Influence of Cross-Linking Conditions on Drying Kinetics of Alginate Hydrogel

Abstract

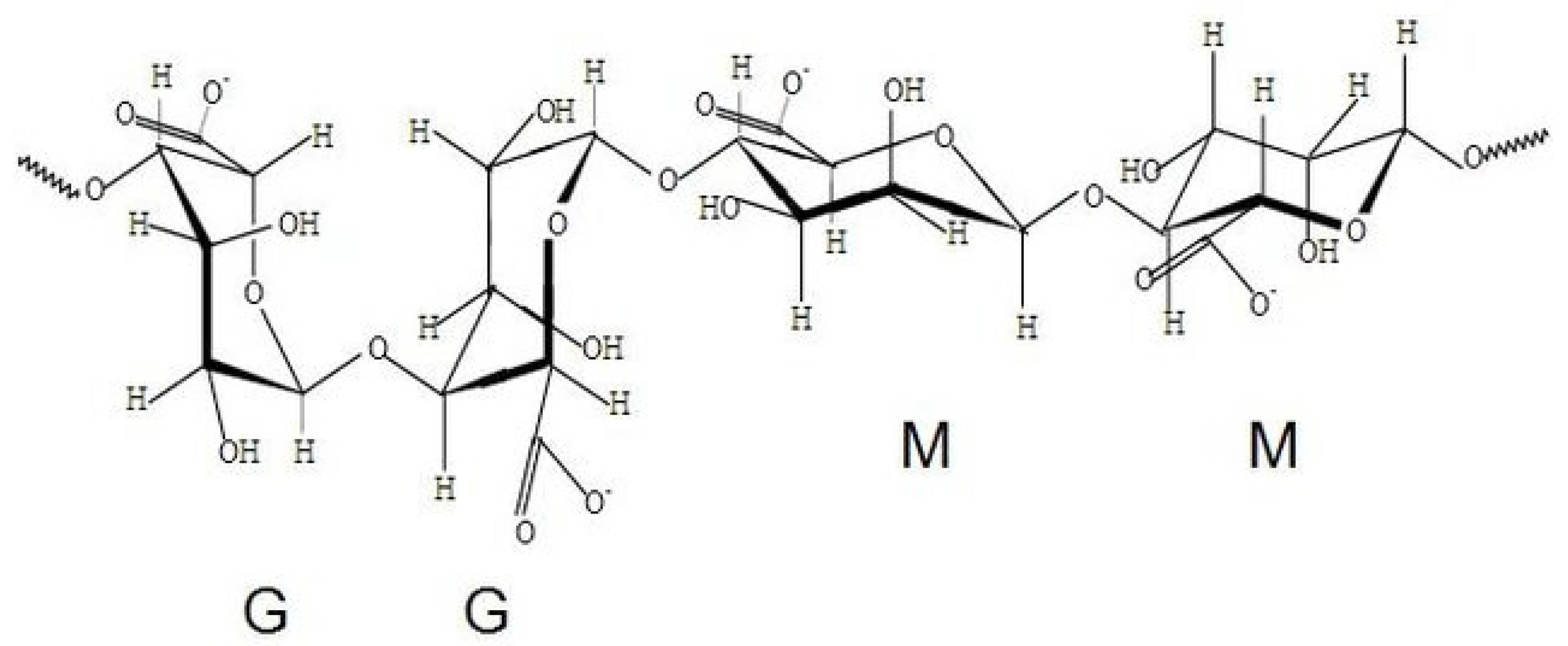

1. Introduction

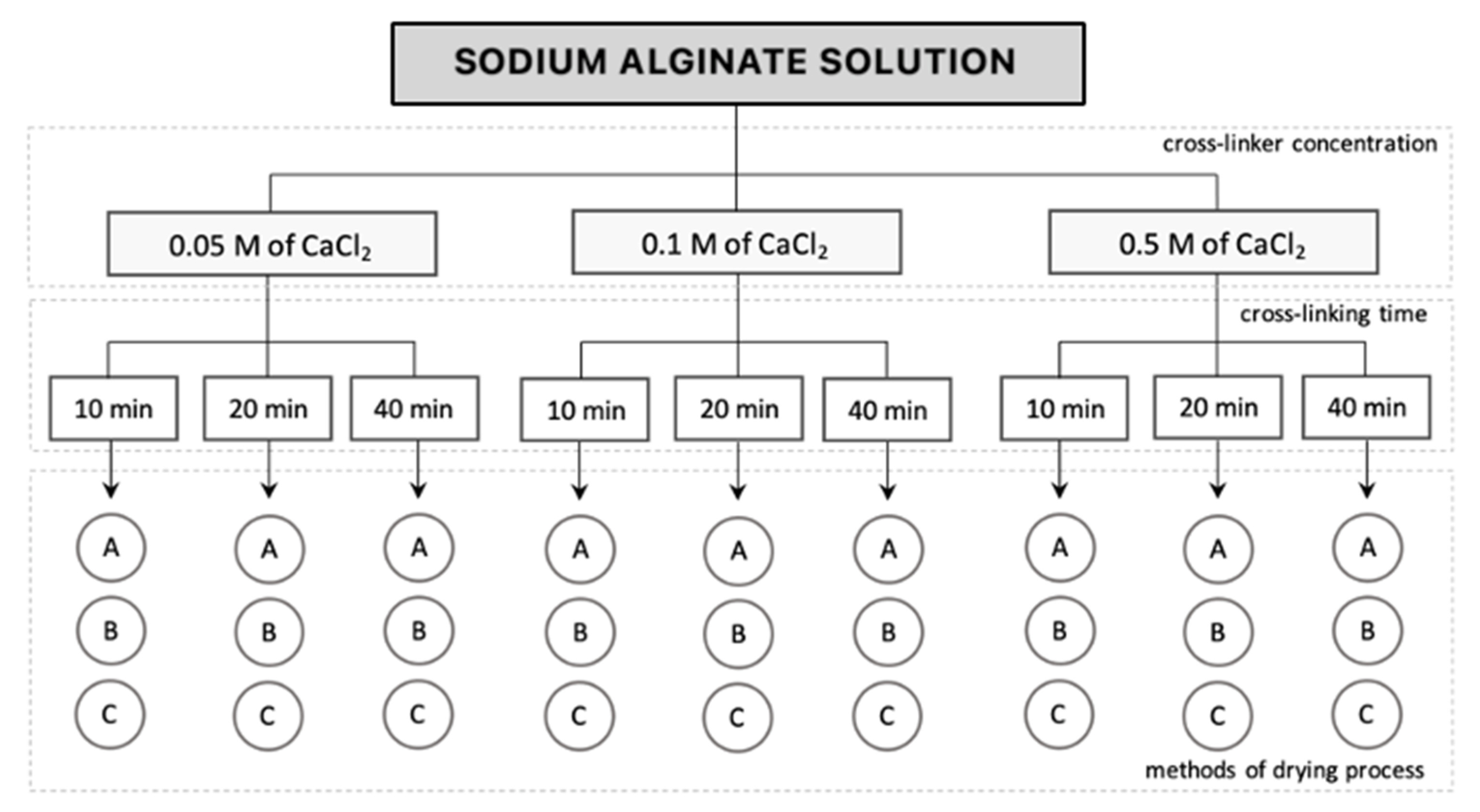

2. Materials and Methods

2.1. Mass Changes of Alginate Hydrogels

2.2. Dimension Changes of Alginate Hydrogels

