An Efficient Iterative Method for Looped Pipe Network Hydraulics Free of Flow-Corrections

Abstract

:1. Introduction

2. Overview of Existing Methods for Calculation of Flow Distribution in A Looped Network of Pipes

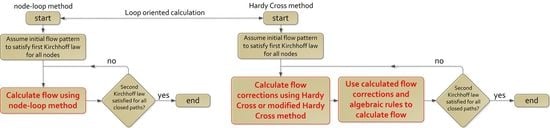

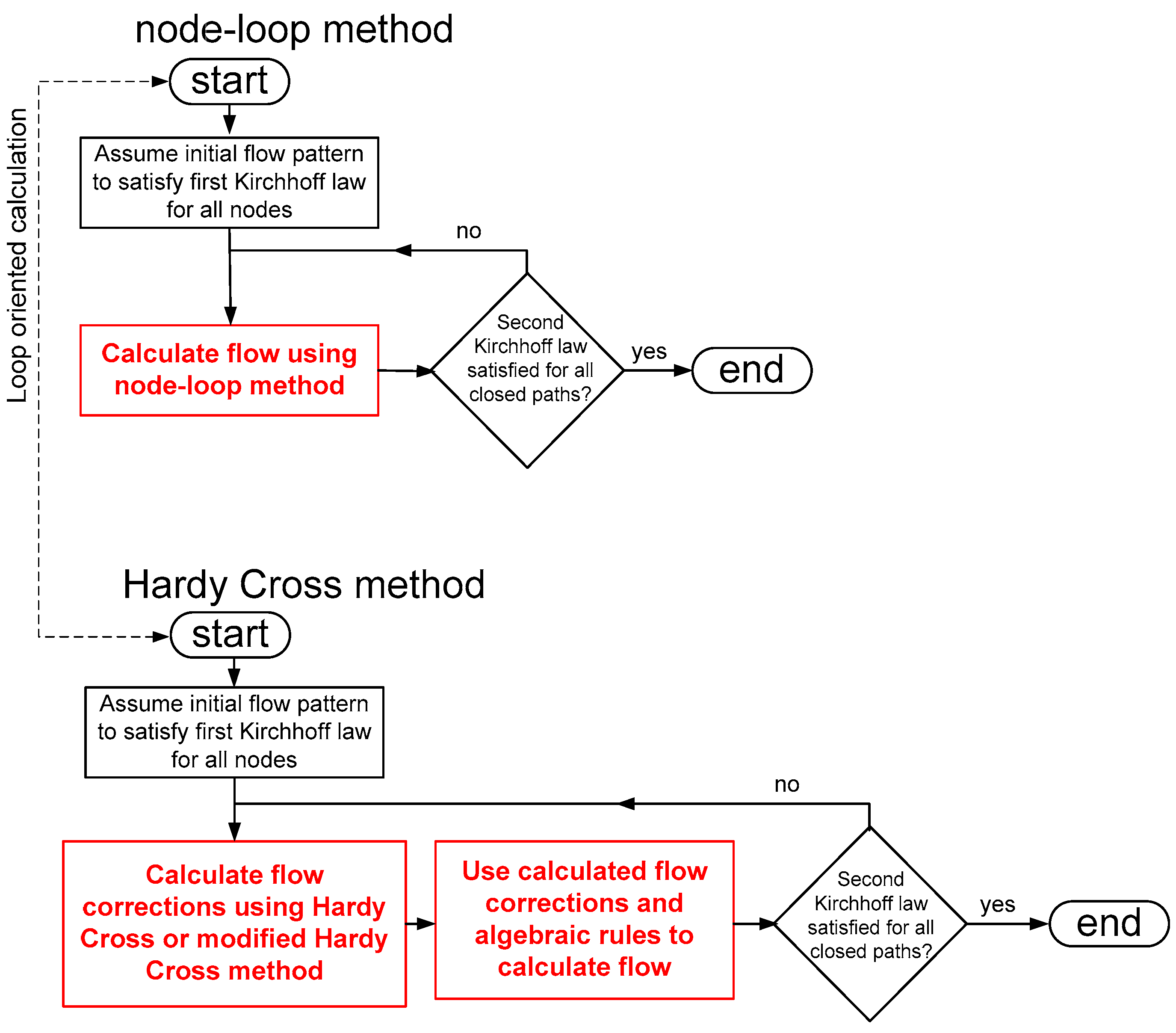

2.1. The Loop-Oriented Methods; The Original and the Improved Hardy Cross Method

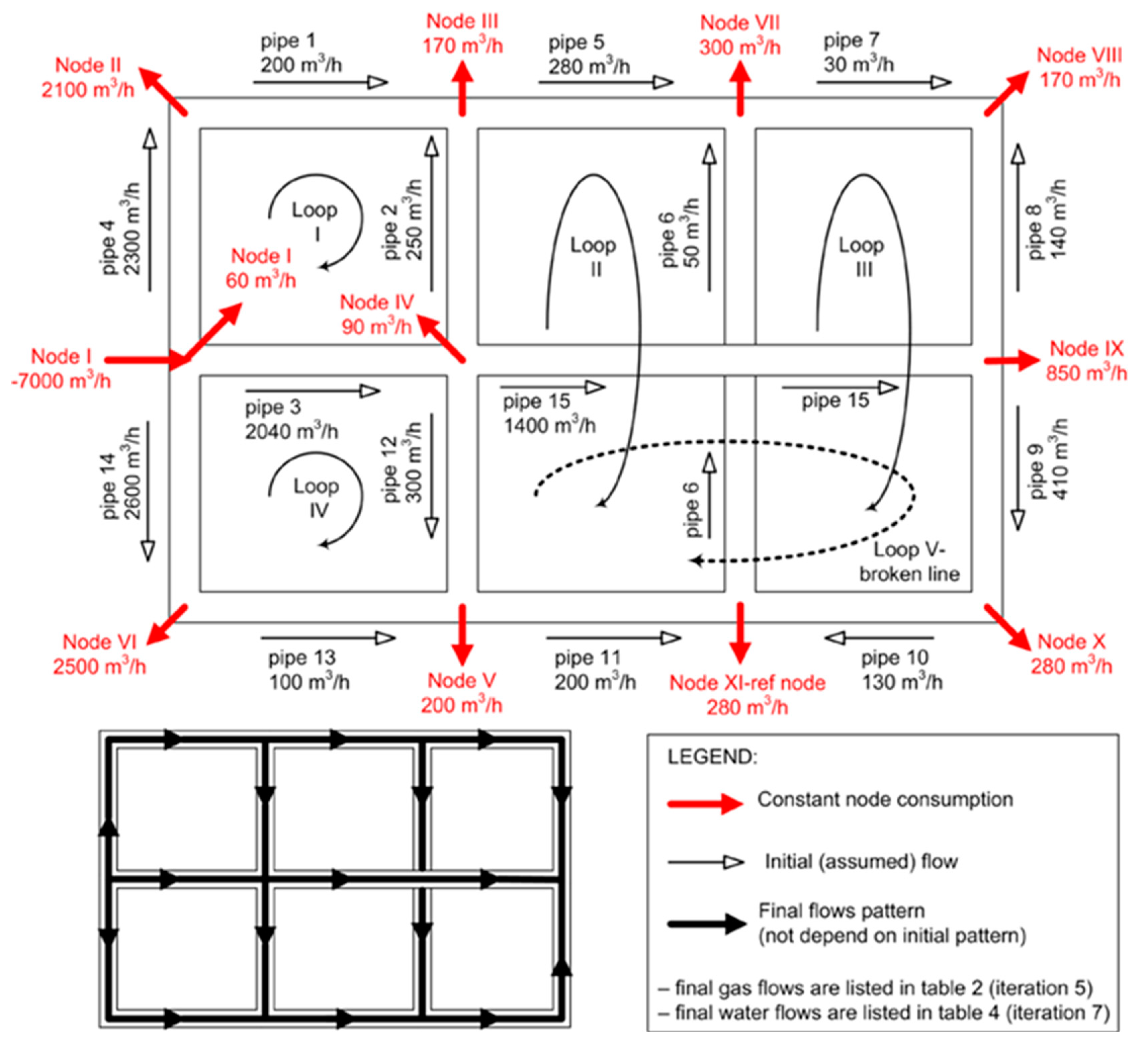

2.2. Node-Oriented Methods

2.3. Node-Loop Oriented Method

3. A Literary Overview of Existing Methods for Calculation of Flow Distribution in A Looped Network of Pipes

4. Hydraulics Resistance of a Single Pipe

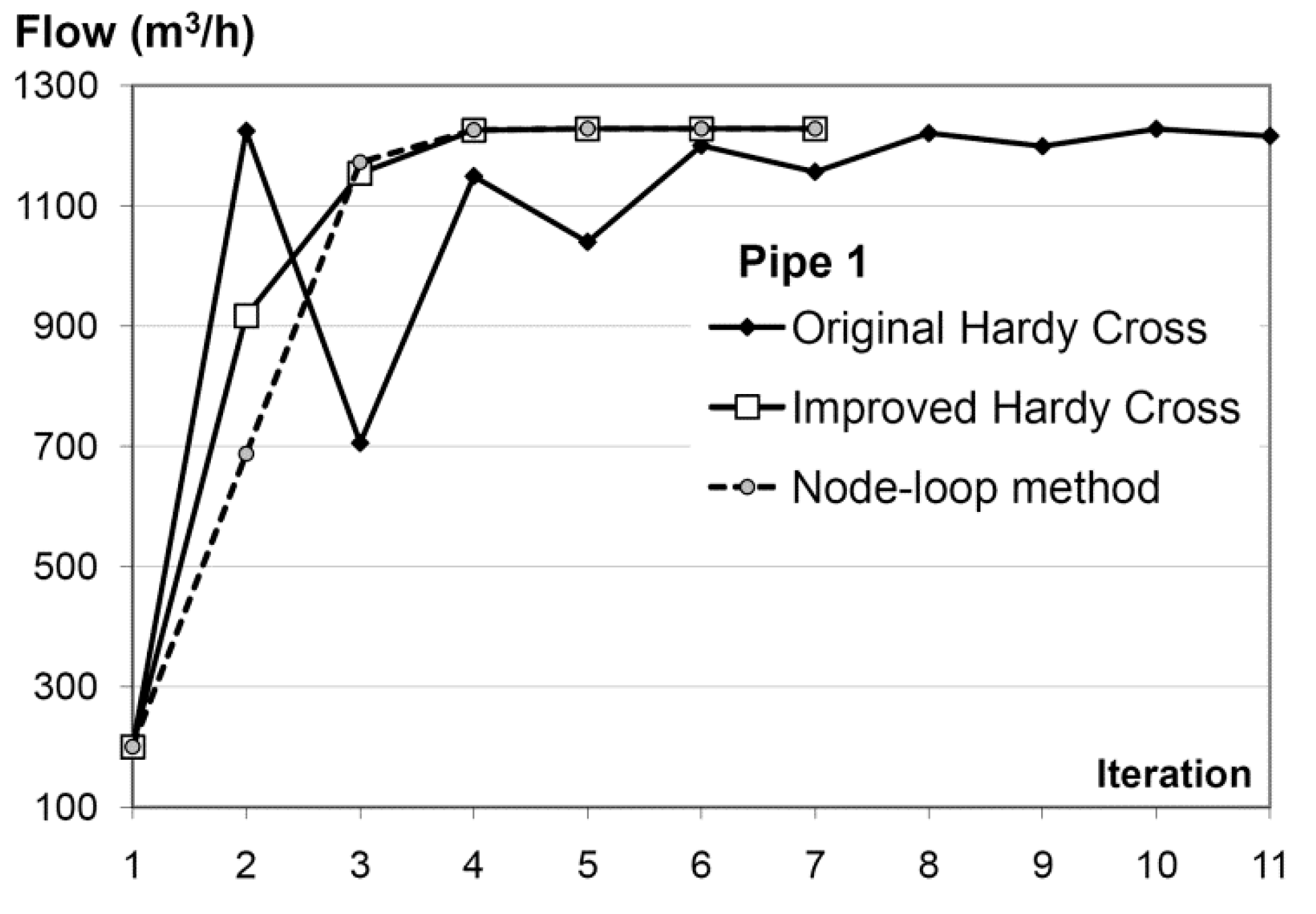

5. Topology of Looped Pipe Systems

6. Topology Equations for the Observed Looped Network of Pipes

6.1. Loop Equations

6.2. Node Equations

7. Network Calculation According to The Node-Loop Method

7.1. The Node-Loop Calculation of Gas Networks

7.2. The Node-Loop Calculation of Waterworks or District Heating Systems

8. A Note on The Optimization Problem

