1. Introduction

The flow around bluff bodies is characterized by the separation of a significant portion of the boundary layer, leading to the formation of a wake. In engineering structures, this wake formation can result in the phenomenon of lock-in, where flow-induced vibrations synchronize with the structure’s natural frequency, potentially causing structural failure. To prevent such failures, the field of wake suppression has garnered significant interest in recent years, with Rashidi [

1] considering three different approaches of suppression: (a) active control methods; (b) passive control methods; and (c) control by employing an external element. This paper will consider the combined effects of surface roughness (a passive control method) and thermal effects (an active control method), specifically assessing the influence of surface roughness on heat transfer and drag coefficients when they are present simultaneously in a fluid flow problem.

Combined effects are present in several industrial and practical applications, leading to the need for better understand them and have models that can predict the structural response. For example, risers from the oil industry tend to increase surface roughness as they age. In the same way, marine structures can have increased roughness as shellfish start living in them. The added effects of a heated surface are useful to understand how shell and tube heat exchangers will respond as the surface rusts or suffers from incrustation. Al-Rubaiy [

2] studied these interactions around a circular cylinder in an experimental setup and how flow turbulence influences the aerodynamic forces and Nusselt number. Increases in surface roughness typically increases drag, but when considering bluff bodies, it can lead to a change in the flow regimen and result in the anticipation of the drag crisis, making the prediction of this flow complex. Dhiman and Dwivedi [

3] studied the effects of the Richardson number and the gap between two heated cylinders with a constant temperature and Re = 100, showing that the heat transfer changes drastically the flow dynamics. This study considered smooth surfaces and observed slight increases in the drag coefficient. Afgan et al. [

4] studied the flow around two smooth heated cylinders in tandem at Re = 3000, investigating the influences of gap ratios and heat transfer in the lift, drag, and pressure coefficients and in the Nusselt number. However, simulations considering both heating and roughness effects are scarce in the literature, and numerical simulations typically work at lower Reynolds values due to the diffusive problem that exists at higher values when using Eulerian methods.

Numerical approaches are useful to simulate wake suppression without needing prohibitive prototype costs, where both Eulerian or Lagrangian methods could be used to simulate flow dynamics. Lagrangian description is useful when compared to approaches which use meshes because they can represent the flow faithfully in regions of strain and do not require setting boundary conditions over the domain. The first application of the Discrete Vortex Method (DVM) considering viscous forces was proposed by Chorin [

5], where the author simulated the flow around a circular cylinder considering a slightly viscous flow and used the Random Walk method to simulate the diffusion. Smith and Stansby [

6] simulated the temperature field with the vorticity field for the first time in a formulation similar to the DVM, which became known as the Temperature Particles Method (TPM). This formulation assumed forced heat transfer from the cylinder to the fluid, as no model of buoyancy had been developed at the time, with Ogami [

7] presenting two different approaches to simulate the vortex–temperature interactions.

Since then, several contributions have been made to the DVM, including different models for the diffusion scheme [

8,

9,

10,

11,

12,

13,

14] and ways to reorganize the vorticity field to circumvent Lagrangian distortion [

15,

16]. In parallel to theoretical considerations and advances, in the past years, several researchers have applied the DVM to engineering applications, considering new effects and how to simulate them numerically. The use of a Lagrangian description is advantageous because of different factors such as (a) there is no mesh in a typical simulation; therefore, there is no need to stipulate boundary conditions on the inlet or outlet of a mesh, nor is there a need to create and refine a mesh and execute mesh independence tests; (b) the properties of interest (like temperature and vorticity) are independently tracked as the time steps increase, which allows for massive parallelization of the numerical code; (c) at every moment in the simulation, the velocity field for both the vortex blobs and temperature particles is directly calculated via the Biot–Savart law. Due to the material derivative, it is not necessary to calculate advective derivatives, and (d) as an extension, since the velocity field is known at every instant, an LES formulation using the second-order velocity structure function is suitable for the method and easy to implement numerically. In addition to that, the use of LES turbulence modeling allows for the simulation of surface roughness effects [

17] that can be extended to the temperature field, which is the focus of this paper.

Turbulence modeling is a defining factor when considering flows with higher Reynolds numbers. Since turbulence is a three-dimensional phenomena, only a few authors have implemented a two-dimensional model to consider the turbulent fluctuations in their works: First, we note the adaptation of the second-order velocity structure function made by Alcântara Pereira [

18], which uses the known velocity at every discrete vortex blob, a characteristic of Lagrangian methods, to calculate the local eddy viscosity and account for turbulence effects. A second implementation was made by Prendergast [

19], which was also used by [

20], consisting of adding discrete vortices once every few time steps to simulate the turbulent velocity fluctuations. However, those studies focused on the vorticity field; recently, Chiaradia et al. [

21] adapted the former approach to consider the turbulent thermal diffusivity on the temperature particles using the velocity fluctuations given by the vorticity field.

The influence of roughness effects in the flow around a cylinder was shown by Achenbach and Heinecke [

22] for a wide range of Reynolds numbers (Re). The experiments revealed that the drag and Strouhal number can either reduce or increase depending on the Reynolds number. In a more recent study, Tian et al. [

23] studied different roughness shapes and heights on the flow past a circular cylinder in a large recirculating tank where

ranged from 40,000 to 200,000. The results showed that the drag coefficient consistently increased with increasing roughness heights. A similar experiment [

24] considered the roughness effects of mussels in the hydrodynamical forces around a circular cylinder using an experimental setup wherein the Reynolds number ranged from 0.5–4.0

, and the authors observed a drag increase at constant Reynolds numbers as the relative roughness surface increased from 0 to 0.136. Also, the roughness delayed the drag crisis in their tests, as well as the reduction in the Strouhal number. Sun et al. [

25] explored different roughness heights and observed a reduction in the Strouhal number as surface roughness increased on the flow past a circular cylinder, attributing this to the forward movement of the separation point.

