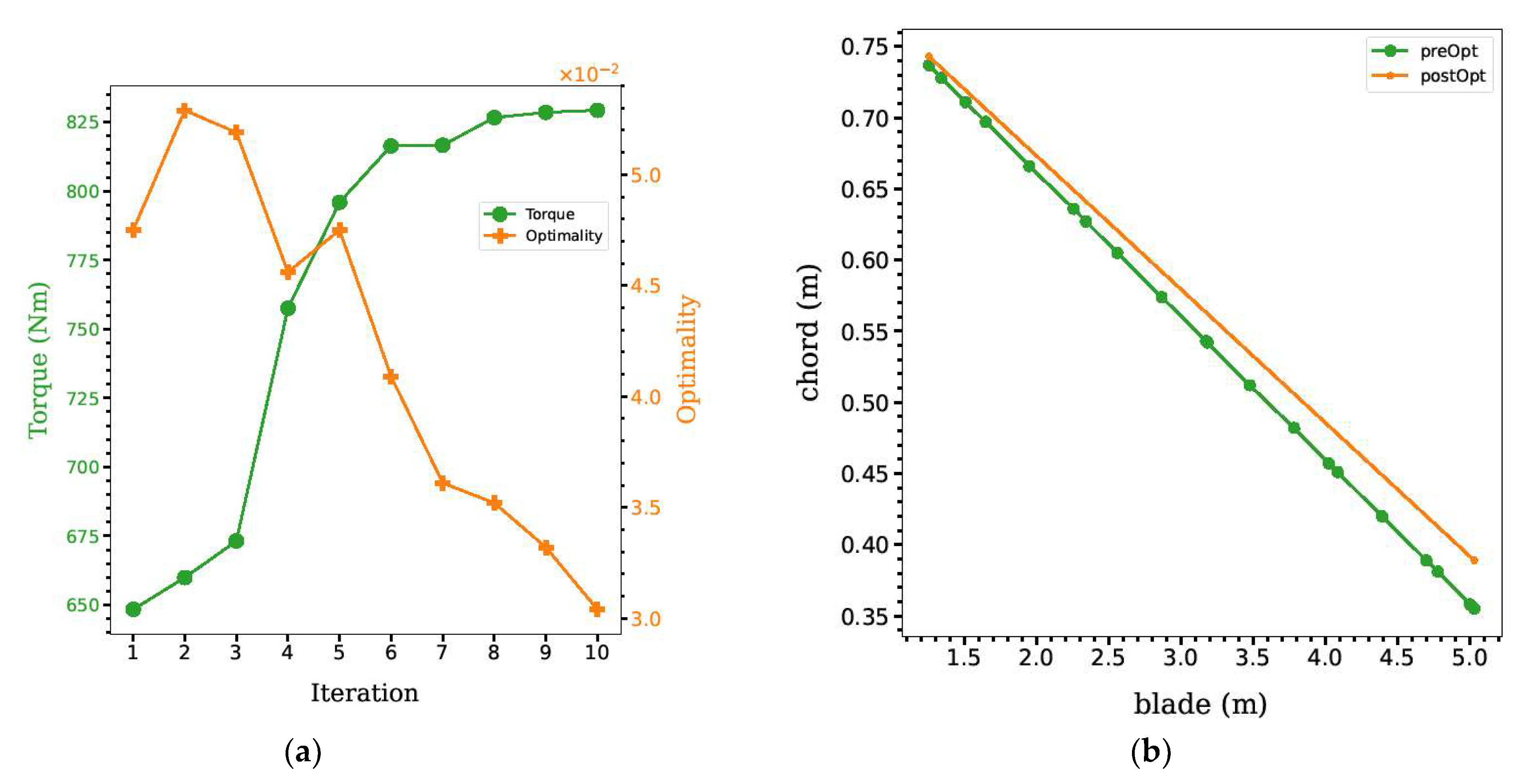

- Optimization scheme S3: shape and chord optimization with 120 shapes in the y direction and 2 chord lengths as design variables (122 in total).

