Hydrodynamic Performance and Cavitation Characteristics of an Integrated Pump-Gate

Abstract

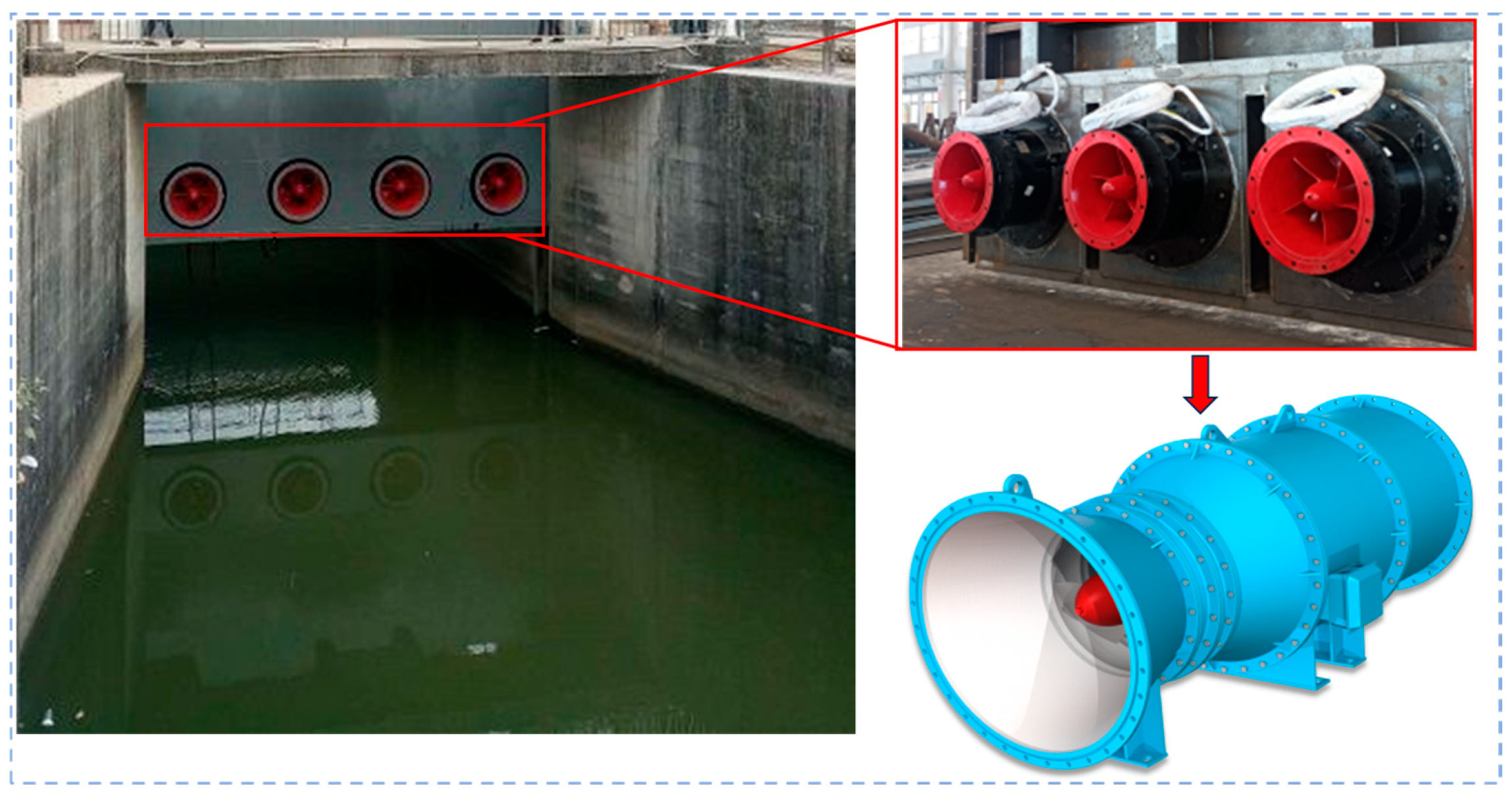

1. Introduction

2. Numerical Calculation Method

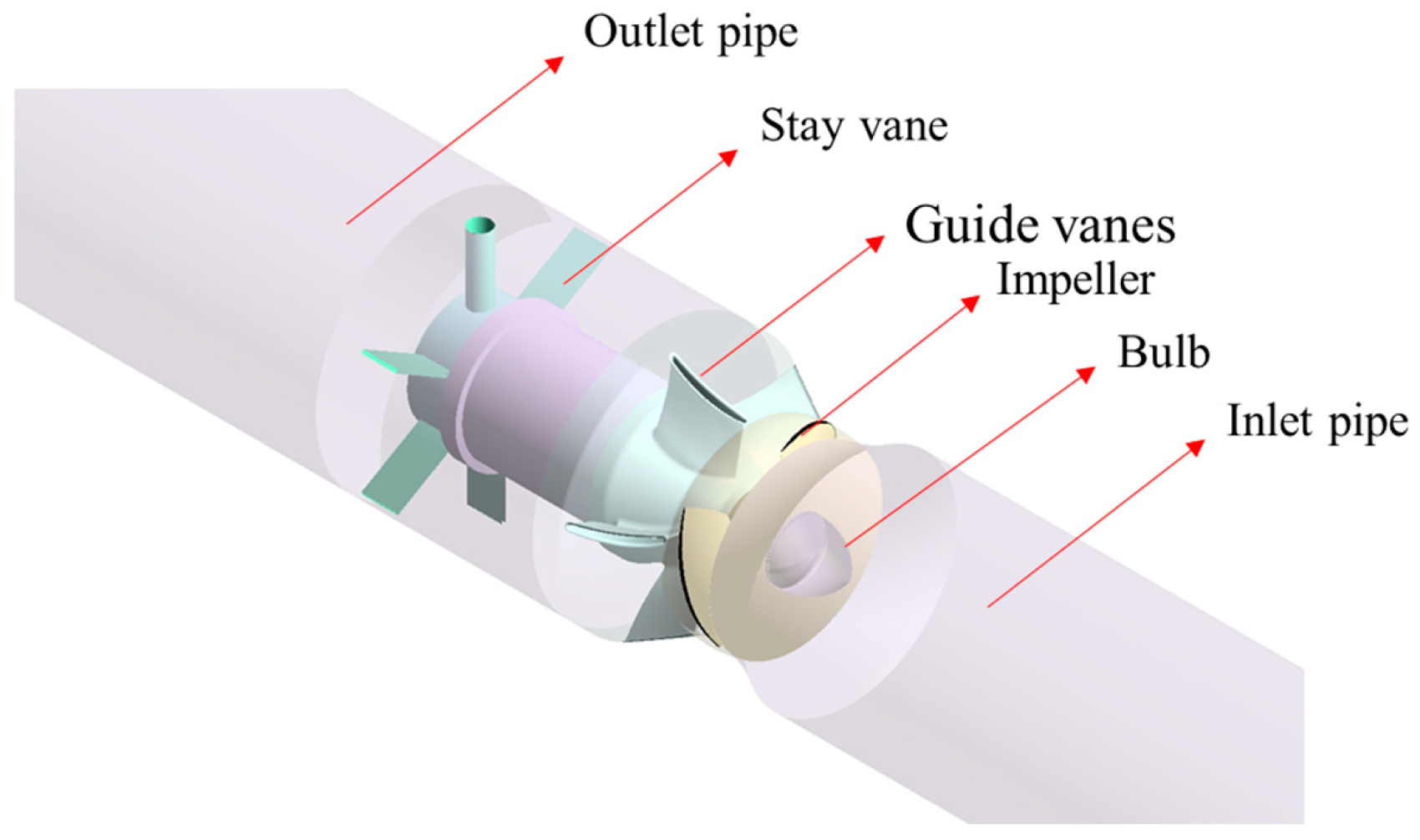

