Physical Model of a Single Bubble Growth during Nucleate Pool Boiling

Abstract

:1. Introduction

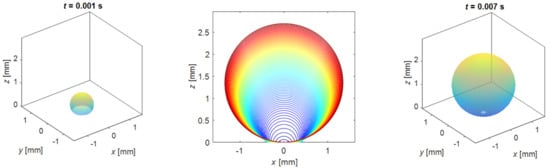

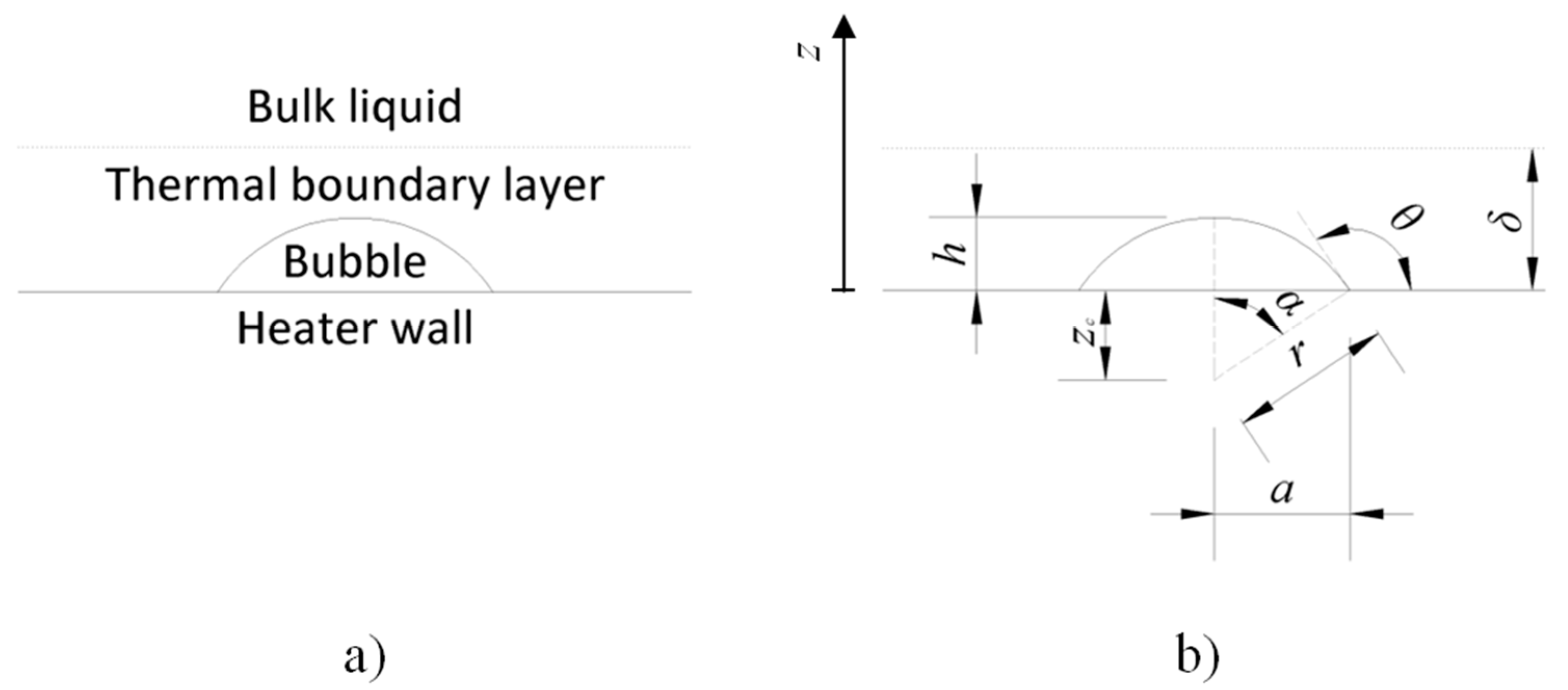

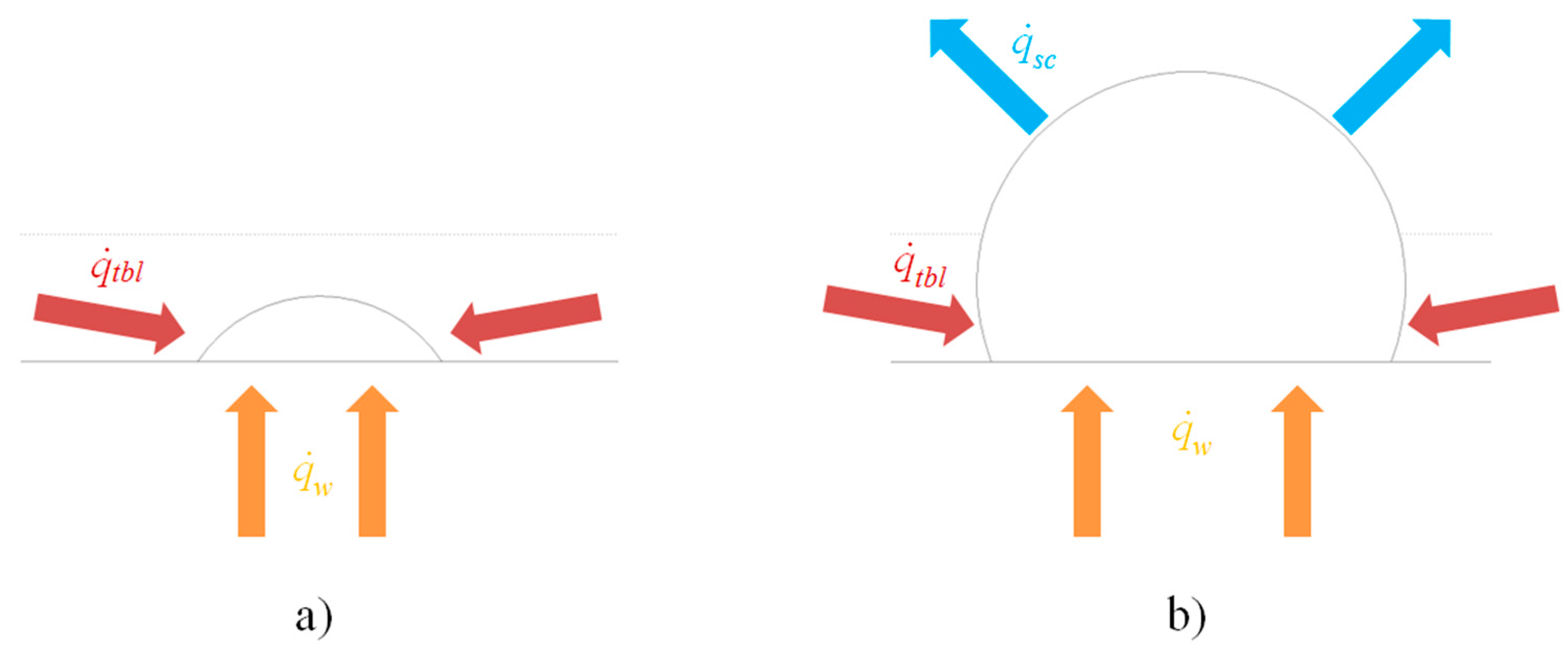

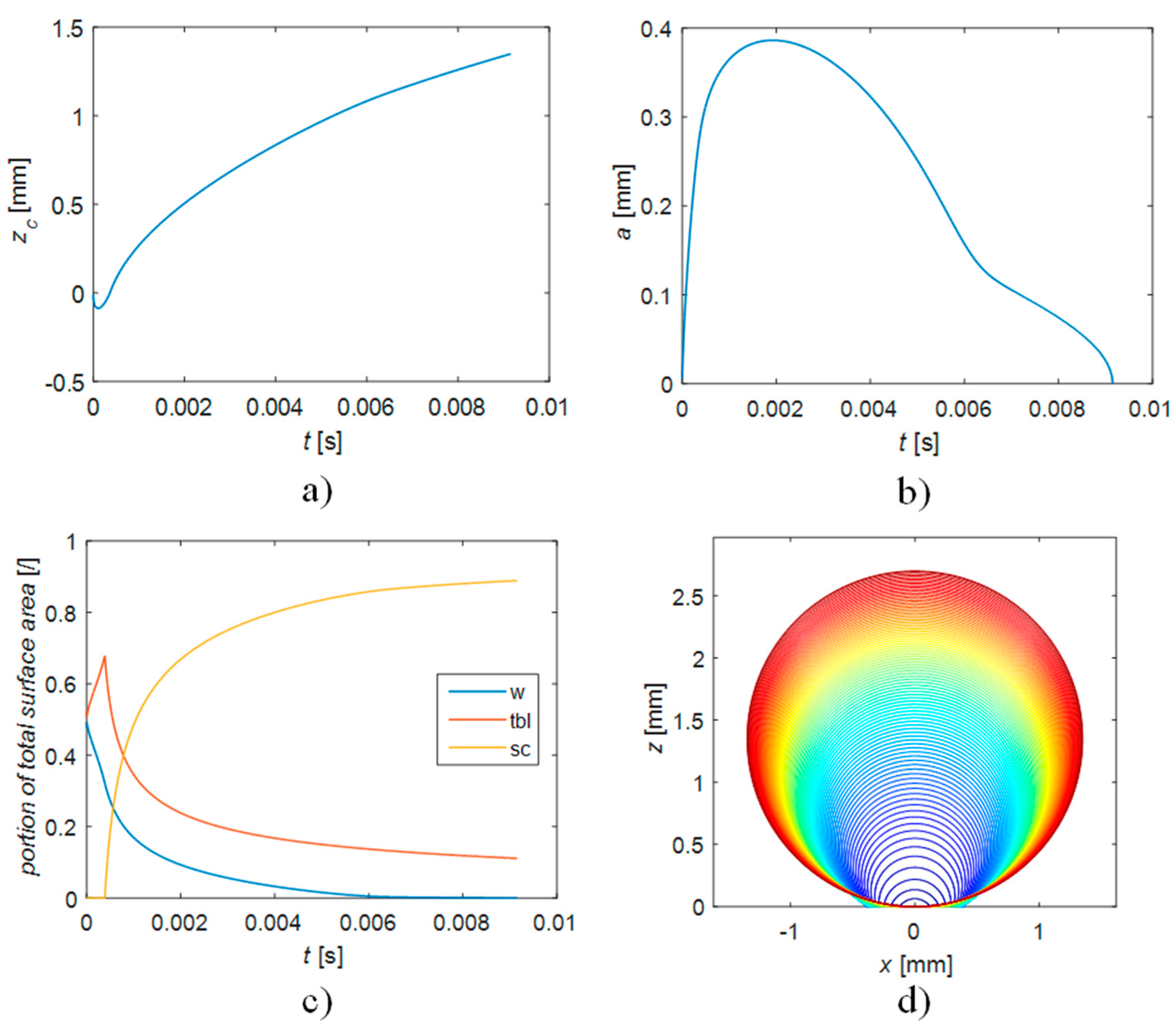

2. Physical Model

2.1. Assumptions of the Model

- The vapor bubble starts to grow from a small initial spherical cap of a vapor attached to the heater surface;

- The surface of the heater is horizontally oriented, and it is flat—ideally smooth;

- The size and geometry of the microlayer are neglected;

- The shape of the bubble is spherical (hemispherical) due to the surface tension of the surrounding liquid;

- The radius of the bubble changes with time following the bubble growth equation (Equation (1));

- The heat transferred to the bubble causes evaporation of the adjacent liquid which is responsible for bubble’s growth;

- The three separated heat fluxes and thickness of the thermal boundary layer do not change with time.

