Starch-Based Hydrogels as a Drug Delivery System in Biomedical Applications

Abstract

:1. Introduction

2. Starch-Based Hydrogels as Drug Delivery Systems

2.1. Types of Pharmaceutical Compounds

2.2. Controlled Release Mechanisms and Kinetics

3. Starch-Based Hydrogels in Biomedical Applications

4. Crosslinking Techniques of Starch-Based Hydrogels

5. Future Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Villa Zabala, C.C.; Villa Zabala, C.C. An overview on starch structure and chemical nature. In Starch-Based Nanomaterials; Springer: Berlin/Heidelberg, Germany, 2020; pp. 3–9. [Google Scholar]

- Martens, B.M.; Gerrits, W.J.; Bruininx, E.M.; Schols, H.A. Amylopectin structure and crystallinity explains variation in digestion kinetics of starches across botanic sources in an in vitro pig model. J. Anim. Sci. Biotechnol. 2018, 9, 91. [Google Scholar] [CrossRef]

- Kalendova, P.; Svoboda, L.; Hroch, J.; Honcova, P.; Drobna, H.; Slang, S. Hydrogels based on starch from various natural sources: Synthesis and characterization. Starch-Stärke 2021, 73, 2100051. [Google Scholar] [CrossRef]

- Yu, F.; Cao, X.; Du, J.; Wang, G.; Chen, X. Multifunctional hydrogel with good structure integrity, self-healing, and tissue-adhesive property formed by combining Diels–Alder click reaction and acylhydrazone bond. ACS Appl. Mater. Interfaces 2015, 7, 24023–24031. [Google Scholar] [CrossRef] [PubMed]

- Hwang, H.S.; Lee, C.-S. Recent progress in hyaluronic-acid-based hydrogels for bone tissue engineering. Gels 2023, 9, 588. [Google Scholar] [CrossRef] [PubMed]

- Elvira, C.; Mano, J.; San Roman, J.; Reis, R. Starch-based biodegradable hydrogels with potential biomedical applications as drug delivery systems. Biomaterials 2002, 23, 1955–1966. [Google Scholar] [CrossRef] [PubMed]

- Ismail, H.; Irani, M.; Ahmad, Z. Starch-based hydrogels: Present status and applications. Int. J. Polym. Mater. Polym. Biomater. 2013, 62, 411–420. [Google Scholar] [CrossRef]

- Cui, C.; Jia, Y.; Sun, Q.; Yu, M.; Ji, N.; Dai, L.; Wang, Y.; Qin, Y.; Xiong, L.; Sun, Q. Recent advances in the preparation, characterization, and food application of starch-based hydrogels. Carbohydr. Polym. 2022, 291, 119624. [Google Scholar] [CrossRef] [PubMed]

- Quintanilla de Stéfano, J.C.; Abundis-Correa, V.; Herrera-Flores, S.D.; Alvarez, A.J. PH-sensitive starch-based hydrogels: Synthesis and effect of molecular components on drug release behavior. Polymers 2020, 12, 1974. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.E.-H.; AlArifi, A. Characterization and in vitro evaluation of starch based hydrogels as carriers for colon specific drug delivery systems. Carbohydr. Polym. 2009, 78, 725–730. [Google Scholar]

- Zhu, T.; Mao, J.; Cheng, Y.; Liu, H.; Lv, L.; Ge, M.; Li, S.; Huang, J.; Chen, Z.; Li, H. Recent progress of polysaccharide-based hydrogel interfaces for wound healing and tissue engineering. Adv. Mater. Interfaces 2019, 6, 1900761. [Google Scholar] [CrossRef]

- Lemos, P.V.F.; Marcelino, H.R.; Cardoso, L.G.; de Souza, C.O.; Druzian, J.I. Starch chemical modifications applied to drug delivery systems: From fundamentals to FDA-approved raw materials. Int. J. Biol. Macromol. 2021, 184, 218–234. [Google Scholar] [CrossRef]

