Enhancement of Aerodynamic Performance of Two Adjacent H-Darrieus Turbines Using a Dual-Rotor Configuration

Abstract

1. Introduction

2. Methodology

2.1. Geometrical Model

2.2. Computational Domain and Boundary Conditions

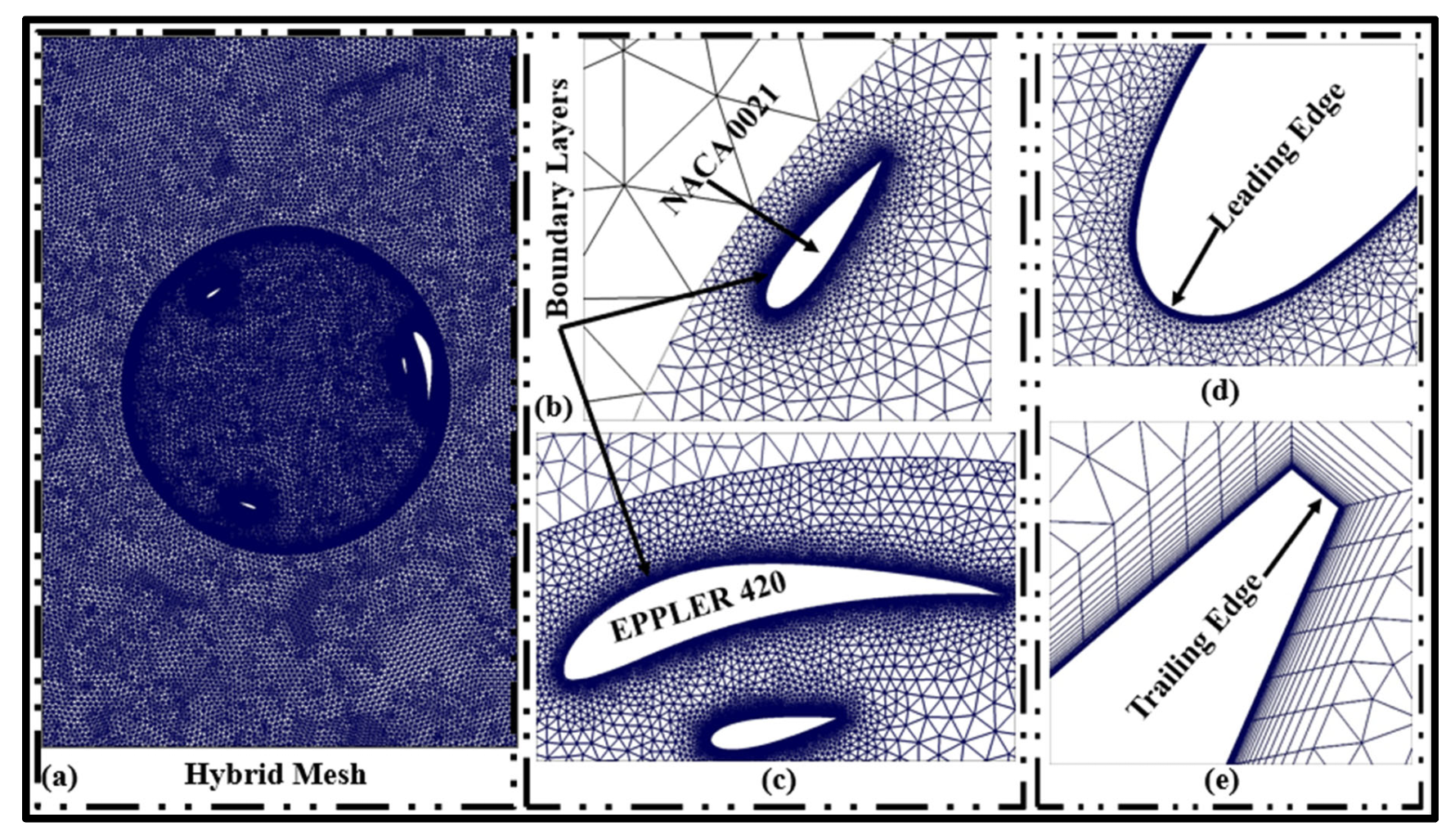

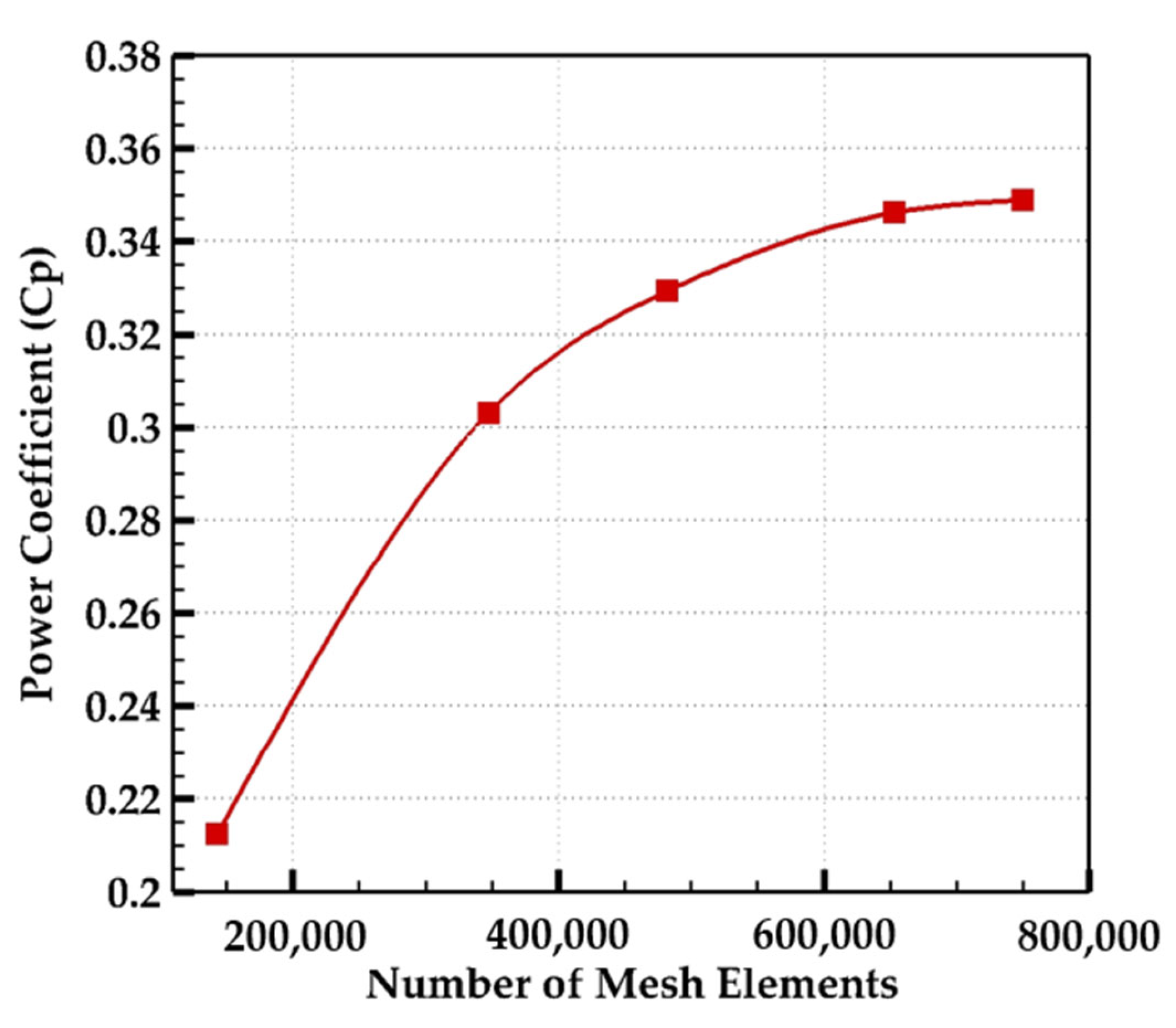

2.3. Mesh Generation and Grid Independence

2.4. Solver Settings

3. URANS Equations

3.1. Mass and Momentum Equations

3.2. Sliding Mesh Technique

3.3. SST K-Omega Turbulence Model

3.4. Performance Indicators

4. Results and Discussion

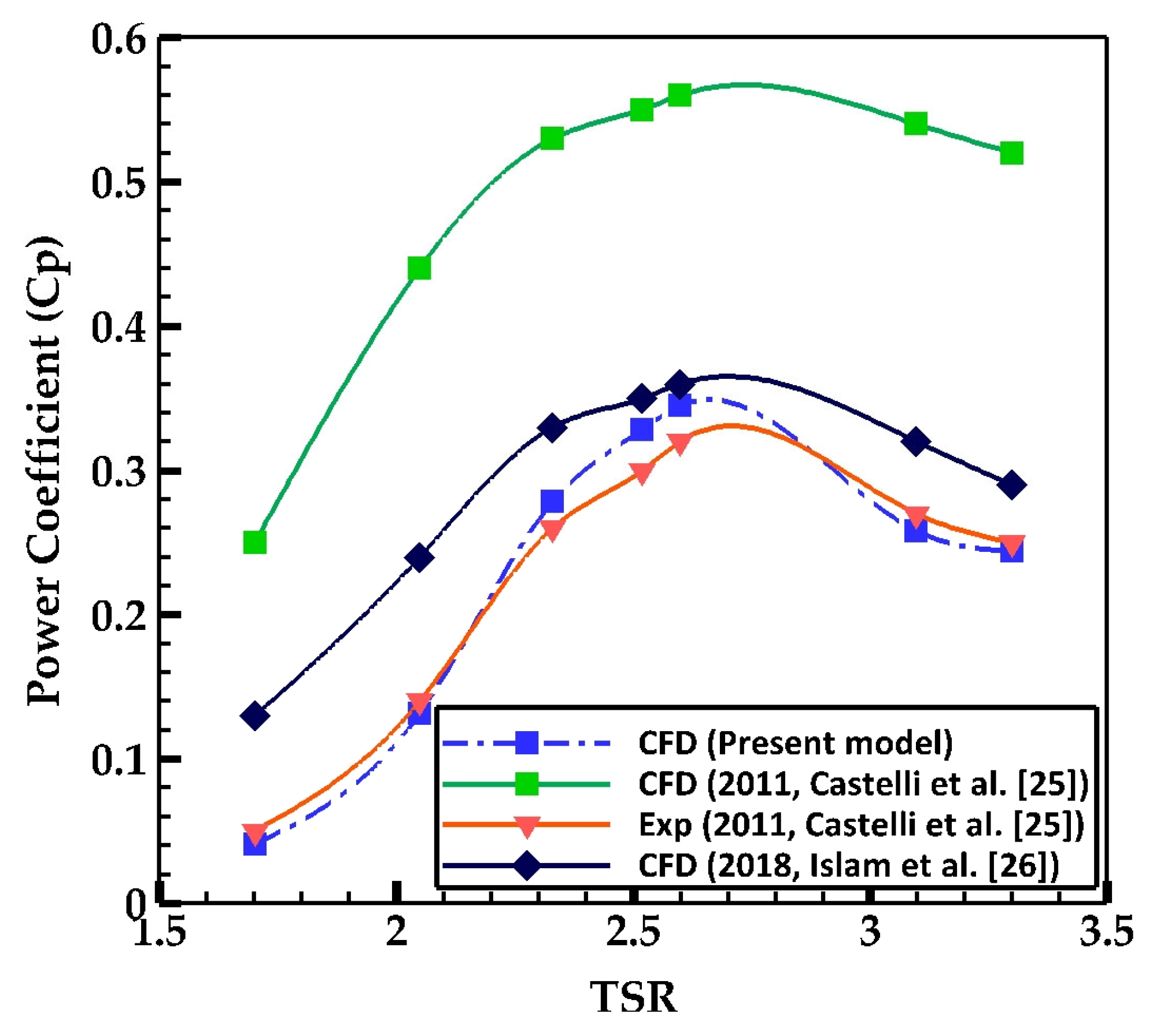

4.1. Validation

4.2. Parametric Study Analysis

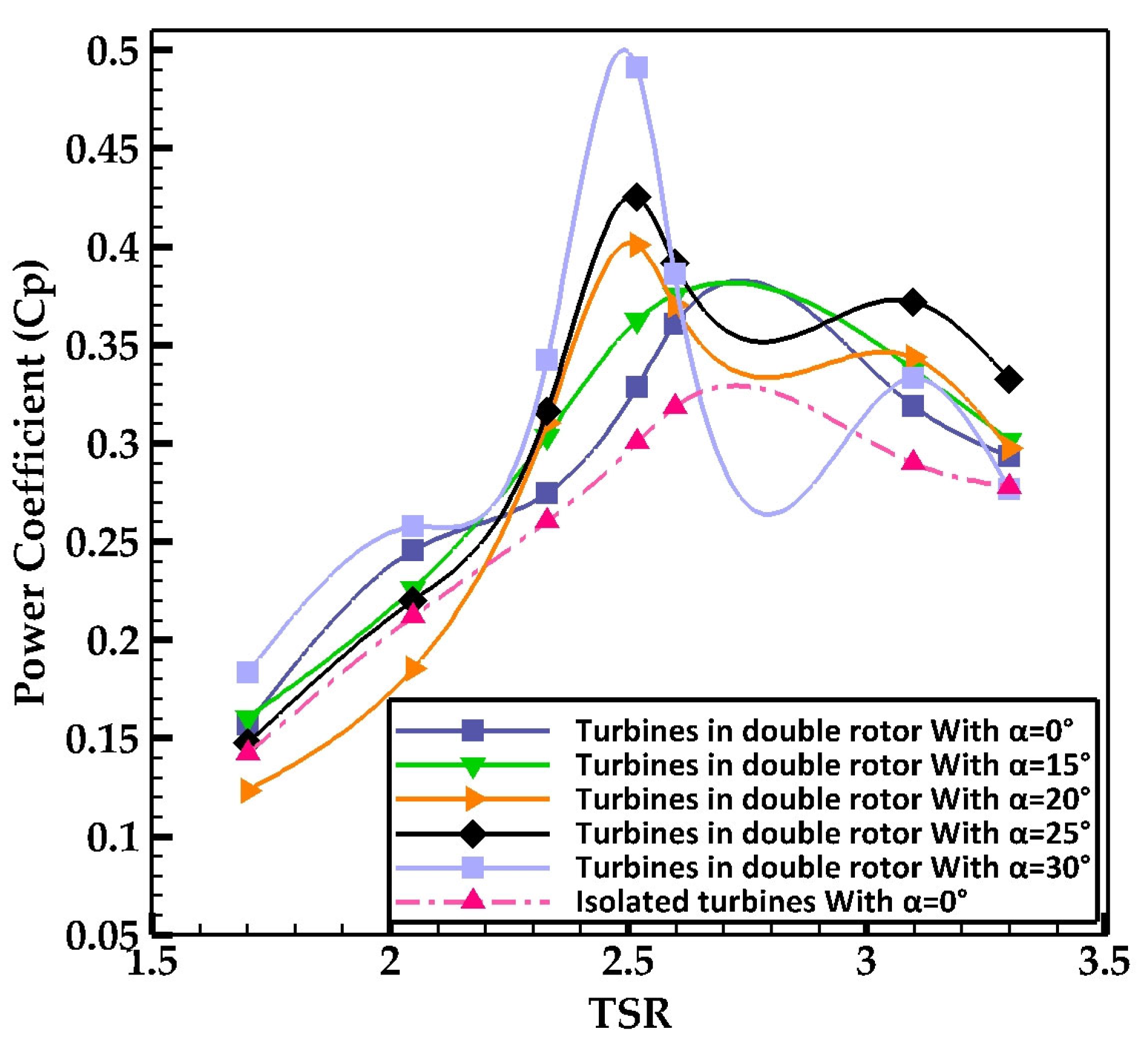

4.2.1. Analysis of Power and Torque Coefficients

4.2.2. Effect of Dual-Rotor Integration on the Performance of Two Turbines

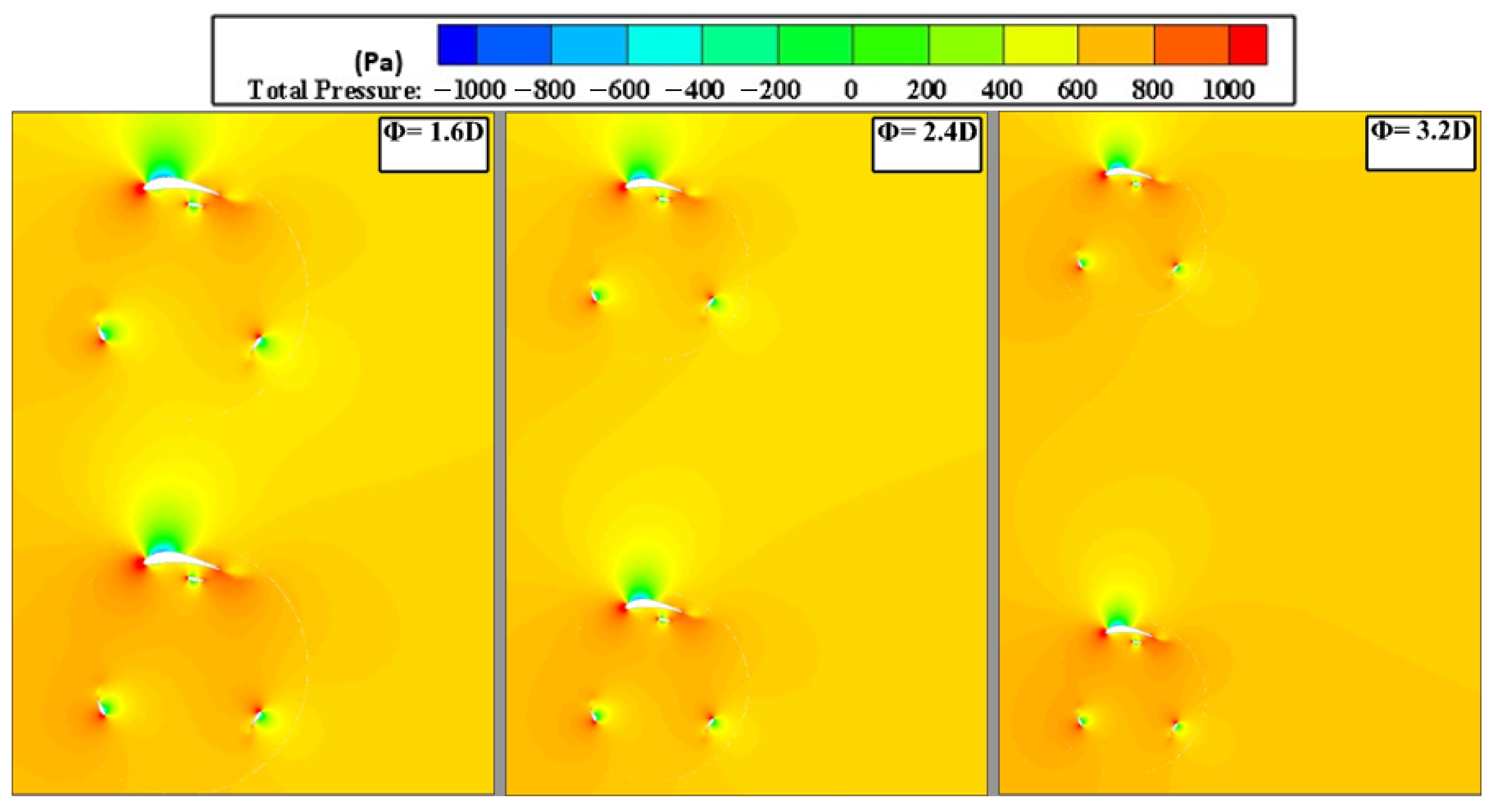

4.2.3. Effect of Distance Between Two Adjacent Turbines on Wind Turbine Performance

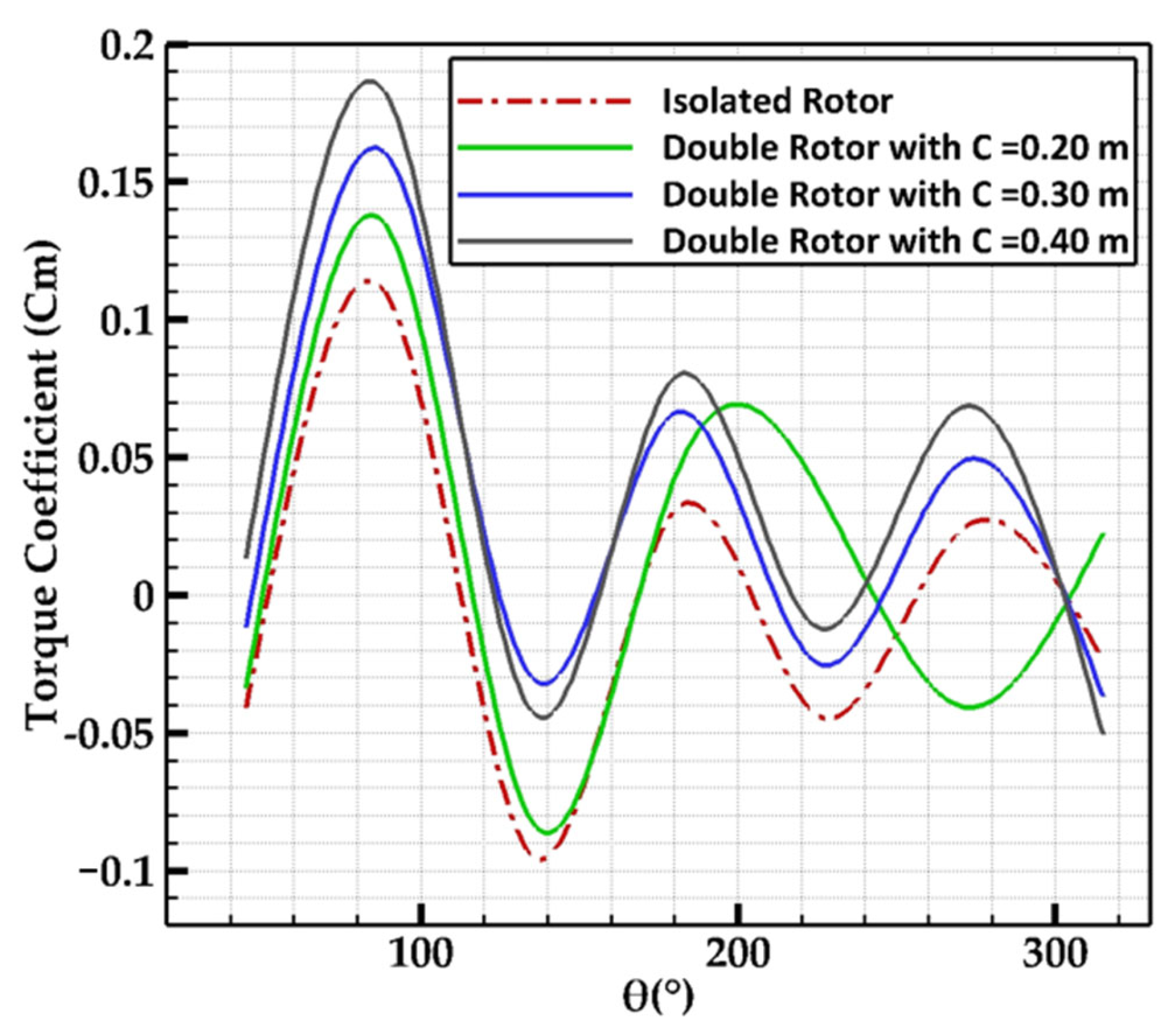

