1. Introduction

Aerostatic systems, known for their high motion accuracy [

1], rapid response [

2], low friction [

3], and pollution-free operation [

4], have been widely applied in ultra-precision machining [

5]. The core component determining system performance is the aerostatic restrictor [

6], which is typically developed using engineering simplification algorithms, finite element and finite difference methods, computational fluid dynamics, multi-physics coupling techniques, and experimental approaches [

7,

8]. Each method, however, has its limitations: engineering simplification algorithms exhibit large errors and have limited applicability, experimental methods require sophisticated and precise testing equipment, and finite element and finite difference methods are hindered by the complexity of grid division and prolonged computation times.

In order to shorten the research process, researchers have drawn inspiration from the concept of electrical resistance, aiming to establish an impedance model for aerostatic throttle via quasi-electric analysis [

9]. This research approach can be traced back to a century ago [

10]. Recently, Xu et al. employed aerodynamic resistance networks to analyse the static characteristics of pneumatic components [

11], and Sachan et al. developed a device to measure and analyse gas flow resistance in porous media [

12]. Stanley et al. proposed a resistor–capacitor model of pneumatic loops and examined its response time, demonstrating that a specific pipeline inner diameter can minimise this response time [

13]. Jing et al. investigated the resistance characteristics of flue tees under varying flow ratios [

14], and Shen et al. explored the flow resistance characteristics of gas in slit flow channels [

15]. Wu et al. applied quasi-electric analysis to study aerostatic bearings with closely spaced micro holes (ABMHs), established a resistance model, and evaluated the effects of series and parallel connections in restrictor orifice structures on the load-bearing capacity of the restrictor. Their findings indicated that the resistance of ABMHs is influenced by both the flow and differential pressure [

16].

Calamas et al. analysed how bifurcation angles and apertures in flow channels affect pressure differentials [

17], and Liao et al. studied porous materials in restrictors and assessed the effect of temperature on pressure drop versus flow rate characteristics [

18,

19]. Pant et al. examined the relationship between pressure drop and mass flow in automotive gas flow systems and developed a model consistent with empirical results, verifying its accuracy [

20]. Liu et al. investigated flow–pressure drop curves for porous graphite using various equations [

21].

