1. Introduction

Modal superposition is a well-established method in structural dynamics, based on the linear combination of modal shapes to describe displacements or strains. It has been widely used in engineering for decades, primarily because it offers considerable savings in time and computational resources compared to direct numerical integration methods [

1]. Its most common application is in the evaluation of the transient dynamic response of structures [

2], but it has also found widespread use in other domains, such as in the study of the response of seismic sites [

3,

4,

5].

Beyond these classical applications, modal superposition plays a central role in modal reconstruction, i.e., the reconstruction of a structure’s deformation field from sparse measurement data. Modal reconstruction algorithms provide a theoretical framework for recovering the full displacement field of a structure starting from a limited number of discrete measurements [

6,

7]. The underlying assumption is that the structural response to dynamic loading can be accurately represented by a reduced set of vibration modes, thus enabling efficient analysis while significantly reducing the amount of required measurement data. In engineering practice, this approach is particularly useful for objects that are isotropic, homogeneous, and linearly elastic, since displacement and strain measurements can then be related to stresses by compatibility conditions and Hooke’s law. In such contexts, reconstructing the displacement and strain fields also enables inference of the stress state of the entire structure, which is of high relevance for monitoring machines and critical safety systems.

Modal reconstruction has also been explored to reconstruct the shape from partial measurements [

8,

9]. In these applications, the deformation of an object can be inferred from limited displacement or strain signals, offering a powerful tool for practical engineering problems. This is particularly relevant in structural health monitoring (SHM), where displacements and strains often need to be estimated in real time from sparse measurements taken in accessible locations that do not compromise system operation [

10,

11]. If modal shapes are available from a finite element (FE) model, the measured displacements at these few points can be used to determine the modal coordinates, which quantify the contribution of each vibration mode to the overall deformation. These coordinates then form the basis for reconstructing the full-field structural response, offering valuable information for damage detection and anomaly identification.

A fundamental challenge in modal reconstruction is the problem of mode selection [

7,

12]. For both computational efficiency and accuracy, it is desirable to retain the smallest number of modes that capture the essential features of the dynamic response. However, the selection cannot be arbitrary: only the modes that significantly contribute to the deformation under the given loading conditions should be retained. Over the years, several selection criteria have been proposed [

13,

14,

15,

16]. Among these, the most relevant for the present study is the Internal Strain Potential Energy Criterion (ISPEC) [

17].

The ISPEC is based on quantifying the reconstruction capability of each vibration mode through its associated internal strain potential energy. This formulation is independent of the full FE solution and can be applied directly from sparse deformation or strain measurements combined with material properties. Unlike other criteria, the ISPEC can operate with measurements from a discrete number of points on the structure without requiring full-field knowledge of the deformation. This makes it particularly attractive for SHM applications, where measurement accessibility is often limited. From a theoretical point of view, the criterion is consistent with the energetic contribution of each mode to the structural deformation, retaining only the modes whose strain energy exceeds a predefined threshold. This ensures both reconstruction accuracy and computational efficiency.

Although the theoretical framework for modal reconstruction and the ISPEC is well established, its integration into SHM opens new opportunities. Real-time reconstruction of displacement fields can be achieved by combining ISPEC-based mode selection with advanced data-driven identification frameworks.

In this work, for the first time, a methodology is proposed that integrates the ISPEC with a machine learning-based classification framework to enable real-time reconstruction of full-field displacements from sparse measurements. Specifically, a random forest classifier is trained on synthetic deformation data generated from a simplified FE model of the monitored structure. The FE model is developed in Ansys APDL and discretised using SOLID185 linear solid elements. These elements are well suited for modelling three-dimensional solid structures, as each element consists of eight nodes with three translational degrees of freedom per node, corresponding to displacements in the global

x,

y, and

z directions [

18]. This modelling choice ensures a reliable representation of the structural behaviour while maintaining computational efficiency, which is essential for the generation of a sufficiently large synthetic dataset to be used for training the classifier. The algorithm is then applied to sparse experimental measurements, reconstructing the displacement field and validating predictions against independent reference points. Experimental data were obtained by placing an aluminium flat plate in an unstable flow generated by a custom-designed water tunnel. The characteristics of the incoming flow were measured using a planar PIV system. The same PIV camera was also used to record the displacement of the plate.

Details on the experimental setup and the methodology are given in

Section 2 and

Section 3, respectively. The main results are reported in

Section 4, while conclusions and final remarks are given in

Section 5.