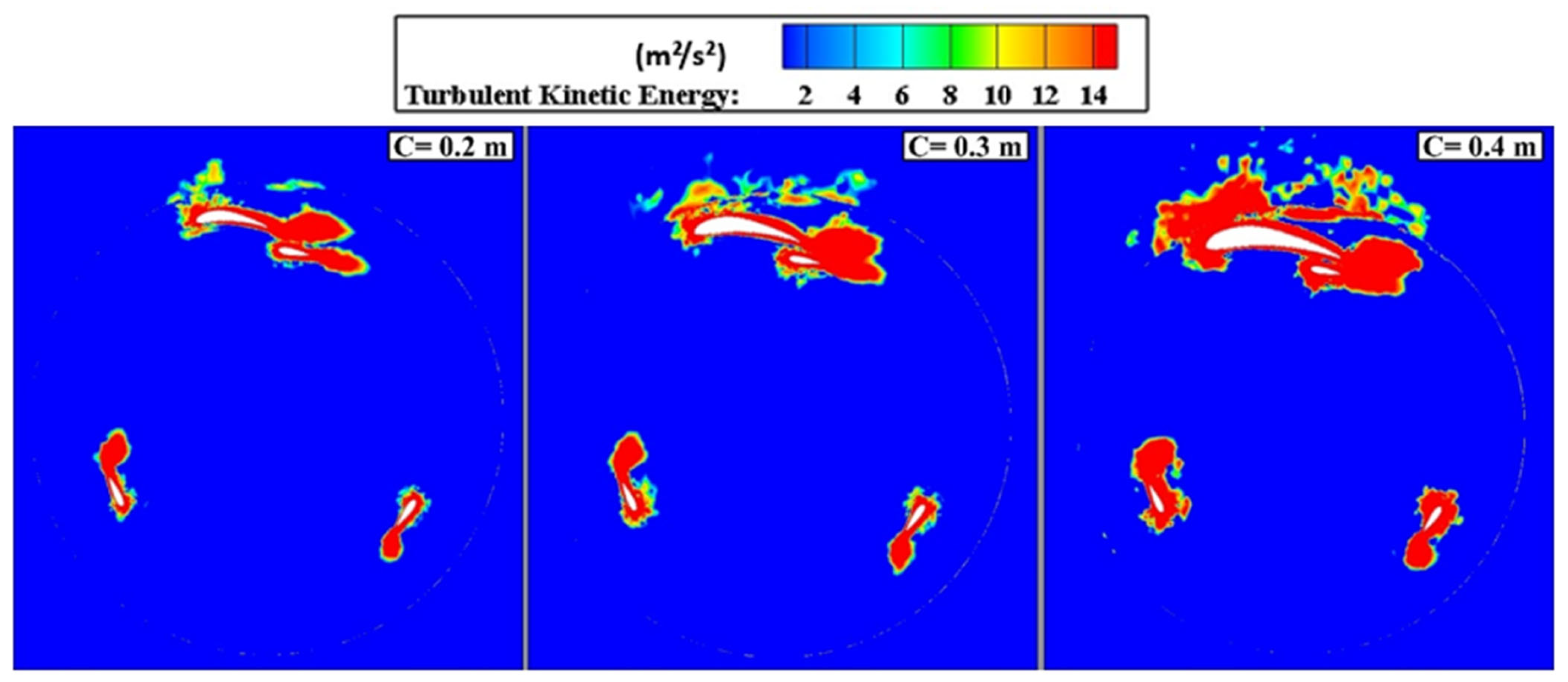

4.2.4. Effect of the Rotor Chord Length on Turbine Performance

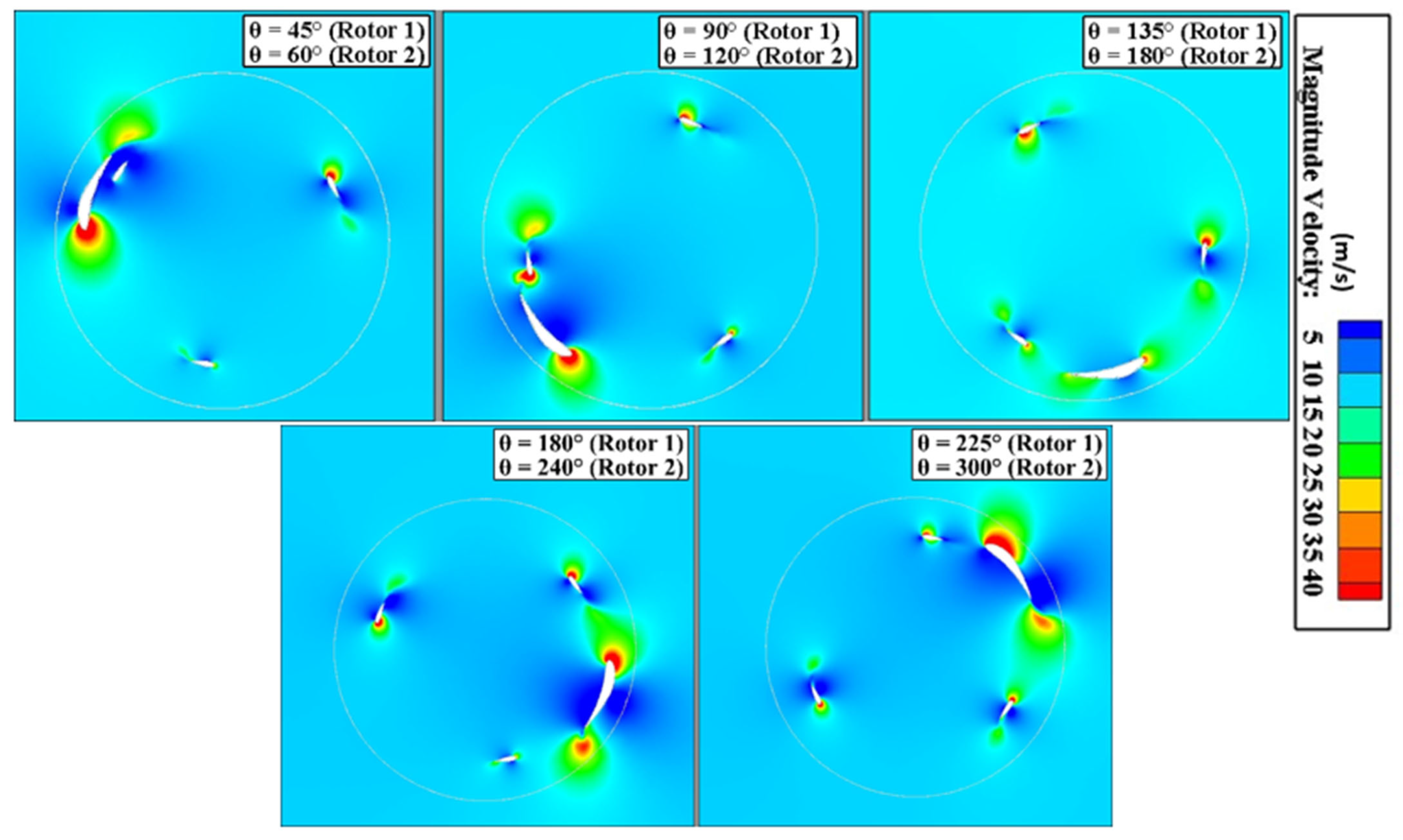

4.2.5. Velocity Contour Analysis

5. Conclusions

- A 12% increase in the coefficient of performance at TSR = 2.6 was observed when a second Eppler 420 airfoil rotor was added to the first three-bladed NACA 0021 airfoil rotor.

- The efficiency of the two turbines incorporating dual rotors was improved by 17% compared with the two isolated turbines for = 0°. In addition, the choice of an optimum angle of attack for the dual-rotor airfoils improves energy efficiency and maximizes the performance of the two H-Darrieus turbines by attenuating wake disturbance.

- Using an optimum distance (Φ) of 4D between two adjacent turbines ensures efficient lift for each turbine, maintains robust energy efficiency, and demonstrates maximum performance within a wind farm.

