Experimental Study of a Gas–Liquid Flow in Vacuum Air-Lift Column Using an Optical Bi-Probe

Abstract

1. Introduction

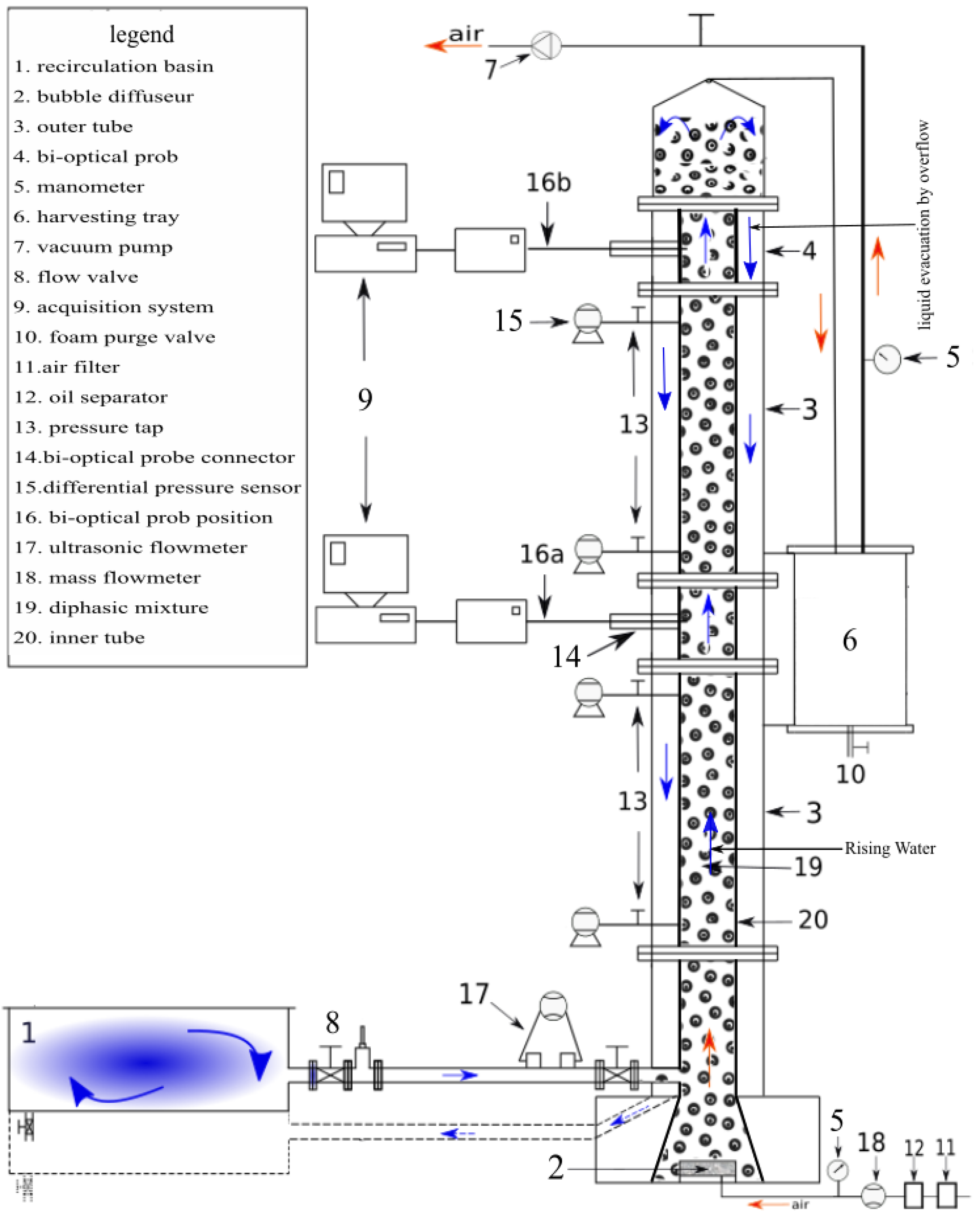

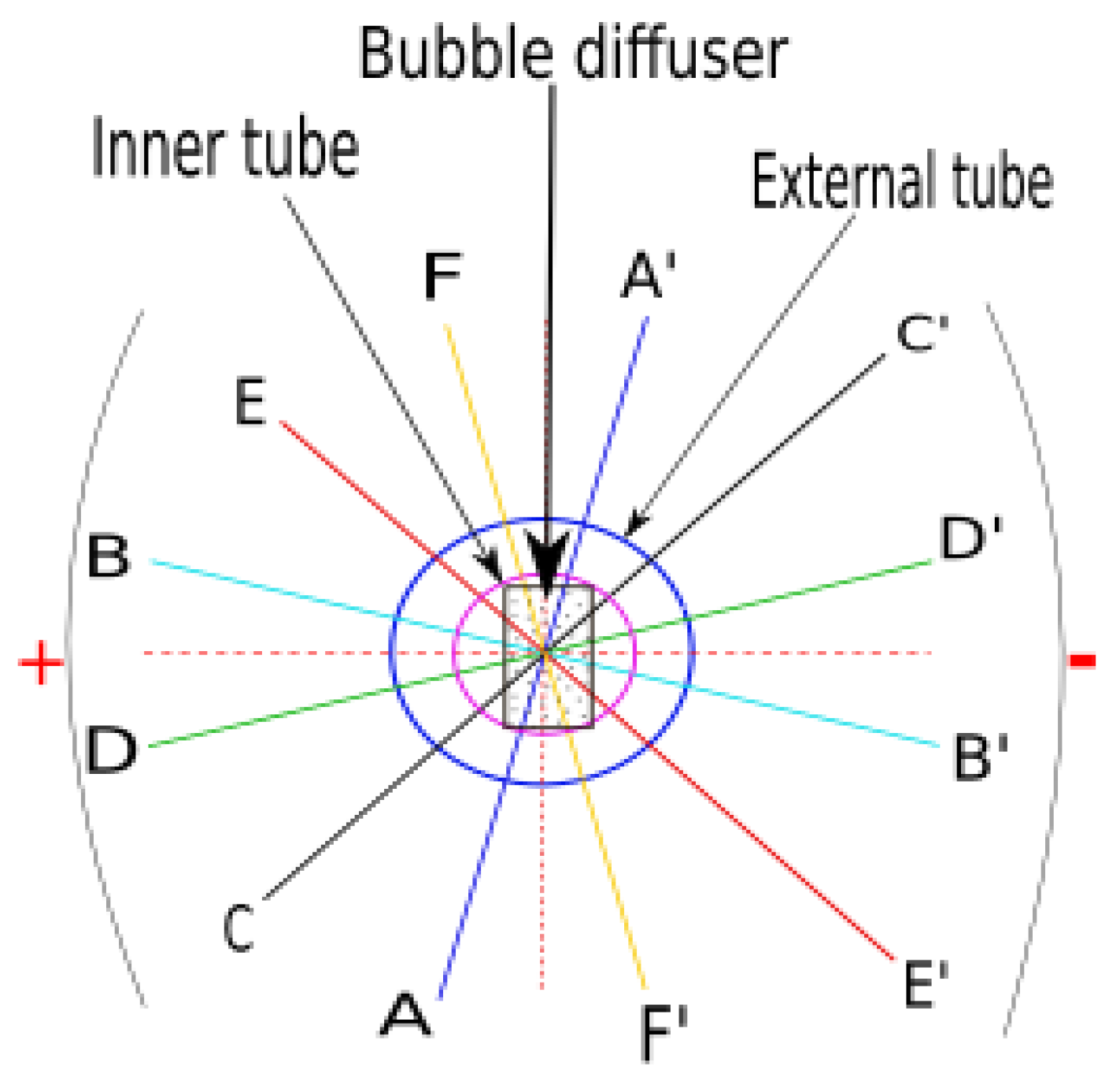

2. Materials and Methods

2.1. Local Gas Holdup

2.2. Bubble Rise Velocity

- v the average bubble rise velocity;

- D the distance between the tips of the bi-probe (2 mm);

- the time shift between the signals of the two optrodes.