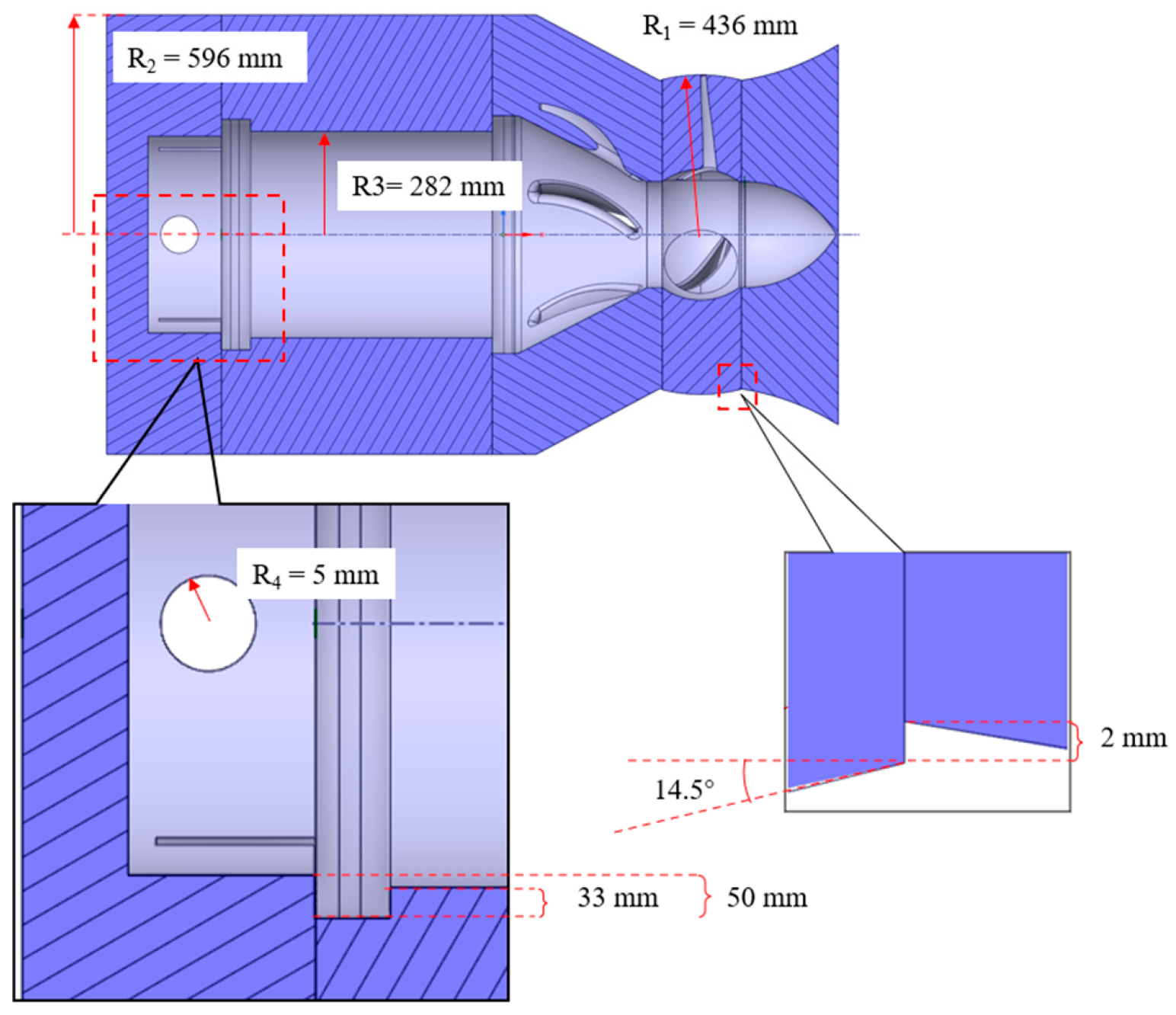

2.1. Geometric Models

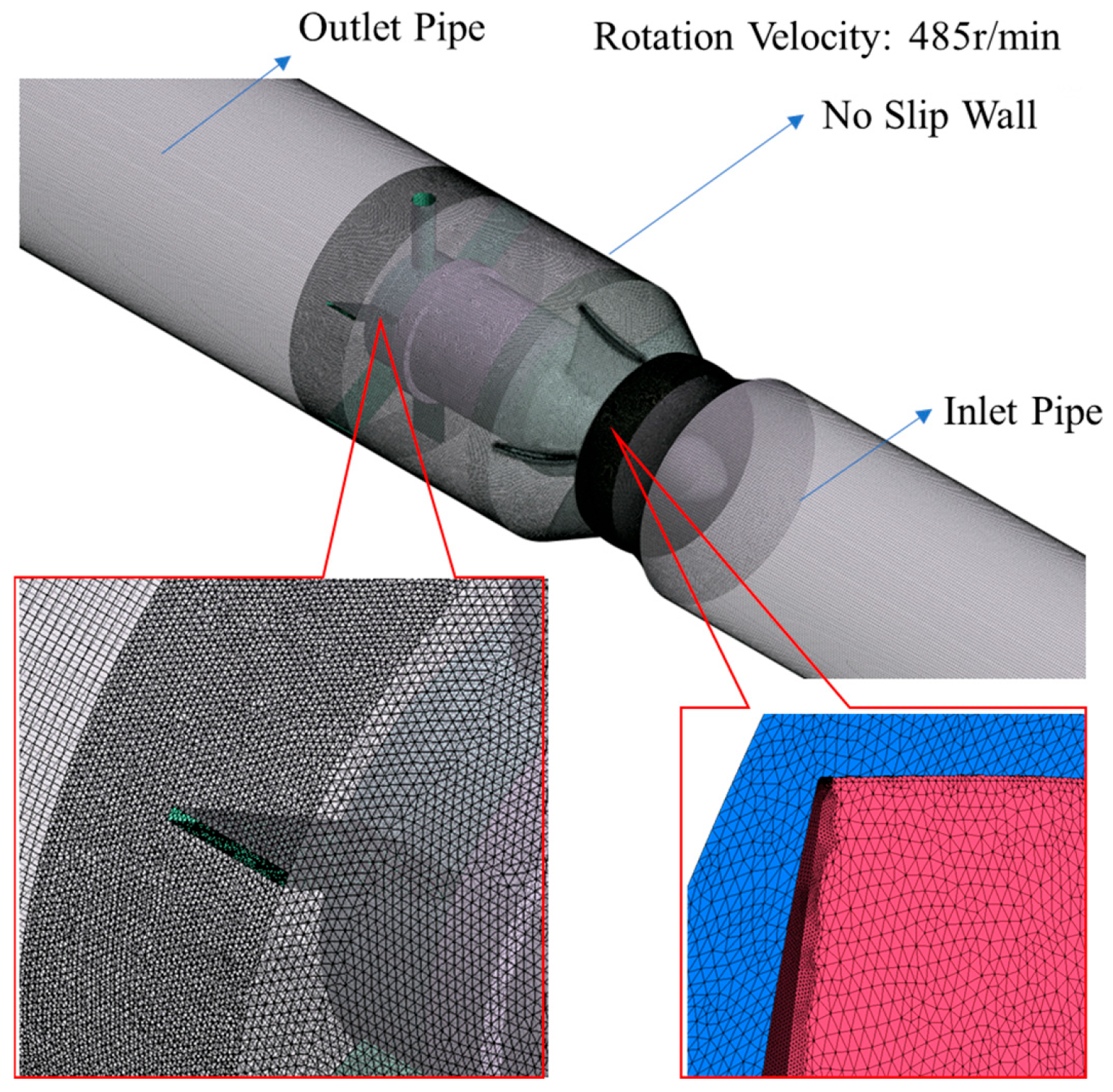

2.2. Mesh Generation

2.3. Governing Equations

2.4. Turbulence and Cavitation Model

2.5. Boundary Conditions