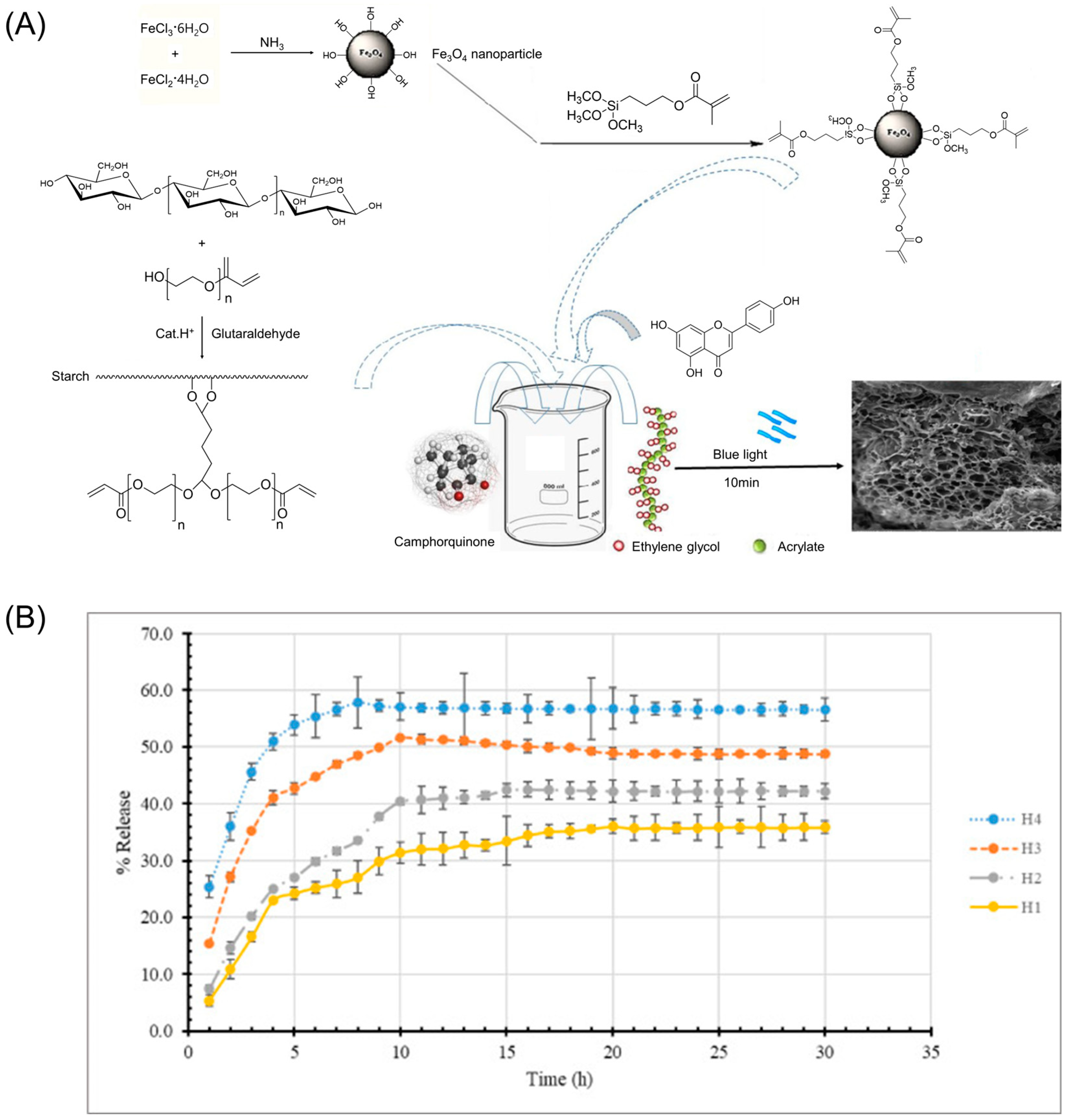

- Massoumi, B.; Mozaffari, Z.; Jaymand, M. A starch-based stimuli-responsive magnetite nanohydrogel as de novo drug delivery system. Int. J. Biol. Macromol. 2018, 117, 418–426. [Google Scholar] [CrossRef]

