Rheological Properties and Flow Behaviour of Cement-Based Materials Modified by Carbon Nanotubes and Plasticising Admixtures

Abstract

1. Introduction

2. Experimental Study

2.1. Materials

2.2. Testing Methodology

3. Experimental Results

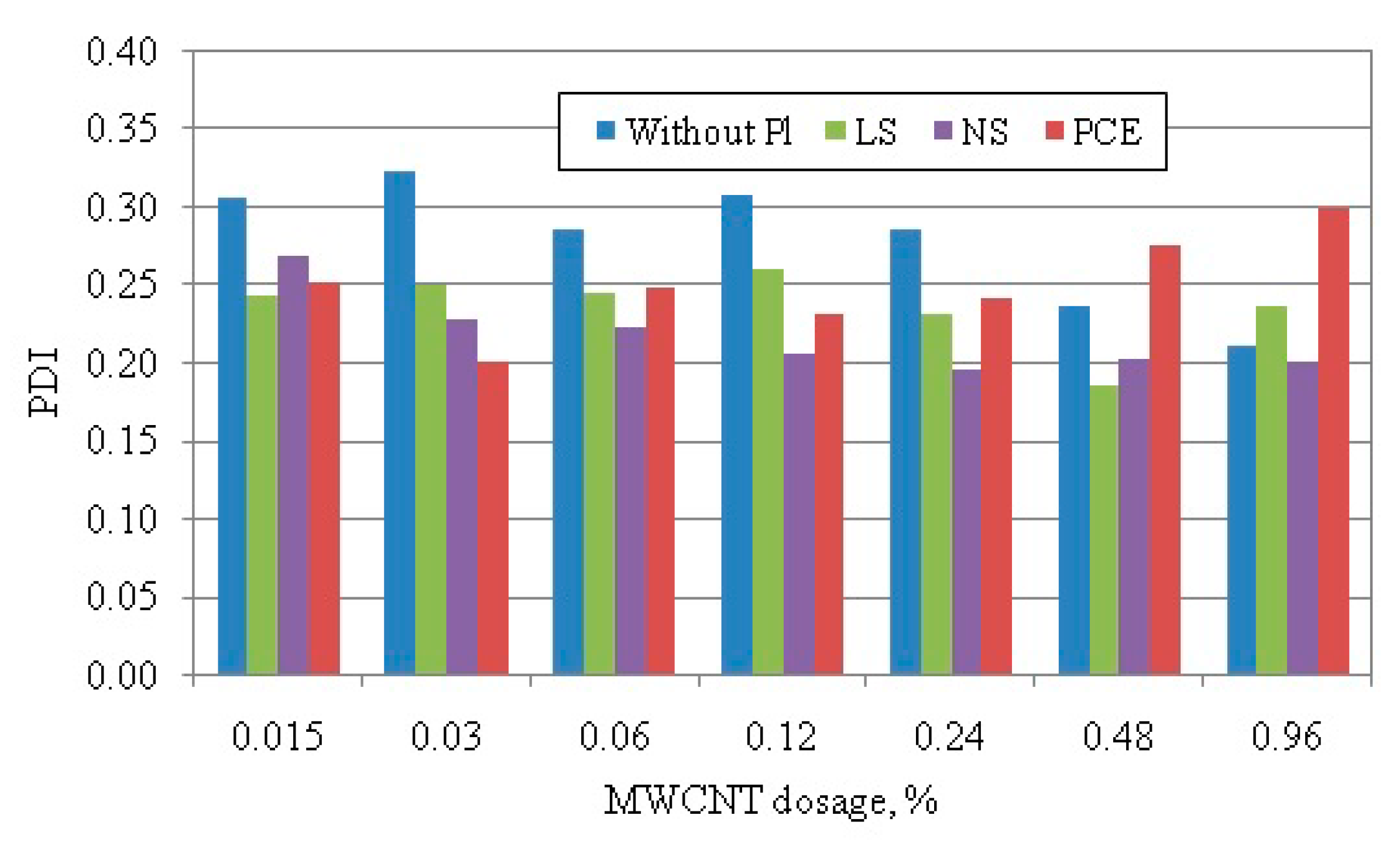

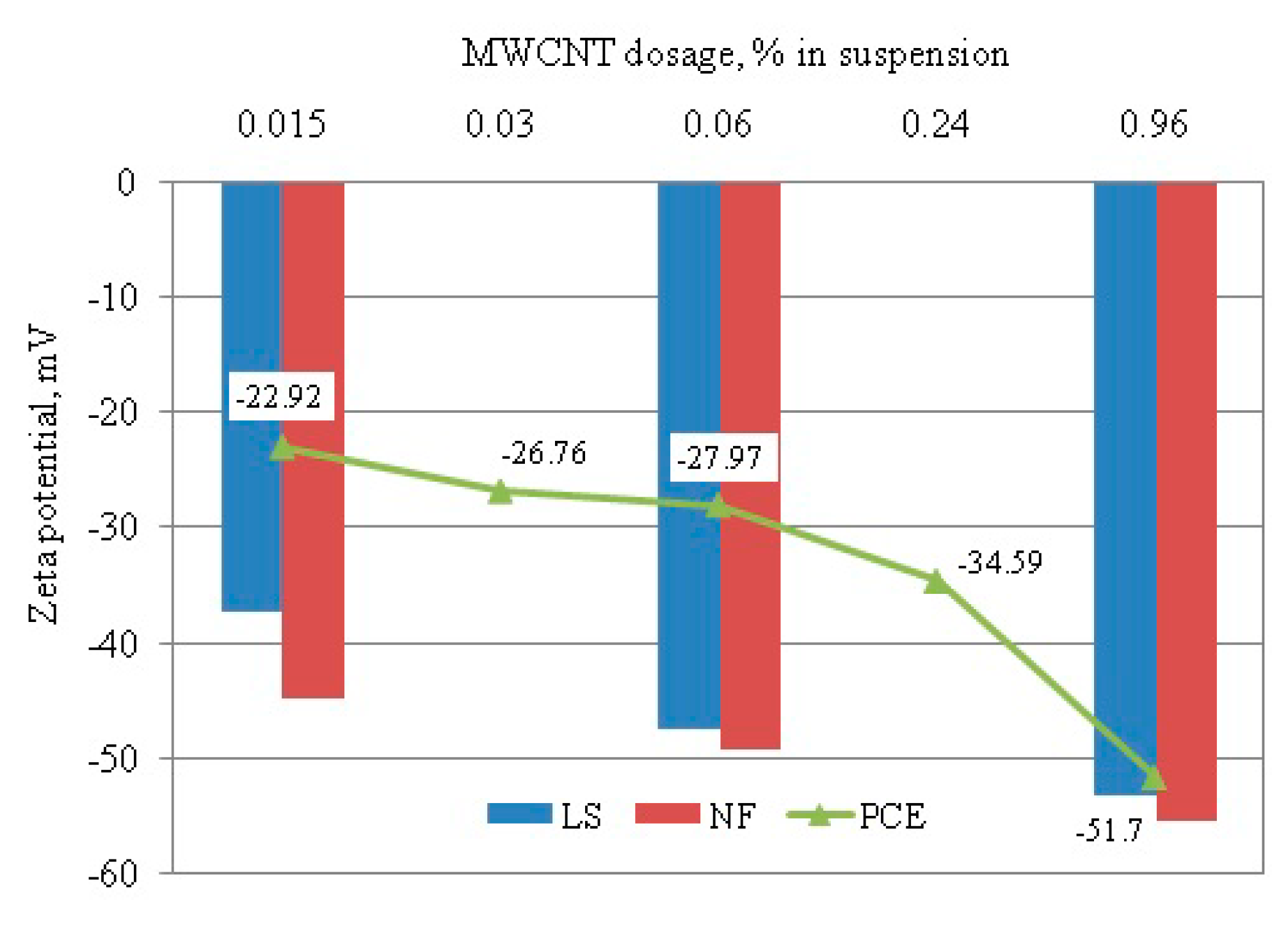

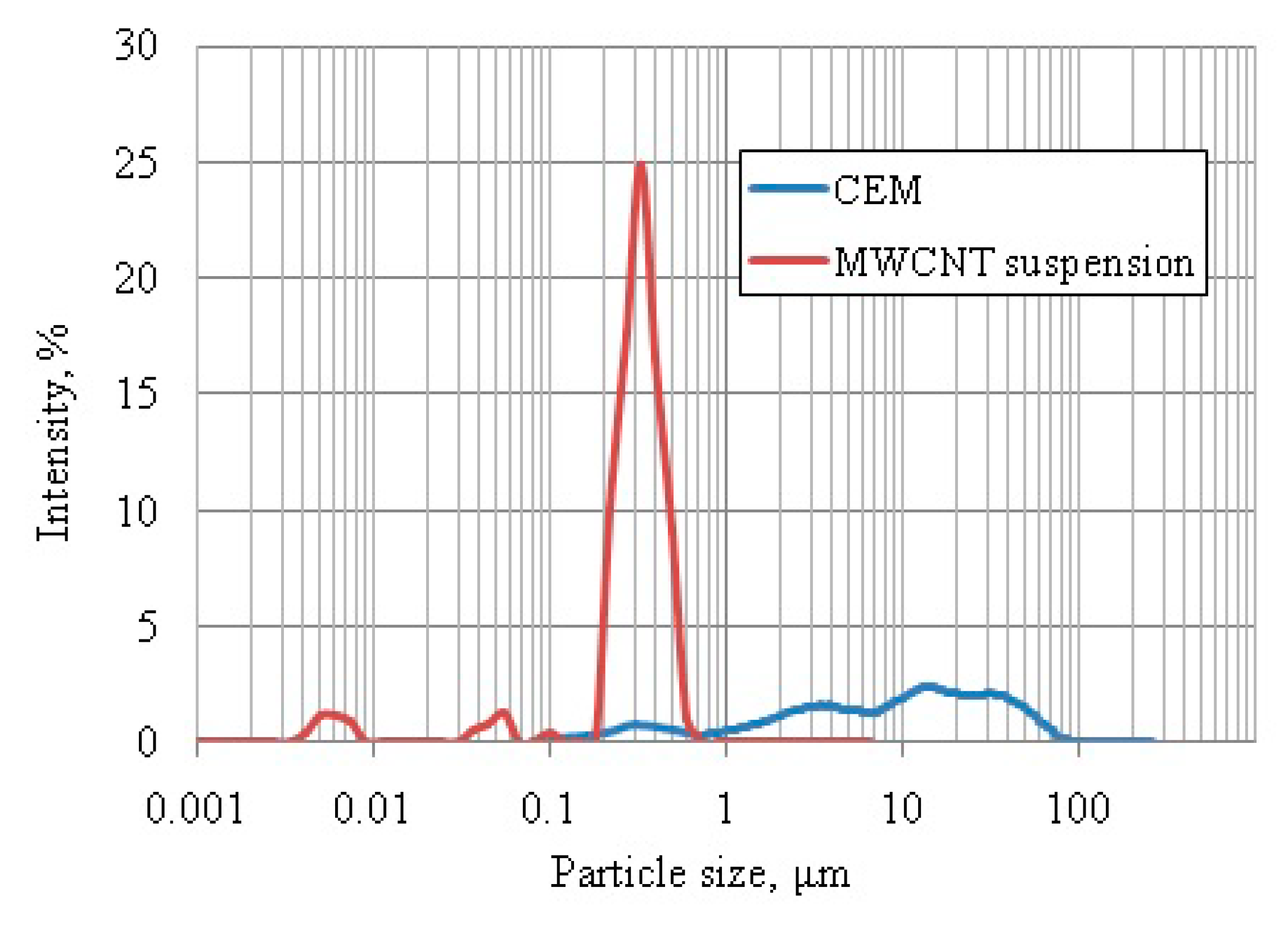

3.1. Characteristics of Suspension Containing Multi-Walled Carbon Nanotubes and Carboxymethyl Cellulose

3.2. MWCNT Influence on the Plasticising Efficiency

3.3. MWCNT Influence on Flow Behaviour of Cement Paste