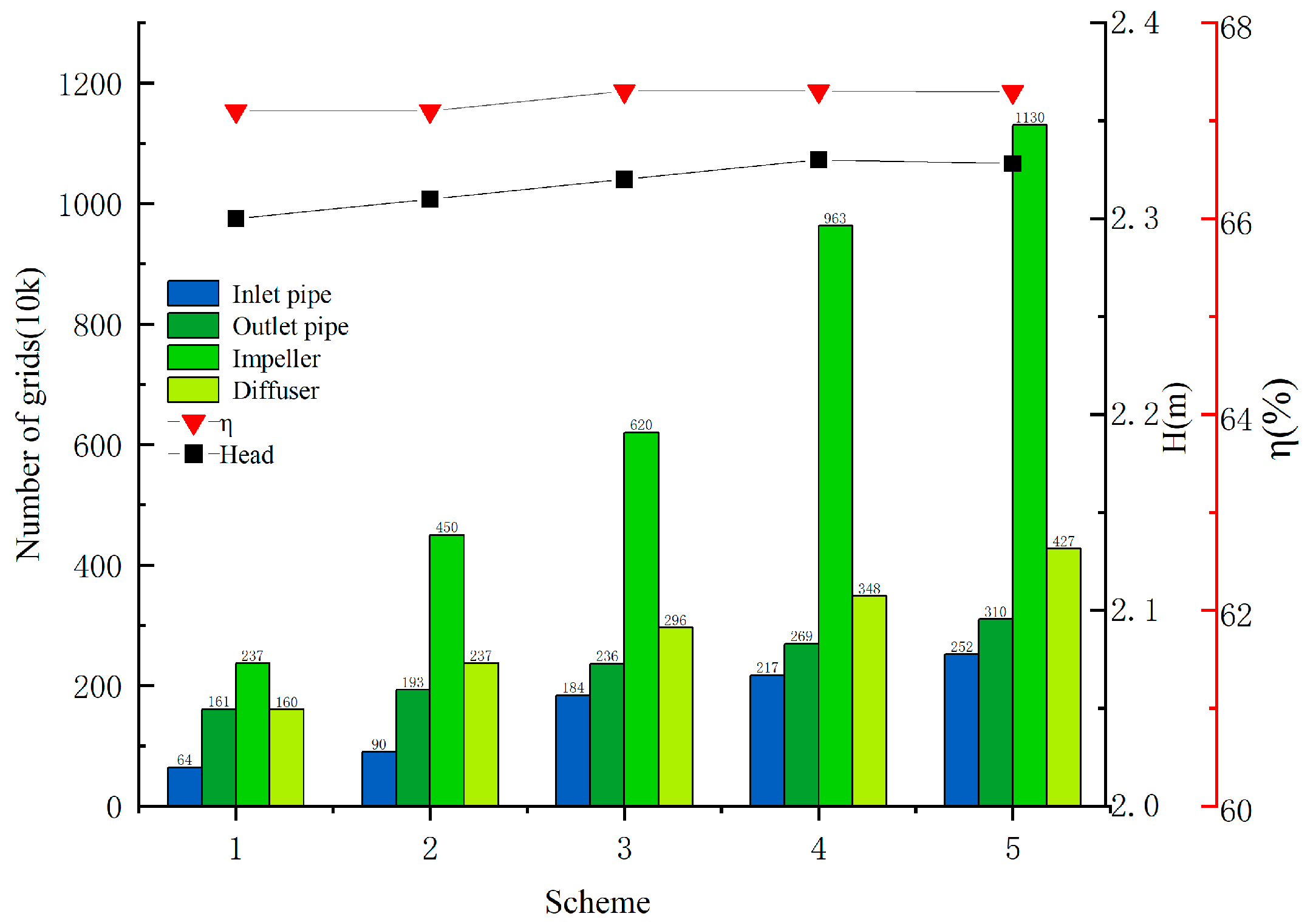

2.6. Grid-Independence

3. Cavitation Characteristics and Coherent Vortical Structures

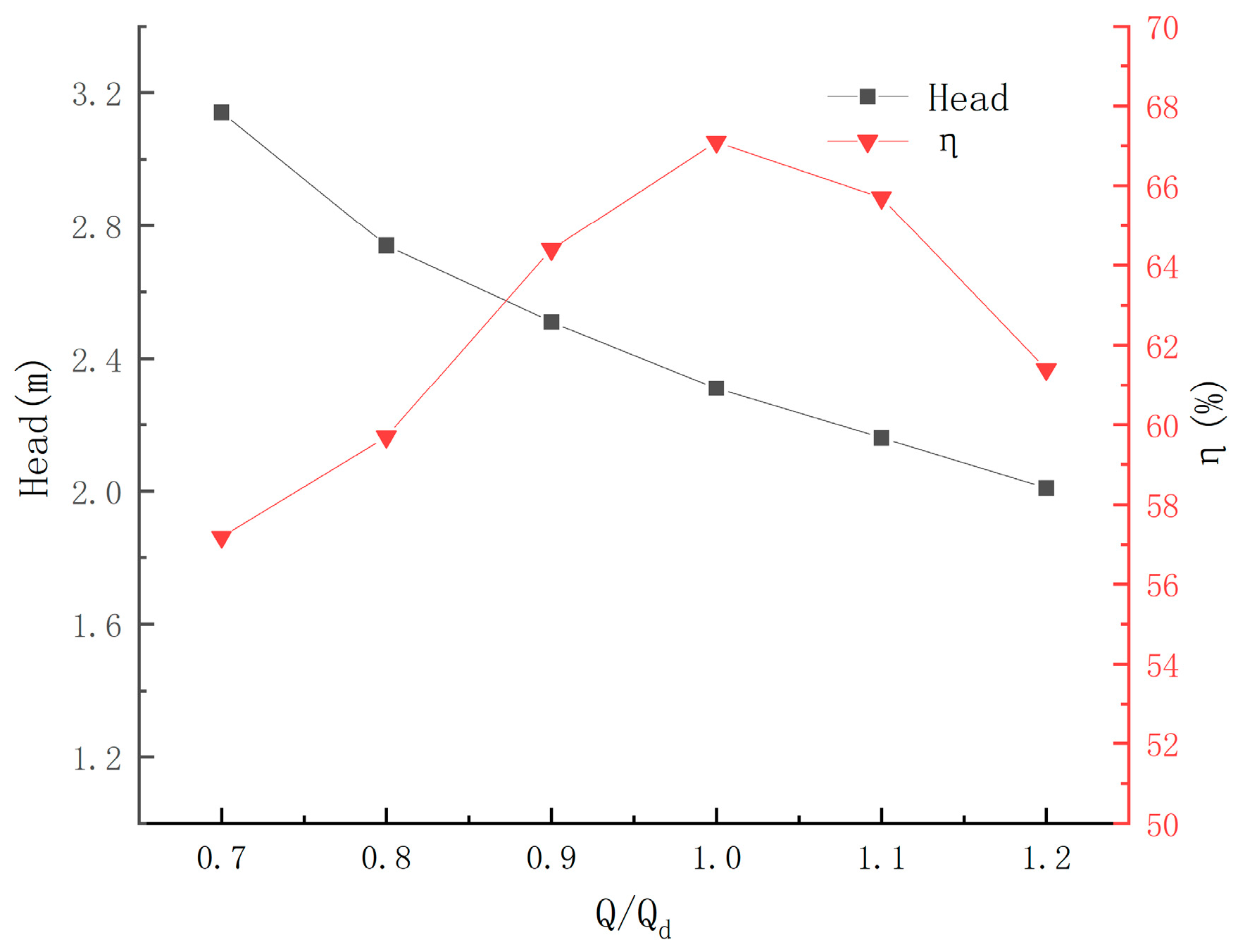

3.1. Hydraulic Performance Test Results