- Moghadam, M.; Dorraji, M.S.S.; Dodangeh, F.; Ashjari, H.R.; Mousavi, S.N.; Rasoulifard, M.H. Design of a new light curable starch-based hydrogel drug delivery system to improve the release rate of quercetin as a poorly water-soluble drug. Eur. J. Pharm. Sci. 2022, 174, 106191. [Google Scholar] [CrossRef]

- Kamoun, E.A. N-succinyl chitosan–dialdehyde starch hybrid hydrogels for biomedical applications. J. Adv. Res. 2016, 7, 69–77. [Google Scholar] [CrossRef]

- Xu, J.; Tan, X.; Chen, L.; Li, X.; Xie, F. Starch/microcrystalline cellulose hybrid gels as gastric-floating drug delivery systems. Carbohydr. Polym. 2019, 215, 151–159. [Google Scholar] [CrossRef]

- Chin, S.F.; Romainor, A.N.B.; Pang, S.C.; Lihan, S. Antimicrobial starch-citrate hydrogel for potential applications as drug delivery carriers. J. Drug Deliv. Sci. Technol. 2019, 54, 101239. [Google Scholar] [CrossRef]

- Nezami, S.; Sadeghi, M.; Mohajerani, H. A novel pH-sensitive and magnetic starch-based nanocomposite hydrogel as a controlled drug delivery system for wound healing. Polym. Degrad. Stab. 2020, 179, 109255. [Google Scholar] [CrossRef]

- Ghaffar, A.A.; Radwan, R.R.; Ali, H. Radiation synthesis of poly (starch/acrylic acid) pH sensitive hydrogel for rutin controlled release. Int. J. Biol. Macromol. 2016, 92, 957–964. [Google Scholar] [CrossRef] [PubMed]

- Faikrua, A.; Wittaya-Areekul, S.; Oonkhanond, B.; Viyoch, J. In vivo chondrocyte and transforming growth factor-β1 delivery using the thermosensitive chitosan/starch/β-glycerol phosphate hydrogel. J. Biomater. Appl. 2013, 28, 175–186. [Google Scholar] [CrossRef] [PubMed]

- Komur, B.; Akyuva, Y.; Karaslan, N.; Isyar, M.; Gumustas, S.A.; Yilmaz, I.; Akkaya, S.; Sirin, D.Y.; Mutlu, C.A.; Batmaz, A.G. Can a biodegradable implanted bilayered drug delivery system loaded with BMP-2/BMP-12 take an effective role in the biological repair process of bone–tendon injuries? A preliminary report. J. Pharm. 2017, 2017, 7457865. [Google Scholar] [CrossRef]

- Kim, S.K.; Youn, Y.S.; Oh, K.T.; Lee, E.S. Development of pH-responsive starch–glycol chitosan nanogels for proapoptotic (KLAKLAK) 2 peptide delivery. J. Bioact. Compat. Polym. 2017, 32, 345–354. [Google Scholar] [CrossRef]

- Reis, A.V.; Guilherme, M.R.; Moia, T.A.; Mattoso, L.H.; Muniz, E.C.; Tambourgi, E.B. Synthesis and characterization of a starch-modified hydrogel as potential carrier for drug delivery system. J. Polym. Sci. Part A Polym. Chem. 2008, 46, 2567–2574. [Google Scholar] [CrossRef]

- Shalviri, A.; Liu, Q.; Abdekhodaie, M.J.; Wu, X.Y. Novel modified starch–xanthan gum hydrogels for controlled drug delivery: Synthesis and characterization. Carbohydr. Polym. 2010, 79, 898–907. [Google Scholar] [CrossRef]