2.3. Statistical Analysis

3. Results and Discussion

3.1. Additives to Alginate Ink Improving Mechanical Properties and Reducing Drying

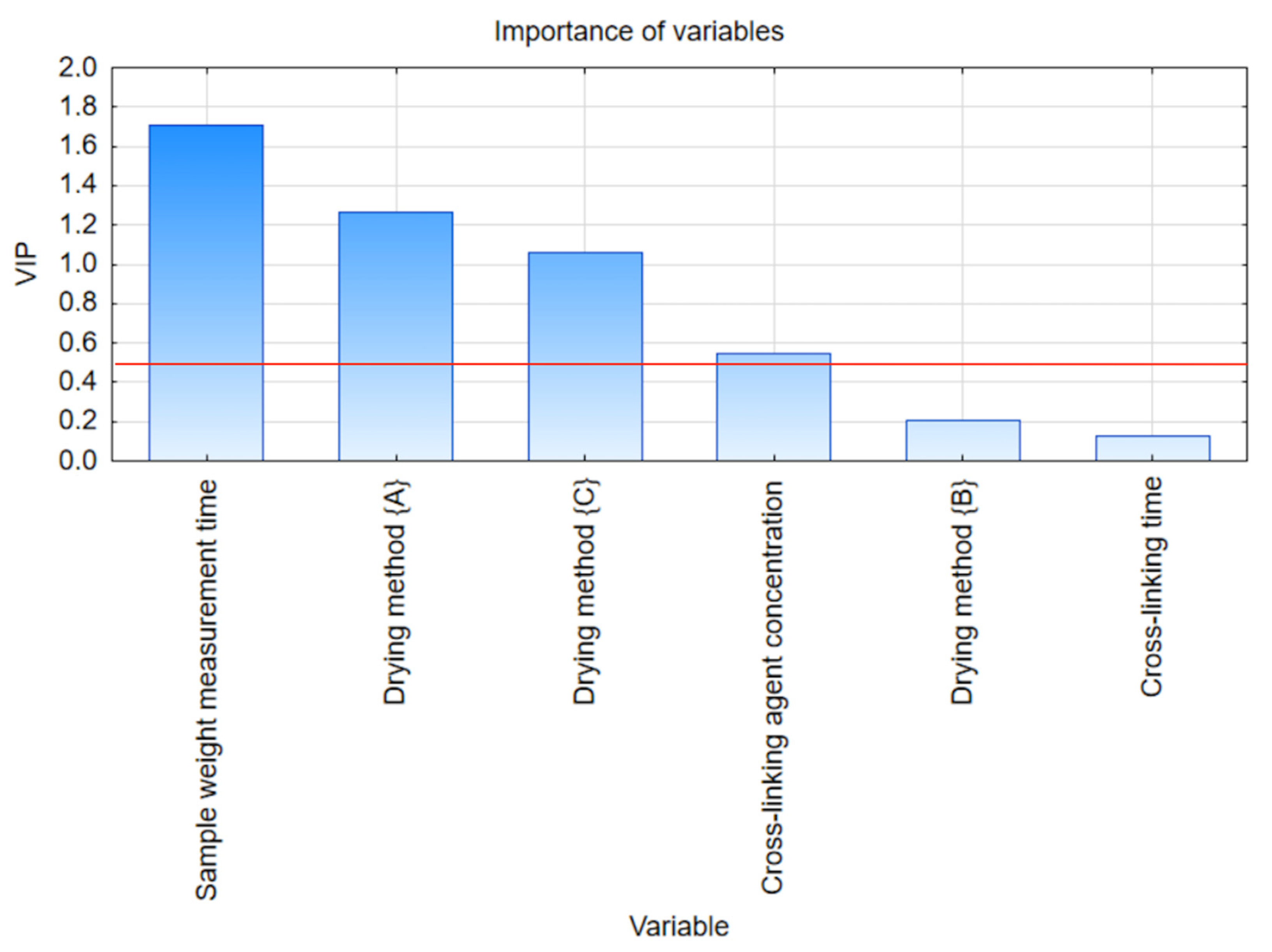

3.2. Influence of Cross-Linking Parameters on Sodium Alginate Hydrogel Water Content

