Polymer Gel-Based Triboelectric Nanogenerators: Conductivity and Morphology Engineering for Advanced Sensing Applications

Abstract

1. Introduction

2. Fundamentals of Polymer Gel-Based Triboelectric Nanogenerators

2.1. Functional Roles of Gels in TENG Architecture

2.1.1. Triboelectric Layer

2.1.2. Electrode Material

2.1.3. Electrolyte Medium

2.1.4. Structural Support

2.1.5. Triboelectric Effect and Electrostatic Induction

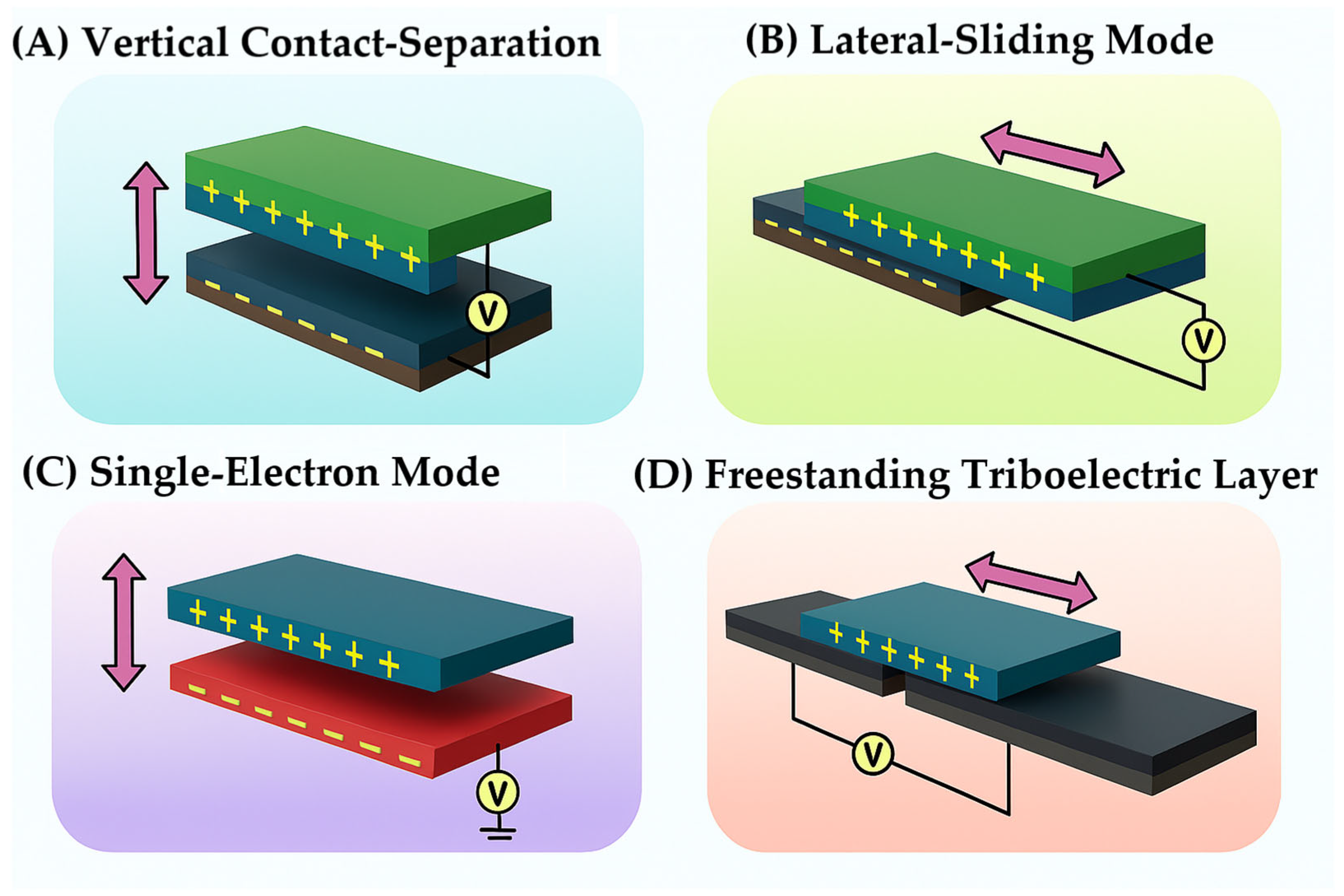

2.2. Working Principles and Structural Configurations of Gel-Based TENGs

2.2.1. Vertical Contact-Separation (VCS) Mode

2.2.2. Lateral-Sliding Mode

2.2.3. Single-Electrode (SE) Mode

2.2.4. Freestanding Triboelectric-Layer (FSTL) Mode

2.3. Key Performance Metrics of Polymer Gel-Based Triboelectric Nanogenerators

2.3.1. Output Voltage

2.3.2. Output Current and Charge Density

2.3.3. Power Density

2.3.4. Application Relevance and Integration

3. Polymer Gels in TENGs: Material Properties and Conductivity

3.1. Classification and Properties of Gel Materials for TENG Applications

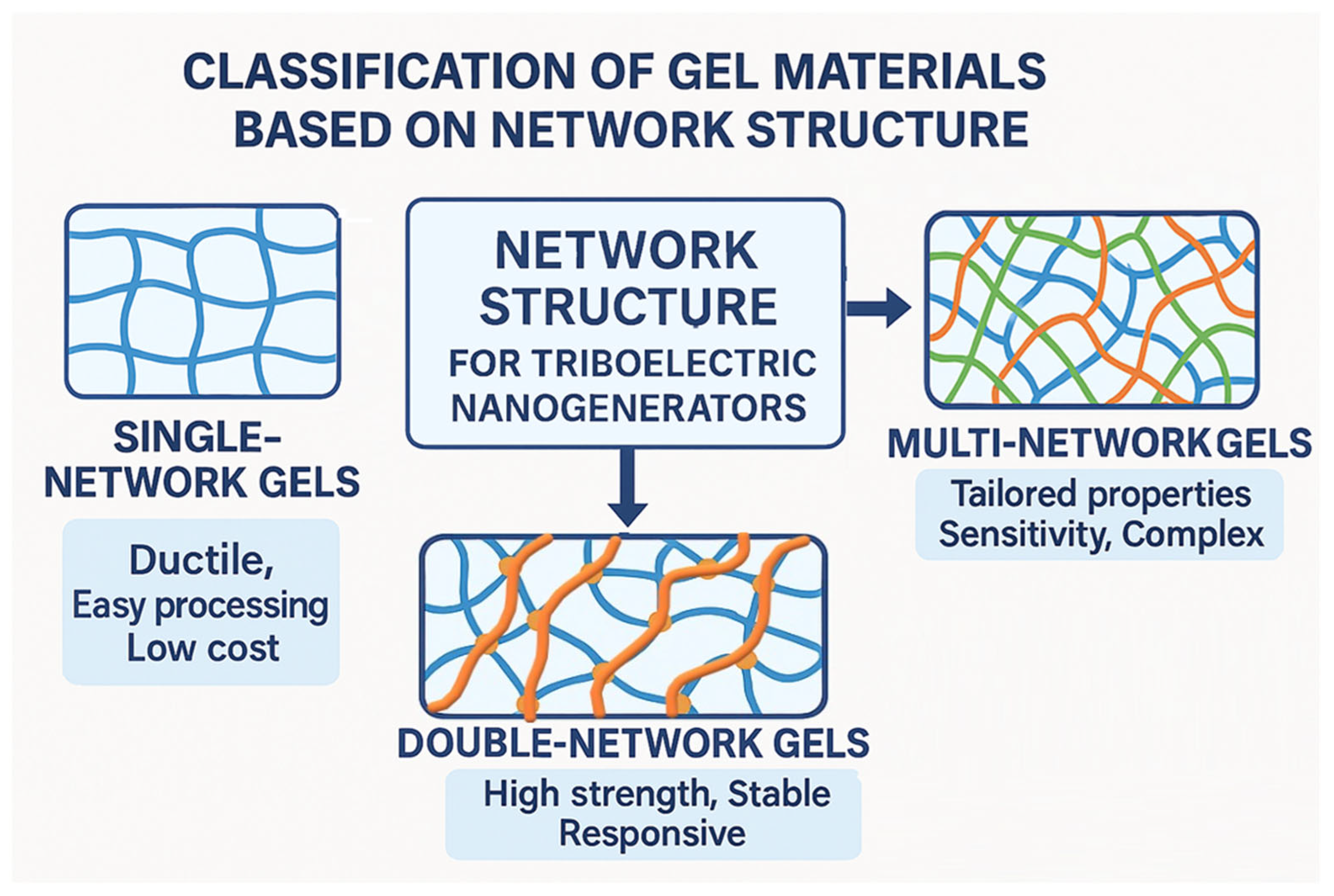

3.1.1. Classification Based on Network Structure

Single-Network Gels

Double-Network (DN) Gels

Multi-Network Gels

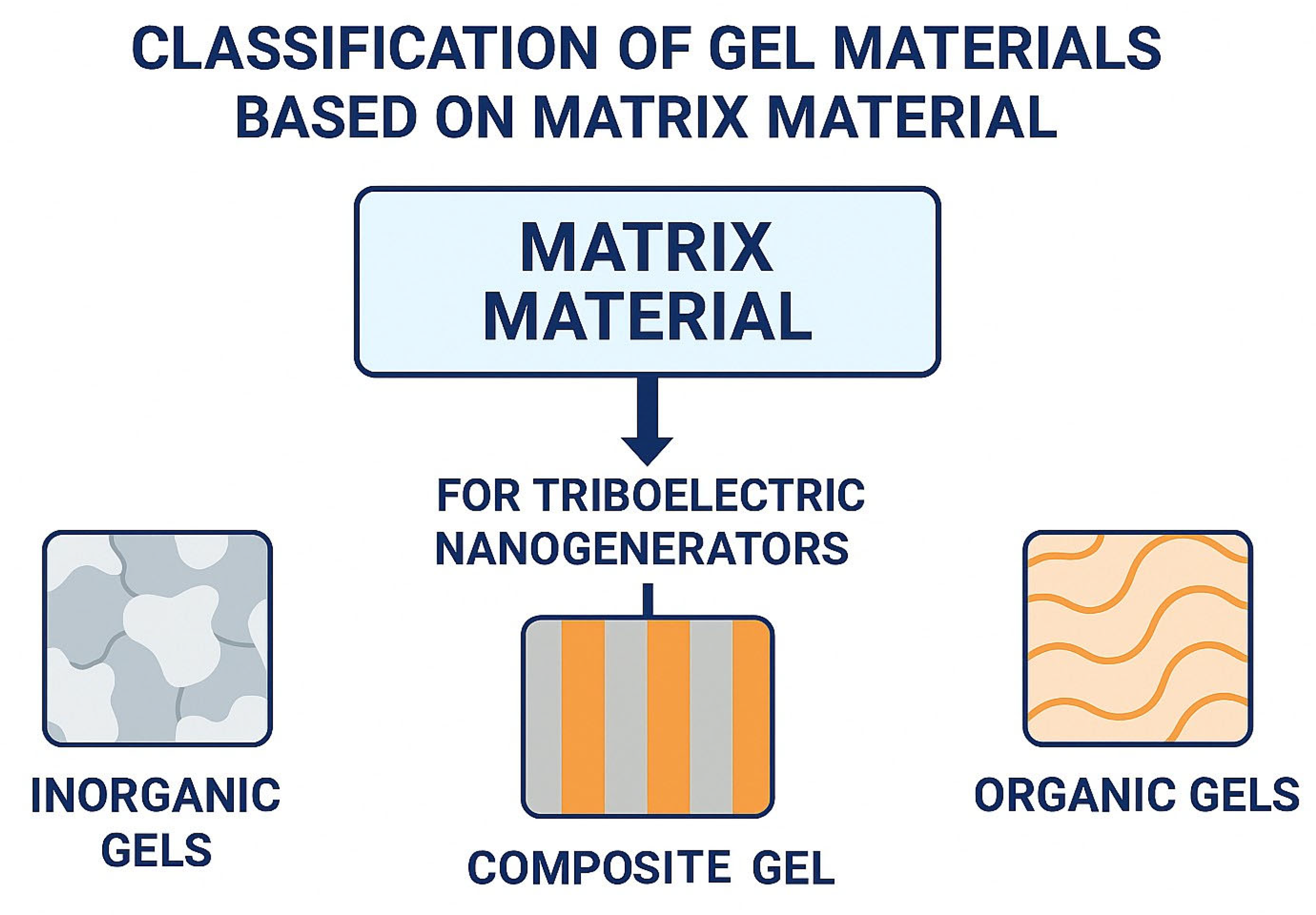

3.1.2. Classification by Matrix Composition

Inorganic Gels

Organic Gels

- Low mechanical strength can lead to deformation or rupture during operation.

- Poor environmental stability, especially sensitivity to humidity, affects performance.

- Low electrical conductivity limits energy conversion efficiency, though doping with conductive materials (e.g., poly(3,4-ethylenedioxythiophene:polystyrenesulfonate), PEDOT:PSS) can help, at the cost of increased complexity and expense.

Composite Gels

- Inorganic gels offer mechanical robustness and environmental stability but lack conductivity and self-healing.

- Organic gels provide better conductivity and healing but suffer from lower mechanical strength and stability.

- Composite gels integrate these advantages, offering flexibility, durability, and enhanced triboelectric performance.

