Low Fatization of High-Fat Surimi-Based Products: Optimization of the Application of Protein Matrix Fat Substitution Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

2.1.1. Experimental Materials

2.1.2. Experimental Equipment

2.2. Experimental Method

2.2.1. Initial Formulation of Low-Fat Nemipterus virgatus Fish Sausage

2.2.2. Processing Process and Operation Points of Low-Fat Nemipterus virgatus Fish Sausage

2.3. Experimental Design of Low-Fat Nemipterus virgatus Fish Sausage Formulation

2.3.1. Optimization of the Composition of Compound Fat Substitutes

2.3.2. Experimental Study of Low-Fat Nemipterus virgatus Fish Sausage Formulation

2.4. Determination of Gel Strength [35]

2.5. Sensory Scoring Criteria for Low-Fat Nemipterus virgatus Fish Sausage

2.6. Flavor Analysis—Electronic Nose Analysis Method

2.7. Statistical Analysis

3. Results and Discussion

3.1. Test Results and Analysis of Low-Fat Nemipterus virgatus Fish Sausage Formulation

3.1.1. Determination of the Composition of the Compound Fat Substitution

3.1.2. Validation Test

3.2. Determination of Single-Factor Parameters for the Process Formulation of Low-Fat Nemipterus virgatus Fish Sausage

3.2.1. Effect of Compound Fat Substitution Addition on Gel Strength and Sensory Quality of Low-Fat Nemipterus virgatus Fish Sausage

3.2.2. Effect of Exogenous Fat Addition on Gel Strength and Sensory Quality of Nemipterus virgatus Fish Sausage

3.2.3. Effect of TGase Addition on Gel Strength and Sensory Quality of Low-Fat Nemipterus virgatus Fish Sausage

3.2.4. Response Surface Testing to Optimize the Process Formulation of Low-Fat Nemipterus virgatus Fish Sausage

3.2.5. Establishment of the Regression Equation and Experimental Analysis of the Process Formulation of Low-Fat Nemipterus virgatus Fish Sausage