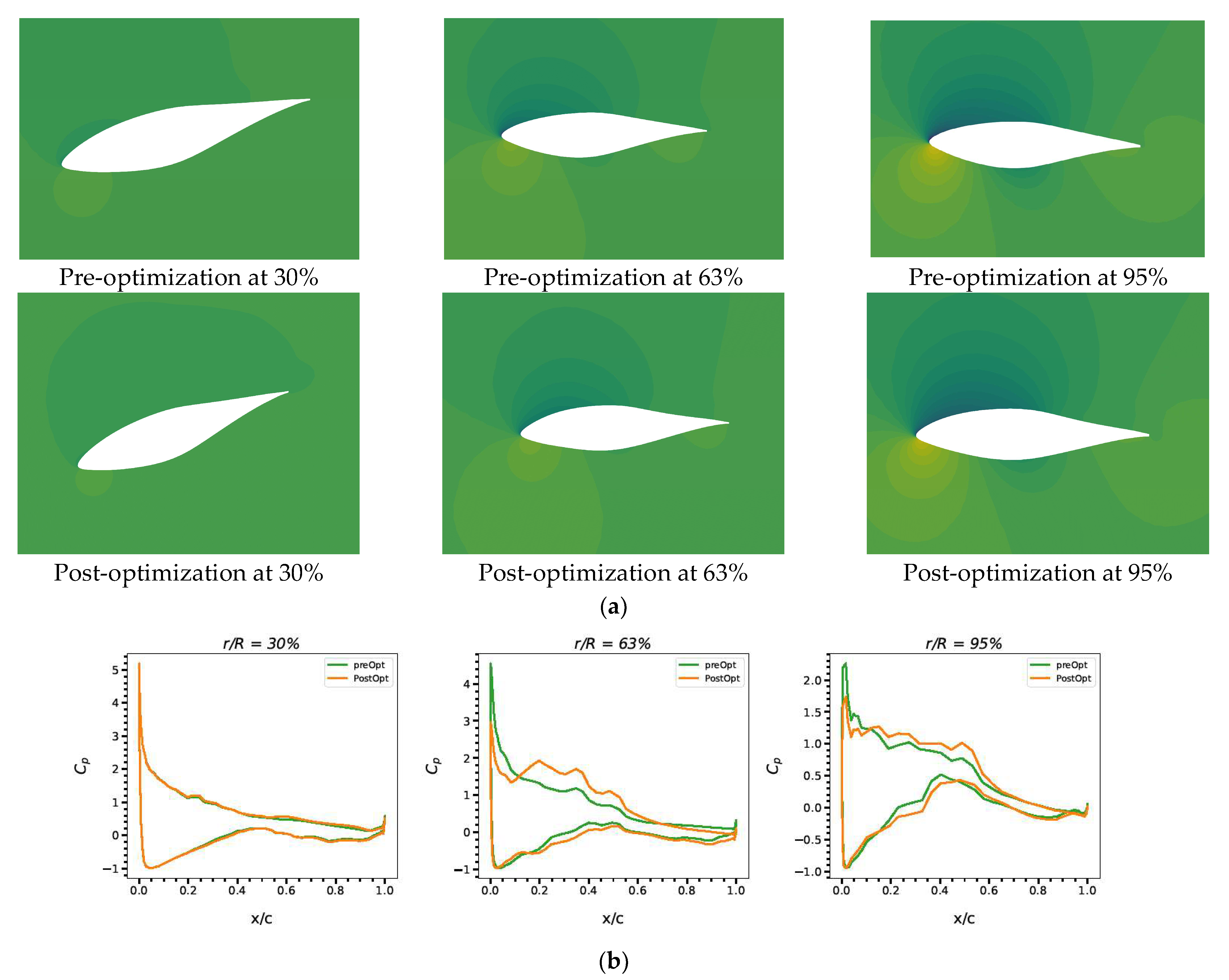

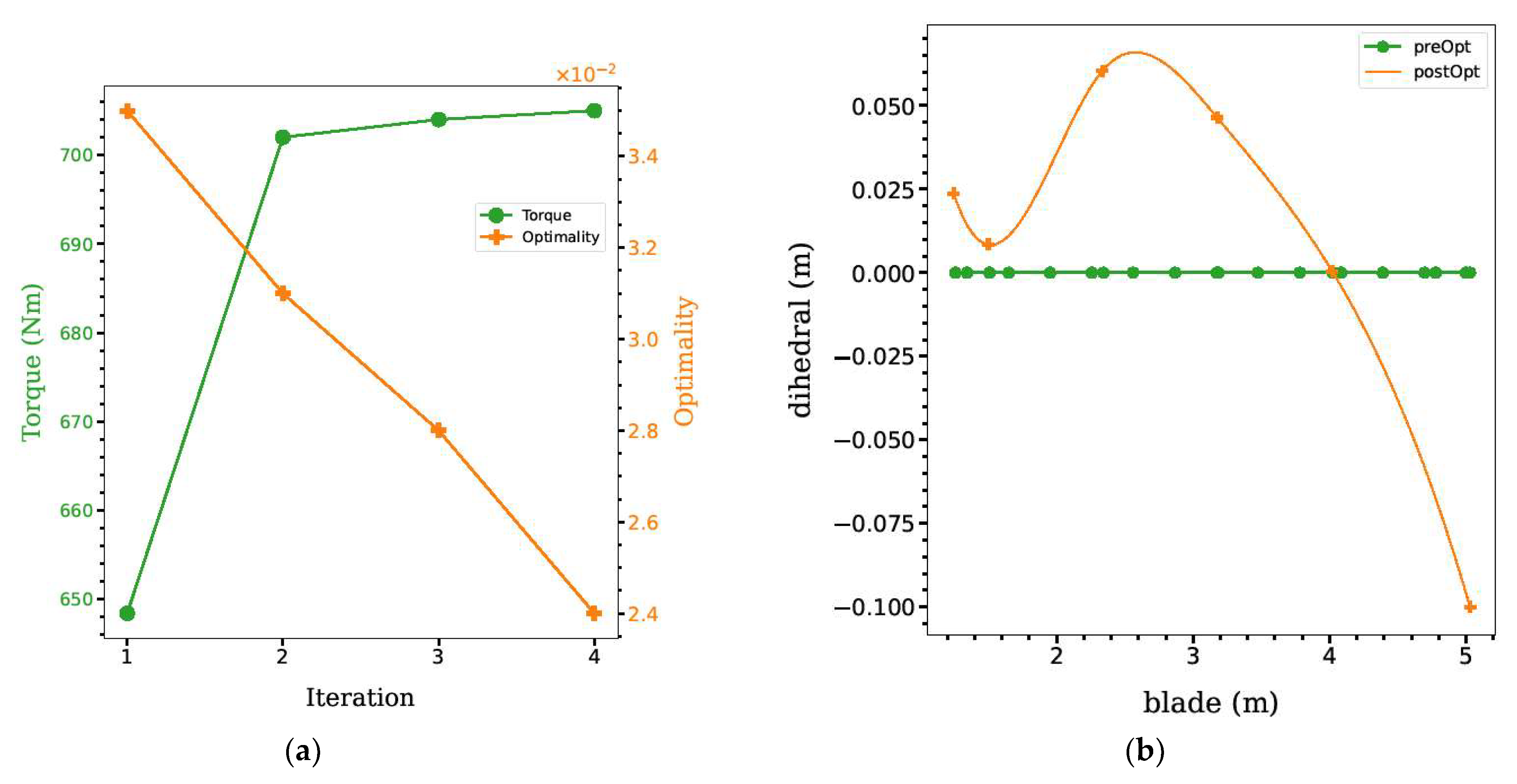

- Optimization scheme S4: shape and dihedral optimization with 120 shapes in the y direction and 6 dihedrals in the y direction as design variables (126 in total).

- Optimization scheme S5: twist, chord, and dihedral optimization with 6 twist angles, 2 chord lengths, and 6 dihedrals in the y direction as design variables (14 in total).