3.4. MWCNT Influence on the Duration of Plasticising Effect

3.5. MWCNT Influence on Water Bleeding of Cement Paste

4. Discussion

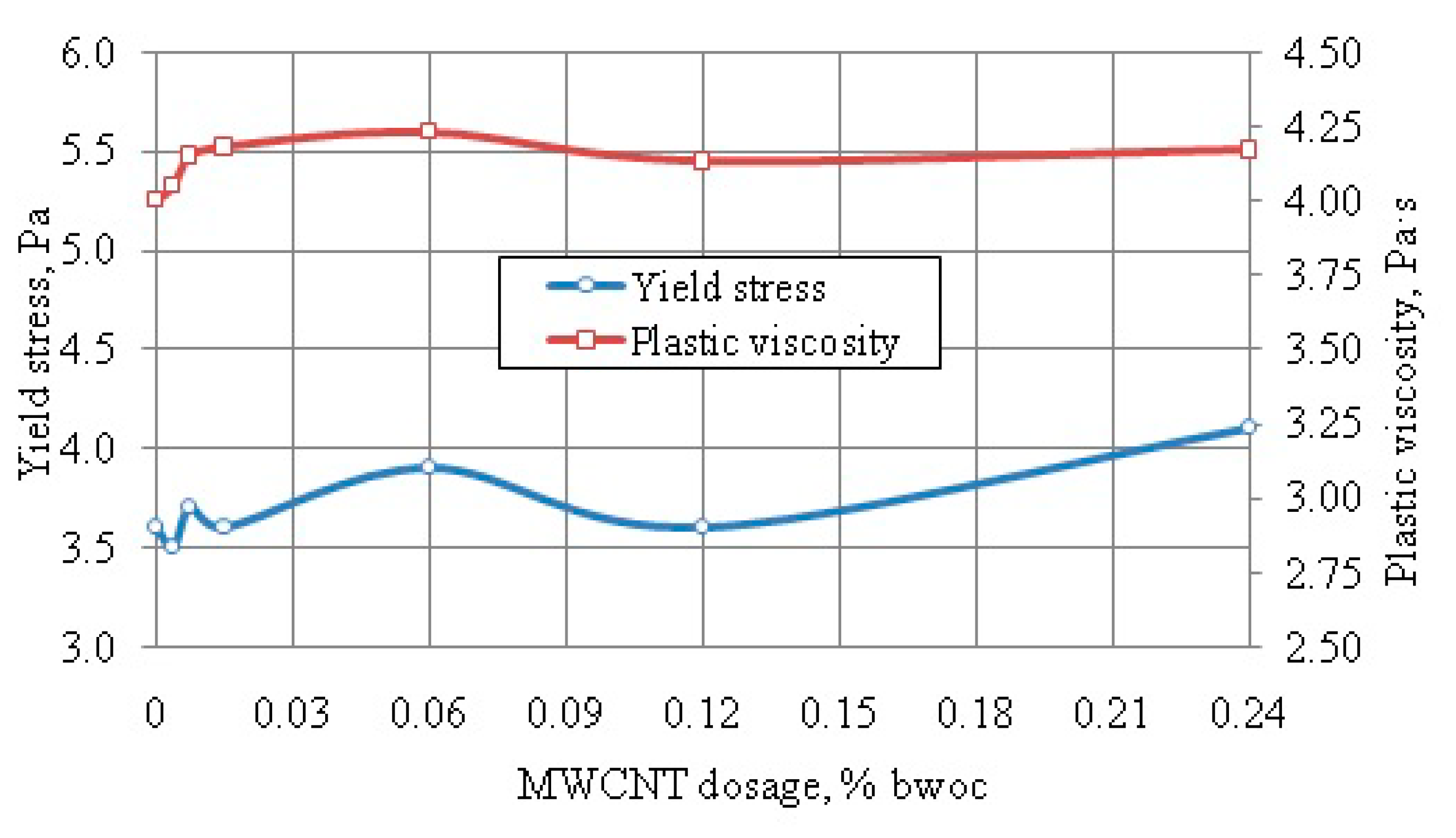

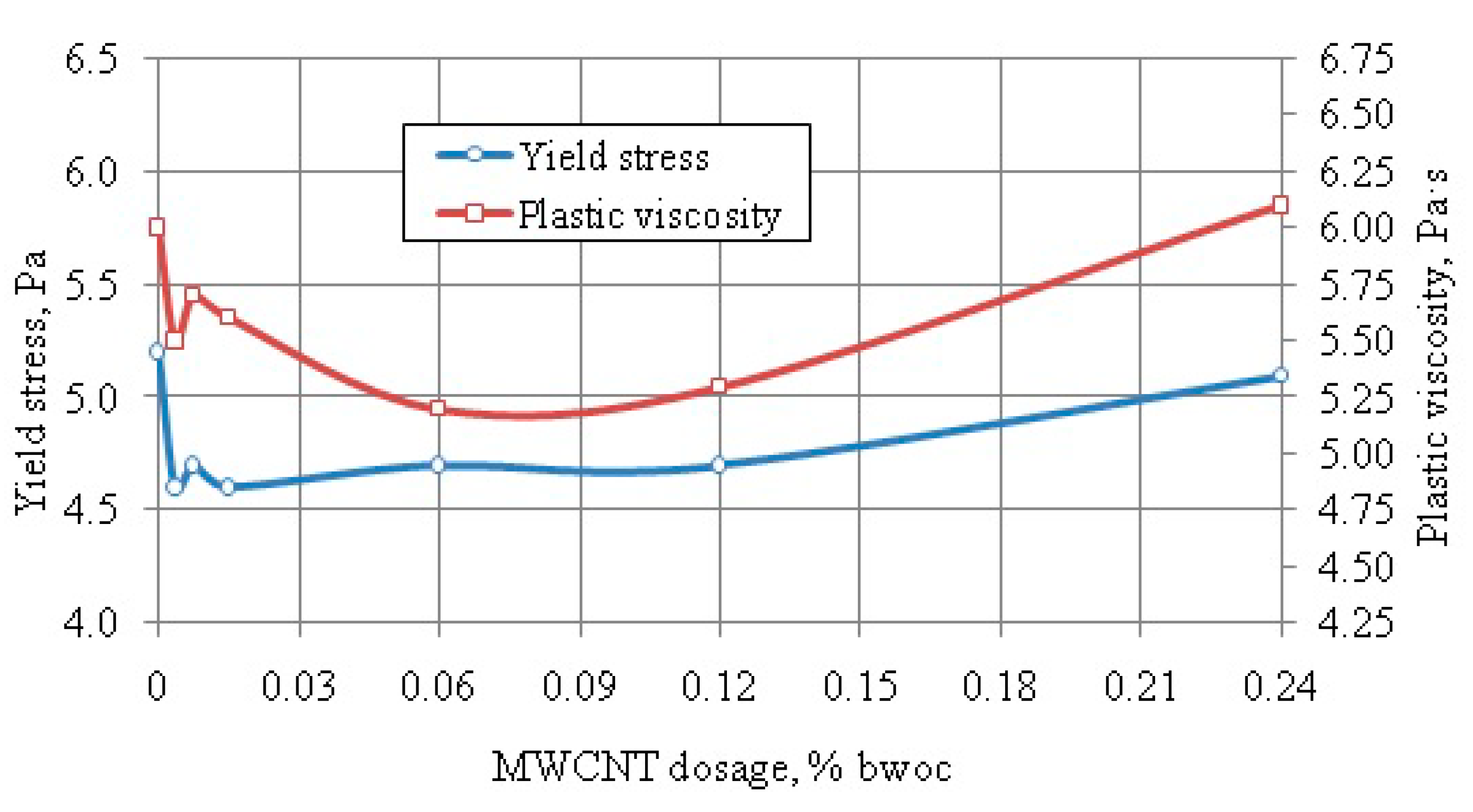

4.1. Rheological Properties of Cement Paste

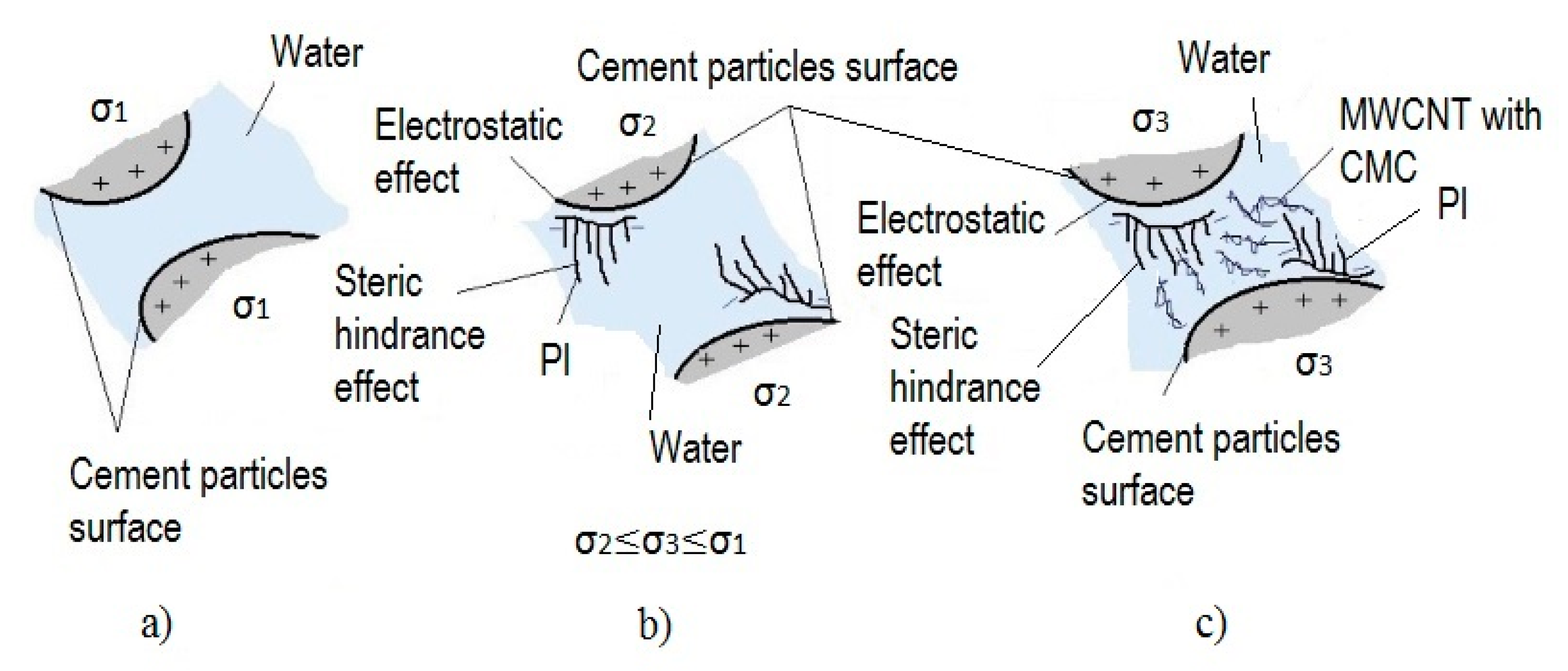

4.1.1. Steric Effect

4.1.2. Surface Area and Particles Distribution Density Effect

4.1.3. Chemical Interaction Effect

4.2. Water Bleeding of Cement Paste

5. Conclusions