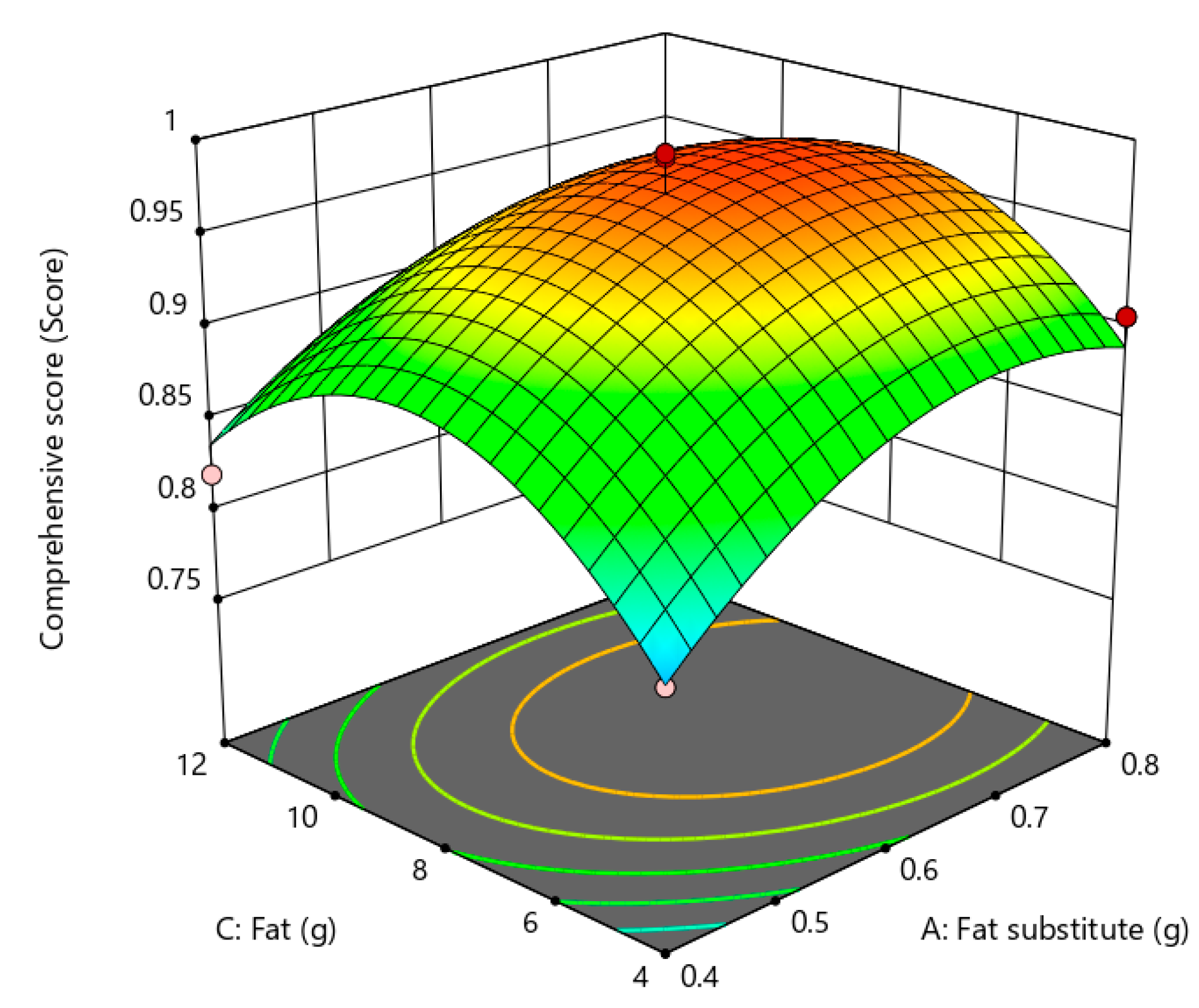

3.2.6. Response Surface Analysis and Optimization

3.2.7. Validation of Optimal Conditions

3.3. Effect of Compound Fat Substitutes on the Quality of Nemipterus virgatus Fish Sausage

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, S.Y.; Zhu, X.X.; Chen, C.G.; Zhou, C.L. Research progress on the nutritional value and carcinogenic risk of meat and meat products. Meat Res. 2015, 29, 41–47. [Google Scholar]

- Dong, X.W.; Zhnag, S.S.; Li, D.Y.; Pang, G.Q.; Zhou, Y.J. Research progress in the application of fat substitutes in meat products. J. Food Saf. Qual. 2017, 8, 1961–1966. [Google Scholar]

- Choi, Y.S.; Park, K.S.; Kim, H.W.; Hwang, K.E.; Song, D.H.; Choi, M.S.; Lee, S.Y.; Paik, H.D.; Kim, C.J. Quality characteristics of reduced-fat frankfurters with pork fat replaced by sunflower seed oils and dietary fiber extracted from makgeolli lees. Meat Sci. 2013, 93, 652–658. [Google Scholar] [CrossRef] [PubMed]

- Tao, D.F. Canada: Writing a low-fat diet into the law. Cook. Knowl. 2015, 10, 61. [Google Scholar]

- Erick, S.S.; Thais, C.M.; Iliani, P.; Juan, D.R.M.; Carmen, J.C.C.; Miriam, M.S. Use of sensory science for the development of healthier processed meat products: A critical opinion. Curr. Opin. Insect Sci. 2020, 40, 13–19. [Google Scholar]

- Choi, J.; Kim, N.; Choi, H.Y.; Han, Y.S. Effect of cacao bean husk powder on the quality properties of pork sausages. Food Sci. Anim. Resour. 2019, 39, 742–755. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.Z.; Ruan, M.Y.; Liu, J.L.; Wilde, P.; Naumova, E.N.; Mozaffarian, D.; Zhang, F.F. Trends in processed meat, unprocessed red meat, poultry, and fish consumption in the United States, 1999–2016. J. Acad. Nutr. Diet. 2019, 119, 1085–1098. [Google Scholar] [CrossRef]

- Cardona, M.; Gorriz, A.; Barat, J.M.; Fernández-Segovia, I. Perception of fat and other quality parameters in minced and burger meat from Spanish consumer studies. Meat Sci. 2020, 166, 108138. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, Y.L.; Zhao, X.; Zou, Y.; Tao, B.B.; Zhao, G. Research progress of fat replacement in low-fat meat products. Sci. Technol. Food Ind. 2013, 34, 347–352. [Google Scholar]

- Cao, X.Y.; Li, X.H. Microbial transglutaminase modified and hydrolytic soybean protein in pork sausages. Food Sci. Technol. 2015, 40, 139–144. [Google Scholar]