2.3. Bubble Size

3. Results and Discussion

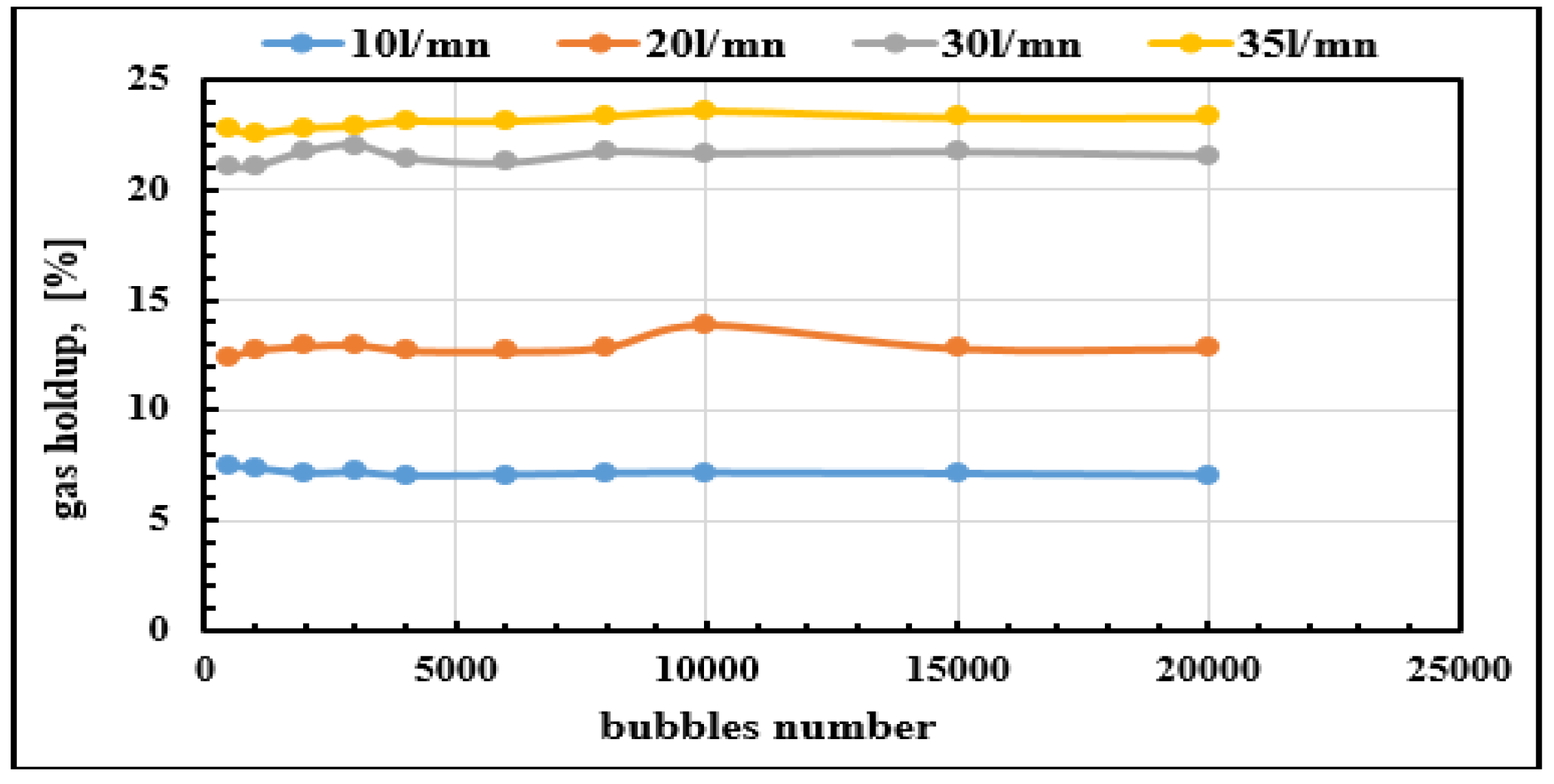

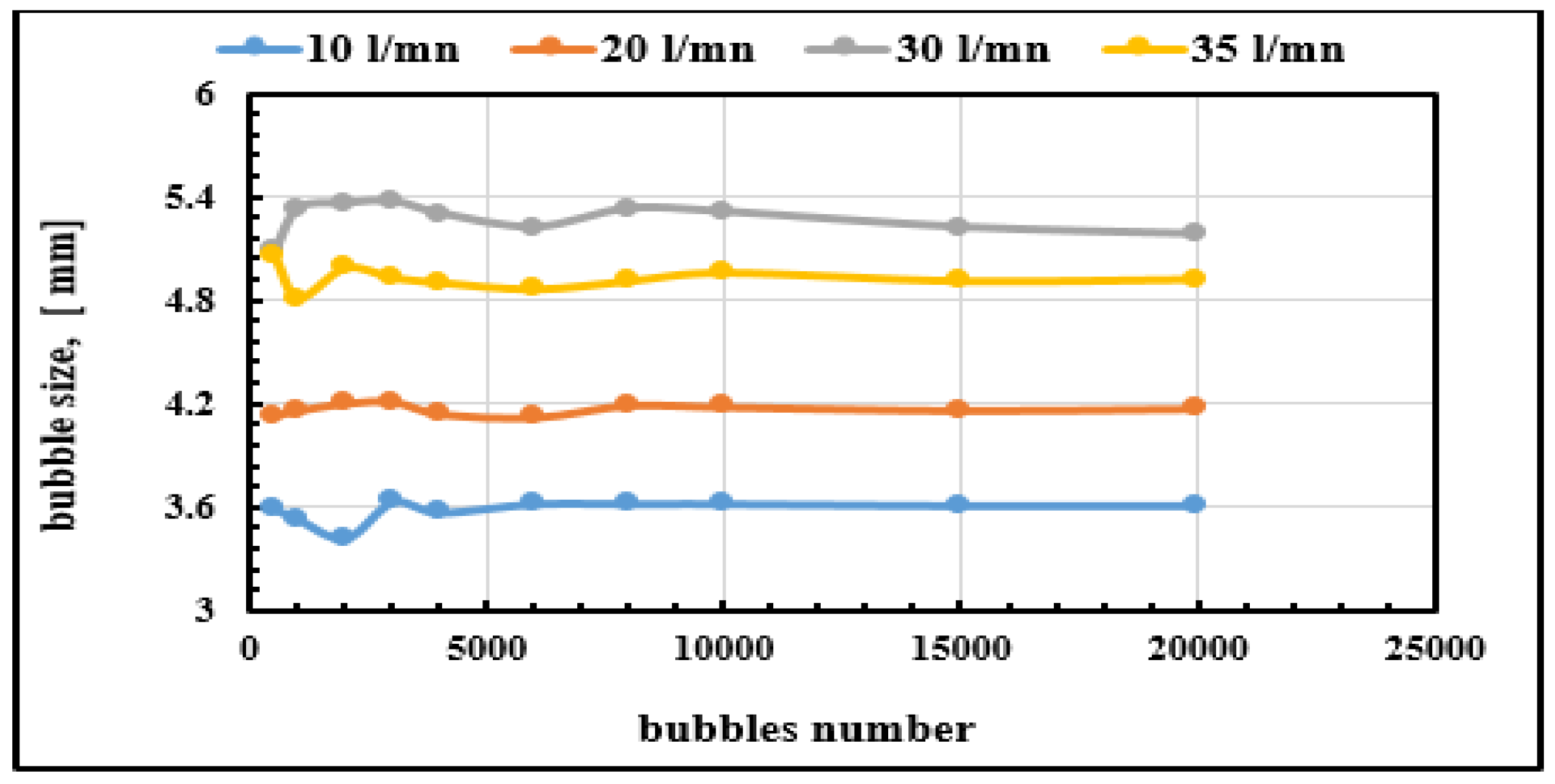

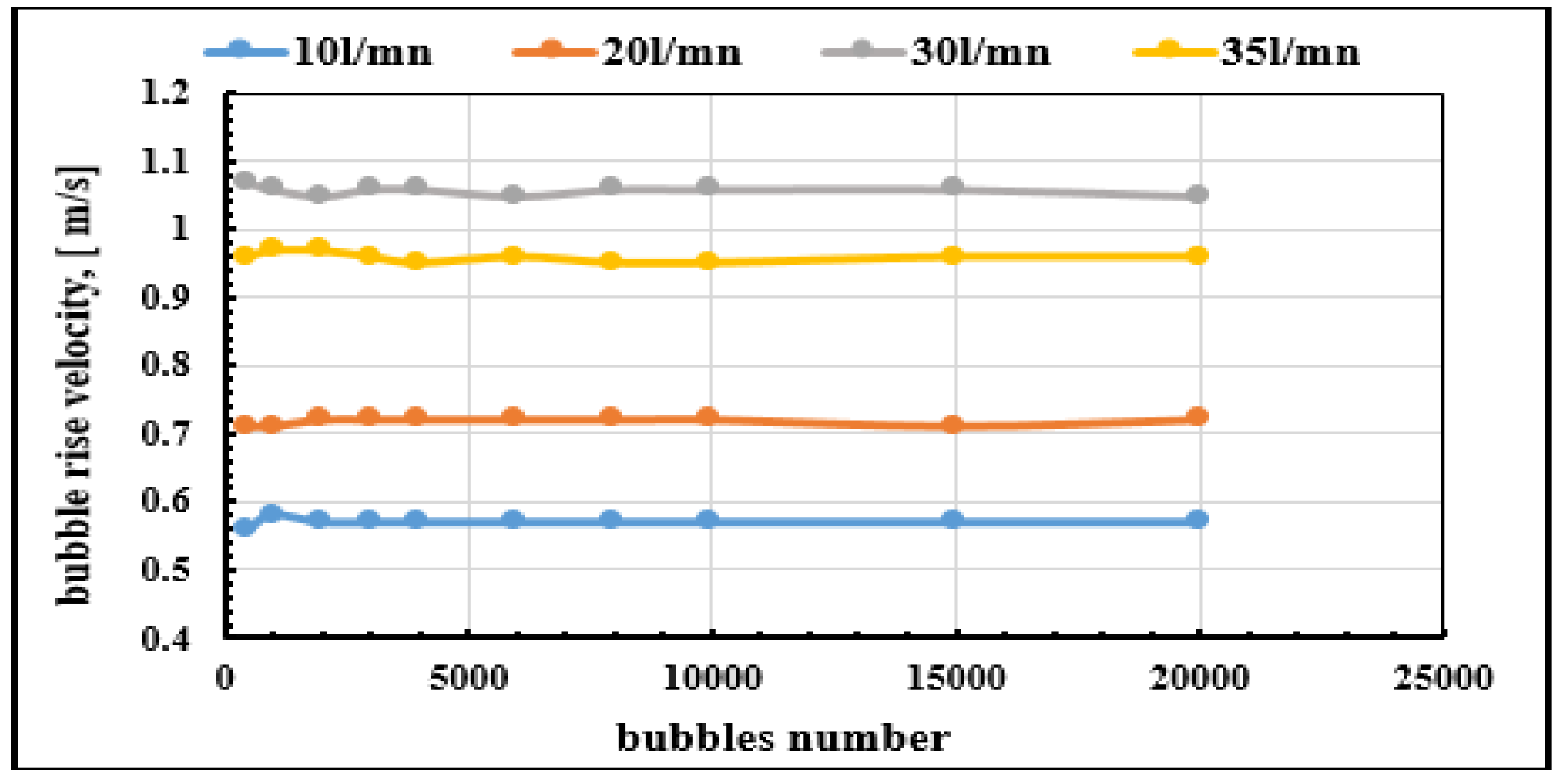

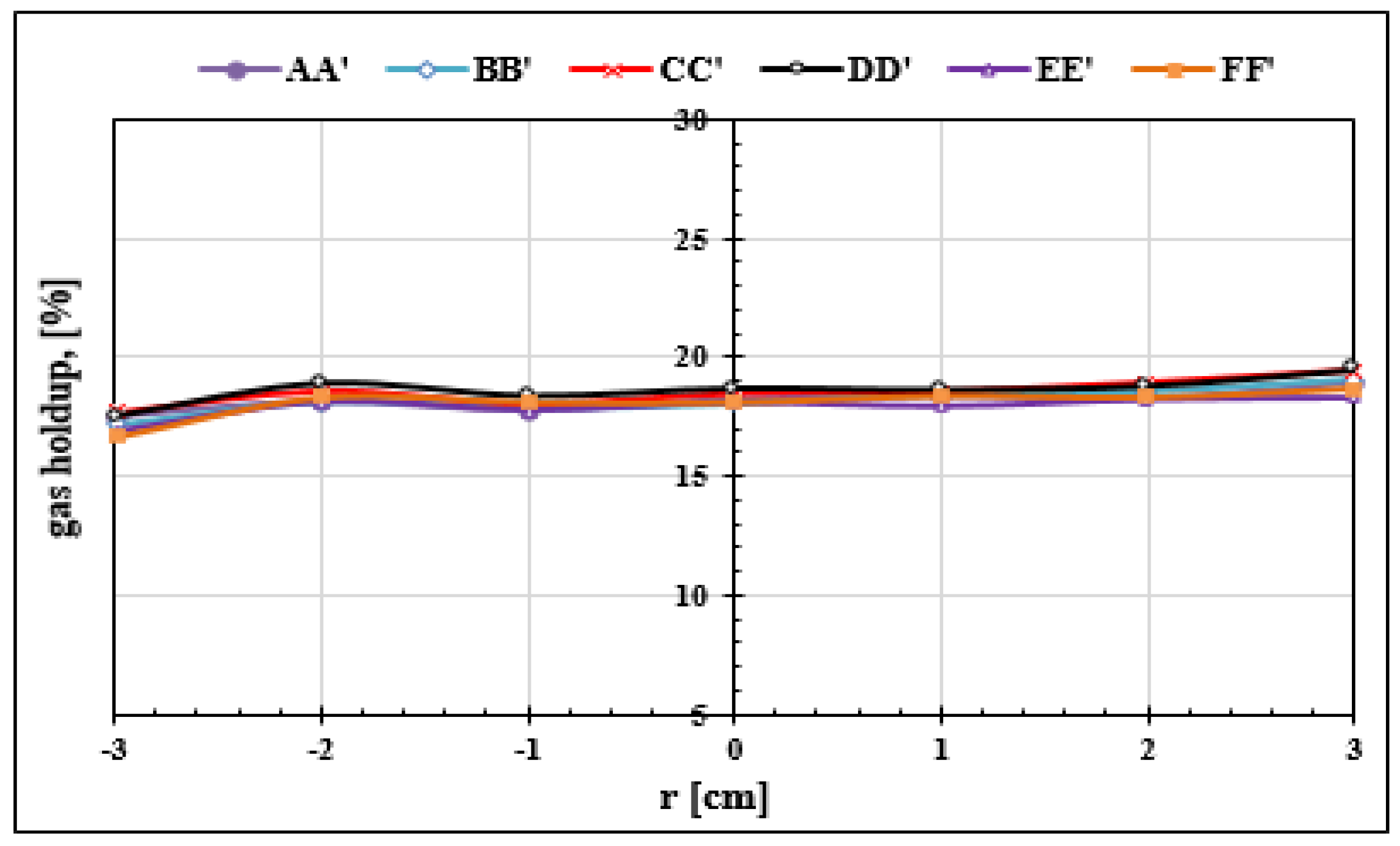

3.1. Convergence of Optical Bi-Probe Measurements

3.2. Hydrodynamics of the Liquid Phase

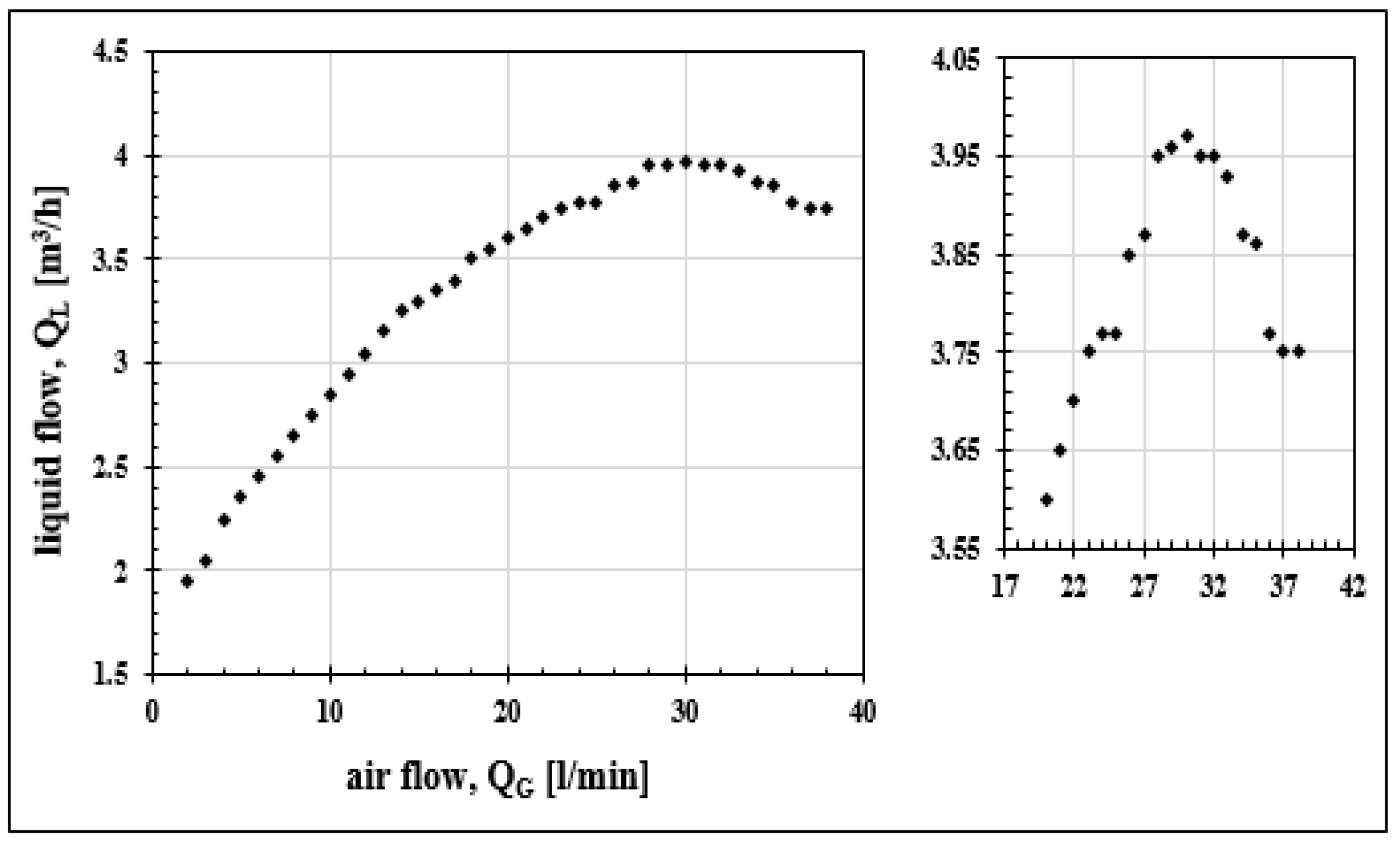

3.2.1. Analysis of the Pumping Function through the Liquid Flow

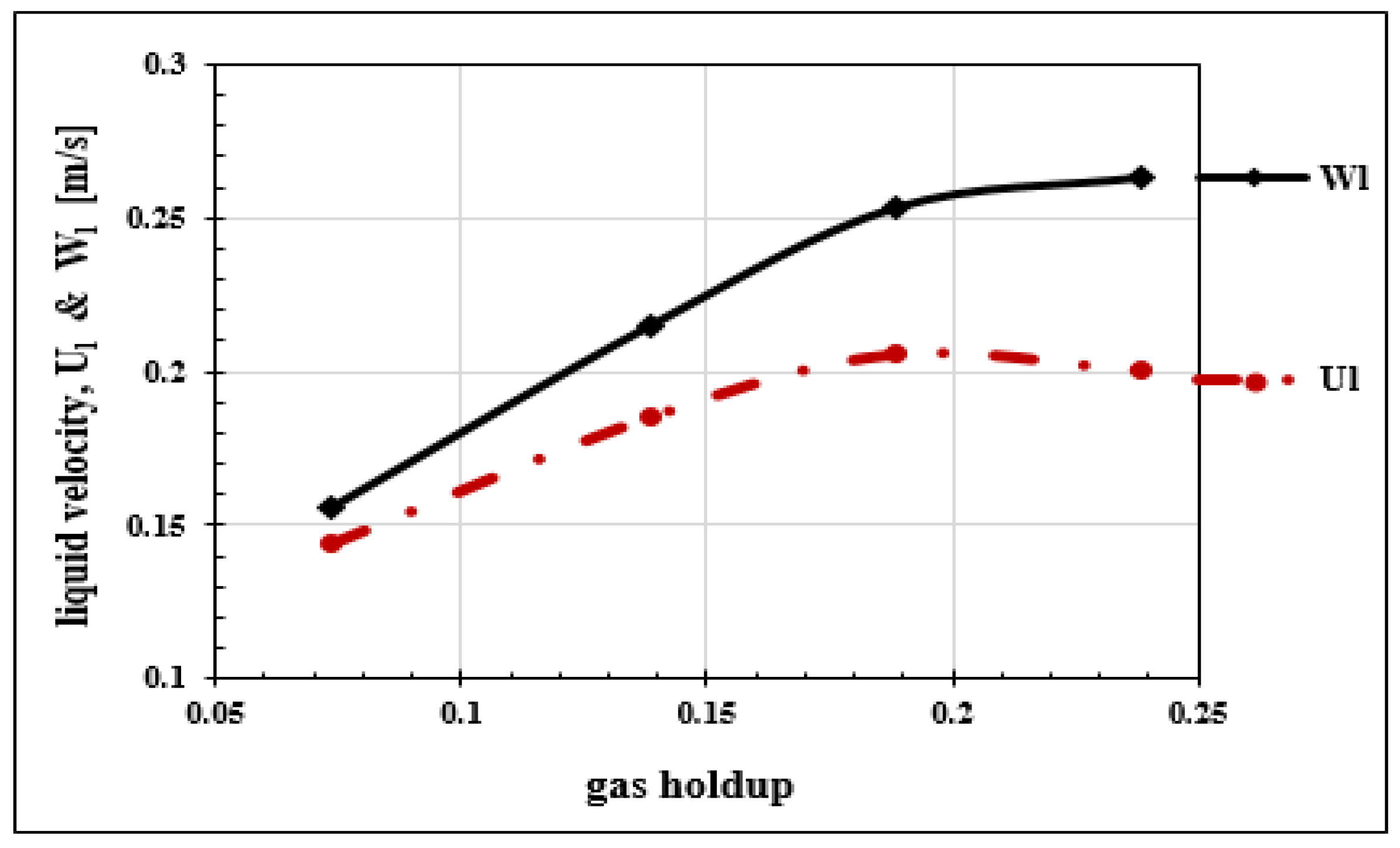