3.1.3. Classification Based on Medium Material

Hydrogels

Aerogels

Ionic Gels

3.2. Gel Network Formation and Crosslinking Mechanisms in Polymer Gels for TENGs

3.3. Materials and Additives Used to Enhance Conductivity in Polymer Gel-Based TENGs

3.3.1. Ionic Conductivity Enhancers

3.3.2. Electronic Conductivity Enhancers

3.3.3. Nanomaterial-Based Additives

3.3.4. Hybrid and Composite Strategies

3.4. Impact of Conductivity on Triboelectric Performance and Sensing Sensitivity in Gel-Based TENGs

3.4.1. Influence on Triboelectric Output

3.4.2. Enhancement of Sensing Sensitivity

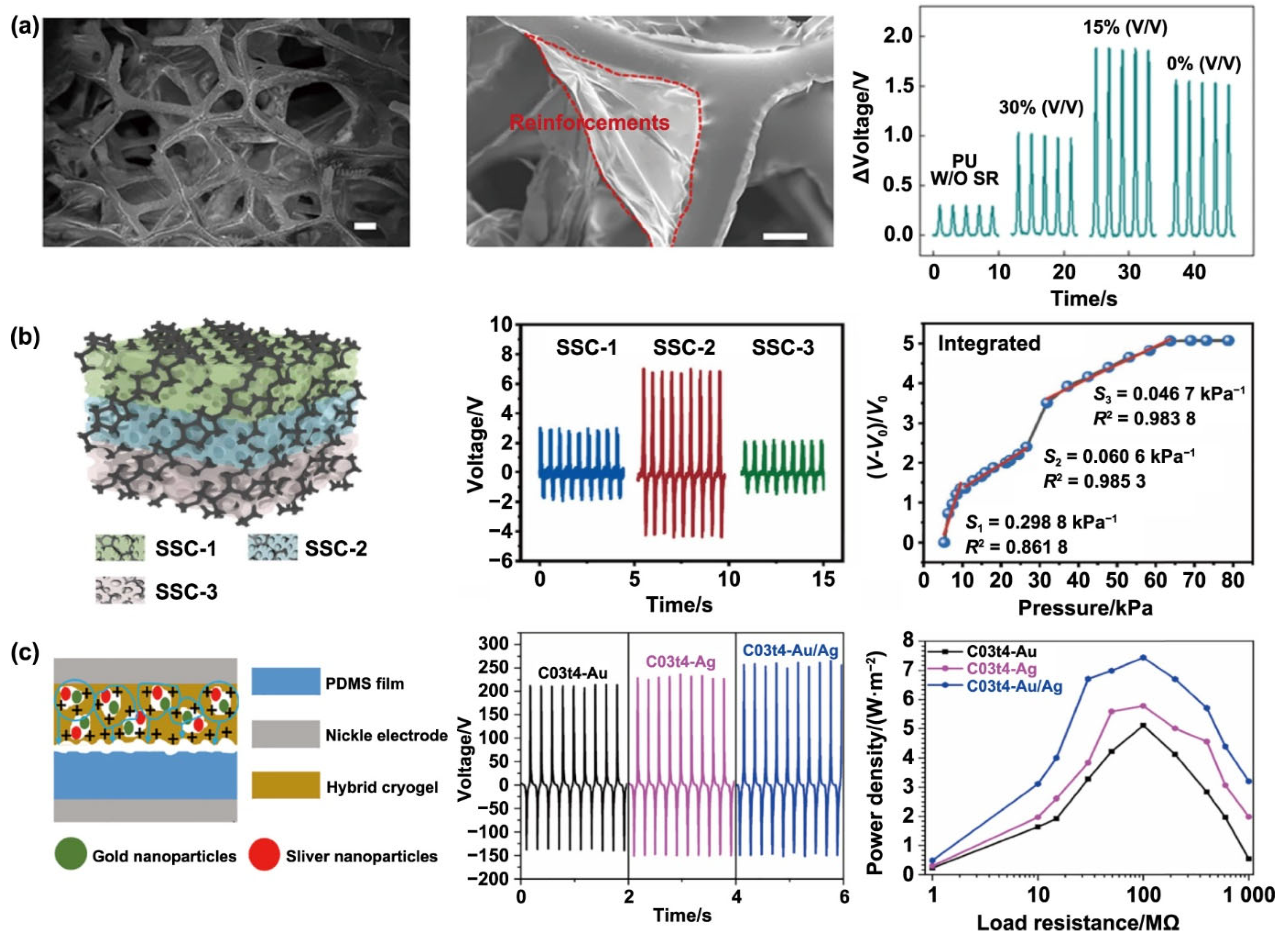

4. Morphological Topography and Correlation with Triboelectric Output

