This section is structured as follows: First, in

Section 3.1, the crown morphology of a normal droplet impact, i.e.,

90°, for different Weber numbers is presented. In the next subsection, the outcome of one oblique impact (

60°) experiment leading to a single central finger on one side of the crown is shown in detail. After that, the morphology change with different impact Weber numbers is presented and discussed in

Section 3.3. At the end, the oblique droplet impact is compared to the normal one in

Section 3.4.

3.1. Crown Morphology for Weber Number Variation at Normal Droplet Impact ( 90°)

Experiments were conducted with

90° in a range of

, as for the oblique droplet impact. The detailed impact conditions of the experiments shown in this and the following sections are summarized in

Table 1.

Figure 4 shows the crown development of Experiments 1–4 at the time of maximum crown height (A), during (B) and after the receding phase (C). With an increase of

, the morphology changes the following way. For Experiment 1 (

323), there is a smooth rim which falls down on the film again without any splashing; see

Figure 4(B1). After that, a small Worthington jet [

4] forms, C1. With an increase in

(Experiment 2,

481), the rim remains smooth until it reaches its maximum crown height, and there is still no crown splash. During the receding, waves appear at the rim and an intense Worthington jet can be observed after that, which leads to a detachment of the jet itself and a separation into up to six droplets. Moving on to the third experiment (

618), an increase in the Weber number results in the emergence of waves in the expansion phase of the crown, A3. During the receding phase, thick fingers start to form and comparably large droplets separate from it, which fall back onto the liquid film, B3. After that, a small Worthington jet is present without further atomization, C3. Finally, as the Weber number is further increased (

708), fingers appear at the rim before the maximum crown height is reached, and many secondary droplets detach; see

Figure 4(A4). The fingers and the secondary droplets at this Weber number are smaller in diameter and fly upwards. Additionally, consecutive detachments of more droplets from these fingers occurs during the receding phase, B4, which fall down onto the liquid film again, C4.

These phenomena described here were already observed by others [

3,

4,

7,

9]. The threshold derived from the correlation by Cossali et al. [

2], at which splashing starts to occur, is

485. They mention a transition region in the vicinity of the threshold, in which both outcomes are possible. At the film thickness and Ohnesorge number we investigated in this study, a splashing from a Worthington jet is observed before the crown splashing. Cossali et al. also investigated this region but did not comment on splashing from a Worthington jet. However, they clearly defined splashing as the formation of secondary droplets and their threshold fits quite well with our observations.