9. Main Advantages of The Node-Loop Method

10. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| p | pressure (Pa) |

| ρr | relative gas density (-) |

| L | pipe length (m) |

| Q | fluid flow rate (m3/s) |

| pipe diameter (m) | |

| Re | Reynolds number (-) |

| ε | absolute roughness of inner pipe surface (m) |

| ρ | water density (kg/m3) |

| υ | velocity (m/s) |

| λ | Darcy (i.e., Moody or Darcy-Weisbach) friction factor (-) |

| F | pressure function (Pa for water, and Pa2 for natural gas) |

| pseudo-pressure drop (Pa) | |

| Subscripts: | |

| n | normal |

| w | water |

| g | gas |

| a | absolute |

| Constants: | |

| π ≈ 3.1415 | |

Appendix A

References

- Cross, H. Analysis of Flow in Networks of Conduits or Conductors; University of Illinois at Urbana Champaign, College of Engineering Engineering Experiment Station: College Station, TX, USA, 1936; Available online: http://hdl.handle.net/2142/4433 (accessed on 1 March 2019).

- Epp, R.; Fowler, A.G. Efficient code for steady-state flows in networks. J. Hydraul. Div. Am. Soc. Civ. Eng. 1970, 96, 43–56. [Google Scholar]

- Brkić, D. An Improvement of Hardy Cross method applied on looped spatial natural gas distribution networks. Appl. Energy 2009, 86, 1290–1300. [Google Scholar] [CrossRef]

- Corfield, G.; Hunt, B.E.; Ott, R.J.; Binder, G.P.; Vandaveer, F.E. Distribution design for increased demand. In Gas Engineers Handbook; Segeler, C.G., Ed.; Chapter 9; Industrial Press: New York, NY, USA, 1974; pp. 63–83. [Google Scholar]

- Brkić, D. A Gas Distribution network hydraulic problem from practice. Petr. Sci. Technol. 2011, 29, 366–377. [Google Scholar] [CrossRef]

- Aynsley, R.M. A Resistance approach to analysis of natural ventilation airflow networks. J. Wind Eng. Ind. Aerodyn. 1997, 67–68, 711–719. [Google Scholar] [CrossRef]

- Kassai, M.; Poleczky, L.; Al-Hyari, L.; Kajtar, L.; Nyers, J. Investigation of the energy recovery potentials in ventilation systems in different climates. Facta Univ. Ser. Mech. Eng. 2018, 16, 203–217. [Google Scholar] [CrossRef]