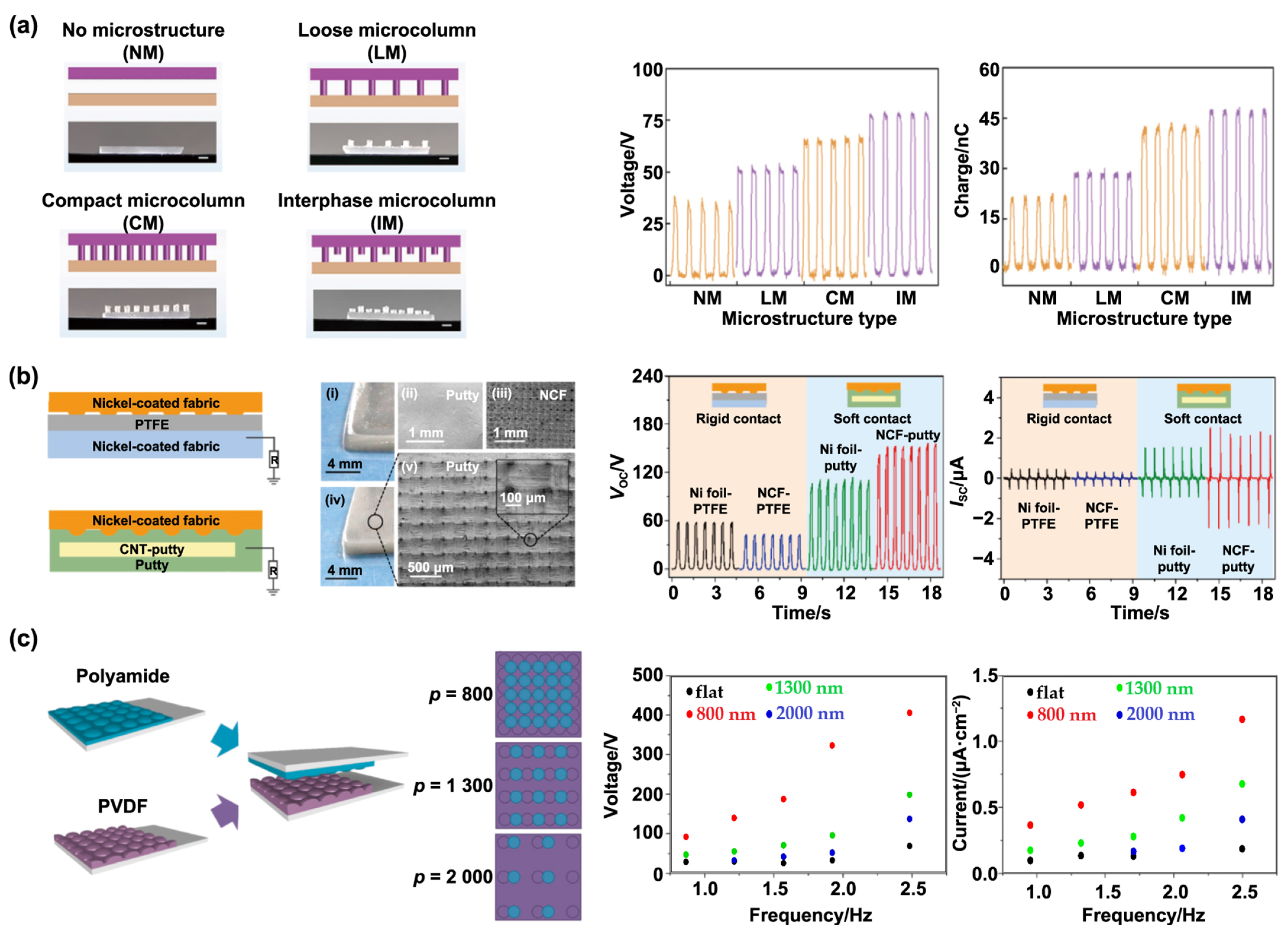

4.1. Surface Topography

4.1.1. Surface Roughness

4.1.2. Micro/Nano-Patterning

4.1.3. Porosity

4.1.4. Layered Architectures and Synergistic Design

5. Sensing Applications of Gel-Based Triboelectric Nanogenerators

5.1. Health Monitoring

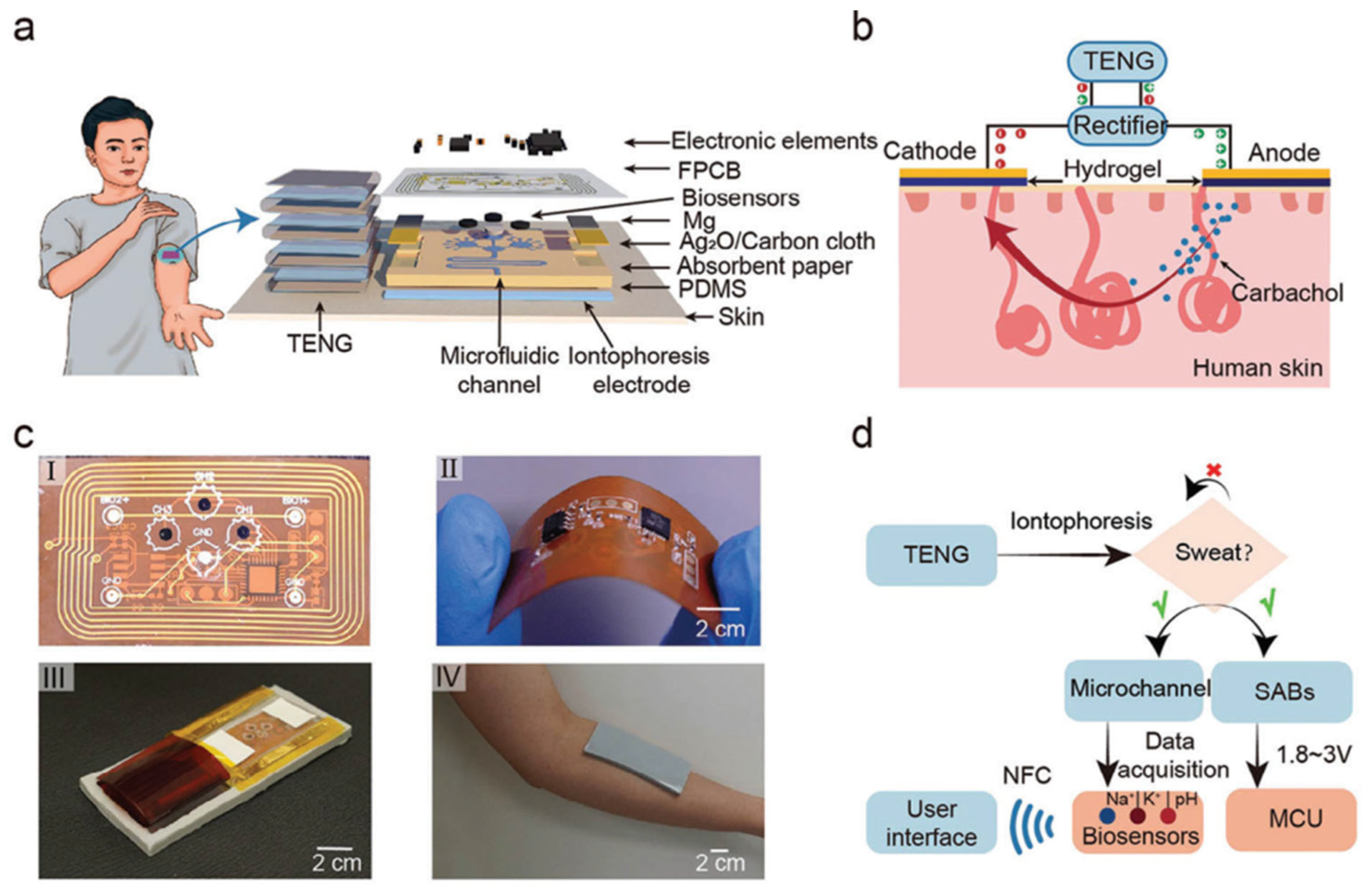

5.1.1. TENG-Integrated Sweat Monitoring

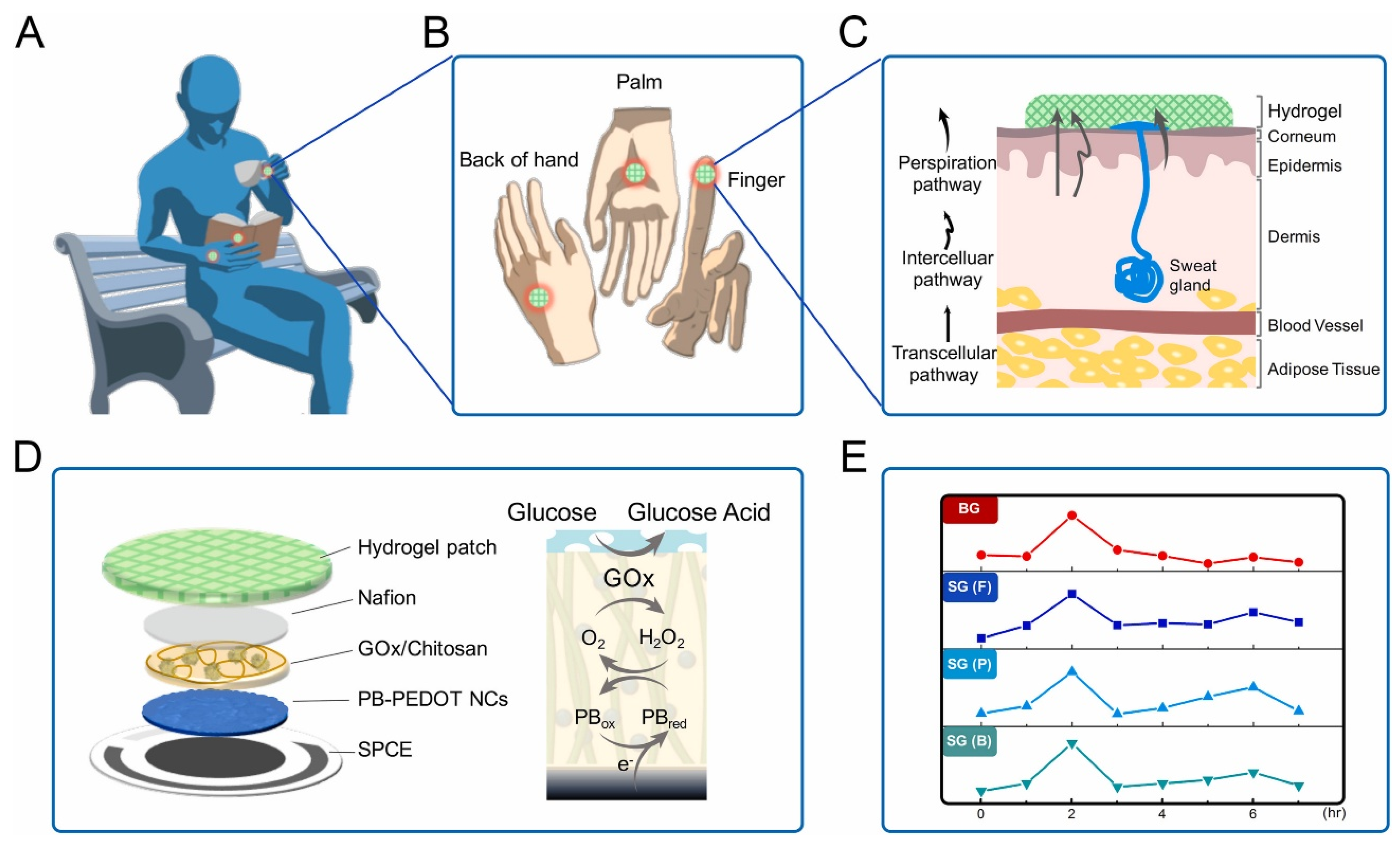

5.1.2. Glucose Monitoring for Diabetes Management

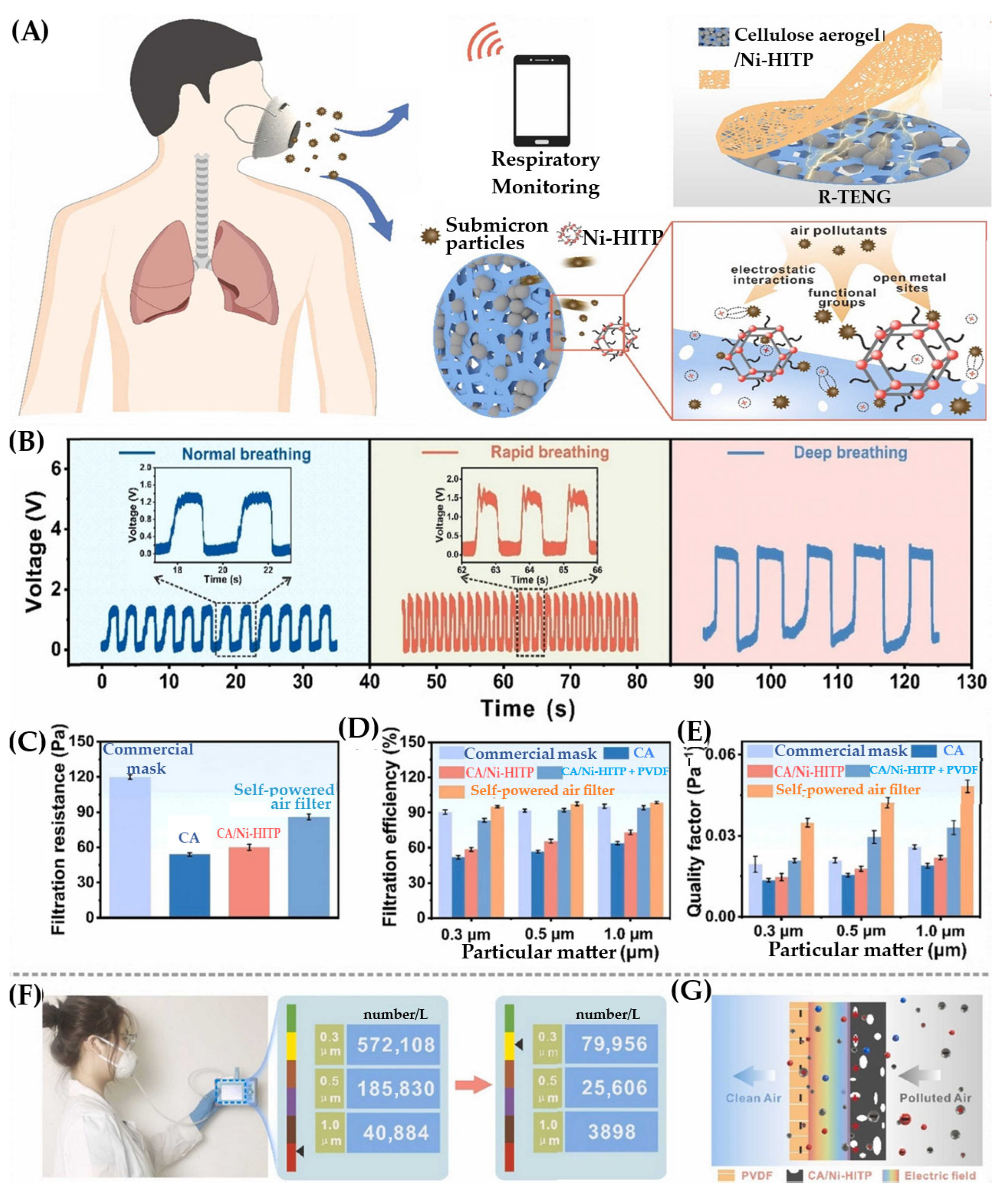

5.1.3. Respiratory Monitoring and Air Filtration

5.1.4. Air Filtration

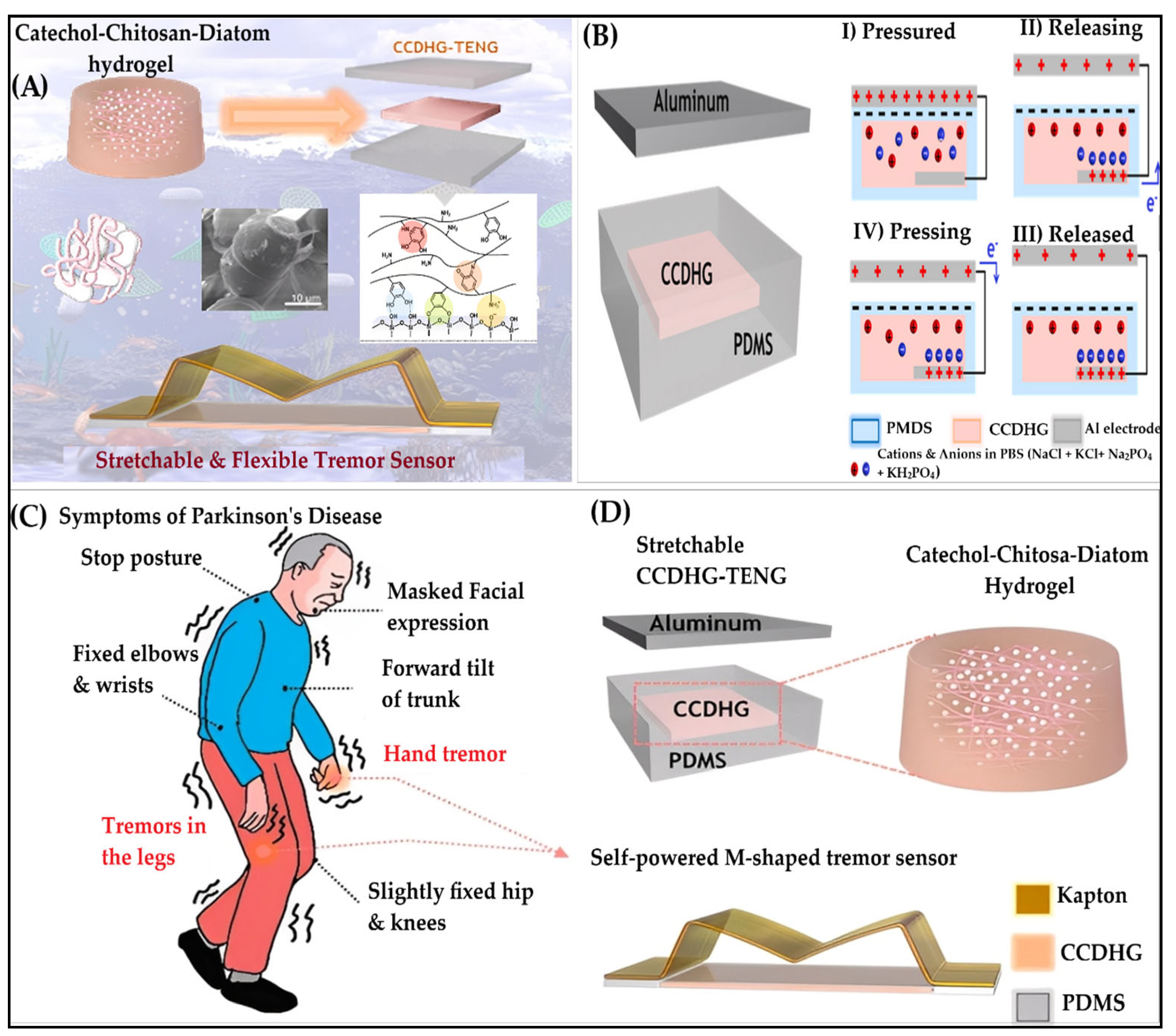

5.1.5. Tremor Detection for Neurological Assessment

5.2. Environmental Monitoring