- Guo, Y.; Wei, J.H.; Shen, S.; Wang, Z.R. Application of specially modified soybean isolate protein in meat products. J. Yellow River Conserv. Tech. Inst. 2006, 18, 52–54. [Google Scholar]

- Qu, L.; Zhang, C.H.; Liu, C.J. Preparation of soy protein isolate by enzymatic modification and its application in meat products. Sci. Technol. Food Ind. 2006, 12, 184–185. [Google Scholar]

- Sun, P.R.; Yi, C.P. Research progress in fat substitutes. China Food Addit. 2011, 167–171. [Google Scholar]

- Luo, Z.G.; Gao, Q.Y.; Yang, L.S. The application of fat substitutes in food. Sci. Technol. Cereals Oils Foods 2002, 10, 6–8. [Google Scholar]

- Ahmad, S.; Rizawi, J.A.; Srivastava, P.K. Effect of soy protein isolate incorporation on quality characteristics and shelf-life of buffalo meat emulsion sausage. J. Food Sci. Technol. 2010, 47, 290. [Google Scholar] [CrossRef]

- Wu, R.F.; Yuan, M.L.; Zhao, L.; Chen, L.L.; Lian, Y.M.; Fu, W.L.; Wen, H.F. Effects of different additive agents on grass Carp surimi quality. Food Sci. 2014, 35, 53–57. [Google Scholar]

- Chen, X.; Wu, J.H.; Li, X.Z.; Yang, F.J.; Yu, L.H.; Li, X.K.; Huang, J.J.; Wang, S.Y. Investigation of the cryoprotective mechanism and effect on quality characteristics of surimi during freezing storage by antifreeze peptides. Food Chem. 2022, 371, 131054. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Lin, C.; Yu, M.; Chen, S.; Guo, J.; Rao, P.; Miao, S.; Liu, S. Heat-induced structural changes in fish muscle collagen related to texture development in fish balls: Using eel ball as a study model. Food Sci. Nutr. 2021, 10, 329–341. [Google Scholar] [CrossRef]

- Dou, R.R.; Zhao, C.Q.; Li, G.M.; Yan, Z.H.; Kang, C.Y. Research progress on extraction, properties and application of fish skin collagen. Food Res. Dev. 2012, 43, 212–218. [Google Scholar]

- Weng, W.Y.; Huang, Y.P.; Zhang, X.C.; Shan, D.D.; Huang, J.L. Effects of fish skin gelatins with different molecular weight distribution on gel properties of silver carp surimi. J. Chin. Inst. Food Sci. Technol. 2013, 13, 83–90. [Google Scholar]

- Jin, C. Extraction of Collagen from Fish Scale of Grass Carp and Preparation of Bioactive Peptide. Food Res. Dev. 2017, 38, 52–55. [Google Scholar]

- Gao, J.J. Application of codfish collagen in food Industry. Agric. Prod. Process. 2014, 10, 79–80. [Google Scholar]

- Chang, C.H.; Niu, F.G.; Su, Y.J.; Qiu, Y.; Gu, L.P.; Yang, Y.J. Characteristics and emulsifying properties of acid and acid-heat induced egg white protein. Food Hydrocoll. 2016, 54, 342–350. [Google Scholar] [CrossRef]

- Özturk, B.; Urgu, M.; Serdaroglu, M. Egg white powder tabilised multiple (water-in-olive oil-in-water) emulsions as beef fatreplacers in model system meat emulsions. J. Sci. Food Agric. 2017, 97, 2075–2083. [Google Scholar] [CrossRef] [PubMed]

- Zou, J.; Wang, Q.; Ma, M.H.; Huang, X.; Sheng, L. Effect of high intensity ultrasound on the foaming characteristics of egg white liquid. J. Chin. Inst. Food Sci. Technol. 2022, 22, 163–171. [Google Scholar]

- Xiong, W.F.; Deng, Q.C.; Li, J.; Zhong, Q.X. Ovalbumin-carboxymethylcellulose complex coacervates stabilized high internal phase emulsions: Comparison of the effects of pH and polysaccharide charge density. Food Hydrocoll. 2019, 98, 105282. [Google Scholar] [CrossRef]

- Campo-Deaño, L.; Tovar, C. The effect of egg albumen on the viscoelasticity of crab sticks made from Alaska Pollock and Pacific Whiting surimi. Food Hydrocoll. 2009, 23, 1641–1646. [Google Scholar] [CrossRef]

