Design and Optimization of Valve Lift Curves for Piston-Type Expander at Different Rotational Speeds

Abstract

1. Introduction

2. Mechanism and Modeling

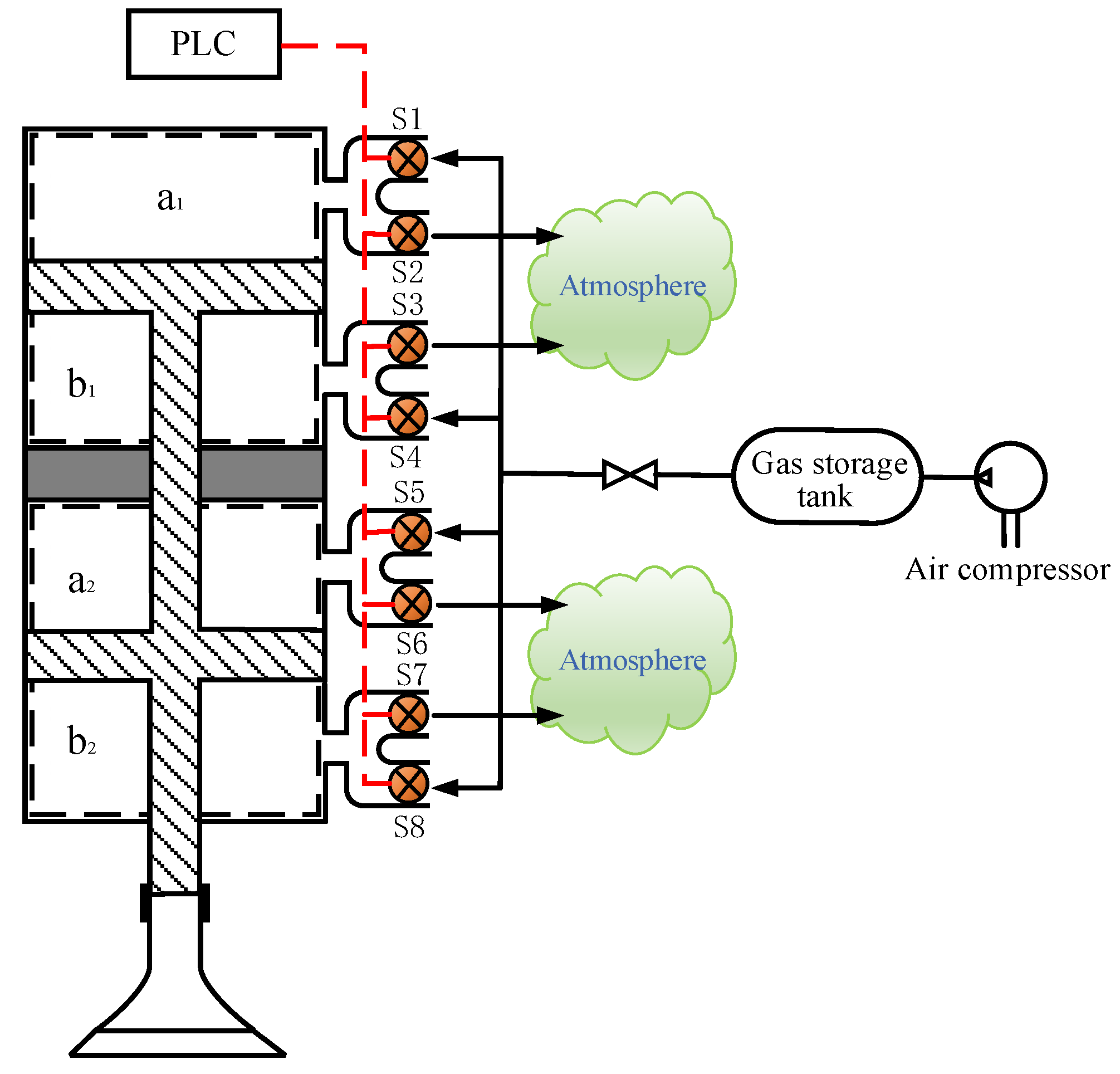

2.1. Introduction to the Electro-Pneumatic VVA System

2.2. Mathematical Modeling of the Electro-Pneumatic VVA System

- The working medium, compressed air, follows the ideal gas law;