- Brkić, D. Discussion of “Economics and statistical evaluations of using Microsoft Excel Solver in pipe network analysis” by I. A. Oke, A. Ismail, S. Lukman, S.O. Ojo, O.O. Adeosun, and M. O. Nwude. J. Pipeline Syst. Eng. Pract. 2018, 9, 7018002. [Google Scholar] [CrossRef]

- Del Hoyo Arce, I.; Herrero López, S.; López Perez, S.; Rämä, M.; Klobut, K.; Febres, J.A. Models for Fast Modelling of District Heating and Cooling Networks. Renew. Sustain. Energy Rev. 2018, 82, 1863–1873. [Google Scholar] [CrossRef]

- Elaoud, S.; Hafsi, Z.; Hadj-Taieb, L. Numerical modelling of hydrogen-natural gas mixtures flows in looped networks. J. Petr. Sci. Eng. 2017, 159, 532–541. [Google Scholar] [CrossRef]

- Nikolić, B.; Jovanović, M.; Milošević, M.; Milanović, S. Function k-as a link between fuel flow velocity and fuel pressure, depending on the type of fuel. Facta Univ. Ser. Mech. Eng. 2017, 15, 119–132. [Google Scholar] [CrossRef]

- Shamir, U.; Howard, C.D.D. Water distribution systems analysis. J. Hydraul. Div. Am. Soc. Civ. Eng. 1968, 94, 219–234. [Google Scholar]

- Brkić, D. Iterative methods for looped network pipeline calculation. Water Resour. Manag. 2011, 25, 2951–2987. [Google Scholar] [CrossRef]

- Niazkar, M.; Afzali, S.H. Analysis of water distribution networks using MATLAB and Excel spreadsheet: Q-based methods. Comput. Appl. Eng. Educ. 2017, 25, 277–289. [Google Scholar] [CrossRef]

- Niazkar, M.; Afzali, S.H. Analysis of water distribution networks using MATLAB and Excel spreadsheet: H-based methods. Comput. Appl. Eng. Educ. 2017, 25, 129–141. [Google Scholar] [CrossRef]

- Spiliotis, M.; Tsakiris, G. Water distribution system analysis: Newton-Raphson method revisited. J. Hydraul. Eng. 2011, 137, 852–855. [Google Scholar] [CrossRef]

- Brkić, D. Discussion of “Water distribution system analysis: Newton-Raphson method revisited” by M. Spiliotis and G. Tsakiris. J. Hydraul. Eng. 2012, 138, 822–824. [Google Scholar] [CrossRef]

- Spiliotis, M.; Tsakiris, G. Closure to “Water distribution system analysis: Newton-Raphson method revisited” by M. Spiliotis and G. Tsakiris. J. Hydraul. Eng. 2012, 138, 824–826. [Google Scholar] [CrossRef]

- Simpson, A.; Elhay, S. Jacobian matrix for solving water distribution system equations with the Darcy-Weisbach head-loss model. J. Hydraul. Eng. 2011, 137, 696–700. [Google Scholar] [CrossRef]

- Brkić, D. Discussion of “Jacobian matrix for solving water distribution system equations with the Darcy-Weisbach head-loss model” by Angus Simpson and Sylvan Elhay. J. Hydraul. Eng. 2012, 138, 1000–1001. [Google Scholar] [CrossRef]

- Simpson, A.R.; Elhay, S. Closure to “Jacobian matrix for solving water distribution system equations with the Darcy-Weisbach head-loss model” by Angus Simpson and Sylvan Elhay. J. Hydraul. Eng. 2012, 138, 1001–1002. [Google Scholar] [CrossRef]

- Wood, D.J.; Charles, C.O.A. Hydraulic network analysis using linear theory. J. Hydraul. Div. Am. Soc. Civ. Eng. 1972, 98, 1157–1170. [Google Scholar]

- Wood, D.J.; Rayes, A.G. Reliability of algorithms for pipe network analysis. J. Hydraul. Div. Am. Soc. Civ. Eng. 1981, 107, 1145–1161. [Google Scholar]

- Boulos, P.F.; Lansey, K.E.; Karney, B.W. Comprehensive Water Distribution Systems Analysis Handbook for Engineers and Planners, 2nd ed.; MWH: Broomfield, CO, USA, 2006. [Google Scholar]

- Todini, E.; Pilati, S. A gradient method for the analysis of pipe networks. In Computer Applications in Water Supply; Coulbeck, B., Orr, C.H., Eds.; John Wiley & Sons Research Studies Press: London, UK, 1988; pp. 1–20. [Google Scholar]

- Hamam, Y.M.; Brameller, A. Hybrid method for the solution of piping networks. Proc. Inst. Electr. Eng. 1971, 118, 1607–1612. [Google Scholar] [CrossRef]

- Mah, R.S.H. Pipeline network calculations using sparse computation techniques. Chem. Eng. Sci. 1974, 29, 1629–1638. [Google Scholar] [CrossRef]

- Mah, R.S.H.; Shacham, M. Pipeline network design and synthesis. Adv. Chem. Eng. 1978, 10, 125–209. [Google Scholar] [CrossRef]