3.2. Single Central Finger Morphology ( 60°)

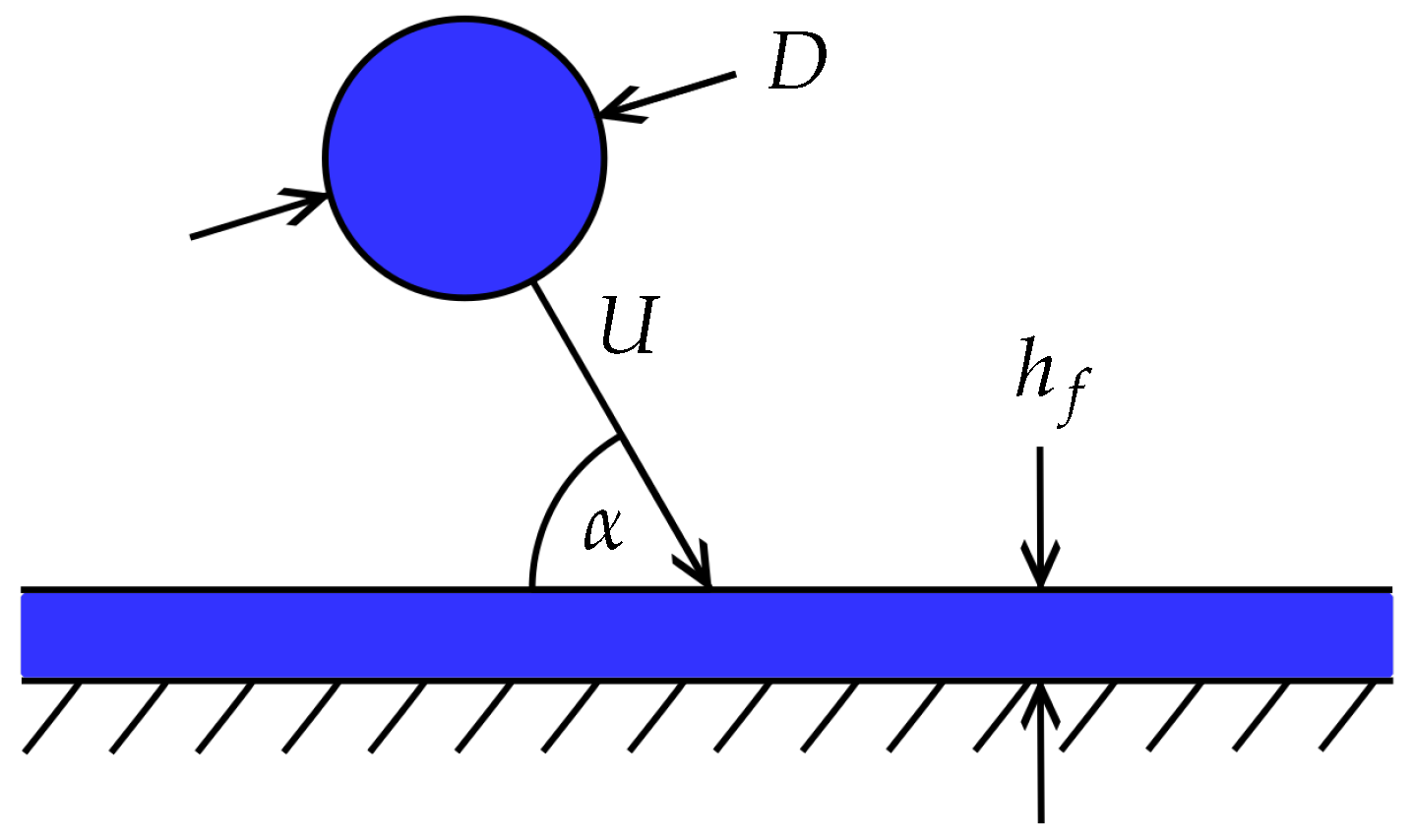

The Weber number of an oblique impact can be defined either with the total impact velocity,

, or with the velocity component normal to the wall film,

. Using the total Weber number yields the same kinetic energy of the impact as in the normal impact. On the other hand, the normal Weber number scales with the velocity component normal to the wall, which could also be the determining quantity for the splashing characteristic. The normal Weber number is always smaller than the total Weber number; here, for

60°, approximately

. In this paper, the Weber number for the oblique impact was calculated with the total impact velocity, meaning that the normal velocity component of the oblique impact is smaller than that of the normal impact at the same

. Nevertheless, as shown later in

Section 3.3 and

Section 3.4, splashing occurs at lower

in the oblique case.

In this section, the outcome of one oblique droplet impact (Experiment 6, see

Table 1,

448,

59.7°) is shown and explained in detail.

Figure 5 presents the development of the impact, captured by the two synchronized high-speed cameras. The left picture shows the morphology from the side view and the right picture from the front view. Both images are scaled to the same size and aligned in height. The difference visible at the film surface is due to a different depths of field and focal points for the two views. The droplet impacts obliquely from the top left; see

Figure 5A showing the droplet shortly after first contact with the wall film. In

Figure 5B, the early stage after impact reveals that the lamella grows flat and horizontally at the front compared to the higher rising lamella on the sides. Shortly after (see

Figure 5C,D), the front lamella turns upwards and reaches higher than the lamella on the side. In picture D, at

4.3, a central finger begins to form on the front side and continues to grow diagonally upwards (

Figure 5E–H). A first secondary droplet detaches from the tip of the finger at

11, see

Figure 5F,G, moving upwards. At this moment, the crown has already reached its maximum height and starts to recede, first at the back and then at the side. Subsequently, the central finger also retracts while a second and a third secondary droplet separate from its tip (

Figure 5I,J), which fall back down on the wall film and coalesce with it. At the rim on the side, no fingers form. Instead, one cusp develops on each side of the crown. It starts to form at

7.4, visible in

Figure 5E, and becomes evident in both views in

Figure 5F,G. On the back side of the crown, the crown is first bent inwards; see

Figure 5C. However, a part of the crown, or at least a small finger, flips outwards later, visible in

Figure 5E.

Yarin and Weiss [

26] provided an explanation for the formation of fingers from the rim bounding the crown during droplet impact. According to their explanation, small disturbances in the Taylor rim [

1] are amplified and lead to the formation of cusps. If the kinetic energy is sufficiently high, fingers grow from these cusps and secondary droplets separate from their tips due to the Rayleigh–Plateau instability. This mechanism is also observed in the oblique impact case shown above. However, in this particular case, one single finger grows only at the front side of the crown, which can be attributed to the horizontal velocity component of the impacting droplet. The rim at the side, however, is more stable; see

Figure 5D,E. The horizontal velocity component present at the oblique impact probably induces a circumferential flow within the rim. This circumferential flow supplies the central finger and facilitates its growth.