2. Experimental Setup

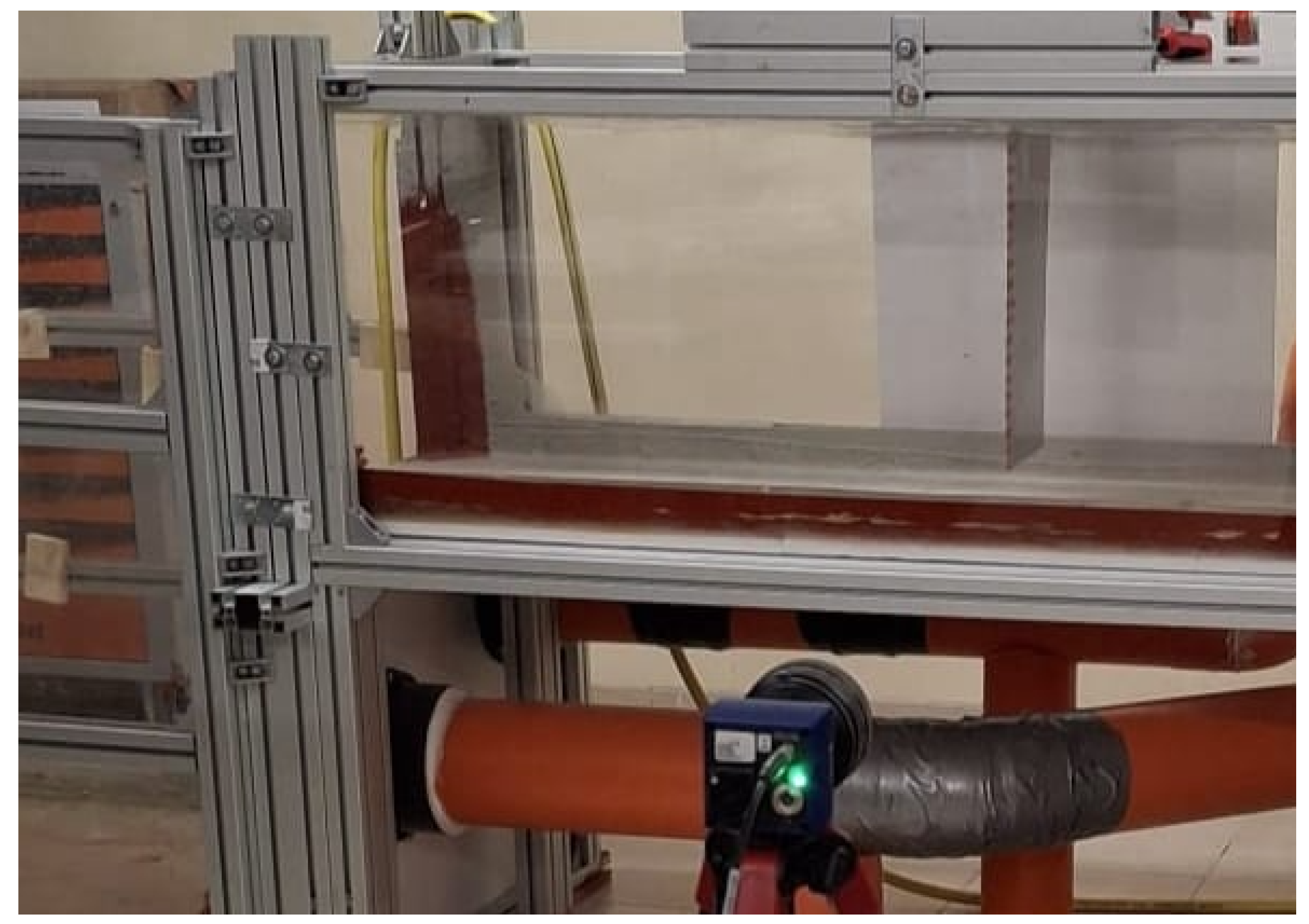

2.1. Water Tunnel Description

The experiments were conducted in the low-speed water tunnel located at the University of Tuscia. The facility is a closed-loop water tunnel featuring a test section with dimensions

. The water flow is provided by a Caprari pump driven by a 4 kW asynchronous electric motor. The flow rate is controlled using a series of bypass valves and flow velocity can be varied from

up to

, enabling the achievement of Reynolds numbers on the order of

with a stable and quite clean flow rate. Details about the experimental facility are reported in

Figure 1.

The facility was equipped with a planar Particle Image Velocimetry (PIV) system provided by LaVision. The system includes a CMOS camera with a sensor resolution of pixels resolving 123 fps at full resolution. The camera was equipped with Nikkor AF-S 58mm f/1.4G lenses by Nikon (Melville, NY, USA). Water was seeded by hollow glass spheres, with a nominal diameter of 10 m and specific weight of 1.05 . The illumination of the field of view is provided by an LED light source capable of producing 1350 lumens, producing a collimated light sheet wide and thick. Camera calibration, acquisition, and post-processing are supported by LaVision Davis 11 software. The statistical analysis was performed over a population of 200 images.