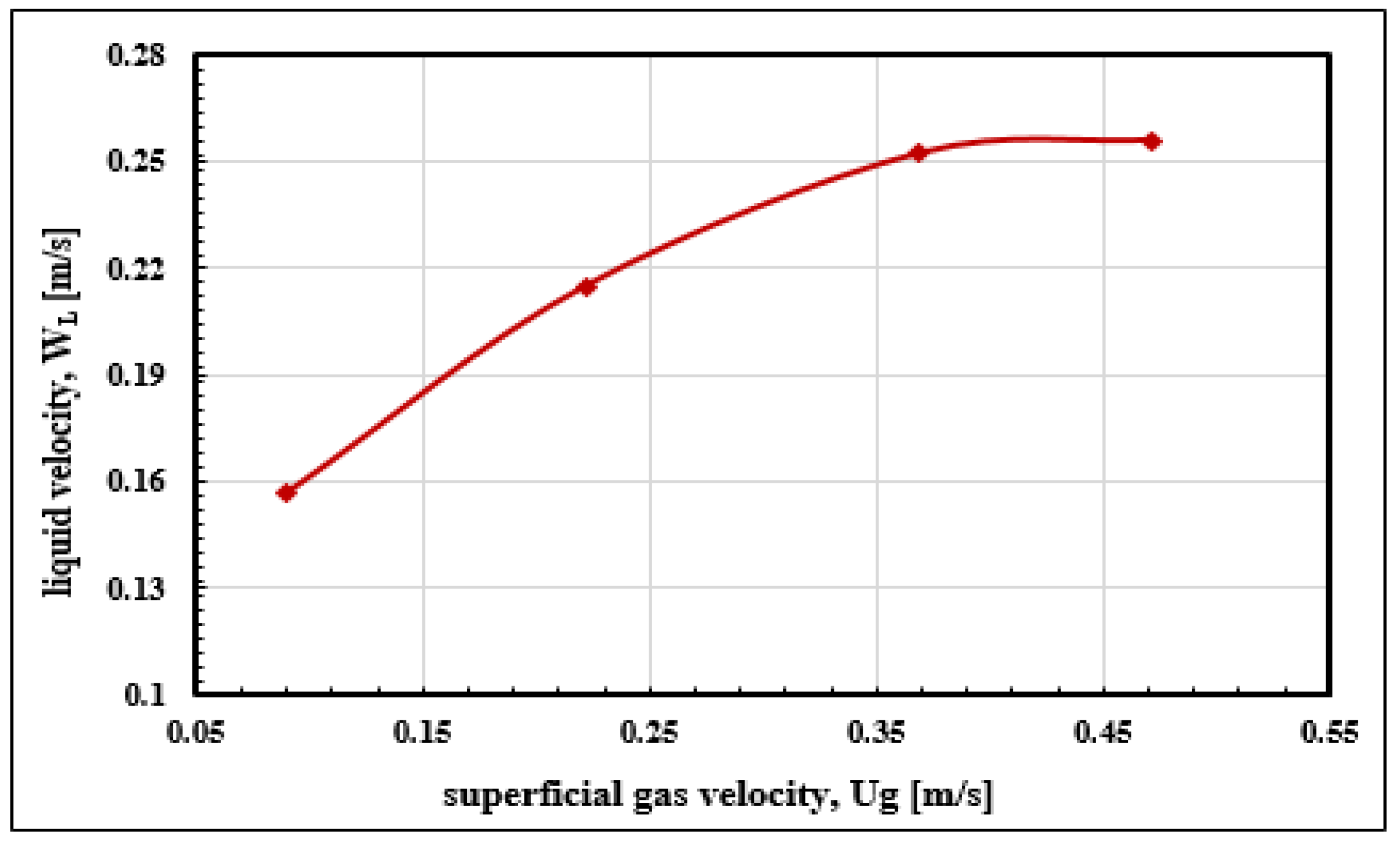

3.2.2. Analysis of the Liquid Phase Velocity

- : liquid flow measured in ms;

- : liquid velocity in m·s;

- : total section of the inner tube of the column in m.

- : actual liquid velocity in m·s;

- : liquid velocity in m·s;

- is the volume holdup of the air given by the expression:with the gas holdup.

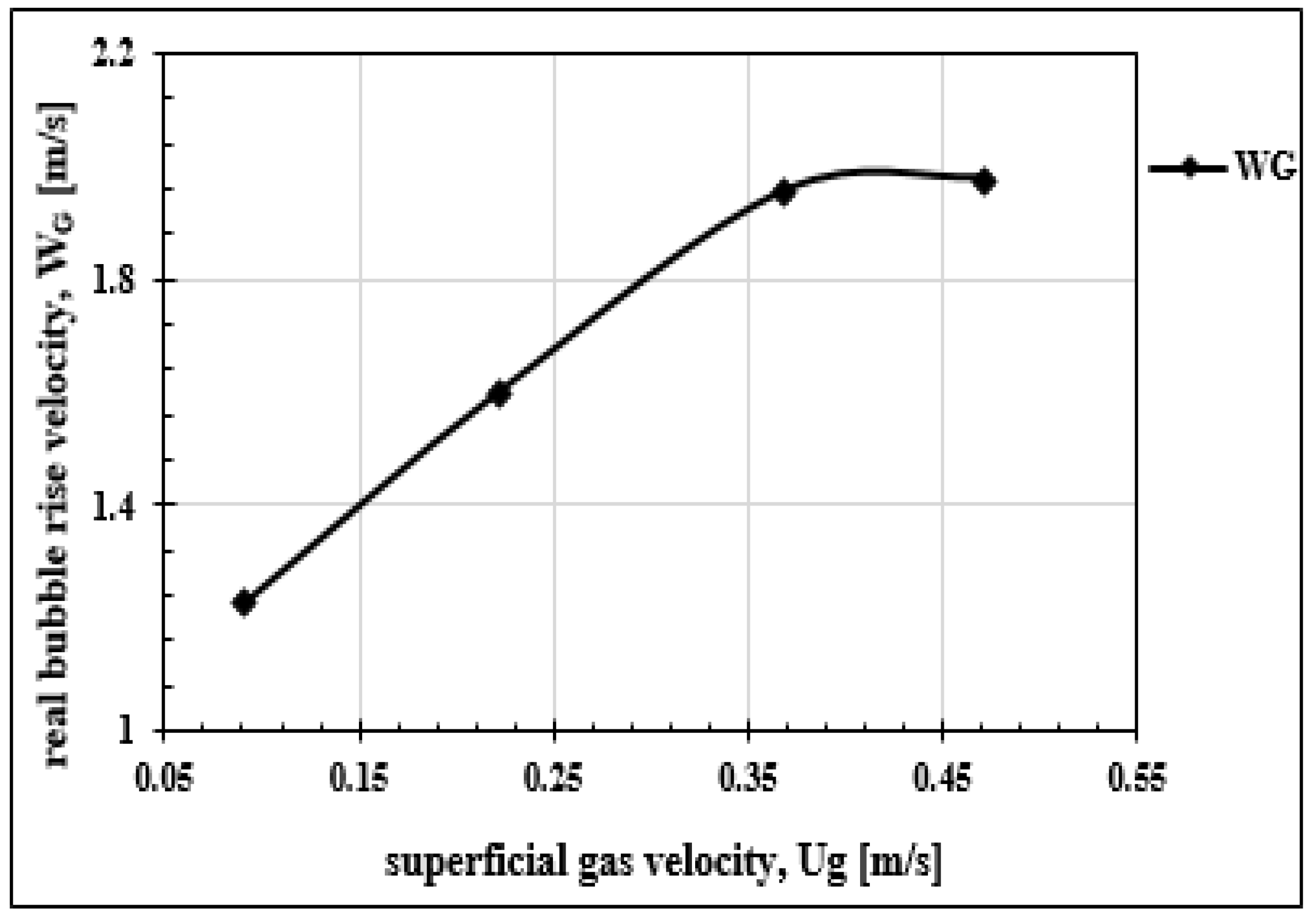

3.3. Hydrodynamics of the Dispersed Phase

3.4. Study of Global Parameters

