Boiling Phenomena and Heat Transfer Enhancement Effect on Micro/Nanoporous Sintered Copper Surfaces

Abstract

1. Introduction

2. Experiments

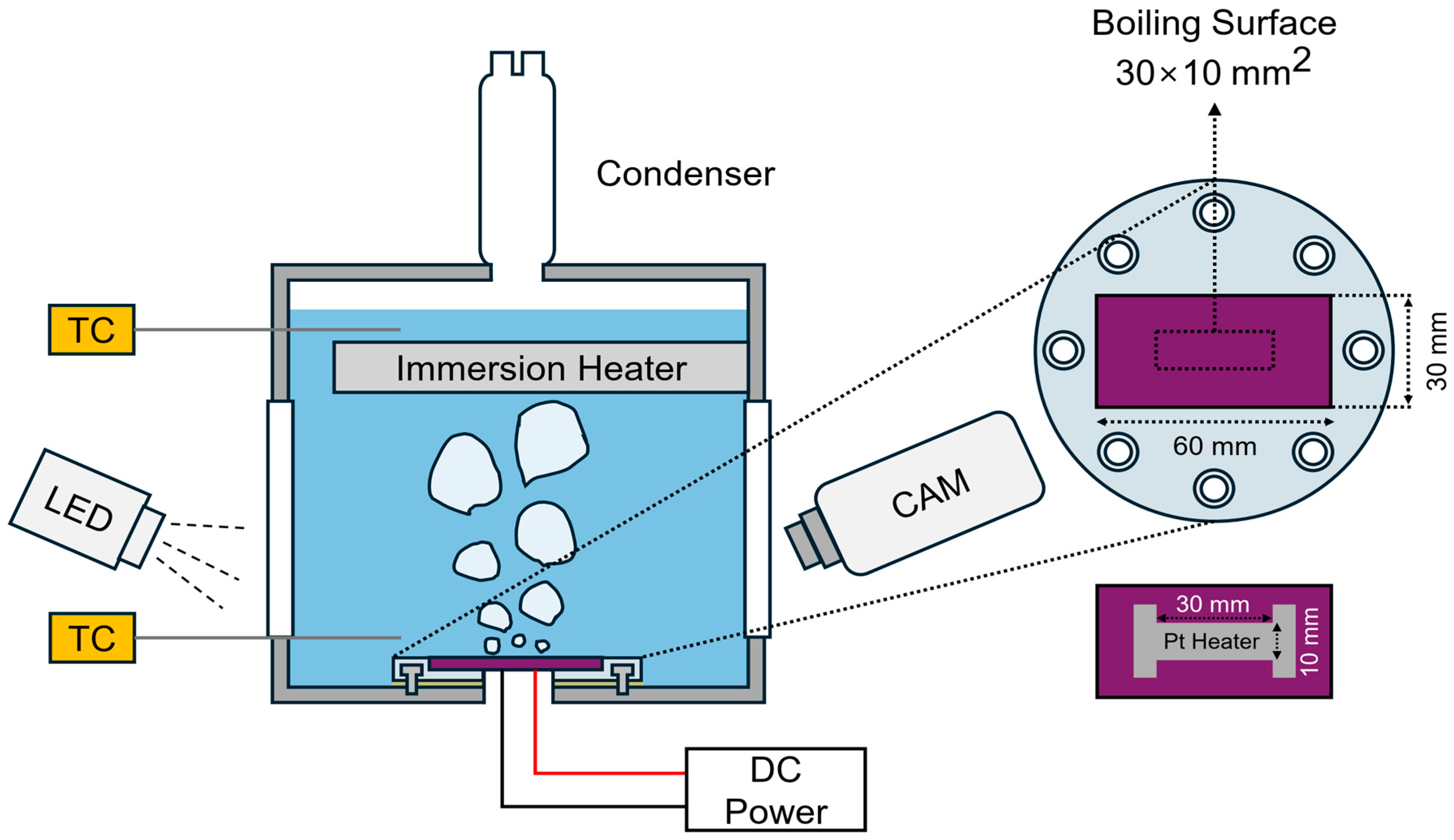

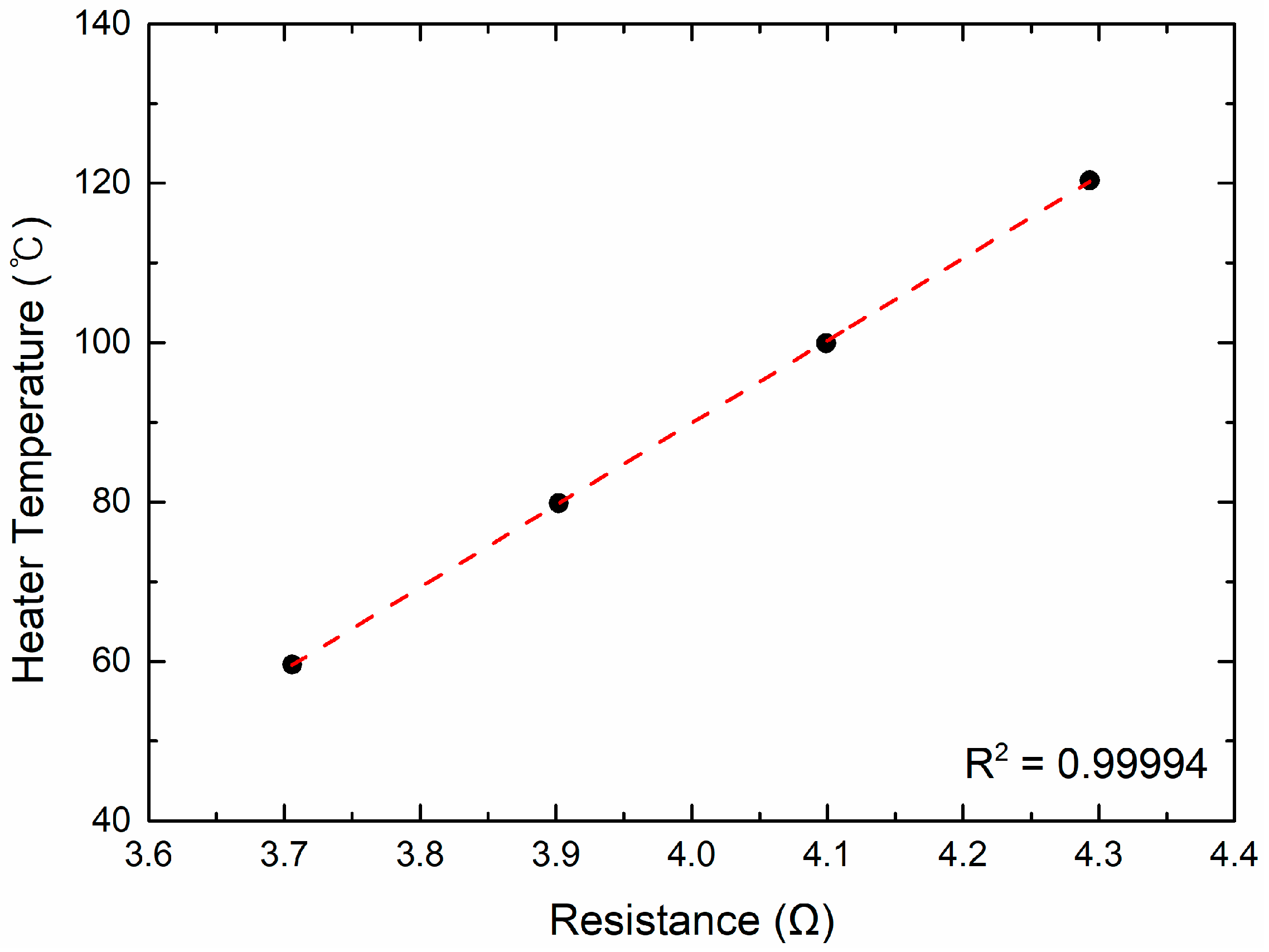

2.1. Pool Boiling Experimental Setup

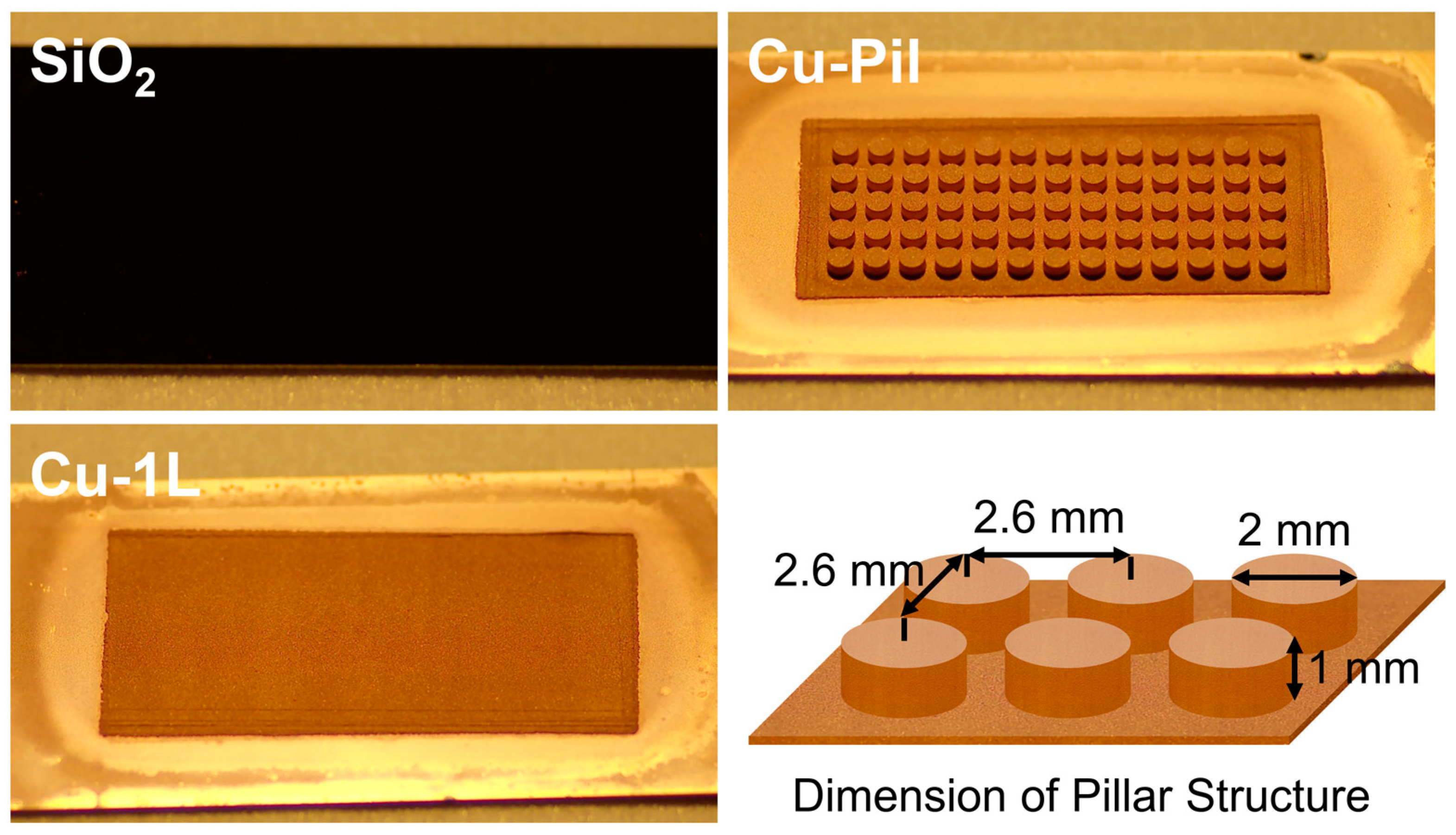

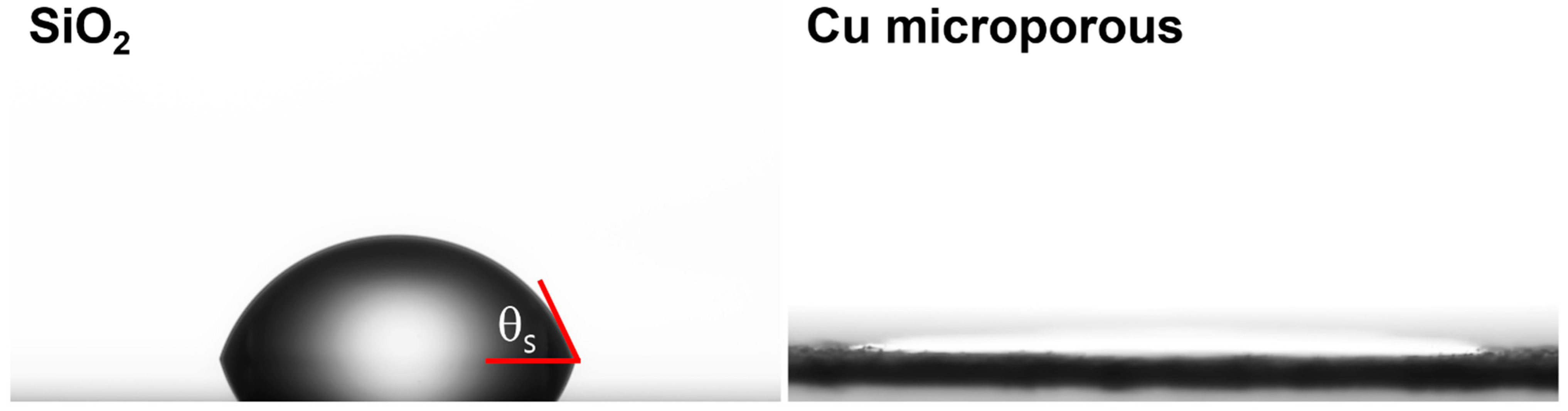