In previous works, our group developed a DVM capable of modeling surface roughness effects [

17] and employed a model proposed by Ogami [

7] to simulate the effects of natural convection in the dissipation of aircraft wingtip vortices [

26]. Recently, the effects of mixed convection were further developed to implement a Large-Eddy Simulation (LES) model into the temperature particles clutter using the Temperature Particles Method (TPM) [

21].

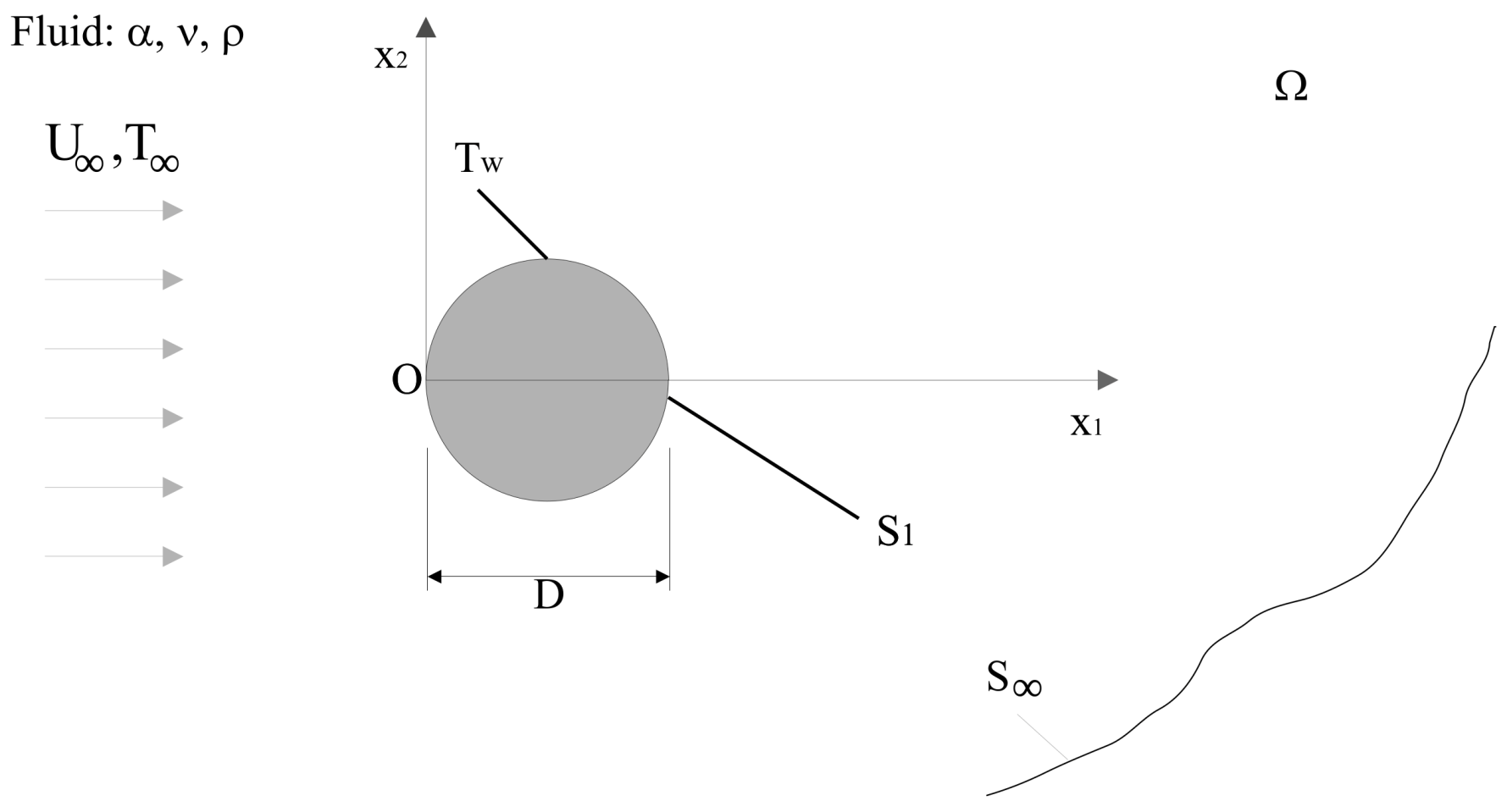

In this work, the TPM is employed to solve the Navier–Stokes equations using a two-dimensional turbulence model with a LES approach and considering both effects of mixed convection and surface roughness to simulate the flow around a circular cylinder. This initial approach serves by proposing a novel model that accounts for the effects of the surface roughness on the thermal boundary layer.

The surface is represented using the Panels Method [

27] whereby the cylinder is substituted by a distribution of sources of uniform density along a polygon inscripted to the circle. The Panels Method was developed as a potential theory tool, hence the need to use a diffusion scheme to simulate a viscous flow. In this paper, we opted to use the Random Walk Method [

5] due to its simplicity and suitability at higher Reynolds numbers. Before the diffusion and advection processes, it is necessary to evaluate the local eddy viscosity at every computational point (vortex blobs and temperature particles). The LES approach is unique in the sense that while the large eddies (low frequencies) are simulated by vortex and temperature clouds, i.e., by the numerical method, the small eddies’ (high frequencies) interactions with the larger scales need to be modeled [

28].

