Heat Transfer Correlations for Smooth and Rough Airfoils

Abstract

1. Introduction

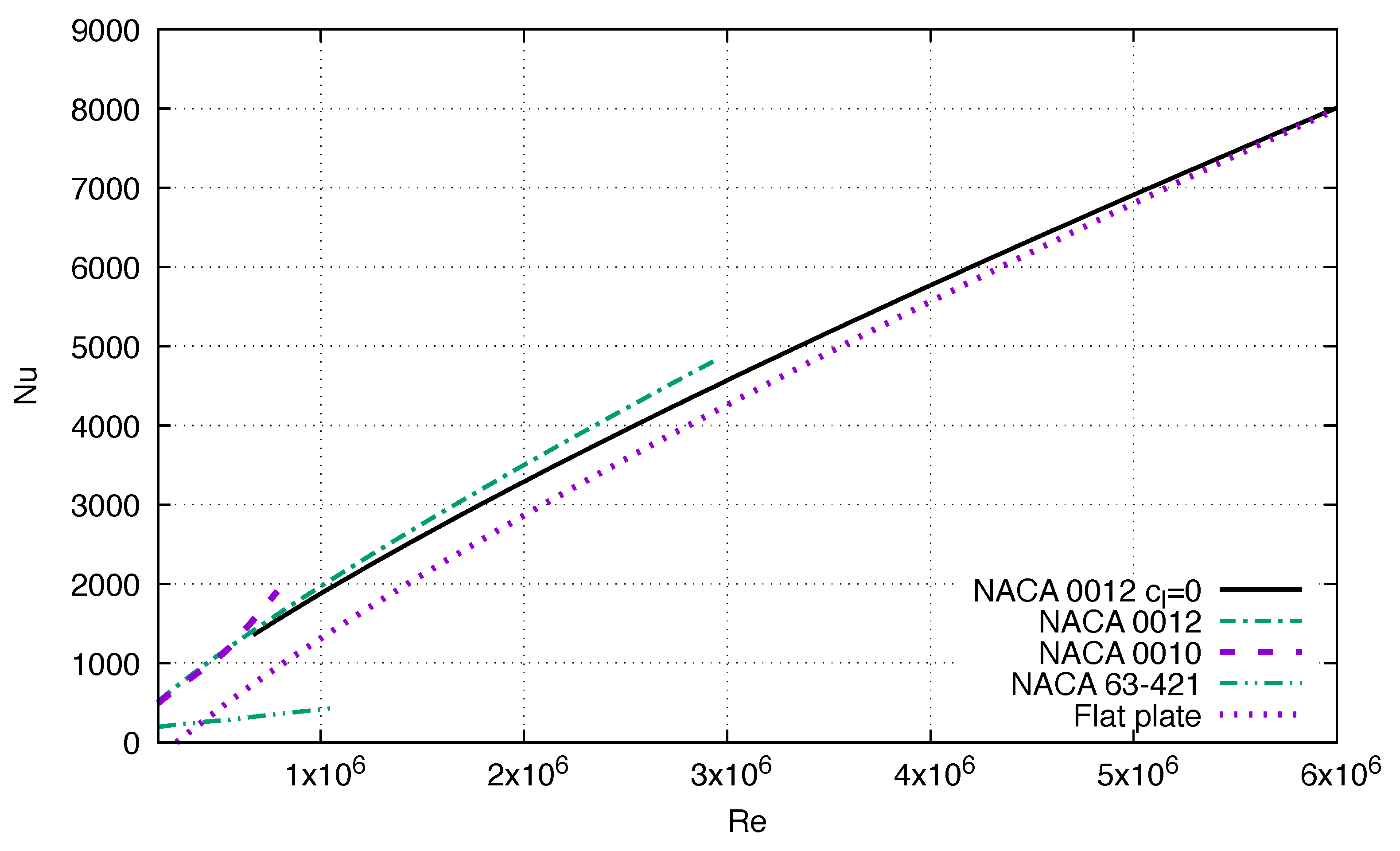

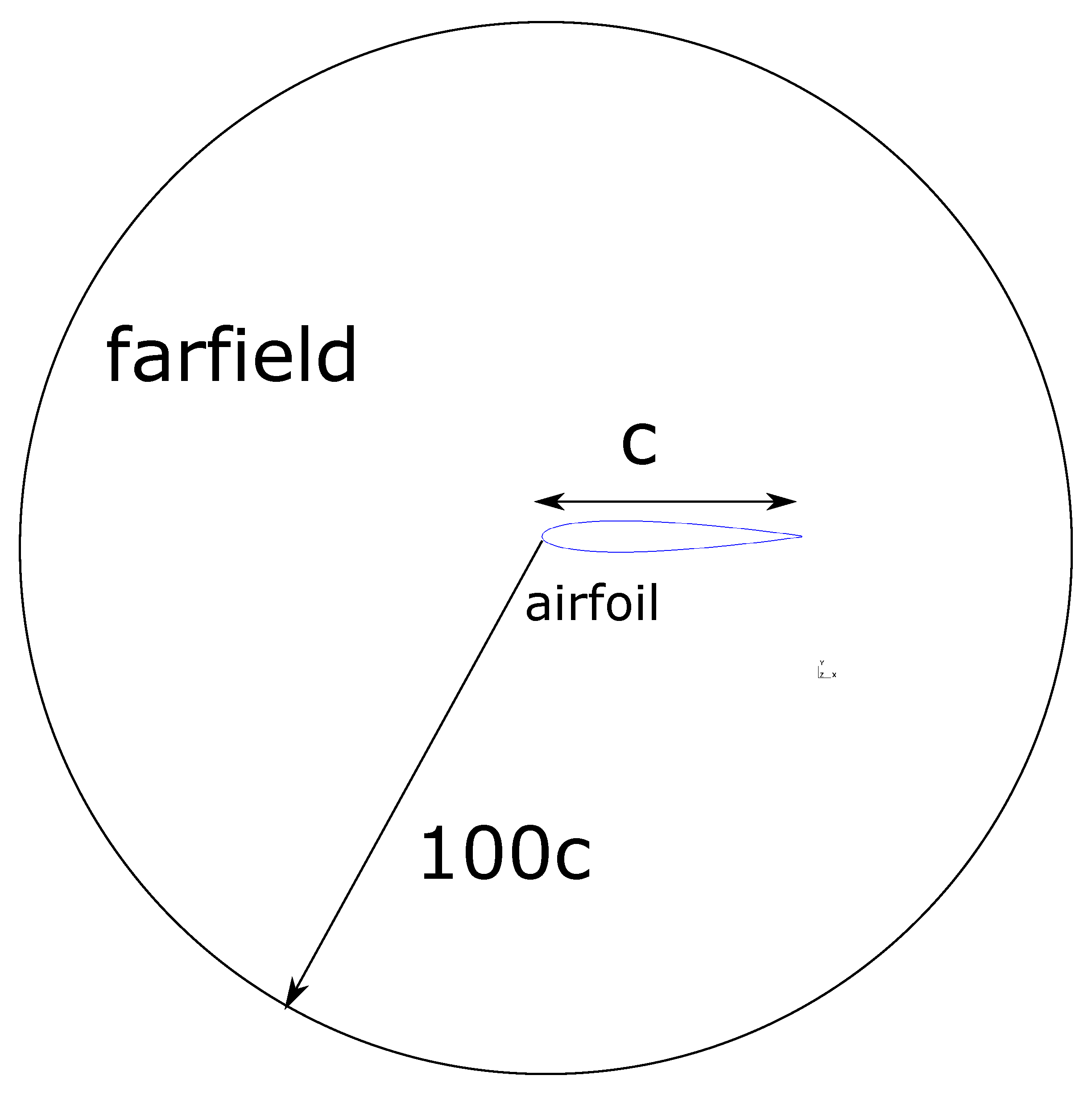

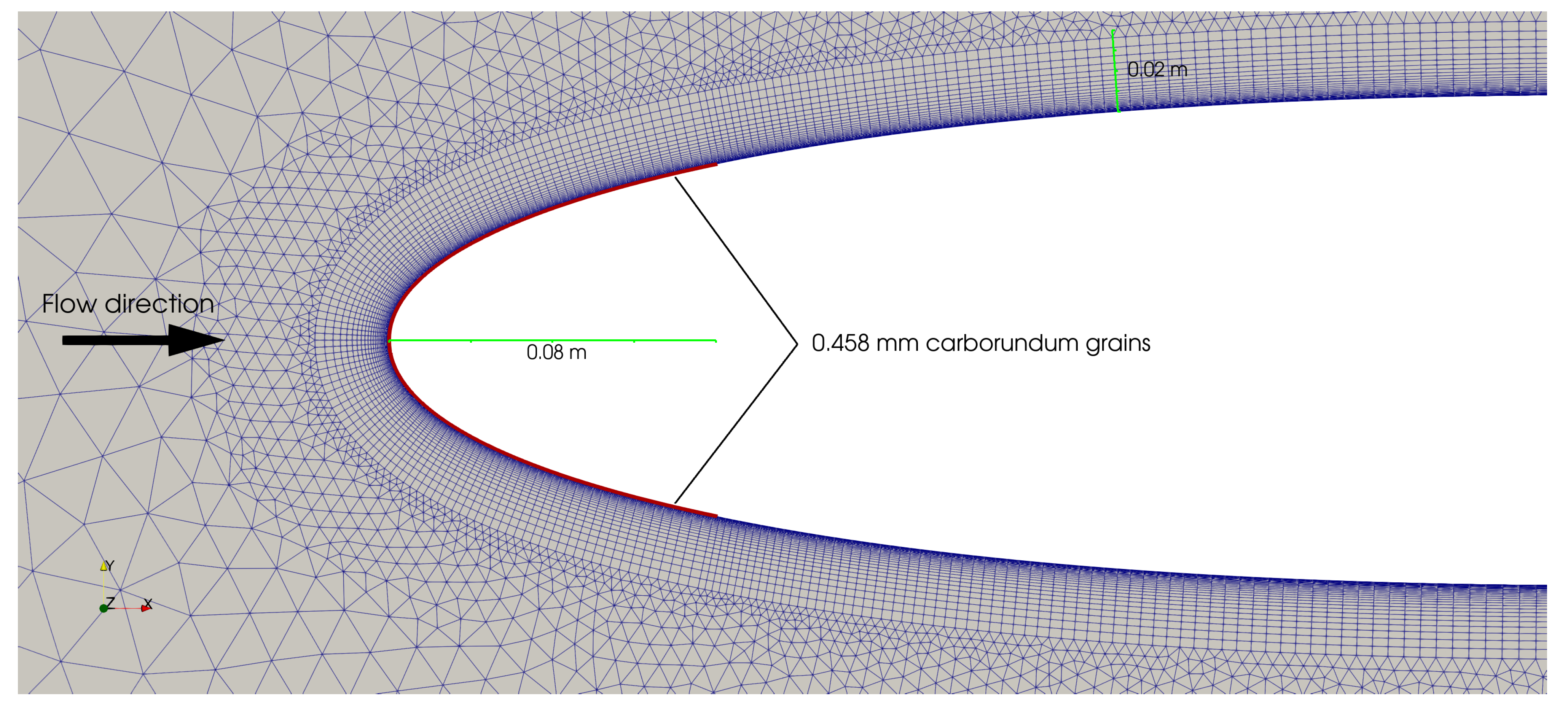

2. Materials and Methods

3. Results

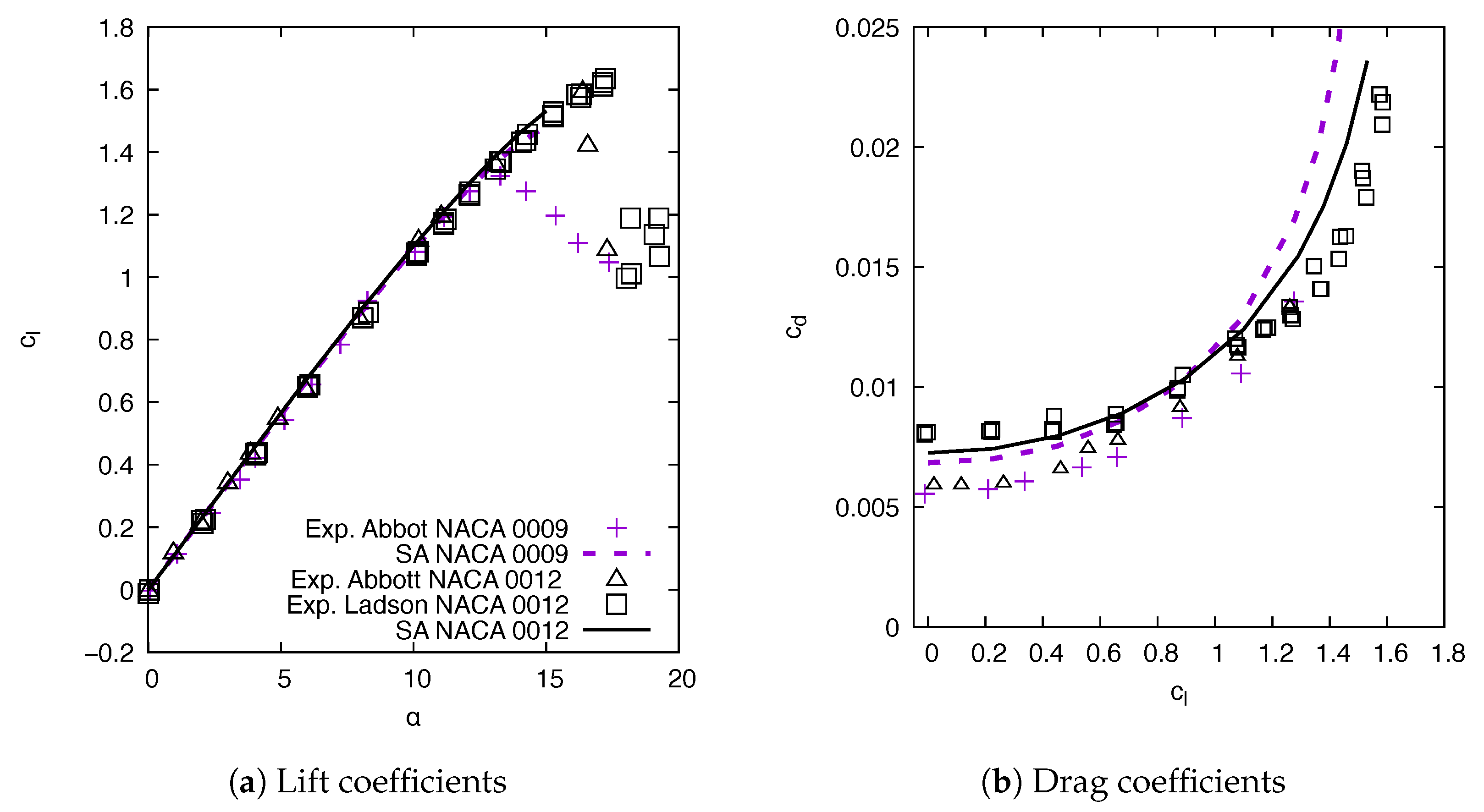

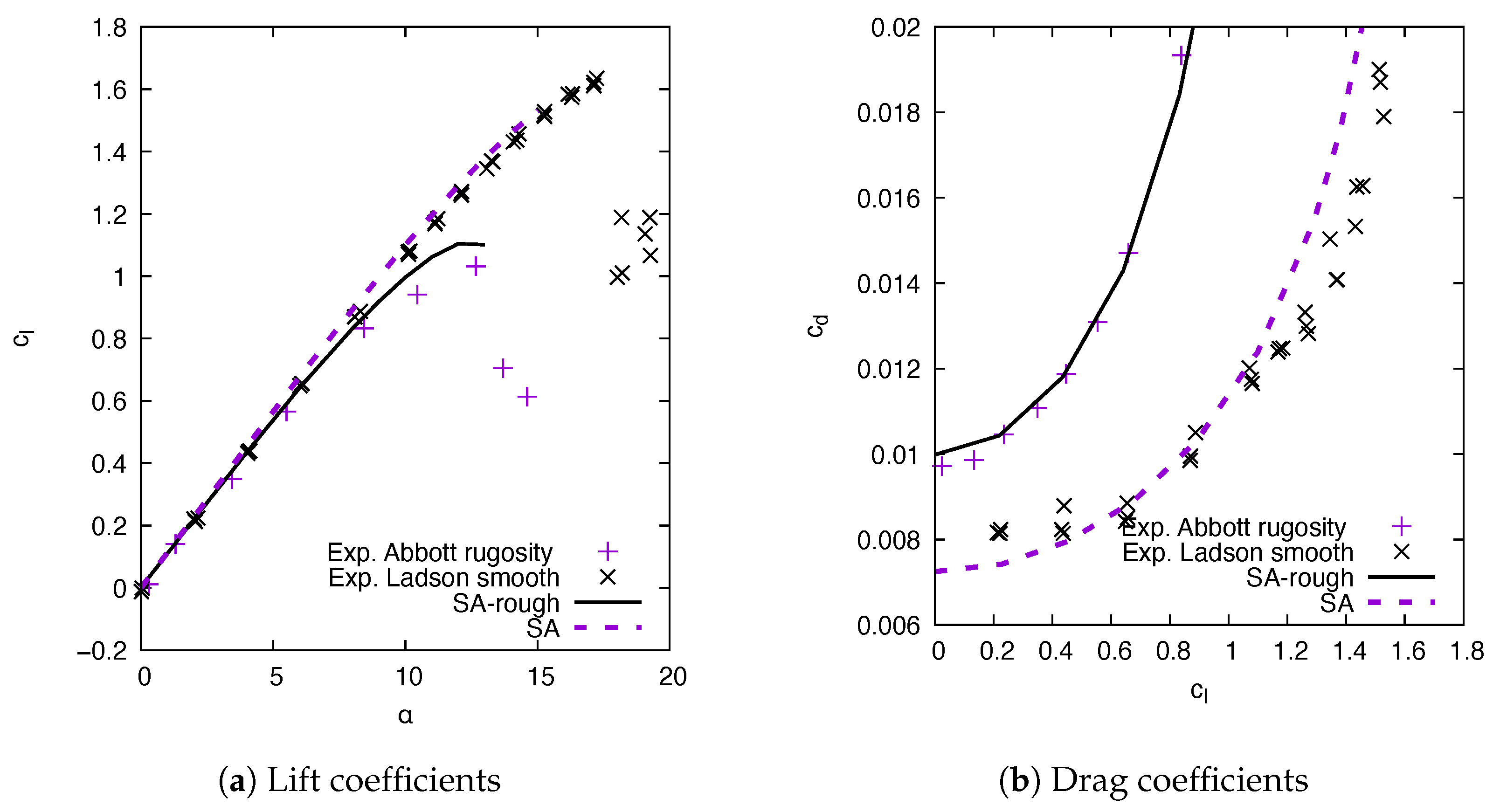

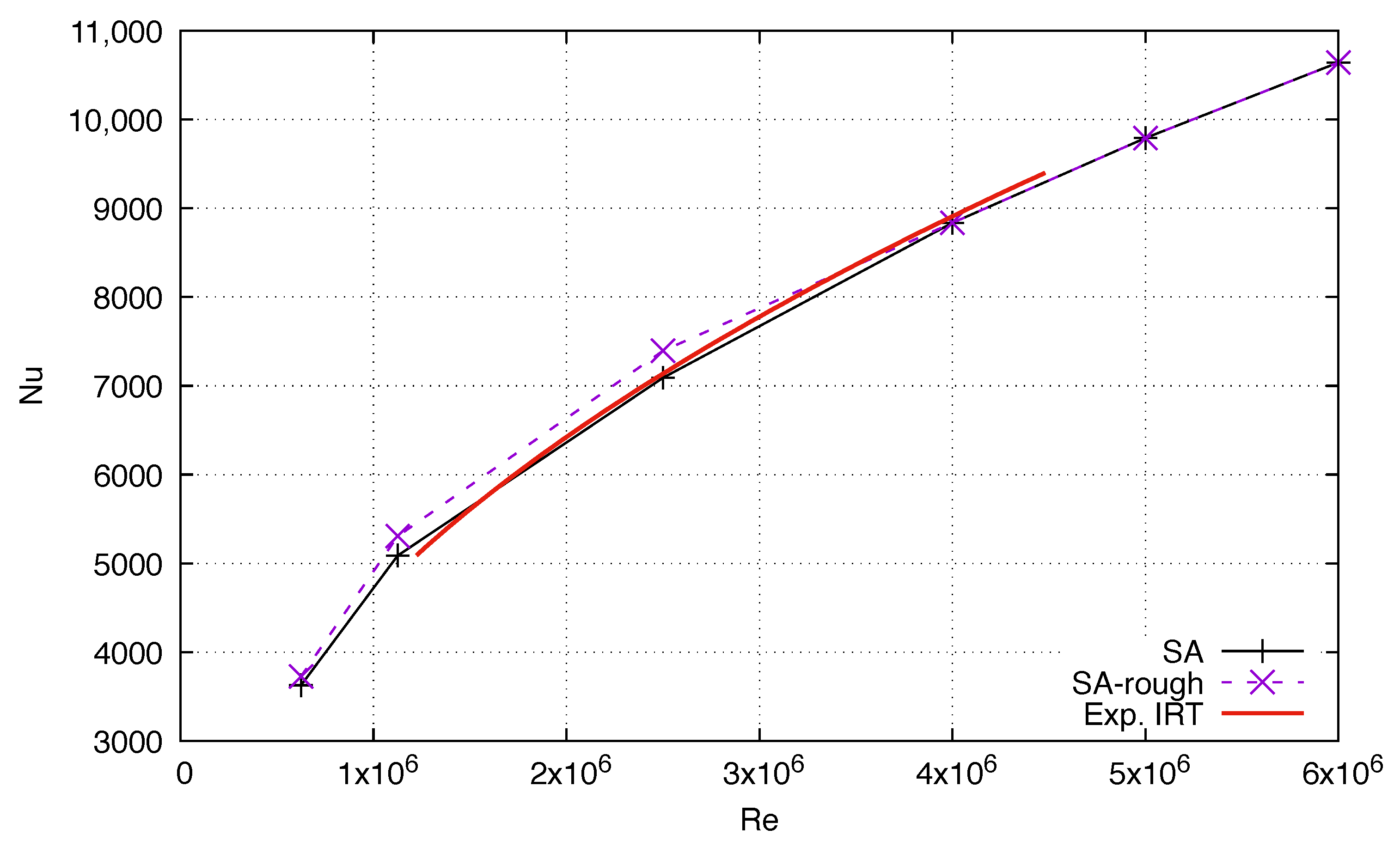

3.1. Validation

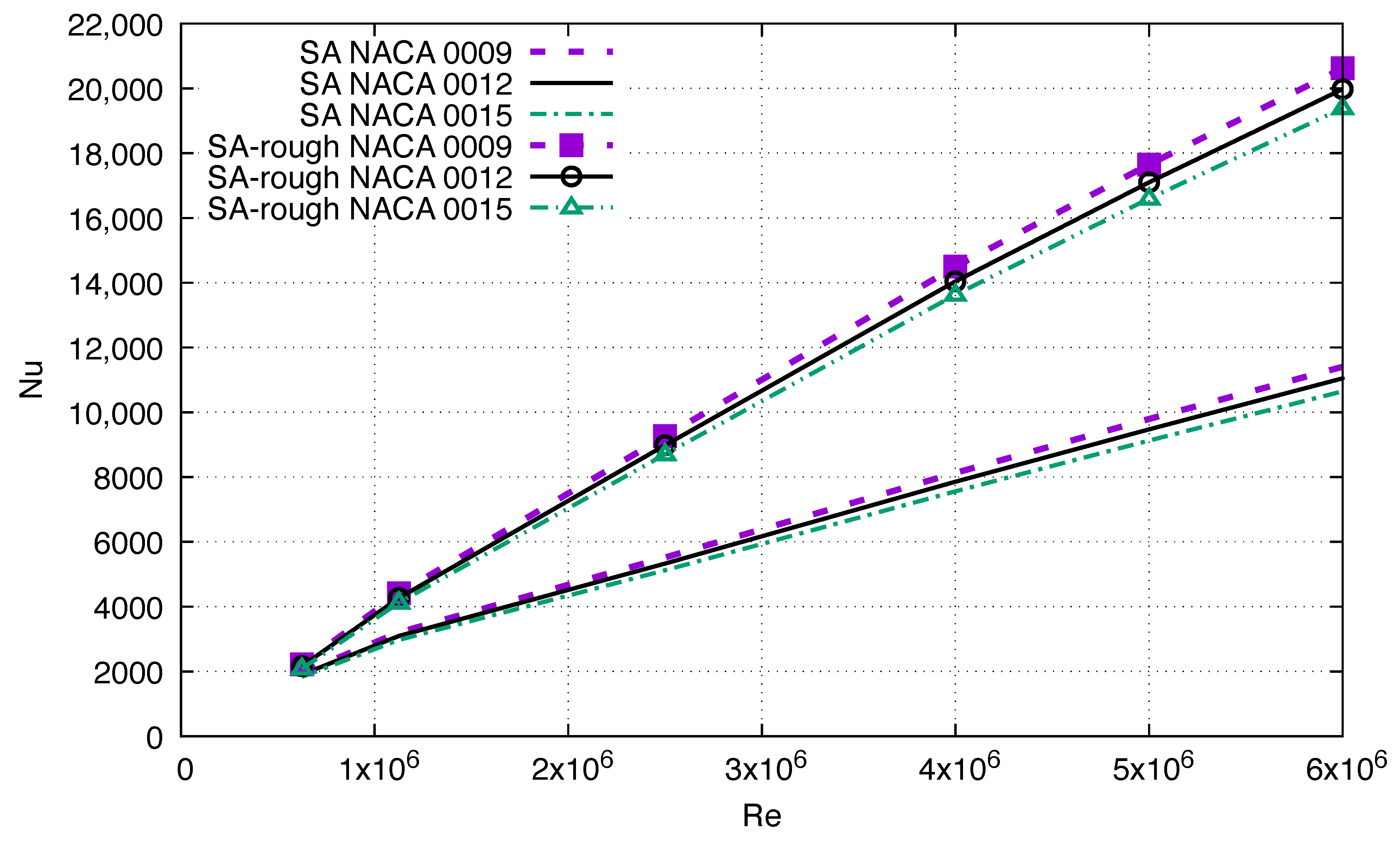