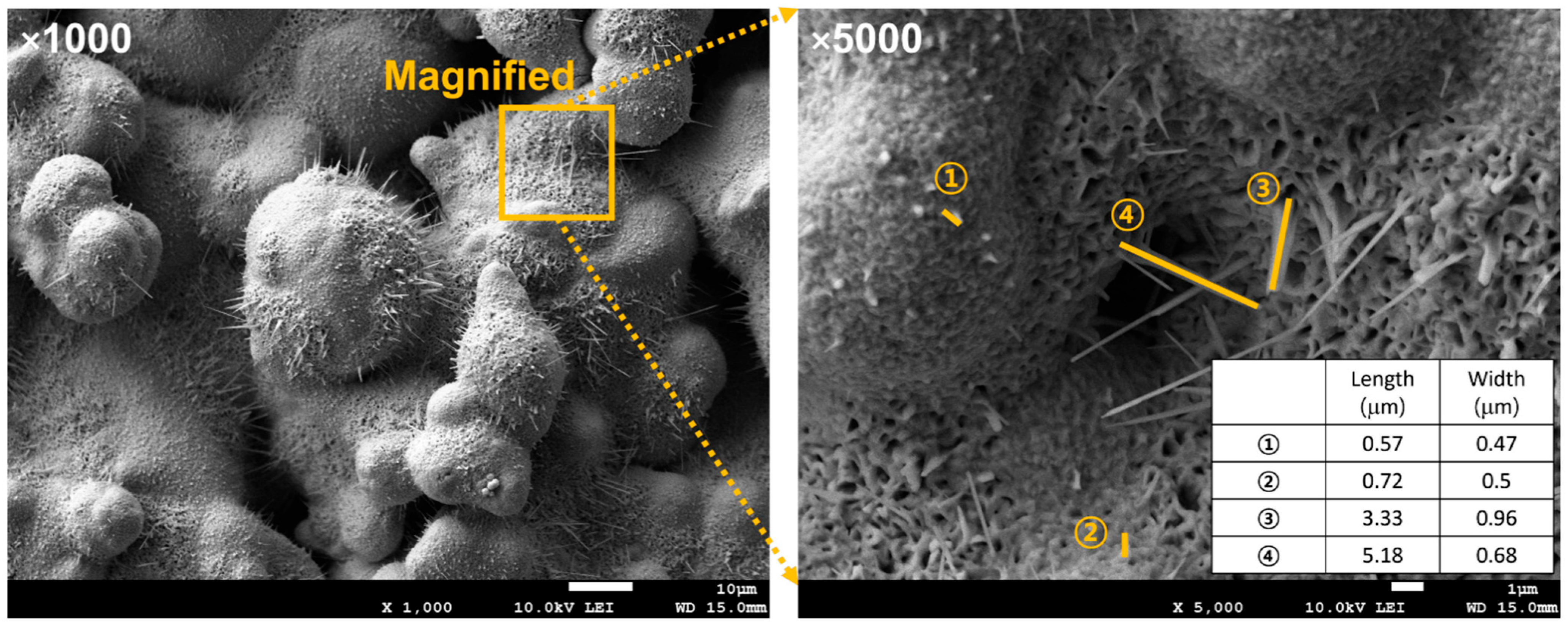

2.2. Surface Characteristics of Tested Substrates

2.3. Characterization of the Tested Substrates

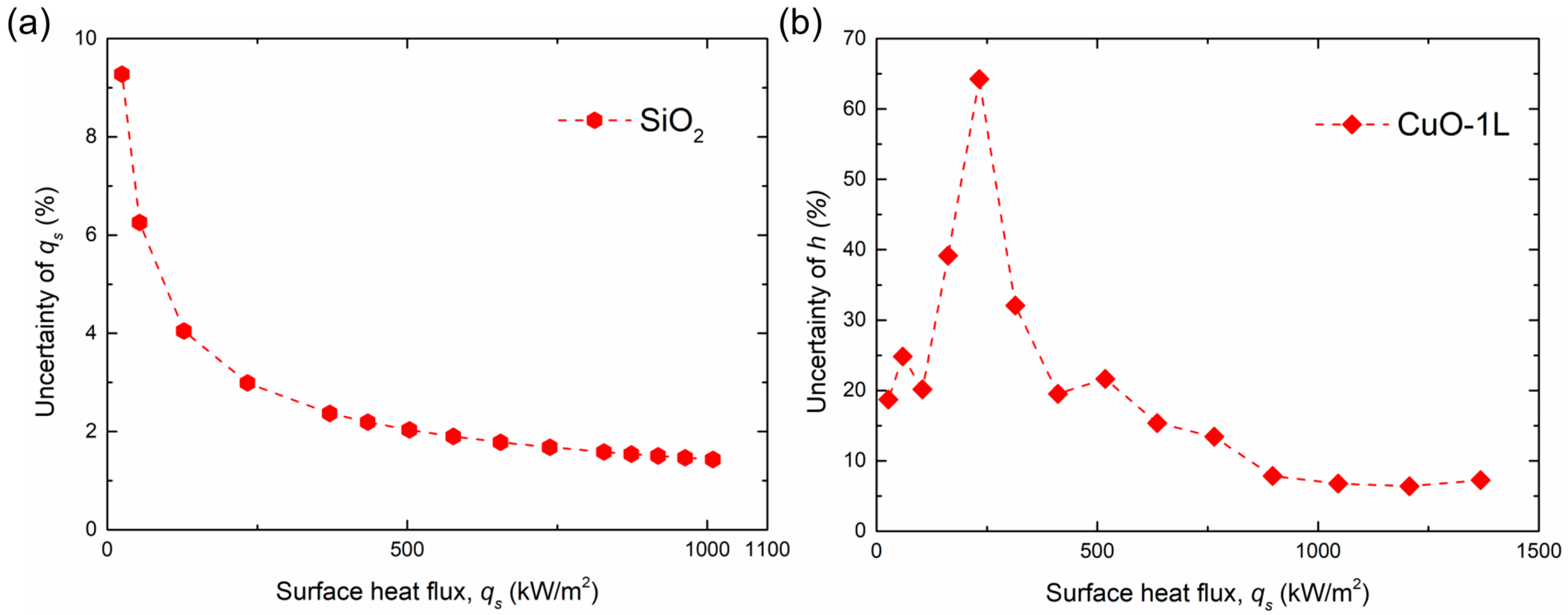

2.4. Uncertainty Analysis

3. Results and Discussion

4. Conclusions

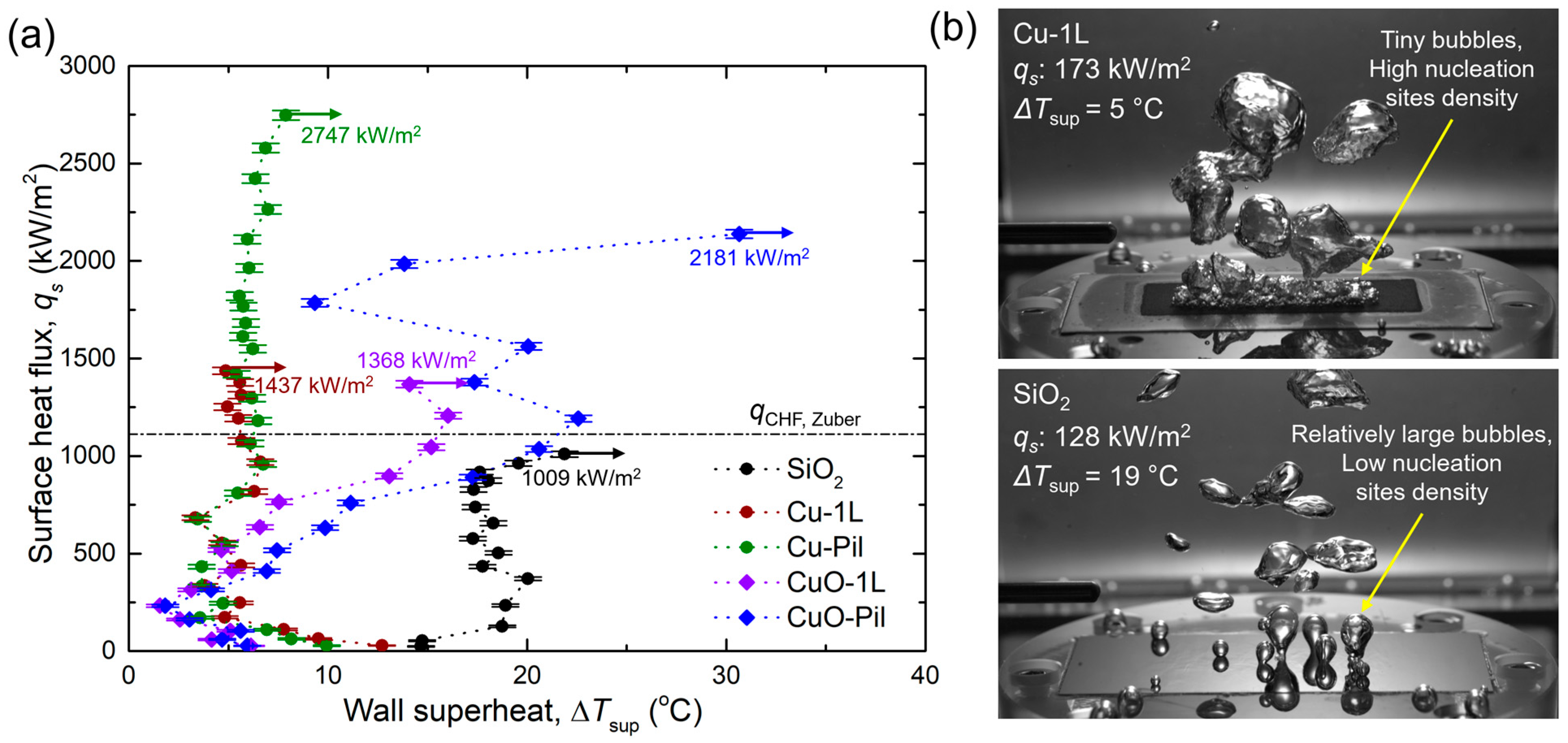

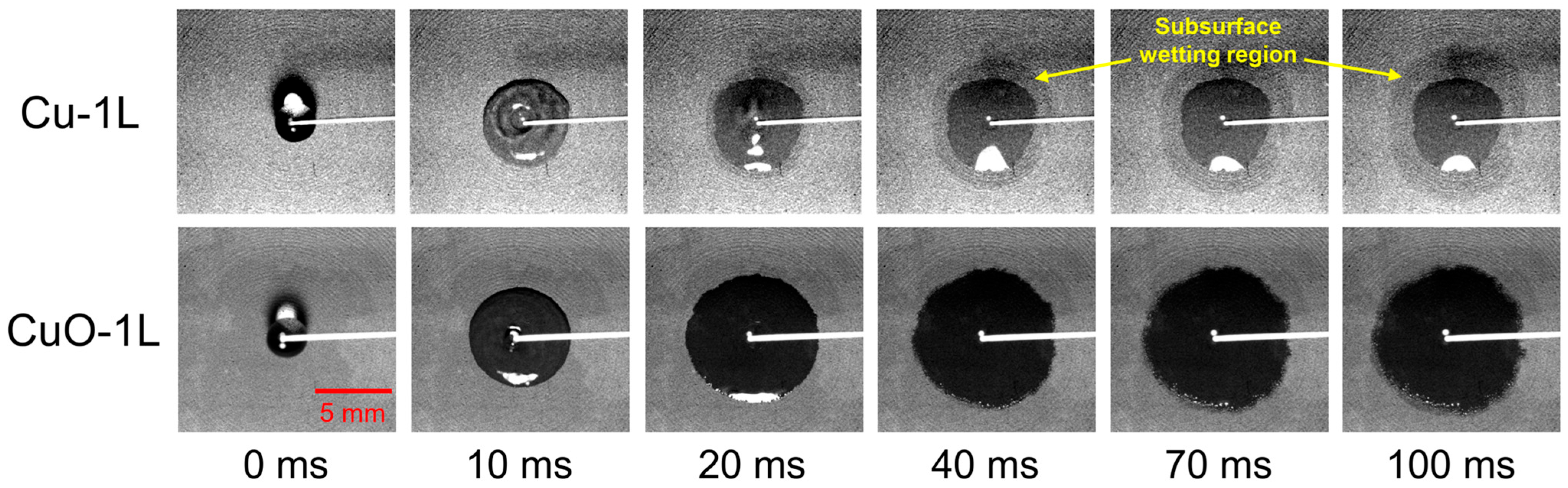