2.2. Setup Definition

The test specimen used in the experimental campaign is a flexible aluminium lamina with dimensions (width × height × thickness). The plate is vertically mounted inside the test section of the water tunnel, with its longer edge (400 mm) oriented vertically and partially immersed in water. The upper portion remains above the free surface and is fully accessible to optical measurements.

The top edge of the lamina is clamped using a rigid vice, ensuring a fixed–free boundary condition. The water level is adjusted so that only the lower section is submerged, while the upper, emerged portion is monitored through the camera. This is positioned laterally to the tunnel and captures the lamina’s out-of-plane deformation induced by the fluid flow.

To track displacements, a sequence of high-contrast reflective tape markers is applied along the vertical midline of the section of the lamina. These markers are made of retroreflective tape and are equally spaced at intervals, starting from the clamped edge and extending downward. The number of markers visible depends on the water level and camera framing, as only those located above the free surface are acquired by the optical system.

Among the visible markers, the first seven from the clamped end are used as input for the SHM algorithm. These provide the minimum spatial information necessary to initialise the modal reconstruction framework. Any additional visible markers positioned further from the clamp are excluded from the input phase and instead used for validation purposes by comparing experimental and reconstructed displacements.

A photograph of the experimental setup, showing the aluminium lamina and its clamping system, is provided in

Figure 2. The distribution and roles of the markers are schematically illustrated in

Figure 3.

3. Methodology

3.1. Measurement Selection and Data Usage

The proposed methodology reconstructs the full deformation field of a flexible aluminium plate using sparse displacement measurements, acquired experimentally through image-based tracking techniques. To ensure consistent spatial sampling, ten equidistant markers were tracked along the longitudinal axis of the plate. Only the first seven markers, those located nearest to the clamped boundary, are used as input for the reconstruction algorithm. The remaining three markers, located closer to the water free surface, are excluded from the modal reconstruction process and instead serve as reference points to validate the accuracy of the predicted displacement field.

3.2. Displacement Measurement via Computer Vision Tracking

Displacement measurements were obtained through a custom Python (3.10 version) script implementing a computer vision tracking routine based on the OpenCV library. The method employs the TrackerCSRT algorithm, which is well-suited for accurate localisation of non-rigid targets under partial occlusion and varying illumination.

The procedure begins with the manual selection of rectangular Regions of Interest (ROIs) corresponding to reflective tape markers applied along the longitudinal axis of the plate. For each ROI, the CSRT tracker estimates the marker’s centroid position in pixel coordinates for every frame of the acquired image sequence. The tracking is performed simultaneously for all markers using the MultiTracker framework, ensuring synchronous displacement histories.

Pixel coordinates are converted into physical units (millimetres) using a calibrated scale factor obtained from the experimental setup. For each marker i, the deflection component is calculated by subtracting the initial reference position from the corresponding time-varying tracked position. The resulting displacement time series are stored as NumPy arrays for subsequent use in the modal reconstruction stage.

3.3. Modal Reconstruction Framework

The SHM strategy is based on modal reconstruction, where the structural response is represented as a linear combination of vibration modes derived from the geometry and boundary conditions of the system. Displacement and strain fields are expressed as follows [

12,

19,

20,

21,

22]:

where

and

are the displacement and strain vectors,

is the vector of modal coordinates, and the matrices

and

contain the modal displacement and strain shapes, respectively.

Considering an over-determined linear equation system, modal coordinates can be estimated through Langrange multipliers as follows [

23]:

It is important to note that, to be valid, the system must be sufficiently determined. Specifically, the number of independent equations, i.e., the product of the number of measurement points and the number of degrees of freedom, must be greater than or equal to the number of retained modes [

23]. This condition ensures that the least-squares inversion used to compute

is mathematically well-posed and does not lead to overfitting or instability in the reconstruction.

3.4. Strain Potential Energy-Based Mode Selection

To achieve accurate yet efficient reconstruction, only the most significant modes are retained. An energy-based criterion is employed to quantify the contribution of each mode to the strain energy of the system, known as the Internal Strain Potential Energy Criterion (ISPEC) [

17,

24]. The internal strain energy of a given deformation is defined as follows:

with

denoting the elasticity matrix, incorporating material properties such as Young’s modulus and Poisson’s ratio [

25,

26].

When using modal superposition, the reconstructed strain energy becomes

and the contribution of each individual mode is given by

A non-dimensional metric, the reconstruction capability, is defined as follows:

where

is the total strain energy of the actual deformation field. Only modes satisfying the following criterion are retained:

where

is a user-defined threshold. This ensures that the reduced basis contains only the most physically relevant modal contributions, improving both numerical stability and interpretability.