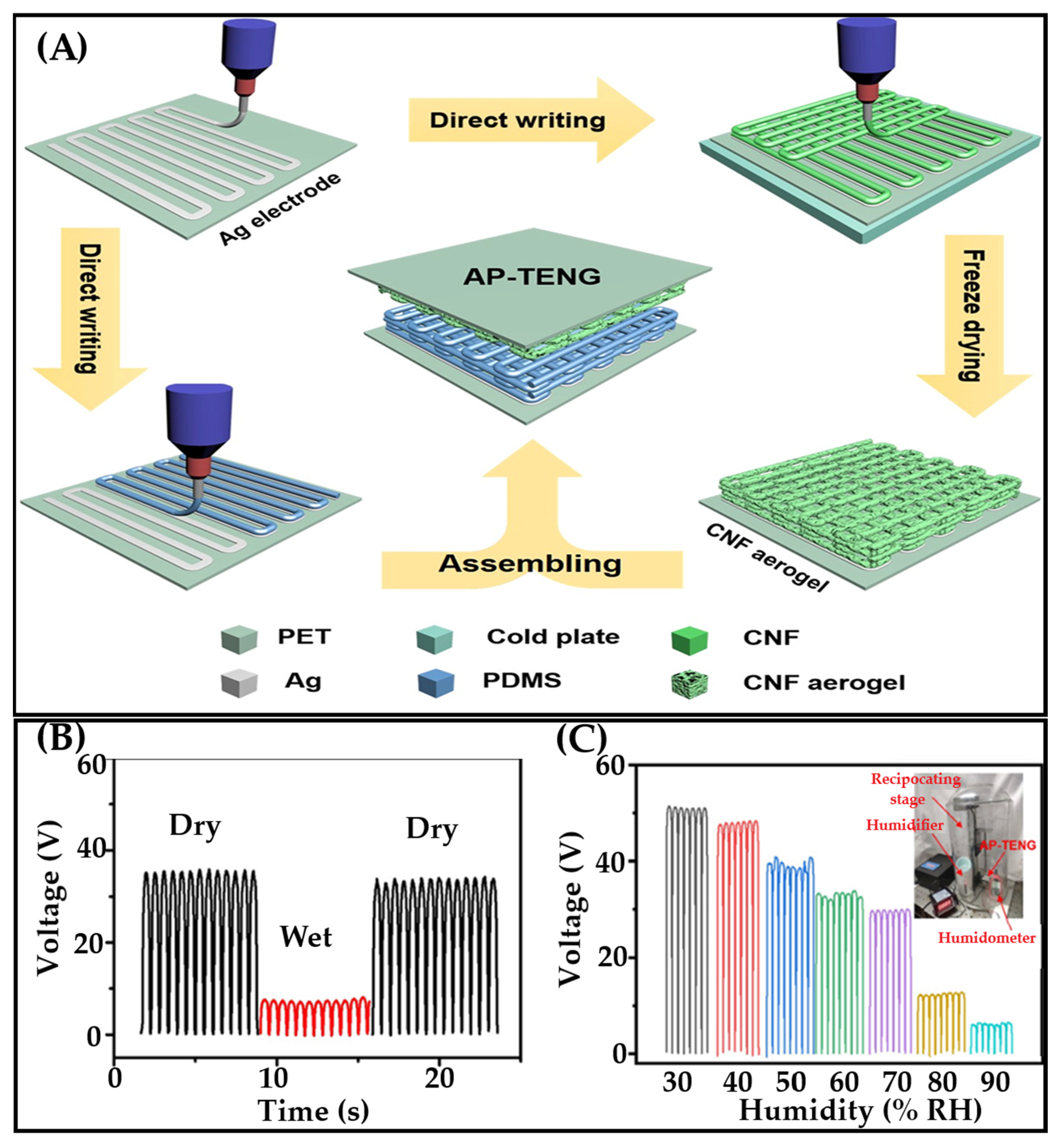

5.2.1. Humidity Sensing via Aerogel-Based TENGs

5.2.2. Fire Detection and Thermal Insulation

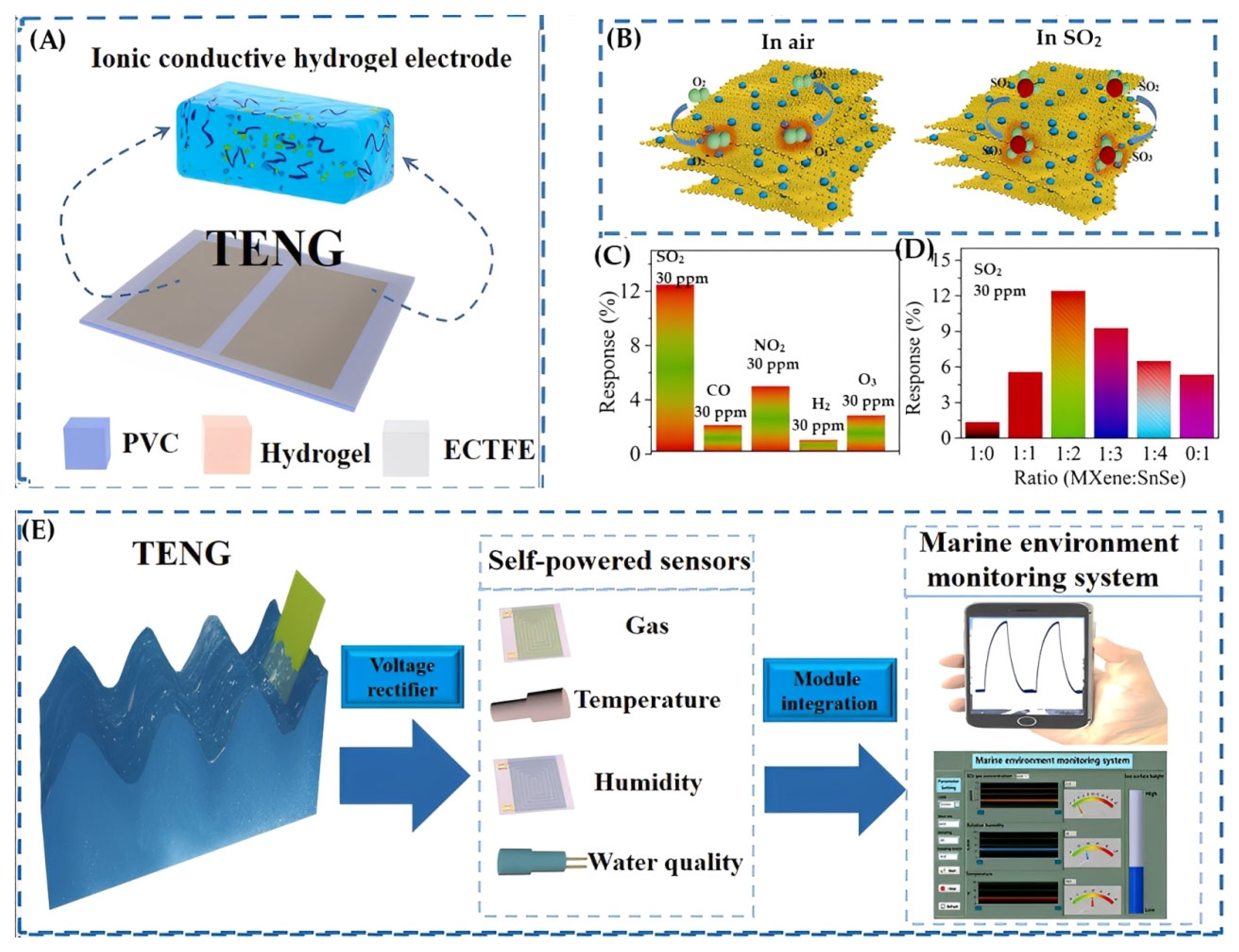

5.2.3. Marine Environmental Monitoring

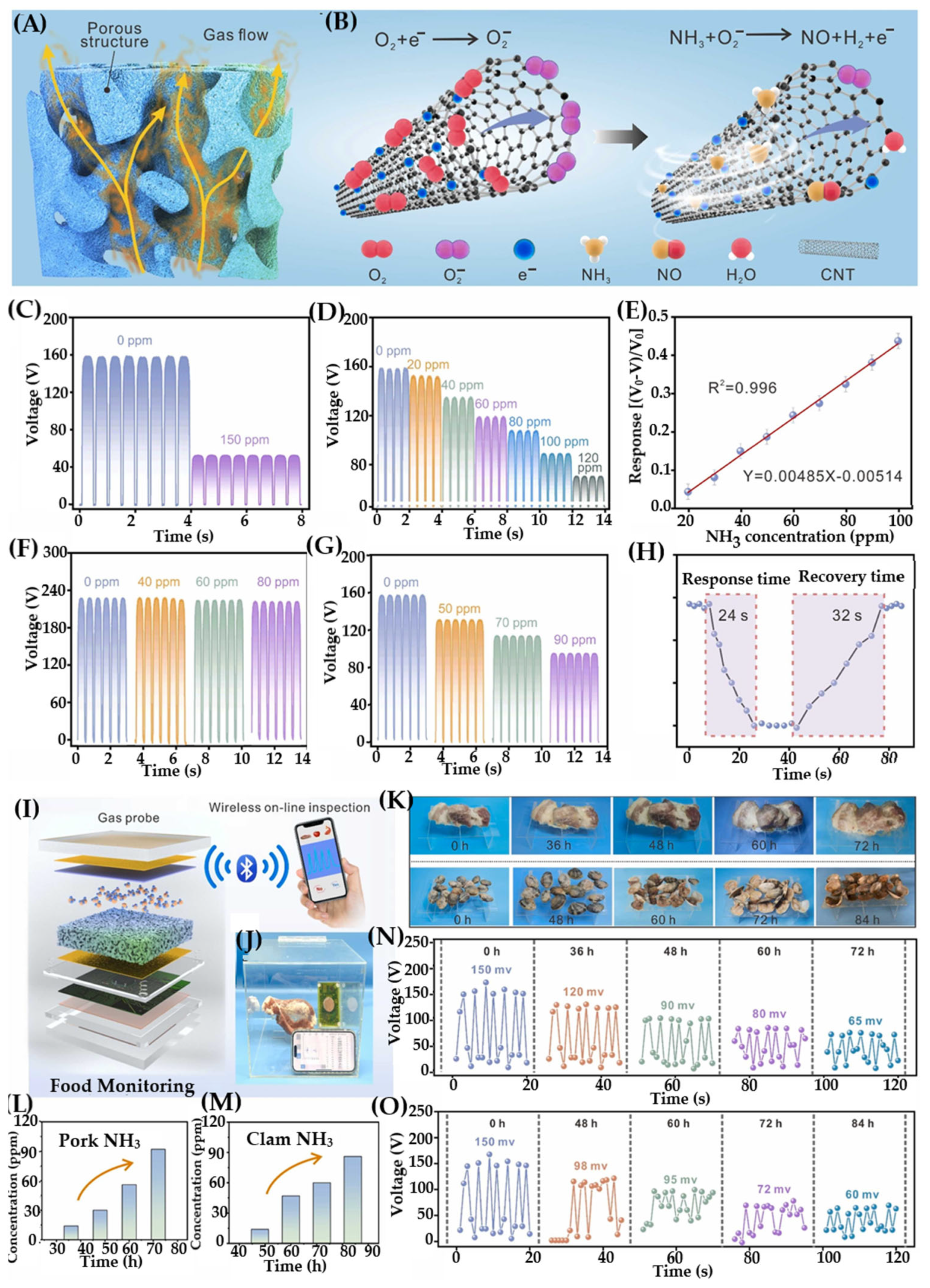

5.2.4. Gas Detection

5.3. TENG-Integrated Tactile Sensing

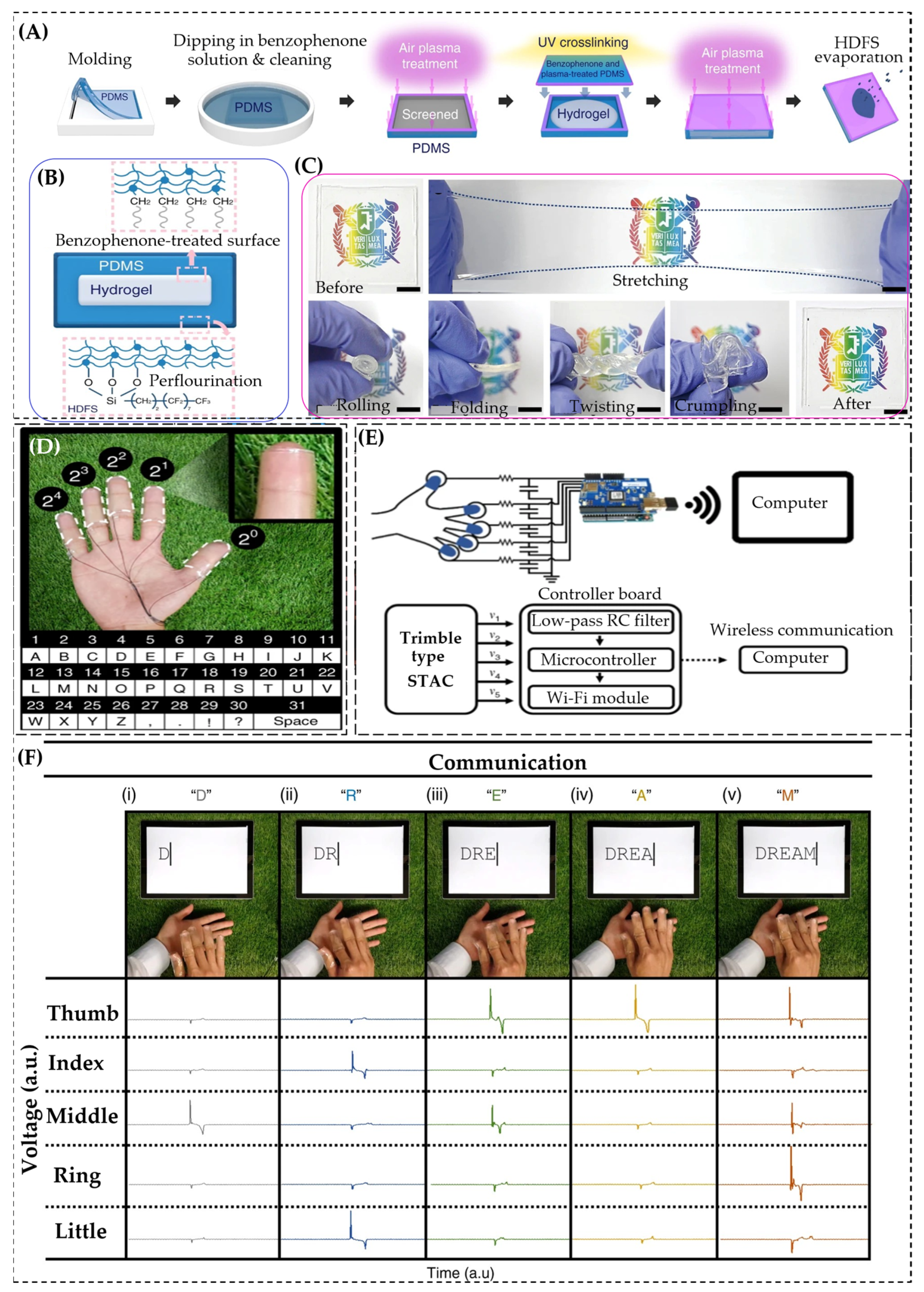

5.3.1. Skin-like STIC for Tactile Communication

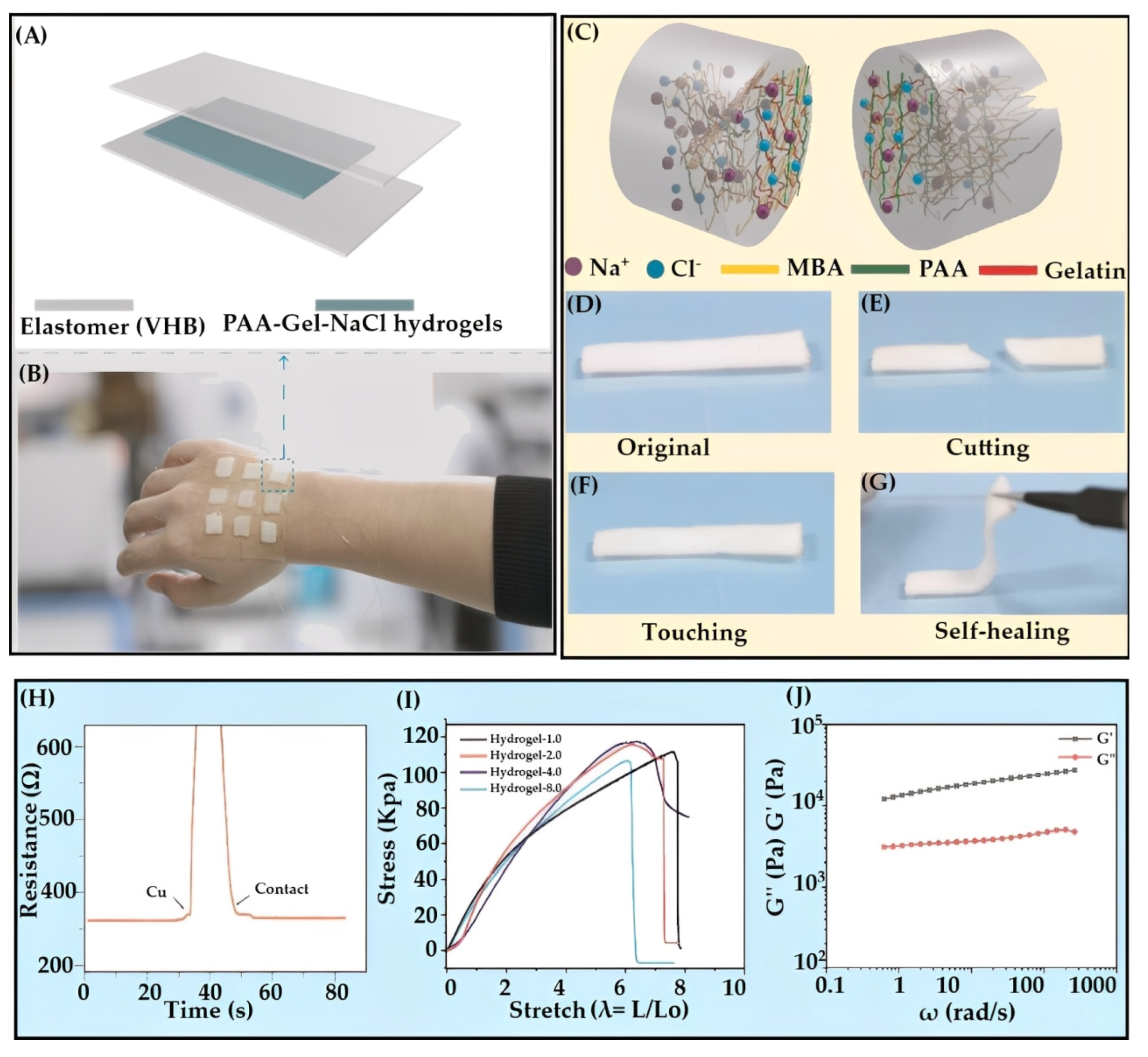

5.3.2. Self-Healable Hydrogel-Based SH-TENG

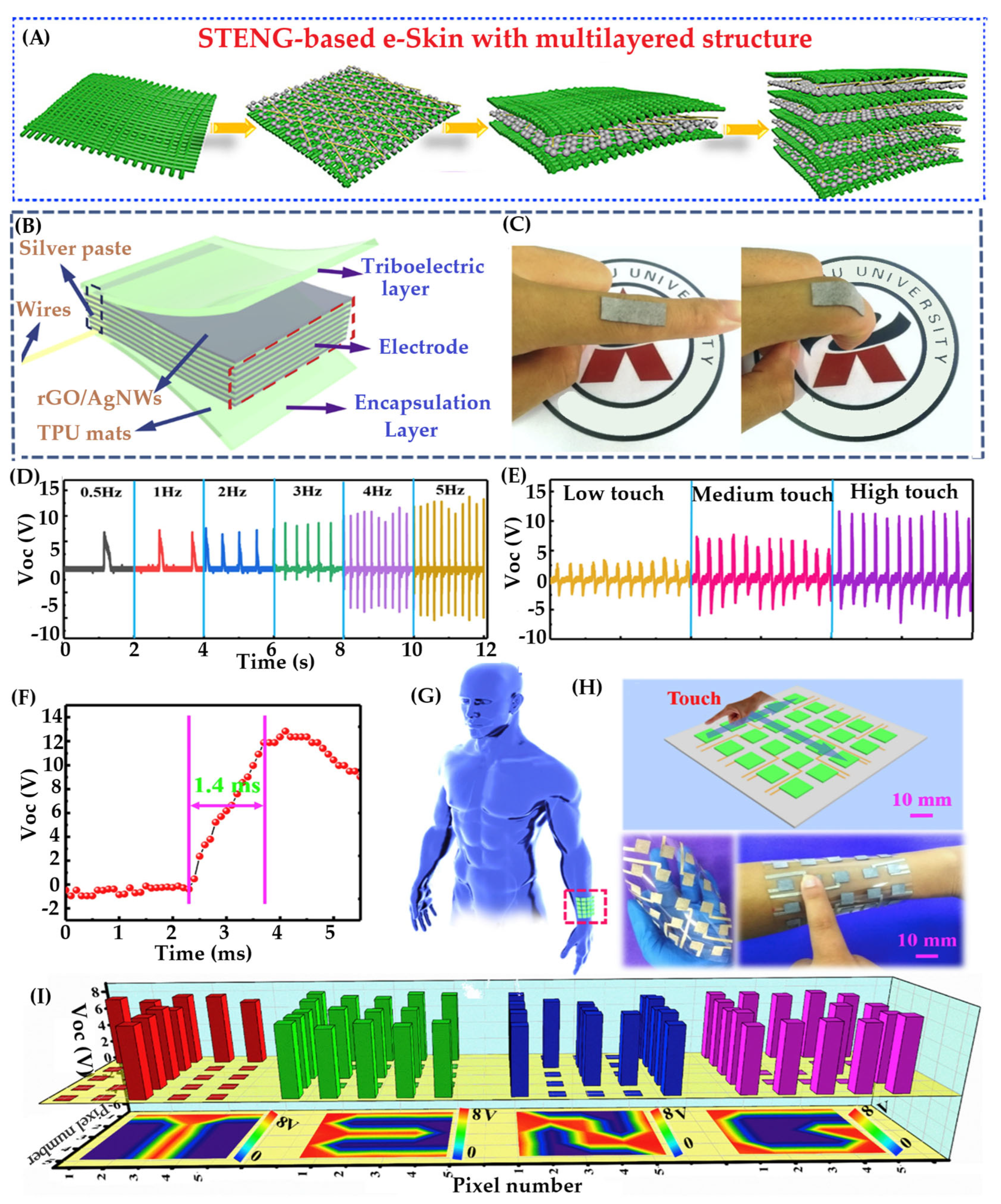

5.3.3. Self-Healable and Ultra-Stretchable Gel-Based TENGs for High-Sensitivity Electronic Skins

5.3.4. Wearable TENGs for Health Monitoring

6. Challenges and Future Perspectives