- Li, Y.J.; Lin, H.; Zhao, Y.H.; Wu, H.H.; Xie, W.C.; Yan, X.H.; Liang, X.G. Application status and development trend of protein additives in fish surimi-based products. Food Res. Dev. 2020, 41, 220–224. [Google Scholar]

- Chen, H.H.; Xue, C.H. The Effect of different additives on the gel properties of carp surimi. Food Ferment. Ind. 2008, 34, 79–84. [Google Scholar]

- Zhou, Y.; Xu, W.; Chen, J.W.; Wang, H.B.; Wang, H.X. Effect of egg white protein powder and isolated soy protein powder on quality of fish ball. Food Sci. Technol. 2018, 43, 299–302. [Google Scholar]

- Xin, M.L.; Wang, X.D.; Zhu, Z.W.; Zeng, Q.X.; Li, B.S. Effect of ingredients on gel properties of common carp(Cyprinus carpio) fish ball and changes of fish ball quality during storage. Mod. Food Sci. Technol. 2010, 26, 809–814. [Google Scholar]

- Huang, X.X.; You, Y.; Liu, Q.Y.; Li, X.L.; Ou, B.Q.; Mai, Y.Z.; Zeng, X.F.; Bai, W.D. Effects of different exogenous substances on gel propertiesand water loss rate of grass carp sausage. Meat Ind. 2022, 12, 14–22. [Google Scholar]

- Xu, Y.B.; Xu, W.; Huang, D. Comparison of improvement effect of egg white solution and egg white powder on gelling properties of silver carp surimi. China Poult. 2016, 38, 34–37. [Google Scholar]

- Shi, Z.Z.; Chen, S.S.; Wang, H. Effect of egg white on gel properties of silver carp surimi. Food Ferment. Ind. 2015, 41, 70–74. [Google Scholar]

- Yan, G.Y.; Qiu, S.L.; Chen, X.T.; Yu, L. Optimization of process formula of Nemipterus virgatus fish sausage. J. Fish. Res. 2021, 43, 212–220. [Google Scholar]

- Wu, X.H.; Chen, W.Y.; Fei, Z.L. Aquatic Product Processing Technology and Formula. Master’s Thesis, Technology Press, Beijing, China, 2001. [Google Scholar]

- Zhang, C.F. Research on Key Technologies for Processing Silver Carp Minced Products and Enzymatic Hydrolysis of Silver Carp Viscera. Ph.D. Thesis, School of Food Science and Nutritional Engineering, China Agricultural University, Beijing, China, 2003. [Google Scholar]

- Li, G.L.; Nei, H.; Su, K.Z.; Li, X.C.; Huang, S.Q.; Wu, S.J.; Luo, Y.H. Sensory evaluation and electronic nose analysis of volatile flavor compounds in water chestnuts at different cooking times. Sci. Technol. Food Ind. 2020, 41, 1–7. [Google Scholar]

- Wu, H.; Liu, Y.; Gu, S.Q.; Fu, N.; Chen, W.H.; Wang, X.C. Category distinction of different surimis by electronic nose, electronic tongue and sensory evaluation. Sci. Technol. Food Ind. 2013, 34, 80–82, 338. [Google Scholar]

- Sun, L.X.; Li, M.Y.; Liu, Y.X.; Gao, X.P.; Zhang, Q.H.; Zhao, G.M. Analysis of the differences in aroma of differentbrands of daokou roasted chicken on market by electronic nose. Food Ind. 2020, 280–283. [Google Scholar]

- Lozupone, C.; Knight, R. UniFrac: A new phylogenetic method for comparing microbial communities. Appl. Environ. Microbiol. 2005, 71, 8228–8235. [Google Scholar] [CrossRef]

- Liu, W.J.; Xiao, Y.; Mai, Z.H.; Zhang, X.S.; Zhou, K.; Yao, W.L.; Ji, P.; Hua, Y.L.; Yuan, Z.W.; Wei, Y.M. Optimization of preparation pechnology of aqueous extracts of astragalus membranaceus-angelicae sinensis by multi-index comprehensive scoring method combined with orthogonal test. Prog. Vet. Med. 2023, 44, 78–83. [Google Scholar]

