1. Introduction

Hydrodynamic cavitation, studied initially as a detrimental phenomenon affecting hydraulic structures, has increasingly been explored for beneficial applications, including water treatment disinfection [

1], pipeline cleaning [

2] and other industrial processes such as emulsification [

3] and biodiesel production [

4]. In this context, innovation is pivotal in developing devices capable of generating cavitation at intensities suitable for specific applications. These advancements are typically pursued through experimental and numerical approaches, enabling data collection and insights that can drive process optimization.

Several studies have investigated hydrodynamic cavitation using computational fluid dynamics (CFD) simulations, employing various modeling techniques to capture the underlying physics accurately. Dastane et al. [

5] utilized two-phase flow simulations to analyze cavitation within a Venturi device. The mass transfer between the liquid and vapor phases was modeled using the cavitation approach proposed by Singhal et al. [

6], while the discrete phase model was applied to predict cavity trajectories. Additionally, the Keller–Miksis equation [

7] was employed to describe cavity dynamics, and turbulence was addressed using two-equation eddy viscosity models. The study demonstrated that single-phase simulations, although limited in predicting collapse intensity, can effectively reproduce the qualitative trends of multiphase models, providing a computationally efficient alternative for preliminary design assessments.

Simpson and Ranade [

8] modeled hydrodynamic cavitation using the Shear Stress Turbulence (SST) κ-ω model within an orifice to investigate the influence of key geometric parameters, such as orifice thickness, hole inlet sharpness and wall angle, on the cavitation behavior. Their results offer valuable guidance for designers of hydrodynamic cavitation devices, enabling them to compare and evaluate different cavitation devices designs and operating parameters.

In similar vein, Li et al. (2024) [

9] investigated the cavitation erosion characteristics of artificial jets using Scale-Adaptative Simulation (SBES) and the Zwarti–Gerber–Belamri (ZGB) model. Their study aimed to understand how the standoff distance affects the periodic distribution pattern of the cavitation cloud. Their findings indicated that an optimal standoff distance led to the generation of a greater number of cavitation clouds on the workpiece surface in numerical simulations, with the most pronounced erosion characteristics being confirmed in experiments. The authors attributed this behavior to the shear effect formed between the two jets, which plays a primary role in generating cavitation bubbles in artificially submerged jets. Moreover, they found that increasing the pressure of the high-pressure internal nozzle can enhance the cavitation effect.

Dutta et al. [

10] conducted axisymmetric 2D Reynolds-Averaged Navier–Stokes (RANS) simulations to examine cavitation in a Venturi configuration. A two-phase mixture model was implemented in the RANS simulations, while the discrete phase model was incorporated to track the trajectories of cavitation bubbles. The study utilized the k-ω SST turbulence model and investigated the influence of different Venturi divergence angles and surface roughness on vapor generation. The authors further proposed and numerically assessed three design strategies to intensify cavitation, finding that a trumpet-shaped diverging section significantly increased vapor volume fraction, outperforming surface roughness and circular hurdle configurations.

Zhou et al. [

11] investigated pressure fluctuations under cavitation conditions, characterized the unsteady internal flow features and analyzed the relationship between cavitation intensity and pressure oscillations. Using the re-normalization group (RNG) κ-ε turbulence model, they predicted the inlet pressure for cavitation development. Even more, they observed the point of strongest pressure fluctuation amplitude. These results provide valuable insights that enable more accurate prediction and understanding of the phenomenon.

Thus, Li et al. [

12] investigated cavitation jet flow fields using three different turbulence models: RNG κ-ε, DES and LES. The findings indicate that the static pressure in the sections studied was below the saturation vapor pressure of water. The LES model demonstrated effective simulation capabilities for accurately representing the cavitating flow phenomena in an organ pipe nozzle. Furthermore, the LES model accurately replicated the evolution of vorticity, which exhibits a consistent pattern during the periodic formation of a cavitation cloud.

A comprehensive review by Hong et al. [

13] examined various cavitation models employed in CFD simulations of cavitation reactors. Commonly used models include those by Singhal et al. [

6], Schnerr–Sauer [

14] and Zwart–Gerber–Belamri [

15], mainly due to their availability in commercial CFD software (2021 R2 version). The authors emphasized the importance of selecting suitable turbulence and cavitation models, noting that commonly used two-equation RANS models may lack accuracy in simulating transient cavitation phenomena. They also reinforced the necessity of mesh sensitivity analysis and experimental validation for reliable predictions of vapor volume fractions.

Liu and Park [

16] used the DeepCFD Model to predict transient cavitation flow around a hydrofoil. Their results showed that while the model accurately predicted cavitation shapes across different flow conditions, it exhibited a discrepancy in velocity predictions, particularly for detached cavitation flows. This study suggests that the selection of a model should be carefully considered based on the specific variables or results required, highlighting that a single model may not be optimal for all aspects of a complex flow phenomenon.

Polgár et al. [

17] investigated shear stress distribution in hydrodynamic cavitation reactors through CFD simulations. The employed turbulence models were derived from the Favre-Averaged Navier–Stokes (FANS) equations, using the k-ε model, widely recognized for its efficiency in characterizing turbulent flows. Their study compared a Venturi-based reactor and an orifice-type reactor, validating their numerical results through experimental bacterial colony reduction tests. The authors showed that reactor geometry strongly influences shear stress distribution and bacterial inactivation, with the Venturi-based design outperforming the bore-type in both CFD and experimental results.

Jia et al. [

18] analyzed the cavitation flow and vorticity transport in jet pump cavitation reactors using a filter-based density correction model (FBDCM), which validated the model with experimental tests. The study yielded results that provide guidance for the application of this reactor in water sterilization and disinfection. Specifically, the findings show that jet pump cavitation reactors with higher area ratios tend to have a higher-pressure recovery rate, making cavitation less likely to occur. A greater area ratio also extends the operating range by increasing the upper limit of the flow ratio. Furthermore, the efficiency of the reactor was found to increase initially with the flow ratio, peaking just before the onset of cavitation.

The research by Zhou et al. [

19] focused on the pre-treatment of food waste via hydrodynamic cavitation, employing 2D axisymmetric CFD simulations. The Herschel–Bulkley model was implemented alongside RANS-based simulations to capture the rheology of non-Newtonian fluids. The study analyzed how variations in inlet pressure affected flow characteristics, viscosity, vapor volume and cavitation number. The results indicated that a pressure drop of ∆P ≥ 0.07 MPa is required to overcome viscosity-induced inhibition, enabling effective cavitation and enhancing vapor generation. Özgünoğlu [

20] investigated cavitation-induced erosion in high-pressure fuel injectors through numerical simulations. The cavitation dynamics were simulated using a modified Zwart–Gerber–Belamri model with RANS and Large Eddy Simulation (LES) approaches. Additionally, an advanced erosion prediction model was employed to enhance the accuracy of cavitation erosion forecasts. The study introduced a unified erosion modeling framework and demonstrated that incorporating realistic surface deviations significantly alters cavitation patterns and erosion predictions in high-pressure fuel injectors.