To evaluate the repeatability of the experiment,

Figure 6 shows the crown morphology from three experiments with the same impact conditions at two moments in time. The first moment is during the early growth phase of the central finger,

5.0, shown in the first row. Notably, the height and the shape of the finger are the same across all experiments. Also, the overall shape of the crown is identical. At a later time,

14.5, the first secondary droplet has detached from the central finger and the crown has already started descending towards the wall film; see the second row in

Figure 6. The shape of the residual crown as well as the position and size of the side cusps are similar in all three experiments. The only observable difference is the position of the secondary droplet, indicating a slight variation in the time of its separation from the finger. A comparison of later times (not shown in this figure) reveals that in all three experiments three secondary droplets detach. Additionally, the crown shape observed in the front view is remarkably symmetric. This demonstrates that the wall film is in fact flat and quiescent prior to droplet impact. Moreover, no noticeable random disturbances, such as oscillations, are introduced by the detachment of the droplet at the droplet generator.

Figure 7 presents a comparison of the non-dimensional crown height on the front side

as function of the non-dimensional time

for the three experiments under the same conditions (Exp 6, Exp 6.1, Exp 6.2) in order to quantify the repeatability of the experiment. The crown height was measured from the front view, excluding the central finger, as indicated with the red line in

Figure 6. The overall development is consistent in all experiments, and they reach their maximum crown height at

10. However, Experiment 6.1 shows a small deviation, with its maximum height being 7% lower compared to the other experiments. It is interesting to note, that the deviation starts at

5, which is the time where the central finger starts to grow. The crown height development of Experiment 6 and 6.2 aligns well within the measurement accuracy until the crown starts to recede,

14. During this phase, the rim becomes wavy, as seen in

Figure 5H. Small variations in the position of the waves along the receding crown result in changes in the measured height, leading to deviations between the experiments in the receding phase.

3.3. Variation of the Weber Number ( 60°)

Figure 8 shows the crown morphology during and oblique droplet impact of four different total Weber numbers,

. It compares Experiment 6 (

448), which was investigated in the last section, with an experiment with lower Weber number (Experiment 5

256) and two experiments with higher

numbers (Experiments 7 + 8,

516,

631). The impact angle and the film thickness were kept almost constant; only the droplet diameter was increased for the last experiment to reach higher Weber numbers. The detailed impact conditions are summarized in

Table 1. Experiments 6 and 7 lie in the vicinity of the deposition/splashing threshold developed by Cossali et al. [

2] for normal droplet impacts on thin wall films,

485. The other experiments represent cases below (Experiment 5) and above it (Experiment 8), which does not mean that they have to lead to deposition and splashing, respectively, because the threshold was not developed for oblique impacts. The left column in

Figure 8 shows a moment shortly after the start of finger formation,

6.1, and the right column a moment where the crown is in the receding phase,

13.9.

As described in the last section, Experiment 6 is characterized by a single central finger forming at the front from which three secondary droplets detach; see

Figure 8(A2,B2). At the side of the crown, two cusps can be observed. For Experiment 5, with a lower We number, shown in

Figure 8(A1,B1), the crown morphology is similar with a single central finger at the front side of the crown. However, only one secondary droplet detaches in the late receding phase and falls back on the film. Furthermore, the finger is shorter and thicker in this case, and also the detached droplet is larger. If the We number is increased to

516 (Experiment 7), the crown morphology changes. Here, the rim at the front gets unstable in the middle and two main fingers are visible as well as a tiny secondary droplet which is generated very early; see

Figure 8(A3). Secondary droplets detach from the fingers at the front. The fingers are thinner than the single central finger for Experiment 6 and the secondary droplets are smaller. In the receding phase, similar to Experiment 6, cusps can be found at the side of the rim. In this case, however, there are two at each side, which are larger and can be already described as small fingers. In Experiment 8, the impact velocity and the droplet diameter were increased further to reach

631. Now, the rim is unstable along the complete front, many tiny droplets are present and many fingers are formed already during the initial finger formation; see

Figure 8(A4). Droplets separate from those fingers at a later point in time. Furthermore, also at the rim on the side, not only cusps, but fingers are visible and droplets detach from them.

On the one hand, the disturbances in the early rim for Experiments 7 + 8 are explained by the increase in the ratio of kinetic energy to surface tension energy, as it can be also observed for the normal droplet impact. On the other hand, here additionally a collision of the early crown with the wall film is the cause. To better observe the early phase after impact, and to confirm this statement, the experiments were reproduced with a higher magnification for the side view.

Figure 9 shows the reproduced experiments which result in the outcome of a single central finger (Exp. 9) as well as an early growth of many fingers (Exp. 10 + 11); see

Table 1. In the case of a single central finger, see

Figure 9 first row (A1/B1), the crown does not touch the wall film at any time in the early phase after impact. However, with an increase in

number, the crown interacts with the wall film in the early time; see

Figure 9(A2). Note that, only the middle part of the front rim touches the film as observed from the front view perspective. This seems to introduce disturbances in this part of the rim, which lead to a partial early rupture and four fingers in the middle of the crown’s front. The third row in

Figure 9(A3/B3) shows a collision of the complete front part of the crown with the wall film. This interaction is more intense and leads to the ejection of tiny droplets. The rim is unstable on the complete front of the crown, which later leads to several fingers and the detachment of many droplets.