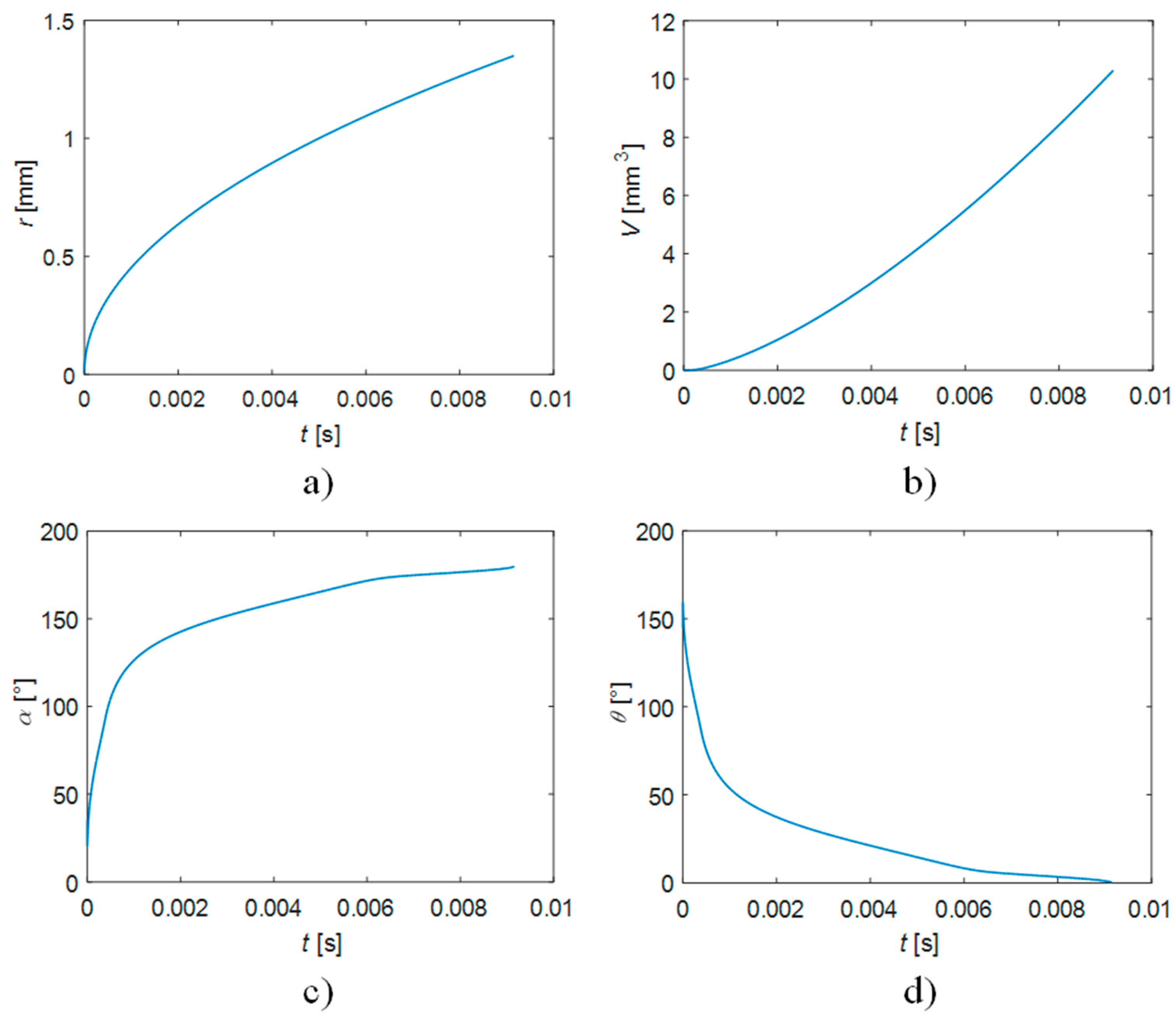

2.2. The Calculation Algorithm

3. Results and Discussion

3.1. Determination of the Heat Flux from the Thermal Boundary Layer to the Bubble

3.2. Influence of the Heater Wall Heat Flux

3.3. Influence of the Heat Flux from the Spherical Cap above the Thermal Boundary Layer

3.4. Influence of the Thermal Boundary Layer Thickness

4. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Conflicts of Interest

References

- Jaikumar, A.; Kandlikar, S.G. Enhanced pool boiling for electronics cooling using porous fin tops on open microchannels with FC-87. Appl. Therm. Eng. 2015, 91, 426–433. [Google Scholar] [CrossRef] [Green Version]

- Ahn, H.S.; Lee, C.; Kim, H.; Jo, H.J.; Kang, S.H.; Kim, J.; Shin, J.; Kim, M.H. Pool boiling CHF enhancement by micro/nanoscale modification of zircaloy-4 surface. Nucl. Eng. Des. 2010, 240, 3350–3360. [Google Scholar] [CrossRef]

- Van Stralen, S.J.D. The mechanism of nucleate boiling in pure liquids and in binary mixtures—Part I. Int. J. Heat Mass Transf. 1966, 9, 995–1020. [Google Scholar] [CrossRef]

- Cooper, M.G.; Lloyd, A.J.P. The microlayer in nucleate pool boiling. Int. J. Heat Mass Transf. 1969, 12, 895–913. [Google Scholar] [CrossRef]

- Thorncroft, G.E.; Klausnera, J.F.; Mei, R. An experimental investigation of bubble growth and detachment in vertical upflow and downflow boiling. Int. J. Heat Mass Transf. 1998, 41, 3857–3871. [Google Scholar] [CrossRef]