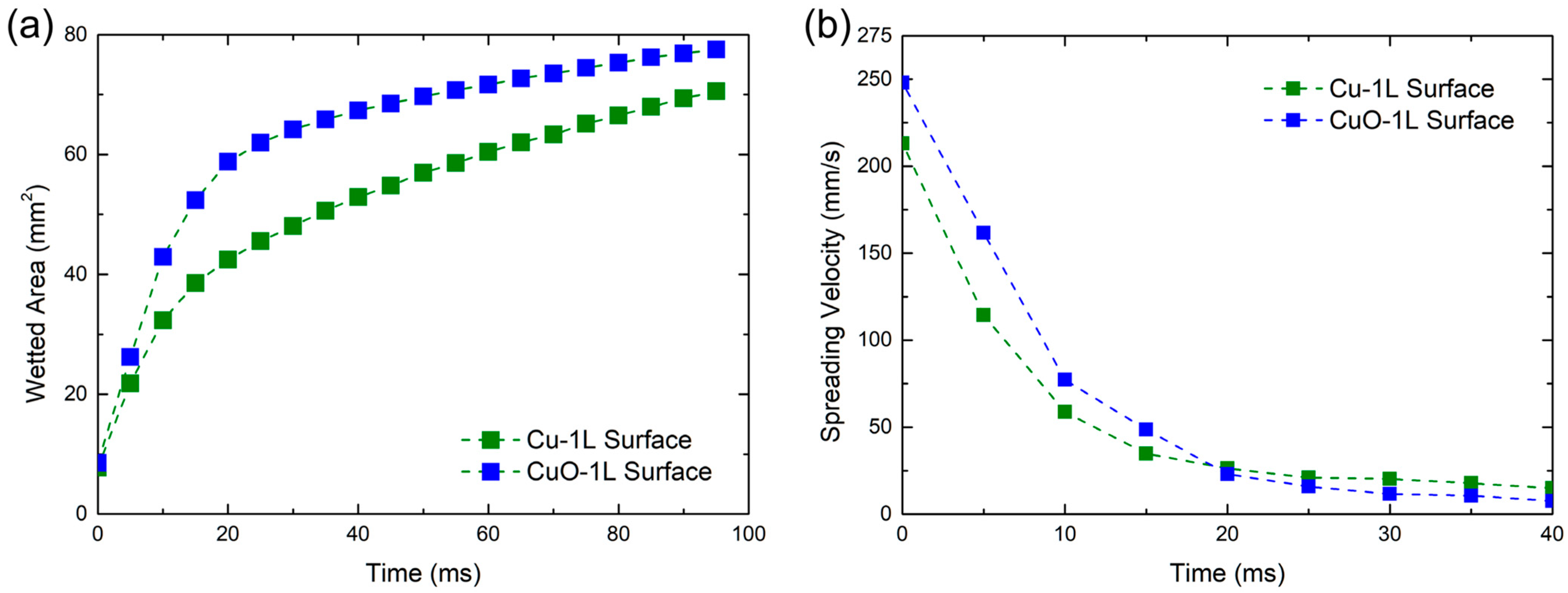

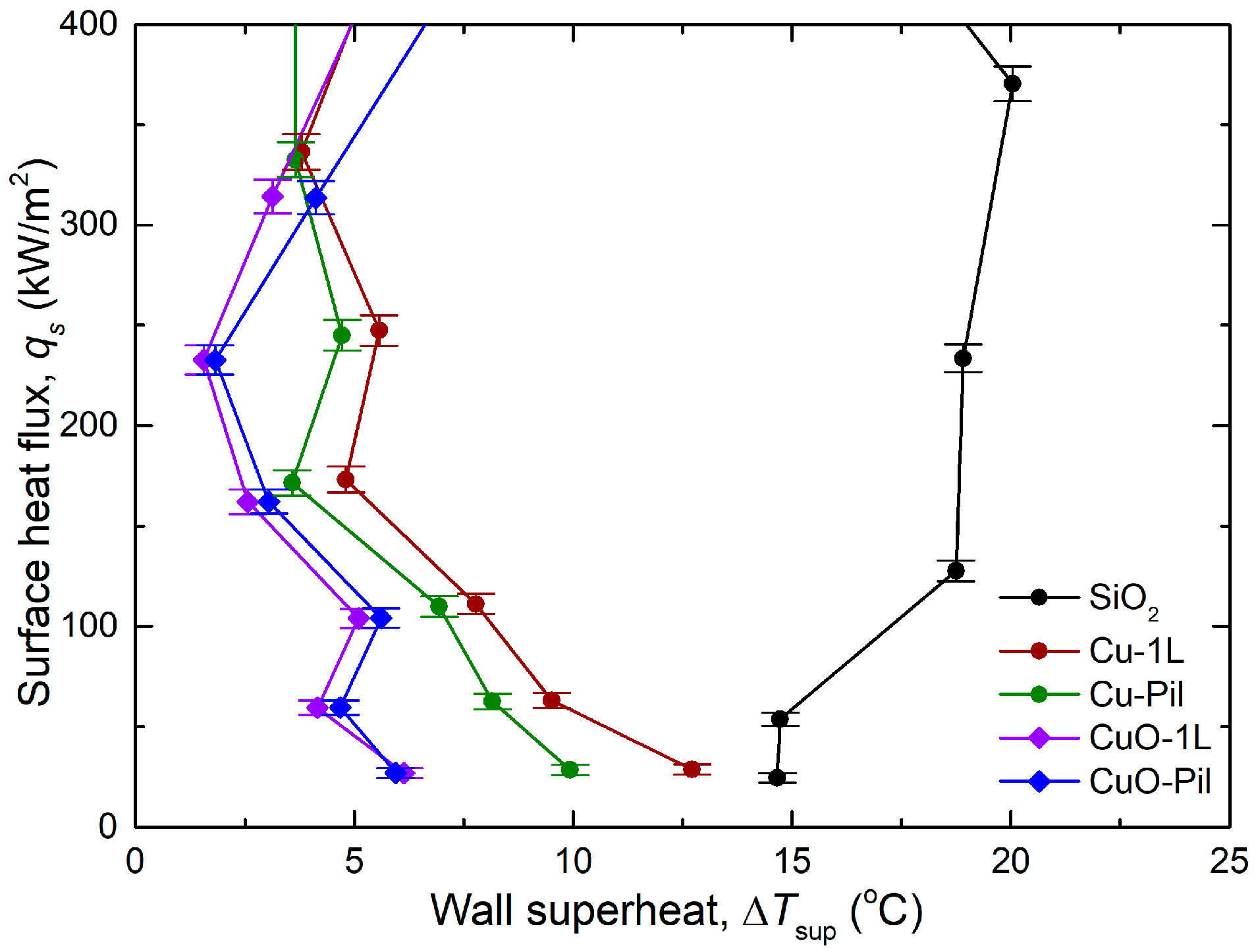

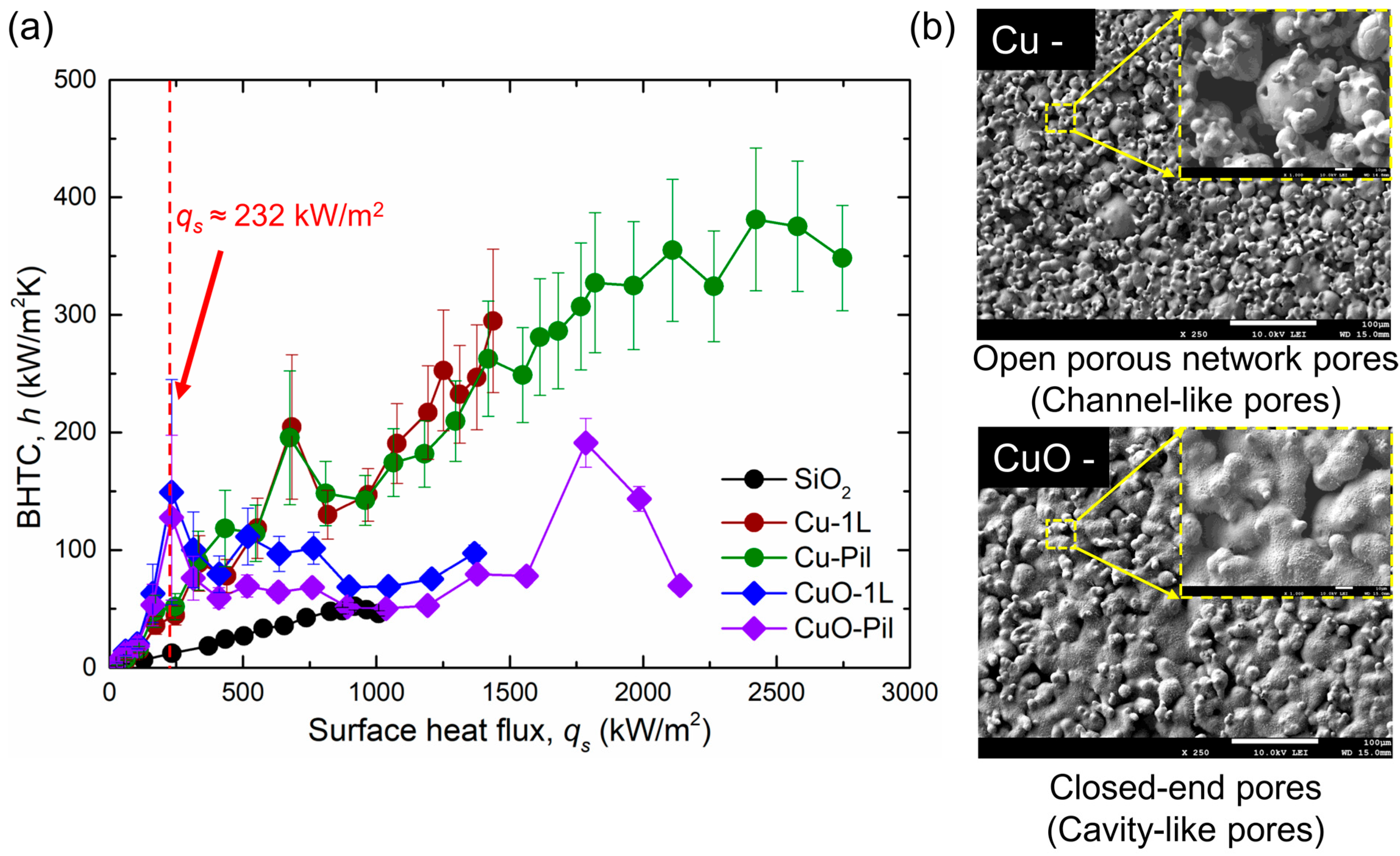

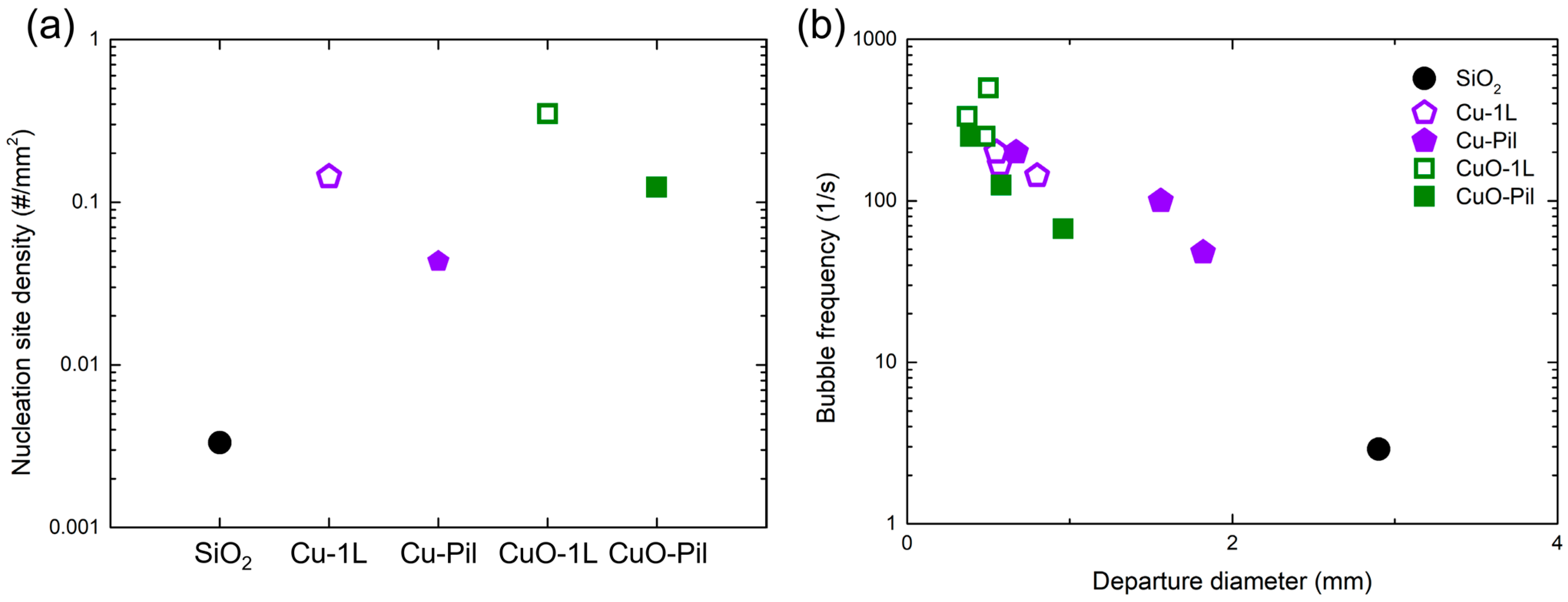

- Under low heat flux, both the Cu and CuO surfaces exhibited similarly enhanced boiling behaviors. However, the CuO surfaces exhibited a higher BHTC owing to the distinct closed-end pore morphology of the CuO surfaces, which provided a higher density of active nucleation sites and produced smaller bubbles. These promoted more frequent bubble nucleation and departure, shorter bubble lifetimes, and faster surface rewetting, thereby sustaining a more efficient heat transfer in the low heat flux regime.