- The cement pastes without and with LS and NF plasticising admixtures possess shear thinning flow behaviour (n < 1), with PCE—the shear thickening flow behaviour (n > 1). MWCNT do not have a significant influence on the flow behaviour of cement paste; however, in the case of use of PCE, the shear thickening effect decreased from a MWCNT dosage of 0.03% bwoc. Mainly, the flow behaviour of the cement paste is determined by the type of applied plasticising admixture.

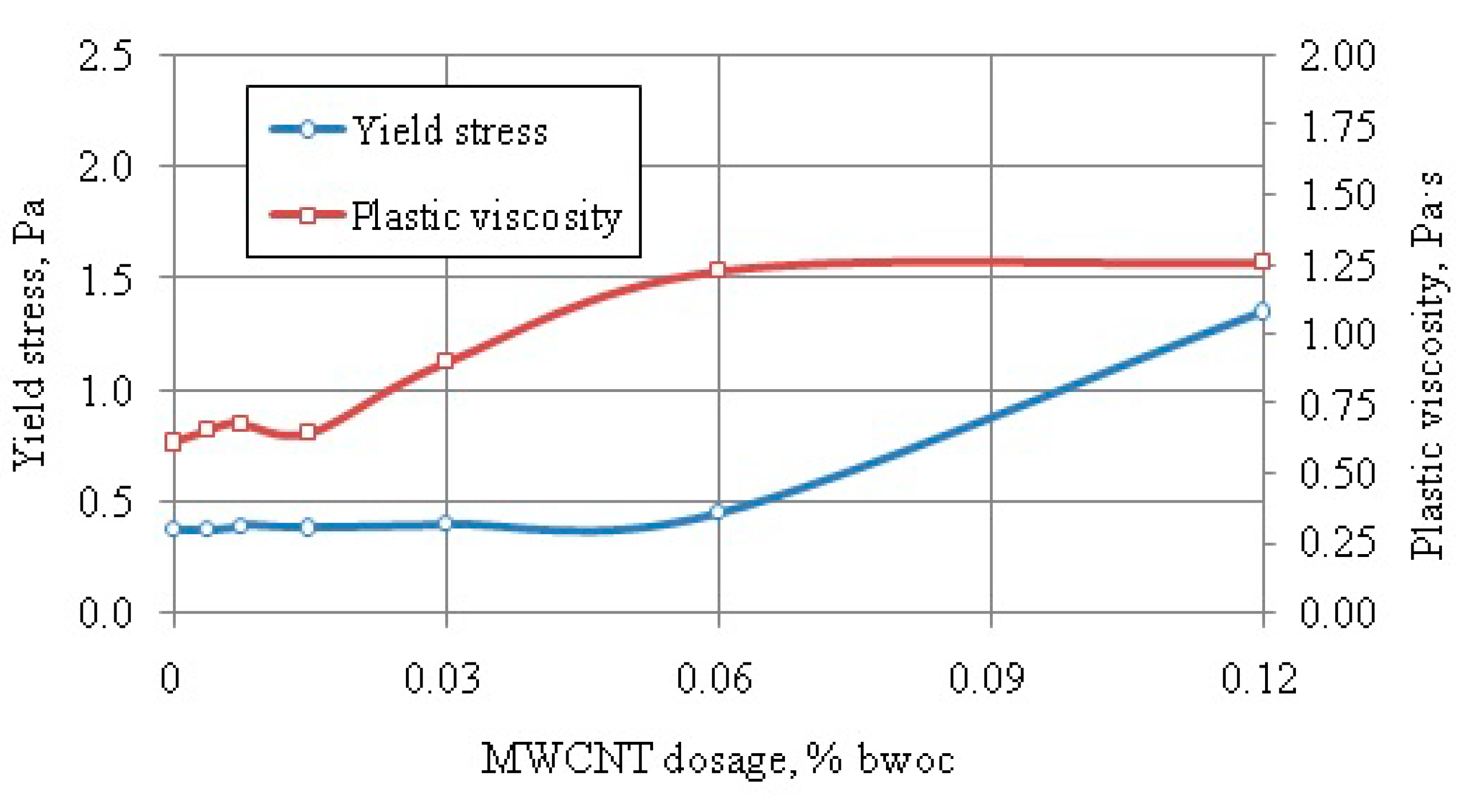

- The MWCNT suspension increases yield stress and plastic viscosity of cement pastes but to different extents depending on the type of plasticising admixture. More remarkable changes in rheological parameters were observed for nanomodified cement paste with PCE due to a combination of physical and chemical interactions in the nanomodified cement systems. The increases in yield stress and plastic viscosity of cement paste by 265% and 107%, respectively, were established with an increase in MWCNT dosage up to 0.12%bwoc.

- The complex modification of cement paste by the MWCNT suspension with LS and NF changes the yield stress and plastic viscosity no more than 10–20%.