- Yoon, H.Y.; Koshizuka, S.; Oka, Y. Direct calculation of bubble growth, departure, and rise in nucleate pool boiling. Int. J. Multiph. Flow 2001, 27, 277–298. [Google Scholar] [CrossRef]

- Gerardi, C.; Buongiorno, J.; Hu, L.; McKrell, T. Study of bubble growth in water pool boiling through synchronized, infrared thermometry and high-speed video. Int. J. Heat Mass Transf. 2010, 53, 4185–4192. [Google Scholar] [CrossRef]

- Mahmoud, M.M.; Karayiannis, T.G. Pool boiling review: Part I–Fundamentals of boiling and relation to surface design. Therm. Sci. Eng. Prog. 2021, 25, 101024. [Google Scholar] [CrossRef]

- Plesset, M.S.; Zwick, S.A. The growth of vapor bubbles in superheated liquids. J. Appl. Phys. 1954, 25, 493–500. [Google Scholar] [CrossRef] [Green Version]

- Niro, A.; Beretta, G.P. Boiling regimes in a closed two-phase thermosyphon. Int. J. Heat Mass Transf. 1990, 33, 2099–2110. [Google Scholar] [CrossRef] [Green Version]

- Kim, J. Review of nucleate pool boiling bubble heat transfer mechanisms. Int. J. Multiph. Flow 2009, 35, 1067–1076. [Google Scholar] [CrossRef]

- Liao, J.; Mei, R.; Klausner, J.F. The influence of the bulk liquid thermal boundary layer on saturated nucleate boiling. Int. J. Heat Fluid Flow 2004, 25, 196–208. [Google Scholar] [CrossRef]

- De, P.L.; Judd, R.L. Bubble nucleation in saturated and subcooled boiling. Can. J. Chem. Eng. 1973, 51, 767–771. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Bai, L.; Jin, H.; Lin, G.; Yao, G.; Wen, D. A comparative study of pool boiling heat transfer in different porous artery structures. Appl. Therm. Eng. 2022, 202, 117759. [Google Scholar] [CrossRef]

- Huang, G.; Tang, K.; Yu, S.; Tang, Y.; Zhang, S. Enhanced pool boiling heat transfer by metallic nanoporous surfaces under low pressure. Int. J. Heat Mass Transf. 2022, 184, 122382. [Google Scholar] [CrossRef]

- Mehdikhani, A.; Moghadasi, H.; Saffari, H. An experimental investigation of pool boiling augmentation using four-step electrodeposited micro/nanostructured porous surface in distilled water. Int. J. Mech. Sci. 2020, 187, 105924. [Google Scholar] [CrossRef]

- Ranjan, A.; Ahmad, I.; Gouda, R.K.; Pathak, M.; Khan, M.K. Enhancement of critical heat flux (CHF) in pool boiling with anodized copper surfaces. Int. J. Therm. Sci. 2022, 172, 107338. [Google Scholar] [CrossRef]

- Nirgude, V.V.; Sahu, S.K. Heat transfer enhancement in nucleate pool boiling using laser processed surfaces: Effect of laser wavelength and power variation. Thermochim. Acta 2020, 694, 178788. [Google Scholar] [CrossRef]

- Singh, S.K.; Sharma, D. Review of pool and flow boiling heat transfer enhancement through surface modification. Int. J. Heat Mass Transf. 2021, 181, 122020. [Google Scholar] [CrossRef]

- Stephan, P.; Hammer, J. A new model for nucleate boiling heat transfer. Heat Mass Transf. 1994, 30, 119–125. [Google Scholar] [CrossRef]

- Chien, L.H.; Webb, R.L. A nucleate boiling model for structured enhanced surfaces. Int. J. Heat Mass Transf. 1998, 41, 2183–2195. [Google Scholar] [CrossRef]

- Tomar, G.; Biswas, G. Numerical simulation of bubble growth in film boiling using a coupled level-set and volume-of-fluid method. Phys. Fluids 2005, 17, 112103. [Google Scholar] [CrossRef]

- Son, G.; Dhir, V.K. Numerical simulation of nucleate boiling on a horizontal surface at high heat fluxes. Int. J. Heat Mass Transf. 2008, 51, 2566–2582. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, P. Lattice Boltzmann simulation of periodic bubble nucleation, growth and departure from a heated surface in pool boiling. Int. J. Heat Mass Transf. 2013, 64, 122–132. [Google Scholar] [CrossRef]