3.4.1. Superficial Gas Velocity

- is the area of the total section of the inner tube of the column m

- is the volumetric gas flow, ms

- is the mass gas flow in ms

- is the gas flow rate is obtained by direct measurement with the mass flow meter, ms

- and : gas density (Kg·m),

- T: temperature,

- P: pressure.

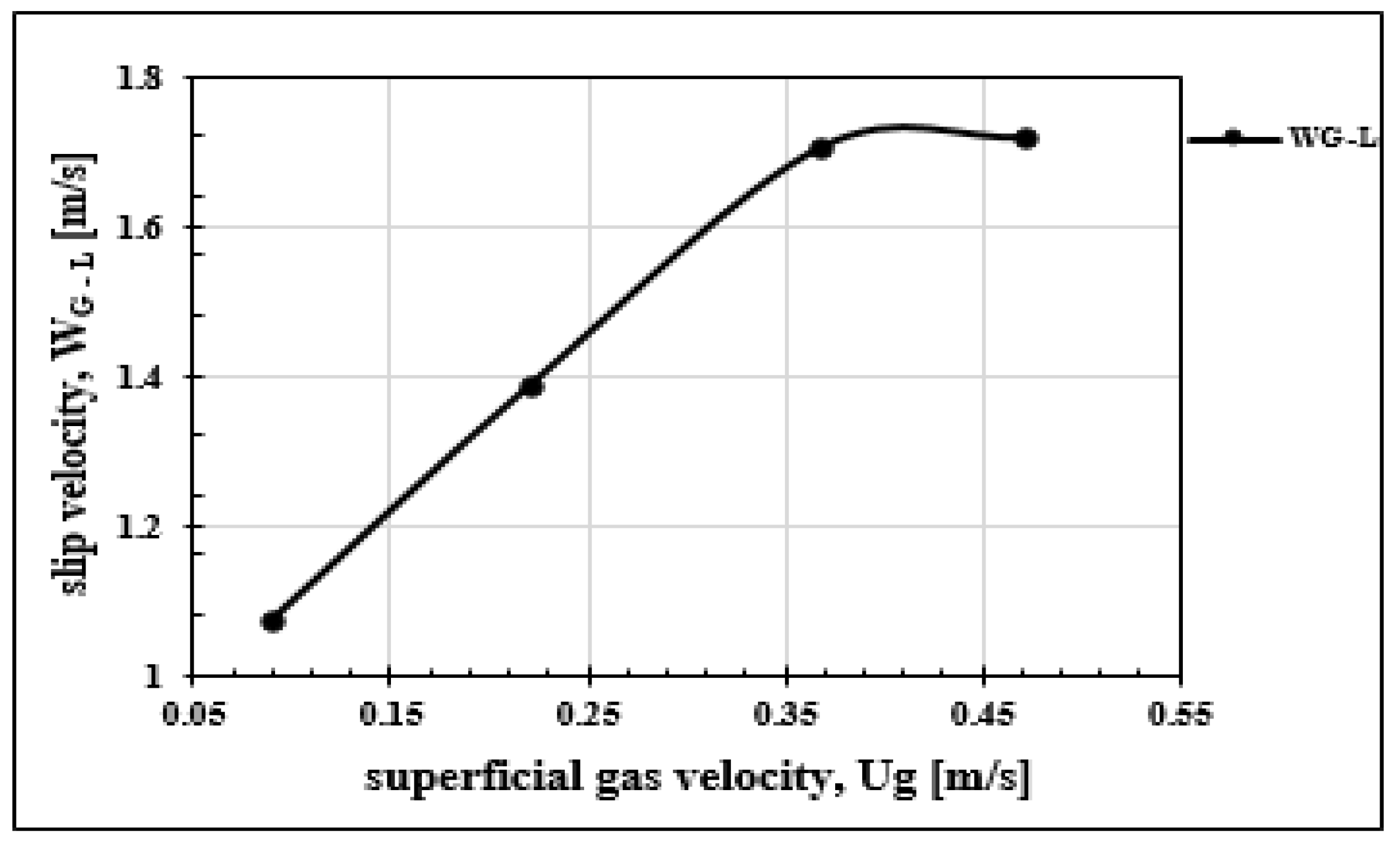

- is the gas holdup,

- is the bubble rise velocity,

- is the superficial gas velocity ().