- There is no gas leakage in the system during operation;

- The inflow and outflow of gas within the cylinder are considered quasi-steady, one-dimensional flows;

- There is no leakage during the operation of the expander;

- The state of the gas inside the cylinder remains uniform during operation;

- Temperature variations inside the chamber are negligible compared to the supply air temperature

3. Design and Optimization of the Valve Lift Curve

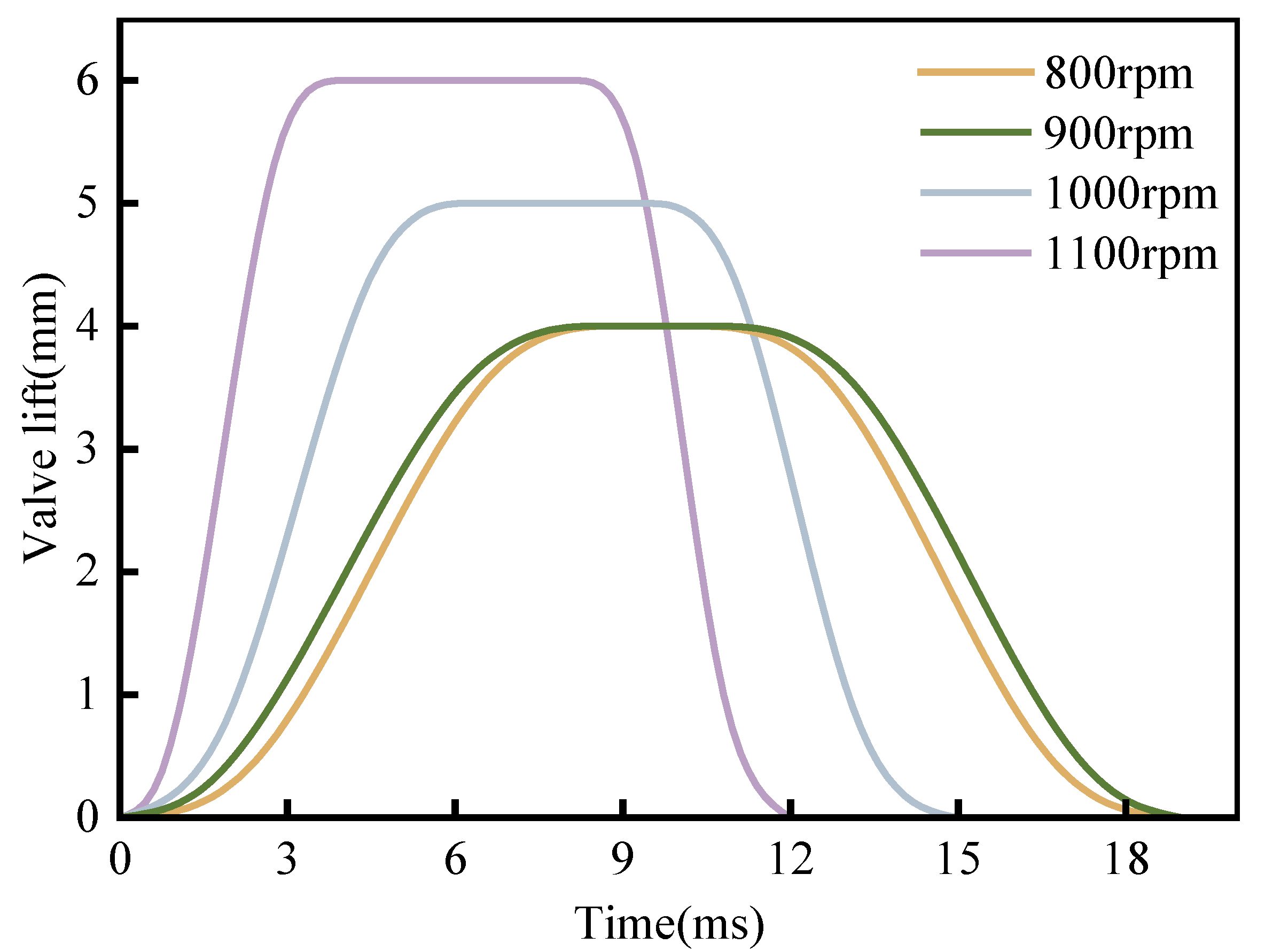

3.1. Design of the Valve Lift Curve

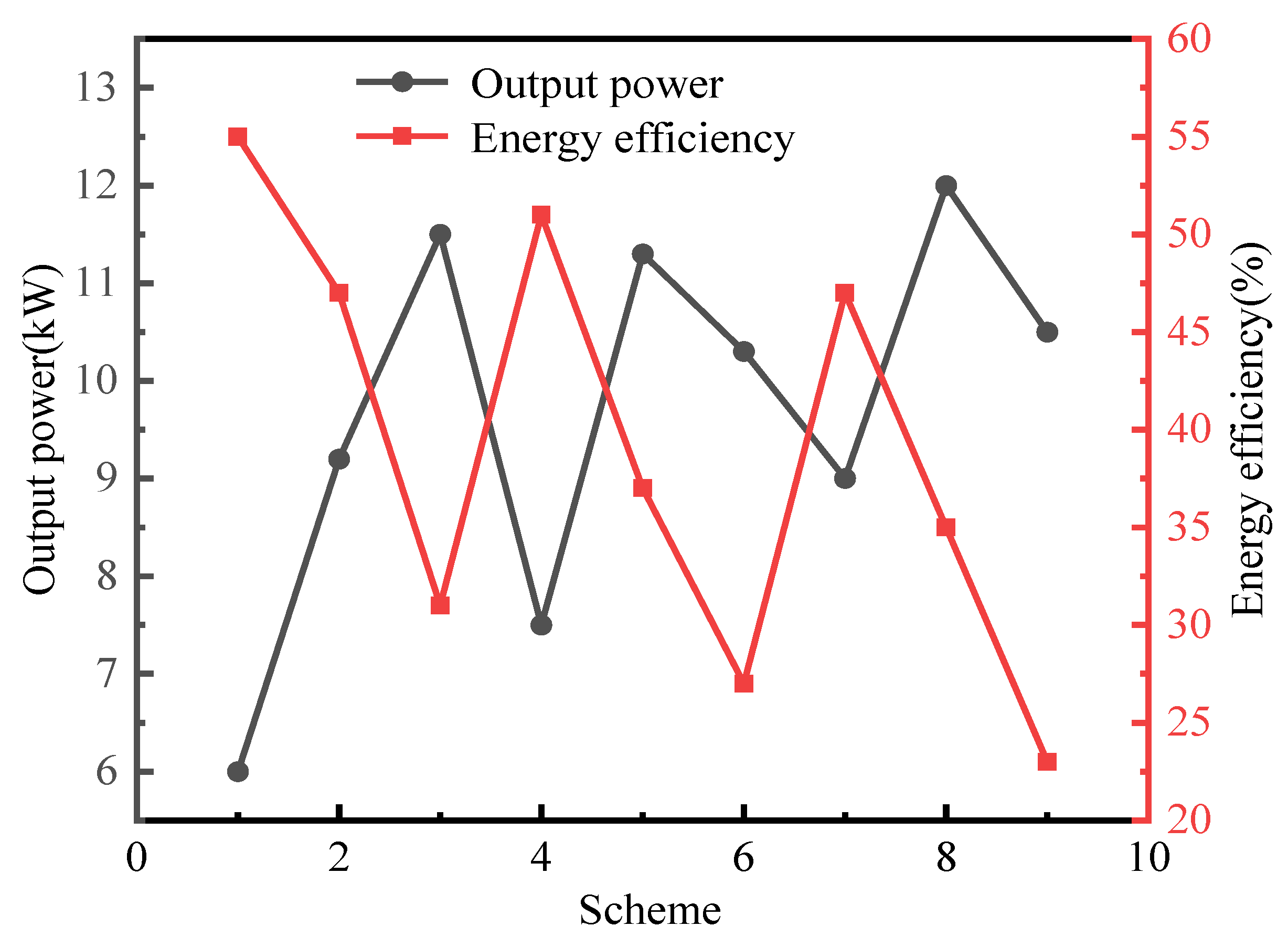

3.2. Optimization of the Valve Lift Curve

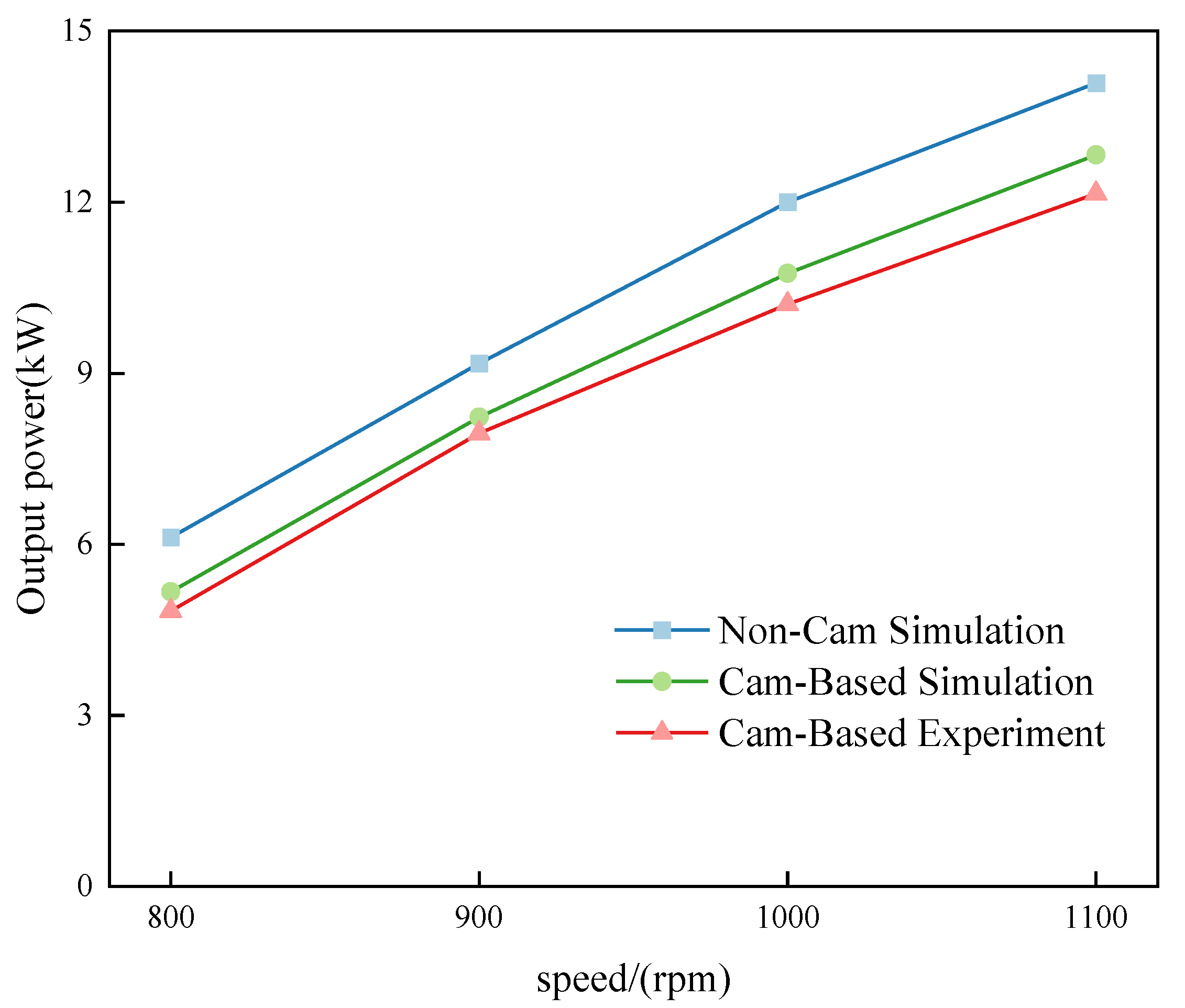

4. Comparative Analysis of the Performance of Non-Cam and Cam-Based Expanders

5. Conclusions

- (1)

- Under certain constraints, the valve lift curve involved in the improved S-curve-based trajectory planning method has a high coefficient of fecundity.

- (2)

- The degree of influence of different valve lift curve design parameters on the output power is . The larger the value of the selected parameter, the larger the intake air volume during PTE operation, which will increase the output power. The degree of influence of each parameter on energy efficiency is also . However, the larger the value of the selected parameter, the greater the energy efficiency of the PTE will be reduced.

- (3)

- Different combinations of parameters for the design of the optimal valve lift curve at different speeds. At 800 rpm, the optimal design parameter combination results in an output power of 7.12 kW and an energy efficiency of 53.5%. At 900 rpm, the optimal combination of design parameters results in an output power of 8.17 kW and an energy efficiency of 50.6%. At 1000 rpm, the optimum combination of design parameters results in an output power of 9.2 kW, with an energy efficiency of 46.8%. At 1100 rpm, the optimum combination of design parameters results in an output power of 12.09 kW with an energy efficiency of 41.2%.

- (4)