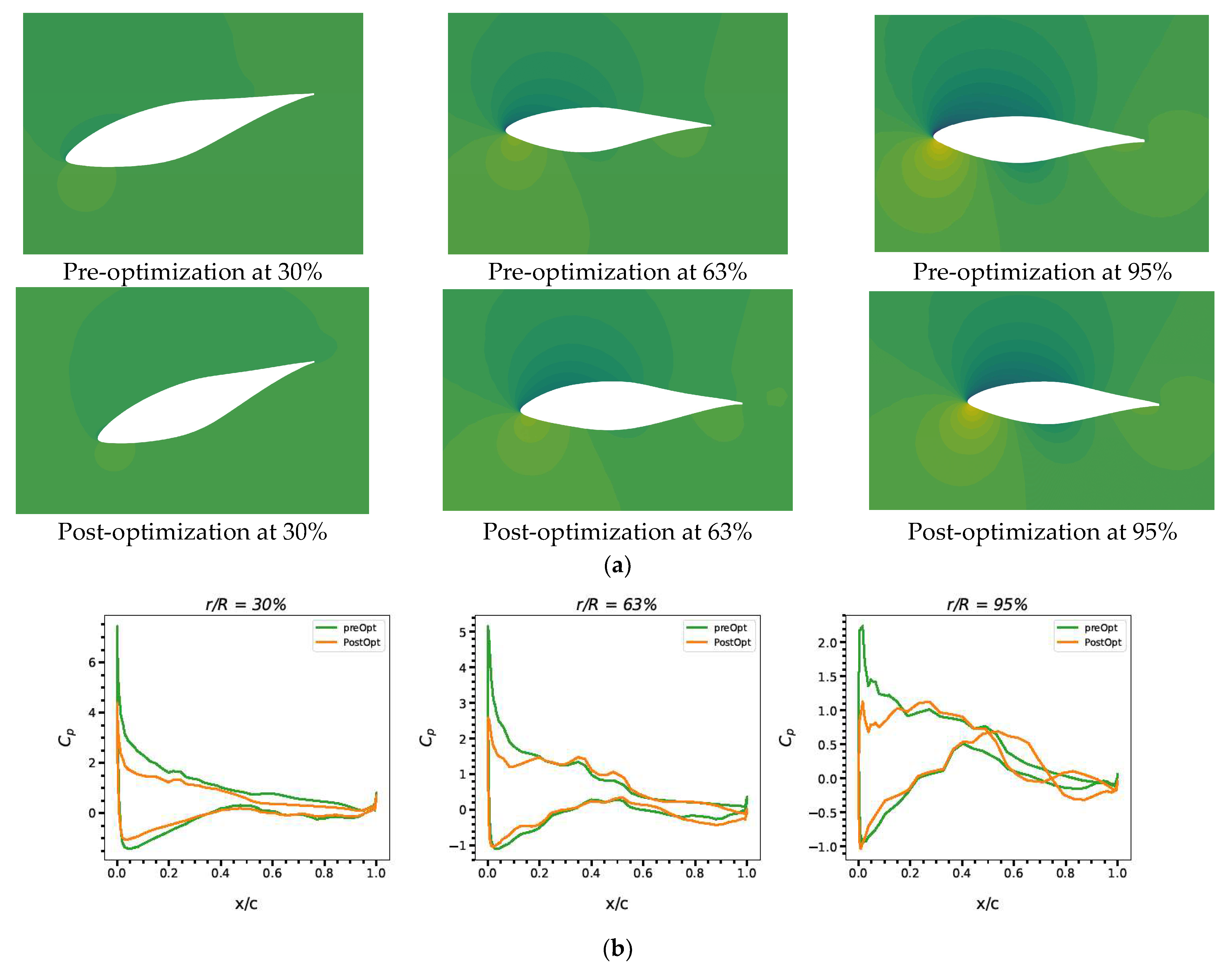

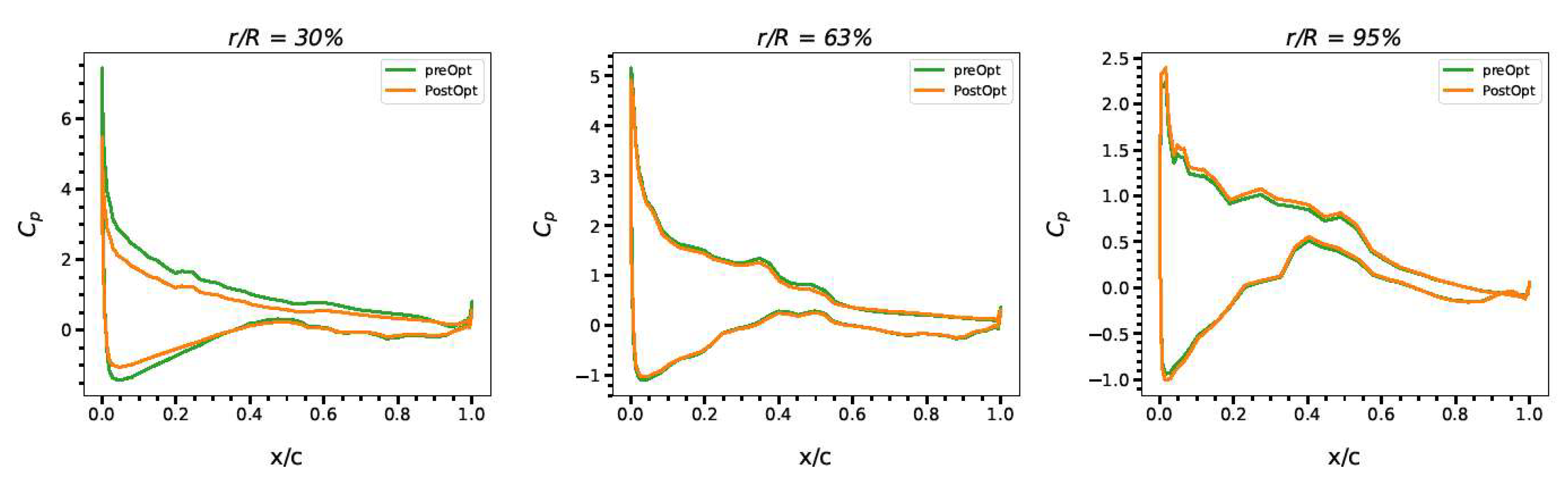

4. Results and Discussion

4.1. S1: Pitch Optimization

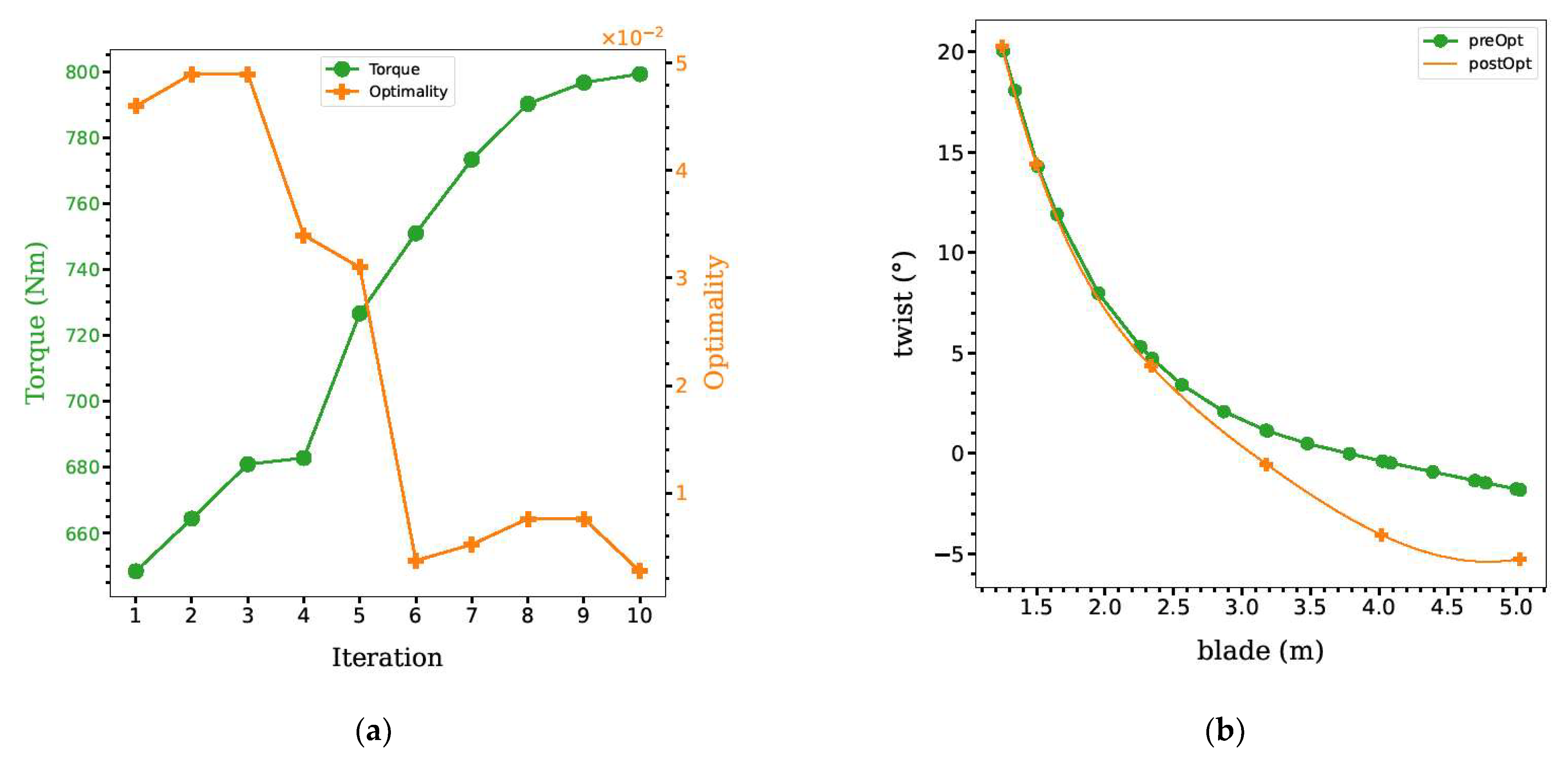

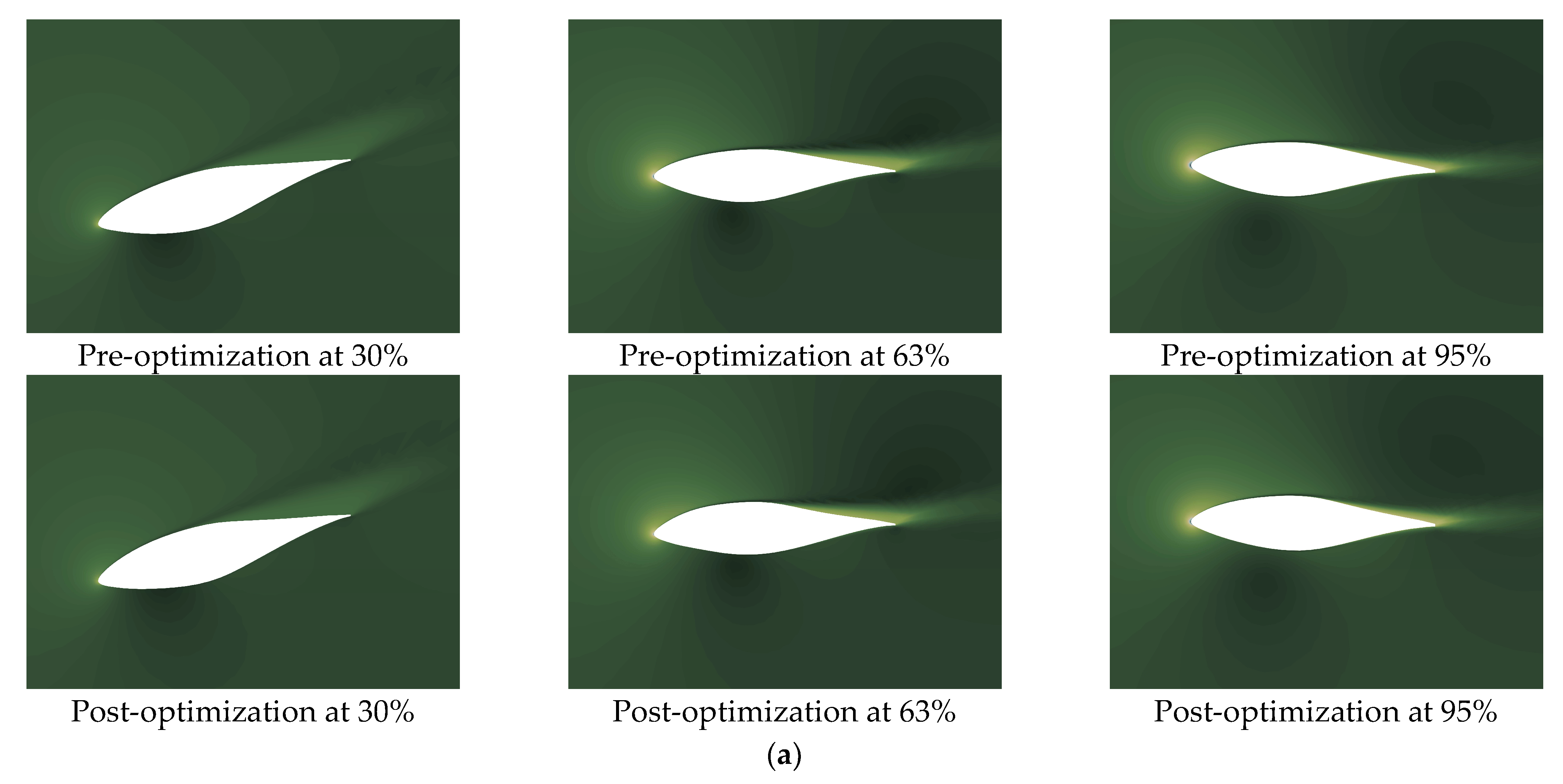

4.2. S2: Shape and Twist Optimization

4.3. S3: Shape and Chord Optimization

4.4. S4: Shape and Dihedral Optimization

4.5. S5: Twist, Chord, and Dihedral

5. Concluding Remarks and Further Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sagimbayev, S.; Kylyshbek, Y.; Batay, S.; Zhao, Y.; Fok, S.; Soo Lee, T. 3D multidisciplinary automated design optimization toolbox for wind turbine blades. Processes 2021, 9, 581. [Google Scholar] [CrossRef]