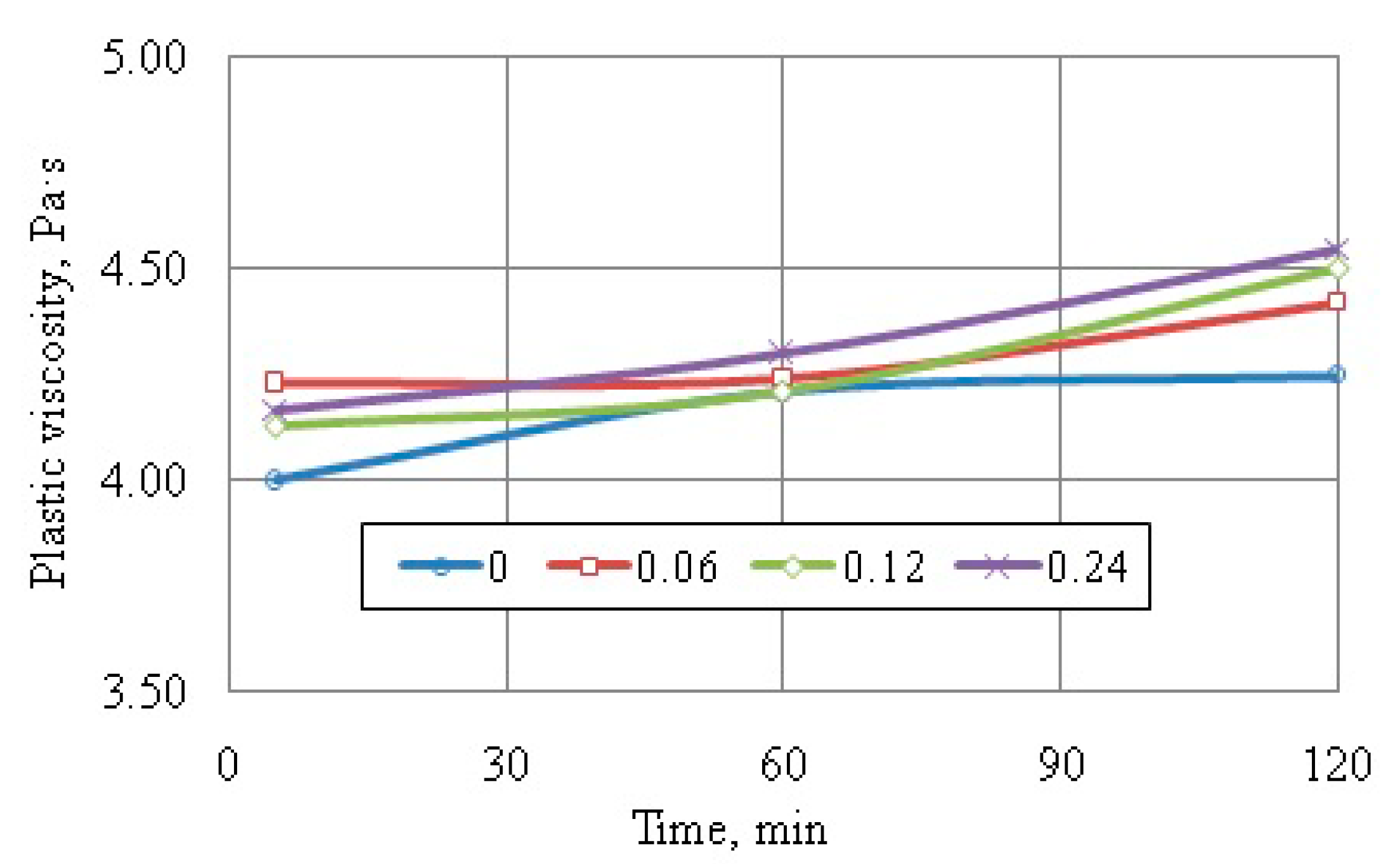

- The addition of MWCNT to the cement pastes enables the maintenance of the plasticising effect of admixtures for more than 2 h. The yield stress and plastic viscosity of nanomodified cement paste without plasticising admixture and with LS and NF slightly increased during the 120 min after cement paste mixing (up to 23%). The addition of MWCNT in the dosage over 0.03% bwoc to the cement pastes with PCE slightly decreased the yield stress and plastic viscosity during the 120 min after cement paste mixing (up to 11%) due to the improvement of the steric effect.

- The shear thinning/thickening indexes of MWCNT-modified cement pastes remained constant for all types of plasticising admixture during the 120 min after cement paste mixing.