- Mah, R.S.H.; Lin, T.D. Comparison of Modified Newton’s methods. Comput. Chem. Eng. 1980, 4, 75–78. [Google Scholar] [CrossRef]

- Lopes, A.M.G. Implementation of the Hardy-Cross method for the solution of piping networks. Comput. Appl. Eng. Educ. 2004, 12, 117–125. [Google Scholar] [CrossRef]

- Huddleston, D.H.; Alarcon, V.J.; Chen, W. Water Distribution network analysis using Excel. J. Hydraul. Eng. 2004, 130, 1033–1035. [Google Scholar] [CrossRef]

- Brkić, D. Spreadsheet-Based Pipe Networks Analysis for Teaching and Learning Purpose. Spreadsheets Educ. 2016, 9, 4. Available online: https://sie.scholasticahq.com/article/4646-spreadsheet-based-pipe-networks-analysis-for-teaching-and-learning-purpose (accessed on 12 April 2019).

- Anonymous. Pipeline-network analyzer. J. Frankl. Inst. 1952, 254, 195. [Google Scholar] [CrossRef]

- Anonymous. Substitution of manufactured gas for natural gas. J. Frankl. Inst. 1930, 209, 121–125. [Google Scholar] [CrossRef]

- Brkić, D. Review of explicit approximations to the Colebrook relation for flow friction. J. Petr. Sci. Eng. 2011, 77, 34–48. [Google Scholar] [CrossRef]

- Brkić, D.; Ćojbašić, Ž. Evolutionary optimization of Colebrook’s turbulent flow friction approximations. Fluids 2017, 2, 15. [Google Scholar] [CrossRef]

- Praks, P.; Brkić, D. Choosing the optimal multi-point iterative method for the Colebrook flow friction equation. Processes 2018, 6, 130. [Google Scholar] [CrossRef]

- Brkić, D.; Praks, P. Accurate and Efficient Explicit Approximations of the Colebrook Flow Friction Equation Based on the Wright ω-Function. Mathematics 2019, 7, 34. [Google Scholar] [CrossRef]

- Brkić, D. Can Pipes be actually really that smooth? Int. J. Refrig. 2012, 35, 209–215. [Google Scholar] [CrossRef]

- Liou, C.P. Limitations and proper use of the Hazen-Williams equation. J. Hydraul. Eng. 1998, 124, 951–954. [Google Scholar] [CrossRef]

- Gay, B.; Middleton, P. The solution of pipe network problems. Chem. Eng. Sci. 1971, 26, 109–123. [Google Scholar] [CrossRef]

- Mathews, E.H.; Köhler, P.A.J. A Numerical optimization procedure for complex pipe and duct network design. Int. J. Numer. Methods Heat Fluid Flow 1995, 5, 445–457. [Google Scholar] [CrossRef]

- Manojlović, V.; Arsenović, M.; Pajović, V. Optimized design of a gas-distribution pipeline network. Appl. Energy 1994, 48, 217–224. [Google Scholar] [CrossRef]

- Chansler, J.M.; Rowe, D.R. Microcomputer analysis of pipe networks. Water Eng. Manag. 1990, 137, 36–39. [Google Scholar]

- Marušić-Paloka, E.; Pažanin, I. On the Viscous Flow through a long pipe with non-constant pressure boundary condition. Zeitschrift für Naturforschung A 2018, 73, 639–644. [Google Scholar] [CrossRef]

- Coelho, P.M.; Pinho, C. Considerations about equations for steady state flow in natural gas pipelines. J. Braz. Soc. Mech. Sci. Eng. 2007, 29, 262–273. [Google Scholar] [CrossRef]

- Colebrook, C.F. Turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. J. Inst. Civ. Eng. 1939, 11, 133–156. [Google Scholar] [CrossRef]

- Raoni, R.; Secchi, A.R.; Biscaia, E.C., Jr. Novel method for looped pipeline network resolution. Comput. Chem. Eng. 2017, 96, 169–182. [Google Scholar] [CrossRef]

- Oliva, G.; Rikos, A.I.; Hadjicostis, C.N.; Gasparri, A. Distributed Flow Network Balancing with Minimal Effort. IEEE Trans. Autom. Control 2019, in press. [Google Scholar] [CrossRef]

- Pambour, K.; Cakir Erdener, B.; Bolado-Lavin, R.; Dijkema, G. Development of a simulation framework for analyzing security of supply in integrated gas and electric power systems. Appl. Sci. 2017, 7, 47. [Google Scholar] [CrossRef]

- Praks, P.; Kopustinskas, V.; Masera, M. Probabilistic modelling of security of supply in gas networks and evaluation of new infrastructure. Reliab. Eng. Syst. Saf. 2015, 144, 254–264. [Google Scholar] [CrossRef]

- Pietrucha-Urbanik, K.; Tchorzewska-Cieslak, B. Water Supply System operation regarding consumer safety using Kohonen neural network. Safety, Reliability and Risk Analysis: Beyond the Horizon, 2014, 1115–1120. In Proceedings of the Advances in Safety, Reliability and Risk Management: ESREL, Amsterdam, The Netherlands, 29 September–2 October 2013. [Google Scholar] [CrossRef]