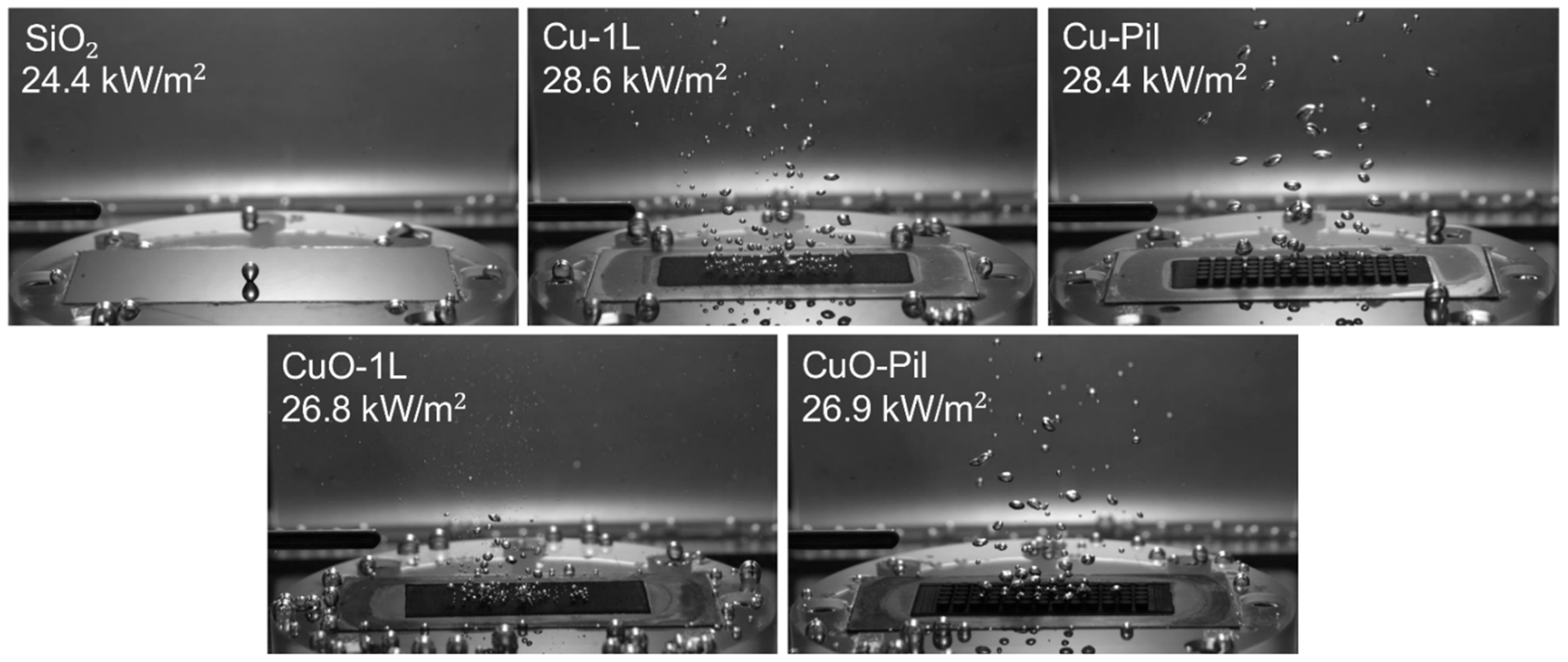

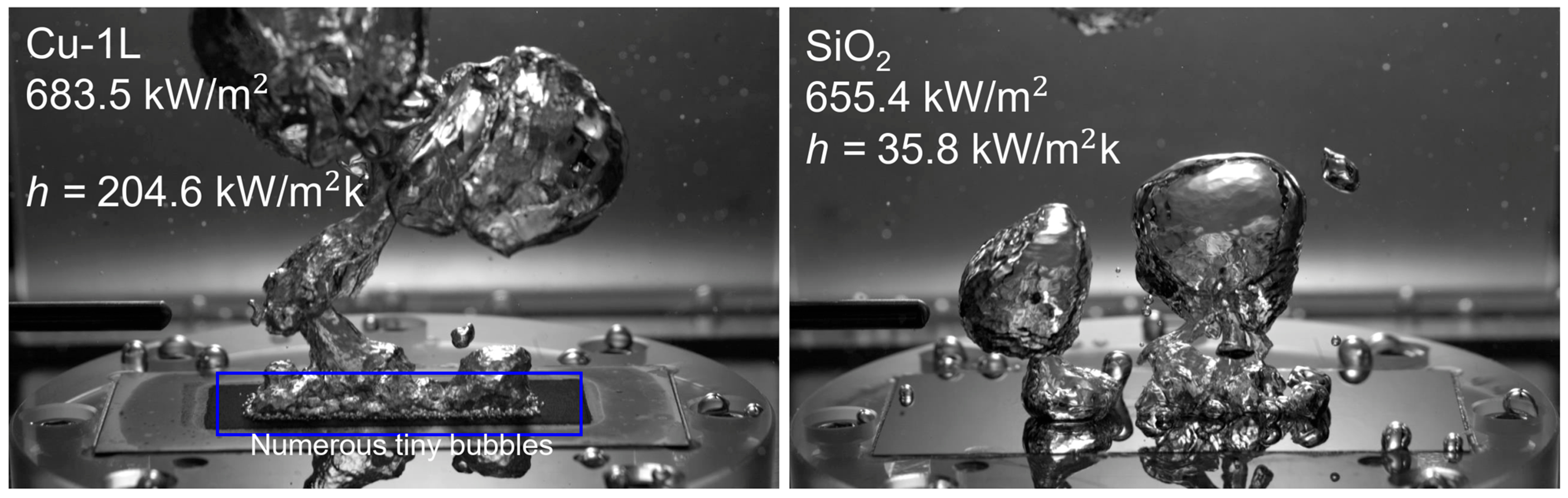

- The enhancement of boiling heat transfer by a thin microporous layer was attributed to the reduced vapor escape resistance achieved by sintering the Cu particles into an almost single layer. At ≈ 670 kW/m2, the BHTC of Cu-1L was enhanced by 471%, while the wall superheat was 15 °C lower than that of SiO2. This improvement was further evidenced by the rapid generation of numerous tiny bubbles on the microporous surface, which were absent on SiO2. The higher bubble frequency associated with these small bubbles facilitated the superior performance of Cu-1L in terms of the boiling heat transfer and CHF.