- Bhati, J.; Paruya, S. Numerical simulation of bubble dynamics in pool boiling at heated surface. Int. J. Heat Mass Transf. 2020, 152, 119465. [Google Scholar] [CrossRef]

- Wang, J.; Diao, M.; Liu, X. Numerical simulation of pool boiling with special heated surfaces. Int. J. Heat Mass Transf. 2019, 130, 460–468. [Google Scholar] [CrossRef]

- Harvey, A.H.; Peskin, A.P.; Klein, S.A. NIST/ASME Steam Properties; National Institute of Standards and Technology: Boulder, CO, USA, 1997. [Google Scholar]

- Hsu, Y.Y. On the Size Range of Active Nucleation Cavities on a Heating Surface. J. Heat Transfer. 1962, 84, 207–213. [Google Scholar] [CrossRef]

- Zuber, N. Hydrodynamic Aspects of Boiling Heat Transfer. No. 4439; United States Atomic Energy Commission, Technical Information Service: Los Angeles, CA, USA, 1959. [Google Scholar]

- Dhir, V.K. Boiling heat transfer. Annu. Rev. Fluid Mech. 1998, 30, 365–401. [Google Scholar] [CrossRef]

- Siedel, S.; Cioulachtjian, S.; Bonjour, J. Experimental analysis of bubble growth, departure and interactions during pool boiling on artificial nucleation sites. Exp. Therm. Fluid Sci. 2008, 32, 1504–1511. [Google Scholar] [CrossRef] [Green Version]

- Kowalewski, T.A.J.J.P.; Trzcinski, R.; Zachara, A. Experimental analysis of vapour bubble growing on a heated surface. Arch. Thermodyn. 2004, 25, 1–12. [Google Scholar]

| [kW/m2] | tg [ms] | rd [mm] |

|---|---|---|

| 885 | >25.0 | >2.224 |

| 890 | 9.2 | 1.349 |

| 895 | 4.2 | 0.921 |

| 900 | 3.4 | 0.827 |

| 905 | 2.9 | 0.764 |

| 910 | 2.5 | 0.717 |

| 950 | 1.4 | 0.532 |

| 1000 | 0.9 | 0.437 |

| [kW/m2] | tg [ms] | rd [mm] |

|---|---|---|

| 0 | >25.0 | >2.224 |

| 5 | 20.2 | 2.002 |

| 10 | 15.5 | 1.755 |

| 25 | 9.8 | 1.399 |

| 50 | 9.2 | 1.349 |

| 150 | 9.1 | 1.347 |

| 250 | 9.1 | 1.343 |

| 500 | 8.9 | 1.334 |

| 890 | 7.9 | 1.258 |

| [kW/m2] | tg [ms] | rd [mm] |

|---|---|---|

| 0 | 5.9 | 1.089 |

| −0.1 | 7.1 | 1.188 |

| −0.2 | 9.2 | 1.349 |

| −0.3 | 17.2 | 1.847 |

| −0.4 | >25.0 | >2.224 |

| δ [mm] | tg [ms] | rd [mm] |

|---|---|---|

| 0.29 | >25.0 | >2.224 |

| 0.30 | 9.2 | 1.349 |

| 0.31 | 2.2 | 0.664 |

| 0.32 | 1.5 | 0.560 |

| 0.33 | 1.3 | 0.505 |

| 0.34 | 1.1 | 0.471 |

| 0.35 | 1.0 | 0.448 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voglar, J. Physical Model of a Single Bubble Growth during Nucleate Pool Boiling. Fluids 2022, 7, 90. https://doi.org/10.3390/fluids7030090

Voglar J. Physical Model of a Single Bubble Growth during Nucleate Pool Boiling. Fluids. 2022; 7(3):90. https://doi.org/10.3390/fluids7030090

Chicago/Turabian StyleVoglar, Jure. 2022. "Physical Model of a Single Bubble Growth during Nucleate Pool Boiling" Fluids 7, no. 3: 90. https://doi.org/10.3390/fluids7030090

APA StyleVoglar, J. (2022). Physical Model of a Single Bubble Growth during Nucleate Pool Boiling. Fluids, 7(3), 90. https://doi.org/10.3390/fluids7030090