- Bermúdez, J.-R.; López-Estrada, F.-R.; Besançon, G.; Valencia-Palomo, G.; Torres, L.; Hernández, H.-R. Modeling and simulation of a hydraulic network for leak diagnosis. Math. Comput. Appl. 2018, 23, 70. [Google Scholar] [CrossRef]

- Adedeji, K.; Hamam, Y.; Abe, B.; Abu-Mahfouz, A. Leakage detection and estimation algorithm for loss reduction in water piping networks. Water 2017, 9, 773. [Google Scholar] [CrossRef]

- Pietrucha-Urbanik, K.; Żelazko, A. Approaches to assess water distribution failure. Period. Polytech. Civ. Eng. 2017, 61, 632–639. [Google Scholar] [CrossRef]

- Brkić, D. Determining friction factors in turbulent pipe flow. Chem. Eng. (N. Y.) 2012, 119, 34–39. [Google Scholar]

- Brkić, D. Solution of the implicit Colebrook Equation for Fflow friction Using Excel. Spreadsheets Educ. 2017, 10, 2. Available online: https://sie.scholasticahq.com/article/4663-solution-of-the-implicit-colebrook-equation-for-flow-friction-using-excel (accessed on 12 April 2019).

| Loop | Pipe | (m) | L (m) | a Q (m3/s) | Sign (Q) | c F | d |F’| |

|---|---|---|---|---|---|---|---|

| I | 1 | 0.4064 | 100 | b A1 = 0.0556 | +1 | 114959 | |a1| = 3766062 |

| 2 | 0.3048 | 100 | A2 = −0.0694 | −1 | −690438 | |a2| = 18094990 | |

| 3 | 0.1524 | 100 | A3 = −0.5667 | −1 | −889949040 | |a3| = 2858306918 | |

| 4 | 0.3048 | 100 | A4 = 0.6389 | +1 | 39193885 | |a4| = 111651451 | |

| Σ | A = −851330634 | ||||||

| II | 5 | 0.1524 | 100 | B1 = 0.0778 | +1 | 23969880 | |b1| = 560895181 |

| 6 | 0.3048 | 200 | B2 = −0.0139 | −1 | −73795 | |b2| = 9670144 | |

| 11 | 0.1524 | 100 | B3 = −0.0556 | −1 | −12993101 | |b3| = 425654001 | |

| 12 | 0.1524 | 100 | B4 = −0.0833 | −1 | −27176838 | |b4| = 593542132 | |

| 2 | 0.3048 | 100 | B5 = 0.0694 | +1 | 690438 | |b5| = 18094990 | |

| Σ | B = −15583417 | ||||||

| III | 7 | 0.1524 | 100 | C1 = 0.0083 | +1 | 411338 | |c1| = 89836237 |

| 8 | 0.1524 | 100 | C2 = −0.0389 | −1 | −6788773 | |c2| = 317714556 | |

| 9 | 0.3048 | 100 | C3 = 0.1139 | +1 | 1698792 | |c3| = 27147529 | |

| 10 | 0.1524 | 100 | C4 = 0.0361 | +1 | 5932191 | |c4| = 298982433 | |

| 6 | 0.3048 | 200 | C5 = 0.0139 | +1 | 73795 | |c5| = 9670144 | |

| Σ | C = 1327344 | ||||||

| IV | 3 | 0.1524 | 100 | D1 = 0.5667 | +1 | 889949040 | |d1| = 2858306918 |

| 12 | 0.1524 | 100 | D2 = 0.0833 | +1 | 27176838 | |d2| = 593542132 | |

| 13 | 0.1524 | 100 | D3 = −0.0278 | −1 | −3679919 | |d3| = 241108279 | |

| 14 | 0.4064 | 100 | D4 = −0.7222 | −1 | −12243919 | |d4| = 30854675 | |

| Σ | D = 901202040 | ||||||

| V | 15 | 0.1524 | 200 | E1 = 0.3889 | +1 | 897059511 | |e1| = 4198238510 |

| 9 | 0.3048 | 100 | E2 = 0.1139 | +1 | 1698792 | |e2| = 27147529 | |

| 10 | 0.1524 | 100 | E3 = 0.0361 | +1 | 5932191 | |e3| = 298982433 | |

| 11 | 0.1524 | 100 | E4 = −0.0556 | −1 | −12993101 | |e4| = 425654001 | |

| 12 | 0.1524 | 100 | E5 = −0.0833 | −1 | −27176838 | |e5| = 593542132 | |

| Σ | E = 864520555 |

| Loop | Pipe | (m) | L (m) | a Q(m3/s) | Sign (Q) | c Re | d ε/δ | e λ | f F | g |F’| |

|---|---|---|---|---|---|---|---|---|---|---|

| I | 1 | 0.4064 | 100 | b A1 = 0.0556 | +1 | 195566.25 | 4.92 × 10−5 | 0.01609 | 363.1919278 | |a1| = 13074.9094 |