- Zhao, Z.L.; Zhao, P.; Deng, G.R.; Li, J.; Liu, Y.M.; Chen, K.L. Optimization of extraction technology for compound selaginella moellendorffii powder with orthogonal test by multiple indicators. China Pharm. 2016, 27, 3996–3998. [Google Scholar]

- Guo, P.; Shen, X.R.; Xu, C.H.; Huang, R. A formula on minced tilapia fish surimi with the addition of gelatin extracted from tilapia fish skin. Food Sci. Technol. 2015, 128–132. [Google Scholar]

- Chen, X.P.; He, J.; Li, Y.; Zheng, X.J. The Effect of subsidiary materials on the quality of trash fish surimi-based products. Food Ind. 2011, 87–90. [Google Scholar]

- Balange, A.; Benjakul, S. Enhancement of gelstrength of bigeye snapper surimi using oxidised phenolic compounds. Food Chem. 2009, 113, 61–70. [Google Scholar] [CrossRef]

- Mi, H.; Zhao, Y.; Li, Y.; Chen, J.; Liu, H.; Yi, S.; Li, X.; Li, J. Combining effect of soybean protein isolate and transglutaminase on the gel properties of Zhikong scallop (Chlamys farreri) adductor muscle. LWT 2021, 138, 110727. [Google Scholar] [CrossRef]

- Wang, W.F.; Li, D.D.; Xiong, S.B.; Hong, Y.P. Effects of Proportion of Pig Lean Meat and Fat on Quality of Surimi-based Product. Food Sci. 2006, 27, 531–534. [Google Scholar]

- Sakamoto, H.; Kumazawa, Y.; Motoki, M. Strength of protein gels preparedwith microbial transglutaminase as related to reaction conditions. J. Food Sci. 1994, 59, 866. [Google Scholar] [CrossRef]

- Chanarat, S.; Benjakul, S. Comparative study on protein cross -linking and gel enhancing effect of microbial transglutaminase on surimi from different fish. J. Sci. Food Agric. 2012, 92, 844–852. [Google Scholar] [CrossRef]

- Jia, D.; Liu, R.; Liu, M.F.; Li, Y.B.; Xiong, S.B. Effect of transglutaminase on heat-induced gel properties of bighead carp (Aristichthys nobilis) surimi. Food Sci. 2013, 34, 37–41. [Google Scholar]

- Sun, Y.L.; Zhu, X.R. Analysis of volatile components in different varieties of Qsmanthus fragrans extract based on GC-MS and electronic nose technology combined with chemometrics method. Food Sci. 2023, 44, 257–264. [Google Scholar]

- Luo, J.; Li, M.; Zhang, Y.; Liu, Y.; Guan, Z.Q. Effect of different drying methods on volatile flavor components of tilapia fillets by electronic nose combined with GC-MS. S. China Fish. Sci. 2022, 18, 135–143. [Google Scholar]

- Chen, X.A.; Cai, H.D.; Liu, J.Y.; Tang, N.; Chen, S.X.; Zhou, A.M. Based on electronic nose, GC-MS and GC-IMS techniques to analyze the changes in volatile components during the fermentation of Laoxianghuang. Sci. Technol. Food Ind. 2021, 42, 70–80. [Google Scholar]

- Zhang, J.; Dong, H.F.; Feng, M.Q.; Han, M.Y.; Sun, J. Optimization of low-sodium compound salt formula for salt-baked chicken thighs by response surface methodology and analysis of volatile flavor compounds. Sci. Technol. Food Ind. 2022, 43, 208–217. [Google Scholar]

- Huang, G.Y.; Zhao, H.J.; Gao, Y.; Xu, L.P.; Xu, G.Y.; Wu, Z.M.; Li, R.L.; Liang, M.; Zhang, J.S. Analysis of volatile components in dried jujube and its different extracts by headspace solid phase microextraction-gas chromatography-mass spectrometry and electronic nose. Food Sci. 2022, 43, 255–262. [Google Scholar]

- Anna, G. Fat substitutes create new issues. J. Am. Oil Chem. Soc. 1988, 11, 1708–1712. [Google Scholar]

- Liu, W.J.; Xu, Z.Q.; Xing, S.J.; Zhu, M.R.; Yang, L.T.; Wang, Z.R. Effects of carrageenan, transglutaminase, and soy protein isolate on water retention and sensory quality of pig PSE low-temperature sausage. Meat Res. 2019, 33, 34–39. [Google Scholar]