- Hamidian, H.; Tavakoli, T. Preparation of a new Fe3O4/starch-g-polyester nanocomposite hydrogel and a study on swelling and drug delivery properties. Carbohydr. Polym. 2016, 144, 140–148. [Google Scholar] [CrossRef]

- De Oliveira Cardoso, V.M.; Cury, B.S.F.; Evangelista, R.C.; Gremião, M.P.D. Development and characterization of cross-linked gellan gum and retrograded starch blend hydrogels for drug delivery applications. J. Mech. Behav. Biomed. Mater. 2017, 65, 317–333. [Google Scholar] [CrossRef]

- Dong, S.; Li, S.; Hao, Y.; Gao, Q. Hydroxybutyl starch-based thermosensitive hydrogel for protein separation. Int. J. Biol. Macromol. 2019, 134, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Gholamali, I.; Hosseini, S.N.; Alipour, E.; Yadollahi, M. Preparation and characterization of oxidized starch/CuO nanocomposite hydrogels applicable in a drug delivery system. Starch-Stärke 2019, 71, 1800118. [Google Scholar] [CrossRef]

- Forouzandehdel, S.; Forouzandehdel, S.; Rami, M.R. Synthesis of a novel magnetic starch-alginic acid-based biomaterial for drug delivery. Carbohydr. Res. 2020, 487, 107889. [Google Scholar] [CrossRef]

- Silva, I.; Gurruchaga, M.; Goñi, I. Physical blends of starch graft copolymers as matrices for colon targeting drug delivery systems. Carbohydr. Polym. 2009, 76, 593–601. [Google Scholar] [CrossRef]