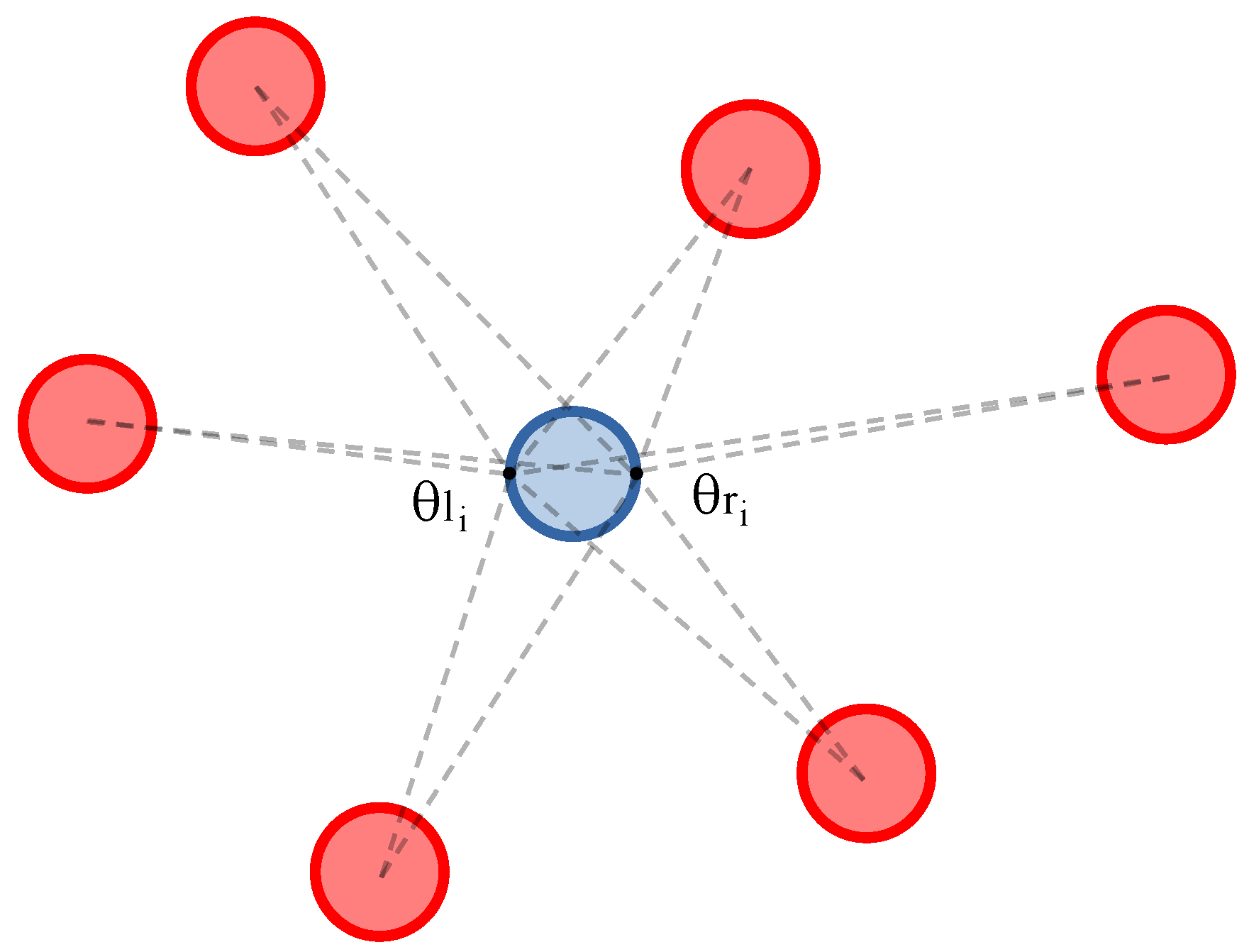

The thermal effects are simulated using a direct interpretation of Fourier’s law [

26], using it to generate temperature particles at shedding points on a panel. Said particles will receive velocity inductions from vortex blobs and populate the wake. The mixed convection is determined by the influence of each temperature particle on every vortex blob [

7], where the temperature inductions to the left and right result in buoyancy forces translated as an increase in each vortex blob intensity. As one can notice, the calculations become progressively more demanding of the machine as the number of particles in the boundary layer and wake increases. This is explained by the complexity of

for a cloud consisting of Z particles interacting with each other, with vortex blobs inducing velocity to other vortices and temperature particles, while the temperature blobs induce temperature to each vortex blob during the natural convection effects. Due to this, it is necessary to adopt parallel programming using OpenMP on the in-house FORTRAN code.

3. Results and Discussion

An initial validation of the numerical method was conducted by comparing the numerical solutions of the surface representation method (the Panels Method) for the diffusion and advection problems with the analytical results.

The first validation consists of representing a cylinder of radius

in two dimensions (a circle) by

uniform source flat panels with constant length, subjecting it to an incident flow. This problem is well-known in fluid dynamics and can be represented using the potential theory as an incident flow superposed to a dipole [

27]. Using the complex potential function, the velocity components (

u and

v) at each point

of the complex plane can be written as follows:

By discretizing the cylinder in

panels, the graphic comparison between Equation (

31) and the Panels Method is shown in

Figure 3.

Figure 3 shows that the Panels Method converges to the potential solution, with

source flat panels discretizing the body. The mean absolute error in each velocity component was about

. This order of error allows the body to be appropriately represented in the numerical solution. However, given the potential nature of the Panels Method, it is necessary to implement a diffusion algorithm, which will be paired with an advection scheme, to simulate the flow.