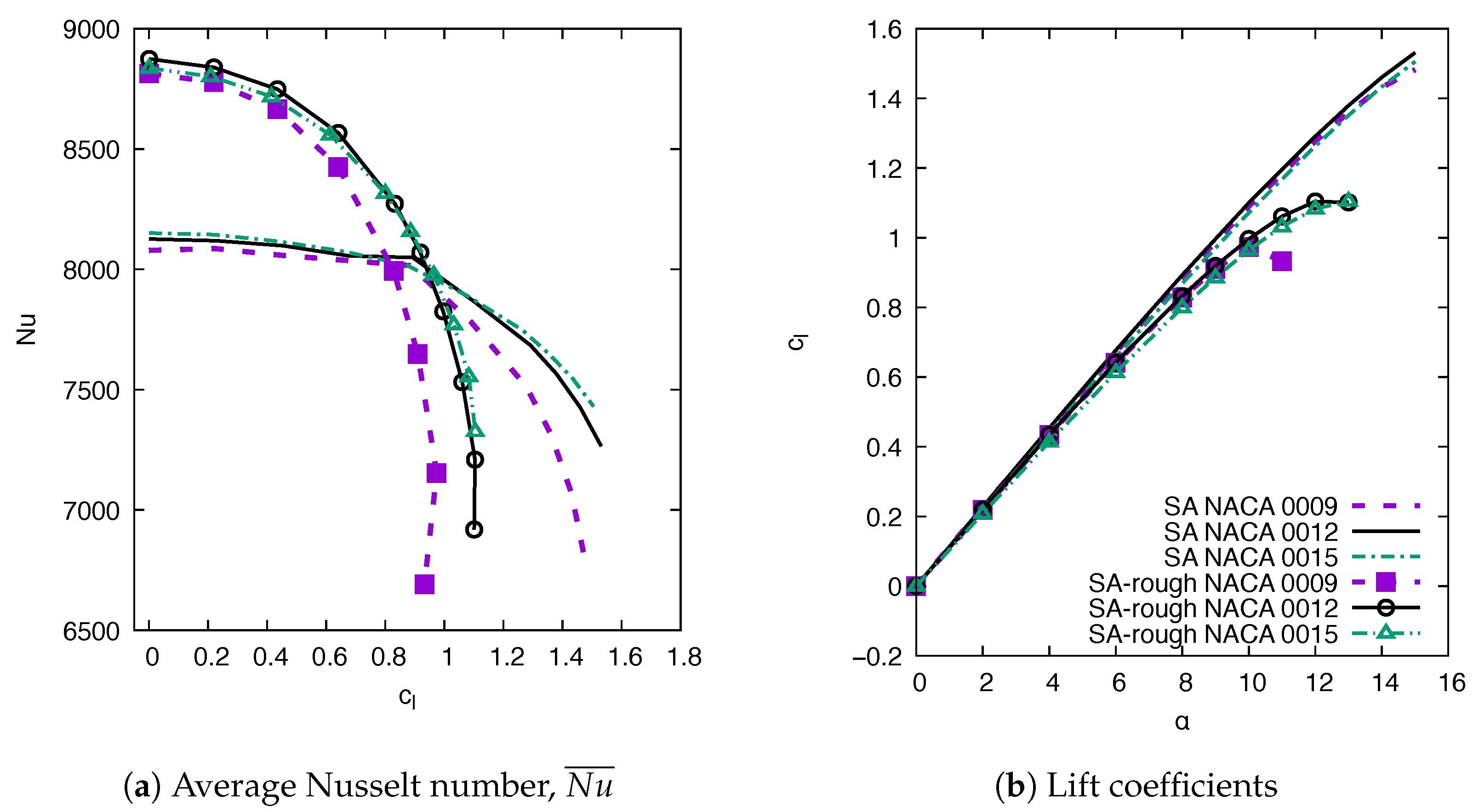

3.2. Database Verification

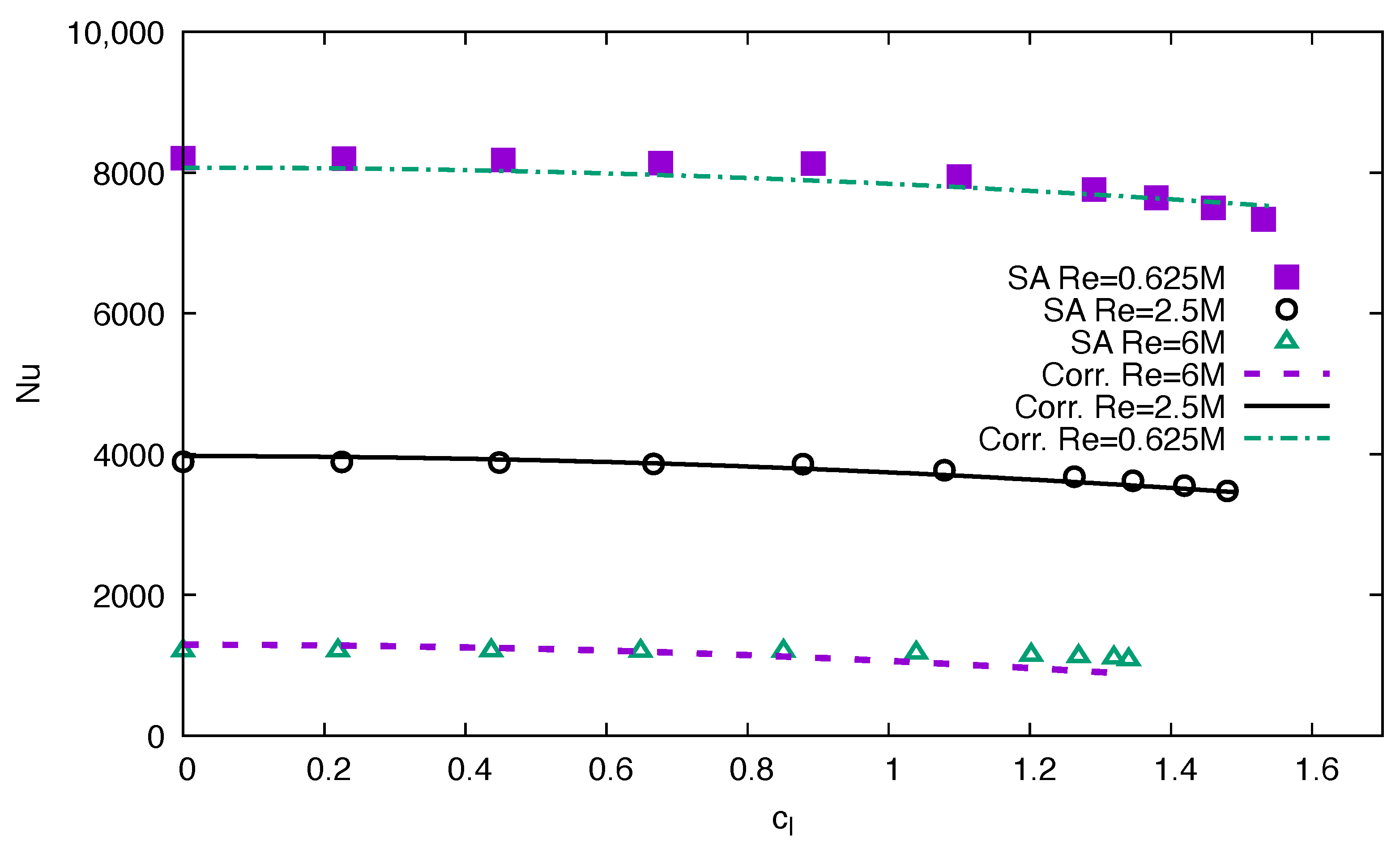

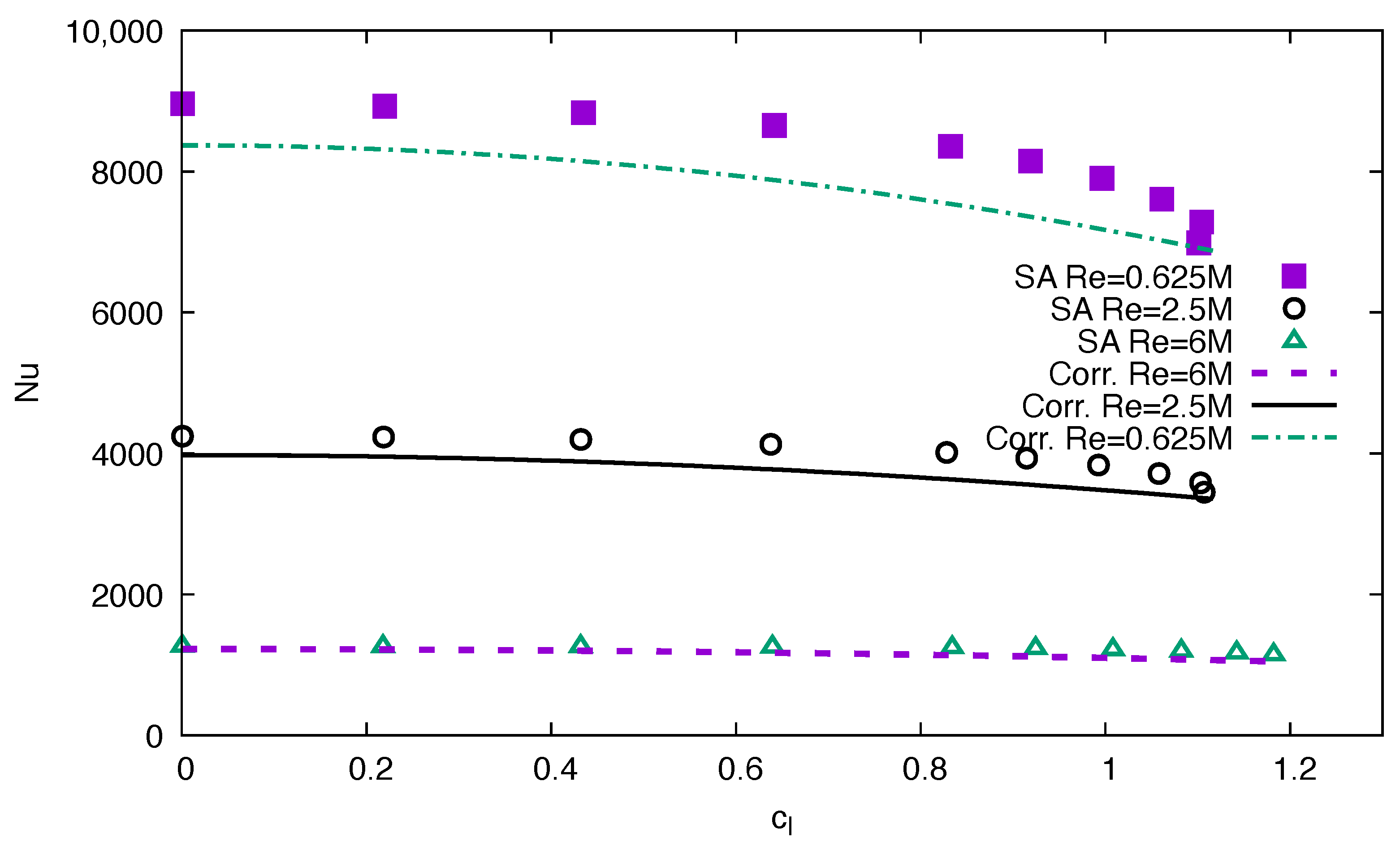

3.3. Correlations

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BEMT | Blade Element Momentum Theory |

| CFD | Computational Fluid Dynamics |

| CFL | Courant–Friedrichs–Lewy |

| IPS | Ice Protection Systems |

| RANS | Reynolds-averaged Navier–Stokes |