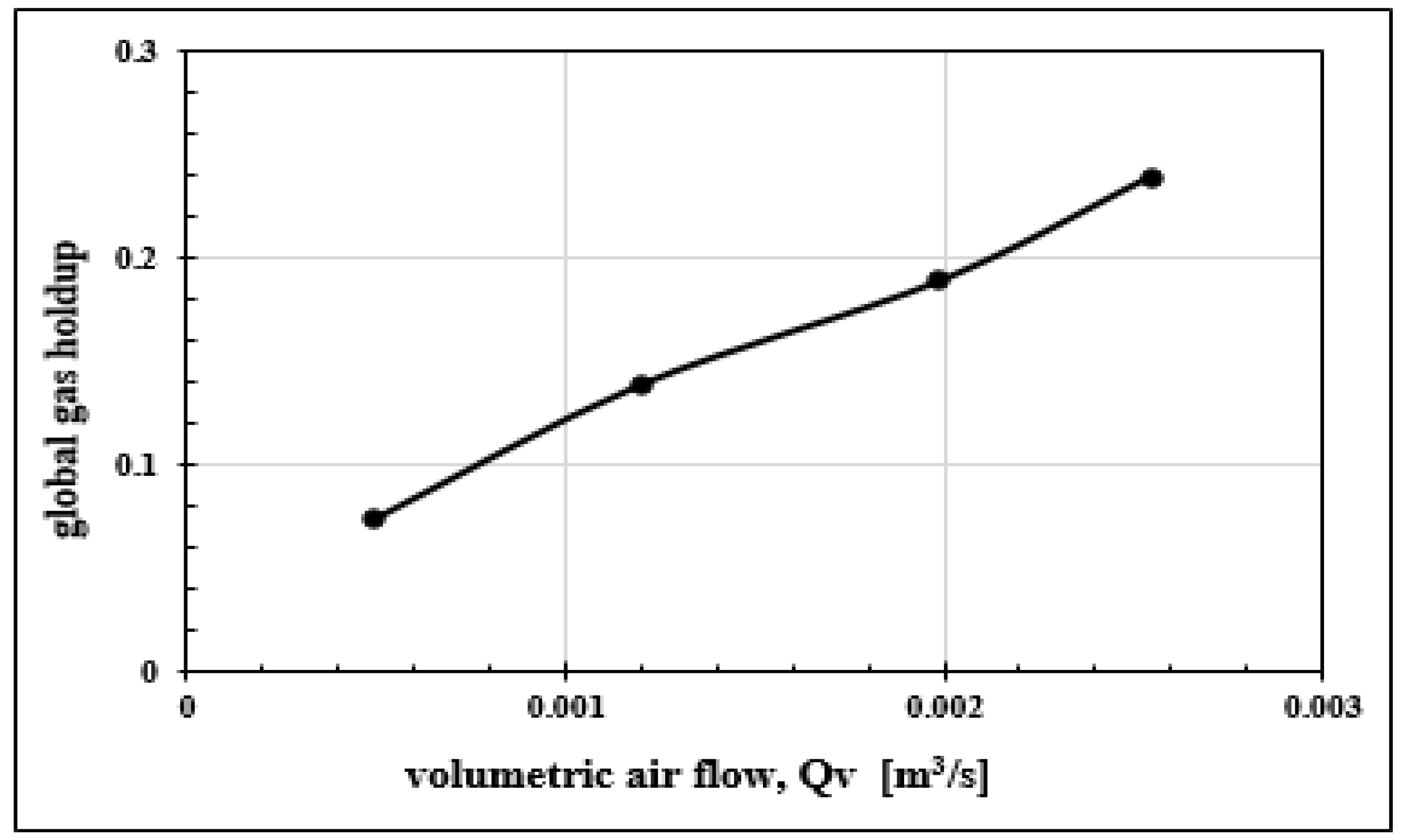

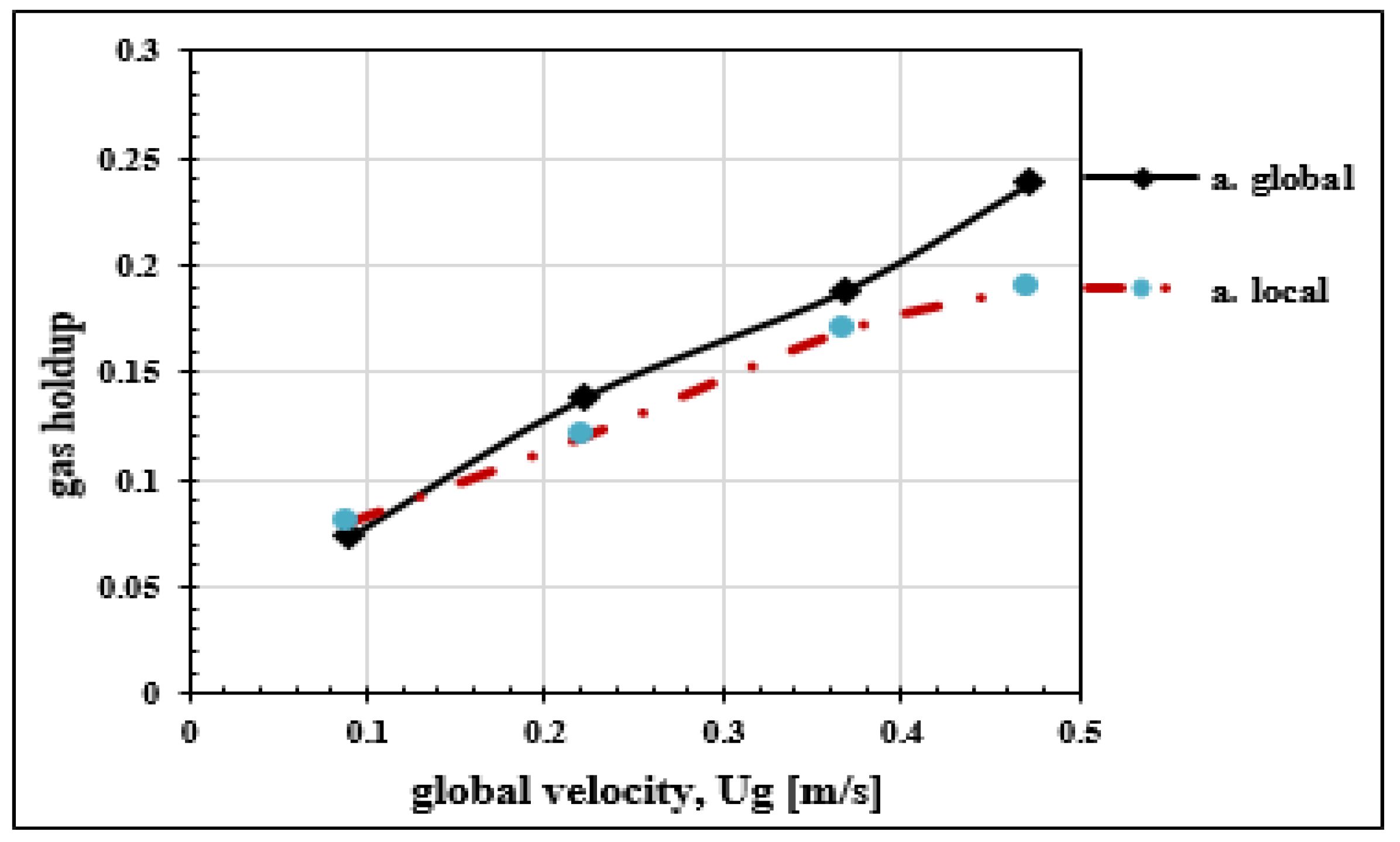

3.4.2. Global Gas Holdup

- there is conservation of gas velocity;

- the pressure losses in the column are negligible (because the wall of the Plexiglas column is smooth).

- g: acceleration of gravity;

- h: mix height;

- : density of the liquid;

- : variation of the measured pressure;

- : global gas holdup.