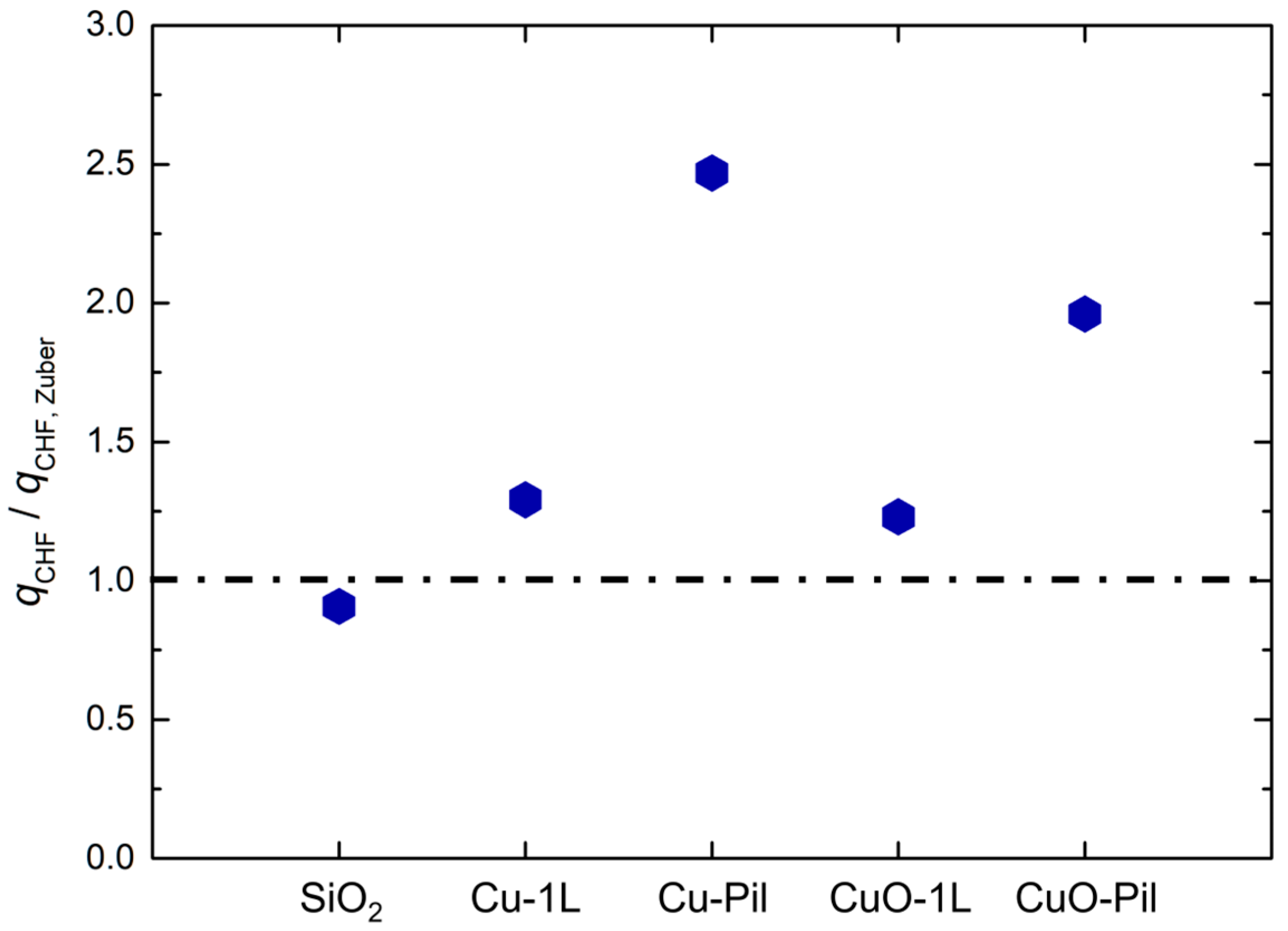

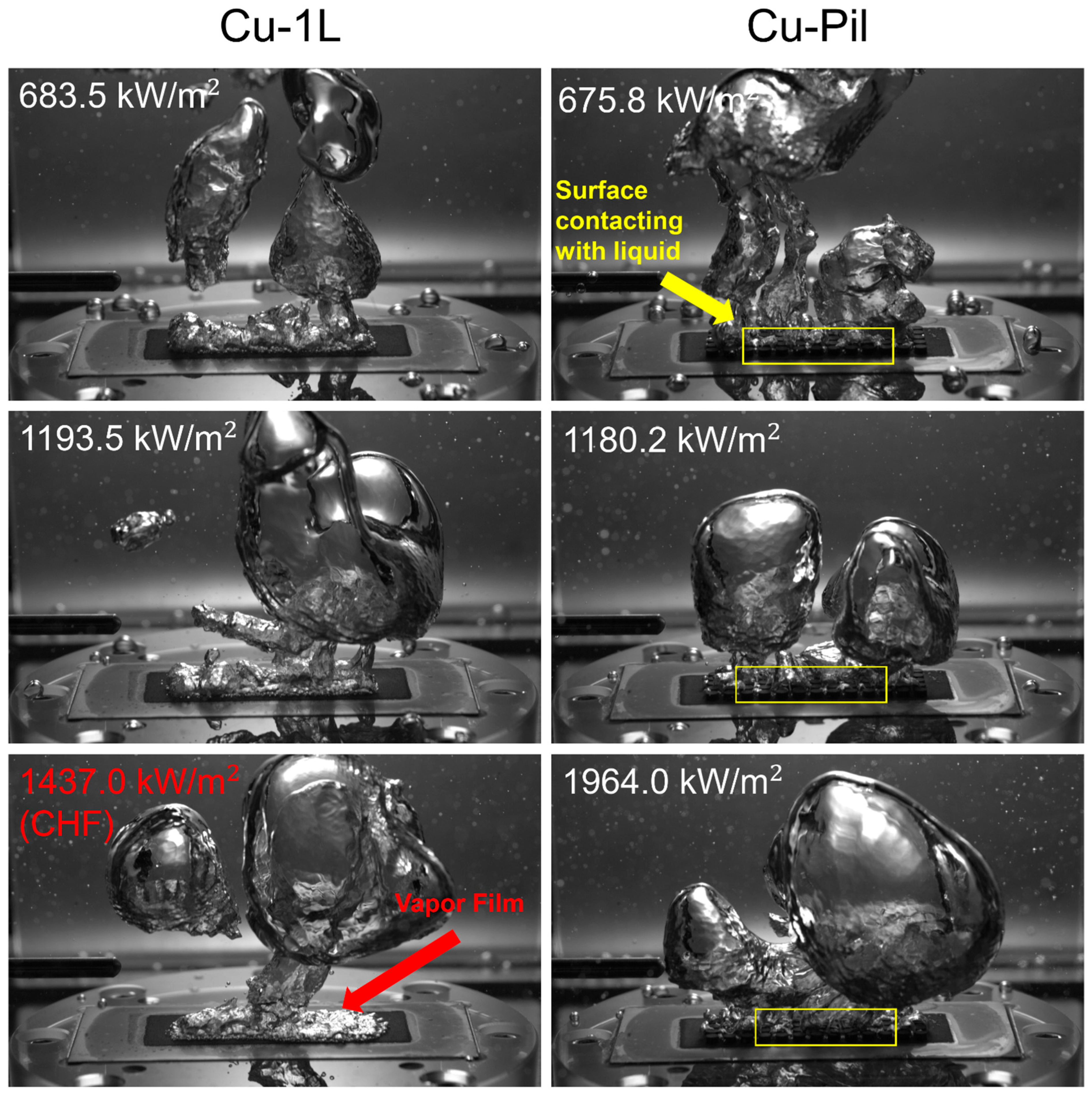

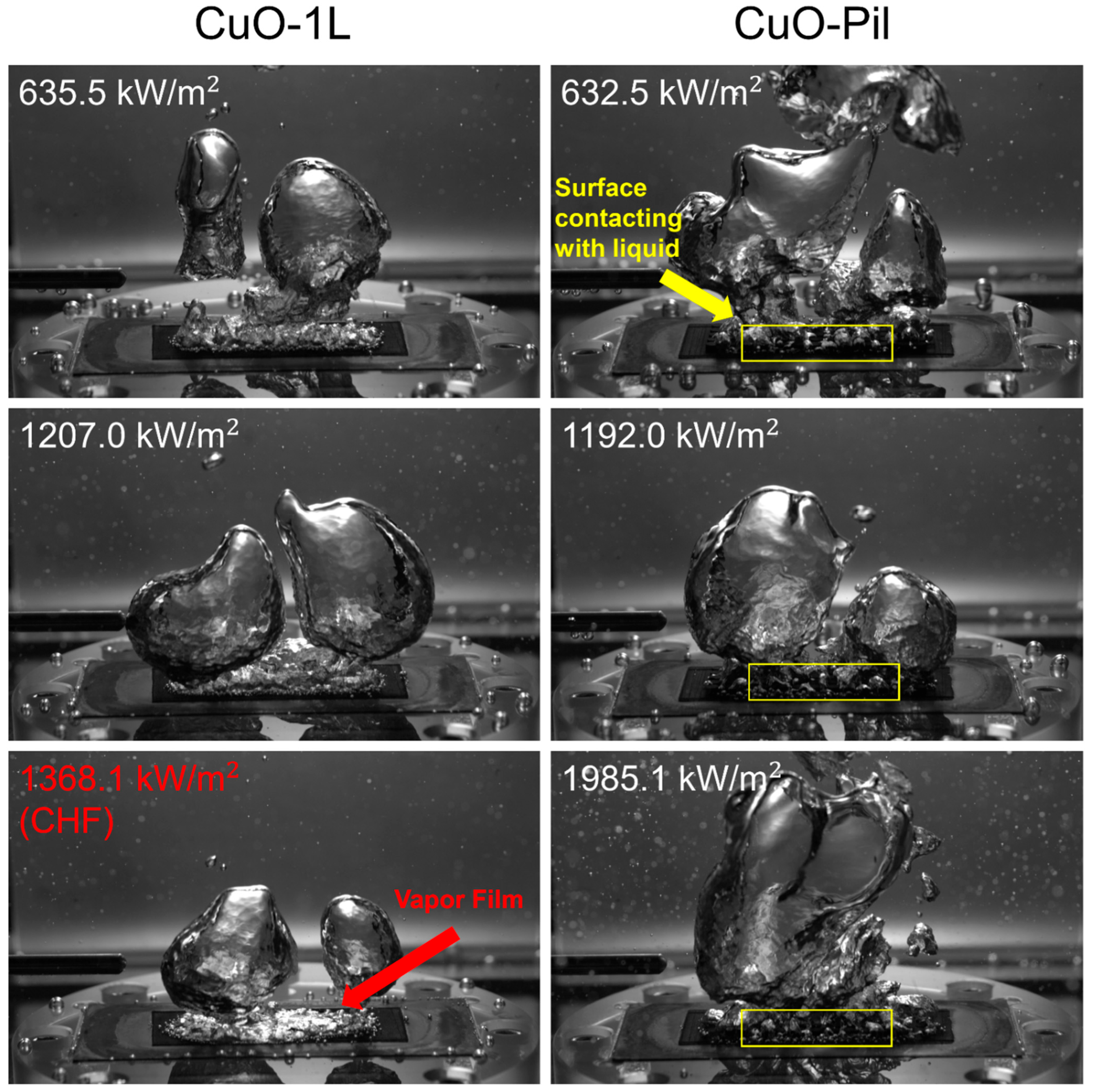

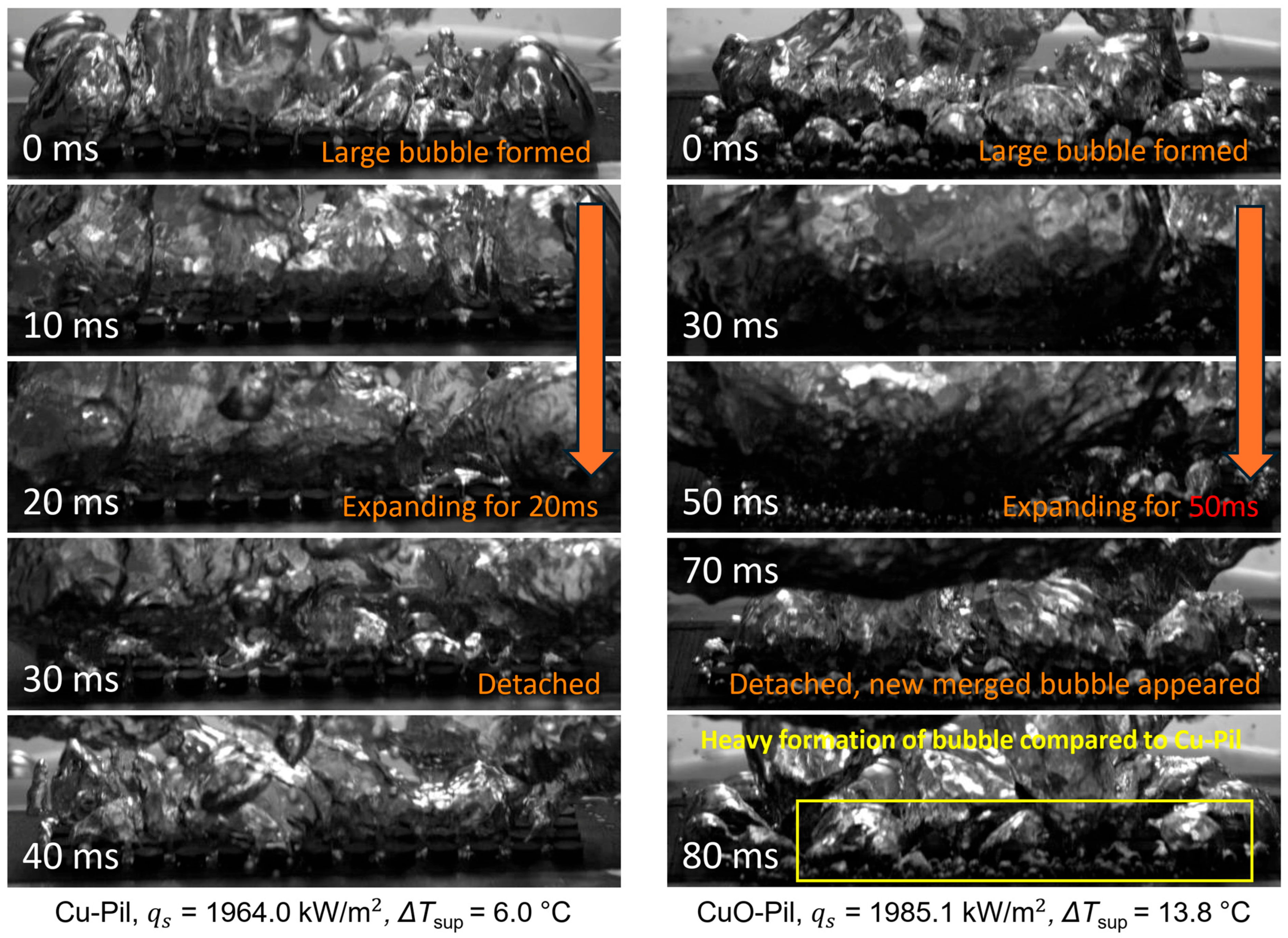

- The microporous pillar structure strongly influenced both the near- and far-field regions of the boiling surface. Thus, the Cu-Pil and CuO-Pil surfaces increased the CHF by factors of 1.9 and 1.6 compared with those of the Cu-1L and CuO-1L surfaces, respectively. The dominant enhancement mechanism at high heat fluxes was the distinct separation of the liquid and vapor pathways. The pillar tops served as the liquid supply channels, whereas the bottom layer between the pillars served as a vapor escape route. This liquid–vapor path separation minimized flow interference and stabilized boiling, as supported by high-speed visualization showing continuous liquid contact on the pillar tops.