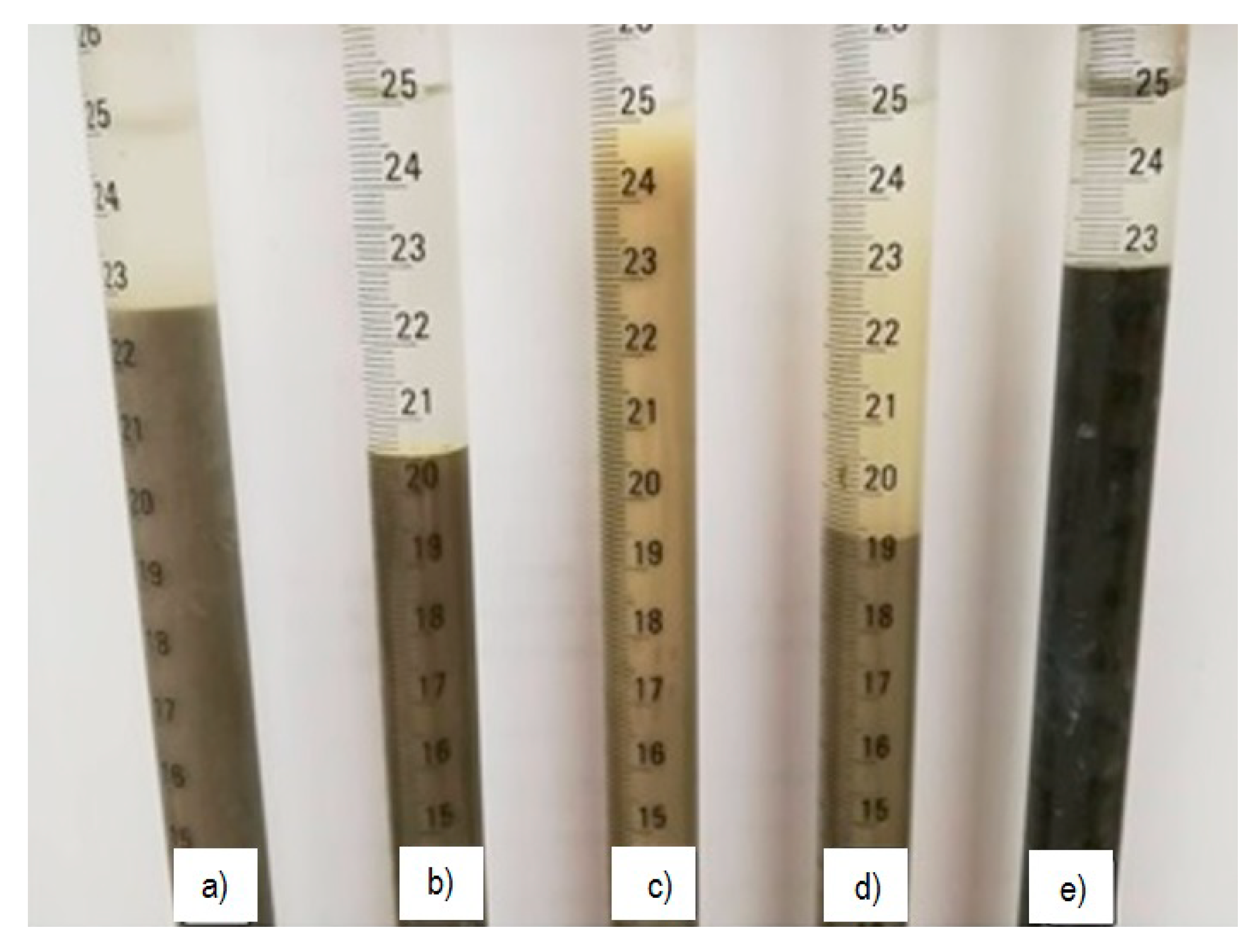

- Modification of cement paste by MWCNT with its high surface area resulted in the reduction in the volume coefficient of water bleeding by 85%, 99%, 100%, and 83%, respectively, for the MWCNT suspension without plasticising admixture and with LS, NF, and PCE with an increase in MWCNT dosage up to 0.24% bwoc.

- The decrease in water bleeding of plasticised cement pastes with an increase in MWCNT dosage can be expressed by exponential dependence.

- The current research proposed the action mechanisms of MWCNT in plasticised cement systems, which consist of changes in the ordinary steric effect of plasticisers, the effect of the high surface area of MWCNT, particles distribution density, and chemical interaction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kostrzanowska-Siedlarz, A.; Golaszewski, J. Rheological properties of high performance self-compacting concrete: Effects of composition and time. Constr. Build. Mater. 2016, 115, 705–715. [Google Scholar] [CrossRef]

- Kim, J.S.; Kwon, S.H.; Jang, K.P.; Choi, M.S. Concrete pumping prediction considering different measurement of the rheological properties. Constr. Build. Mater. 2018, 171, 493–503. [Google Scholar] [CrossRef]

- Feys, D.; Khayat, K.H.; Khatib, R. How do concrete rheology, tribology, flow rate and pipe radius influence pumping pressure? Cem. Concr. Compos. 2016, 66, 38–46. [Google Scholar] [CrossRef]

- Wu, Q.; An, X. Development of a mix design method for SCC based on the rheological characteristics of paste. Constr. Build. Mater. 2014, 53, 642–651. [Google Scholar] [CrossRef]

- Esmaeilkhanian, B.; Khayat, K.H.; Yahia, A.; Feys, D. Effects of mix design parameters and rheological properties on dynamic stability of self-consolidating concrete. Cem. Concr. Compos. 2014, 54, 21–28. [Google Scholar] [CrossRef]

- Wallevik, J.E.; Wallevik, O.H. Concrete mixing truck as a rheometer. Cem. Concr. Res. 2020, 127, 105930. [Google Scholar] [CrossRef]

- Lomboy, G.R.; Wang, X.; Wang, K. Rheological behavior and formwork pressure of SCC, SFSCC, and NC mixtures. Cem. Concr. Compos. 2014, 54, 110–116. [Google Scholar] [CrossRef]

- Mueller, F.V.; Wallevik, O.H.; Khayat, K.H. Linking solid particle packing of eco-SCC to material performance. Cem. Concr. Compos. 2014, 54, 117–125. [Google Scholar] [CrossRef]

- Banfill, P.F.G. The rheology of fresh cement and concrete—A review. In Proceedings of the 11th International Congress on the Chemistry of Cement, Durban, South Africa, 11–16 May 2003; Volume 1, pp. 50–62. [Google Scholar]

- Jiang, S.; Shan, B.; Ouyang, J.; Zhang, W.; Yu, X.; Li, P.; Han, B. Rheological properties of cementitious composites with nano/fiber fillers. Constr. Build. Mater. 2018, 158, 786–800. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Kawashima, S.; Kim, J.H.; Corr, D.J.; Shah, S.P. Study of the mechanisms underlying the fresh-state response of cementitious materials modified with nanoclays. Constr. Build. Mater. 2012, 36, 749–757. [Google Scholar] [CrossRef]

- Li, H.; Ding, S.; Zhang, L.; Ouyang, J.; Han, B. Effect of particle size, crystal phase and surface treatment of nano-TiO2 on the rheological parameters of cement paste. Constr. Build. Mater. 2020, 239, 117897. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Lucas, S.; Ferreira, V.M.; Labrincha, J.A. Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater. Sci. Engin. A 2012, 532, 354–361. [Google Scholar] [CrossRef]

- Reales, O.A.M.; Filho, R.D.T. A review on the chemical, mechanical and microstructural characterization of carbon nanotubes-cement based composites. Constr. Build. Mater. 2017, 154, 697–710. [Google Scholar] [CrossRef]

- Shi, T.; Li, Z.; Gong, H.; Gu, C. Research progress on CNTs/CNFs-modified cement-based composites—A review. Constr. Build. Mater. 2019, 202, 290–307. [Google Scholar] [CrossRef]

- Rashad, A.M. Effect of carbon nanotubes (CNTs) on the properties of traditional cementitious materials. Constr. Build. Mater. 2017, 153, 81–101. [Google Scholar] [CrossRef]

- Cui, X.; Han, B.; Zheng, Q.; Yu, X.; Dong, S.; Zhang, L.; Ou, J. Mechanical properties and reinforcing mechanisms of cementitious composites with different types of multiwalled carbon nanotubes. Compos. Part A 2017, 103, 131–147. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem. Concr. Comp. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Danoglidis, P.A.; Falara, M.G. Fresh and mechanical properties, and strain sensing of nanomodified cement mortars: The effects of MWCNT aspect ratio, density and fictionalization. Cem. Concr. Compos. 2017, 82, 137–151. [Google Scholar] [CrossRef]

- Ma, S.; Qian, Y.; Kawashima, S. Performance-based study on the rheological and hardened properties of blended cement mortars incorporating palygorskite clays and carbon nanotubes. Constr. Build. Mater. 2018, 171, 663–671. [Google Scholar] [CrossRef]

- Souza, T.C.; Pinto, G.; Cruz, V.S.; Moura, M.; Ladeira, L.O.; Calixto, J.M. Evaluation of the rheological behavior, hydration process, and mechanical strength of Portland cement pastes produced with carbon nanotubes synthesized directly on clinker. Constr. Build. Mater. 2020, 248, 118686. [Google Scholar] [CrossRef]

- Paula, J.N.; Calixto, J.M.; Ladeira, L.O.; Ludvig, P.; Souza, T.C.C.; Rocha, J.M.; Melo, A.A.V. Mechanical and rheological behavior of oil-well cement slurries produced with clinker containing carbon nanotubes. J. Petrol. Sci. Eng. 2014, 122, 274–279. [Google Scholar] [CrossRef]

- Reales, O.A.M.; Jaramillo, Y.P.A.; Botero, J.C.O.; Delgado, C.A.; Quintero, J.H.; Filho, R.D.T. Influence of MWCNT/surfactant dispersions on the rheology of Portland cement pastes. Cem. Concr. Res. 2018, 107, 101–109. [Google Scholar] [CrossRef]