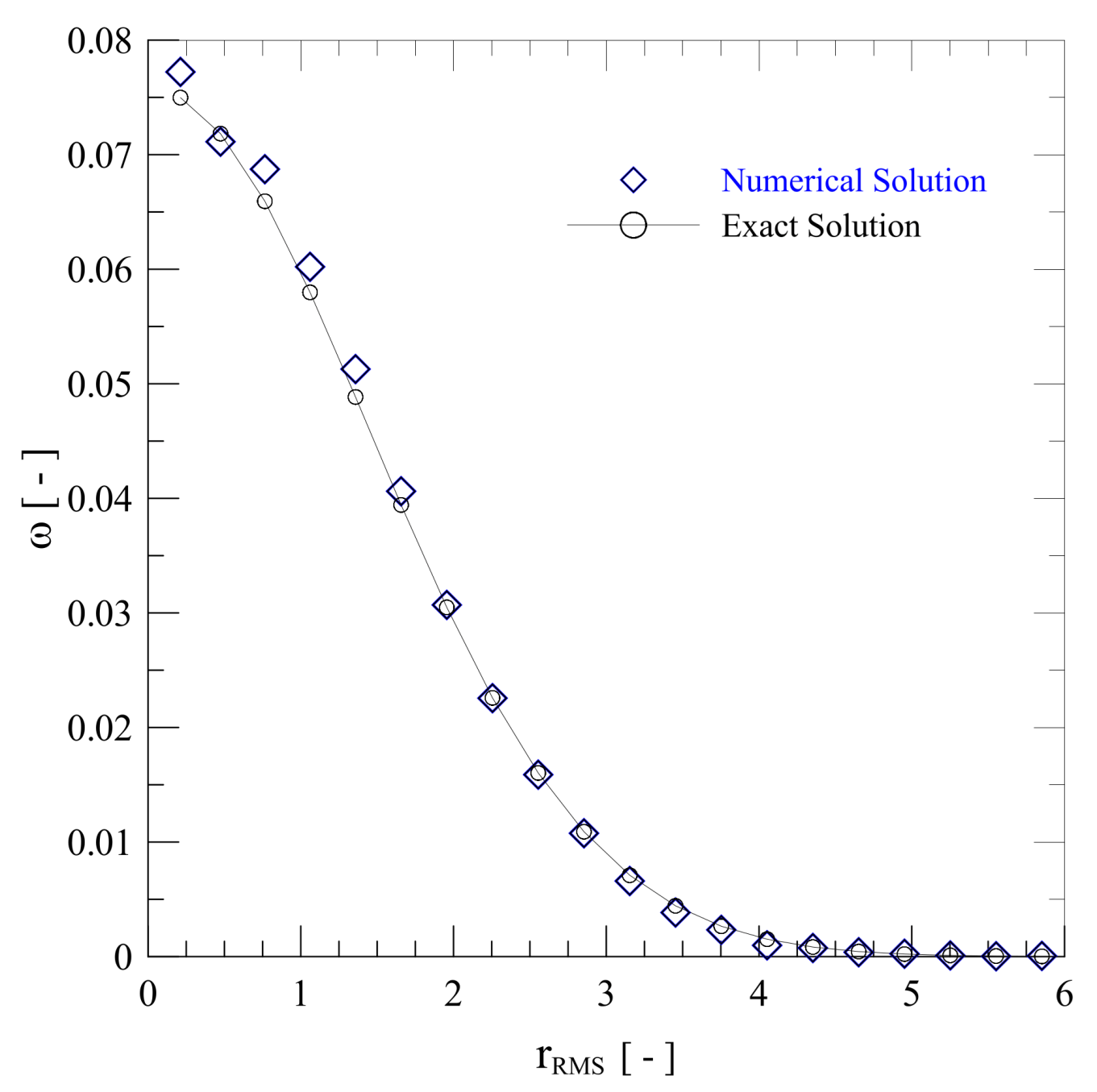

The verification of the diffusion method is made by distributing

Z vortex blobs at the origin of a polar plane, each with strength

. The fluid is assumed to have a unitary kinematic viscosity coefficient. Then, the particles are allowed to diffuse in 20 time steps of

via Random Walk Method [

5]. After the last time step, the polar plane is divided into 20 radial strips ranging from

to

. At each annular region, the root main square (RMS) radius is calculated, and this is the value where the vorticity distribution is considered to be concentrated for graphical representation. If

n vortex blobs are inside an annular region, the vorticity value is then obtained as follows:

Then, Equation (

32) is compared with the analytical distribution:

Using the previous values, the distribution can be seen in

Figure 4.

The average relative error at each data point is , which is considered acceptable for the number of vortex elements used. In a larger simulation, the error tends to be lower since the number of elements is higher, which is beneficial for the Random Walk Method.