- Increasing the chord length of the second rotor Eppler 420 blade by C = 0.4 m results in a higher moment coefficient, which translates into higher efficiency generation for H-Darrieus turbines.

- Analysis of the flow field reveals stable flow around the dual rotors of the H-Darrieus turbine as a function of the optimum parameter of the two airfoils. In addition, the second rotor contributes positively to improving the flow around the first rotor, thereby enhancing turbine efficiency and reducing wake size, enabling higher flow quality to be achieved. This configuration could be considered for future applications. On the other hand, choosing the optimum distance between two turbines incorporating dual rotors enhances their aerodynamic performance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 2D | Two-Dimensional |

| CFD | Computational Fluid Dynamics |

| NACA | National Advisory Committee for Aeronautics |

| SST | Shear Stress Transport |

| TSR | Tip Speed Ratio |

| TSST | Turbulent Scale Simulation Transport Model |

| VAWT | Vertical-Axis Wind Turbine |

| SM | Sliding Mesh |

| RANS | Steady Reynolds-Averaged Navier–Stokes |

| HAWT | Horizontal-Axis Wind Turbine |

| µ | Dynamic Viscosity (kg/(m.s.)) |

| Darrieus Angular Velocity (rad/s) | |

| Fluid Density (kg/m3) | |

| Angle of Attack (degrees) | |

| SST Shear Stress Transport Turbulence Model | |

| Turbulence Model | |

| A | Area Swept by Darrieus (m2) |

| R | Darrieus Radius (m) |

| Re | Reynolds Number |

| Drag Coefficient | |

| Lift Coefficient | |

| Torque Coefficient | |

| Power Coefficient | |

| g | Acceleration Due to Gravity Vector (m/s2) |

| P | Pressure (Pa) |

| Free Stream Velocity (m/s) | |

| y+ | Dimensionless Wall Distance |

| Azimuth Angle (degrees) | |

| Φ | Distance between Adjacent Turbines (m) |

| Δ t | Time Step (s) |

References