- Zhou, S.Q.; Liu, X.; Liu, S.W. Effect of compound emulsion gel as fat substitute on physicochemical properties of chicken intestines. Sci. Technol. Food Ind. 2020, 41, 7–14. [Google Scholar]

- Jimenez-Colmenero, F.; Herrero, A.; Pintado, T.; Solas, M.T.; Ruiz-Capillas, C. Influence of emulsified olive oil stabilizing system used for pork backfat replacement in frankfurters. Food Res. Int. 2010, 43, 2068–2076. [Google Scholar] [CrossRef]

- Zhang, H.B.; Cao, W.; Wang, Z.G. Study on the formula of fat substitutes for low fat sausages. Food Sci. Technol. 2015, 40, 149–156. [Google Scholar]

| Test Items | Score Standard | Score/100 |

|---|---|---|

| Taste (20) | Poor taste and rough texture | 0~4 |

| Taste salty or light, no juiciness | 4~8 | |

| Medium salty and juicy | 8~16 | |

| Moderately salty, with a strong sense of juice | 16~20 | |

| Smell (20) | Bad smell | 0~4 |

| No meat flavor, too much fish smell | 4~8 | |

| Insufficient meat flavor, slightly fishy taste | 8~16 | |

| With mixed fragrance | 16~20 | |

| Color and luster (20) | Off-white, lusterless | 0~4 |

| Light white color, slightly yellowish | 4~8 | |

| Light white, slightly glossy | 8~16 | |

| Pale white, glossy | 16~20 | |

| Tissue morphology (20) | Smooth surface, hollow, loose structure, with more free fat and water precipitation | 0~4 |

| Smoother surface, with cavities, looser structure, slightly free from fat and water precipitation in the form of swimming tissue | 4~8 | |

| Smooth surface, small pores, denser and more uniform structure, no free fat or water precipitation | 8~16 | |

| Smooth surface, non-porous structure dense and uniform, no free fat or water precipitation | 16~20 | |

| Elasticity (20) | No elasticity, chewing with gritty feeling and residue | 0~4 |

| Poor elasticity, chewing with sandy feeling, no residue | 4~8 | |

| Elasticity general, chewing no sandy feeling no residue | 8~16 | |

| Good elasticity, chewing without gritty feeling, no residue | 16~20 |

| No. | Factor | ||

|---|---|---|---|

| A Collagen/g | B Soy Protein Peptide/g | C Ovalbumin/g | |

| 1 | 0.10 | 0.05 | 0.10 |

| 2 | 0.20 | 0.10 | 0.20 |

| 3 | 0.30 | 0.15 | 0.30 |

| No. | Factor | Sensory Score/100 | Comprehensive Score | ||||

|---|---|---|---|---|---|---|---|

| A Collagen/g | B Soy Protein Peptide/g | C Ovalbumin/g | D Empty Column | Gel Strength/g·cm | |||

| 1 | 0.10 | 0.05 | 0.10 | 1 | 152.790 | 60.32 | 0.6674 |

| 2 | 0.10 | 0.01 | 0.20 | 2 | 170.186 | 63.15 | 0.7024 |

| 3 | 0.10 | 0.15 | 0.30 | 3 | 191.755 | 65.26 | 0.7316 |

| 4 | 0.20 | 0.05 | 0.20 | 3 | 299.960 | 72.08 | 0.8398 |

| 5 | 0.20 | 0.01 | 0.30 | 1 | 555.559 | 78.08 | 0.9927 |

| 6 | 0.20 | 0.15 | 0.10 | 2 | 213.332 | 65.56 | 0.7424 |

| 7 | 0.30 | 0.05 | 0.30 | 2 | 444.133 | 79.50 | 0.9670 |

| 8 | 0.30 | 0.10 | 0.10 | 3 | 313.484 | 70.77 | 0.8313 |

| 9 | 0.30 | 0.15 | 0.20 | 1 | 410.687 | 77.43 | 0.9339 |

| 0.700 | 0.824 | 0.747 | 0865 | ||||

| 0.858 | 0.842 | 0.825 | 0.804 | ||||

| 0.911 | 0.803 | 0.897 | 0.801 | ||||

| Range (R) | 0.211 | 0.039 | 0.150 | 0.064 | |||

| Ordering | A > C > B | ||||||

| Optimal combination | A2B2C3 | ||||||

| Factor | Mean Sum of Deviations (SS) | Freedom (df) | Variance (Ms) | F | Fɑ |

|---|---|---|---|---|---|

| A (Collagen) | 7.2 × 10−2 | 2 | 3.6 × 10−2 | 2.000 | F0.05(2,2) = 5.14 F0.01(2,2) = 10.9 |