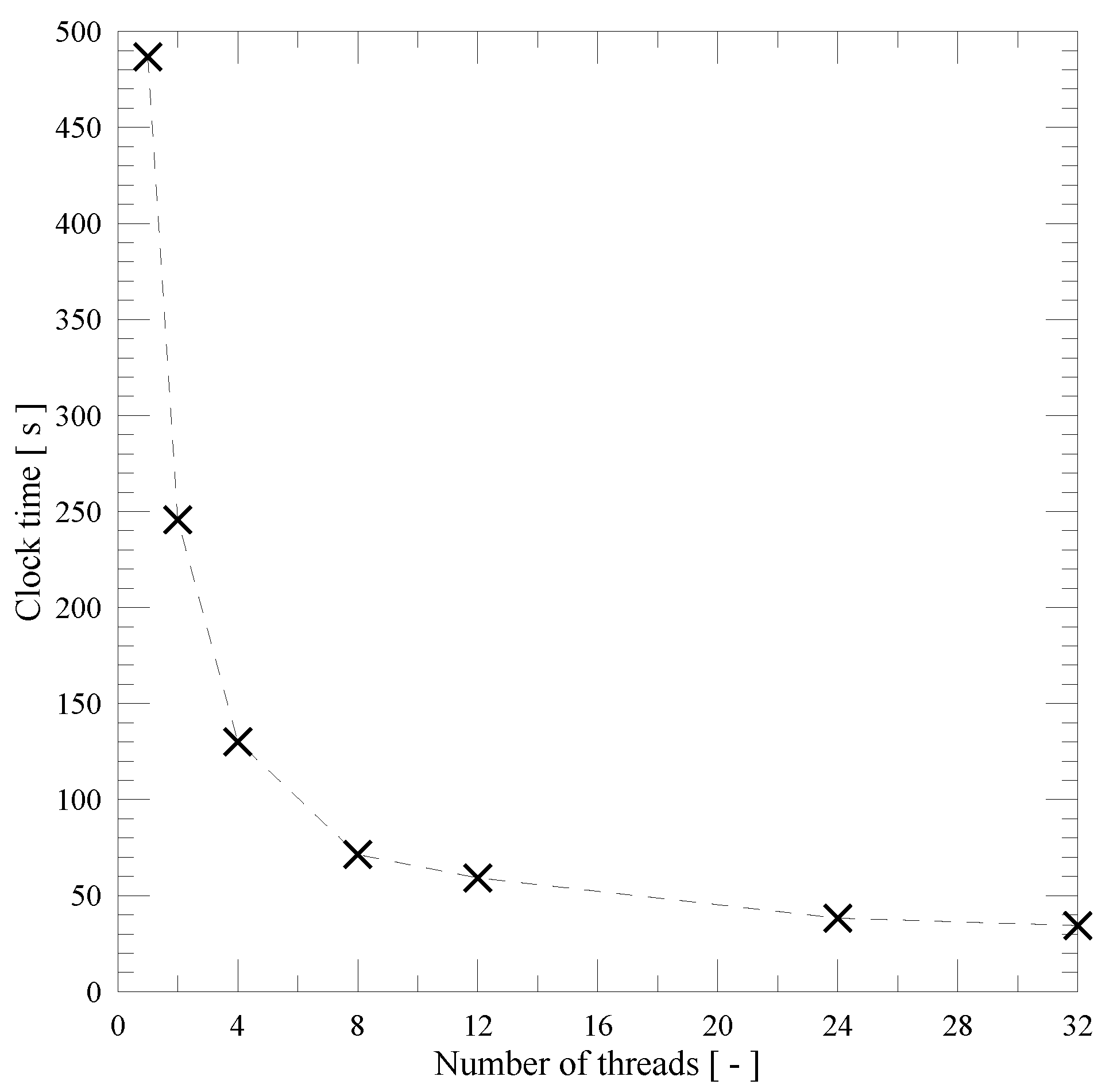

Considering that the vortex–temperature interactions are computationally expensive, consisting of three kinds of operations, each with a complexity of

for

N particles, this paper opted to use an OpenMP implementation in the numerical code to accelerate such interactions.

Figure 5 shows the wall clock time needed to simulate only the three vortex–temperature interactions for

N = 300,000 vortex blobs and 300,000 temperature particles, with increasingly more threads. The particles were randomly distributed inside a rectangle of unitary side length for this test. A speedup of 14.15 times was obtained when comparing the 32 threads implementation with the serial approach (1 thread), with the diminishing returns becoming smaller when using 24–32 threads. This acceleration allows for the simulation of simultaneous vortex–temperature interactions while keeping the number of panels used to discretize the solid surface. All simulations were executed using 32 threads, a processor Intel Core i9-13900KF 3.0 GHz with 32 threads, and a cache of 32 MB. The parallel simulations showed the same numerical precision as the serial version.

Since the initial validation of the numerical code is complete, it is now possible to present the test cases for the flow past a heated circular cylinder.

Table 1 shows the non-dimensional parameters adopted as input values in the simulation, and

Table 2 shows the mean values for drag and lift coefficients obtained through the simulations, as well as the separation point and Strouhal number. It can be seen that the drag coefficient increases with higher values of surface roughness.

Test case #1 is a benchmark simulation without surface roughness effects and heat transfer from [

33], using the same method but only considering the vortex wake, whereas the experimental results from [

34] are

and

. When considering mixed convection (case #2), a reduction in drag followed by an increase in the separation angle,

, is observed, showing how the mixed convection interacts with the smooth cylinder.