Fang et al. [

21] used Large Eddy Simulations (LESs) to explore the turbulent cavitation flow outside of an organ-pipe nozzle. The findings indicate that the dominant fluid frequency is positively correlated with the inlet pressure but is not related to the nozzle’s divergence angle. They found the best divergence angle for cavitation intensity and highest observed vorticity is 30°. Their analysis, which combined simulation with the Dynamic Mode Decomposition (DMD) method, revealed that the motion of the cavitation cloud is guided by the coherent vortex structure.

In Venturi tubes, Apte et al. [

22] investigated the mechanisms of driving hydrodynamic cavitation tube using numerical simulations. They compared Detached Eddy Simulation (DES) and Shear Stress Turbulence (SST) κ-ω models. Their results showed that the DES models accurately replicated the mean cavity shape observed in experiments. In contrast, the URANS calculations produced an unrealistic “arrowhead” cavity shape. This is attributed to the re-entrant jet in the URANS simulation breaking the primary cavity much farther downstream than in the DES models. Thus, turbulence and vortex dynamics were tested, and given a vorticity budget, analysis of the cavitation–vortex interaction showed that both vortex stretching and vortex dilatation are crucial for vortex dynamics during a cavitating shedding cycle.

Guo et al. [

23] investigated the geometrical parameters of a Venturi tube using the SST κ-ω turbulence model. Their findings indicated that the divergent angle, convergent angle and throat diameter are the three most important geometrical parameters for enhancing cavitation intensity. Consequently, they determined optimal angles to maximize the cavitation intensity.

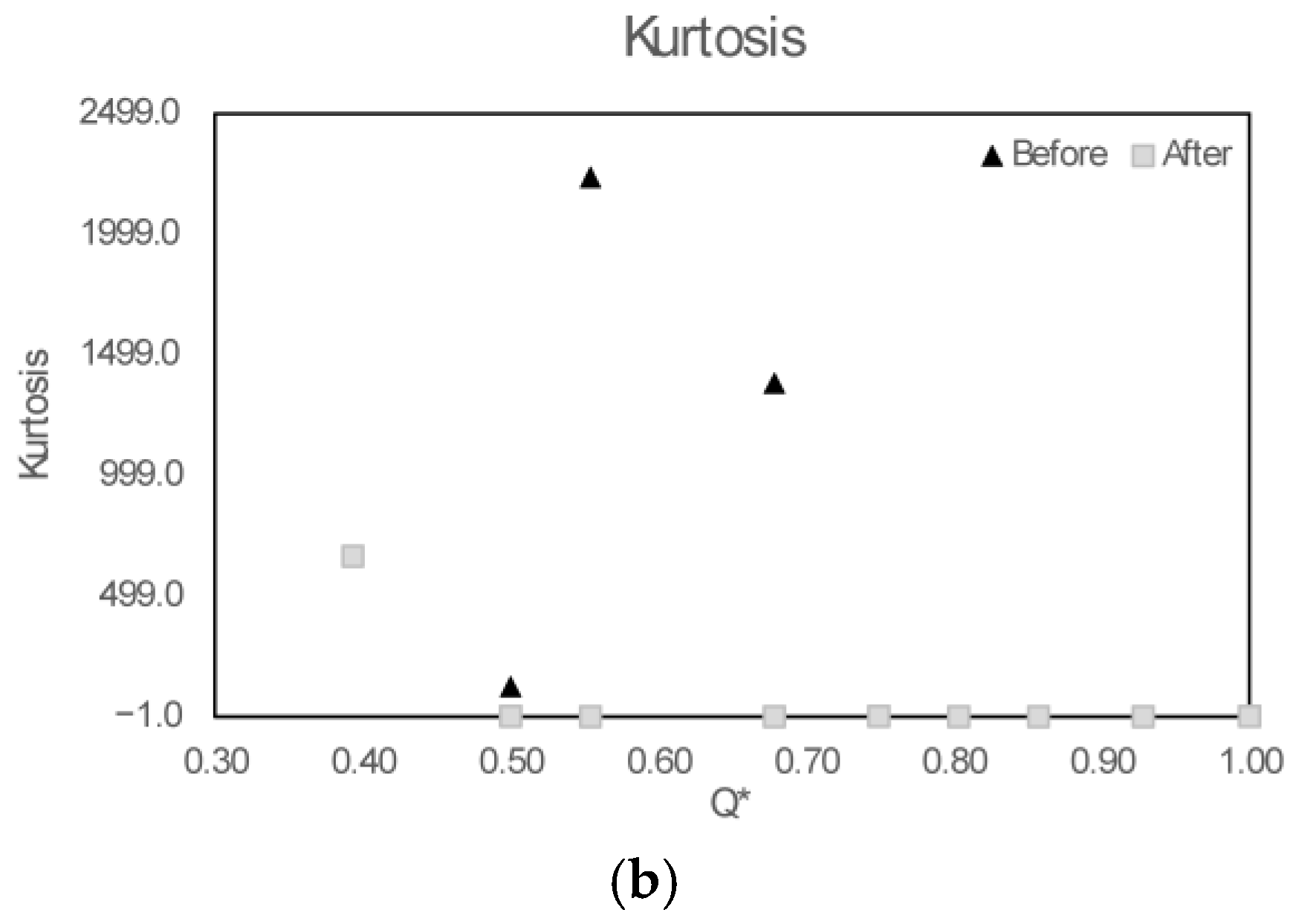

These studies have emphasized the growing importance of numerical modeling in hydrodynamic cavitation research, particularly the need for robust CFD methodologies that accurately predict cavitation behavior in complex geometries. Although previous investigations have explored both experimental and numerical approaches for modeling hydrodynamic cavitation in conventional devices, further research is required to support the development of systems with innovative configurations, especially for applications related to molecular degradation and microorganism inactivation. The present work aims to experimentally and numerically analyze the average characteristics of cavitation generated by a triangular nozzle, employing optical detection with a phototransistor, a piezoelectric pressure transducer, and three-dimensional modeling based on Reynolds-Averaged Navier–Stokes (RANS) equations. The specific objectives are (1) to analyze the influence of turbulence anisotropy; (2) to investigate the complementarity between experimental measurements and numerical simulations through the correlation of physical variables; (3) to evaluate the correspondence between the regions of steam occurrence observed experimentally at the beginning of the nozzle and those calculated numerically.