| B (Soy Protein Peptide) | 2.0 × 10−3 | 2 | 1.0 × 10−3 | 0.056 | |

| C (Ovalbumin) | 3.4 × 10−2 | 2 | 1.7 × 10−2 | 0.944 | |

| Error | 0.11 | 6 | 0.055 | ||

| Total variation | 0.218 | 12 |

| No. | Fat Substitute Addition/g | Gel Strength/g·cm | Sensory Score/100 | Comprehensive Score |

|---|---|---|---|---|

| 0 | 0 | 353.324 ± 14.435 | 58.5 ± 1.6 | 0.7605 ± 0.0021 f |

| 1 | 0.4 | 403.028 ± 23.182 | 63.2 ± 3.2 | 0.8496 ± 0.0021 e |

| 2 | 0.6 | 498.587 ± 19.416 | 72.8 ± 2.4 | 0.9707 ± 0.0018 a |

| 3 | 0.8 | 553.075 ± 9.535 | 69.2 ± 1.7 | 0.9498 ± 0.0009 b |

| 4 | 1.0 | 576.541 ± 3.262 | 58.8 ± 2.8 | 0.8436 ± 0.0011 c |

| 5 | 1.2 | 584.095 ± 7.501 | 56.0 ± 4.1 | 0.8154 ± 0.0010 d |

| No. | Fat Addition/g | Gel Strength/g·cm | Sensory Score/100 | Comprehensive Score |

|---|---|---|---|---|

| 1 | 20.0 | 520.120 ± 6.539 | 62.7 ± 2.1 | 0.8734 ± 0.013 d |

| 2 | 16.0 | 518.526 ± 16.209 | 69.3 ± 2.9 | 0.9444 ± 0.015 c |

| 3 | 12.0 | 516.381 ± 8.067 | 70.5 ± 0.6 | 0.9569 ± 0.003 b |

| 4 | 8.0 | 518.876 ± 15.437 | 74.4 ± 1.5 | 0.9995 ± 0.009 a |

| 5 | 4.0 | 393.438 ± 6.406 | 65.2 ± 2.1 | 0.8522 ± 0.012 e |

| No. | TGase Addition/g | Gel Strength/g·cm | Sensory Score/100 | Comprehensive Score |

|---|---|---|---|---|

| 0 | 0 | 400.672 ± 11.189 | 62.0 ± 1.3 | 0.7781 ± 0.013 e |

| 1 | 0.12 | 500.966 ± 28.933 | 60.7 ± 1.1 | 0.7872 ± 0.011 d |

| 2 | 0.16 | 624.958 ± 19.320 | 68.7 ± 0.9 | 0.9046 ± 0.008 c |

| 3 | 0.20 | 783.499 ± 10.500 | 70.0 ± 0.9 | 0.9561 ± 0.006 b |

| 4 | 0.24 | 853.221 ± 20.234 | 72.5 ± 1.2 | 1.000 ± 0.009 a |

| 5 | 0.28 | 663.221 ± 20.234 | 52.4 ± 0.9 | 0.7337 ± 0.012 f |

| Level. | Factor | ||

|---|---|---|---|

| A Fat Substitute Addition/g | B TGase Addition/g | C Fat Addition/g | |

| −1 | 0.4 | 0.20 | 4.0 |

| 0 | 0.6 | 0.24 | 8.0 |

| 1 | 1.2 | 0.28 | 12.0 |

| No. | Fat Substitute Addition/g | TGase Addition/g | Fat Addition/g | Gel Strength/g·cm | Sensory Score/100 | Comprehensive Score |