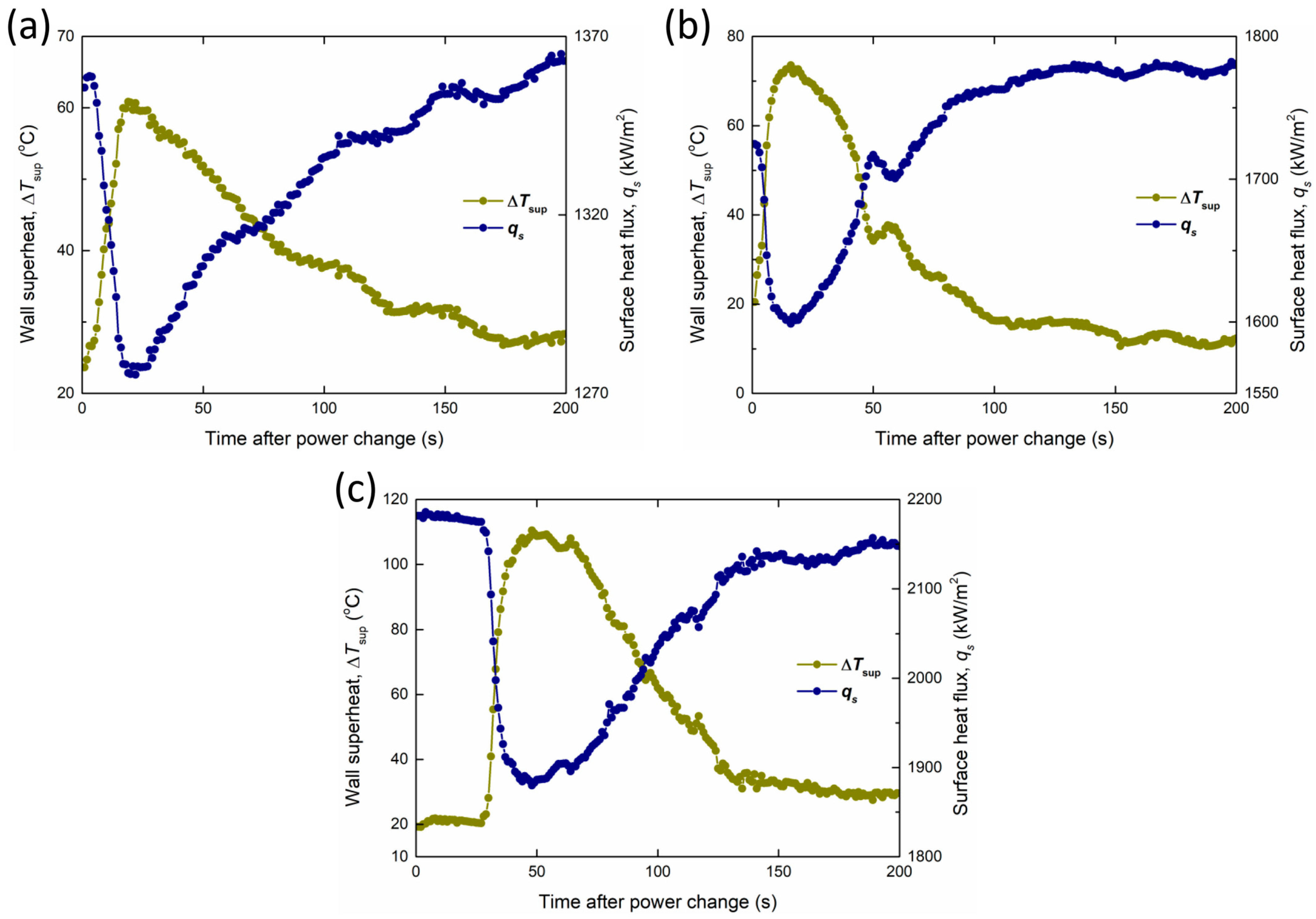

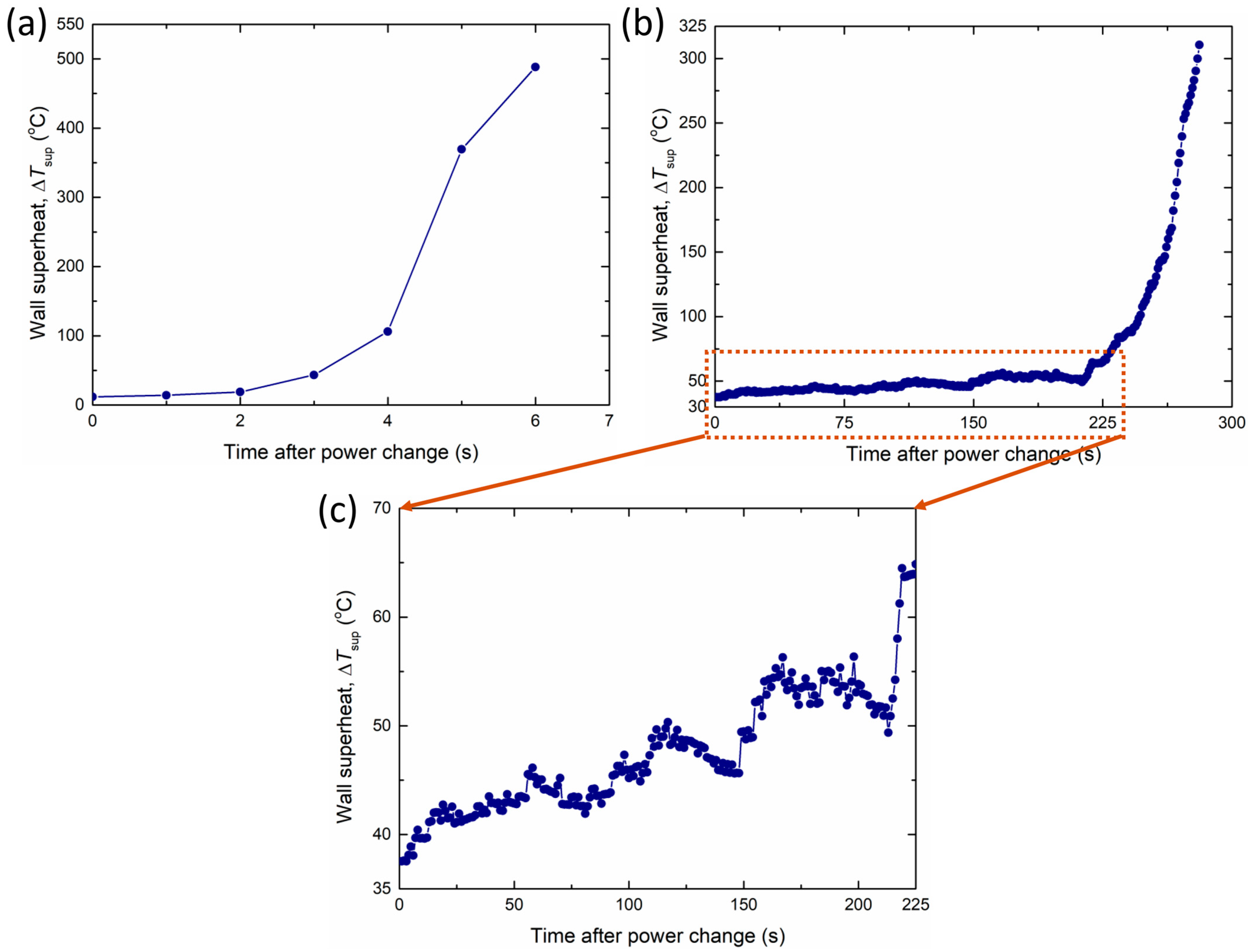

- At high heat flux, the CuO-Pil surfaces exhibited a reduced BHTC and elevated wall superheat owing to delayed vapor detachment and severe bubble expansion arising from their high nucleation site density and closed-end pore morphology. Moreover, the CuO-Pil surface exhibited a unique “temperature peak and recovery” phenomenon, where temporal dry spots were rewetted by strong capillary wicking and liquid–vapor pathway separation from superhydrophilic micro/nanostructured design, thereby preventing irreversible burnout. Even near CHF, the temperature rise rate of the CuO-Pil surface was considerably slower (14.9 °C/s) than that of CuO-1L (263.1 °C/s), demonstrating that the integrated micro/nanostructured design extended the stable boiling regime and improved CHF tolerance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, W.; Lyu, P.; Liu, X.; Rao, Z. Temperature equalization strategy in immersion flow boiling battery thermal management: Optimization of flow regime in boiling heat transfer. Appl. Therm. Eng. 2025, 267, 125825. [Google Scholar] [CrossRef]

- Ebrahim, S.A.; Pradeep, E.; Ahmed, M. Role of sea salt deposition on the advances in pool boiling heat transfer in nuclear reactors. Appl. Therm. Eng. 2022, 217, 119146. [Google Scholar] [CrossRef]

- Huang, T.C.; Pan, C. Pool boiling in seawater, NaCl solution and de-ionized water. Nucl. Eng. Des. 2019, 344, 46–53. [Google Scholar] [CrossRef]

- Sun, Y.; Li, H.; Chen, J.; Wu, C.; Tang, H.; Zhang, S.; Tang, Y. Hierarchical sintered porous surfaces with enhanced pool boiling heat transfer performance for high-power cooling applications. Appl. Therm. Eng. 2024, 249, 123368. [Google Scholar] [CrossRef]

- Xiong, H.; Li, X.; Chen, C.; Xin, G.; Li, J.; Chen, Y. Experimental study on the heat transfer performance of a gravity-assisted separated heat pipe for high-power chip cooling. Energy 2025, 332, 136066. [Google Scholar] [CrossRef]

- Kim, D.E.; Oh, J.S. Local phase and thermal behaviors in pool boiling on different wettability surfaces. Exp. Therm. Fluid Sci. 2022, 139, 110728. [Google Scholar] [CrossRef]

- Kim, H.; Kim, D.E. Effects of surface wettability on pool boiling process: Dynamic and thermal behaviors of dry spots and relevant critical heat flux triggering mechanism. Int. J. Heat Mass Transf. 2021, 180, 121762. [Google Scholar] [CrossRef]

- Kim, D.E.; Park, J. Experimental study of critical heat flux in pool boiling using visible-ray optics. Int. J. Heat Mass Transf. 2021, 169, 120937. [Google Scholar] [CrossRef]

- Sun, X.; Li, Q.; Liu, B.; Chang, H. Composite microstructured surface with micro-cavities and micro-ditches on micro-pin-fins for enhancing pool boiling heat transfer. Appl. Therm. Eng. 2024, 252, 123713. [Google Scholar] [CrossRef]

- Wang, X.; Fadda, D.; Godinez, J.; Lee, J.; You, S.M. Effect of wettability on pool boiling heat transfer with copper microporous coated surface. Int. J. Heat Mass Transf. 2022, 194, 123059. [Google Scholar] [CrossRef]

- Wang, D.; Lin, T.; Quan, X. Enhanced liquid replenishment for pool boiling heat transfer and its CHF mechanism on patterned freeze-casted surfaces. Exp. Therm. Fluid Sci. 2024, 150, 111035. [Google Scholar] [CrossRef]

- Park, S.C.; Kim, J.M.; Kim, T.; Kim, M.H.; Ahn, H.S. Boiling characteristics on a serpentine-like geometry thin-film platinum heater under pool boiling. Int. J. Heat Mass Transf. 2016, 95, 214–223. [Google Scholar] [CrossRef]

- Lv, Z.; An, Y.; Huang, C. Enhanced pool boiling heat transfer by adding metalized diamond in copper porous materials. Appl. Therm. Eng. 2023, 226, 120288. [Google Scholar] [CrossRef]

- Zhang, K.; Bai, L.; Yao, G.; Wen, D. Influence of pore size distribution on pool boiling heat transfer in porous artery structure. Int. J. Heat Mass Transf. 2023, 209, 124116. [Google Scholar] [CrossRef]

- Kumar, R.; Premachandran, B. Enhancement of pool boiling performance through an asymmetric dual V-groove microchannel structured surface. Int. J. Heat Mass Transf. 2024, 221, 125096. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Gu, Z.; Fei, X.; Zhang, L. Enhancement of pool boiling heat transfer using 3D-printed groove structure. Int. J. Heat Mass Transf. 2022, 183, 122155. [Google Scholar] [CrossRef]

- Tang, Y.-Q.; Hu, X.-J.; Wang, Z.-J.; Sun, C.-H.; Fang, W.-Z.; Tao, W.-Q. Enhanced pool boiling of Novec-7100 using nano/micro structured surfaces. Int. J. Heat Mass Transf. 2025, 250, 127320. [Google Scholar] [CrossRef]

- Gouda, R.K.; Pathak, M.; Khan, M.K. Pool boiling heat transfer enhancement with segmented finned microchannels structured surface. Int. J. Heat Mass Transf. 2018, 127, 39–50. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, Y.; Zeng, J.; Yuan, W.; Chen, J.; Chen, C. Pool boiling heat transfer enhancement by porous interconnected microchannel nets at different liquid subcooling. Appl. Therm. Eng. 2016, 93, 1135–1144. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, Y.; Lai, Z.; Hu, C. Influence of surface wettability on pool boiling heat transfer on metal foam covers. Int. J. Therm. Sci. 2021, 168, 107069. [Google Scholar] [CrossRef]

- Lim, H.; Doh, S.-Y.; Choi, J.; Moc, J.; You, S.M.; Lee, J. Pool boiling heat transfer enhancement using the micro-thick metallic foam surface in saturated water. Int. Commun. Heat Mass Transf. 2024, 152, 107310. [Google Scholar] [CrossRef]

- Sharifzadeh, A.M.; Moghadasi, H.; Shakeri, H.; Saffari, H. Influence of bubble departure control on nucleate pool boiling heat transfer of electrodeposited copper foam: Experiments and correlation. Int. Commun. Heat Mass Transf. 2022, 138, 106381. [Google Scholar] [CrossRef]

- Kim, H.; Jung, E.; Ryu, C.; Lee, H.; In, J.B. Nanosecond laser structuring for enhanced pool boiling performance of SiC surfaces. Appl. Surf. Sci. 2024, 675, 160977. [Google Scholar] [CrossRef]

- Lee, S.; Kim, Y.; Ki, H.; Lee, J. Femtosecond laser-treated copper sintering surface to enhance pool boiling heat transfer. Int. Commun. Heat Mass Transf. 2024, 152, 107270. [Google Scholar] [CrossRef]

- Lou, D.; Yang, D.; Dong, C.; Chen, C.; Jiang, H.; Li, Q.; Cheng, J.; Lu, G.; Liu, D. Enhancement of pool boiling heat transfer by laser texture-deposition on copper surface. Appl. Surf. Sci. 2024, 661, 160015. [Google Scholar] [CrossRef]

- Wong, K.K.; Leong, K.C. Saturated pool boiling enhancement using porous lattice structures produced by Selective Laser Melting. Int. J. Heat Mass Transf. 2018, 121, 46–63. [Google Scholar] [CrossRef]

- Kalita, S.; Sen, D.; Sen, P.; Das, S.; Saha, B.B. Pool boiling heat transfer enhancement and bubble visualization on a microporous copper over CuO filmed surface through combination of chemical etching and electrochemical deposition. Int. Commun. Heat Mass Transf. 2023, 144, 106740. [Google Scholar] [CrossRef]