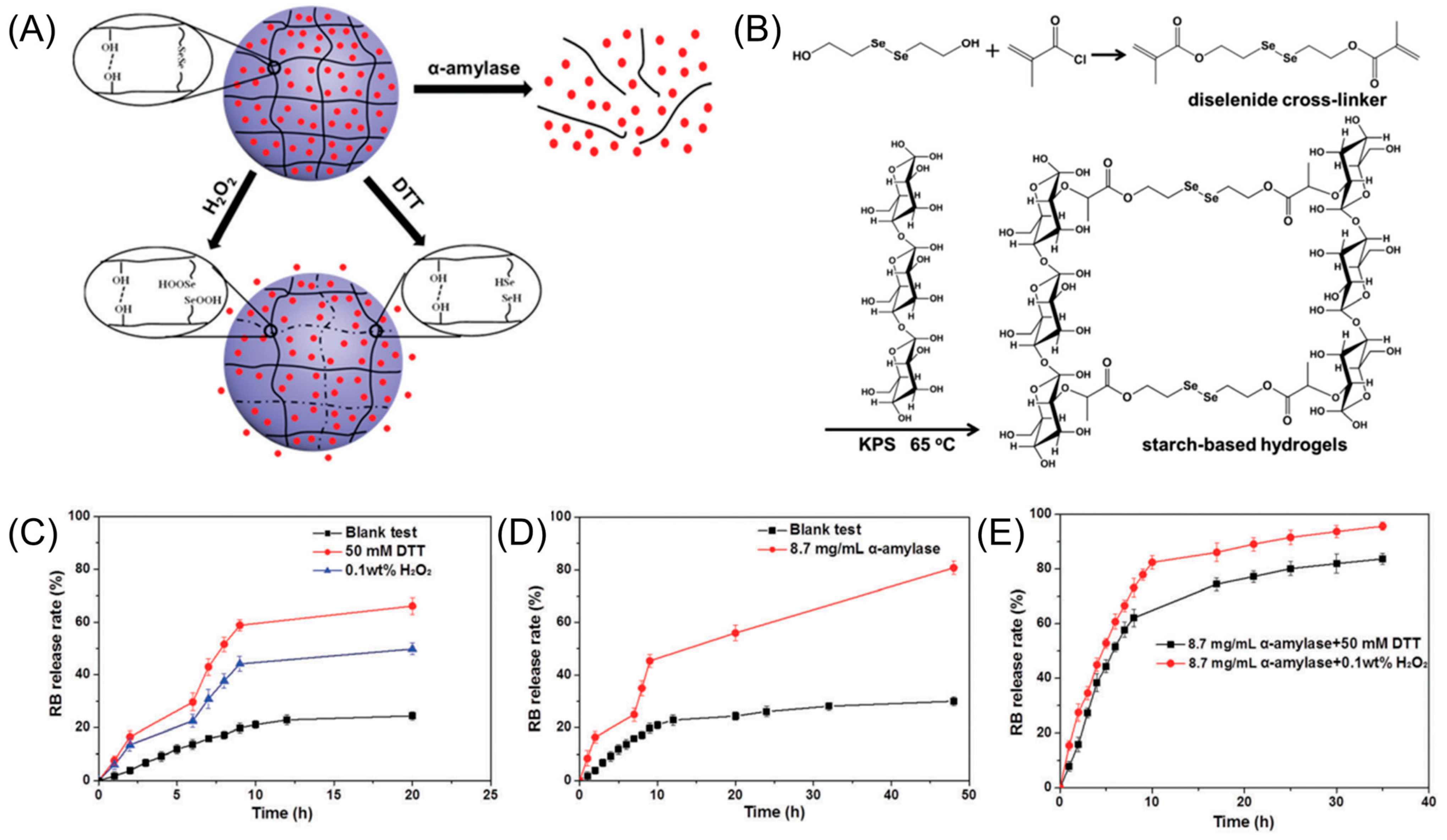

- Sun, T.; Zhu, C.; Xu, J. Multiple stimuli-responsive selenium-functionalized biodegradable starch-based hydrogels. Soft Matter 2018, 14, 921–926. [Google Scholar] [CrossRef]

- Saboktakin, M.R.; Tabatabaie, R.M.; Ostovarazar, P.; Maharramov, A.; Ramazanov, M.A. Synthesis and characterization of modified starch hydrogels for photodynamic treatment of cancer. Int. J. Biol. Macromol. 2012, 51, 544–549. [Google Scholar] [CrossRef] [PubMed]

- Alwaan, I.M.; Jafar, M.M.R.M.; Allebban, Z.S.M. Development of biodegradable starch nanocrystals/gum Arabic hydrogels for controlled drug delivery and cancer therapy. Biomed. Phys. Eng. Express 2019, 5, 025021. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, L.; Wu, H.; Zheng, W.; Kan, D.; Cheng, R.; Yan, J.; Yu, C.; Sun, S.-K. Biocompatible iodine–starch–alginate hydrogel for tumor photothermal therapy. ACS Biomater. Sci. Eng. 2019, 5, 3654–3662. [Google Scholar] [CrossRef]

- Fan, M.; Li, M.; Wang, X.; Liao, Y.; Wang, H.; Rao, J.; Yang, Y.; Wang, Q. Injectable Thermosensitive Iodine-Loaded Starch-g-poly (N-isopropylacrylamide) Hydrogel for Cancer Photothermal Therapy and Anti-Infection. Macromol. Rapid Commun. 2022, 43, 2200203. [Google Scholar] [CrossRef] [PubMed]

- Aslzad, S.; Savadi, P.; Abdolahinia, E.D.; Omidi, Y.; Fathi, M.; Barar, J. Chitosan/dialdehyde starch hybrid in situ forming hydrogel for ocular delivery of betamethasone. Mater. Today Commun. 2022, 33, 104873. [Google Scholar] [CrossRef]

- Lee, C.-S.; Singh, R.K.; Hwang, H.S.; Lee, N.-H.; Kurian, A.G.; Lee, J.-H.; Kim, H.S.; Lee, M.; Kim, H.-W. Materials-based nanotherapeutics for injured and diseased bone. Prog. Mater. Sci. 2023, 135, 101087. [Google Scholar] [CrossRef]