3.5. Hydrodynamics Parameters by Optical Bi-Probe

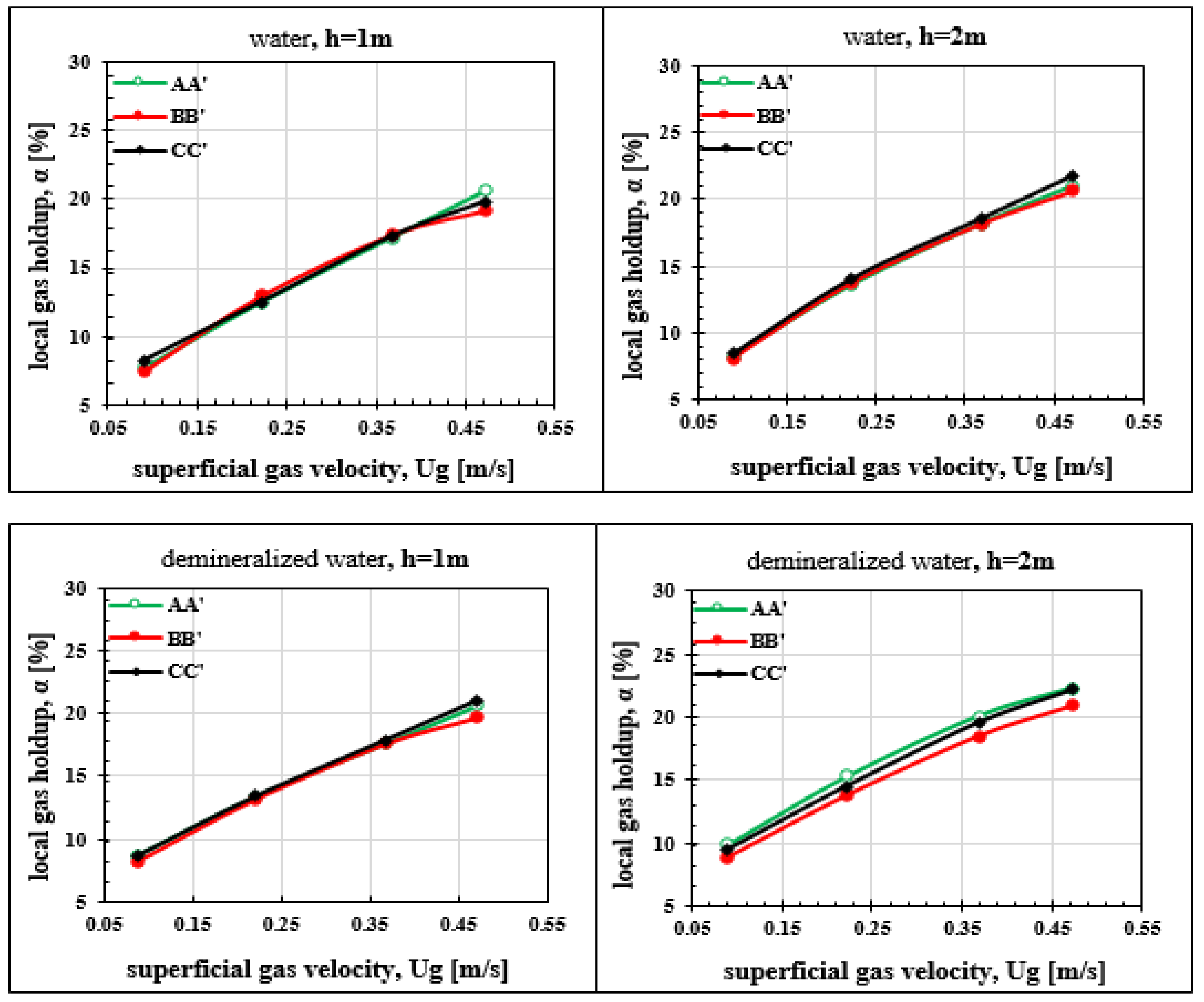

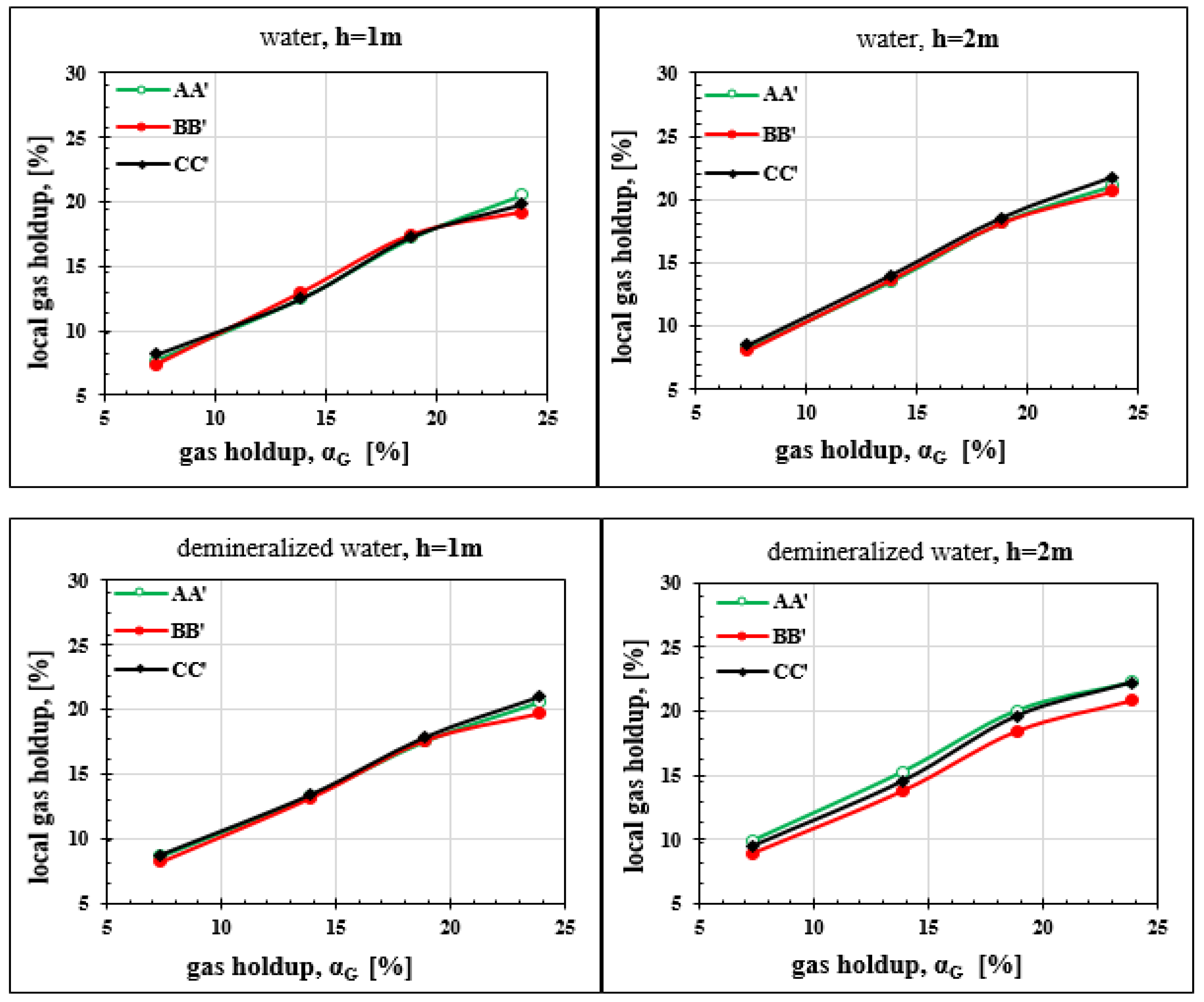

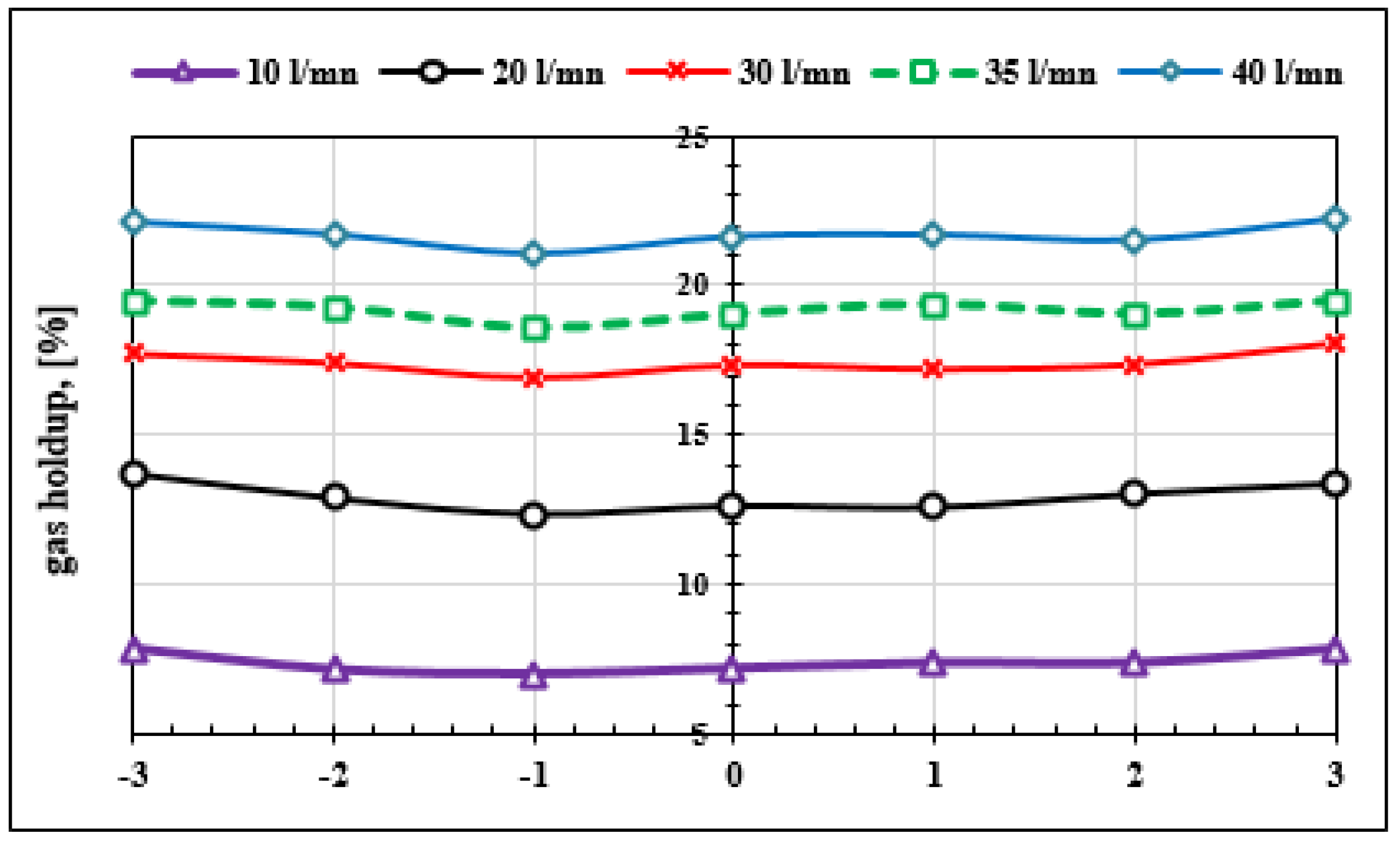

3.5.1. Local Gas Holdup

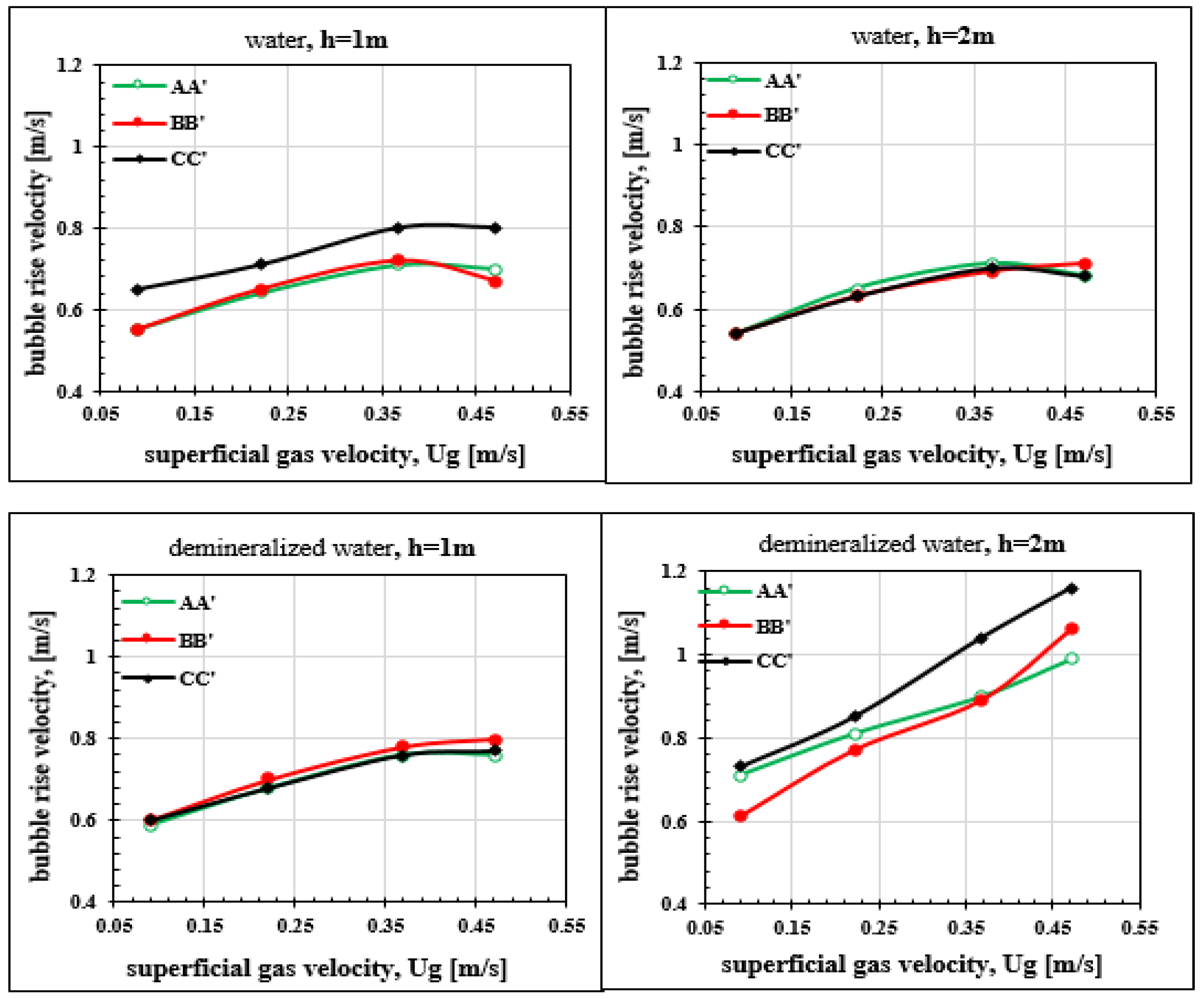

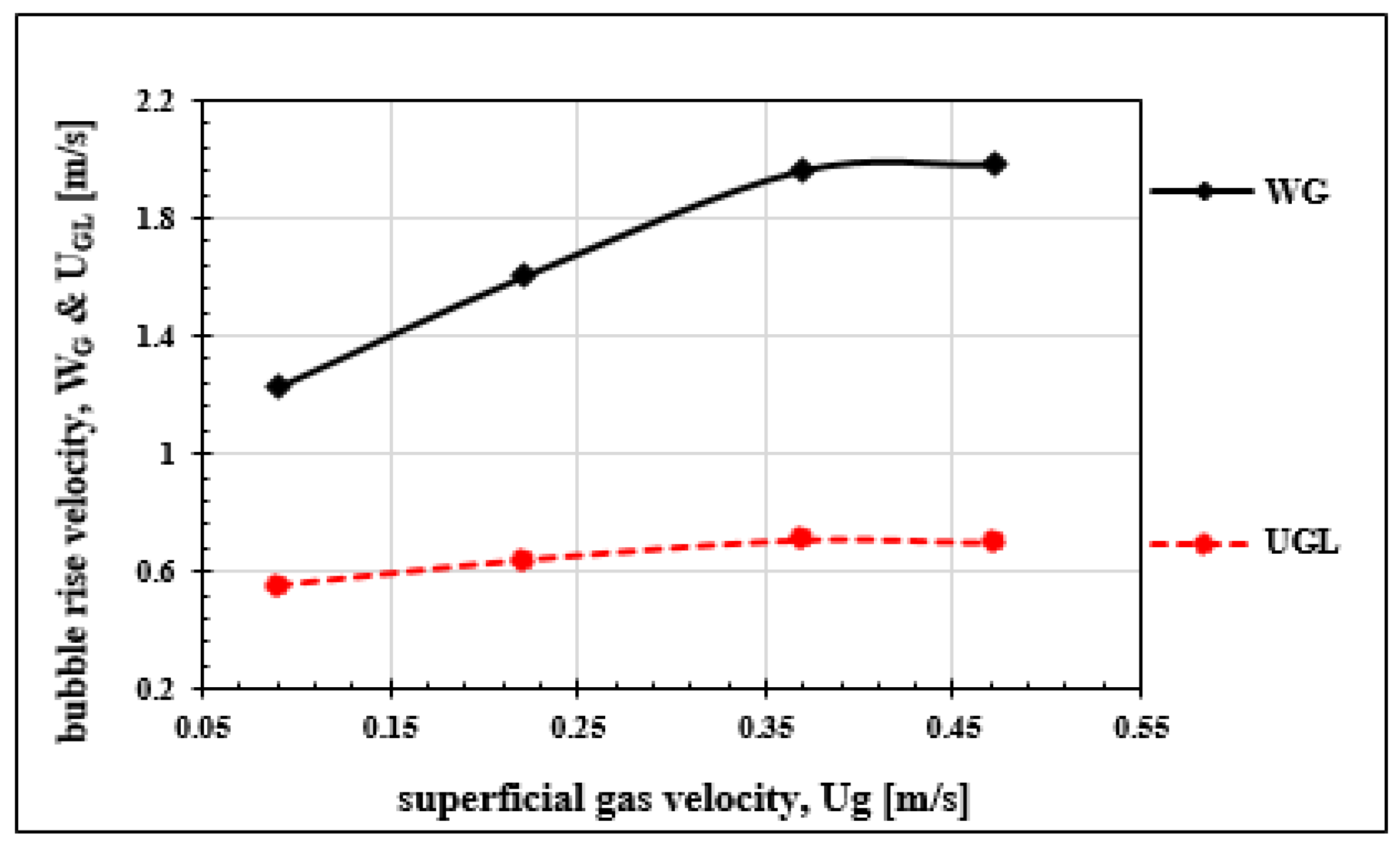

3.5.2. Bubble Rise Velocity