- Tasneem, Z.; Al Noman, A.; Das, S.K.; Saha, D.K.; Islam, M.R.; Ali, M.F.; R Badal, M.F.; Ahamed, M.H.; Moyeen, S.I.; Alam, F. An analytical review on the evaluation of wind resource and wind turbine for urban application: Prospect and challenges. Dev. Built Environ. 2020, 4, 100033. [Google Scholar] [CrossRef]

- Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Wallaaldin, A.E.; Jarupula, S. Performance enhancement of Darrieus wind turbines using Plain Flap and Gurney Flap configurations: A CFD analysis. Results Eng. 2024, 24, 103400. [Google Scholar] [CrossRef]

- Mohamed, M.H. Performance investigation of H-rotor Darrieus turbine with new airfoil shapes. Energy 2012, 47, 522–530. [Google Scholar] [CrossRef]

- Carlos, S.F.; Gijs, V.K.; Gerard, V.B.; Fulvio, S. Visualization by PIV of dynamic stall on a vertical axis wind turbine. Exp. Fluids 2009, 46, 97–108. [Google Scholar]

- Raciti, C.M.; Pavesi, G.; Battisti, L.; Benini, E.; Ardizzon, G. Modeling strategy and numerical validation for a Darrieus vertical axis micro-wind turbine. In Proceedings of the ASME 2010 International Mechanical Engineering Congress and Exposition, Vancouver, BC, Canada, 12–18 November 2010; p. IMECE2010-39548. [Google Scholar]

- Mohamed, M.H.; Dessoky, A.; Faris, A. Blade shape effect on the behavior of the H-rotor Darrieus wind turbine: Performance investigation and force analysis. Energy 2019, 179, 1217–1234. [Google Scholar] [CrossRef]

- Mohamed, O.S.; Ibrahim, A.; Etman, A.K.; Abdelfatah, A.A.; Elbaz, A.M.R. Numerical investigation of Darrieus wind turbine with slotted airfoil blades. Energy Convers. Manag. X 2020, 5, 100026. [Google Scholar] [CrossRef]

- Ma, N.; Lei, H.; Han, Z.; Zhou, D.; Bao, Y.; Zhang, K. Airfoil optimization to improve power performance of a high-solidity vertical axis wind turbine at a moderate tip speed ratio. Energy 2018, 150, 236–252. [Google Scholar] [CrossRef]

- Sobhani, E.; Ghaffari, M.; Maghrebi, M.J. Numerical investigation of dimple effects on Darrieus vertical axis wind turbine. Energy 2017, 133, 231–241. [Google Scholar] [CrossRef]