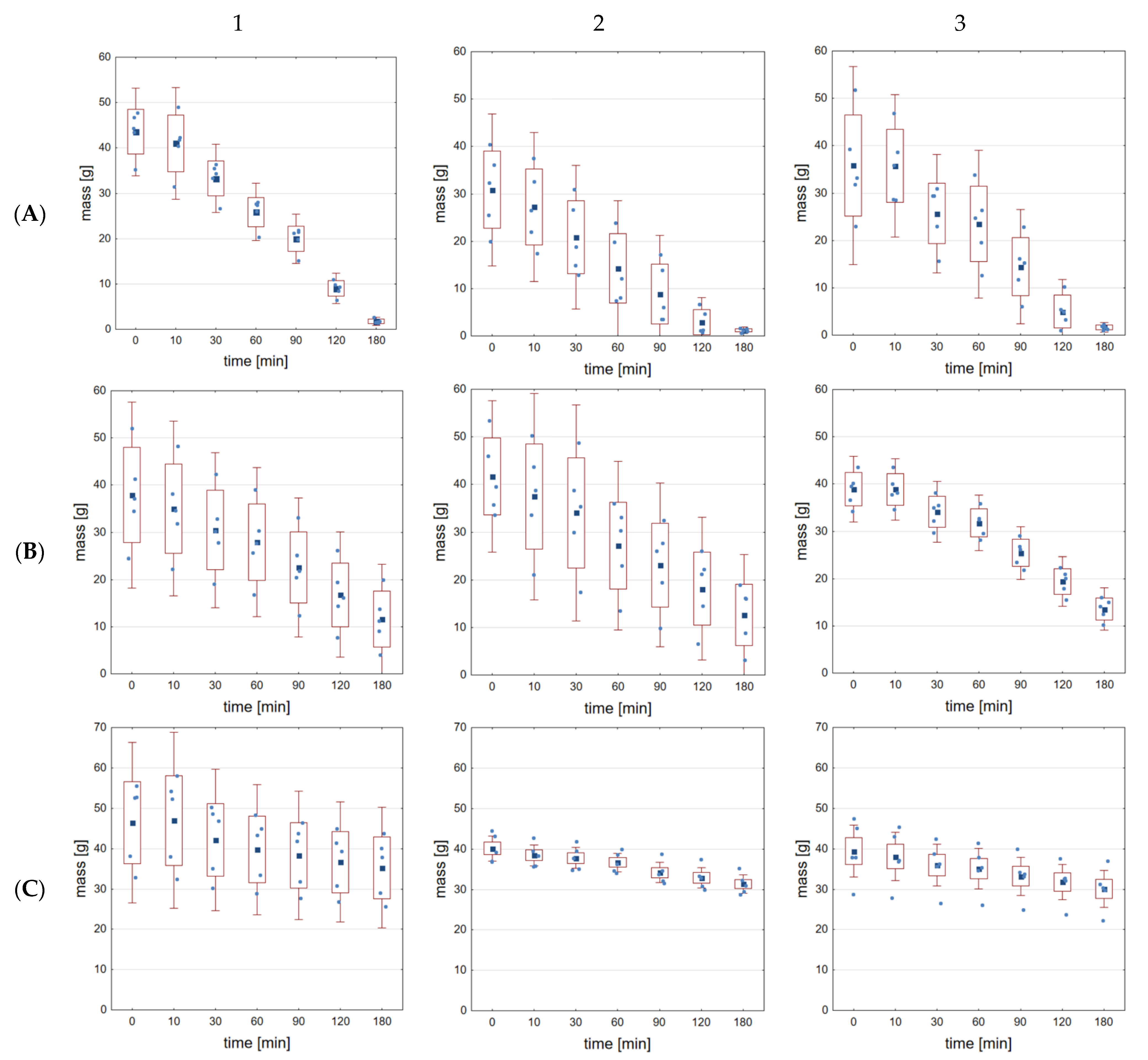

3.3. Mass Changes of Sodium Alginate Hydrogels in Different Environment Conditions

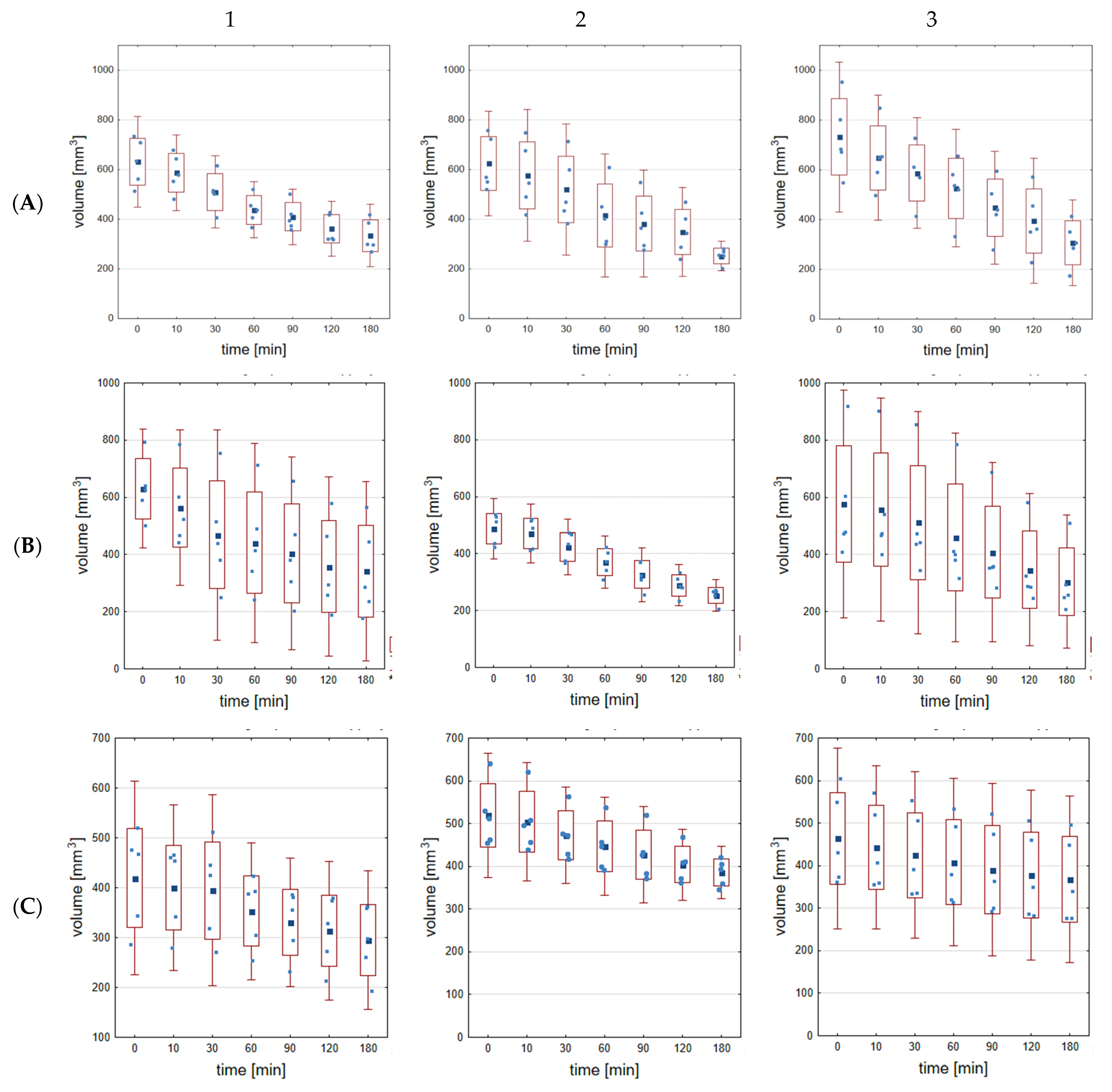

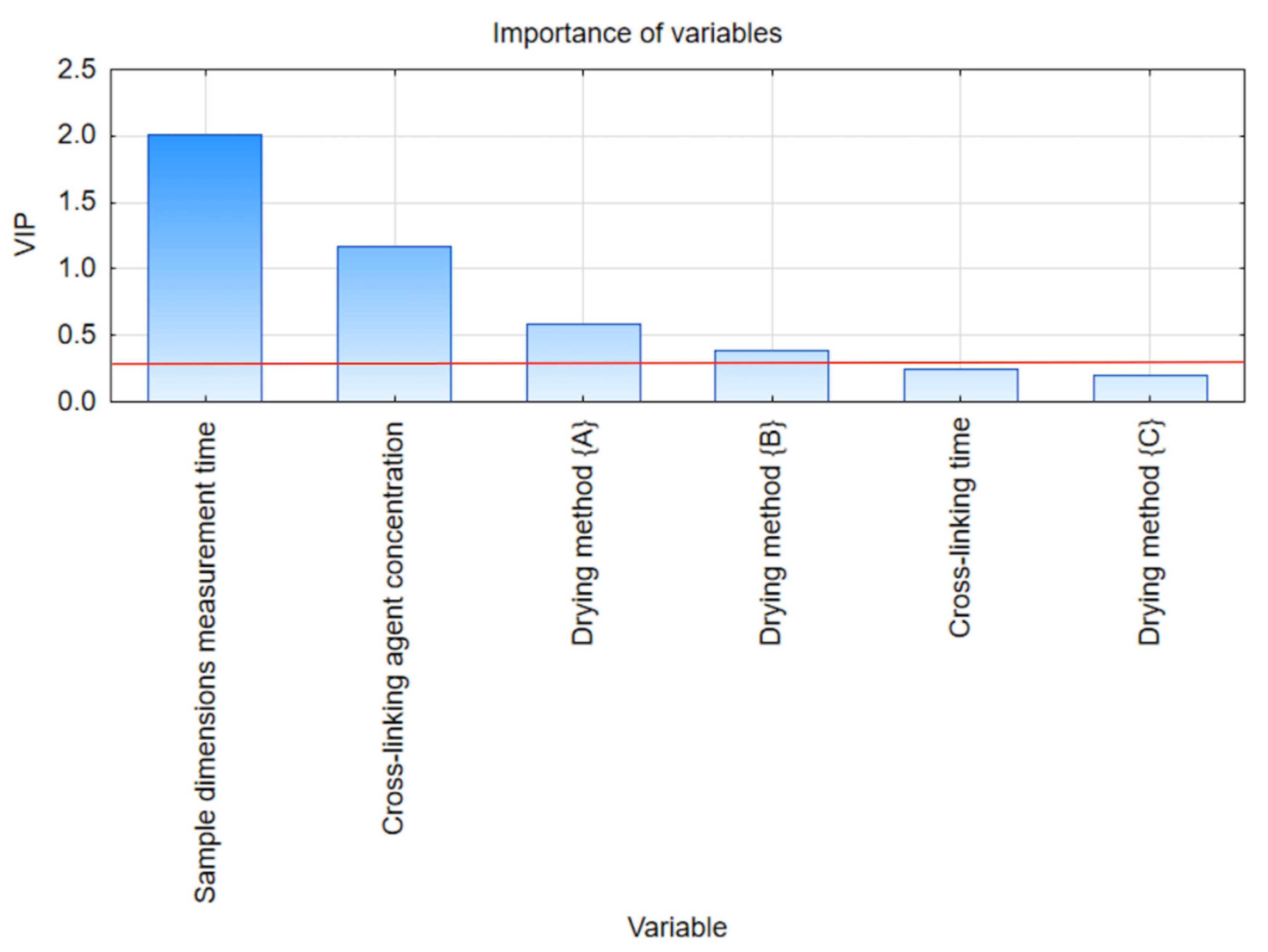

3.4. Diameter Changes of Alginate Hydrogels in Different Environment Conditions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Schacht, E.H. Polymer chemistry and hydrogel systems. J. Phys. Conf. Ser. 2004, 3, 22–28. [Google Scholar] [CrossRef]

- Laftah, W.A.; Hashim, S.; Ibrahim, A.N. Polymer hydrogels: A review. Polym. Plast. Technol. Eng. 2011, 50, 1475–1486. [Google Scholar] [CrossRef]