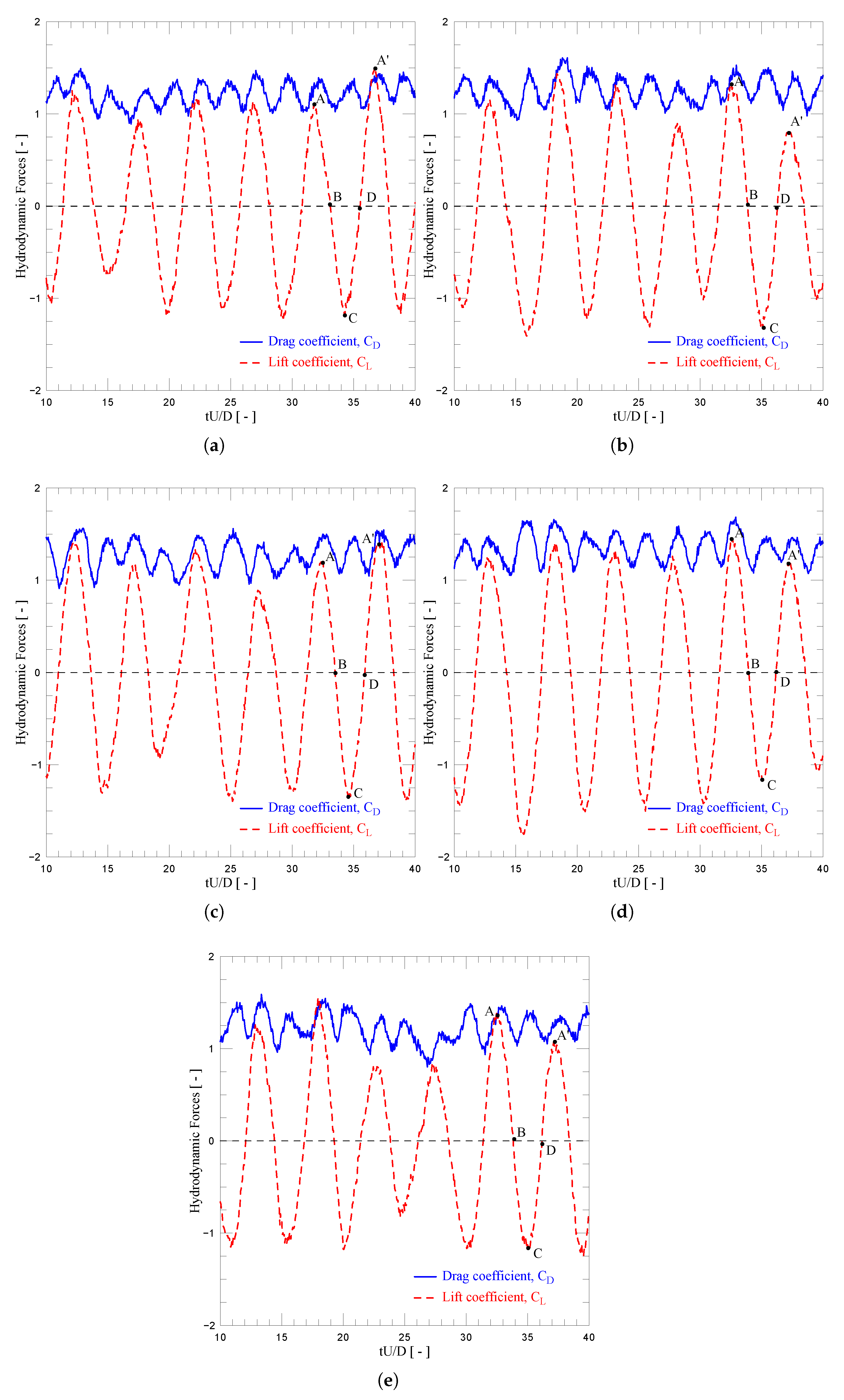

Figure 4 shows the transient drag and lift coefficients in every simulation. Im test cases #2 and #3, the main difference was due to the effects of surface roughness, which increases in test cases #4 and #5. This effect can be observed in the increase in the amplitude of the drag curve as

increases from 0.0 to 0.007. This is caused by the influence of the surface roughness in the boundary layer flow, which leads to an increase in the drag forces of approximately 12.9%. In the present simulations, an early transition s not observed and/or drag crisis is noted in in [

17,

33]. This happens due to the combined effects of a rough surface and mixed heat transfer, indicating that the temperature field interacts with the vorticity field avoiding the drag crisis occurrence in the studied cases.

However, when considering

in

Figure 6e, it can be observed that the behavior of the drag and lift curves changed when compared to the previous cases in the interval between tU/D = 20 and 30. This happens due to the interaction of the first pair of counter-rotating vortices in the near wake. The average drag coefficient in this scenario, with more intense buoyancy forces, is reduced by approximately 3.6% when compared to test case #3. Therefore, the proposed description of this kind of turbulent flow, using a Lagrangian approach, can capture the drag reduction using this mixed convection technique.

The average pressure coefficient at each discrete angular position of the cylinder (being zero the frontal stagnation point in the origin and

the stagnation point at (1.0, 0.0) measured in a clockwise manner) is shown in

Figure 7 for the five test cases. Overall,

Figure 7 shows that higher roughness value tends to increase the base pressure, with simulation #5 being the exception with the lowest base pressure. This value also has the largest deviation from the others as the angular position increases, suggesting that this roughness value impacts the vortex formation in different ways than the previous cases at the same Richardson number. Meanwhile, test case #6 at a higher Richardson number captured a reduction in the drag coefficient, which can be seen by its pressure coefficient consistently above the other test cases. The deviation from the lowest pressure near

to the experimental results [

34] can be attributed to the constant length of each panel used to discretize the surface, and a finer distribution at this region could better capture the pressure gradient.