3. Results and Discussion

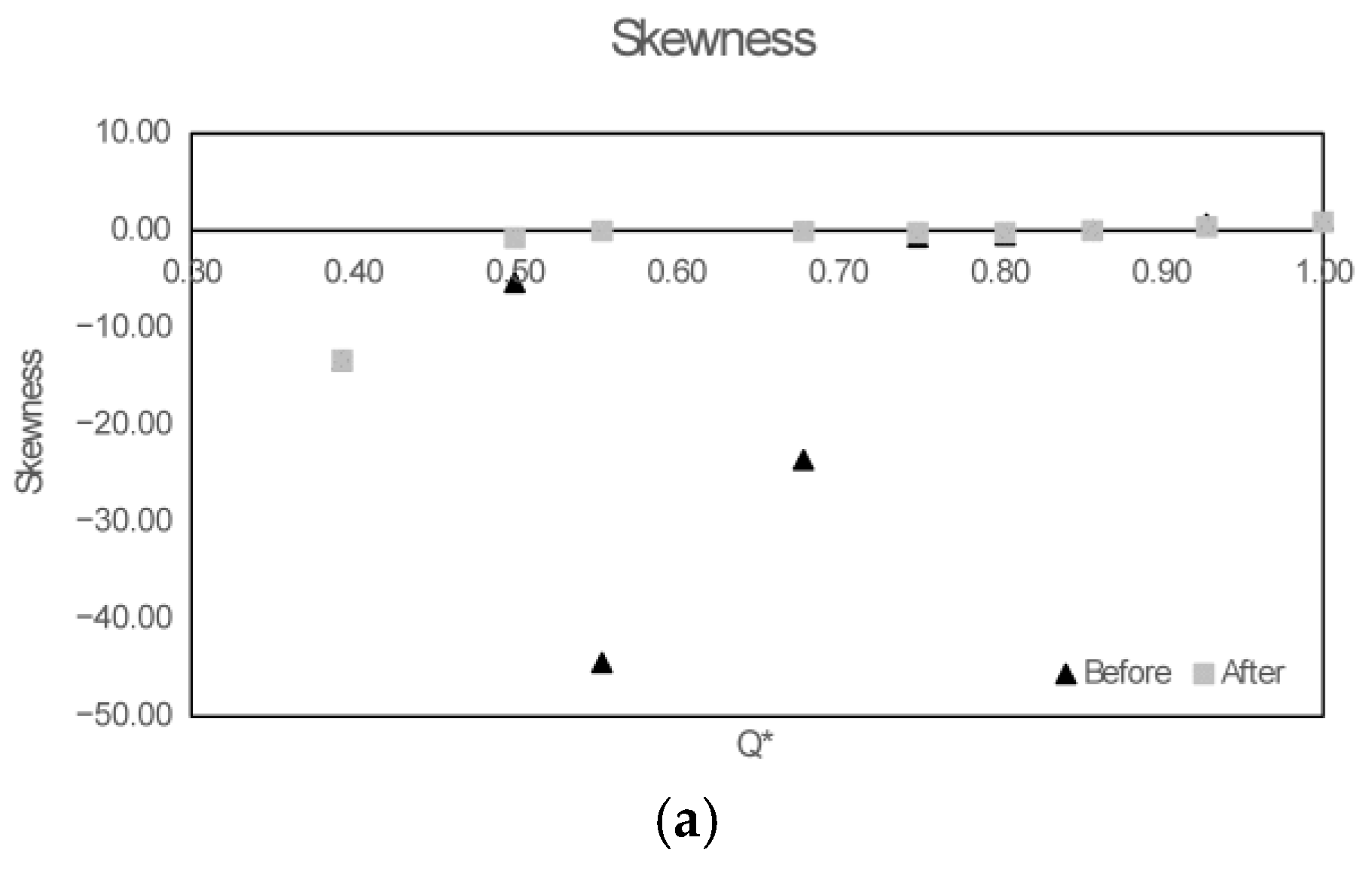

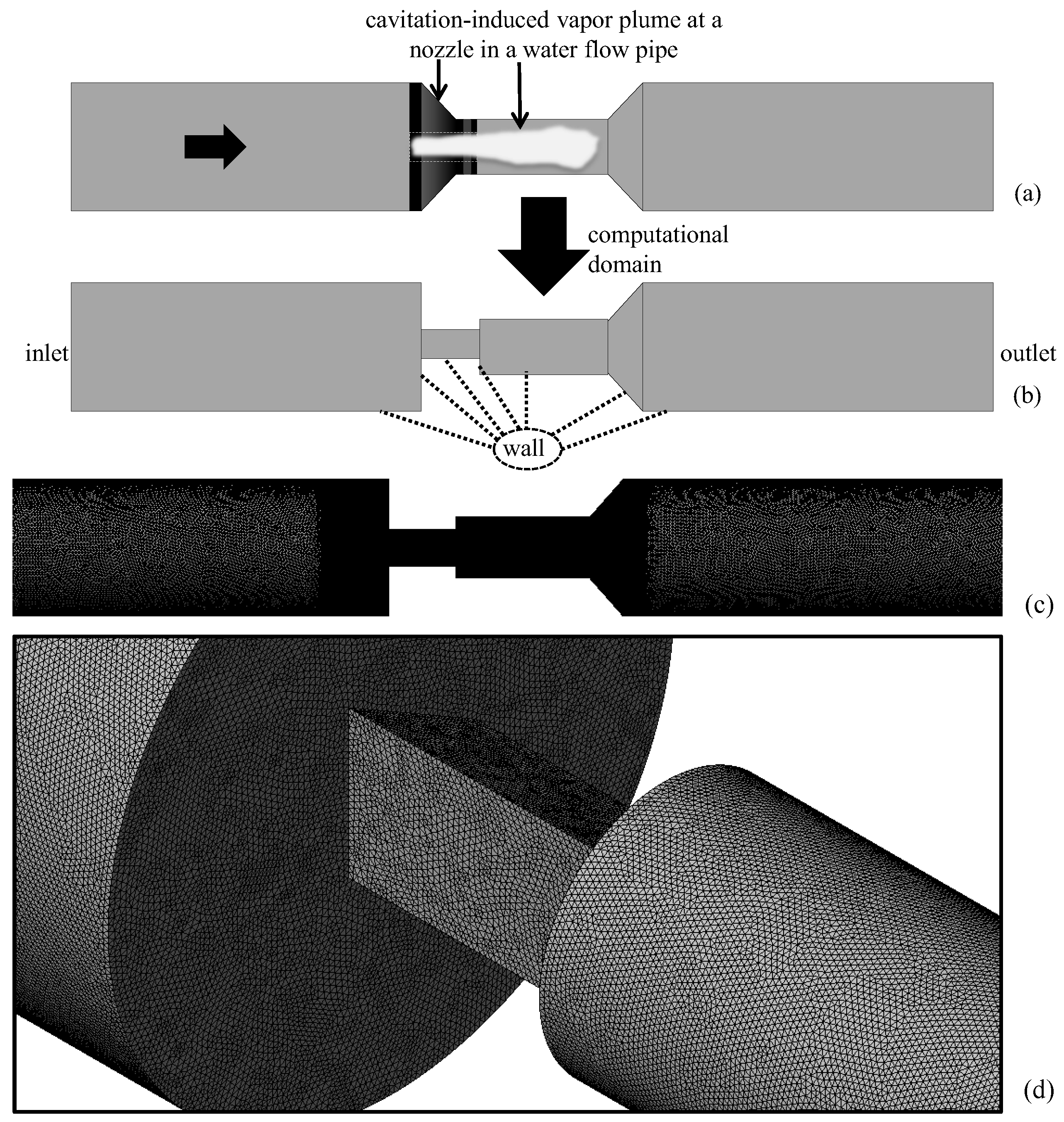

The photographs presented in

Figure 5 were captured using a shutter speed of 1/6000 s and represent images of the flow downstream of the triangular nozzle. As observed, there is a precise formation of bubble-laden jets downstream of the triangular nozzle for