| SA | Spalart–Allmaras One-Equation Model |

| SA-rough | Wall Roughness Correction in Spalart–Allmaras One-Equation Model |

| VLM | Vortex Lattice Method |

References

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft Anti-Icing and De-Icing Techniques and Modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Wu, Q. Heat transfer optimization and experimental validation of anti-icing component for helicopter rotor. Appl. Therm. Eng. 2017, 127, 662–670. [Google Scholar] [CrossRef]

- Strobl, T.; Storm, S.; Thompson, D.; Hornung, M.; Thielecke, F. Feasibility Study of a Hybrid Ice Protection System. J. Aircr. 2015, 52, 2064–2076. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Liu, Z.; Zhang, Y. An experimental investigation on heat transfer performance of rotating anti-/deicing component. Appl. Therm. Eng. 2020, 177, 115488. [Google Scholar] [CrossRef]

- Pellissier, M.P.C.; Habashi, W.G.; Pueyo, A. Optimization via FENSAP-ICE of aircraft hot-air anti-icing systems. J. Aircr. 2011, 48, 265–276. [Google Scholar] [CrossRef]

- Anthony, J.; Habashi, W.G. Helicopter rotor ice shedding and trajectory analyses in forward flight. J. Aircr. 2021, 58, 1051–1067. [Google Scholar] [CrossRef]

- Targui, A.; Habashi, W.G. On a reduced-order model-based optimization of rotor electro-thermal anti-icing systems. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 2885–2913. [Google Scholar] [CrossRef]

- Fujiwara, G.E.C.; Bragg, M.B. 3D computational icing method for aircraft conceptual design. In Proceedings of the 9th AIAA Atmospheric and Space Environments Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef]