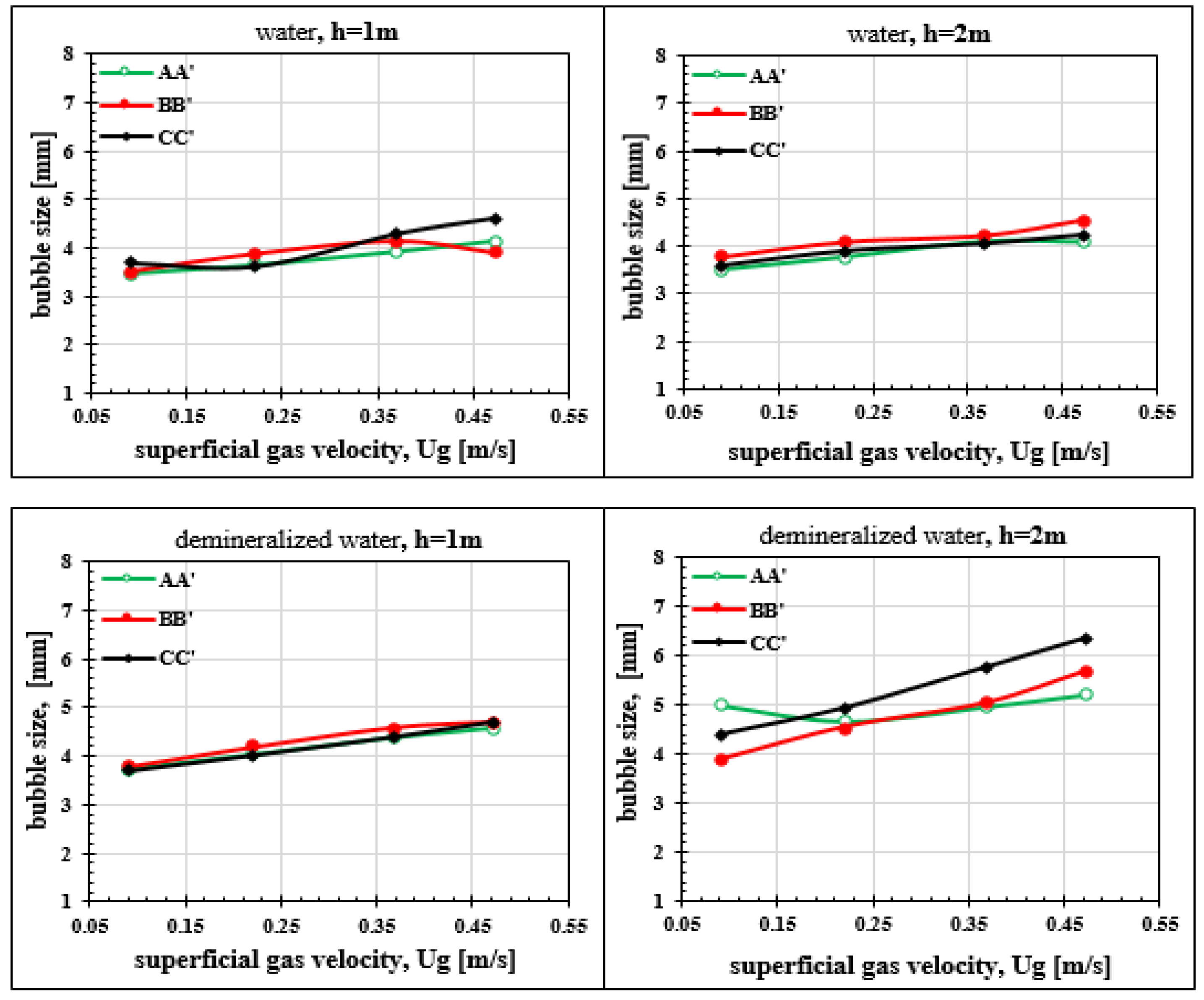

3.5.3. Bubble Size

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Deen, N.G.; Mudde, R.F.; Kuipers, J.A.M.; Zehner, P.; Kraume, M. Bubble columns. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag: Weinheim, Germany, 2000. [Google Scholar]