Q* > 0.80 (

Figure 5c–f). The initially transparent appearance of the water is progressively replaced as the mean bubble population increases, leading to a more visually distinct cavitating region. For lower flow rates, chaotic bubble motion within the liquid phase is evident, which can be analyzed through high-speed imaging and slow-motion recordings. At higher flow rates, the increased bubble density results in an opaquer two-phase mixture, restricting the random motion of bubbles compared to lower flow conditions. This transition suggests that, at higher cavitation intensities, the interaction between vapor structures and the surrounding liquid phase becomes more constrained, altering the overall flow characteristics. The jet can reach lengths that extend beyond the Venturi throat, as shown in

Figure 5g.

Virtually, no vapor bubble formation is observed for the three lowest flow rates. Sporadic bubble formation becomes noticeable starting from the fourth flow rate, with bubbles appearing chaotically and convecting downstream of the nozzle, randomly distributed throughout the flow, as shown in

Figure 5a. At the fifth flow rate (

Figure 5b), a more significant number of bubbles is observed, and this trend intensifies with increasing flow rate, eventually reaching a high bubble density condition at the maximum flow rate, as illustrated in

Figure 5f. As a result, the mean irradiance decreases with increasing flow rate due to the reduction in white light transmission (

Figure 6a). This behavior was previously described by West et al. [

24] and modeled using Equation (5), which, when fitted to the data from the present study, yielded a correlation coefficient of 0.998. The residuals, shown in

Figure 6c, exhibit a well-distributed pattern, indicating a strong agreement between the model and the experimental data.

The standard deviation of irradiance increases with the growing number of bubbles due to enhanced light scattering compared to the single-phase condition. From a wave optics perspective, the transmitted light undergoes interference due to its interaction with the vapor bubble surfaces. This is compounded by the light’s passage through the bubbles, which are less refractive than the surrounding water. Combined with the chaotic motion of the bubble swarm, this results in a measurement of turbulent intensity, as demonstrated by West et al. [

24].

This trend continues until it reaches a maximum, after which it decreases as the bubble density increases further, leading to a more uniform optical signal passing through the dense vapor region. This behavior, observed experimentally and quantified through the standard deviation of irradiance, was successfully fitted using a Gaussian function (Equation (6a)), yielding a correlation coefficient 0.990 between the experimental and calculated data. The residuals, shown in

Figure 6d, confirm the agreement between the Gaussian model and the experimental observations. The standard deviation of the instantaneous pressure measurements obtained from the pressure transducer exhibited a similar trend, with an initial increase followed by a subsequent decrease. This behavior was modeled using Equation (6b), which yielded a correlation coefficient of 0.977, with the data distribution shown in

Figure 6e,f.

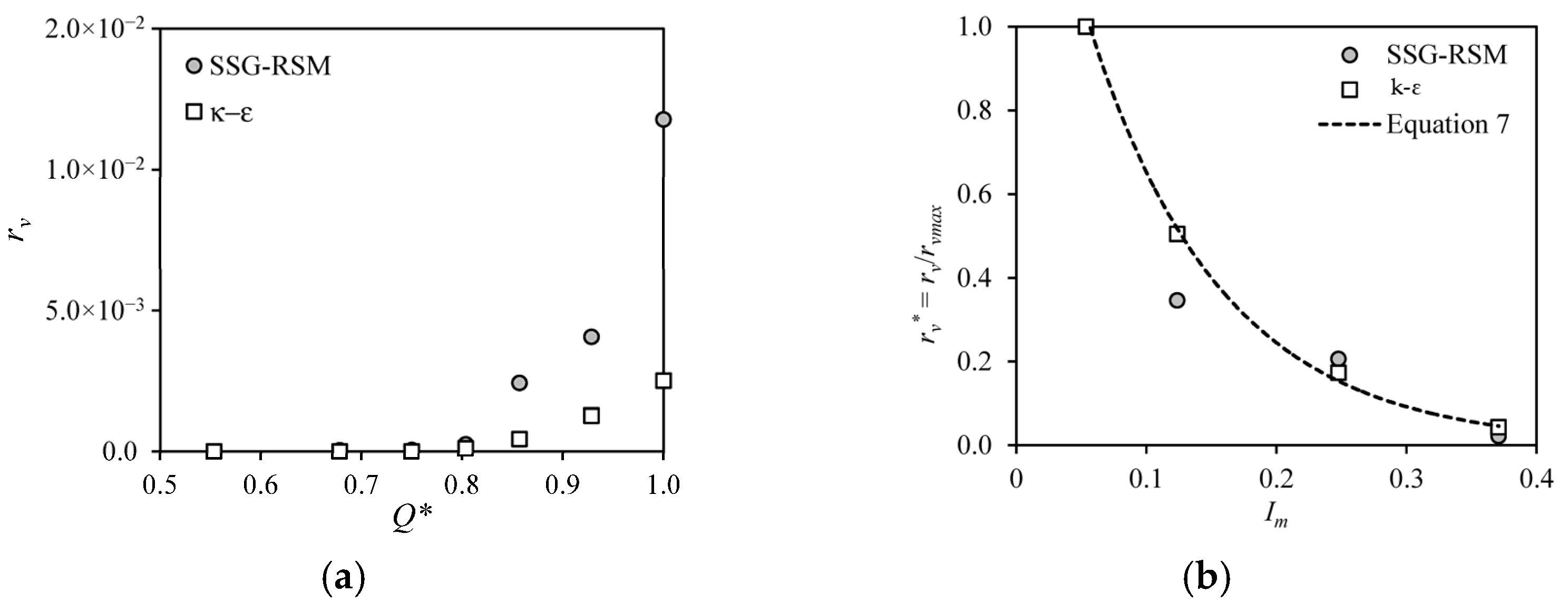

The mean values of the vapor volume fraction (

rv) were computed at the central position of the Venturi throat, where irradiance measurements were taken using the phototransistor.

rvmax is the maximum vapor fraction calculated in simulations, acquired in the maximum normalized flow rate. A strong correlation between

rv and

Q* was observed, as shown in

Figure 7a. It was noted that higher flow rates correspond to higher vapor fractions, consistent with experimental observations and the photographs presented in

Figure 5. The normalized vapor fraction, denoted as

rv∗, exhibited a strong correlation with

Im, following an exponential model expressed by Equation (7), with a correlation coefficient of 0.999, indicating excellent agreement with the experimental data, as illustrated in

Figure 6b.