- Quan, N.N.H.; Van Lam, P. Wind Turbine Blade Design Optimization Using OpenFOAM and DAKOTA Software. Transp. Res. Procedia 2021, 56, 71–78. [Google Scholar] [CrossRef]

- Liao, C.; Zhao, X.; Xu, J. Blade layers optimization of wind turbines using FAST and improved PSO Algorithm. Renew. Energy 2012, 42, 227–233. [Google Scholar] [CrossRef]

- Chetan, M.; Sakib, M.; Griffith, D.; Gupta, A.; Rotea, M. Design of a 3.4-MW wind turbine with integrated plasma actuator-based load control. Wind. Energy 2022, 25, 517–536. [Google Scholar] [CrossRef]

- Altmimi, A.; Alaskari, M.; Abdullah, O.; Alhamadani, A.; Sherza, J. Design and optimization of vertical axis wind turbines using QBlade. Appl. Syst. Innov. 2021, 4, 74. [Google Scholar] [CrossRef]

- Sessarego, M.; Ramos-García, N.; Shen, W.Z.; Sørensen, J. Large wind turbine rotor design using an aero-elastic/free-wake panel coupling code. J. Phys. Conf. Ser. 2016, 753, 042017. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.; Beauson, J.; McGugan, M.; Sørensen, B. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [Green Version]

- Akram, M.; Kim, M.-H. CFD analysis and shape optimization of airfoils using class shape transformation and genetic algorithm—Part I. Appl. Sci. 2021, 11, 2211. [Google Scholar] [CrossRef]

- Eminoglu, U.; Ayasun, S. Modeling and design optimization of variable-speed wind turbine systems. Energies 2014, 7, 402–419. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Cao, Y.; Zhang, C.; He, Z. Structural Optimization Design of Large Wind Turbine Blade considering Aeroelastic Effect. Math Probl. Eng. 2017, 2017, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook; John Wiley & Sons, Ltd.: Chichester, UK, 2011. [Google Scholar]

- Bortolotti, P.; Bottasso, C.; Croce, A.; Sartori, L. Integration of multiple passive load mitigation technologies by automated design optimization—The case study of a medium-size onshore wind turbine. Wind. Energy 2019, 22, 65–79. [Google Scholar] [CrossRef] [Green Version]

- Bottasso, C.; Campagnolo, F.; Croce, A. Multi-disciplinary constrained optimization of wind turbines. Multibody Syst. Dyn. 2012, 27, 21–53. [Google Scholar] [CrossRef]

- Bottasso, C.; Bortolotti, P.; Croce, A.; Gualdoni, F. Integrated aero-structural optimization of wind turbines. Multibody Syst. Dyn. 2016, 38, 317–344. [Google Scholar] [CrossRef] [Green Version]

- Van Kuik, G.; Peinke, J.; Nijssen, R.; Lekou, D.; Mann, J.; Sørensen, J.; Ferreira, C.; van Wingerden, J.; Schlipf, D.; Gebraad, P.; et al. Long-term research challenges in wind energy—A research agenda by the European Academy of Wind Energy. Wind Energy Science 2016, 1, 1–39. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Cai, X.; Gu, R. Aerodynamic and structural integrated optimization design of horizontal-axis wind turbine blades. Energies 2016, 9, 66. [Google Scholar] [CrossRef] [Green Version]

- Lanzafame, R.; Messina, M. Fluid dynamics wind turbine design: Critical analysis, optimization and application of BEM theory. Renew. Energy 2007, 32, 2291–2305. [Google Scholar] [CrossRef]

- Southwell, R.V. The Elements of Aerofoil and Airscrew Theory. By H. Glauert. Pp. 228. 14s. 1926.(Cambridge University Press.). Math. Gaz. 1927, 13, 394–395. [Google Scholar] [CrossRef]

- Maniaci, D. An Investigation of WT_Perf Convergence Issues. In Proceedings of the 49th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2011. [Google Scholar]

- Ning, S.A. A simple solution method for the blade element momentum equations with guaranteed convergence. Wind Energy 2013, 17, 1327–1345. [Google Scholar]

- Hansen, M. Aerodynamics of Wind Turbines, 2nd ed.; Routledge: London, UK, 2013. [Google Scholar]

- Chehouri, A.; Younes, R.; Ilinca, A.; Perron, J. Review of performance optimization techniques applied to wind turbines. Appl. Energy 2015, 142, 361–388. [Google Scholar] [CrossRef]

- Ceyhan, Ö. Aerodynamic Design and Optimization of Horizontal Axis Wind Turbines by Using Bem Theory and Genetic Algorithm. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2008. [Google Scholar]

- Jameson, A. Aerodynamic design via control theory. J. Sci. Comput. 1988, 3, 233–260. [Google Scholar] [CrossRef] [Green Version]

- Chernukhin, O.; Zingg, D.W. Multimodality and global optimization in aerodynamic design. AIAA J. 2013, 51, 1342–1354. [Google Scholar] [CrossRef] [Green Version]

- Hicks, R.; Henne, P. Wing design by numerical optimization. J. Aircr. 1978, 15, 407–412. [Google Scholar] [CrossRef]

- Peter, J.; Dwight, R. Numerical sensitivity analysis for aerodynamic optimization: A survey of approaches. Comput. Fluids 2010, 39, 373–391. [Google Scholar] [CrossRef]

- Martins, J.R.R.A.; Hwang, J.T. Review and unification of methods for computing derivatives of multidisciplinary computational models. AIAA J. 2013, 51, 2582–2599. [Google Scholar] [CrossRef] [Green Version]