|---|---|---|---|---|---|---|

| A | B | C | ||||

| 1 | 0.8 | 0.24 | 12 | 712.910 | 71.91 | 0.8918 |

| 2 | 0.6 | 0.24 | 8 | 803.620 | 76.89 | 0.9631 |

| 3 | 0.6 | 0.28 | 12 | 764.620 | 60.000 | 0.7836 |

| 4 | 0.6 | 0.24 | 8 | 854.047 | 78.667 | 0.9928 |

| 5 | 0.6 | 0.28 | 4 | 598.730 | 61.667 | 0.7618 |

| 6 | 0.8 | 0.2 | 8 | 653.150 | 72.333 | 0.8821 |

| 7 | 0.6 | 0.2 | 4 | 497.422 | 68.422 | 0.8064 |

| 8 | 0.6 | 0.24 | 8 | 838.278 | 79.273 | 0.9953 |

| 9 | 0.4 | 0.2 | 8 | 563.822 | 70.333 | 0.8411 |

| 10 | 0.6 | 0.24 | 8 | 858.620 | 78.333 | 0.9905 |

| 11 | 0.6 | 0.24 | 8 | 795.435 | 76.435 | 0.9566 |

| 12 | 0.4 | 0.28 | 8 | 667.961 | 60.667 | 0.7678 |

| 13 | 0.4 | 0.24 | 12 | 568.240 | 68.240 | 0.8210 |

| 14 | 0.8 | 0.28 | 8 | 776.475 | 64.475 | 0.8315 |

| 15 | 0.6 | 0.2 | 12 | 578.632 | 70.667 | 0.8479 |

| 16 | 0.4 | 0.24 | 4 | 497.160 | 68.160 | 0.8037 |

| 17 | 0.8 | 0.24 | 4 | 556.774 | 70.000 | 0.9064 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Significant |

|---|---|---|---|---|---|---|

| Model | 0.0959 | 9 | 0.0107 | 30.09 | <0.0001 | ** |

| A | 0.0097 | 1 | 0.0097 | 27.51 | 0.0012 | ** |

| B | 0.0068 | 1 | 0.0068 | 19.14 | 0.0033 | ** |

| C | 0.0005 | 1 | 0.0005 | 1.50 | 0.2608 | |

| AB | 0.0001 | 1 | 0.0001 | 0.3639 | 0.5654 | |

| AC | 0.0002 | 1 | 0.0002 | 0.6787 | 0.4372 | |

| BC | 0.0001 | 1 | 0.0001 | 0.2741 | 0.6168 | |

| A² | 0.0077 | 1 | 0.0077 | 21.72 | 0.0023 | ** |

| B² | 0.0407 | 1 | 0.0407 | 114.96 | <0.0001 | ** |

| C² | 0.0227 | 1 | 0.0227 | 64.14 | <0.0001 | ** |

| Residual | 0.0025 | 7 | 0.0004 | |||

| Lack of Fit | 0.0011 | 3 | 0.0004 | 1.08 | 0.4529 | Not significant |

| Pure Error | 0.0014 | 4 | 0.0003 | |||

| Cor Total | 0.0983 | 16 | ||||

| R2 | 0.7979 | |||||

| Adjusted R2 | 0.9424 | |||||

| Intercept | 0.9717 | |||||

| Adeq Precision | 14.6018 > 4 |

| Test Group | Fat/g | Gel Strength/g·cm | Sensory Score/100 |

|---|---|---|---|

| Control group | 20.0 | 276.714 ± 18.272 b | 62.1 ± 2.2 b |

| Low-fat group | 8.03 | 837.400 ± 12.89 a | 79.4 ± 1.7 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, G.; Yu, L.; Chen, X.; Liu, Z.; Chen, H. Low Fatization of High-Fat Surimi-Based Products: Optimization of the Application of Protein Matrix Fat Substitution Methods. Gels 2023, 9, 724. https://doi.org/10.3390/gels9090724

Yan G, Yu L, Chen X, Liu Z, Chen H. Low Fatization of High-Fat Surimi-Based Products: Optimization of the Application of Protein Matrix Fat Substitution Methods. Gels. 2023; 9(9):724. https://doi.org/10.3390/gels9090724

Chicago/Turabian StyleYan, Guangyu, Lei Yu, Xiaoting Chen, Zhiyu Liu, and Hui Chen. 2023. "Low Fatization of High-Fat Surimi-Based Products: Optimization of the Application of Protein Matrix Fat Substitution Methods" Gels 9, no. 9: 724. https://doi.org/10.3390/gels9090724

APA StyleYan, G., Yu, L., Chen, X., Liu, Z., & Chen, H. (2023). Low Fatization of High-Fat Surimi-Based Products: Optimization of the Application of Protein Matrix Fat Substitution Methods. Gels, 9(9), 724. https://doi.org/10.3390/gels9090724