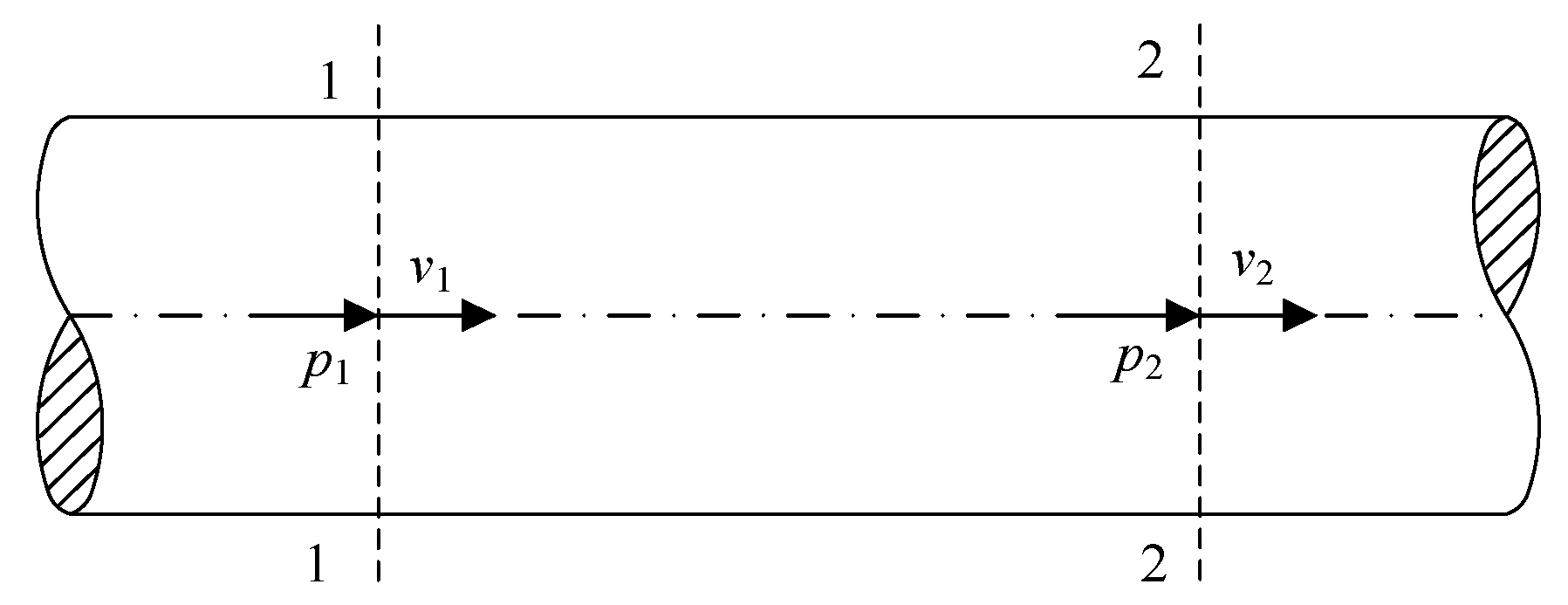

Although the concept of gas resistance has been explored to some extent, most studies have merely drawn simplistic analogies with Ohm’s law when analysing aerostatic restrictors, as they have neither conducted in-depth investigations into the validity of establishing gas resistance models based on this relationship nor differentiated gas resistance models according to the compressibility of gases. Since the primary structure of the restrictor’s flow channel is a pipe, the restrictor can be regarded as a combination of pipe structures connected in series or parallel. Consequently, this study focuses on pipelines (i.e., thin and long pipes) as the research object to advance the theory of gas resistance, establish a gas resistance model for pipelines, and investigate the series characteristics of gas resistance. This study differentiates gas resistance models based on Bernoulli’s equation and the gas flow velocity, proposes new definitions of gas resistance corresponding to velocity ranges, and further reveals the nonlinear superposition characteristics of series-connected gas resistances through the established models. In summary, we find that our theoretical model is effective and reliable, providing theoretical support for impedance analysis of aerostatic systems. This study redefined the gas resistance model of pipelines under different states through the Bernoulli equation, established the theoretical calculation method of series gas resistance, and verified the model through simulation and experiments, with the error controlled within 5%. It provides high-precision theoretical support for the impedance analysis of gas static pressure systems.

In this paper,

Section 1 introduces the current research status and existing problems of the gas resistance theory.

Section 2, through theoretical analysis, obtains the calculation models of gas resistance in pipelines under low-speed and high-speed conditions, as well as the series gas resistance.

Section 3, based on the simulation results, derives the formula for calculating the friction factor along the pipeline and validating the calculation model proposed in

Section 2 under low-speed conditions.

Section 4 builds an experimental setup based on the calculation model proposed in

Section 2 for low-speed conditions, and verifies the accuracy of the proposed gas resistance model by combining experimental and simulation results.

Section 5 summarises the research content and looks towards future research directions.

3. Simulation Analysis of Pipeline Gas Resistance Value

3.1. Simulation Model and Boundary Conditions

To verify the accuracy of pipeline gas resistance modelling, COMSOL software was used to model and simulate a single gas resistance pipeline under low-Mach-number conditions. Owing to the simple structure of the model, a free tetrahedral mesh was used for partitioning. For instance, a gas resistance pipeline model with an inner diameter of 5 mm and a length of 500 mm was divided into an average unit size of 0.70 mm, resulting in 571,281 units, as shown in

Figure 3.

To minimise the impact of grid size on the simulation results, the model was validated for grid size independence. Five different grid sizes were used for calculations, and the results are presented in

Table 1. When the average unit size was less than 0.7 mm, there were minimal differences in the calculation results for the average flow velocity,

, maximum flow velocity,

, and mass flow rate,

.

The standard model for turbulence in fluid flow was selected, and steady-state research was conducted for the physical field. Gaseous air was chosen as the material with default material properties. The two sections of the pipeline were configured with inlet pressure and outlet pressure conditions (atmospheric pressure), while all other surfaces were set as non-slip wall surfaces. Surface roughness was not considered, and the fluid temperature was set to 293.15 K.

3.2. Validation of Friction Factor Fitting and Gas Resistance Model

The friction factor,

, in the determination formula for gas resistance, must either be obtained experimentally or calculated using empirical formulas. However, as Wang et al. [

24] noted, when derived from empirical formulas,

is not universally applicable to all fluid media and can deviate significantly, with errors sometimes exceeding 50%, compared with experimentally obtained friction factors.

To address this issue, the

for air in a circular tube under a low Mach number was determined via simulation and curve fitting. By substituting the definition Formula (6) into the determination Formula (7), the value of

was calculated. A pipeline with an inner diameter ranging from 1 to 6 mm and a length of 0.5 m was simulated, with the results illustrated in

Figure 4.