- Polat, O.; Tuncer, I. Aerodynamic shape optimization of wind turbine blades using a parallel genetic algorithm. Procedia Eng. 2013, 61, 28–31. [Google Scholar] [CrossRef] [Green Version]

- Pourrajabian, A.; Dehghan, M.; Rahgozar, S. Genetic algorithms for the design and optimization of horizontal axis wind turbine (HAWT) blades: A continuous approach or a binary one? Sustain. Energy Technol. Assess. 2021, 44, 101022. [Google Scholar] [CrossRef]

- Sun, F.; Xu, Z.; Zhang, D. Optimization Design of Wind Turbine Blade Based on an Improved Particle Swarm Optimization Algorithm Combined with Non-Gaussian Distribution. Adv. Civ. Eng. 2021, 2021, 1–9. [Google Scholar] [CrossRef]

- Yang, K. Geometry design optimization of a wind turbine blade considering effects on aerodynamic performance by linearization. Energies 2020, 13, 2320. [Google Scholar] [CrossRef]

- Simpson, T.; Poplinski, J.; Koch, P.; Allen, J. Metamodels for computer-based engineering design: Survey and recommendations. Eng. Comput. 2001, 17, 129–150. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Lyu, Z.; Xu, Z.; Martins, J.R.R.A. On the influence of optimization algorithm and initial design on wing aerodynamic shape optimization. Aerosp. Sci. Technol. 2018, 75, 183–199. [Google Scholar] [CrossRef]

- Martins, J.R.; Sturdza, P.; Alonso, J.J. The complex-step derivative approximation. ACM Trans. Math. Softw. 2003, 29, 245–262. [Google Scholar] [CrossRef] [Green Version]

- Pironneau, O. On optimum profiles in Stokes flow. J. Fluid Mech. 1973, 59, 117–128. [Google Scholar] [CrossRef]

- ENielsen, J.; Anderson, W. Aerodynamic design optimization on unstructured meshes using the Navier-Stokes equations. AIAA J. 1999, 37, 1411–1419. [Google Scholar] [CrossRef] [Green Version]

- Mavriplis, D.J. Discrete adjoint-based approach for optimization problems on three-dimensional unstructured meshes. AIAA J. 2007, 45, 741–750. [Google Scholar] [CrossRef] [Green Version]

- Anderson, W.; Venkatakrishnan, V. Aerodynamic design optimization on unstructured grids with a continuous adjoint formulation. Comput. Fluids 1999, 28, 443–480. [Google Scholar] [CrossRef] [Green Version]

- Othmer, C. A continuous adjoint formulation for the computation of topological and surface sensitivities of ducted flows. Int. J. Numer. Methods Fluids 2008, 58, 861–877. [Google Scholar] [CrossRef]

- Papoutsis-Kiachagias, E.; Giannakoglou, K. Continuous adjoint methods for turbulent flows, applied to shape and topology optimization: Industrial applications. Arch. Comput. Methods Eng. 2016, 23, 255–299. [Google Scholar] [CrossRef]

- Economon, T.D.; Palacios, F.; Alonso, J.J. Proceedings of the 21st AIAA Computational Fluid Dynamics Conference, San Diego, CA, USA, 24–27 June 2013; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2013.

- Dhert, T.; Ashuri, T.; Martins, J. Aerodynamic shape optimization of wind turbine blades using a Reynolds-averaged Navier–Stokes model and an adjoint method. Wind. Energy 2017, 20, 909–926. [Google Scholar] [CrossRef]

- Madsen, M.H.A.; Zahle, F.; Sørensen, N.N.; Martins, J.R. Multipoint high-fidelity CFD-based aerodynamic shape optimization of a 10 MW wind turbine. Wind. Energy Sci. 2019, 4, 163–192. [Google Scholar] [CrossRef] [Green Version]

- Dias, M.M.G.; Ramirez Camacho, R.G. Optimization of NREL phase VI wind turbine by introducing blade sweep, using CFD integrated with genetic algorithms. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 52. [Google Scholar] [CrossRef]

- Kaya, M.; Elfarra, M. Effect of taper distribution on the torque and thrust generated by a wind turbine rotor blade. In Proceedings of the 2019 10th International Renewable Energy Congress (IREC), Sousse, Tunis, 26–28 March 2019; IEEE: Piscataway, NJ, USA; pp. 1–6. [Google Scholar]

- Kaya, M.; Elfarra, M. Optimization of the taper/twist stacking axis location of NREL VI wind turbine rotor blade using neural networks based on computational fluid dynamics analyses. J. Sol. Energy Eng. 2019, 141, 011011. [Google Scholar] [CrossRef]

- Vorspel, L.; Stoevesandt, B.; Peinke, J. Optimize rotating wind energy rotor blades using the adjoint approach. Appl. Sci. 2018, 8, 1112. [Google Scholar] [CrossRef] [Green Version]

- He, P.; Mader, C.A.; Martins, J.R.R.A.; Maki, K.J. An aerodynamic design optimization framework using a discrete adjoint approach with OpenFOAM. Comput. Fluids 2018, 168, 285–303. [Google Scholar] [CrossRef]

- He, P.; Mader, C.A.; Martins, J.R.R.A.; Maki, K.J. Dafoam: An open-source adjoint framework for multidisciplinary design optimization with openfoam. AIAA J. 2020, 58, 1304–1319. [Google Scholar] [CrossRef]