| 2 | 0.3048 | 100 | A2 = −0.0694 | −1 | 325943.75 | 6.56 × 10−5 | 0.01492 | −2217.677686 | |a2| = 63869.11737 | |

| 3 | 0.1524 | 100 | A3 = −0.5667 | −1 | 5319401.99 | 1.31 × 10−4 | 0.01290 | −4084603.502 | |a3| = 14416247.66 | |

| 4 | 0.3048 | 100 | A4 = 0.6389 | +1 | 2998682.50 | 6.56 × 10−5 | 0.01184 | 148932.0282 | |a4| = 466222.0014 | |

| Σ | A = −3937526 | |||||||||

| II | 5 | 0.1524 | 100 | B1 = 0.0778 | +1 | 730114.00 | 1.31 × 10−4 | 0.01423 | 84860.18126 | |b1| = 2182118.947 |

| 6 | 0.3048 | 200 | B2 = −0.0139 | −1 | 65188.75 | 6.56 × 10−5 | 0.01998 | −237.4945042 | |b2| = 34199.2086 | |

| 11 | 0.1524 | 100 | B3 = −0.0556 | −1 | 521510.00 | 1.31 × 10−4 | 0.01470 | −44732.90001 | |b3| = 1610384.4 | |

| 12 | 0.1524 | 100 | B4 = −0.0833 | −1 | 782265.00 | 1.31 × 10−4 | 0.01414 | −96832.35986 | |b4| = 2323976.637 | |

| 2 | 0.3048 | 100 | B5 = 0.0694 | +1 | 325943.75 | 6.56 × 10−5 | 0.01492 | 2217.677686 | |b5| = 63869.11737 | |

| Σ | B = −54725 | |||||||||

| III | 7 | 0.1524 | 100 | C1 = 0.0083 | +1 | 78226.50 | 1.31 × 10−4 | 0.01954 | 1338.024663 | |c1| = 321125.9191 |

| 8 | 0.1524 | 100 | C2 = −0.0389 | −1 | 365057.00 | 1.31 × 10−4 | 0.01531 | −22830.90776 | |c2| = 1174160.971 | |

| 9 | 0.3048 | 100 | C3 = 0.1139 | +1 | 534547.75 | 6.56 × 10−5 | 0.01391 | 5557.748158 | |c3| = 97599.47985 | |

| 10 | 0.1524 | 100 | C4 = 0.0361 | +1 | 338981.50 | 1.31 × 10−4 | 0.01545 | 19868.97118 | |c4| = 1100435.327 | |

| 6 | 0.3048 | 200 | C5 = 0.0139 | +1 | 65188.75 | 6.56 × 10−5 | 0.01998 | 237.4945042 | |c5| = 34199.2086 | |

| Σ | C = 4171 | |||||||||

| IV | 3 | 0.1524 | 100 | D1 = 0.5667 | +1 | 5319401.99 | 1.31 × 10−4 | 0.01290 | 4084603.502 | |d1| = 14416247.66 |

| 12 | 0.1524 | 100 | D2 = 0.0833 | +1 | 782265.00 | 1.31 × 10−4 | 0.01414 | 96832.35986 | |d2| = 2323976.637 | |

| 13 | 0.1524 | 100 | D3 = −0.0278 | −1 | 260755.00 | 1.31 × 10−4 | 0.01600 | −12174.73104 | |d3| = 876580.635 | |

| 14 | 0.4064 | 100 | D4 = −0.7222 | −1 | 2542361.25 | 4.92 × 10−5 | 0.01157 | −44129.48853 | |d4| = 122204.7375 | |

| Σ | D = 4125132 | |||||||||

| V | 15 | 0.1524 | 200 | E1 = 0.3889 | +1 | 3650569.99 | 1.31 × 10−4 | 0.01302 | 3882751.322 | |e1| = 19968435.37 |

| 9 | 0.3048 | 100 | E2 = 0.1139 | +1 | 534547.75 | 6.56 × 10−5 | 0.01391 | 5557.748158 | |e2|= 97599.47985 | |

| 10 | 0.1524 | 100 | E3 = 0.0361 | +1 | 338981.50 | 1.31 × 10−4 | 0.01545 | 19868.97118 | |e3| = 1100435.327 | |

| 11 | 0.1524 | 100 | E4 = −0.0556 | −1 | 521510.00 | 1.31 × 10−4 | 0.01470 | −44732.90001 | |e4| = 1610384.4 | |

| 12 | 0.1524 | 100 | E5 = −0.0833 | −1 | 782265.00 | 1.31 × 10−4 | 0.01414 | −96832.35986 | |e5| = 2323976.637 | |