- Tedesco, M.B.; Hall, K.C. Blade Vibration and Its Effect on the Optimal Performance of Helicopter Rotors. J. Aircr. 2022, 59, 184–195. [Google Scholar] [CrossRef]

- Proulx-Cabana, V.; Nguyen, M.T.; Prothin, S.; Michon, G.; Laurendeau, E. A Hybrid Non-Linear Unsteady Vortex Lattice-Vortex Particle Method for Rotor Blades Aerodynamic Simulations. Fluids 2022, 7, 81. [Google Scholar] [CrossRef]

- Parenteau, M.; Sermeus, K.; Laurendeau, E. VLM Coupled with 2.5D RANS Sectional Data for High-Lift Design. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar] [CrossRef]

- Han, Y.; Rocco, E.; Palacios, J. Verification of a LEWICE-based icing code with coupled heat transfer prediction and aerodynamics performance determination. In Proceedings of the 9th AIAA Atmospheric and Space Environments Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef]

- Scroger, S.P.; Palacios, J.; Han, Y. Empirical modeling of urban air mobility rotor icing thrust degradation. In Proceedings of the AIAA AVIATION 2020 FORUM, Virtual, 15–19 June 2020. [Google Scholar] [CrossRef]

- Han, Y.; Palacios, J. Airfoil-Performance-Degradation Prediction Based on Nondimensional Icing Parameters. AIAA J. 2013, 51, 2570–2581. [Google Scholar] [CrossRef]

- Samad, A.; Tagawa, G.B.; Morency, F.; Volat, C. Predicting Rotor Heat Transfer Using the Viscous Blade Element Momentum Theory and Unsteady Vortex Lattice Method. Aerospace 2020, 7, 90. [Google Scholar] [CrossRef]

- Samad, A.; Tagawa, G.B.S.; Khamesi, R.R.; Morency, F.; Volat, C. Frossling Number Assessment for Airfoil Under Fully Turbulent Flow Conditions. J. Thermophys. Heat Transf. 2022, 36, 389–398. [Google Scholar] [CrossRef]

- Anderson, J.D. Fundamentals of Aerodynamics, 4th ed.; McGraw-Hill series in aeronautical and aerospace engineering; McGraw-Hill Higher Education: Boston, MSA, USA, 2007; p. xxiv. 1008p. [Google Scholar]

- Battisti, L.; Zanne, L.; Castelli, M.R.; Bianchini, A.; Brighenti, A. A generalized method to extend airfoil polars over the full range of angles of attack. Renew. Energy 2020, 155, 862–875. [Google Scholar] [CrossRef]

- Bianchini, A.; Balduzzi, F.; Rainbird, J.M.; Peiro, J.; Graham, J.M.R.; Ferrara, G.; Ferrari, L. An Experimental and Numerical Assessment of Airfoil Polars for Use in Darrieus Wind Turbines—Part II: Post-stall Data Extrapolation Methods. J. Eng. Gas Turbines Power 2015, 138. [Google Scholar] [CrossRef]

- Hoerner, S.F. Fluid-dynamic drag; practical information on aerodynamic drag and hydrodynamic resistance. Aeronaut. J. 1965, 80, 371. [Google Scholar]

- Gudmundsson, S. 15.2.2.8 Drag of Airfoils and Wings. In General Aviation Aircraft Design—Applied Methods and Procedures; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Götten, F.; Havermann, M.; Braun, C.; Marino, M.; Bil, C. Airfoil Drag at Low-to-Medium Reynolds Numbers: A Novel Estimation Method. AIAA J. 2020, 58, 2791–2805. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P. Introduction to Heat Transfer, 4th ed.; J. Wiley: New York, NY, USA; Toronto, ON, Canada, 2002; p. xxiii. 892p. [Google Scholar]

- Lienhard, J.H.V. Heat Transfer in Flat-Plate Boundary Layers: A Correlation for Laminar, Transitional, and Turbulent Flow. J. Heat Transf. 2020, 142. [Google Scholar] [CrossRef]

- Ahmed, G.R.; Yovanovich, M.M. Analytical method for forced convection from flat plates, circular cylinders, and spheres. J. Thermophys. Heat Transf. 1995, 9, 516–523. [Google Scholar] [CrossRef]

- Achenbach, E. The effect of surface roughness on the heat transfer from a circular cylinder to the cross flow of air. Int. J. Heat Mass Transf. 1977, 20, 359–369. [Google Scholar] [CrossRef]

- Han, Y.; Palacios, J. Heat Transfer Evaluation on Ice-Roughened Cylinders. AIAA J. 2017, 55, 1070–1074. [Google Scholar] [CrossRef]

- Jayranaiwachira, N.; Promvonge, P.; Thianpong, C.; Skullong, S. Entropy generation and thermal performance of tubular heat exchanger fitted with louvered corner-curved V-baffles. Int. J. Heat Mass Transf. 2023, 201, 123638. [Google Scholar] [CrossRef]

- Zhai, C.; Islam, M.; Simmons, R.; Barsoum, I. Heat transfer augmentation in a circular tube with delta winglet vortex generator pairs. Int. J. Therm. Sci. 2019, 140, 480–490. [Google Scholar] [CrossRef]

- Sharma, V.R.; S, S.S.; N, M.; S, M.M. Enhanced thermal performance of tubular heat exchanger using triangular wing vortex generator. Cogent Eng. 2022, 9, 2050021. [Google Scholar] [CrossRef]

- Turgut, E.; Yardımcı, U. Detailed evaluation of a heat exchanger in terms of effectiveness and second law. J. Turbul. 2022, 23, 515–547. [Google Scholar] [CrossRef]

- Poinsatte, P.E.; Van Fossen, G.J.; De Witt, K.J. Roughness effects on heat transfer from a NACA 0012 airfoil. J. Aircr. 1991, 28, 908–911. [Google Scholar] [CrossRef]

- Poinsatte, P.E.; Van Fossen, G.J.; Newton, J.E.; De Witt, K.J. Heat transfer measurements from a smooth NACA 0012 airfoil. J. Aircr. 1991, 28, 12. [Google Scholar] [CrossRef]

- Dukhan, N.; DeWitt, K.J.; Masiulaniec, K.C.; Van Fossen, G.J., Jr. Experimental Frossling Numbers for Ice-Roughened NACA 0012 Airfoils. J. Aircr. 2003, 40, 1161–1167. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. An experimental investigation on the unsteady heat transfer process over an ice accreting airfoil surface. Int. J. Heat Mass Transf. 2018, 122, 707–718. [Google Scholar] [CrossRef]