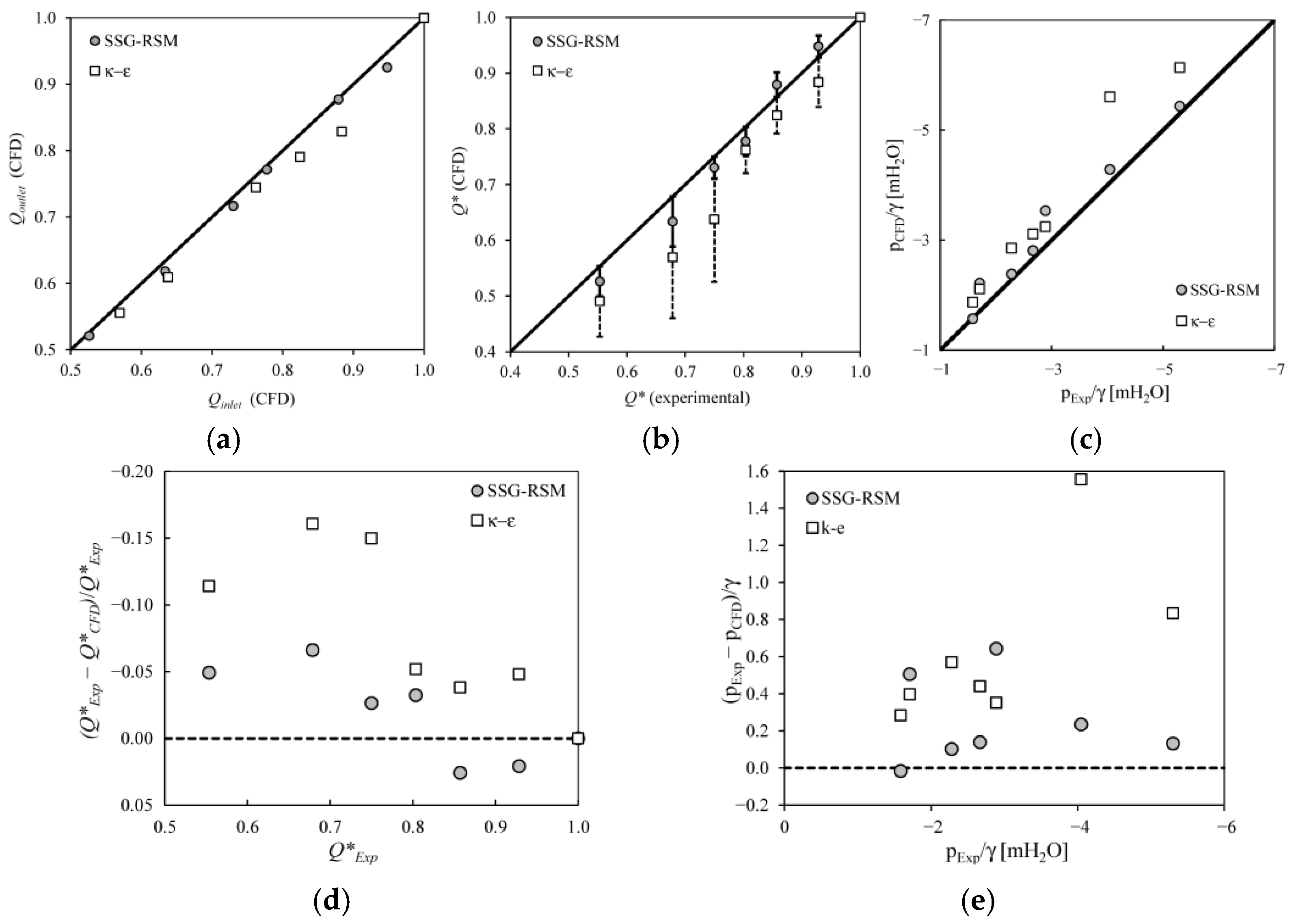

The simulations performed using the k-ε and SSG-RSM turbulence models converged in terms of inlet and outlet flow rates, with a maximum relative difference of 4.3% for the k-ε model, as shown in

Figure 7a.

Figure 6b compares the numerically computed flow rates and the experimentally measured values, normalized by their respective maximum values. The error bars were calculated as the difference between the identity line and the numerical value, for up and down sides. The results obtained with the SSG-RSM turbulence model showed better agreement with the experimental data, with relative deviations ranging from 2.1% to 6.6%. In contrast, the k-ε model exhibited more significant relative deviations, varying between 3.8% and 16%.

Figure 8c presents the mean pressure values obtained experimentally alongside those computed using the turbulence modeling approach proposed in this study. The SSG-RSM model yielded results closer to the experimental data than those obtained using the k-ε model. Among the seven analyzed points, five exhibited relative deviations below 5.8% for the SSG-RSM model, while two points showed higher deviations of 22% and 28%. In contrast, when using the k-ε model, deviations ranged between 15.7% and 38.4% for mean pressure. In the same way, Polgár et al. [

17] compared simulated data with the k-ε model and the experimental data from rotational cavitation device, finding relative errors between 3% and 57%. Furthermore, the results obtained with the k-ε model showed a systematic deviation for

Q* and mean pressure (see

Figure 8d,e), while the SSG-RSM predictions were distributed around or closer to the exact-fit reference line. These findings support this study’s initial hypothesis regarding the need for anisotropic turbulence modeling due to the asymmetries introduced by cavitation. Consequently, all subsequent numerical evaluations in this work were conducted using the SSG-RSM model.

Murthy and Joshi [

34] compared several turbulence models against experimental data including RMS using SSG to model the pressure–strain term, standard κ-ε model and LES. In their discussion, they concluded that the RSM performed better than κ-ε during comparison with a disc turbine, especially when recirculation was present.

Similarly, Lee et al. [

35] found that SSG models are in better agreement with the experimental data and predict the anisotropy of turbulent structures better than the standard κ-ε model.

The velocity and pressure fields calculated using the adopted turbulence models are shown in

Figure 9 for the minimum and maximum flow rates. It is noted that the velocities calculated with the κ-ε model were lower compared to the results obtained with the SSG model, which also resulted in an underestimation of the flow rates, as shown in

Figure 9b. It is also observed that the κ-ε model produced a more symmetric velocity field in the region of the jet originating from the triangular nozzle, whereas the SSG model produced less symmetric mean jets. This asymmetry was also observed experimentally via stroboscopic illumination, which demonstrated the occurrence of similar oscillations in the vapor bubble jet. The pressure fields showed greater discrepancies between the models for the lower flow rate, with the results converging at the maximum flow rate. Despite this, the symmetric pattern calculated by the κ-ε model is clearly visible, in contrast to the SSG model.