| Σ | E = 3766613 |

| Flow in m3/h | c Gas Velocity | ||||||

|---|---|---|---|---|---|---|---|

| Iteration | a 0 | 1 | 2 | 3 | 4 | b 5 | m/s |

| Pipe 1 | 200 | 687.38 | 1172.23 | 1225.74 | 1228.19 | 1228.19 | 0.66 |

| Pipe 2 | 250 | 33.55 | −307.01 | 360.38 | 362.80 | 362.80 | 0.35 |

| Pipe 3 | 2040 | 988.81 | 618.87 | 550.48 | 547.68 | 547.68 | 2.08 |

| Pipe 4 | 2300 | 2787.38 | 3272.23 | 3325.74 | 3328.19 | 3328.19 | 3.17 |

| Pipe 5 | 280 | 550.93 | 695.22 | 695.36 | 695.39 | 695.39 | 2.65 |

| Pipe 6 | 50 | 78.54 | −60.99 | 50.63 | 50.73 | 50.73 | 0.05 |

| Pipe 7 | 30 | 329.48 | 334.23 | 344.74 | 344.66 | 344.66 | 1.31 |

| Pipe 8 | 140 | −159.48 | 164.23 | 174.74 | 174.66 | 174.66 | 0.66 |

| Pipe 9 | 410 | 20.26 | −121.61 | 115.19 | 115.28 | 115.28 | 0.11 |

| Pipe 10 | 130 | −259.74 | 401.61 | 395.19 | 395.28 | 395.28 | 1.50 |

| Pipe 11 | 200 | 618.28 | 620.62 | 624.57 | 624.55 | 624.55 | 2.38 |

| Pipe 12 | 300 | 154.48 | 271.72 | 260.79 | 260.43 | 260.43 | 0.99 |

| Pipe 13 | 100 | 663.80 | 548.90 | 563.78 | 564.13 | 564.13 | 2.15 |

| Pipe 14 | 2600 | 3163.80 | 3048.90 | 3063.78 | 3064.13 | 3064.13 | 1.64 |

| Pipe 15 | 1400 | 710.78 | 564.16 | 560.07 | 560.05 | 560.05 | 2.13 |

| Flow in m3/h | Water Velocity m/s | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Iteration | a 0 | 1 | 2 | 3 | 4 | 5 | 6 | b 7 | |

| Pipe 1 | 200 | 619.22 | 1117.82 | 1205.89 | 1214.92 | 1215.25 | 1215.26 | 1215.26 | 2.6 |

| Pipe 2 | 250 | 69.21 | −260.68 | 345.80 | 354.68 | 355.00 | 355.01 | 355.01 | 1.4 |

| Pipe 3 | 2040 | 1071.47 | 671.88 | 567.12 | 556.60 | 556.22 | 556.21 | 556.21 | 8.5 |

| Pipe 4 | 2300 | 2719.22 | 3217.82 | 3305.89 | 3314.92 | 3315.25 | 3315.26 | 3315.26 | 12.6 |

| Pipe 5 | 280 | 518.43 | 687.14 | 690.09 | 690.24 | 690.25 | 690.25 | 690.25 | 10.5 |

| Pipe 6 | 50 | 90.95 | −57.70 | 43.41 | 43.11 | 43.10 | 43.10 | 43.10 | 0.2 |

| Pipe 7 | 30 | 309.38 | 329.44 | 346.68 | 347.13 | 347.15 | 347.15 | 347.15 | 5.3 |

| Pipe 8 | 140 | −139.38 | 159.44 | 176.68 | 177.13 | 177.15 | 177.15 | 177.15 | 2.7 |

| Pipe 9 | 410 | 47.60 | −115.49 | 113.24 | 113.39 | 113.39 | 113.39 | 113.39 | 0.4 |

| Pipe 10 | 130 | −232.40 | 395.49 | 393.24 | 393.39 | 393.39 | 393.39 | 393.39 | 6.0 |

| Pipe 11 | 200 | 603.35 | 617.79 | 629.83 | 630.28 | 630.29 | 630.29 | 630.29 | 9.6 |

| Pipe 12 | 300 | 154.04 | 267.49 | 262.84 | 261.80 | 261.76 | 261.76 | 261.76 | 4.0 |

| Pipe 13 | 100 | 649.31 | 550.30 | 566.99 | 568.48 | 568.53 | 568.54 | 568.54 | 8.7 |

| Pipe 14 | 2600 | 3149.31 | 3050.30 | 3066.99 | 3068.48 | 3068.53 | 3068.54 | 3068.54 | 6.6 |

| Pipe 15 | 1400 | 758.22 | 575.07 | 560.08 | 559.48 | 559.46 | 559.46 | 559.46 | 8.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brkić, D.; Praks, P. An Efficient Iterative Method for Looped Pipe Network Hydraulics Free of Flow-Corrections. Fluids 2019, 4, 73. https://doi.org/10.3390/fluids4020073

Brkić D, Praks P. An Efficient Iterative Method for Looped Pipe Network Hydraulics Free of Flow-Corrections. Fluids. 2019; 4(2):73. https://doi.org/10.3390/fluids4020073

Chicago/Turabian StyleBrkić, Dejan, and Pavel Praks. 2019. "An Efficient Iterative Method for Looped Pipe Network Hydraulics Free of Flow-Corrections" Fluids 4, no. 2: 73. https://doi.org/10.3390/fluids4020073

APA StyleBrkić, D., & Praks, P. (2019). An Efficient Iterative Method for Looped Pipe Network Hydraulics Free of Flow-Corrections. Fluids, 4(2), 73. https://doi.org/10.3390/fluids4020073