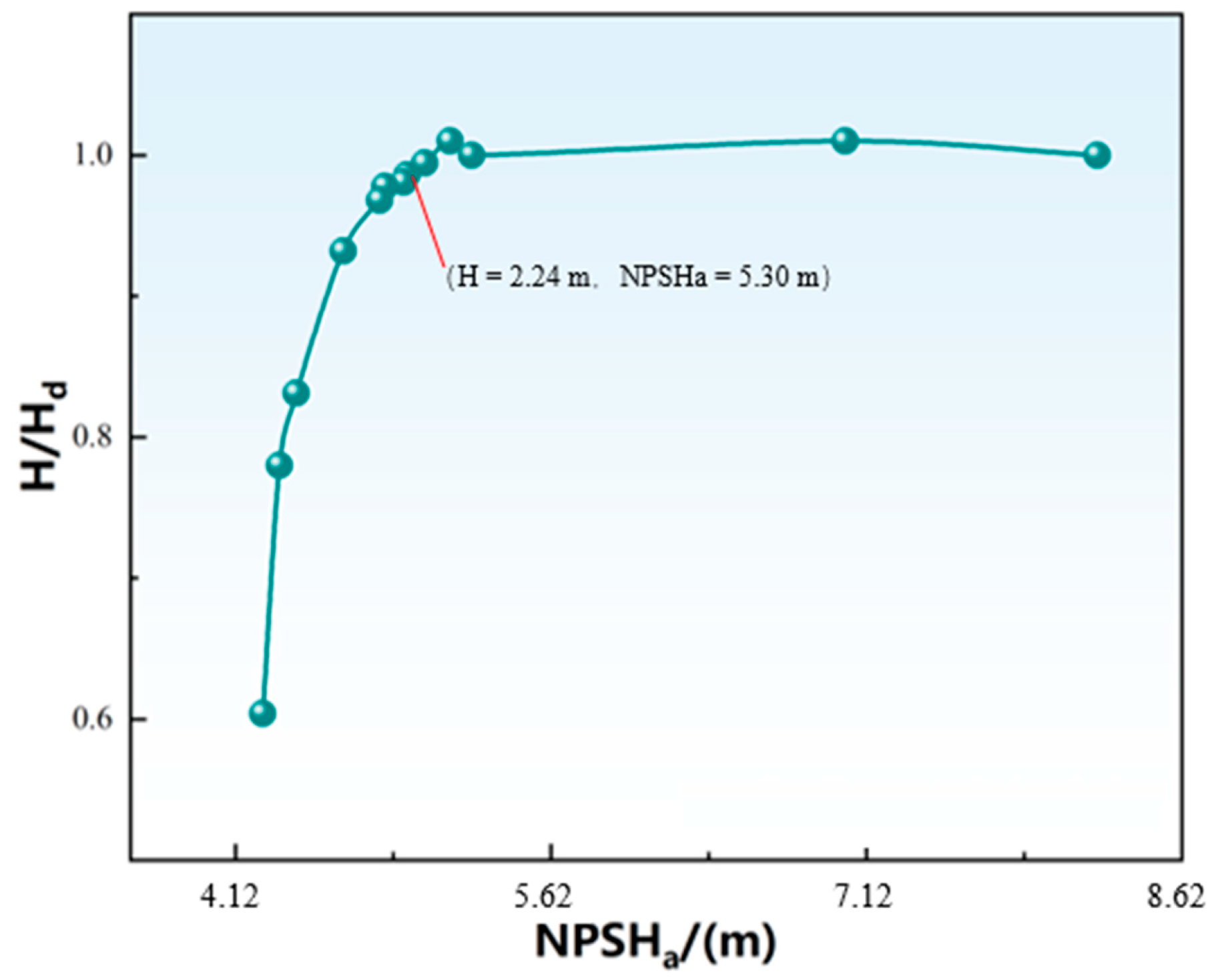

3.2. Cavitation Performance Curve and Inception Characteristics

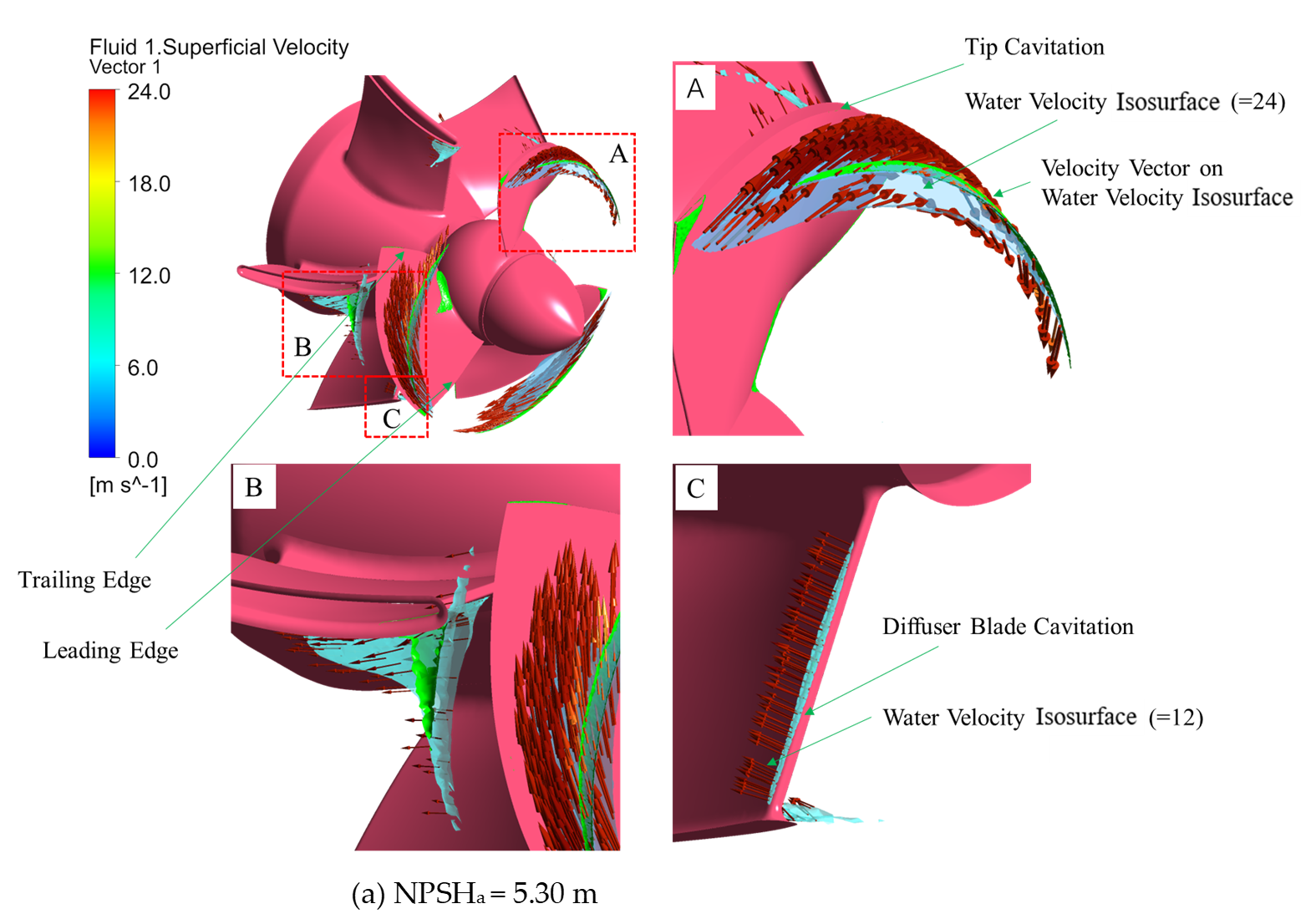

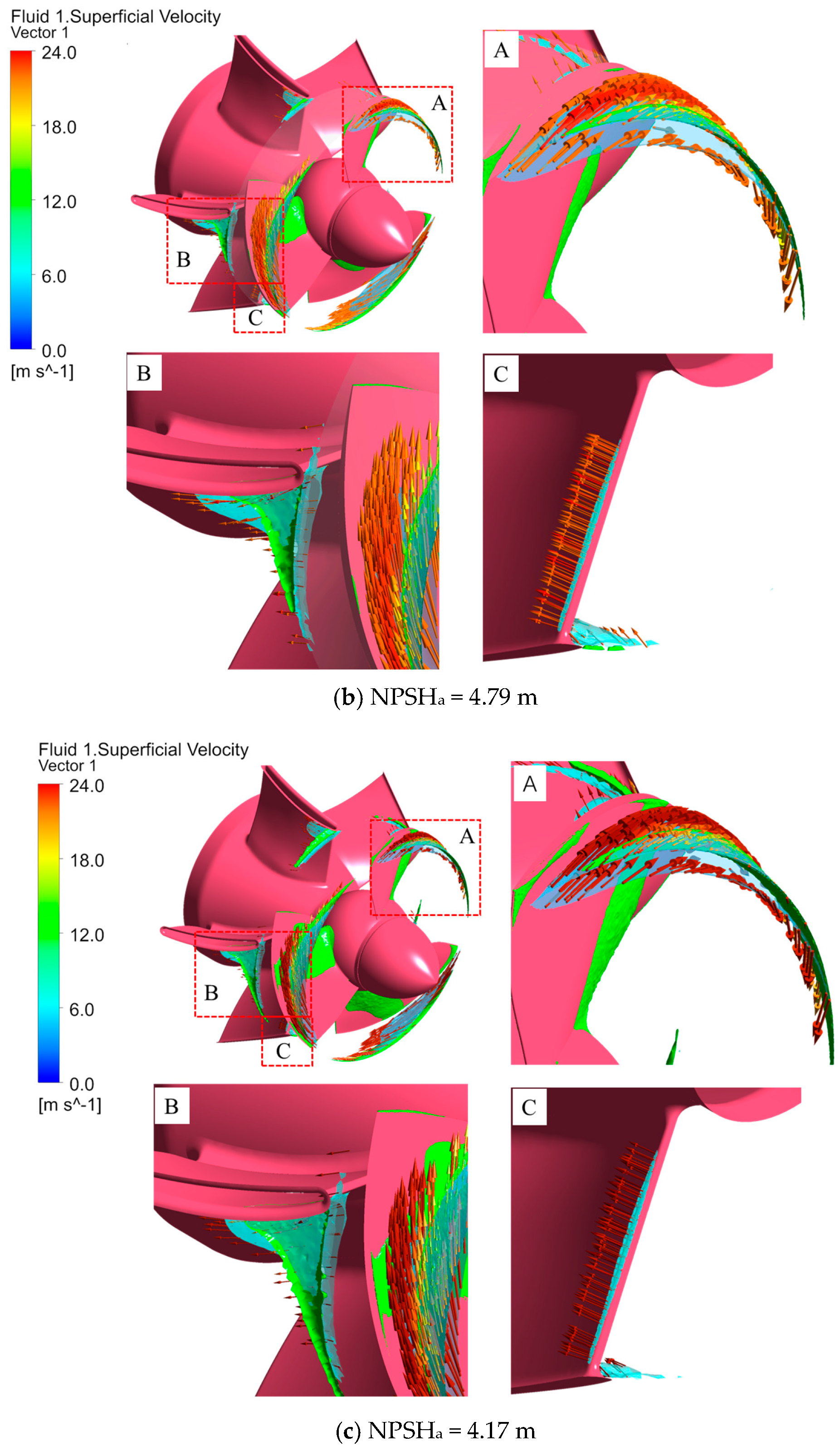

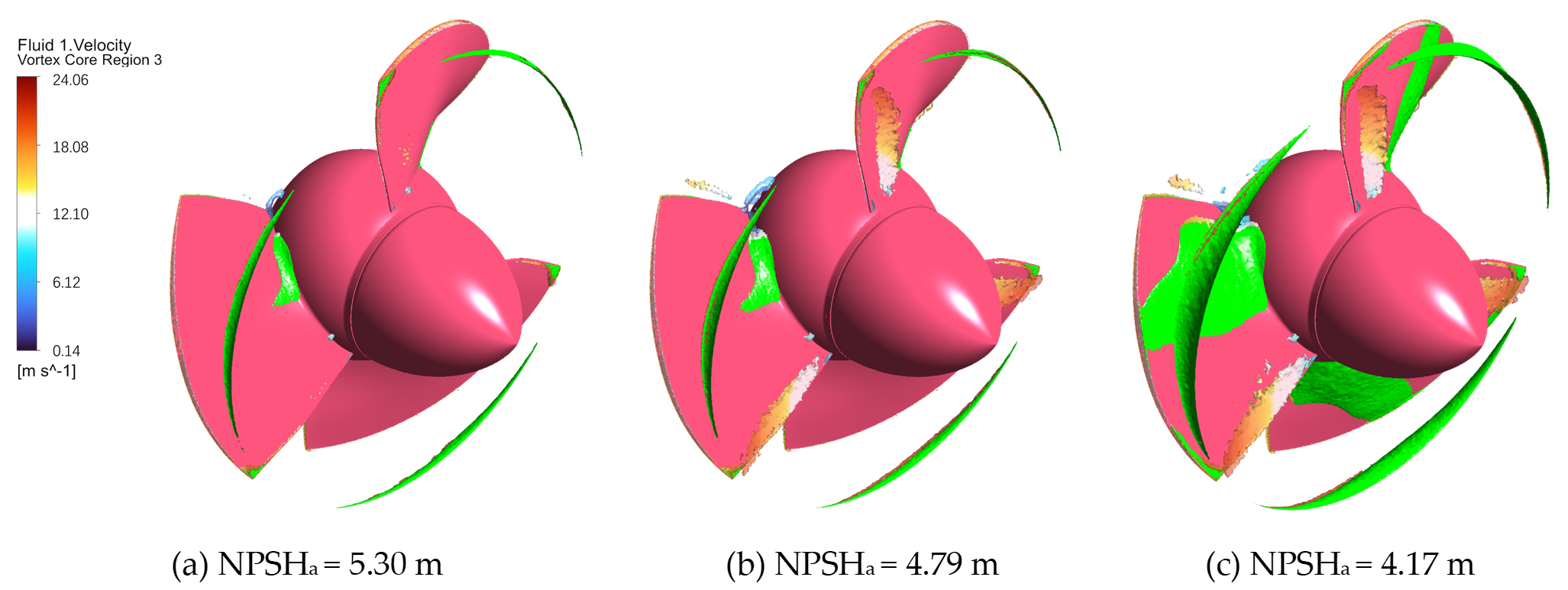