- Nadiv, R.; Vasilyev, G.; Shtein, M.; Peled, A.; Zussman, E.; Regev, O. The multiple roles of a dispersant in nanocomposite systems. Compos. Sci. Technol. 2016, 133, 192–199. [Google Scholar] [CrossRef]

- Skripkiunas, G.; Karpova, E.; Barauskas, I.; Bendoraitiene, J.; Yakovlev, G. Rheological Properties of Cement Pastes with Multiwalled Carbon Nanotubes. Adv. Mater. Sci. Eng. 2018, 2018, 8963542. [Google Scholar] [CrossRef]

- Skripkiunas, G.; Karpova, E.; Bendoraitiene, J.; Barauskas, I. Effect of MWCNT and PCE plasticizer on the properties of cement pastes. IOP Conf. Series Mat. Sci. Eng. 2019, 660, 012032. [Google Scholar] [CrossRef]

- Skripkiunas, G.; Karpova, E.; Dauksys, M. Rheological behaviour modelling of cement paste with nanotubes and plasticizer. J. Silic. Based Compos. Mater. 2019, 71, 184–189. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Schmidt, W.; Mota, B.; Leinitz, S.; Kuhne, H.C.; Rogge, A. The effect of superplasticizers on rheology and early hydration kinetics of rice husk ash-blended cementitious systems. Constr. Build. Mater. 2017, 150, 511–519. [Google Scholar] [CrossRef]

- Chandra, S.; Bjornstrom, J. Influence of superplasticizer type and dosage on the slump loss of Portland cement mortars—Part II. Cem. Concr. Res. 2002, 32, 1613–1619. [Google Scholar] [CrossRef]

- Houst, Y.F.; Bowen, P.; Perche, F.; Kauppi, A.; Borget, P.; Galmiche, L.; Meins, J.F.L.; Lafuma, F.; Flatt, R.J.; Schober, I.; et al. Design and function of novel superplasticizers for more durable high performance concrete (superplast project). Cem. Concr. Res. 2008, 38, 1197–1209. [Google Scholar] [CrossRef]

- Lu, Z.; Kong, X.; Zhang, C.; Xing, F.; Zhang, Y. Effect of colloidal polymers with different surface properties on the rheological property of fresh cement pastes. Colloids Surf. A Physicochem. Eng. Asp. 2017, 520, 154–165. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, X.; Kong, X.; Wang, F.; Gao, L. Rheological properties and microstructure of fresh cement pastes with varied dispersion media and superplasticizers. Powder Technol. 2018, 330, 219–227. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, B.; Zhi, Z.; Tan, H.; Liu, M.; Jian, S.; Guo, Y. Effect of polyacrylic acid emulsion on fluidity of cement paste. Colloids Surf. A 2017, 535, 139–148. [Google Scholar] [CrossRef]

- Shrivastava, A.K.; Kumar, M. Compatibility issues of cement with water reducing admixture in concrete. Perspect. Sci. 2016, 8, 290–292. [Google Scholar] [CrossRef]

- Uchikawa, H.; Hanehara, S.; Sawaki, D. The role of steric repulsive force in the dispersion of cement particles in fresh paste prepared with organic admixture. Cem. Concr. Res. 1997, 27, 37–50. [Google Scholar] [CrossRef]

- Kalliola, A.; Vehmas, T.; Liitia, T.; Tamminen, T. Alkali-O2 oxidized lignin—A bio-based concrete plasticizer. Ind. Crop. Prod. 2015, 74, 150–157. [Google Scholar] [CrossRef]

- Huynh, L.; Beattie, D.A.; Fornasiero, D.; Ralston, J. Effect of polyphosphate and naphthalene sulfonate formaldehyde condensate on the rheological properties of dewatered tailings and cemented paste backfill. Miner. Eng. 2006, 19, 28–36. [Google Scholar] [CrossRef]

- Yahia, A.; Tanimure, M. Rheology of belite-cement—Effect of w/c and high-range water-reducer type. Constr. Build. Mater. 2015, 88, 169–174. [Google Scholar] [CrossRef]

- Qian, Y.; Schutter, G.D. Different effects of NSF and PCE superplasticizer on adsorption, dynamic yield stress and thixotropy of cement pastes. Materials 2018, 11, 695. [Google Scholar] [CrossRef]

- Dalas, F.; Pourchet, S.; Nonat, A.; Rinaldi, D.; Sabio, S.; Mosquet, M. Fluidizing efficiency of comb-like superplasticizers: The effect of the anionic function, the side chain length and the grafting degree. Cem. Concr. Res. 2015, 71, 115–123. [Google Scholar] [CrossRef]

- Gupta, C.; Sverdlove, M.J.; Washburn, N.R. Molecular architecture requirements for polymer-grafted lignin superplasticizers. Soft Matter 2015, 11, 2691–2699. [Google Scholar] [CrossRef] [PubMed]

- Areskogh, D.; Li, J.; Gellerstedt, G.; Henriksson, G. Structural modification of commercial lignosulphonates through laccase catalysis and ozonolysis. Industr. Crops. Prod. 2010, 32, 458–466. [Google Scholar] [CrossRef]

- Marchon, D.; Boscaro, F.; Flatt, R.J. First steps to the molecular structure optimization of polycarboxylate ether superplasticizers: Mastering fluidity and retardation. Cem. Concr. Res. 2019, 115, 116–123. [Google Scholar] [CrossRef]

- Qian, S.; Yao, Y.; Wang, Z.; Cui, S.; Liu, X.; Jiang, H.; Guo, Z.; Lai, G.; Xu, Q.; Guan, J. Synthesis, characterization and working mechanism of a novel polycarboxylate superplasticizer for concrete possessing reduced viscosity. Constr. Build. Mater. 2018, 169, 452–461. [Google Scholar] [CrossRef]

- Winnefeld, F.; Becker, S.; Pakusch, J.; Gotz, T. Effects of the molecular architecture of comb-shaped superplasticizers on their performance in cementitious systems. Cem. Concr. Comp. 2007, 29, 251–262. [Google Scholar] [CrossRef]

- Han, J.; Wang, K. Influence of bleeding on properties and microstructure of fresh and hydrated Portland cement paste. Constr. Build. Mater. 2016, 115, 240–246. [Google Scholar] [CrossRef]

- Peng, Y.; Jacobsen, S. Influence of water/cement ratio, admixtures and filler on sedimentation and bleeding of cement paste. Cem. Concr. Res. 2013, 54, 133–142. [Google Scholar] [CrossRef]

- MacLeod, A.J.N.; Fehervari, A.; Gates, W.P.; Garcez, E.O.; Aldridge, L.P. Enhancing fresh properties and strength of concrete with a pre-dispersed carbon nanotube liquid admixture. Constr. Build. Mater. 2020, 247, 118524. [Google Scholar] [CrossRef]

- Gelardi, G.; Mantellato, S.; Marchon, D.; Palacios, M.; Eberhardt, A.B.; Flatt, R.J. Chemistry of chemical admixtures. In Science and Technology of Concrete Admixtures; Aïtcin, P.C., Flatt, R.J., Eds.; Woodhead Publishing: Kidlington, UK, 2015; pp. 149–171. [Google Scholar]