- Barrut, B. Etude et Optimisation du Fonctionnement d’une Colonne Airlift à Dépression: Application à L’aquaculture. Ph.D. Thesis, Université Montpellier, Montpellier, France, 2011. [Google Scholar]

- Chaumat, H.; Billet-Duquenne, A.; Augier, F.; Mathieu, C.; Delmas, H. On the reliability of an optical fibre probe in bubble column under industrial relevant operating conditions. Exp. Therm. Fluid Sci. 2007, 31, 495–504. [Google Scholar] [CrossRef]

- Rene, F.; Lemarie, G.; Champagne, J.Y.; Morel, R. Procédé et Installation de Traitement d’un Effluent Aqueux, en vue d’en Extraire au Moins un Composé Gazeux Dissous; Application à L’aquaculture en Milieu Aqueux Recirculé. FR0702308A, 29 March 2007. (In French). [Google Scholar]

- Singh, B.K.; Quiyoom, A.; Buwa, V.V. Dynamics of gas–liquid flow in a cylindrical bubble column: Comparison of electrical resistance tomography and voidage probe measurements. Chem. Eng. Sci. 2017, 158, 124–139. [Google Scholar] [CrossRef]

- Besagni, G.; Inzoli, F.; De Guido, G.; Pellegrini, L.A. The dual effect of viscosity on bubble column hydrodynamics. Chem. Eng. Sci. 2017, 158, 509–538. [Google Scholar] [CrossRef]

- Azzopardi, B.; Zhao, D.; Yan, Y.; Morvan, H.; Mudde, R.; Lo, S. Hydrodynamics of Gas-Liquid Reactors: Normal Operation and Upset Conditions; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Young, M.A.; Carbonell, R.G.; Ollis, D.F. Airlift bioreactors: Analysis of local two-phase hydrodynamics. AIChE J. 1991, 37, 403–428. [Google Scholar] [CrossRef]

- Adetunji, O.; Rawatlal, R. Estimation of bubble column hydrodynamics: Image-based measurement method. Flow Meas. Instrum. 2017, 53, 4–17. [Google Scholar] [CrossRef]

- Besbes, S.; El Hajem, M.; Aissia, H.B.; Champagne, J.Y.; Jay, J. PIV measurements and Eulerian–Lagrangian simulations of the unsteady gas–liquid flow in a needle sparger rectangular bubble column. Chem. Eng. Sci. 2015, 126, 560–572. [Google Scholar] [CrossRef]

- Giovannettone, J.; Tsai, E.; Gulliver, J. Gas void ratio and bubble diameter inside a deep airlift reactor. Chem. Eng. J. 2009, 149, 301–310. [Google Scholar] [CrossRef]

- Lau, Y.M.; Sujatha, K.T.; Gaeini, M.; Deen, N.G.; Kuipers, J.A.M. Experimental study of the bubble size distribution in a pseudo-2D bubble column. Chem. Eng. Sci. 2013, 98, 203–211. [Google Scholar] [CrossRef]

- Chaouki, J.; Larachi, F.; Duduković, M.P. Noninvasive Tomographic and Velocimetric Monitoring of Multiphase Flows. Ind. Eng. Chem. Res. 1997, 36, 4476–4503. [Google Scholar] [CrossRef]

- Cartellier, A. Optical probes for local void fraction measurements: Characterization of performance. Rev. Sci. Instrum. 1990, 61, 874–886. [Google Scholar] [CrossRef]

- Galaup, J.P.; Delhaye, J.M. Utilisation de sondes optiques miniatures en écoulement diphasique gaz-liquide. Application à la mesure du taux de présence local et de la vitesse locale de la phase gazeuse. La Houille Blanche 1976, 1, 17–30. [Google Scholar] [CrossRef][Green Version]

- Hinata, S. A study on the measurement of the local void fraction by the optical fiber glass probe. Bull. JSME 1972, 15, 1228–1235. [Google Scholar] [CrossRef]

- Danel, F.; Delhaye, J.M. Sonde optique pour mesure du taux de présence local en écoulement diphasique. Mes. Regul. Autom. 1971, 36, 99–101. [Google Scholar]

- Miller, N.; Mitchie, R.E. The Development of a Universal Probe for Measurement of Local Voidage in Liquid-Gas Two-Phase Flow Systems; Atomic Power Constructions Ltd.: Heston, UK, 1969. [Google Scholar]

- Cartellier, A.; Barrau, E. Monofiber optical probes for gas detection and gas velocity measurements: Conical probes. Int. J. Multiph. Flow 1998, 24, 1265–1294. [Google Scholar] [CrossRef]

- Rojas, G.; Loewen, M.R. Fiber-optic probe measurements of void fraction and bubble size distributions beneath breaking waves. Exp. Fluids 2007, 43, 895–906. [Google Scholar] [CrossRef]

- Yamada, M.; Saito, T. A newly developed photoelectric optical fiber probe for simultaneous measurements of a CO2 bubble chord length, velocity, and void fraction and the local CO2 concentration in the surrounding liquid. Flow Meas. Instrum. 2012, 27, 8–19. [Google Scholar] [CrossRef]

- Pjontek, D.; Parisien, V.; Macchi, A. Bubble characteristics measured using a monofibre optical probe in a bubble column and freeboard region under high gas holdup conditions. Chem. Eng. Sci. 2014, 111, 153–169. [Google Scholar] [CrossRef]

- Raimundo, P.M. Analysis and Modelization of Local Hydrodynamics in Bubble Columns. Ph.D. Thesis, Université Grenoble Alpes, Grenoble, France, 2015. [Google Scholar]

- Besagni, G.; Brazzale, P.; Fiocca, A.; Inzoli, F. Estimation of bubble size distributions and shapes in two-phase bubble column using image analysis and optical probes. Flow Meas. Instrum. 2016, 52, 190–207. [Google Scholar] [CrossRef]

- Aliyu, A.M.; Kim, Y.K.; Choi, S.H.; Ahn, J.H.; Kim, K.C. Development of a dual optical fiber probe for the hydrodynamic investigation of a horizontal annular drive gas/liquid ejector. Flow Meas. Instrum. 2017, 56, 45–55. [Google Scholar] [CrossRef]

- Peytraud, J.F. Etude de la Tomographie Electrique Pour la Mesure du Taux de Vide Local en Ecoulements Diphasiques. Ph.D. Thesis, Grenoble INPG, Grenoble, France, 1995. [Google Scholar]

- Serdula, C.D.; Loewen, M.R. Experiments investigating the use of fiber-optic probes for measuring bubble-size distributions. IEEE J. Ocean. Eng. 1998, 23, 385–399. [Google Scholar] [CrossRef]

- Kiambi, S.L.; Duquenne, A.M.; Dupont, J.B.; Colin, C.; Risso, F.; Delmas, H. Measurements of Bubble Characteristics: Comparison Between Double Optical Probe and Imaging. Can. J. Chem. Eng. 2003, 81, 764–770. [Google Scholar] [CrossRef]

- Vejražka, J.; Večeř, M.; Orvalho, S.; Sechet, P.; Ruzicka, M.C.; Cartellier, A. Measurement accuracy of a mono-fiber optical probe in a bubbly flow. Int. J. Multiph. Flow 2010, 36, 533–548. [Google Scholar] [CrossRef]

- Mizushima, Y.; Sakamoto, A.; Saito, T. Measurement technique of bubble velocity and diameter in a bubble column via single-tip optical-fiber probing with judgment of the pierced position and angle. Chem. Eng. Sci. 2013, 100, 98–104. [Google Scholar] [CrossRef]

- Clark, N.N.; Turton, R. Chord length distributions related to bubble size distributions in multiphase flows. Int. J. Multiph. Flow 1988, 14, 413–424. [Google Scholar] [CrossRef]

- Liu, W.; Clark, N.N. Relationships between distributions of chord lengths and distributions of bubble sizes including their statistical parameters. Int. J. Multiph. Flow 1995, 21, 1073–1089. [Google Scholar] [CrossRef]

- Simonnet, M. Étude Expérimentale du Mouvement de Bulles en Essaim: Application à la Simulation Numérique de Colonnes à Bulles. Ph.D. Thesis, Vandoeuvre-les-Nancy, INPL, Lorraine, France, 2005. [Google Scholar]

- Colombet, D. Modélisation de Réacteurs Gaz-Liquide de Type Colonne à Bulles en Conditions Industrielles. Ph.D. Thesis, Toulouse, INSA, Toulouse, France, 2012. [Google Scholar]

- Moujaes, S.; Dougall, R.S. Experimental investigation of cocurrent two-phase flow in a vertical rectangular channel. Can. J. Chem. Eng. 1987, 65, 705–715. [Google Scholar] [CrossRef]

- Besagni, G.; Inzoli, F. Influence of internals on counter-current bubble column hydrodynamics: Holdup, flow regime transition and local flow properties. Chem. Eng. Sci. 2016, 145, 162–180. [Google Scholar] [CrossRef]

- Wilkinson, P.M.; Spek, A.P.; van Dierendonck, L.L. Design parameters estimation for scale-up of high-pressure bubble columns. AIChE J. 1992, 38, 544–554. [Google Scholar] [CrossRef]

- Clift, R.; Grace, J.; Weber, M. Bubbles, Drops, and Particles; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Xue, J.; Al-Dahhan, M.; Dudukovic, M.P.; Mudde, R.F. Bubble Dynamics Measurements Using Four-Point Optical Probe. Can. J. Chem. Eng. 2003, 81, 375–381. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan Barkai, A.; El Hajem, M.; Lacassagne, T.; Champagne, J.-Y. Experimental Study of a Gas–Liquid Flow in Vacuum Air-Lift Column Using an Optical Bi-Probe. Fluids 2019, 4, 80. https://doi.org/10.3390/fluids4020080

Hassan Barkai A, El Hajem M, Lacassagne T, Champagne J-Y. Experimental Study of a Gas–Liquid Flow in Vacuum Air-Lift Column Using an Optical Bi-Probe. Fluids. 2019; 4(2):80. https://doi.org/10.3390/fluids4020080

Chicago/Turabian StyleHassan Barkai, Allatchi, Mahmoud El Hajem, Tom Lacassagne, and Jean-Yves Champagne. 2019. "Experimental Study of a Gas–Liquid Flow in Vacuum Air-Lift Column Using an Optical Bi-Probe" Fluids 4, no. 2: 80. https://doi.org/10.3390/fluids4020080

APA StyleHassan Barkai, A., El Hajem, M., Lacassagne, T., & Champagne, J.-Y. (2019). Experimental Study of a Gas–Liquid Flow in Vacuum Air-Lift Column Using an Optical Bi-Probe. Fluids, 4(2), 80. https://doi.org/10.3390/fluids4020080