In summary, the Weber number has a big influence on the impact process and changes its outcome fundamentally. Three different morphologies can be distinguished with increasing . The first is a single central finger with the detachment of between one and four secondary droplets. Starting at low , the central finger is comparably thick and only one secondary droplet detaches during the end of the receding phase, which falls down on the film again. The rim at the side of the crown is stable without any cusps or waves on it. With an increase in , the central finger gets longer and thinner. The first secondary droplet detaches earlier, flies upwards and is smaller. Also, a second, a third and a fourth secondary droplet detach from the central finger. With increased , the rim at the side starts to show small waves and cusps. The second morphology is characterized by a partial early rim rupture in the middle with two (up to four) fingers. This is caused by a collision of the middle of the early front crown with the wall film. The fingers are thinner than the single central finger of the first morphology. Also, the trend continues so that the secondary droplets detach earlier and are smaller than at lower . The rim at the side becomes increasingly unstable showing more cusps. A third morphology was observed consisting of a complete early rim rupture with several (>4) fingers. Here, the early rupture is not only limited to the middle of the front crown, and it is caused by an intense collision of the complete front side of the early crown with the wall film.

These different outcomes are summarized in

Table 2 with the

range in which they were observed. The ranges overlap slightly, which is also reported in other studies that separate regimes of droplet impact, e.g., Cossali et al. [

2]. The

numbers separating the regime of the single central finger from the partial early rim rupture and the complete early rim rupture result to

500 and

600, respectively. Deposition, e.g., an impact without the separation of any secondary droplets, was not observed in the investigated

range.

Table 3 shows the splashing characteristics in from the three different morphologies by giving the numbers of fingers and secondary droplets.

In total, 80 experiments were conducted in a range of 249 675 for the 60° impact case with 0.22. At the points of a change in morphology ( 500 ± 20, 600 ± 20), more than ten experiments were conducted.

Table 4 gives examples of three phenomena from the literature for oblique droplet impacts, which are similar to the morphologies observed in this study. The impact conditions are listed in the table. Okawa at al. described the formation of a prow-like structure and the detachment of secondary droplets from it. This splashing mechanism is similar to the single central finger observed in this study. The Weber number was the same as in this study and the impact angle was smaller. The most significant difference is the

3.8, which can be already described as a deep pool impact. At larger

and larger impact angles, Okawa et al. [

12] observed an early detachment of many tiny droplets, called prompt splash. Gielen et al. [

14] investigated the impact on deep pools (

) and determined the Weber number at which splashing starts to occur at the front side in the 60° to

370.

3.4. Comparison of the Oblique Impact with the Normal Impact

Comparing the oblique impact with 60° to the normal impact, the following differences in morphology become evident. The most obvious difference is that the oblique impact has only one symmetry plane and the crown is asymmetric from the side view perspective, while the normal impact is axisymmetric. Consequently, the occurrence of different phenomena, e.g., a single central finger on the front and cusps at the side, are unique features of the oblique impact. Also, a collision of the early crown with the wall film can only be observed during an oblique impact. Furthermore, the crown recedes first at the back and last at the front, whereas the crown collapses at once in the 90° case. This explains why a Worthington jet can only occur in the normal droplet impact. Another difference is that at the oblique impact splashing can be observed already at 249, while splashing from a Worthington jet and crown splash only happens at 400 and 600, respectively, in the conducted normal impact experiments. In addition to that, the trajectory of the secondary droplets follows all radial directions, while for the oblique impact, the trajectories are only directed in the direction of impact.

In addition to these differences, there are also various observations, which are similar. The progression of phenomena with increasing Weber number is the same. First, only waves and cusps form, and then fingers and the detachment of secondary droplets, which fall down on the film again. This starts to occur in the late receding phase first and shifts to earlier times if is increases further, which then leads to a ejection of secondary droplets, that fly upwards. The only difference is that this process happens for the whole crown at once for the normal impact, whereas at the oblique impact, it progresses individually for the different parts of the crown, e.g., first at the front and then for the rim at the sides. Another similarity is that the diameter of the fingers and secondary droplet decreases with an increase in .

The practical implication of the splashing characteristic of the oblique droplet impact is a significant lower splashing threshold. In other words, secondary droplets are ejected during an oblique impact at conditions where no secondary droplets are generated at a normal impact. Furthermore, the secondary droplets do not fly in all radial directions as observed in the normal impact but are ejected only in the tangential direction of the impact. These differences can be crucial for spray impact applications.