- Shen, Z.; Gong, S.; Zu, H.; Guo, W. Multi-objective optimization study on the performance of double Darrieus hybrid vertical axis wind turbine based on DOE-RSM and MOPSO-MODM. Energy 2024, 299, 131406. [Google Scholar] [CrossRef]

- Cheng, B.; Du, J.; Yao, Y. Power prediction formula for blade design and optimization of Dual Darrieus Wind Turbines based on Taguchi Method and Genetic Expression Programming model. Renew. Energy 2022, 192, 583–605. [Google Scholar] [CrossRef]

- Farzad, G.; Seyed, R.M.; Mohammad, E.; Mehdi, M. A systematic investigation on the hybrid Darrieus-Savonius vertical axis wind turbine aerodynamic performance and self-starting capability improvement by installing a curtain. Next Energy 2025, 6, 100203. [Google Scholar]

- Mahmoud, H.; Abdel, R.; Mohamed, E.; Shinichi, O.; Hamdy, H. Optimization of the power performance for three hybrid Darrieus-Savonius rotors based on the Taguchi method. Conf. Ser. 2024, 2857, 012011. [Google Scholar]

- Mohan Kumar, P.; Surya, M.R.; Sivalingam, K.; Lim, T.-C.; Ramakrishna, S.; Wei, H. Computational Optimization of Adaptive Hybrid Darrieus Turbine: Part 1. Fluids 2019, 4, 90. [Google Scholar] [CrossRef]

- Mirzaeian, H.; Ghobadian, B.; Mirhosseini, M. Performance Analysis and Optimization of Dual-Row Vertical Axis Wind Turbines with Innovative Hybrid Blades. Energy Sci. Eng. 2025, 13, 3171–3184. [Google Scholar] [CrossRef]

- Amgad, D.; Pradip, Z.; Thorsten, L.; Ewald, K. Numerical Investigations of Two Darrieus Turbine Rotors Placed One Behind the Other with Respect to Wind Direction. In Proceedings of the Thirteenth International Conference of Fluid Dynamics, Cairo, Egypt, 21–22 December 2018. [Google Scholar]

- Omar, S.M.; Pier, F.M.; Francesco, P.; Francesco, B.; Alessandro, B. Is the Actuator line method able to reproduce the interaction between closely-spaced Darrieus rotors a critical assessment on wind and hydrokinetic turbines. Energy Convers. Manag. 2023, 293, 117473. [Google Scholar] [CrossRef]

- Tian, W.; Ni, X.; Li, B.; Yang, G.; Mao, Z. Improving the efficiency of Darrieus turbines through a gear-like turbine layout. Energy 2023, 267, 126580. [Google Scholar] [CrossRef]

- Mohammed, S.; Shaaban, A. Efficient clusters and patterned farms for Darrieus wind turbine. Sustain. Energy Technol. Assess. 2017, 19, 125–135. [Google Scholar]

- Jin, G.; Zong, Z.; Jiang, Y.; Zou, L. Aerodynamic analysis of side-by-side placed twin vertical-axis wind turbines. Ocean Eng. 2020, 209, 107296. [Google Scholar] [CrossRef]

- Esmaeel, F.; Rakesh, M.; Frankie, F.J.; Hossein, F. Optimization and analysis of self-starting capabilities of vertical axis wind turbine pairs: A CFD-Taguchi approach. Ocean Eng. 2024, 302, 117614. [Google Scholar]

- Fertahi, S.e.-D.; Belhadad, T.; Kanna, A.; Samaouali, A.; Kadiri, I. Assessment of fairing geometry effects on H-Darrieus hydroturbine performance using 2D URANS CFD simulations. Energy Convers. Manag. 2023, 293, 117434. [Google Scholar] [CrossRef]

- Castelli, M.R.; Englaro, A.; Benini, E. The Darrieus wind turbine: Proposal for a new performance 8prediction model based on CFD. Energy 2011, 36, 4919–4934. [Google Scholar] [CrossRef]

- Islam, H.; Mohamed, M. Aerodynamic performance enhancements of H-rotor darrieus wind turbine. Energy 2018, 142, 531–545. [Google Scholar] [CrossRef]

- Chandra, S.; Tyagi, R. Study of Eppler 423 Airfoil with Gurney Flap and Vortex Generators. Adv. Aerosp. Sci. Technol. 2020, 5, 51001. [Google Scholar] [CrossRef]

- Didane, D.H.; Rosly, N.; Zulkafli, M.F.; Shamsudin, S.S. Numerical investigation of a novel contra-rotating vertical axis wind turbine. Sustain. Energy Technol. Assess. 2019, 31, 43–53. [Google Scholar] [CrossRef]

- Fluent, A. Ansys Fluent Theory Guide; ANSYS Inc.: Canonsburg, PA, USA, 2020; pp. 0001–1026. [Google Scholar]

- Mahdi, Z.; Mohammad, J.M.; Seyed, R.V. Starting torque improvement using J-shaped straight-bladed Darrieus vertical axis wind turbine by means of numerical simulation. Renew. Energy 2016, 95, 109–126. [Google Scholar]

- Wilberforce, T.; Alaswad, A. Performance analysis of a vertical axis wind tur bine using computational fluid dynamics. Energy 2023, 263, 125892. [Google Scholar] [CrossRef]

- Asr, M.T.; Nezhad, E.Z.; Mustapha, F.; Wiriadidjaja, S. Study on start-up characteristics of H-Darrieus vertical axis wind turbines comprising NACA 4-digit series blade airfoils. Energy 2016, 112, 528–537. [Google Scholar] [CrossRef]

- Balduzzi, F.; Bianchini, A.; Ferrara, G.; Ferrari, L. Dimensionless numbers for the assessment of mesh and timestep requirements in CFD simulations of Darrieus wind turbines. Energy 2016, 97, 246–261. [Google Scholar] [CrossRef]

- Marsh, P.; Ranmuthugala, D.; Penesis, I.; Thomas, G. The influence of turbulence model and two and three-dimensional domain selection on the simulated performance characteristics of vertical axis tidal turbines. Renew. Energy 2017, 105, 106–116. [Google Scholar] [CrossRef]