- Mousa, M.H.; Roni, M.R.H.; Rao, R.; Ganesan, V.; Khodakarami, S.; Yang, C.-M.; Rabbi, K.F.; Upot, N.V.; Nawaz, K.; Miljkovic, N. Water flow boiling heat transfer and pressure drop in smooth, etched, and herringbone aluminum tubes. Appl. Therm. Eng. 2024, 257, 124426. [Google Scholar] [CrossRef]

- Kim, H.; Park, Y.; Kim, H.; Lee, C.; Jerng, D.W.; Kim, D.E. Critical heat flux enhancement by single-layered metal wire mesh with micro and nano-sized pore structures. Int. J. Heat Mass Transf. 2017, 115, 439–449. [Google Scholar] [CrossRef]

- Dang, C.; Min, R.; Pan, L.; Yin, L.; Zhang, Z.; Hu, Y. Saturated pool boiling heat transfer enhancement of R245fa based on the surface covered by sintered copper powder with and without nanostructure. Int. J. Therm. Sci. 2023, 187, 108183. [Google Scholar] [CrossRef]

- Jaikumar, A.; Kandlikar, S.G. Enhanced pool boiling heat transfer mechanisms for selectively sintered open microchannels. Int. J. Heat Mass Transf. 2015, 88, 652–661. [Google Scholar] [CrossRef]

- Jun, S.; Kim, J.; Son, D.; Kim, H.Y.; You, S.M. Enhancement of pool boiling heat transfer in water using sintered copper microporous coatings. Nucl. Eng. Technol. 2016, 48, 932–940. [Google Scholar] [CrossRef]

- Wang, X.; Wan, Z. Heat transfer performance of a heat pipe with sintered stainless-steel fiber wick. Case Stud. Therm. Eng. 2023, 45, 103016. [Google Scholar] [CrossRef]

- Zhang, D.; Mao, J.; Qu, J.; Lei, Q.; Li, C.; Chen, Y. Characterizing effect of particle size on flow boiling in sintered porous-microchannels. Appl. Therm. Eng. 2023, 229, 120571. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, T.H.; Wang, C.-C. Pool boiling performance for GaldenR HT 55 subject to smooth, pin fin, and sintered pin fin heat sink. Int. J. Therm. Sci. 2024, 202, 109090. [Google Scholar] [CrossRef]

- Lee, S.; Kim, Y.; Ki, H.; Lee, J. Critical heat flux in pool boiling on femtosecond laser-irradiated copper powder-sintered surfaces. Therm. Sci. Eng. Prog. 2025, 60, 103421. [Google Scholar] [CrossRef]

- Ranjan, A.; Ahmad, I.; Gouda, R.K.; Pathak, M.; Khan, M.K. Enhancement of critical heat flux (CHF) in pool boiling with anodized copper surfaces. Int. J. Therm. Sci. 2022, 172, 107338. [Google Scholar] [CrossRef]

- Shim, D.I.; Yun, M.; Kim, Y.-H.; Lee, D.; Cho, H.H. 3D-Printed vapor guiding structures for enhanced pool boiling heat transfer. Int. J. Mech. Sci. 2025, 286, 109865. [Google Scholar] [CrossRef]

- Chen, Y.; Li, P.; Zou, Q.; Liu, X.; Yang, R. Enhancing pool boiling with separated liquid-vapor pathways on perforated micromesh surface. Int. J. Heat Mass Transf. 2025, 244, 126949. [Google Scholar] [CrossRef]

- Jin, L.W.; Leong, K.C.; Pranoto, I. Saturated pool boiling heat transfer from highly conductive graphite foams. Appl. Therm. Eng. 2011, 31, 2685–2693. [Google Scholar] [CrossRef]

- Pranoto, I.; Leong, K.C.; Jin, L.W. The role of graphite foam pore structure on saturated pool boiling enhancement. Appl. Therm. Eng. 2012, 42, 163–172. [Google Scholar] [CrossRef]

- Liu, B.; Yang, X.; Jie, Z.; Wei, J.; Li, Q. Enhanced pool boiling on micro-nano composited surfaces with nanostructures on micro-pin-fins. Int. J. Heat Mass Transf. 2022, 190, 122812. [Google Scholar] [CrossRef]

- Jiang, X.; Shah, S.W.A.; Chen, G.; Xie, S. Extraordinary boiling enhancement by hybrid dividing zonesS of micro-nano structures. Int. Commun. Heat Mass Transf. 2024, 153, 107345. [Google Scholar] [CrossRef]

- Ahn, H.S.; Lee, C.; Kim, J.; Kim, M.H. The effect of capillary wicking action of micro/nano structures on pool boiling critical heat flux. Int. J. Heat Mass Transf. 2012, 55, 89–92. [Google Scholar] [CrossRef]

- Milanova, D.; Kumar, R. Heat transfer behavior of silica nanoparticles in pool boiling experiment. J. Heat Transf. 2008, 130, 042401. [Google Scholar] [CrossRef]

- Raveshi, M.R.; Keshavarz, A.; Mojarrad, M.S.; Amiri, S. Experimental investigation of pool boiling heat transfer enhancement of alumina-water-ethylene glycol nanofluids. Exp. Therm. Fluid Sci. 2013, 44, 805–814. [Google Scholar] [CrossRef]

- Khan, A.; Muhammad, A.F. A comprehensive review on pool boiling heat transfer using nanofluids. Therm. Sci. 2019, 23, 3209–3237. [Google Scholar] [CrossRef]

- Du, J.; Wang, Y.; Yang, W.; Wang, J.; Cao, Z.; Sundén, B. Effect of nanoparticle concentration and surfactants on nanofluid pool boiling. Int. J. Heat Mass Transf. 2024, 221, 125080. [Google Scholar] [CrossRef]

- Bregar, T.; Hadžić, A.; Robinson, J.; Askounis, A.; Zupančič, M.; Golobič, I. Additively manufactured copper surfaces with porous microfeatures for enhanced pool boiling performance. Int. J. Therm. Sci. 2026, 220, 110325. [Google Scholar] [CrossRef]

- Liu, X.; Liu, B.; Li, Q.; Li, W. Enhanced pool boiling heat transfer on multilayer-gradient-porosity pillar-structured surfaces. Int. J. Heat Mass Transf. 2026, 255, 127747. [Google Scholar] [CrossRef]

- Guan, S.Y.; Zhang, Z.H.; Wu, R.; Zhao, C.Y. Boiling heat transfer via micro–nano composite gradient and grooved porous structures: Liquid film and vapor dynamics insights. Int. J. Heat Mass Transf. 2026, 254, 127655. [Google Scholar] [CrossRef]

- Kumar, R.; Premachandran, B. Pool boiling performance enhancement using a scalable thermally sprayed porous copper coating. Int. J. Heat Mass Transf. 2025, 247, 127199. [Google Scholar] [CrossRef]

- Balsamy-Kamaraj, A.; Hasan, M.M.; Merugu, S.; Gupta, A. Comparison of 3D-printed copper surfaces for enhanced pool boiling heat transfer. Manuf. Lett. 2025, 44, 1649–1656. [Google Scholar] [CrossRef]

- Lee, D.J.; Yang, Y.J.; Kim, D.E. Boiling performance enhancement and self-recovery of nucleate boiling regime on micro- and nanostructured porous surfaces. Int. J. Heat Mass Transf. 2025, 238, 126516. [Google Scholar] [CrossRef]

- Liu, D.; Jiao, R.; Sun, C.; Wang, Y. Effects of substrates on the performance of Pt thin-film resistance temperature detectors. Coatings 2024, 14, 969. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Wang, B.; Kong, M.; Xu, D.; Gao, L.; Li, Q.; Zhao, Z.; Lu, W.; Zhao, X.; et al. Stability enhancement of the platinum thin-film temperature detector up to 1400 °C by printing Al2O3 protective layer. IEEE Sensors J. 2024, 24, 17433–17440. [Google Scholar] [CrossRef]

- Yamasue, E.; Susa, M.; Fukuyama, H.; Nagata, K. Thermal conductivities of silicon and Germanium in solid and liquid states measured by non-stationary hot wire method with silica coated probe. J. Cryst. Growth 2002, 234, 121–131. [Google Scholar] [CrossRef]

- Love, C.J.; Smith, J.D.; Cui, Y.; Varanasi, K.K. Size-dependent thermal oxidation of copper: Single-step synthesis of hierarchical nanostructures. Nanoscale 2011, 3, 4972. [Google Scholar] [CrossRef]

- Kline, S.J. Describing uncertainties in single-sample experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Jaikumar, A.; Kandlikar, S.G. Pool boiling inversion through bubble induced macroconvection. Appl. Phys. Lett. 2017, 110, 094107. [Google Scholar] [CrossRef]

- Zuber, N. Hydrodynamic Aspects of Boiling Heat Transfer. Ph.D. Thesis, University of California, Los Angeles, CA, USA, 1959. [Google Scholar]

| Surface | Composition | Fabrication Process |

|---|---|---|

| SiO2 | SiO2, 500 nm | Thermal oxidation of Si wafer |

| Cu-1L | Microporous Cu layer, thickness ≈ 70 mm | Powder sintering |

| Cu-Pil | Microporous Cu layer with pillars | Powder sintering |

| CuO-1L | Oxidized microporous Cu layer | Powder sintering + thermal oxidation |

| CuO-Pil | Oxidized microporous Cu layer with pillars | Powder sintering + thermal oxidation |

| Absolute Uncertainty | Relative Uncertainty | |||

|---|---|---|---|---|

| Value | Unit | Value | Unit | |

| Power | 0.68–7.48 | W | 0.91–9.27 | % |

| ) | 2.27–24.92 | kW/m2 | 0.91–9.27 | % |

| ) | 1.00–1.01 | °C | 3.29–64.17 | % |

| ) | 0.19–95.82 | kW/m2K | 3.44–34.24 | % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.J.; Yang, Y.J.; Jerng, D.-W.; Kim, D.E. Boiling Phenomena and Heat Transfer Enhancement Effect on Micro/Nanoporous Sintered Copper Surfaces. Fluids 2025, 10, 303. https://doi.org/10.3390/fluids10110303

Lee DJ, Yang YJ, Jerng D-W, Kim DE. Boiling Phenomena and Heat Transfer Enhancement Effect on Micro/Nanoporous Sintered Copper Surfaces. Fluids. 2025; 10(11):303. https://doi.org/10.3390/fluids10110303

Chicago/Turabian StyleLee, Dong Ju, Young Jae Yang, Dong-Wook Jerng, and Dong Eok Kim. 2025. "Boiling Phenomena and Heat Transfer Enhancement Effect on Micro/Nanoporous Sintered Copper Surfaces" Fluids 10, no. 11: 303. https://doi.org/10.3390/fluids10110303

APA StyleLee, D. J., Yang, Y. J., Jerng, D.-W., & Kim, D. E. (2025). Boiling Phenomena and Heat Transfer Enhancement Effect on Micro/Nanoporous Sintered Copper Surfaces. Fluids, 10(11), 303. https://doi.org/10.3390/fluids10110303