- Bharskar, G.R. A review on hydrogel. World J. Pharm. Pharm. Sci. 2020, 9, 1288–1298. [Google Scholar] [CrossRef]

- Chirani, N.; Yahia, L.; Gritsch, L. History and applications of hydrogels. J. Biomed. Sci. 2015, 2, 1–23. [Google Scholar] [CrossRef]

- Gun’ko, V.; Savina, I.; Mikhalovsky, S. Properties of water bound in hydrogels. Gels 2017, 3, 37. [Google Scholar] [CrossRef]

- Aswathy, S.H.; Narendrakumar, U.; Manjubala, I. Commercial hydrogels for biomedical applications. Heliyon 2020, 6, e03719. [Google Scholar] [CrossRef]

- Ropek, D.; Kulikowski, E. Potential of Hydrogel Application for Plant Protection. Ecol. Chem. Eng. A 2009, 16, 1191–1198. [Google Scholar]

- Correa, S.; Grosskopf, A.K.; Lopez Hernandez, H.; Chan, D.; Yu, A.C.; Stapleton, L.M.; Appel, E.A. Translational applications of hydrogels. Chem. Rev. 2021, 121, 11385–11457. [Google Scholar] [CrossRef]

- Akther, F.; Little, P.; Li, Z.; Nguyen, N.Y.; Ta, H.T. Hydrogels as artificial matrices for cell seeding in microfluidic devices. RSC Adv. 2020, 10, 43682–43703. [Google Scholar] [CrossRef]

- Majcher, M.J.; Hoare, T. Applications of Hydrogels; Springer: Cham, Switzerland, 2019; pp. 453–490. [Google Scholar] [CrossRef]

- Lynch, C.R.; Kondiah, P.P.D.; Choonara, Y.E.; Du Toit, L.C.; Ally, N.; Pillay, V. Hydrogel biomaterials for application in ocular drug delivery. Front. Bioeng. Biotechnol. 2020, 8, 228. [Google Scholar] [CrossRef]

- Catoira, M.; Fusaro, L.; Di Francesco, D.; Ramella, M.; Boccafoschi, F. Overview of natural hydrogels for regenerative medicine applications. J. Mater. Sci. Mater. Med. 2019, 30, 115. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef] [PubMed]

- Kaklamani, G.; Cheneler, D.; Grover, L.M.; Adams, M.J.; Anastasiadis, S.H.; Bowen, J. Anisotropic dehydration of hydrogel surfaces. Prog. Biomater. 2017, 6, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarek-Pawelska, A. Alginate-based hydrogels in regenerative medicine. In Alginates—Recent Uses of This Natural Polymer; Pereira, L., Ed.; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar] [CrossRef]

- Abasalizadeh, F.; Moghaddam, S.V.; Alizadeh, E.; Akbari, E.; Kashani, E.; Fazljou, S.M.B.; Torbati, M.; Akbarzadeh, A. Alginate-based hydrogels as drug delivery vehicles in cancer treatment and their applications in wound dressing and 3D bioprinting. J. Biol. Eng. 2020, 14, 8. [Google Scholar] [CrossRef]

- Bar, A.; Ramon, O.; Cohen, Y.; Mizrahi, S. Shrinkage behaviour of hydrophobic hydrogel during dehydration. J. Food Eng. 2002, 55, 193–199. [Google Scholar] [CrossRef]

- Zhang, F.; Zhou, J.; Gu, Z.; Yang, M.; Li, S.; Song, Y.; Fan, J.B.; Meng, J.; Wu, P.; Jiang, L.; et al. Flexible dry hydrogel with lamella-like structure engineered via dehydration in poor solvent. CCS Chem. 2019, 1, 533–543. [Google Scholar] [CrossRef]

- Chimene, D.; Kaunas, R.; Gaharwar, A.K. Hydrogel bioink reinforcement for additive manufacturing: A focused review of emerging strategies. Adv. Mater. 2019, 32, 1902026. [Google Scholar] [CrossRef]

- Fan, D.; Staufer, U.; Accardo, A. Engineered 3D polymer and hydrogel microenvironments for cell culture applications. Bioengineering 2019, 6, 113. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Chu, P.K.; Gelinsky, M. 3D printing of hydrogels: Rational design strategies and emerging biomedical applications. Mater. Sci. Eng. R Rep. 2020, 140, 100543. [Google Scholar] [CrossRef]

- Matyash, M.; Despang, F.; Ikonomidou, C.; Gelinsky, M. Swelling and mechanical properties of alginate hydrogels with respect to promotion of neural growth. Tissue Eng Part. C 2014, 20, 401–411. [Google Scholar] [CrossRef]

- Vargas, P.O.; Pereira, N.R.; Guimarães, A.O.; Waldman, W.R.; Pereira, V.R. Shrinkage and deformation during convective drying of calcium alginate. LWT 2018, 97, 213–222. [Google Scholar] [CrossRef]

- Lyn, M.E.; Ying, D. Drying model for calcium alginate beads. Ind. Eng. Chem. Res. 2010, 49, 1986–1990. [Google Scholar] [CrossRef]

- Porta, G.D.; Gaudio, P.D.; Cicco, F.D.; Aquino, R.P.; Reverchon, E. Supercritical drying of alginate beads for the development of aerogel biomaterials: Optimization of process parameters and exchange solvents. Ind. Eng. Chem. Res. 2013, 52, 12003–12009. [Google Scholar] [CrossRef]

- Mustapa, A.N.; Martín, Á.; Cocero, M.J. Alginate aerogels dried by supercritical CO2 as herbal delivery carrier. Malays. J. Anal. Sci. 2018, 22, 522–531. [Google Scholar] [CrossRef]

- Oualid, H.A.; Amadine, O.; Essamlali, Y.; Dânoun, K.; Zahouily, M. Supercritical CO2 drying of alginate/zinc hydrogels: A green and facile route to prepare ZnO foam structures and ZnO nanoparticles. RSC Adv. 2018, 8, 20737–20747. [Google Scholar] [CrossRef] [PubMed]