- Mao, Q.; Hoffmann, O.; Yu, K.; Lu, F.; Lan, G.; Dai, F.; Shang, S.; Xie, R. Self-contracting oxidized starch/gelatin hydrogel for noninvasive wound closure and wound healing. Mater. Des. 2020, 194, 108916. [Google Scholar] [CrossRef]

- Pal, K.; Banthia, A.; Majumdar, D. Starch based hydrogel with potential biomedical application as artificial skin. Afr. J. Biomed. Res. 2006, 9, 23–29. [Google Scholar] [CrossRef]

- Dong, D.; Li, J.; Cui, M.; Wang, J.; Zhou, Y.; Luo, L.; Wei, Y.; Ye, L.; Sun, H.; Yao, F. In situ “clickable” zwitterionic starch-based hydrogel for 3D cell encapsulation. ACS Appl. Mater. Interfaces 2016, 8, 4442–4455. [Google Scholar] [CrossRef]

- Dong, D.; Hao, T.; Wang, C.; Zhang, Y.; Qin, Z.; Yang, B.; Fang, W.; Ye, L.; Yao, F.; Li, J. Zwitterionic starch-based hydrogel for the expansion and “stemness” maintenance of brown adipose derived stem cells. Biomaterials 2018, 157, 149–160. [Google Scholar] [CrossRef]

- Cui, R.; Chen, F.; Zhao, Y.; Huang, W.; Liu, C. A novel injectable starch-based tissue adhesive for hemostasis. J. Mater. Chem. B 2020, 8, 8282–8293. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lee, M. Rational design of hydrogels to enhance osteogenic potential. Chem. Mater. 2020, 32, 9508–9530. [Google Scholar] [CrossRef] [PubMed]

- Sundaramurthi, D.; Rauf, S.; Hauser, C. 3D bioprinting technology for regenerative medicine applications. Int. J. Bioprinting 2016, 2, 9–26. [Google Scholar] [CrossRef]

- Qamruzzaman, M.; Ahmed, F.; Mondal, M.I.H. An overview on starch-based sustainable hydrogels: Potential applications and aspects. J. Polym. Environ. 2022, 30, 19–50. [Google Scholar] [CrossRef]

- Mallick, S.P. Development and Characterization of Genipin Crosslinked Gelatin Emulsion Hydrogels and Gelatin-Starch Inclusion Physical Hydrogels. Master’s Thesis, National Institute of Technology, Rourkela, India, 2013. [Google Scholar]

- Ghorpade, V.S. Preparation of hydrogels based on natural polymers via chemical reaction and cross-Linking. In Hydrogels Based on Natural Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 91–118. [Google Scholar]

- Sapuła, P.; Bialik-Wąs, K.; Malarz, K. Are Natural Compounds a Promising Alternative to Synthetic Cross-Linking Agents in the Preparation of Hydrogels? Pharmaceutics 2023, 15, 253. [Google Scholar] [CrossRef]

- Bustamante-Torres, M.; Romero-Fierro, D.; Arcentales-Vera, B.; Palomino, K.; Magaña, H.; Bucio, E. Hydrogels classification according to the physical or chemical interactions and as stimuli-sensitive materials. Gels 2021, 7, 182. [Google Scholar] [CrossRef]

- Kaczmarek, B.; Nadolna, K.; Owczarek, A. The physical and chemical properties of hydrogels based on natural polymers. In Hydrogels Based on Natural Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 151–172. [Google Scholar]

- Celli, A.; Sabaa, M.W.; Jyothi, A.N.; Kalia, S. Chitosan and starch-based hydrogels via graft copolymerization. In Polymeric Hydrogels as Smart Biomaterials; Springer: Berlin/Heidelberg, Germany, 2016; pp. 189–234. [Google Scholar]

- Hossain, K.M.Z.; Calabrese, V.; Da Silva, M.A.; Bryant, S.J.; Schmitt, J.; Ahn-Jarvis, J.H.; Warren, F.J.; Khimyak, Y.Z.; Scott, J.L.; Edler, K.J. Monovalent salt and pH-induced gelation of oxidised cellulose nanofibrils and starch networks: Combining rheology and small-angle X-ray scattering. Polymers 2021, 13, 951. [Google Scholar] [CrossRef]