- Skripkiunas, G.; Dauksys, M. Dilatancy of cement slurries with chemical admixtures. J. Civ. Eng. Manag. 2004, 3, 227–233. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Ashour, A.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotubes reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Collepardi, M. Admixtures used to enhance placing characteristics of concrete. Cem. Concr. Compos. 1998, 20, 103–112. [Google Scholar] [CrossRef]

- Yoshioka, K.; Sakai, E.; Daimon, M.; Kitahara, A. Role of steric hindrance in performance of superplasticizers for concrete. J. Am. Ceram. Soc. 1997, 80, 2667–2671. [Google Scholar] [CrossRef]

- Chuang, P.H.; Tseng, Y.H.; Fang, Y.; Gui, M.; Ma, X.; Luo, J. Effect of side chain length on polycarboxylate superplasticizer in aqueous solution: A computational study. Polymers 2019, 11, 346. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, J.; Lv, C.; Cui, X.; Li, S.; Wang, X. Rheological behavior of fresh cement pastes with a graphene oxide additive. New Carbon Mat. 2016, 31, 574–584. [Google Scholar] [CrossRef]

- Nazar, S.; Yang, J.; Thomas, B.S.; Azim, I.; Rehman, S.K.U. Rheological properties of cementitious composites with and without nanomaterials: A comprehensive review. J. Clean. Prod. 2020, 122701. [Google Scholar] [CrossRef]

- Leonavicius, D.; Pundiene, I.; Girskas, G.; Pranckeviciene, J.; Kligis, M.; Kairyte, A. The effect of multi-walled carbon nanotubes on the rheological properties and hydration process of cement pastes. Constr. Build. Mater. 2018, 189, 947–954. [Google Scholar] [CrossRef]

- Mahaut, F.; Mokeddem, S.; Chateau, X.; Roussel, N.; Ovarlez, G. Effect of coarse particle volume fraction on the yield stress and thixotropy of cementitious materials. Cem. Concr. Res. 2008, 38, 1276–1285. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Kang, S.-T.; Seo, J.-Y.; Park, S.-H. The characteristics of CNT/Cement Composites with Acid-Treated MWCNTs. Adv. Mat. Sci. Eng. 2015, 308725. [Google Scholar] [CrossRef]

| Characteristic | Lignosulphonate(LS) | Naphthalene Formaldehyde (NF) | Polycarboxylate Ether (PCE) |

|---|---|---|---|

| Form | liquid | liquid | liquid |

| Colour | dark brown | yellow | yellow |

| Dry content, % | 30–40 | 40–50 | 50 |

| Specific gravity, g/cm3 | 1.14 | 1.20 | 1.10 |

| pH | 4–6 | 7–9.5 | 4 |

| Recommended dosage, % | 0.4–1.2 | 0.5–2.0 | 0.2–2.0 |

| Designation | MWCNT/CMC Suspension without Pl | Designation | MWCNT/CMC Suspension with Pl | Time of Ultrasonication, min | |||

|---|---|---|---|---|---|---|---|

| MWCNT in Volume of Suspension, % | CMC in the Volume of Suspension, % | MWCNT in Volume of Suspension, % | CMC in the Volume of Suspension, % | Pl in Volume of Suspension, % | |||

| S15 | 0.015 | 0.018 | SP15 | 0.015 | 0.018 | 3.8 | 6 |

| S30 | 0.030 | 0.037 | SP30 | 0.030 | 0.037 | ||

| S60 | 0.060 | 0.073 | SP60 | 0.060 | 0.073 | ||

| S120 | 0.120 | 0.146 | SP120 | 0.120 | 0.146 | ||

| S240 | 0.240 | 0.293 | SP240 | 0.240 | 0.293 | ||

| S480 | 0.480 | 0.586 | SP480 | 0.480 | 0.586 | ||

| S960 | 0.960 | 1.171 | SP960 | 0.960 | 1.171 | ||

| Designation | Cement, g | W/C | Water, g | MWCNT/CMC Suspension, g | MWCNT, % bwoc | CMC, % bwoc |

|---|---|---|---|---|---|---|

| C0 | 200 | 0.30 | 60 | 0 | 0 | 0 |

| C4 | 200 | 0.30 | 0 | 60 | 0.00375 | 0.00460 |

| C8 | 200 | 0.30 | 0 | 60 | 0.0075 | 0.0092 |

| C15 | 200 | 0.30 | 0 | 60 | 0.015 | 0.018 |

| C30 | 200 | 0.30 | 0 | 60 | 0.030 | 0.037 |

| C60 | 200 | 0.30 | 0 | 60 | 0.060 | 0.073 |

| C120 | 200 | 0.30 | 0 | 60 | 0.120 | 0.146 |

| C240 | 200 | 0.30 | 0 | 60 | 0.240 | 0.293 |

| Designation | Cement, g | W/C | Water, g | Pl, % bwoc | MWCNT/CMC Suspension with Pl, g | MWCNT, % bwoc | CMC, % bwoc |

|---|---|---|---|---|---|---|---|

| CP0 | 200 | 0.25 | 50 | 1 | 0 | 0 | 0 |

| CP4 | 200 | 0.25 | 0 | 1 | 50 | 0.00375 | 0.00460 |

| CP8 | 200 | 0.25 | 0 | 1 | 50 | 0.0075 | 0.0092 |

| CP15 | 200 | 0.25 | 0 | 1 | 50 | 0.015 | 0.018 |

| CP30 | 200 | 0.25 | 0 | 1 | 50 | 0.030 | 0.037 |

| CP60 | 200 | 0.25 | 0 | 1 | 50 | 0.060 | 0.073 |

| CP120 | 200 | 0.25 | 0 | 1 | 50 | 0.120 | 0.146 |

| CP240 | 200 | 0.25 | 0 | 1 | 50 | 0.240 | 0.293 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skripkiunas, G.; Karpova, E.; Bendoraitiene, J.; Barauskas, I. Rheological Properties and Flow Behaviour of Cement-Based Materials Modified by Carbon Nanotubes and Plasticising Admixtures. Fluids 2020, 5, 169. https://doi.org/10.3390/fluids5040169

Skripkiunas G, Karpova E, Bendoraitiene J, Barauskas I. Rheological Properties and Flow Behaviour of Cement-Based Materials Modified by Carbon Nanotubes and Plasticising Admixtures. Fluids. 2020; 5(4):169. https://doi.org/10.3390/fluids5040169

Chicago/Turabian StyleSkripkiunas, Gintautas, Ekaterina Karpova, Joana Bendoraitiene, and Irmantas Barauskas. 2020. "Rheological Properties and Flow Behaviour of Cement-Based Materials Modified by Carbon Nanotubes and Plasticising Admixtures" Fluids 5, no. 4: 169. https://doi.org/10.3390/fluids5040169

APA StyleSkripkiunas, G., Karpova, E., Bendoraitiene, J., & Barauskas, I. (2020). Rheological Properties and Flow Behaviour of Cement-Based Materials Modified by Carbon Nanotubes and Plasticising Admixtures. Fluids, 5(4), 169. https://doi.org/10.3390/fluids5040169