- Yuk, H.; Zhang, T.; Parada, G.A.; Liu, X.; Zhao, X. Skin-inspired hydrogel–elastomer hybrids with robust interfaces and functional microstructures. Nat. Commun. 2016, 7, 12028. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-network hydrogels with extremely high mechanical strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Curti, F.; Drăgușin, D.M.; Serafim, A.; Iovu, H.; Stancu, I.C. Development of thick paste-like inks based on superconcentrated gelatin/alginate for 3D printing of scaffolds with shape fidelity and stability. Mater. Sci. Eng. C 2021, 122, 111866. [Google Scholar] [CrossRef]

- Vinzi, V.E.; Chin, W.W.; Henseler, J.; Wang, H. Handbook of Partial Least Squares. Concepts, Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Axpe, E.; Oyen, M.L. Applications of alginate-based bioinks in 3D bioprinting. Int. J. Mol. Sci. 2016, 17, 1976. [Google Scholar] [CrossRef]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th Anniversary Article: Engineering Hydrogels for Biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef]

- Ma, X.; Li, R.; Zhao, X.; Ji, Q.; Xing, Y.; Sunarso, J.; Xia, Y. Biopolymer composite fibres composed of calcium alginate reinforced with nanocrystalline cellulose. Compos. Part. A Appl. Sci. Manuf. 2017, 96, 155–163. [Google Scholar] [CrossRef]

- Siqueira, G.; Kokkinis, D.; Libanori, R.; Hausmann, M.K.; Gladman, A.S.; Neels, A.; Tiangaut, P.; Zimmermann, T.; Lewis, J.A.; Studart, A.R. Cellulose Nanocrystal Inks for 3D Printing of Textured Cellular Architectures. Adv. Funct. Mater. 2017, 27, 1604619. [Google Scholar] [CrossRef]

- Jia, W.; Gungor-Ozkerim, P.S.; Zhang, Y.S.; Yue, K.; Zhu, K.; Liu, W.; Pi, Q.; Byambaa, B.; Dokmeci, M.R.; Shin, S.R.; et al. Direct 3D bioprinting of perfusable vascular constructs using a blend bioink. Biomaterials 2016, 106, 58–68. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.H.Y.; Naficy, S.; Yue, Z.; Kapsa, R.; Quigley, A.; Moulton, S.E.; Wallace, G.G. Bio-ink properties and printability for extrusion printing living cells. Biomater. Sci. 2013, 1, 763–773. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, Y.; Zhang, X.; Rahman, S.E.; Su, S.; Wei, J.; Ning, F.; Hu, Z.; Martínez-Zaguilán, R.; Sennoune, S.R.; et al. 3D printed agar/calcium alginate hydrogels with high shape fidelity and tailorable mechanical properties. Polymer 2021, 214, 123238. [Google Scholar] [CrossRef]

- Habib, A.; Sathish, V.; Mallik, S.; Khoda, B. 3D Printability of Alginate-Carboxymethyl Cellulose Hydrogel. Materials 2018, 11, 454. [Google Scholar] [CrossRef]

- Zhang, X.; Morits, M.; Jonkergouw, C.; Ora, A.; Valle-Delgado, J.J.; Farooq, M.; Ajdary, R.; Huan, S.; Linder, M.; Rojas, O.; et al. Three-Dimensional Printed Cell Culture Model Based on Spherical Colloidal Lignin Particles and Cellulose Nanofibril-Alginate Hydrogel. Biomacromolecules 2020, 21, 1875–1885. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G. Potential and Limitations of Nanocelluloses as Components in Biocomposite Inks for Three-Dimensional Bioprinting and for Biomedical Devices. Biomacromolecules 2018, 19, 701–711. [Google Scholar] [CrossRef]

- Aarstad, O.; Heggset, E.B.; Pedersen, I.S.; Bjørnøy, S.H.; Syverud, K.; Strand, B.L. Mechanical Properties of Composite Hydrogels of Alginate and Cellulose Nanofibrils. Polymers 2017, 9, 378. [Google Scholar] [CrossRef]

- Hölzl, K.; Lin, S.; Tytgat, L.; Vlierberghe, S.V.; Gu, L.; Ovsianikov, A. Bioink properties before, during and after 3D bioprinting. Biofabrication 2016, 8, 032002. [Google Scholar] [CrossRef]

- Giuseppe, M.D.; Law, N.; Webb, B.; Macrae, R.A.; Liew, L.J.; Sercombe, T.B.; Dilley, R.J.; Doyle, B.J. Mechanical behaviour of alginate-gelatin hydrogels for 3D bioprinting. J. Mech. Behav. Biomed. Mater. 2018, 79, 150–157. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Gillispie, G.J.; Copus, J.S.; Pr, A.K.; Seol, Y.J.; Atala, A.; Yoo, J.J.; Lee, S.J. Optimization of gelatin-alginate composite bioink printability using rheological parameters: A systematic approach. Biofabrication 2018, 10, 034106. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Wang, J.; Su, S.; Wang, S.; Qiu, J.; Zhang, Z.; Christopher, G.; Ning, F.; Cong, W. 3D printing of an extremely tough hydrogel. RSC Adv. 2015, 5, 81324–81329. [Google Scholar] [CrossRef]

- Yin, Z.C.; Wang, Y.L.; Wang, K. A pH-responsive composite hydrogel beads based on agar and alginate for oral drug delivery. J. Drug Deliv. Sci. Technol. 2018, 43, 12–18. [Google Scholar] [CrossRef]

- Wüst, S.; Godla, M.E.; Müller, R.; Hofmann, H. Tunable hydrogel composite with two-step processing in combination with innovative hardware upgrade for cell-based three-dimensional bioprinting. Acta Biomater. 2014, 10, 630–640. [Google Scholar] [CrossRef]