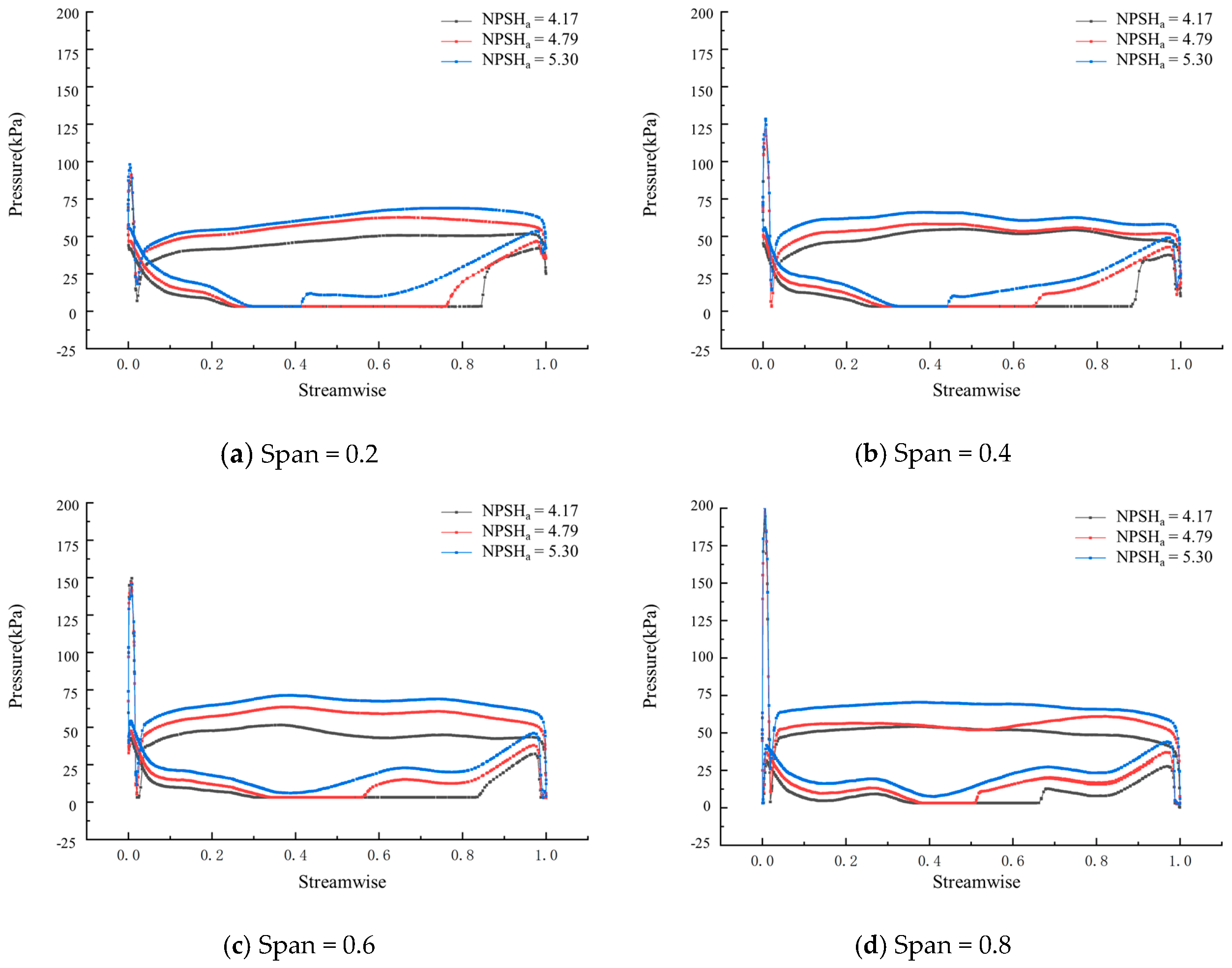

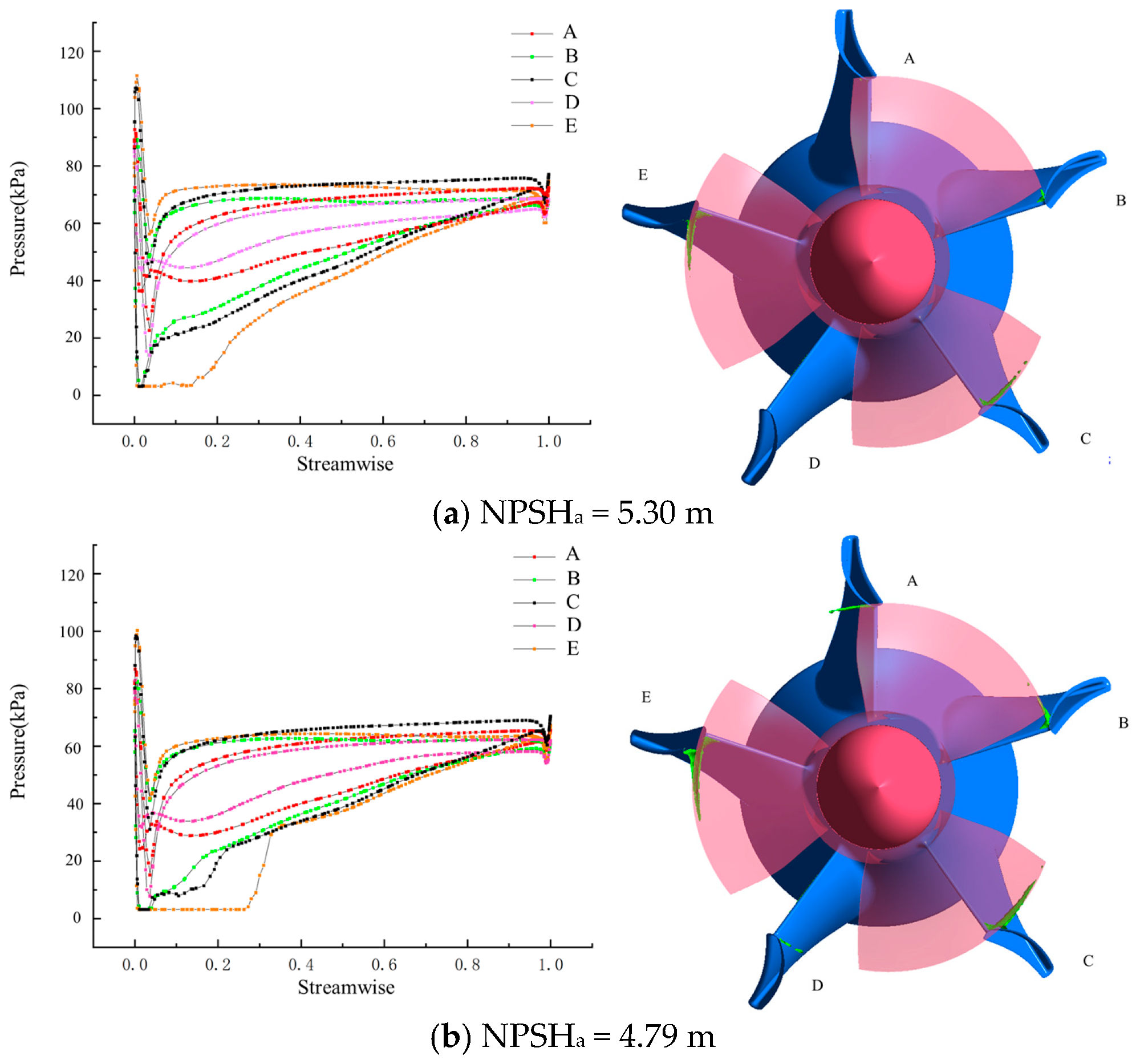

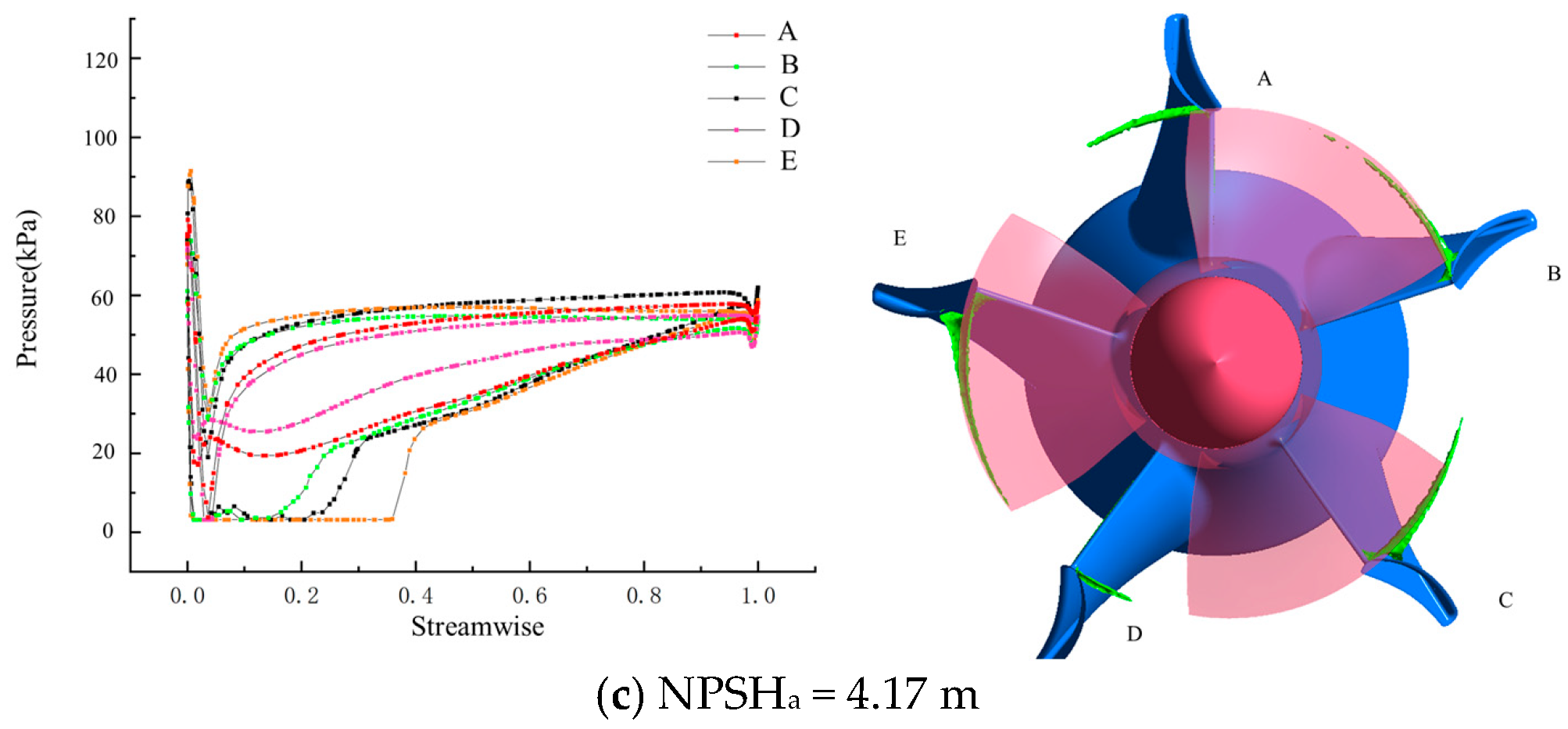

3.3. Cavitation Distribution and Its Coupling with Local Flow Topology

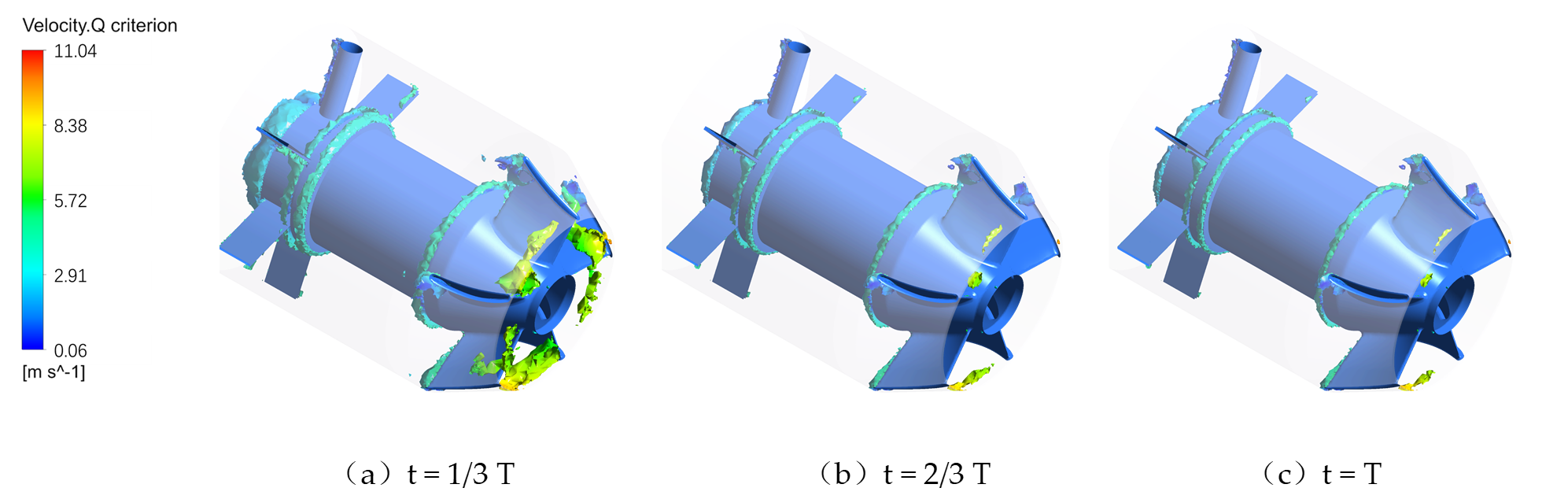