Owing to the small dynamic viscosity coefficient of gas, most of its flow within the pipeline occurs in the hydraulically smooth pipe region. Consequently, the friction factor,

, is primarily related to the Reynolds number,

. As shown in

Figure 4, although

varies with different gas resistance pipeline inner diameters, the overall trend of its variation with

exhibits good consistency. Referring to the classical empirical formula for

, the calculation formula for the

of air in a circular tube is given as

. The best estimated values of coefficients

and

were obtained by fitting

to

using the least-squares method. Therefore, the formula for calculating

of air in a circular tube is expressed as follows:

To verify the accuracy of the proposed gas resistance model, simulations were conducted on pipelines with inner diameters of 1 and 6 mm at a length of 1 m. Equation (25) was substituted into Equation (6) to calculate their gas resistance, which was then compared with the gas resistance values calculated using Equation (5). The results, shown in

Figure 5, indicate that the relative error between the gas resistance values calculated using Equations (5) and (6) remained within 10%, confirming that the proposed gas resistance model at low Mach numbers is accurate.

3.3. Simulation Results of Series Gas Resistance

Using the proposed series gas resistance model, simulations were conducted to examine two cases of series gas resistance under low-Mach-number conditions, employing the same grid division method. Case 1 involved a series gas resistance model composed of pipes with inner diameters of 2 and 3 mm, both with lengths of 0.5 m. Case 2 consisted of pipes with inner diameters of 1 and 6 mm, also with lengths of 0.5 m. The deterministic gas resistance values were calculated using Equation (22).

Taking Case 1 as an example, the determination formula for series gas resistance includes five terms, and their values are shown in

Table 2. The results indicate that the pressure difference increases from top to bottom under varying pressure conditions. The sum of the five terms in each row corresponds to the series gas resistance value at the respective pressure difference.

From

Table 2, it can be seen that because the last three terms depend on the structural parameters of the pipeline and are unaffected by the flow state, their influence on the series gas resistance value increases with the pressure difference across the series pipeline. For example, in Case 1, when the pressure difference is 1.5 kPa, the last three terms account for only 3% of the series gas resistance. However, when the pressure difference increases to 34 kPa, the contribution of these terms rises to 13%.

When the inner diameters of the two series gas resistance pipelines differ significantly, the impact of the last three terms on the series gas resistance value is minimal. Using the same method, the terms in the determination formula for Case 2 were calculated. At a pressure difference of 92 kPa, the last three terms had the most significant influence on the series gas resistance value, yet they still accounted for only 0.3% of the total series gas resistance value.

The gas resistance values were calculated using both the definition Formula (5) and the determination Formula (22). The gas resistance value–pressure difference relationship curves were plotted based on the calculation results, as shown in

Figure 6. The results indicate that the gas resistance value of the series pipeline decreases as the pressure difference at its ends increases. Overall, the gas resistance values calculated using the definition Formula (5) were consistent with those calculated using the determination Formula (22), with discrepancies appearing only at small pressure differences.

In Case 1, the maximum relative error was 6.8% at a pressure difference of 1.5 kPa, whereas the relative error at other points was less than 3.6%. In Case 2, the maximum relative error was 13.4% at a pressure difference of 4.4 kPa, with errors at other points below 7.8%. These discrepancies can be attributed to the low Reynolds number at lower pressures, which introduces larger errors in the friction factor, , calculated from . These results demonstrate that the proposed low-Mach-number series gas resistance model is suitable for pipe combinations with inner diameters ranging from 1 to 6 mm.

4. Experiment and Result Analysis

4.1. Gas Resistance Experimental Device and Process

The experimental setups shown in

Figure 7 and

Figure 8 were designed for the gas resistance experiment and the series gas resistance experiment, respectively. The pipeline to be measured and the sensor installation module were connected via threaded joints. The sensor installation module was flexibly connected to the electrical proportional valve and flow metre using quick connectors, and the measuring device was placed on a vibration isolation platform.

The air source consisted of a two-stage series closed-loop stabilised pressure system, capable of continuously and stably providing compressed air with a maximum pressure of 0.5 MPa. The air supply pressure was controlled by the electric proportional valve to adjust the pressure difference at both ends of the gas resistance. The pressure at both ends of the gas resistance was measured using a micro pressure sensor, and the mass flow rate through the gas resistance was measured using a flow metre, ensuring that the flow rate remained within the low-Mach-number range. The micro pressure sensor model utilised was HM91, with a range of 0–0.5 MPa and an accuracy of ±0.1%. The flow metre model employed was HK25, with a range of 0–8 m³/h and an accuracy of 0.75%. The electrical proportional valve model utilised was ITV2050, with a pressure regulation range of (0.005 to 0.9) MPa and a sensitivity better than 0.2% F.S. The oil mist separator model employed was AFM30, with a precision of 0.5 μm. The ambient temperature during the experiments was 18.3 °C.