- Shim, J.-H.; Lee, J.-S.; Kim, J.Y.; Cho, D.W. Bioprinting of a mechanically enhanced three-dimensional dual cell-laden construct for osteochondral tissue engineering using a multi-head tissue/organ building system. J. Micromech. Microeng. 2012, 22, 085014. [Google Scholar] [CrossRef]

- Łabowska, M.B.; Jankowska, A.M.; Michalak, I.; Detyna, J. Shrinkage of Alginate Hydrogel Bioinks Potentially Used in 3D Bioprinting Technology. Key Eng. Mater. 2021, 885, 39–45. [Google Scholar] [CrossRef]

- Gaharwar, A.K.; Rivera, C.; Wu, C.J.; Chan, B.K.; Schmidt, G. Photocrosslinked nanocomposite hydrogels from PEG and silica nanospheres: Structural, mechanical and cell adhesion characteristics. Mater. Sci. Eng. C 2013, 33, 1800–1807. [Google Scholar] [CrossRef]

- Fang, Y.; Li, L.; Vreeker, R.; Yao, X.; Wang, J.; Ma, Q.; Jiang, F.; Phillips, G.O. Rehydration of dried alginate gel beads: Effect of the presence of gelatin and gum arabic. Carbohydr. Polym. 2011, 86, 1145–1150. [Google Scholar] [CrossRef]

- Vreeker, R.; Li, L.; Fang, Y.; Appelqvist, I.; Mendes, E. Drying and Rehydration of Calcium Alginate Gels. Food Biophys. 2008, 3, 361–369. [Google Scholar] [CrossRef]

- Leppiniemi, J.; Lahtinen, P.; Paajanen, A.; Mahlberg, R.; Metsä-Kortelainen, S.; Pinomaa, T.; Pajari, H.; Vikholm-Lundin, I.; Pursula, P.; Hytönen, V.P. 3D-Printable Bioactivated Nanocellulose–Alginate Hydrogels. ACS Appl. Mater. Interfaces 2017, 9, 21959–21970. [Google Scholar] [CrossRef] [PubMed]

- Cuadros, T.R.; Erices, A.A.; Aguilera, J.M. Porous matrix of calcium alginate/gelatin with enhanced properties as scaffold for cell culture. J. Mech. Behav. Biomed. Mater. 2015, 46, 331–342. [Google Scholar] [CrossRef] [PubMed]

- Chopra, M.; Bernela, M.; Kaur, P.; Manuja, A.; Kumar, B.; Thakur, R. Alginate/gum acacia bipolymeric nanohydrogels—Promising carrier for Zinc oxide nanoparticles. Int. J. Biol. Macromol. 2015, 72, 827–833. [Google Scholar] [CrossRef] [PubMed]

- Nami, Y.; Haghshenas, B.; Khosroushahi, A.Y. Effect of psyllium and gum Arabic biopolymers on the survival rate and storage stability in yogurt of Enterococcus durans IW3 encapsulated in alginate. Food Sci. Nutr. 2017, 5, 554–563. [Google Scholar] [CrossRef]

- Nayak, A.K.; Das, B.; Maji, R. Calcium alginate/gum Arabic beads containing glibenclamide: Development and in vitro characterization. Int. J. Biol. Macromol. 2012, 51, 1070–1078. [Google Scholar] [CrossRef]

- Tsai, F.H.; Kitamura, Y.; Kokawa, M. Effect of gum arabic-modified alginate on physicochemical properties, release kinetics, and storage stability of liquid-core hydrogel beads. Carbohydr. Polym. 2017, 174, 1069–1077. [Google Scholar] [CrossRef]

- Naghieh, S.; Sarker, M.; Sharma, N.K.; Barhoumi, Z.; Chen, X. Printability of 3D printed hydrogel scaffolds: Influence of hydrogel composition and printing parameters. Appl. Sci. 2019, 10, 292. [Google Scholar] [CrossRef]

- Simoni, R.C.; Lemes, G.F.; Fialho, S.; Gonçalves, O.H.; Gozzo, A.M.; Chiaradia, V.; Sayer, C.; Shirai, M.A.; Leimann, F.V. Effect of drying method on mechanical, thermal and water absorption properties of enzymatically crosslinked gelatin hydrogels. An. Acad. Bras. Cienc. 2017, 89, 745–755. [Google Scholar] [CrossRef]

- Naranjo, A.; Martín, C.; López-Díaz, A.; Martín-Pacheco, A.; Rodríguez, A.M.; Patiño, F.J.; Herrero, M.A.; Vázquez, A.S.; Vázquez, E. Autonomous self-healing hydrogel with anti-drying properties and applications in soft robotics. Appl. Mater. Today 2020, 21, 100806. [Google Scholar] [CrossRef]

- Wang, L.; Cavaco-Paulo, A.; Xu, B.; Martins, M. Humidity induces changes in the dimensions of hydrogel-coated wool yarns. Polymers 2018, 10, 260. [Google Scholar] [CrossRef]

- Pérez, M.; Carou, D.; Rubio, E.M.; Teti, R. Current advances in additive manufacturing. Procederia CIRP 2020, 88, 439–444. [Google Scholar] [CrossRef]

| Sample | Environmental Conditions | Cross-Linking Conditions | ||

|---|---|---|---|---|

| Temperature [°C] | Humidity [%] | CaCl2 Concentration [M] | Cross-Linking Time [min] | |