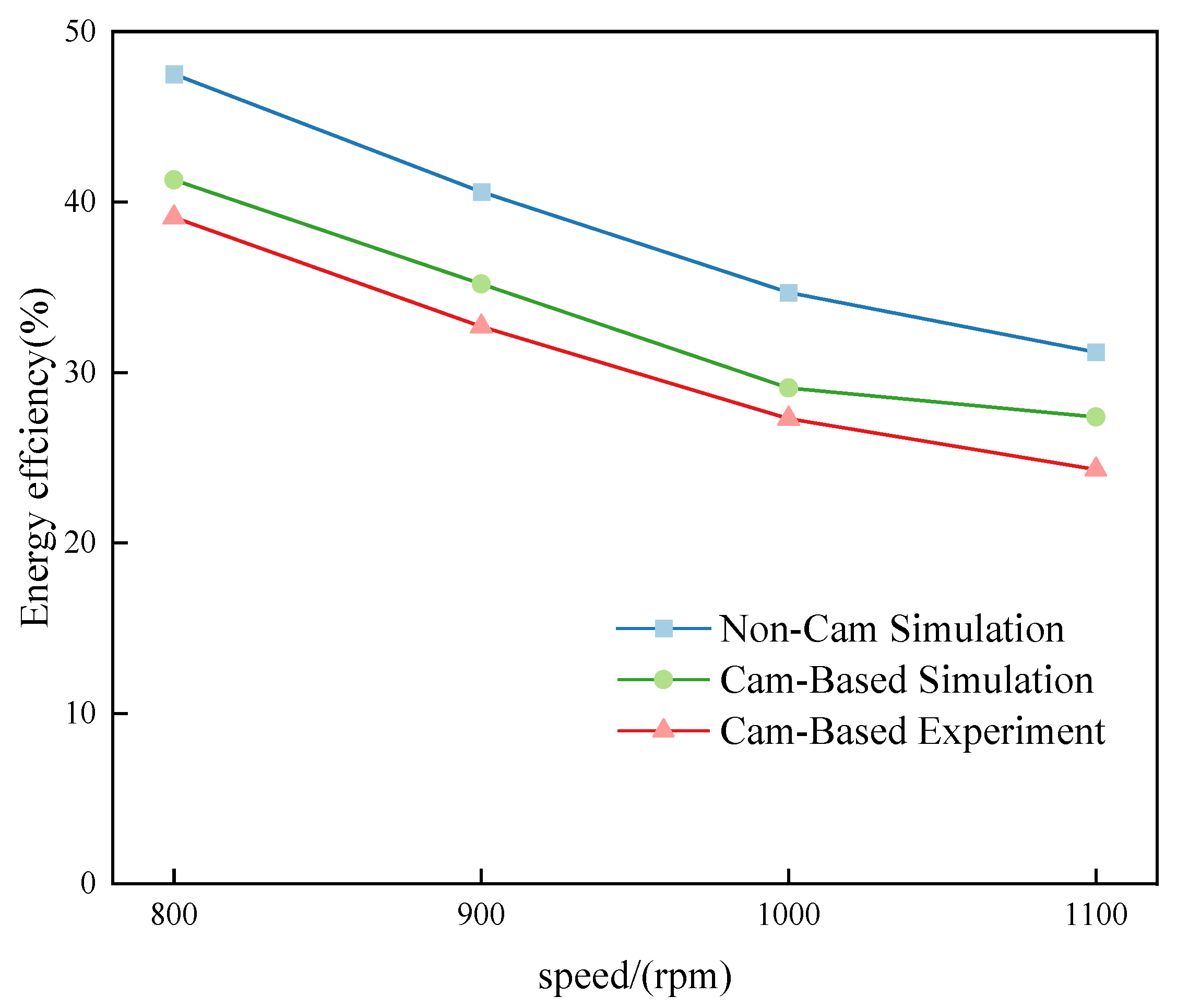

- The output performance of a non-cam expander is better than that of a cam-based piston expander at different speeds. Through simulation comparison, the output power increased by 18.37%, 11.42%, 11.62%, and 9.82%, respectively, at different speeds. Energy efficiency improved by 15.01%, 15.05%, 14.24%, and 13.86%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y. New energy storage enters large-scale development period. People’s Daily of China, 18 March 2024.

- Sun, X.; Gui, Z.; Zhang, X.; Li, Y.; Li, X.; Xu, Y.; Chen, H. Research progress on compressed air energy storage coupled with renewable energy. Chin. J. Electr. Eng. 2023, 43, 9224–9242. [Google Scholar]

- Lu, Y.; Xu, W. Analysis of frequency characteristics of compressed air energy storage for power generation. Hydraul. Pneum. 2024, 48, 124–130. [Google Scholar]

- Minutillo, M.; Lavadera, A.; Jannelli, E. Assessment of design and operating parameters for a small compressed air energy storage system integrated with a standalone renewable power plant. J. Energy Storage 2015, 4, 135–144. [Google Scholar] [CrossRef]

- Li, S.; Dai, Y. Design and simulation analysis of a small-scale compressed air energy storage system directly driven by vertical axis wind turbine for isolated areas. Energy Eng. 2015, 141, 4014032. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Izadi, S.; Pishbin, S.I.; Sheikhani, H.; Deymi-Dashtebayaz, M. Thermodynamic analysis of medium pressure reciprocating natural gas expansion engines. Pol. J. Chem. Technol. 2015, 17, 119–125. [Google Scholar] [CrossRef]

- He, W.; Wang, J. Optimal selection of air expansion machine in Compressed air energy storage: A review. Renew. Sustain. Energy Rev. 2018, 87, 77–95. [Google Scholar] [CrossRef]