6.1. Dehydration, Stability and Durability, and Integration Challenges of Gel-Based TENGs

6.2. Integration with Electronics and Data Systems

6.3. Scalability and Cost-Effectiveness

6.4. Emerging Trends: Self-Healing Gels, Hybrid Systems, and AI-Assisted Sensing

7. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hao, N.; Liu, Y.; Cai, C.; Shao, Y.; Meng, X.; Du, G.; Luo, B.; Wei, Z.; Wang, J.; Wang, S.; et al. Advanced Triboelectric Materials for Self-Powered Gas Sensing Systems. Nano Energy 2024, 122, 109335. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Tang, M.; Zhang, H.; Sun, T.; Yang, C.; Mao, R.; Li, K.; Wang, J. Ethylene Chlorotrifluoroethylene/Hydrogel-Based Liquid-Solid Triboelectric Nanogenerator Driven Self-Powered Mxene-Based Sensor System for Marine Environmental Monitoring. Nano Energy 2022, 100, 107509. [Google Scholar] [CrossRef]

- Bai, Z.; Wang, X.; Huang, M.; Feng, Y.; Sun, S.; Zheng, M.; Zou, X.; Xie, L.; Wang, X.; Hao, D.; et al. Smart Battery-Free and Wireless Bioelectronic Platform Based on a Nature-Skin-Derived Organohydrogel for Chronic Wound Diagnosis, Assessment, and Accelerated Healing. Nano Energy 2023, 118, 108989. [Google Scholar] [CrossRef]

- Wu, Y.; Luo, Y.; Cuthbert, T.J.; Shokurov, A.V.; Chu, P.K.; Feng, S.P.; Menon, C. Hydrogels as Soft Ionic Conductors in Flexible and Wearable Triboelectric Nanogenerators. Adv. Sci. 2022, 9, 2106008. [Google Scholar] [CrossRef]

- Cao, H.; Duan, L.; Zhang, Y.; Cao, J.; Zhang, K. Current Hydrogel Advances in Physicochemical and Biological Response-Driven Biomedical Application Diversity. Signal Transduct. Target. Ther. 2021, 6, 426. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Ma, Y.; Huang, Y. Material Innovation and Mechanics Design for Substrates and Encapsulation of Flexible Electronics: A Review. Mater. Horiz. 2021, 8, 383–400. [Google Scholar] [CrossRef]

- Liu, H.; Li, M.; Liu, S.; Jia, P.; Guo, X.; Feng, S.; Lu, T.J.; Yang, H.; Li, F.; Xu, F. Spatially Modulated Stiffness On Hydrogels For Soft And Stretchable Integrated Electronics. Mater. Horiz. 2020, 7, 203–213. [Google Scholar] [CrossRef]