4.2. Analysis of Experimental Results of Gas Resistance

In

Figure 7, the measured pipe was a cold-rolled seamless 304 stainless steel round pipe with an inner diameter of 6 mm and a length of 0.5 m. The mass flow through the measured pipe was obtained under different pressure differences. The experimental gas resistance value was calculated using Equations (5) and (6), and the gas resistance value–pressure difference relationship curve was plotted, as shown in

Figure 9a.

An analogue simulation model of the experimental device was constructed in COMSOL, and the simulated gas resistance values were calculated using Equation (6). The relationship curve between the gas resistance value and the pressure difference is shown in

Figure 9b.

Figure 9 shows that the gas resistance values calculated using Equation (6) closely matched those calculated using Equation (5), with a maximum relative error of 4.8%. The good consistency between the two curves demonstrates that the friction factor calculation formula is suitable for circular pipes with an inner diameter of 6 mm. As the pressure difference between the two ends of the gas resistance pipeline increased, both the experimental and simulated gas resistance values showed a gradual decreasing trend, with a maximum relative error of 3.5% between the two.

The error between the experimental and simulated gas resistance values arises mostly from practical issues, such as the gap between the measured gas resistance pipeline and the sensor installation module. Although the experimental device was designed to avoid damaging the pipeline flow channel structure, inevitable gaps create additional cavities that form a series gas resistance. These gaps are not accounted for in the simulation model or in Equation (6).

Because the assembly gap length is smaller and the inner diameter is larger than those of the gas resistance pipe, the gas resistance value of the assembly gap is smaller than that of the pipe. As a result, the gas resistance value calculated using Equation (6) is slightly lower than that calculated using Equation (5). Nevertheless, the good agreement between the experimental and simulated gas resistance values in the pressure difference curve demonstrates that the proposed low-Mach-number gas resistance model and formula for the coefficient of friction fitted are suitable for pipelines with an inner diameter of 6 mm.

4.3. Analysis of Experimental Results of Series Gas Resistance

The device shown in

Figure 8 was used to conduct the series gas resistance measurement experiment. The lengths of the two series pipes were 0.5 m each, with inner diameters of 4 and 6 mm. From the gas resistance experiment analysis, it can be observed that there is a noticeable difference between the experimental flow channel and the simulation model of the experimental device.

In the series gas resistance experiment, the increased number of connectors made it challenging to build a simulation model that accurately represented the experimental pipeline flow channel. Additionally, it was difficult to strike a balance between the simulation model’s accuracy and computational efficiency. The experimental gas resistance was calculated using Equations (5) and (22), and the gas resistance–pressure difference relationship curve was plotted, as shown in

Figure 10.

From

Figure 10, it can be observed that the gas resistance values calculated using Equations (5) and (22) decrease as the pressure difference at both ends of the gas resistance increases. The maximum relative error between the gas resistance values calculated using the two methods is 3.8%, primarily due to the connection between the two gas resistance pipes.

The analysis of simulated series gas resistance shows that, for series gas resistance, the influence of frictional resistance loss on gas resistance is significantly greater than that of local resistance loss and kinetic energy variation. Owing to the complexity of the flow channel at the connection points, accurately calculating the local resistance loss is challenging. When using the determination formula to calculate gas resistance, only the frictional resistance loss at the connection points is considered.

The relative error between the gas resistance values calculated using both methods remained within 4% during the experiment, demonstrating that the proposed series gas resistance model for low Mach numbers is applicable to series pipelines composed of pipes with inner diameters of 4 and 6 mm. Due to the limitation of the experimental conditions, this paper does not conduct experiments on single and series gas resistance under high-Mach conditions.

5. Conclusions

Inspired by Ohm’s law on electricity, a concept of pipeline gas resistance was proposed. Using the Bernoulli equation, gas resistance and series gas resistance models for pipelines at both low and high Mach numbers were developed and verified through simulations and experiments. Based on the simulation results, the friction factor, , of gas resistance pipelines with inner diameters ranging from 1 to 6 mm at low Mach numbers was fitted, and the accuracy of the expression for this diameter range was confirmed. Unlike electrical resistance, the gas resistance value decreases as the pressure difference at both ends of the pipeline increases.

The experimental results indicate that the maximum relative error between the theoretical analysis and simulation results is 3.1%, whereas the maximum relative error between the definition formula and determination formula is 3.8%. These findings confirm that the theoretical model is effective and reliable, providing strong theoretical support for the impedance analysis of aerostatic systems.

There are limitations in this study. The inner diameter of the air resistance pipeline studied in this paper is in millimetres, but there are structures with smaller inner diameters in the aerostatic pressure system, and whether the flow state of the gas in these structures will change is not discussed in depth in this paper. It is believed that after the gas resistance theory is perfected in the future, it will become an important method for the analysis and design of gas static pressure systems.