- Spalart, P.; Allmaras, S. A one-equation turbulence model for aerodynamic flows. In Proceedings of the 30th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1992; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1992. [Google Scholar]

- Wu, N.; Kenway, G.; Mader, C.; Jasa, J.; Martins, J. pyOptSparse: A Python framework for large-scale constrained nonlinear optimization of sparse systems. J. Open Source Softw. 2020, 5, 2564. [Google Scholar] [CrossRef]

- Kenway, G.; Kennedy, G.; Martins, J. A CAD-Free Approach to High-Fidelity Aerostructural Optimization. In Proceedings of the 13th AIAA/ISSMO Multidisciplinary Analysis Optimization Conference, Fort Worth, TX, USA, 13–15 September 2010; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2010. [Google Scholar]

- Gill, P.; Murray, W.; Saunders, M. SNOPT: An SQP algorithm for large-scale constrained optimization. SIAM J. Optim. 2002, 12, 979–1006. [Google Scholar] [CrossRef] [Green Version]

- Hand, M.; Simms, D.; Fingersh, L.; Jager, D.; Cotrell, J.; Schreck, S.; Larwood, S. Unsteady Aerodynamics Experiment Phase VI: Wind Tunnel Test Configurations and Available Data Campaigns; National Renewable Energy Laboratory: Golden, CO, USA, 2001.

- Simms, D.; Schreck, S.; Hand, M.; Fingersh, L. NREL Unsteady Aerodynamics Experiment in the NASA-Ames Wind Tunnel: A Comparison of Predictions to Measurements; NREL: Golden, CO, USA, 2001.

- Ramsay, R.; Hoffman, M.; Gregorek, G. Effects of Grit Roughness and Pitch Oscillations on the S809 AirfoilL; NREL: Golden, CO, USA, 1995.

- Somers, D.W. Design and Experimental Results for the S809 Airfoil; NREL: Golden, CO, USA, 1997.

- Kenway, G.; Mader, C.; He, P.; Martins, J. Effective adjoint approaches for computational fluid dynamics. Prog. Aerosp. Sci. 2019, 110, 100542. [Google Scholar] [CrossRef]

- Mader, C.; Martins, J.; Alonso, J.; van der Weide, E. ADjoint: An approach for the rapid development of discrete adjoint solvers. AIAA J. 2008, 46, 863–873. [Google Scholar] [CrossRef]

- Lambe, A.B.; Martins, J.R.R.A. Extensions to the design structure matrix for the description of multidisciplinary design, analysis, and optimization processes. Struct. Multidiscip. Optim. 2012, 46, 273–284. [Google Scholar] [CrossRef]

| Boundary Conditions | Epsilon | Nut | nuTilda | k | Omega | P | U |

|---|---|---|---|---|---|---|---|

| Blade | epsilonWallFunction | nutUSpaldingWallFunction | fixedValue | kqRWallFunction | omegaWallFunction | zeroGradient | fixedValue |

| In/out | inletOutlet | fixedValue | inletOutlet | inletOutlet | inletOutlet | fixedValue | inletOutlet |

| Mesh# | Mesh Type | Cells (106) | Torque (Nm) | Error (%) |

|---|---|---|---|---|

| L0 | Fine mesh | 17.857 | 712 | 9.2 |

| L1 | Medium mesh | 6.315 | 695 | 11.5 |

| L2 | Course mesh | 2.657 | 648.4 | 17.27 |

| NREL Exp. | - | - | 785 | - |

| Optimization Schemes | ||||||

|---|---|---|---|---|---|---|

| Design Variables | Number of Design Variables | S1 | S2 | S3 | S4 | S5 |

| Pitch | 1 | ✓ | ||||

| Shape | 120 | ✓ | ✓ | ✓ | ||

| Twist | 6 | ✓ | ✓ | |||

| Chord | 2 | ✓ | ✓ | |||

| Dihedral | 6 | ✓ | ✓ | |||

| Total | 1 | 126 | 122 | 126 | 14 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batay, S.; Kamalov, B.; Zhangaskanov, D.; Zhao, Y.; Wei, D.; Zhou, T.; Su, X. Adjoint-Based High-Fidelity Concurrent Aerodynamic Design Optimization of Wind Turbine. Fluids 2023, 8, 85. https://doi.org/10.3390/fluids8030085

Batay S, Kamalov B, Zhangaskanov D, Zhao Y, Wei D, Zhou T, Su X. Adjoint-Based High-Fidelity Concurrent Aerodynamic Design Optimization of Wind Turbine. Fluids. 2023; 8(3):85. https://doi.org/10.3390/fluids8030085

Chicago/Turabian StyleBatay, Sagidolla, Bagdaulet Kamalov, Dinmukhamed Zhangaskanov, Yong Zhao, Dongming Wei, Tongming Zhou, and Xiaohui Su. 2023. "Adjoint-Based High-Fidelity Concurrent Aerodynamic Design Optimization of Wind Turbine" Fluids 8, no. 3: 85. https://doi.org/10.3390/fluids8030085

APA StyleBatay, S., Kamalov, B., Zhangaskanov, D., Zhao, Y., Wei, D., Zhou, T., & Su, X. (2023). Adjoint-Based High-Fidelity Concurrent Aerodynamic Design Optimization of Wind Turbine. Fluids, 8(3), 85. https://doi.org/10.3390/fluids8030085