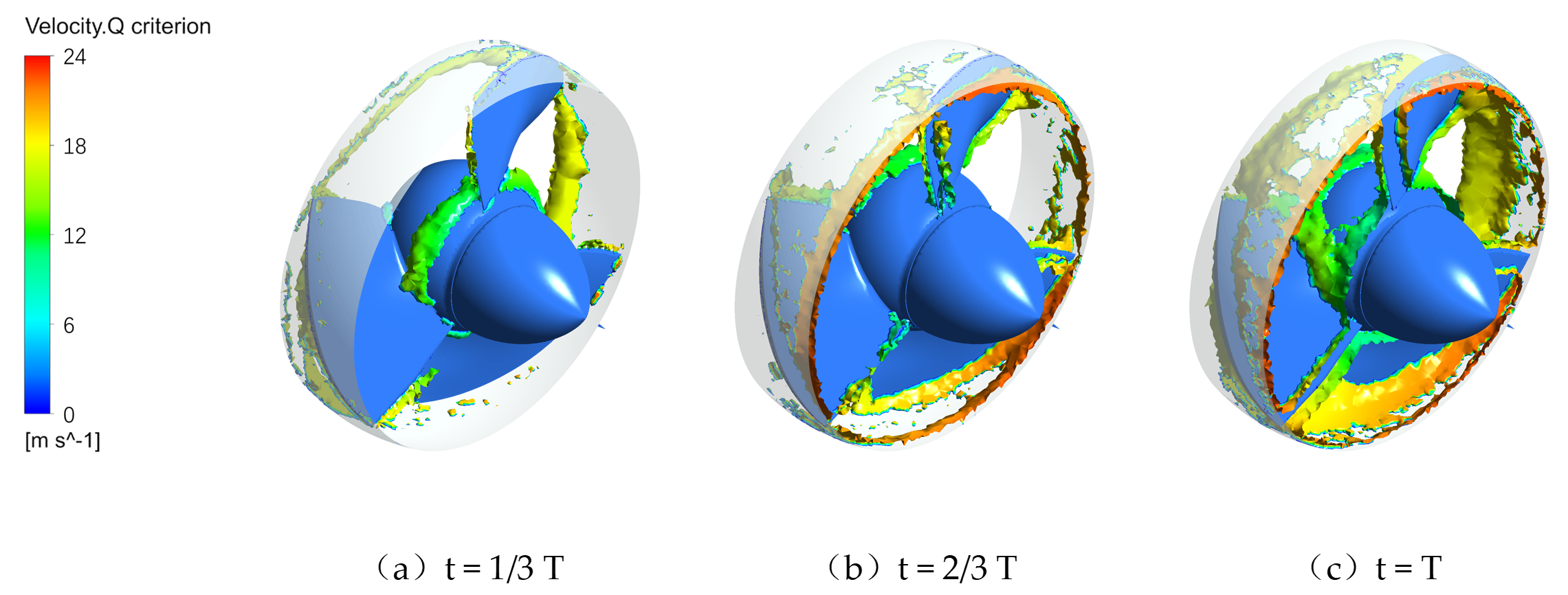

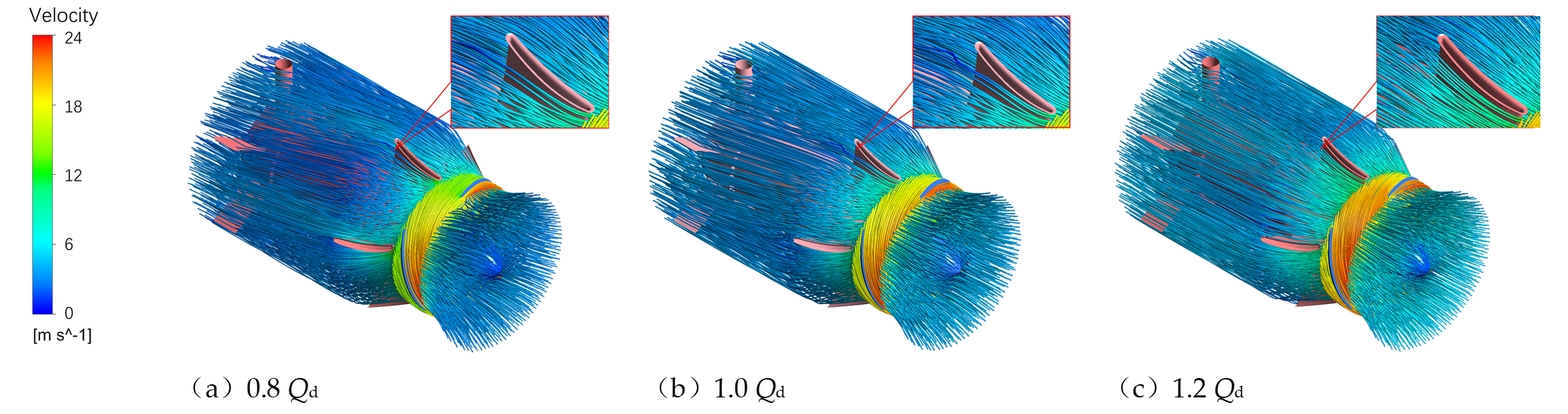

3.4. Unsteady Flow Characteristics of Integrated Pump Gates

4. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Zang, J.; Shi, W.; Zhang, D. Analysis of the formation mechanism and evolution of the perpendicular cavitation vortex of tip leakage flow in an axial-flow pump for off-design conditions. J. Mar. Sci. Eng. 2021, 9, 1045. [Google Scholar] [CrossRef]