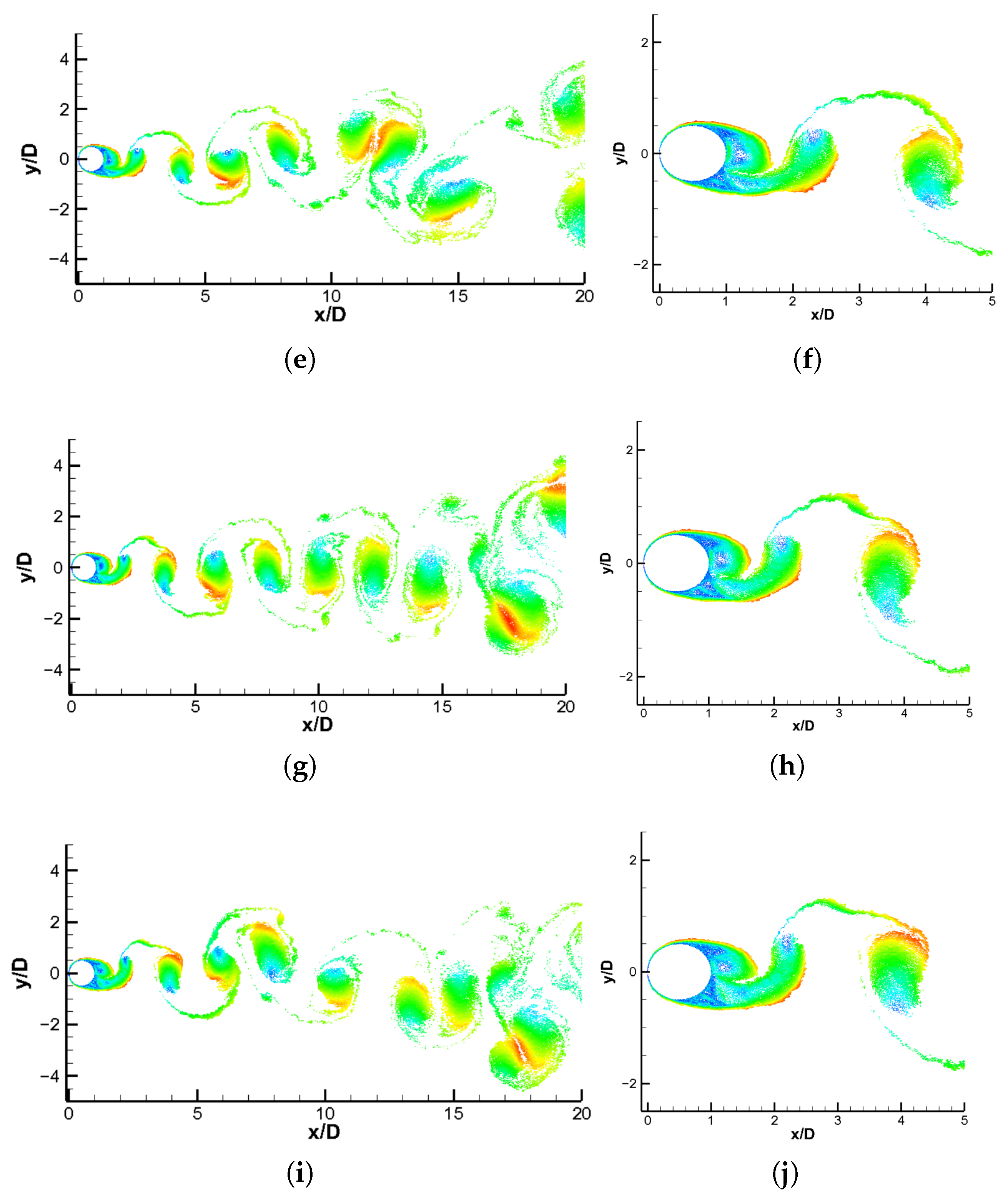

If one compares the wakes at the last time step for test cases #2 and #5, the surface roughness effects in the vortex dynamics become more apparent (

Figure 8). Test case #5 changes the wake more strongly, causing a larger region of lower velocities in the rear part of the cylinder.

When comparing the influence of the Richardson number effects, the wake is affected in a significant way. Test case #3 had a Strouhal number of 0.202, while test case #6 presented a Strouhal number of 0.208, showing that the frequency of the shedding was close in both cases; however, a qualitative view of each wake shows an expressive change (see

Figure 9). The Richardson number of 0.336 causes the spacing among the initial structures to increase, and the shapes become stretched, deforming the structure in the direction of the gravitational acceleration. The separation angle did not change in an expressive way, as can be seen in

Table 2, indicating that the buoyancy forces are determinant in the drag reduction in this situation.

A broader comparison can be made by inspecting the vortex wake near the end of all simulations, which is shown in

Figure 10. In this comparison, it can be seen that the roughness effects cause the wake and the vortex sheets to deform more as

increases. Additionally, for test case #5, the highest surface roughness simulated, the velocity field is characterized by more areas, with a higher magnitude in the far wake, and those intense vortical structures affect the sheets, making them less visible as the vorticity disperses at higher

values.

The wake of point A′ is shown in

Figure 10 for test cases #2 to #6 to aid in the physical interpretation of what happens to the flow due to the combined effects of roughness surface and natural convection in the simulations.

Figure 10a shows lower velocities in the near wake, particularly in the boundary layer detachment region, while the other test cases have higher velocities in the near wake due to the roughness effects. This higher velocity, in addition to the recirculating region that forms the clockwise vortex, which will be released into the domain, results in lower pressure at the top of the cylinder and an increasing drag coefficient at this instant (as shown in

Figure 6; the maximum lift peak is close to the maximum drag coefficient). When comparing

Figure 10a–h with

Figure 10i,j, it can be observed that at this time step, the near wake has a slight dislocation in the positive direction of the y-axis. Thus, the near wake becomes thinner in case #6, which explains the smaller drag coefficient that was observed in

Table 2. This displacement is due to the increased effects of the buoyancy forces at the near wake, represented by a Richardson number of 0.336.