3.5. Modal Identification via Machine Learning

Once the most informative modes are selected, they are used to train a machine learning model capable of predicting modal participation based on sparse displacement data.

A random forest classifier, implemented in scikit-learn, is trained using synthetic datasets generated by random linear combinations of the retained modes. The random forest classifier is chosen because the purpose of the machine learning model is not to directly predict continuous modal amplitudes, but rather to identify which modes are active at each timestep, i.e., those contributing most effectively to the reconstruction of the deformation field.

During training, each input sample corresponds to a set of displacements at the 7 selected marker locations, and the target output is the set of chosen modes. Once trained, the classifier predicts modal activations from new experimental measurements. After obtaining the predicted active modes from the classifier for each timestep, a new modal decomposition is performed on the measured points in order to compute the corresponding modal coordinates. These coordinates are then used to reconstruct the full displacement field by superimposing the identified modes weighted by their computed modal coordinates.

These predictions are used to reconstruct the full displacement field using Equation (

1).

The quality of the reconstruction is assessed by comparing predicted displacements at the 3 unused marker locations with those measured through image-based tracking. This validation step confirms the ability of the algorithm to generalise beyond the input space and accurately recover unobserved portions of the deformation field.

3.6. Validation Metrics

Let

and

denote, respectively, the measured and reconstructed component

i of displacement at a validation marker. To assess the accuracy of the reconstruction, the instantaneous residual (or absolute error) is defined as follows:

Time histories of

are examined alongside the measured and reconstructed signals,

and

, to identify any systematic deviations, phase lags, or transient discrepancies. Visual inspection of these time series provides insight into the dynamic performance of the reconstruction algorithm and highlights periods where reconstruction errors may be more pronounced.

For quantitative assessment, a single-number indicator over a finite time window

T is defined using the root-mean-square error (RMSE) [

27]:

where

N is the number of samples within

T. The RMSE captures the overall magnitude of the reconstruction error, providing a clear measure of how closely the reconstructed signal tracks the actual measurement over the selected interval.

To allow comparison across different validation points and deformation amplitudes, a normalised version of the RMSE is also employed:

The NRMSE expresses the reconstruction error as a percentage of the full measured signal range, facilitating intuitive interpretation and comparison between experiments or different sensor locations.

In addition to NRMSE, the normalised cross-correlation between the measured and reconstructed signals is employed to assess the similarity in shape and phase. It is defined as follows:

Here,

and

denote the mean values of the measured and reconstructed signals, respectively. The normalised cross-correlation ranges from

to 1, with values close to 1 indicating strong agreement in both amplitude and phase. While NRMSE quantifies the magnitude of the reconstruction error,

provides a complementary assessment of temporal and structural similarity between the signals.

Furthermore, the temporal lag between the measured and reconstructed signals can be computed from the cross-correlation function. A lag close to zero indicates that the reconstructed signal is well-synchronised with the measurement, while larger lags reveal phase shifts or delays. Thus, serves as an additional indicator of reconstruction fidelity.

By combining both time-domain inspection of residuals, single-number error indicators such as NRMSE, the normalised cross-correlation, and the temporal lag, the validation framework provides a robust and comprehensive assessment of reconstruction performance.

5. Conclusions

This study presented an experimental and numerical framework for reconstructing the full-field deformation of a flexible aluminium plate operating under unsteady fluid loading in a water tunnel. The proposed methodology integrates sparse displacement measurements, acquired via a digital CMOS camera, with a modal reconstruction approach informed by mode selection based on strain energy contribution. A random forest classifier, trained on a synthetic database generated from a high-fidelity digital twin, was employed to map sparse sensor data to modal coordinates, enabling accurate SHM from limited measurements.

The experimental setup allowed for the tracking of seven measurement markers for reconstruction and three independent verification markers for accuracy assessment. The reconstructed deflections showed good agreement with the camera-measured signals at the verification markers, with reconstruction errors remaining within a few tenths of a millimetre, demonstrating the robustness of the approach under realistic fluid–structure interaction conditions.

Flow visualisation using planar PIV provided a complementary global estimate of the flow loading on the plate, clearly highlighting the local flow deceleration in its vicinity.

Overall, the integrated methodology, combining visualisation, modal reconstruction, and machine learning, proved effective for real-time deformation monitoring of partially submerged flexible structures. This approach offers a strong foundation for developing SHM systems in marine and hydraulic engineering, particularly where direct full-field measurements are impractical. Future work will focus on extending the method to multi-directional displacement components, implementing adaptive mode selection strategies, and performing in situ validation under operational conditions.