- Xie, C.; Fu, T.; Xuan, W.; Bai, C.; Wu, L. Optimization and internal flow analysis of inlet and outlet horn of integrated pump gate. Processes 2022, 10, 1753. [Google Scholar] [CrossRef]

- Li, S.; Shen, C.; Sun, T.; Cheng, L.; Lei, S.; Xia, C.; Zhang, C. Numerical simulation analysis on hydraulic optimization of the integrated pump gate. Energies 2022, 15, 4664. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, F.; Shi, L.; Hu, Q.; Zhou, Y. Effects of an inlet vortex on the performance of an axial-flow pump. Energies 2020, 13, 2854. [Google Scholar] [CrossRef]

- Guo, Z.; Pan, J.; Qian, Z.; Ji, B. Experimental and numerical analysis of the unsteady influence of the inlet guide vanes on cavitation performance of an axial pump. Part C J. Mech. Eng. Sci. 2019, 233, 11. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, L. Tip clearance on pressure fluctuation intensity and vortex characteristic of a mixed-flow pump as turbine at pump mode. Renew. Energy 2018, 129, 606–615. [Google Scholar] [CrossRef]

- Kim, M.-C.; Chun, H.-H. Experimental investigation into the performance of the axial-flow-type waterjet according to the variation of impeller tip clearance. Ocean Eng. 2007, 34, 275–283. [Google Scholar] [CrossRef]

- Fan, X.; Dong, W.; Li, P.; Li, S. Research on cavitation energy characteristics of mixed-flow pump based on entropy production theory and multi-resolution dynamic mode decomposition (MRDMD). Int. J. Heat Mass Transf. 2026, 255, 127812. [Google Scholar] [CrossRef]

- Boulon, O.; Callenaere, M.; Franc, J.-P.; Michel, J.-M. An experimental insight into the effect of confinement on tip vortex cavitation of an elliptical hydrofoil. J. Fluid Mech. 2000, 390, 1–23. [Google Scholar] [CrossRef]

- Higashi, S.; Yoshida, Y.; Tsujimoto, Y. Tip leakage vortex cavitation from the tip clearance of a single hydrofoil. JSME Int. J. Ser. B Fluids Therm. Eng. 2002, 45, 662–671. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, D.; Jin, Y.; Shi, W.; van Esch, B.P.M. A study on tip leakage vortex dynamics and cavitation in axial-flow pump. Fluid Dyn. Res. 2017, 49, 035504. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, D.; Zhao, R.; Shi, W.; Jin, Y. Effect of blade tip geometry on tip leakage vortex dynamics and cavitation pattern in axial-flow pump. Sci. China Technol. Sci. 2017, 60, 1480–1493. [Google Scholar] [CrossRef]

- Al-Obaidi, A.R.; Alwatban, A. Investigation of hydraulic transient flow and dynamic response performance of an axial pump based on novel vibration signal characteristics and numerical analyses. Alex. Eng. J. 2025, 125, 104–126. [Google Scholar] [CrossRef]

- Yu, L.; Cheng, L.; Xu, W.; Lei, S. Study on the influence of tip clearance on cavitation performance and entropy production of an axial flow pump. J. Mar. Sci. Eng. 2024, 12, 101. [Google Scholar] [CrossRef]

- He, G.; Tang, C.; Yang, K.; Yang, D.; Yuan, L.; Lan, Z.; Zhang, R.; Chen, J.; Li, Y.; Hu, X. Study on pressure pulsation characteristics of integrated pump gate. J. Appl. Fluid Mech. 2025, 19, 92–102. [Google Scholar] [CrossRef]

- Liu, H.; Tang, F.; Shi, L.; Dai, L.; Shen, J.; Liu, J. The analysis of cavitation flow and pressure pulsation of a bi-directional pump. J. Mar. Sci. Eng. 2023, 11, 268. [Google Scholar] [CrossRef]

- Liu, M.; Long, Y.; Zheng, Y.; Zhong, J.; Yin, H. Research on the comparison of the flow evolution mechanisms of a water-jet pump between valley and peak conditions. J. Mar. Sci. Eng. 2024, 12, 2352. [Google Scholar] [CrossRef]

- Long, Y.; An, C.; Zhu, R.; Chen, J. Research on hydrodynamics of high-velocity regions in a water-jet pump based on experimental and numerical calculations at different cavitation conditions. Phys. Fluids 2021, 33, 045124. [Google Scholar] [CrossRef]

- Jiao, W.; Jia, X.; Cheng, L.; Xu, J.; Liang, A.; Fan, H.; Lu, J. Numerical simulation and experimental study on cavitation and pressure fluctuation characteristics of low-head pumped storage system under pump operating conditions. Energy 2025, 328, 136515. [Google Scholar] [CrossRef]

- Zheng, Y.; Long, Y.; Liu, M.; Han, H.; Wang, K.; Zhong, J. Study on cavitation flow structure evolution in the hump region of water-jet pumps under the valley condition. J. Mar. Sci. Eng. 2025, 13, 1598. [Google Scholar] [CrossRef]

- Zheng, Y.; Long, Y.; Wan, C.; Chen, J.; Cai, Y.; Zhong, J. Effects of airfoil parameters on the cavitation performance of water-jet propulsion pumps. Fluids 2025, 10, 227. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, H.; Ji, B.; Peng, X. Numerical investigation of inner structure and its formation mechanism of cloud cavitating flow. Int. J. Multiph. Flow 2023, 165, 104484. [Google Scholar] [CrossRef]

- Knapp, R.T. Recent investigations of the mechanics of cavitation and cavitation damage. Trans. ASME 1955, 77, 1045–1054. [Google Scholar] [CrossRef]

- Girimaji, S.S.; Abdol-Hamid, K.S. Partially-averaged Navier–Stokes model for turbulence: Implementation and validation. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005. AIAA Paper 2005-0502. [Google Scholar]

- Pelz, P.F.; Keil, T.; Gross, T.F. The transition from sheet to cloud cavitation. J. Fluid Mech. 2017, 817, 439–454. [Google Scholar] [CrossRef]

- Nichik, M.Y.; Ilyushin, B.B.; Kadivar, E.; Ould el Moctar, B.; Pervunin, K.S. Cavitation suppression and transformation of turbulence structure in the cross flow around a circular cylinder: Surface morphology and wettability effects. Ultrason. Sonochem. 2024, 106, 106875. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Unit | Value |

|---|---|---|

| Head | m | 2.3 |

| Rotational Speed | r/min | 485 |

| Blade number of impeller | 3 | |

| Number of guide vanes | 5 | |

| Mass flow rate | m3/h | 3040 |

| Tip clearance diameter | mm | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Li, Y.; Tang, Z.; Chen, Q.; Liu, D.; Zou, J.; Yang, D.; Luo, X.; Long, Y. Hydrodynamic Performance and Cavitation Characteristics of an Integrated Pump-Gate. Fluids 2026, 11, 41. https://doi.org/10.3390/fluids11020041

Li Y, Tang Z, Chen Q, Liu D, Zou J, Yang D, Luo X, Long Y. Hydrodynamic Performance and Cavitation Characteristics of an Integrated Pump-Gate. Fluids. 2026; 11(2):41. https://doi.org/10.3390/fluids11020041

Chicago/Turabian StyleLi, Yiming, Zhengwen Tang, Qiqing Chen, Deyang Liu, Jinxin Zou, David Yang, Xiangrong Luo, and Yun Long. 2026. "Hydrodynamic Performance and Cavitation Characteristics of an Integrated Pump-Gate" Fluids 11, no. 2: 41. https://doi.org/10.3390/fluids11020041

APA StyleLi, Y., Tang, Z., Chen, Q., Liu, D., Zou, J., Yang, D., Luo, X., & Long, Y. (2026). Hydrodynamic Performance and Cavitation Characteristics of an Integrated Pump-Gate. Fluids, 11(2), 41. https://doi.org/10.3390/fluids11020041