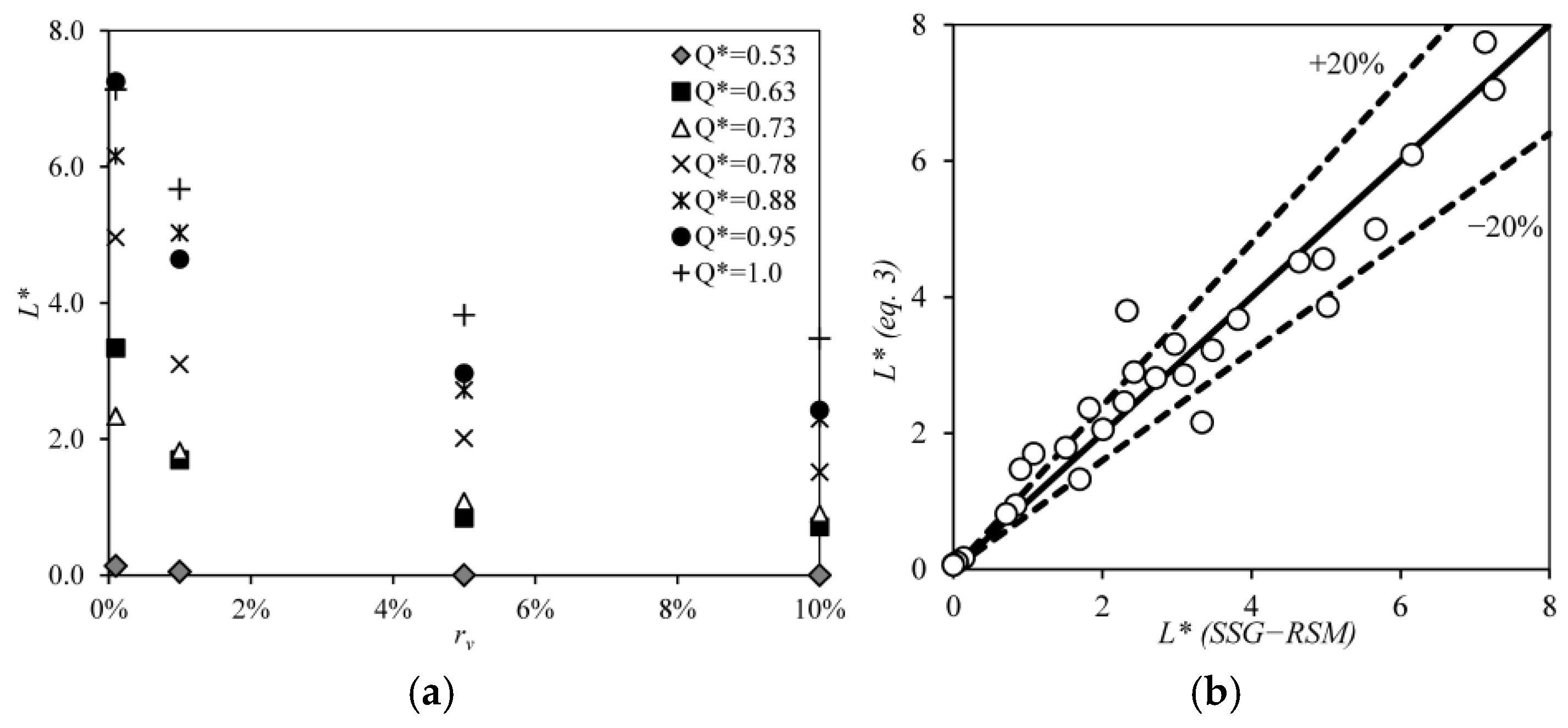

The vapor jet length,

L, measured from the nozzle inlet, was nondimensionalized using the triangle side length,

l, resulting in the dimensionless parameter

L* =

L/

l. Each vapor jet was computed based on the isosurface corresponding to a vapor volume fraction,

rv, of 0.10, 0.05, 0.01 and 0.001.

Figure 10a, obtained for

Q* = 1.0, shows that for

rv = 0.10, the vapor jet extends beyond the nozzle length, reaching the Venturi throat region. For

rv = 0.001, the corresponding jet extends further downstream of the Venturi, indicating the occurrence of advective pulses that give the jet an even greater average range, although for a smaller volume fraction. This behavior could be observed experimentally, as presented in

Figure 5g.

The numerical results suggest that

L* is related to

rv through a power law (

Figure 11a, Equation (8a)), with coefficients that can be approximated by series in the form of Equations (8b) and (8c). The coefficients

ψ1 and

ψ2 were analyzed using cubic, quadratic and linear approximations, yielding coefficients of determination (R

2) of 0.942, 0.941 and 0.937, respectively, with mean squared errors (MSEs) of 0.253, 0.257 and 0.276. The Akaike Information Criterion (AIC), based on likelihood theory, was applied to assess the model complexity. The linear approximation for

ψ1 and

ψ2 was ultimately adopted, as there was no reasonable justification for higher-order approximations.

Equation (8a,b,c) was developed based on the results obtained using the SSG-RSM turbulence model for the range 0.001 ≤

rv ≤ 0.10 and 0.53 ≤

Q* ≤ 1.0, requiring further experimental validation. However, a common approach for modeling free and isotropic jets involves using a Gaussian function to describe both longitudinal and transverse decay of concentration and velocity, as Holley and Jirka [

36] proposed. Although the Gaussian approach is not directly applicable to the present case, primarily due to the inherent isotropy assumed in Gaussian modeling, the resulting decay behavior in Gaussian models is also well represented by a power law. This similarity reinforces the validity of the power-law formulation adopted in this study, suggesting that the observed decay follows a comparable mathematical structure despite the asymmetries introduced by cavitation and the confinement within the conduit.