- Benissan, M.; Akwaboa, S.; Mensah, P. Experimental Measurement of Nusselt Number Correlations on Flat Plate and NACA 0010 Section Surfaces. In Proceedings of the ASME 2012 Heat Transfer Summer Conference collocated with the ASME 2012 Fluids Engineering Division Summer Meeting and the ASME 2012 10th International Conference on Nanochannels, Microchannels, and Minichannels, Rio Grande, PR, USA, 8–12 July 2012; pp. 809–818. [Google Scholar] [CrossRef]

- Wang, X.; Bibeau, E.; Naterer, G.F. Experimental correlation of forced convection heat transfer from a NACA airfoil. Exp. Therm. Fluid Sci. 2007, 31, 1073–1082. [Google Scholar] [CrossRef]

- Wang, X.; Naterer, G.F.; Bibeau, E. Convective Heat Transfer from a NACA Airfoil at Varying Angles of Attack. J. Thermophys. Heat Transf. 2008, 22, 457–463. [Google Scholar] [CrossRef]

- Samad, A.; Villeneuve, E.; Blackburn, C.; Morency, F.; Volat, C. An Experimental Investigation of the Convective Heat Transfer on a Small Helicopter Rotor with Anti-Icing and De-Icing Test Setups. AEROSPACE 2021, 8, 96. [Google Scholar] [CrossRef]

- Abbott, I.H.; Von Doenhoff, A.E. Theory of Wing Sections, Including a Summary of Airfoil Data; Dover Publications: New York, NY, USA, 1959; p. 693. [Google Scholar]

- Blazek, J. Computational Fluid Dynamics: Principles and Applications, 3rd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Tsilingiris, P.T. Thermophysical and transport properties of humid air at temperature range between 0 and 100 °C. Energy Convers. Manag. 2008, 49, 1098–1110. [Google Scholar] [CrossRef]

- Spalart, P.; Allmaras, S. A One-Equation Turbulence Model for Aerodynamic Flows. Rech. AéRospatiale 1994, 1, 5–21. [Google Scholar]

- Aupoix, B.; Spalart, P.R. Extensions of the Spalart–Allmaras turbulence model to account for wall roughness. Int. J. Heat Fluid Flow 2003, 24, 454–462. [Google Scholar] [CrossRef]

- Morency, F.; Beaugendre, H. Comparison of turbulent Prandtl number correction models for the Stanton evaluation over rough surfaces. Int. J. Comput. Fluid Dyn. 2020, 34. [Google Scholar] [CrossRef]

- Geuzaine, C.; Remacle, J.F. Gmsh: A three-dimensionnal finite element mesh generator with built-in pre- and post-processing facilities. Int. J. Numer. Methods Eng. 2009, 79, 1309–1331. [Google Scholar] [CrossRef]

- Palacios, F.; Economon, T.D.; Aranake, A.C.; Copeland, S.R.; Lonkar, A.K.; Lukaczyk, T.W.; Manosalvas, D.E.; Naik, K.R.; Santiago Padron, A.; Tracey, B.; et al. Stanford university unstructured (SU2): Open-source analysis and design technology for turbulent flows. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MA, USA, 13–17 January 2014. [Google Scholar] [CrossRef]

- Toro, E.F. Riemann Solvers and Numerical Methods for Fluid Dynamics: A Practical Introduction, 3rd ed.; Springer: Berlin, Germany, 2009; p. xxiv. 724p. [Google Scholar] [CrossRef]

- Wang, Z.J. A fast nested multi-grid viscous flow solver for adaptive Cartesian/Quad grids. Int. J. Numer. Methods Fluids 2000, 33, 657–680. [Google Scholar] [CrossRef]

- Roache, P.J. Perspective: A method for uniform reporting of grid refinement studies. J. Fluids Eng. Trans. ASME 1994, 116, 405–413. [Google Scholar] [CrossRef]

- Seber, G.A.F.; Wild, C.J. Nonlinear Regression; Wiley series in probability and statistics; Wiley-Interscience: Hoboken, NJ, USA, 2003; p. xx. 768p. [Google Scholar] [CrossRef]

- Ladson, C.L.; Hill, A.S.; Johnson, W.G., Jr. Pressure Distributions from High Reynolds Number Transonic Tests of an NACA 0012 Airfoil in the Langley 0.3-Meter Transonic Cryogenic Tunnel; Report NASA TM 100526; NASA: Hampton, VA, USA, 1987.

- Bertagnolio, F. NACA0015 Measurements in LM Wind Tunnel and Turbulence Generated Noise. Report Risoe-R No. 1657, Danmarks Tekniske Universitet, Risø Nationallaboratoriet for Bæredygtig Energi; Forskningscenter Risoe: Roskilde, Denmark, 2008. [Google Scholar]

- Gilling, L.; Sørensen, N.; Davidson, L. Detached Eddy Simulations of an Airfoil in Turbulent Inflow. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2014. [Google Scholar] [CrossRef]

- Ignatowicz, K.; Solaï, E.; Morency, F.; Beaugendre, H. Data-Driven Calibration of Rough Heat Transfer Prediction Using Bayesian Inversion and Genetic Algorithm. Energies 2022, 15, 3793. [Google Scholar] [CrossRef]

- Poinsatte, P.E. Heat Transfer Measurements from a NACA0012 Airfoil in Flight and in the NASA Lewis Icing Research Tunnel. Ph.D. Thesis, University of Toledo, Toledo, OH, USA, 1989. [Google Scholar]

- White, F.M. Viscous Fluid Flow, 3rd ed.; McGraw-Hill series in mechanical engineering; McGraw-Hill Higher Education: New York, NY, USA, 2006; p. xxi. 629p. [Google Scholar]

- Kays, W.M.; Crawford, M.E. Convective Heat and Mass Transfer, 3rd ed.; McGraw-Hill series in mechanical engineering; McGraw-Hill: New York, NY, USA, 1993; p. xxxii. 601p. [Google Scholar]

- Dukhan, N.; Masiulaniec, K.C.; De Witt, K.J.; Van Fossen, G.J. Experimental Heat Transfer Coefficients from Ice-Roughened Surfaces for Aircraft Deicing Design. J. Aircr. 1999, 36, 948–956. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samadani, S.; Morency, F. Heat Transfer Correlations for Smooth and Rough Airfoils. Fluids 2023, 8, 66. https://doi.org/10.3390/fluids8020066

Samadani S, Morency F. Heat Transfer Correlations for Smooth and Rough Airfoils. Fluids. 2023; 8(2):66. https://doi.org/10.3390/fluids8020066

Chicago/Turabian StyleSamadani, Sepehr, and François Morency. 2023. "Heat Transfer Correlations for Smooth and Rough Airfoils" Fluids 8, no. 2: 66. https://doi.org/10.3390/fluids8020066

APA StyleSamadani, S., & Morency, F. (2023). Heat Transfer Correlations for Smooth and Rough Airfoils. Fluids, 8(2), 66. https://doi.org/10.3390/fluids8020066