- Baudron, V.; Gurikov, P.; Smirnova, I.; Whitehouse, S. Porous starch materials via supercritical-and freeze-drying. Gels 2019, 5, 12. [Google Scholar] [CrossRef]

- Zheng, Q.; Tian, Y.; Ye, F.; Zhou, Y.; Zhao, G. Fabrication and application of starch-based aerogel: Technical strategies. Trends Food Sci. Technol. 2020, 99, 608–620. [Google Scholar] [CrossRef]

- Ahmadzadeh, S.; Ubeyitogullari, A. Generation of porous starch beads via a 3D food printer: The effects of amylose content and drying technique. Carbohydr. Polym. 2023, 301, 120296. [Google Scholar] [CrossRef]

- Sadeghi, M. Synthesis of starch-g-poly (acrylic acid-co-2-hydroxy ethyl methacrylate) as a potential pH-sensitive hydrogel-based drug delivery system. Turk. J. Chem. 2011, 35, 723–733. [Google Scholar] [CrossRef]

- Kuang, J.; Yuk, K.Y.; Huh, K.M. Polysaccharide-based superporous hydrogels with fast swelling and superabsorbent properties. Carbohydr. Polym. 2011, 83, 284–290. [Google Scholar] [CrossRef]

- Hadisi, Z.; Nourmohammadi, J.; Mohammadi, J. Composite of porous starch-silk fibroin nanofiber-calcium phosphate for bone regeneration. Ceram. Int. 2015, 41, 10745–10754. [Google Scholar] [CrossRef]

- Mistry, P.; Chhabra, R.; Muke, S.; Narvekar, A.; Sathaye, S.; Jain, R.; Dandekar, P. Fabrication and characterization of starch-TPU based nanofibers for wound healing applications. Mater. Sci. Eng. C 2021, 119, 111316. [Google Scholar] [CrossRef] [PubMed]

| Hydrogel Composition (Active Agent) | Driving Force for Gelation | Key Findings | Reference |

|---|---|---|---|

| Fe3O4-g-[poly(N-isopropylacrylamide-co-maleic anhydride)], corn starch (doxorubicin hydrochloride) | Chemical crosslinking between the anhydride group of maleic anhydride and the hydroxyl group of starch |

| [13] |

| Starch-g-poly(ethylene glycol acrylate), silane-modified Fe3O4 (quercetin) | Chemical crosslinking between acrylate groups of starch-g-poly(ethylene glycol acrylate) and silane-modified Fe3O4 |

| [14] |

| N-succinyl chitosan, dialdehyde starch (curcumin) | Chemical crosslinking via Schiff’s base reaction |

| [15] |

| Starch (Gelose 50), Microcrystalline cellulose (PH101) (ranitidine hydrochloride) | Physical mixing, coagulation, and freeze-drying |

| [16] |

| Starch, ctric acid, poly(vinyl alcohol), poly(ethylene glycol) (penicilline G) | Physical mixing, freezing, and thawing |

| [17] |

| Itaconic acid-g-potato starch, Fe3O4 nanoparticles, (guaifenesin) | Chemical crosslinking between the carboxyl groups and Fe3O4 nanoparticles |

| [18] |

| Starch, acrylic acid (rutin) | Chemical crosslinking via gamma irradiation |

| [19] |

| Starch, poly(vinyl alcohol), sodium tetraborate (bone morphogenic protein-2; BMP-2) | Physical mixing |

| [21] |

| Corn starch, chitosan, β-glycerol phosphate (transforming growth factor-β1; TGF-β1) | Physical crosslinking via the thermosensitivity of β-glycerol phosphate as a crosslinking agent |

| [20] |

| Corn starch, xanthan gum, sodium trimethaphosphate (FITC-dextran, vitamin B12, verapamil HCl, pyrogallol Red, Methylene Blue, caffeine, ibuprofen sodium salt, sodium salicylate) | Chemical crosslinking by sodium trimethaphosphate |