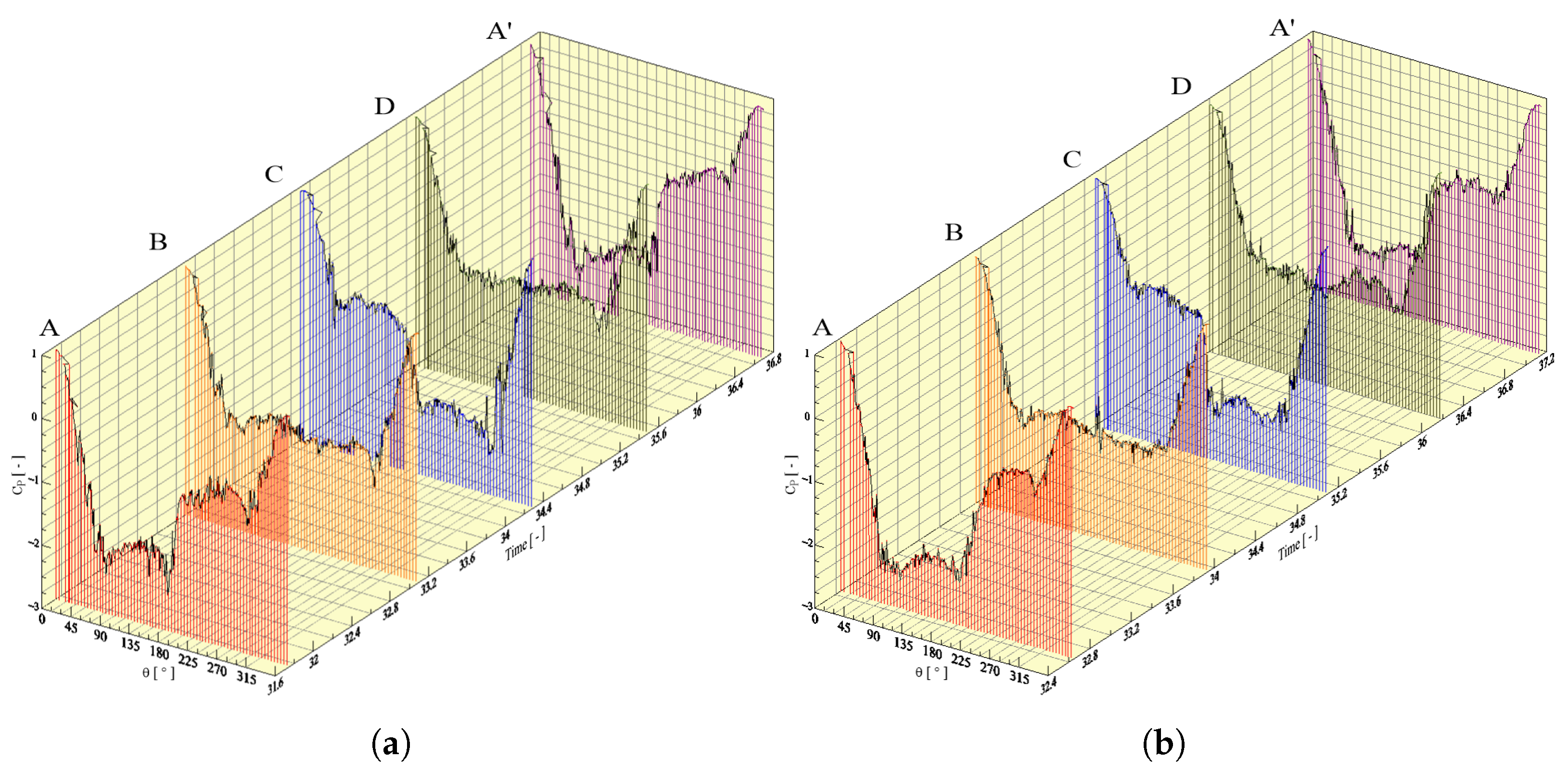

Focusing once more on the pressure coefficient, the effects of roughness and the Richardson number can be compared, analyzing the distribution of

at points of interest (A, B, C, D, and A

′) to investigate the Gerrard mechanism [

35]. Point A represents the instant when a clockwise vortex sheds from the top of the cylinder (also the maximum lift coefficient value). Point B is the instant at which this vortex is incorporated in the wake (and when the lift coefficient changes its signal). Point C denotes the shedding of a counter clockwise vortex (minimum lift coefficient), and point D is where this counterclockwise vortex joins the wake (lift coefficient changes signal). The comparison between cases #2 and #5 is shown in

Figure 11.

Figure 11 shows how the pressure coefficient behaves at every point of interest. It can be seen that point A of test case #2 has a higher pressure coefficient at the rear part of the cylinder (around

) than the one observed in case #5. The peak after

for test case #5 has a higher value than the value obtained in case #2. This results in the higher drag coefficient for case #5 and explains how the higher roughness surface affected the distribution of the pressure coefficient. Moreover, it can be seen that in the instant represented by point A, a clockwise vortex structure is shedding from the upper surface of the cylinder due to the lower pressure coefficient in this region, resulting in the maximum lift coefficient at this instant (see

Figure 6a,d). At point B, when the lift coefficient changes its signal, an equilibrium of the forces can be seen on the upper and lower half of the cylinder, indicating that the initial clockwise structure has entered the flow, and the counterclockwise vortex starts gaining circulation. This vortex keeps gaining circulation until it is ready to shed at point C in the lower half of the cylinder. When it sheds, the alternating mechanism starts feeding the upper half with circulation, and the point where the forces are once again in balance is seen in point D. Point A′ is physically the same as point A but after a period of the oscillation.