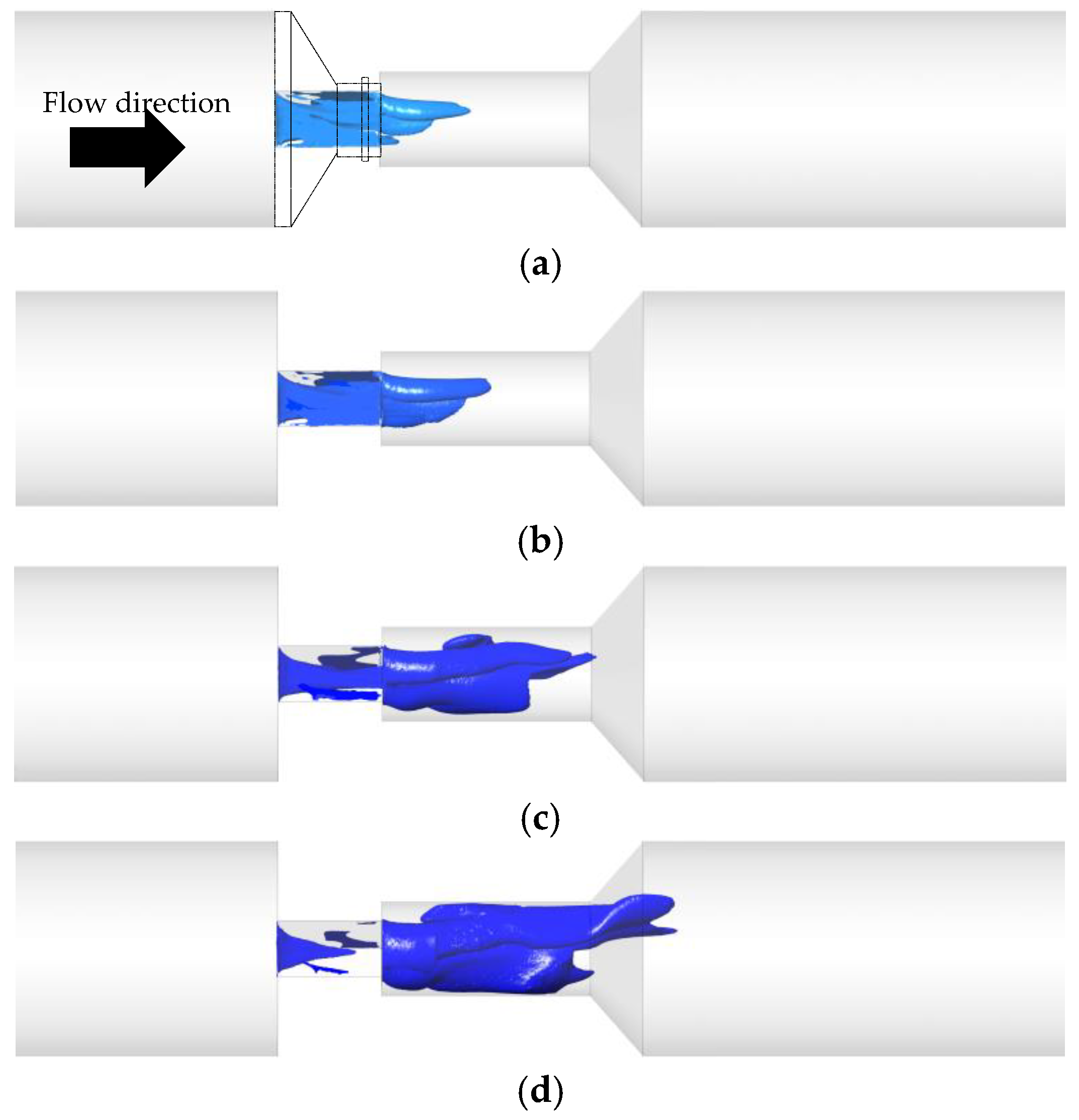

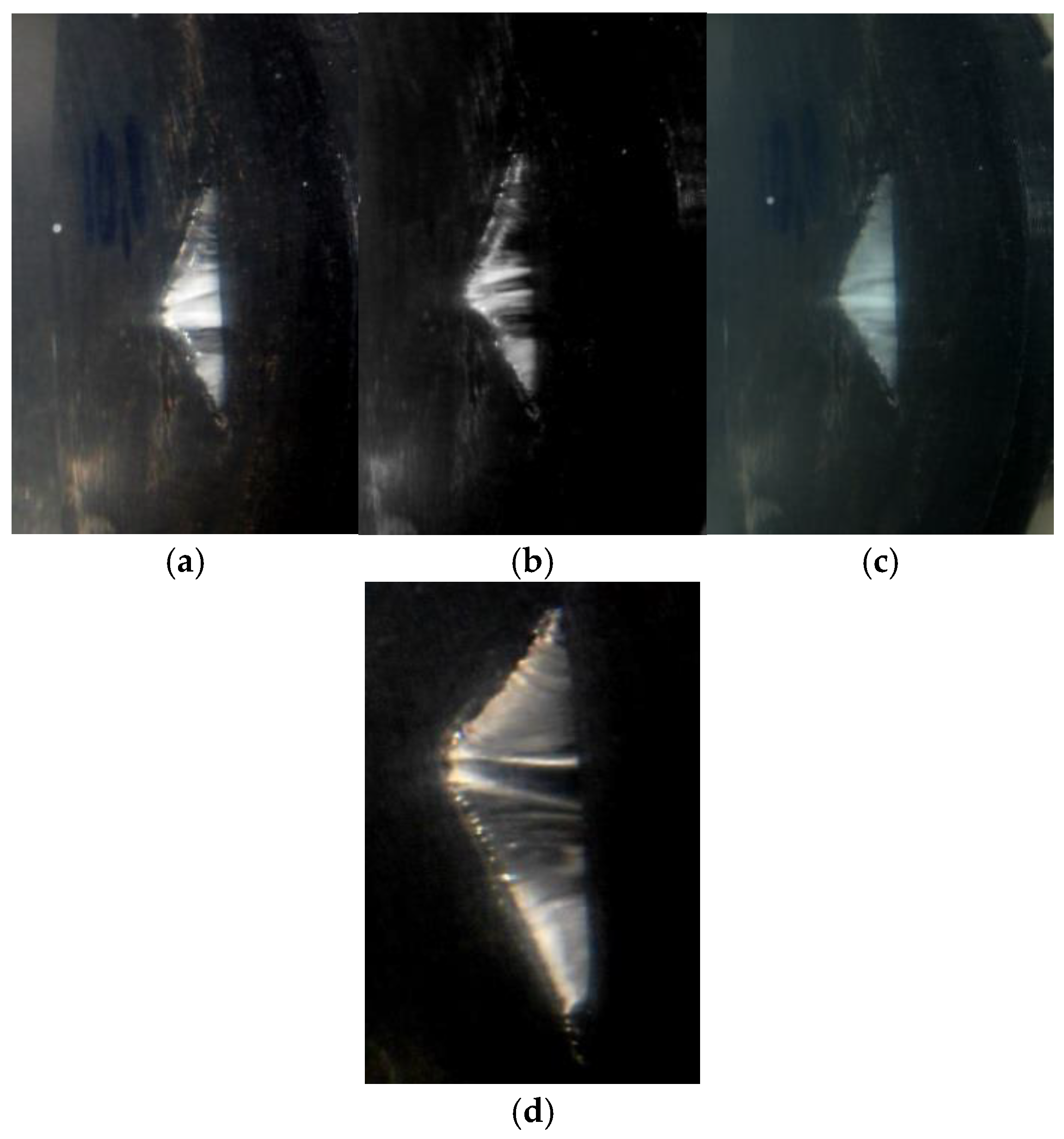

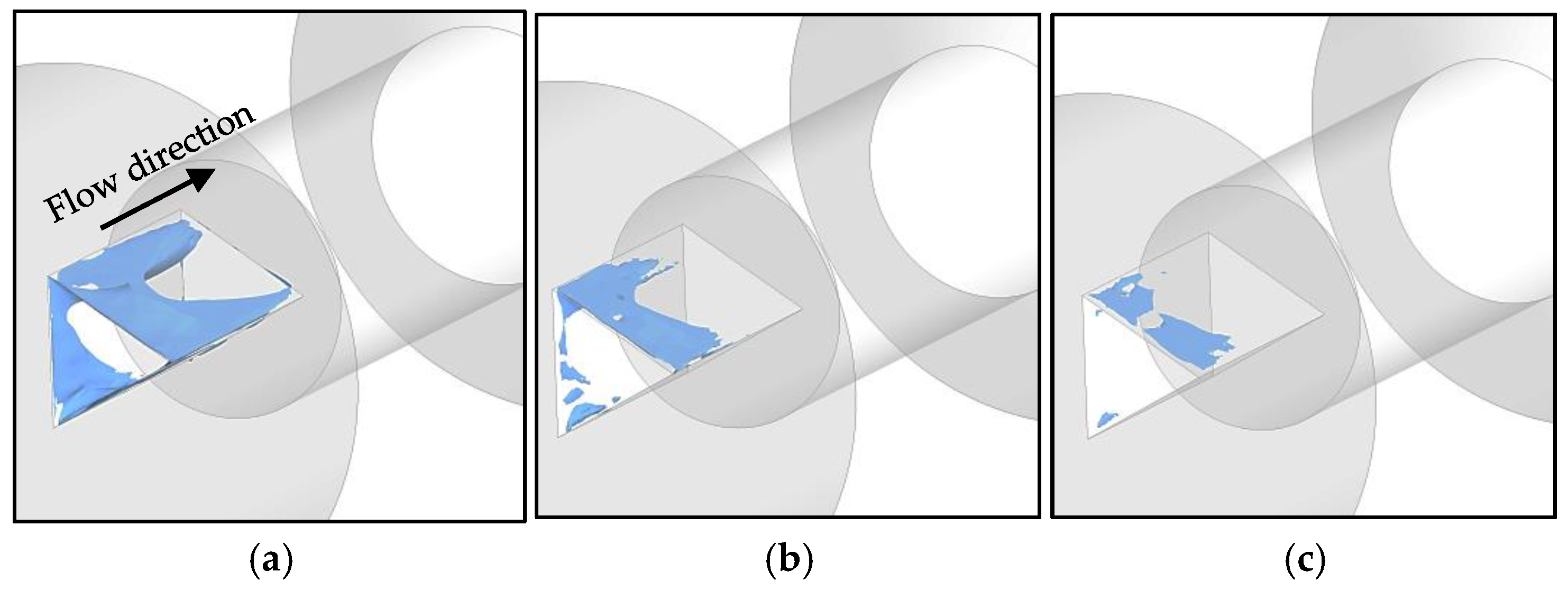

Cavitation initiates at the abrupt transition from the 44 mm tube to the triangular nozzle, as observed in the photographs in

Figure 12a–d. These images reveal the phase change through the appearance of white coloration at the onset of the triangular section. In this region, the sudden change in flow direction is expected to cause flow separation and vortex formation, leading to localized low-pressure zones that promote phase change. Additionally, the contraction of the cross-sectional area results in flow acceleration, further reducing the pressure at the center of the triangular conduit.

The incipient cavitation recorded experimentally through high-speed photography suggests the presence of vortical structures within the white-water region. It is well known that abrupt transitions promote flow separation and the formation of large recirculating vortices, which in turn contribute to localized pressure drops in cases like this. The temporal variation observed in the images reveals intermittent behavior, indicating that cavitation occurs in a pulsating manner. This behavior is likely influenced by turbulent ejections originating from the velocity boundary layer and local pressure fluctuations. Such intermittency may play a significant role in the nucleation and collapse of vapor bubbles, affecting the overall cavitation dynamics.

Figure 13 presents the isosurfaces computed numerically for

rv values of 0.50, 0.90 and 0.99, illustrating the spatial distribution of the vapor region. These results indicate that the pattern captured in the 1/6000 s photograph closely resembles the mean distribution observed for

rv = 0.50 and 0.90. Similarly, Omelyanyuk et al. [

37] observed that cavitation appears in the transition from a wide to the narrow section in the flow direction. In CFD simulation, that maximum vapor concentration was 80% with a maximum inlet pressure of 2.8 atm. This comparison qualitatively suggests that the RANS approach with the SSG-RSM turbulence model is suitable for predicting cavitation occurrence in nozzles, providing a reasonable approximation of the mean vapor distribution observed experimentally.

4. Conclusions