| [24] |

| Starch, Fe3O4 nanoparticle, poly(ethylene phthalate) (tungstophosphoric acid) | Chemical crosslinking |

| [25] |

| High amylose starch (Hylon VII—68% amylose); gellan gum (ketoprofen) | Chemical crosslinking by aluminum chloride and glutaraldehyde |

| [26] |

| Hydroxybutyl waxy corn starch, Poly(ethylene glycol) 4000 (PEG), N-isopropyl acrylamide (NIPAM) | Physical crosslinking by temperature change |

| [27] |

| Oxidized starch, CuO nanoparticle (39–50 nm) (ibuprofen) | Chemical crosslinking via oxidation |

| [28] |

| Starch, alginic acid, Fe3O4 nanoparticle, graphene sheet (guaifenesin) | Chemical crosslinking by epichlorohydrin and ammonium persulfate |

| [29] |

| Methacrylate-g-high amylose starch (70% of amylose), hydroxyethyl methacrylate-g-high amylose starch (theophylline, procaine hydrochloride, bovine serum albumin) | Physical blending |

| [30] |

| Corn starch, di-(1-hydroxyethylene)diselenide (rhodamine B as a model drug) | Chemical crosslinking by potassium persulphate |

| [31] |

| Carboxymethyl starch (CMS), dextran sulfate (mTHPP) | Physical mixing |

| [32] |

| Starch, sulfuric acid, gum arabic, K2S2O8 | Acid hydrolysis and Physical mixing |

| [33] |

| Iodine, starch, alginate | Ionic cross-linking |

| [34] |

| Starch, poly(N-isopropylacrylamide) (Iodine) | Chemical crosslinking (graft copolymerization) |

| [35] |

| Dialdehyde starch, chitosan (betamethasone) | Physical mixing |

| [36] |

| Starch, gelatin | Chemical crosslinking via Schiff base reaction |

| [38] |

| Corn starch, polyvinyl alcohol, glutaraldehyde | Physical mixing |

| [39] |

| Starch, ammonium propanesulfonate, acrylic acid, PEG, 3-mercaptopropionic acid | Chemical crosslinking via “copper- and light- free” Michael-type “thiol-ene” addition |

| [40] |

| Sulfobetaine derived starch, 3-dimethyl (chloropropyl) ammonium propanesulfonate, methacrylate | Chemical crosslinking via “thiol-ene” Michael addition |

| [41] |

| Caboxylic starch, dopamine, horseradish peroxidase | Chemical crosslinking (enzymatic crosslinking reaction) |

| [42] |

| Starch, acrylic acid, 2-hydroxy ethyl methacrylate (5-fluorouracil) | Chemical crosslinking via free radical polymerization |

| [56] |

| Corn starch, ammonium persulfate, pyridine, acryloyl chloride | Chemical crosslinking via radical crosslinking reaction and gas-blowing foaming process |

| [57] |

| Potato starch, silk fibroin, glutaraldehyde | Physical mixing, particulate leaching, freeze drying |

| [58] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-S.; Hwang, H.S. Starch-Based Hydrogels as a Drug Delivery System in Biomedical Applications. Gels 2023, 9, 951. https://doi.org/10.3390/gels9120951

Lee C-S, Hwang HS. Starch-Based Hydrogels as a Drug Delivery System in Biomedical Applications. Gels. 2023; 9(12):951. https://doi.org/10.3390/gels9120951

Chicago/Turabian StyleLee, Chung-Sung, and Hee Sook Hwang. 2023. "Starch-Based Hydrogels as a Drug Delivery System in Biomedical Applications" Gels 9, no. 12: 951. https://doi.org/10.3390/gels9120951

APA StyleLee, C.-S., & Hwang, H. S. (2023). Starch-Based Hydrogels as a Drug Delivery System in Biomedical Applications. Gels, 9(12), 951. https://doi.org/10.3390/gels9120951