- Olivier, D.; Antoine, P.; Remi, D.; Vincent, L. Experimental investigation and optimal performance assessment of four volumetric expanders (scroll, screw piston, and roots) tested in a small-scale organic Rankine cycle system. Energy 2018, 165, 1119–1127. [Google Scholar] [CrossRef]

- Yu, Q.; Li, X.; Li, X. Performance analysis and experimental verification of piston expander. Hydraul. Pneum. 2022, 46, 34–43. [Google Scholar]

- Xu, Q.; Cai, M.; Yu, Q. Multi-parameter and multi-objective optimisation method for pneumatic engines. J. Beijing Univ. Aeronaut. Astronaut. 2013, 39, 803–807. [Google Scholar]

- Hannibal, W.; Flierl, R.; Stiegler, L.; Meyer, R. Overview of Current Continuously Variable Valve Lift Systems for Fourstroke Spark-Ignition Engines and the Criteria for Their Design Ratings; SAE Technical Papers: Detroit, MI, USA, 2004. [Google Scholar]

- Fan, X.; Chang, S.; Lu, J.; Liu, L.; Yao, S.; Xiao, M. Energy consumption investigation of electromagnetic valve train at gas pressure conditions. Appl. Therm. Eng. 2019, 146, 768–774. [Google Scholar] [CrossRef]

- Dimitrova, Z.; Tari, M.; Lanusse, P.; Aioun, F.; Moreau, X. Robust control for an electromagnetic actuator for a camless engine. Mechatronics 2019, 57, 109–128. [Google Scholar] [CrossRef]

- Yang, X.; Liang, K. Measurement and modelling of a linear electromagnetic actuator driven camless valve train for spark ignition IC engines under full load condition. Mechatronics 2021, 77, 102604. [Google Scholar] [CrossRef]

- Du, Q.; Zhang, Z.; Zhao, C. Dynamic characteristic test of camless electro-hydraulic variable valve train. J. Intern. Combust. Engine 2023, 41, 271–279. [Google Scholar]

- Zhang, S.; Zhao, Z.; Zhao, C.; Zhang, F.; Wang, S. Development and validation of electro-hydraulic camless free-piston engine. Appl. Therm. Eng. 2016, 102, 1197–1205. [Google Scholar] [CrossRef]

- Watson, J.; Wakeman, R. Simulation of a Pneumatic Valve Actuation System for Internal Combustion Engine; SAE Technical Paper: Detroit, MI, USA, 2005. [Google Scholar] [CrossRef]

- Ma, J.; Stuecken, T.; Schock, H. Model Reference Adaptive Control of a Pneumatic Valve Actuator for Infinitely Variable Valve Timing and Lift; SAE Technical Paper: Detroit, MI, USA, 2007. [Google Scholar] [CrossRef]

- Ma, J.; Zhu, G.; Schock, H. A Dynamic Model of an Electropneumatic Valve Actuator for Internal Combustion Engines. J. Dyn. Syst. Meas. Control. 2010, 132, 021007. [Google Scholar] [CrossRef]

- Venkatesh, D.; Selvakumar, A. A Novel Design of Pneumatic Actuator for Camless Engines; SAE Technical Paper: Detroit, MI, USA, 2016. [Google Scholar] [CrossRef]

- Tripathy, S.; Das, A.; Sahu, B.; Srivastava, D.K. Electro-pneumatic variable valve actuation system for camless engine: Part I—development and characterization. Energy 2020, 193, 116740. [Google Scholar] [CrossRef]

- Shi, Y.; Yu, Q.; Sun, G.; Li, X. Intake Valve Profile Optimization for a Piston-Type Expander Based on Load. Process 2023, 11, 843. [Google Scholar] [CrossRef]