The optical measurement system effectively detected cavitation bubble-induced variations in light transmission, confirming its applicability to investigate two-phase flow in confined geometries. The irradiance standard deviation exhibited a well-defined trend, increasing with vapor bubbles up to a maximum and decreasing as the vapor fraction increased further. This behavior, described mathematically by a Gaussian function, demonstrates the system’s sensitivity to cavitation dynamics and its potential to characterize bubble-laden flows. The standard deviation of instantaneous pressures, a parameter capable of representing the intensity of cavitation, showed similar behavior with growth and subsequent decay. This condition reinforces the suitability of the optical instrumentation used.

The flow rates calculated with the k-ε and SSG-RSM turbulence models yielded different values. The SSG-RSM model produced results closer to the measured values for flow rate and pressure, indicating that modeling the Reynolds tensor components with the anisotropic approach is necessary for determining fundamental average quantities, such as flow rate and pressure, for the problem studied in the present work. Numerical simulations successfully captured the formation and evolution of cavitation structures in the flow, with steam jet lengths following a power-law dependence on the vapor volume fraction. The computed isosurfaces of the vapor volume fraction showed qualitative agreement with high-speed photographs, suggesting that the Reynolds-Averaged Navier–Stokes (RANS) approach with the SSG-RSM turbulence model can provide reliable predictions of the average cavitation behavior. Furthermore, vortex identification methods such as the vorticity, λ2-criterion, Q criterion, and swirling strength suggest the presence of large eddies near the nozzle exit, reinforcing the hypothesis that low-pressure zones induced by the abrupt geometry change contribute to the incipient cavitation at this position.

The results demonstrate the role of turbulence anisotropy in cavitation modeling and suggest that turbulence models capable of capturing recirculating vortices are essential to accurately predict cavitation in nozzle flows. The results also indicate that the onset and evolution of cavitation follow trends observed in free-shear jets despite the geometric confinement of the flow. The agreement between experimental and computational findings provides a basis for future studies aimed at optimizing nozzle designs to control cavitation intensity in several applications, including water treatment, biodiesel synthesis and microorganism inactivation, among others.