| A/0.05 M/10 min | 23 | 45 | 0.05 | 10 |

| A/0.05 M/20 min | 23 | 45 | 0.05 | 20 |

| A/0.05 M/40 min | 23 | 45 | 0.05 | 40 |

| B/0.05 M/10 min | 7 | 50 | 0.05 | 10 |

| B/0.05 M/20 min | 7 | 50 | 0.05 | 20 |

| B/0.05 M/40 min | 7 | 50 | 0.05 | 40 |

| C/0.05 M/10 min | 7 | 95 | 0.05 | 10 |

| C/0.05 M/20 min | 7 | 95 | 0.05 | 20 |

| C/0.05 M/40 min | 7 | 95 | 0.05 | 40 |

| A/0.1 M/ 10 min | 23 | 45 | 0.1 | 10 |

| A/0.1 M/20 min | 23 | 45 | 0.1 | 20 |

| A/0.1 M/40 min | 23 | 45 | 0.1 | 40 |

| B/0.1 M/10 min | 7 | 50 | 0.1 | 10 |

| B/0.1 M/20 min | 7 | 50 | 0.1 | 20 |

| B/0.1 M/40 min | 7 | 50 | 0.1 | 40 |

| C/0.1 M/10 min | 7 | 95 | 0.1 | 10 |

| C/0.1 M/20 min | 7 | 95 | 0.1 | 20 |

| C/0.1 M/40 min | 7 | 95 | 0.1 | 40 |

| A/0.5 M/10 min | 23 | 45 | 0.5 | 10 |

| A/0.5 M/20 min | 23 | 45 | 0.5 | 20 |

| A/0.5 M/40 min | 23 | 45 | 0.5 | 40 |

| B/0.5 M/10 min | 7 | 50 | 0.5 | 10 |

| B/0.5 M/20 min | 7 | 50 | 0.5 | 20 |

| B/0.5 M/40 min | 7 | 50 | 0.5 | 40 |

| C/0.5 M/10 min | 7 | 95 | 0.5 | 10 |

| C/0.5 M/20 min | 7 | 95 | 0.5 | 20 |

| C/0.5 M/40 min | 7 | 95 | 0.5 | 40 |

| Drying Method | Cross-Linking Time | Percentage of Water Lost [%] for Different Concentrations of CaCl2 | ||

|---|---|---|---|---|

| 0.05 M | 0.1 M | 0.5 M | ||

| A | 10 min * | 95.94 ± 0.80 a | 95.69 ± 0.53 b | 86.77 ± 0.83 ab |

| 20 min * | 96.15 ± 0.25 cd | 94.86 ± 0.43 ce | 82.55 ± 0.57 de | |

| 40 min ** | 95.56 f | 94.12 | 82.44 f | |

| B | 10 min * | 71.00 ± 8.33 ab | 54.19 ± 2.40 ac | 45.24 ± 0.90 abc |

| 20 min * | 70.88 ± 12.36 d | 65.68 ± 3.51 e | 52.93 ± 1.37 de | |

| 40 min * | 65.25 ± 3.09 fg | 52.93 ± 1.79 fh | 60.59 ± 1.52 gh | |

| C | 10 min * | 23.81 ± 2.61 a | 29.55 ± 2.37 ab | 19.53 ± 3.30 b |

| 20 min ** | 20.91 c | 21.57 d | 18.06 cd | |

| 40 min ** | 21.94 | 36.34 e | 20.00 e | |

| Drying Method | Cross-Linking Time | Percentage of Dimension Changes [%] for Different Concentrations of CaCl2 | ||

|---|---|---|---|---|

| 0.05 M | 0.1 M | 0.5 M | ||

| A | 10 min * | 47.21 ± 3.64 a | 43.24 ± 9.92 b | 64.57 ± 2.87 ab |

| 20 min * | 57.44 ± 5.18 | 49.38 ± 8.73 | 54.63 ± 4.92 | |

| 40 min ** | 56.90 c | 58.90 d | 33.63 cd | |

| B | 10 min ** | 54.20 a | 29.69 a | 20.43 |

| 20 min * | 47.91 ± 3.74 bc | 35.84 ± 6.05 bd | 33.52 ± 6.93 cd | |

| 40 min * | 47.50 ± 2.62 | 42.68 ± 5.36 e | 49.05 ± 1.81 e | |

| C | 10 min * | 29.53 ± 5.16 a | 26.23 ± 6.12 a | 24.59 ± 7.65 |

| 20 min ** | 26.26 b | 25.71 c | 19.35 bc | |

| 40 min * | 24.21 ± 3.22 | 16.76 ± 8.24 | 14.52 ± 3.28 | |

| Variable | Variable Number | VIP | Importance |

|---|---|---|---|

| Sample weight measurement time | 2 | 1.709 | 1 |

| Drying method {A} | 4 | 1.265 | 2 |

| Drying method {C} | 4 | 1.061 | 3 |

| Cross-linking agent concentration | 5 | 0.544 | 4 |

| Drying method {B} | 4 | 0.204 | 5 |

| Cross-linking time | 3 | 0.131 | 6 |

| Variable | Variable Number | VIP | Importance |

|---|---|---|---|

| Sample dimensions measurement time | 2 | 2.013 | 1 |

| Cross-linking agent concentration | 5 | 1.164 | 2 |

| Drying method {A} | 4 | 0.585 | 3 |

| Drying method {B} | 4 | 0.385 | 4 |

| Cross-linking time | 3 | 0.247 | 5 |

| Drying method {C} | 4 | 0.200 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łabowska, M.B.; Skrodzka, M.; Sicińska, H.; Michalak, I.; Detyna, J. Influence of Cross-Linking Conditions on Drying Kinetics of Alginate Hydrogel. Gels 2023, 9, 63. https://doi.org/10.3390/gels9010063

Łabowska MB, Skrodzka M, Sicińska H, Michalak I, Detyna J. Influence of Cross-Linking Conditions on Drying Kinetics of Alginate Hydrogel. Gels. 2023; 9(1):63. https://doi.org/10.3390/gels9010063

Chicago/Turabian StyleŁabowska, Magdalena B., Maria Skrodzka, Hanna Sicińska, Izabela Michalak, and Jerzy Detyna. 2023. "Influence of Cross-Linking Conditions on Drying Kinetics of Alginate Hydrogel" Gels 9, no. 1: 63. https://doi.org/10.3390/gels9010063

APA StyleŁabowska, M. B., Skrodzka, M., Sicińska, H., Michalak, I., & Detyna, J. (2023). Influence of Cross-Linking Conditions on Drying Kinetics of Alginate Hydrogel. Gels, 9(1), 63. https://doi.org/10.3390/gels9010063