- Yu, Q.; Hao, X.; Tan, X. Comparative study on air distribution system for piston-type compressed air engine. Adv. Mech. Eng. 2017, 9, 1687814017697625. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, B.; Zhang, H.; Guo, Q.; Zhang, Y.; Ll, H. Optimisation study of motion control trajectory of loading and unloading robot for CNC machine tools. Meas. Control. Technol. 2021, 40, 32–38. [Google Scholar]

| Speed (rpm) | Scheme | Parameter A (mm) | Parameter B (ms) | Parameter C (ms) |

|---|---|---|---|---|

| 800 | 1 | 3 | 2 | 19 |

| 2 | 4 | 3 | 22 | |

| 3 | 5 | 4 | 25 | |

| 900 | 1 | 3 | 2 | 16 |

| 2 | 4 | 3 | 19 | |

| 3 | 5 | 4 | 22 | |

| 1000 | 1 | 4 | 3 | 15 |

| 2 | 5 | 4 | 18 | |

| 3 | 6 | 5 | 21 | |

| 1100 | 1 | 5 | 4 | 12 |

| 2 | 6 | 5 | 15 | |

| 3 | 7 | 6 | 18 |

| Scheme | Parameter A (mm) | Parameter B (ms) | Parameter C (ms) |

|---|---|---|---|

| 1 | 4 | 3 | 15 |

| 2 | 4 | 4 | 18 |

| 3 | 4 | 5 | 21 |

| 4 | 5 | 3 | 18 |

| 5 | 5 | 4 | 21 |

| 6 | 5 | 5 | 15 |

| 7 | 6 | 3 | 21 |

| 8 | 6 | 4 | 15 |

| 9 | 6 | 5 | 18 |

| Parameter | Value |

|---|---|

| Cylinder diameter (mm) | 0.085 |

| Cylinder stroke (m) | 0.088 |

| Crank radius (m) | 0.044 |

| Connecting rod length (m) | 0.139 |

| Clearance volume (m3) | 3.97 × 10−5 |

| Piston ring thickness (m) | 0.0014 |

| Piston mass (kg) | 1.011 |

| Inlet and exhaust valve area (mm2) | 74.61 |

| Parameter | Parameter A | Parameter B | Parameter C |

|---|---|---|---|

| 8.9 | 7.5 | 9.33 | |

| 9.7 | 10.83 | 9.07 | |

| 10.5 | 10.77 | 10.6 | |

| R | 1.6 | 3.33 | 1.53 |

| Parameter | Parameter A | Parameter B | Parameter C |

|---|---|---|---|

| 44.33 | 51 | 39 | |

| 38.33 | 39.67 | 40.33 | |

| 35 | 27 | 38.33 | |

| R | 9.33 | 24 | 2 |

| Speed (rpm) | P (kW) | η (%) | (mm) | (ms) | (ms) |

|---|---|---|---|---|---|

| 800 | 6.12 | 47.5 | 4 | 2 | 19 |

| 900 | 9.17 | 40.6 | 4 | 3 | 19 |

| 1000 | 12 | 34.7 | 5 | 4 | 15 |

| 1100 | 14.09 | 31.2 | 6 | 4 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Yu, Q.; Han, Z.; Qin, R.; Hao, X. Design and Optimization of Valve Lift Curves for Piston-Type Expander at Different Rotational Speeds. Fluids 2025, 10, 204. https://doi.org/10.3390/fluids10080204

Sun Y, Yu Q, Han Z, Qin R, Hao X. Design and Optimization of Valve Lift Curves for Piston-Type Expander at Different Rotational Speeds. Fluids. 2025; 10(8):204. https://doi.org/10.3390/fluids10080204

Chicago/Turabian StyleSun, Yongtao, Qihui Yu, Zhenjie Han, Ripeng Qin, and Xueqing Hao. 2025. "Design and Optimization of Valve Lift Curves for Piston-Type Expander at Different Rotational Speeds" Fluids 10, no. 8: 204. https://doi.org/10.3390/fluids10080204

APA StyleSun, Y., Yu, Q., Han, Z., Qin, R., & Hao, X. (2025). Design and Optimization of Valve Lift Curves for Piston-Type Expander at Different Rotational Speeds. Fluids, 10(8), 204. https://doi.org/10.3390/fluids10080204