- Tescione, G.; Ragni, D.; He, C.; Simão, F.C.J.; Van Bussel, G.J.W. Near wake flow analysis of a vertical axis wind turbine by stereoscopic particle image velocimetry. Renew. Energy 2014, 70, 47–61. [Google Scholar] [CrossRef]

- Boulla, D.; Fertahi, S.e.-D.; Bernatchou, M.; Samaouali, A. CFD Numerical Simulation Study of Aerodynamic Performance of H Darrieus Rotor. CFD Lett. 2025, 17, 117. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Marini, M.; Aristide, M.; Antonio, S. Performance of vertical axis wind turbines with different shapes. J. Wind Eng. Ind. Aerodyn. 1992, 39, 83–93. [Google Scholar] [CrossRef]

- Boulla, D.; Fertahi, S.e.-D.; Bernatchou, M.; Samaouali, A.; Ajani, M.; Boussaq, C. Enhancement of aerodynamic performance of H-Darrieus rotor using wraparound fairing system: A 2D CFD study. Int. J. Renew. Energy Dev. 2025, 14, 1058–1071. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education: London, UK, 2007. [Google Scholar]

- Hoseinzadeh, S.; Amin, B.; Seyed, M.M.; Ali, S.; Stephan, H. A detailed experimental airfoil performance investigation using an equipped wind tunnel. Flow Meas. Instrum. 2020, 72, 101717. [Google Scholar] [CrossRef]

- Vennell, R. Exceeding the betz limit with tidal turbines. Renew. Energy 2013, 55, 277–285. [Google Scholar] [CrossRef]

- Wang, S.; Ingham, D.B.; Ma, L.; Pourkashanian, M.; Tao, Z. Numerical Investigation on dynamic stall of low Reynolds number flow around oscillating airfoils. Comput. Fluids 2010, 39, 1529–1541. [Google Scholar] [CrossRef]

- Hao, W.; Ding, Q.; Li, C. Optimal performance of adaptive flap on flow separation control. Comput. Fluids 2019, 179, 437–448. [Google Scholar] [CrossRef]

- Willmott, C.J.; Ackleson, S.G.; Davis, R.E.; Feddema, J.J.; Klink, K.M.; Legates, D.R.; O’donnell, J.; Rowe, C.M. Statistics for the evaluation and comparison of models. Oceans 1985, 90, 8995–9005. [Google Scholar] [CrossRef]

- Baizhuma, Z.; Kim, T.; Son, C. Numerical method to predict ice accretion shapes and performance penalties for rotating vertical axis wind turbines under icing conditions. J. Wind Eng. Ind. Aerodyn. 2021, 216, 104708. [Google Scholar] [CrossRef]

- Ahmad, M.; Shahzad, A.; Akram, F.; Ahmad, F.; Shah, S.I.A. Design optimization of Double Darrieus hybrid vertical axis wind turbine. Ocean Eng. 2022, 254, 111171. [Google Scholar] [CrossRef]

- Paulo, A.S.F.; Silva, P.; Tsoutsanis, A.; Antoniadis, F. Simple multiple reference frame for high order solution of hovering rotors with and without ground effect. Aerosp. Sci. Technol. 2021, 111, 10651. [Google Scholar] [CrossRef]

- Fertahi, S.e.-D.; Samaouali, A.; Kadiri, I. CFD comparison of 2D and 3D aerodynamics in H-Darrieus prototype wake. E-Prime-Adv. Electr. Eng. Electron. Energy 2023, 4, 100178. [Google Scholar] [CrossRef]

- Zhang, W.; Cao, Y.; Qian, Z.; Wang, J.; Zhu, Y.; Yang, Y.; Wang, Y.; Wu, G. Research on Aerodynamic Performance of Asynchronous-Hybrid Dual-Rotor Vertical Axis Wind Turbines. Energies 2024, 17, 4424. [Google Scholar] [CrossRef]

- Huang, H.; Li, J.; Li, G. Improving the self-starting and operating characteristics of vertical axis wind turbine by changing center distance in part of blades. J. Build. Eng. 2023, 68, 105974. [Google Scholar] [CrossRef]

- Yang, Y.; Cao, Y.; Qian, Z.; Wang, J.; Zhu, Y.; Chen, X.; Zhang, W.; Wang, Y.; Wu, G.; Chen, S. A Study on the Effect of Turbulence Intensity on Dual Vertical-Axis Wind Turbine Aerodynamic Performance. Energies 2024, 17, 4124. [Google Scholar] [CrossRef]

| Characteristics | Rotor 1 | Rotor 2 |

|---|---|---|

| Number of blades Blade airfoil | 3 NACA 0021 | 1 Eppler 420 |

| Diameter (m) | 1.030 | 1.25 |

| Chord (m) Solidity | 0.0858 0.5 | 0.30 0.5 |

| Height (m) | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boulla, D.; Fertahi, S.e.-D.; Bernatchou, M.; Samaouali, A.; Arbaoui, A. Enhancement of Aerodynamic Performance of Two Adjacent H-Darrieus Turbines Using a Dual-Rotor Configuration. Fluids 2025, 10, 239. https://doi.org/10.3390/fluids10090239

Boulla D, Fertahi Se-D, Bernatchou M, Samaouali A, Arbaoui A. Enhancement of Aerodynamic Performance of Two Adjacent H-Darrieus Turbines Using a Dual-Rotor Configuration. Fluids. 2025; 10(9):239. https://doi.org/10.3390/fluids10090239

Chicago/Turabian StyleBoulla, Douha, Saïf ed-Dîn Fertahi, Maryam Bernatchou, Abderrahim Samaouali, and Asmae Arbaoui. 2025. "Enhancement of Aerodynamic Performance of Two Adjacent H-Darrieus Turbines Using a Dual-Rotor Configuration" Fluids 10, no. 9: 239. https://doi.org/10.3390/fluids10090239

APA StyleBoulla, D., Fertahi, S. e.-D., Bernatchou, M., Samaouali, A., & Arbaoui, A. (2025). Enhancement of Aerodynamic Performance of Two Adjacent H-Darrieus Turbines Using a Dual-Rotor Configuration. Fluids, 10(9), 239. https://doi.org/10.3390/fluids10090239