- Han, S.T.; Peng, H.; Sun, Q.; Venkatesh, S.; Chung, K.-S.; Lau, S.C.; Zhou, Y.; Roy, V.A.L.; Han, S.-T.; Peng, H.; et al. REVIEW 1700375 (1 of 22) an Overview of the Development of Flexible Sensors. Adv. Mater. 2017, 29, 1700375. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, Z.; Zeng, J.; Zhang, J.; He, P.; Su, J.; Zeng, Y.; Fan, R.; Zhao, D.; Ma, W.; et al. Immunogenicity and Safety of an Inactivated Enterovirus 71 Vaccine Administered Simultaneously With Hepatitis B Vaccine and Group A Meningococcal Polysaccharide Vaccine: A Phase 4, Open-Label, Single-Center, Randomized, Noninferiority Trial. J. Infect. Dis. 2019, 220, 392–399. [Google Scholar] [CrossRef]

- Dai, Y.; Yu, K.; Li, H.; Zhu, H.; Xie, J.; Nie, D.; Liu, T.; Luo, B.; Gao, C.; Luo, Y.; et al. Triboelectric Negative Air Ion Generators for Efficient Membrane Fouling Control. Chem. Eng. J. 2024, 481, 148581. [Google Scholar] [CrossRef]

- Xu, B.; Peng, W.; He, J.; Zhang, Y.; Song, X.; Li, J.; Zhang, Z.; Luo, Y.; Meng, X.; Cai, C.; et al. Liquid Metal-Based Triboelectric Nanogenerators for Energy Harvesting and Emerging Applications. Nano Energy 2024, 120, 109107. [Google Scholar] [CrossRef]

- Wang, Z.L. From Contact Electrification to Triboelectric Nanogenerators. Rep. Prog. Phys. 2021, 84, 096502. [Google Scholar] [CrossRef]

- Xia, R.; Zhang, R.; Jie, Y.; Zhao, W.; Cao, X.; Wang, Z. Natural Cotton-Based Triboelectric Nanogenerator as A Self-Powered System for Efficient Use of Water and Wind Energy. Nano Energy 2022, 92, 106685. [Google Scholar] [CrossRef]

- He, L.; Zhang, C.; Zhang, B.; Yang, O.; Yuan, W.; Zhou, L.; Zhao, Z.; Wu, Z.; Wang, J.; Wang, Z.L. A Dual-Mode Triboelectric Nanogenerator for Wind Energy Harvesting and Self-Powered Wind Speed Monitoring. ACS Nano 2022, 16, 6244–6254. [Google Scholar] [CrossRef]

- Cao, B.; Wang, P.; Rui, P.; Wei, X.; Wang, Z.; Yang, Y.; Tu, X.; Chen, C.; Wang, Z.; Yang, Z.; et al. Broadband and Output-Controllable Triboelectric Nanogenerator Enabled by Coupling Swing-Rotation Switching Mechanism with Potential Energy Storage/Release Strategy for Low-Frequency Mechanical Energy Harvesting (Adv. Energy Mater. 46/2022). Adv. Energy Mater. 2022, 12, 2202627. [Google Scholar] [CrossRef]

- Guo, L.; Wu, G.; Wang, Q.; Li, T.; Yao, B.; Zou, Y.; Xu, M. Advances in Triboelectric Pressure Sensors. Sens. Actuators A Phys. 2023, 355, 2270194. [Google Scholar] [CrossRef]

- Singh, A.N.; Nam, K.-W. Gel-Based Self-Powered Nanogenerators: Materials, Mechanisms, and Emerging Opportunities. Gels 2025, 11, 451. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zheng, C.; Ma, T.; Wang, T.; Gao, S.; Dai, Q.; Han, Q.; Chu, F. Tooth Backlash Inspired Comb-Shaped Single-Electrode Triboelectric Nanogenerator for Self-Powered Condition Monitoring of Gear Transmission. Nano Energy 2024, 123, 109429. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible Triboelectric Generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, H.; Gong, X.; Li, X. Performance and Application of Gel Materials in Triboelectric Nanogenerators (TENG): Review and Strategies for Improvement. J. Mater. Sci. Mater. Electron. 2025, 36, 129. [Google Scholar] [CrossRef]

- Chen, B.; Wang, Z.L. Toward a New Era of Sustainable Energy: Advanced Triboelectric Nanogenerator for Harvesting High Entropy Energy. Small 2022, 18, e2107034. [Google Scholar] [CrossRef]

- Hsu, H.H.; Zhang, X.; Xu, K.; Wang, Y.; Wang, Q.; Luo, G.; Xing, M.; Zhong, W. Self-Powered and Plant-Wearable Hydrogel as LED Power Supply and Sensor for Promoting and Monitoring Plant Growth in Smart Farming. Chem. Eng. J. 2021, 422, 129499. [Google Scholar] [CrossRef]

- Jiang, B.; Long, Y.; Pu, X.; Hu, W.; Wang, Z.L. A stretchable, Harsh Condition-Resistant and Ambient-Stable Hydrogel and Its Applications in Triboelectric Nanogenerator. Nano Energy 2021, 86, 106086. [Google Scholar] [CrossRef]

- Bao, D.; Wen, Z.; Shi, J.; Xie, L.; Jiang, H.; Jiang, J.; Yang, Y.; Liao, W.; Sun, X. An Anti-Freezing Hydrogel Based Stretchable Triboelectric Nanogenerator for Biomechanical Energy Harvesting at Sub-Zero Temperature. J. Mater. Chem. A 2020, 8, 13787–13794. [Google Scholar] [CrossRef]

- Luo, Y.; Yu, M.; Zhang, Y.; Wang, Y.; Long, L.; Tan, H.; Li, N.; Xu, L.; Xu, J. Highly Sensitive Strain Sensor and Self-Powered Triboelectric Nanogenerator Using a Fully Physical Crosslinked Double-Network Conductive Hydrogel. Nano Energy 2022, 104, 107955. [Google Scholar] [CrossRef]

- Rogovina, L.Z.; Vasil’eV, V.G.; Braudo, E.E. Definition of the Concept of Polymer Gel. Polym. Sci. Ser. C 2008, 50, 85–92. [Google Scholar] [CrossRef]

- Ren, Y.; Guo, J.; Liu, Z.; Sun, Z.; Wu, Y.; Liu, L.; Yan, F. Ionic Liquid–Based Click-Ionogels. Sci. Adv. 2019, 5, eaax0648. [Google Scholar] [CrossRef] [PubMed]

- Kuzina, M.A.; Kartsev, D.D.; Stratonovich, A.V.; Levkin, P.A. Organogels versus Hydrogels: Advantages, Challenges, and Applications. Adv. Funct. Mater. 2023, 33, 2301421. [Google Scholar] [CrossRef]

- Jing, T.; Wang, S.; Yuan, H.; Yang, Y.; Xue, M.; Xu, B. Interfacial Roughness Enhanced Gel/Elastomer Interfacial Bonding Enables Robust and Stretchable Triboelectric Nanogenerator for Reliable Energy Harvesting. Small 2023, 19, e2206528. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Zhao, Y.; Jiao, S.; Wang, C.; Jia, Y.; Dai, K.; Zheng, G.; Liu, C.; Wan, P.; Shen, C. Environment Tolerant Conductive Nanocomposite Organohydrogels as Flexible Strain Sensors and Power Sources for Sustainable Electronics. Adv. Funct. Mater. 2021, 31, 2101696. [Google Scholar] [CrossRef]

- Rastegardoost, M.M.; Tafreshi, O.A.; Saadatnia, Z.; Ghaffari-Mosanenzadeh, S.; Park, C.B.; Naguib, H.E. Recent Advances on Porous Materials and Structures for High-Performance Triboelectric Nanogenerators. Nano Energy 2023, 111, 108365. [Google Scholar] [CrossRef]

- Mi, H.-Y.; Jing, X.; Zheng, Q.; Fang, L.; Huang, H.-X.; Turng, L.-S.; Gong, S. High-Performance Flexible Triboelectric Nanogenerator Based on Porous Aerogels and Electrospun Nanofibers for Energy Harvesting and Sensitive Self-Powered Sensing. Nano Energy 2018, 48, 327–336. [Google Scholar] [CrossRef]

- Xu, W.; Huang, L.-B.; Wong, M.-C.; Chen, L.; Bai, G.; Hao, J. Environmentally Friendly Hydrogel-Based Triboelectric Nanogenerators for Versatile Energy Harvesting and Self-Powered Sensors. Adv. Energy Mater. 2017, 7, 1601529. [Google Scholar] [CrossRef]

- Lu, P.; Liao, X.; Guo, X.; Cai, C.; Liu, Y.; Chi, M.; Du, G.; Wei, Z.; Meng, X.; Nie, S. Gel-Based Triboelectric Nanogenerators for Flexible Sensing: Principles, Properties, and Applications. Nano-Micro Lett. 2022, 16, 206. [Google Scholar] [CrossRef]

- He, H.; Liu, J.; Wang, Y.; Zhao, Y.; Qin, Y.; Zhu, Z.; Yu, Z.; Wang, J. An Ultralight Self-Powered Fire Alarm e-Textile Based on Conductive Aerogel Fiber with Repeatable Temperature Monitoring Performance Used in Firefighting Clothing. ACS Nano 2022, 16, 2953–2967. [Google Scholar] [CrossRef]

- Lee, Y.; Cha, S.H.; Kim, Y.-W.; Choi, D.; Sun, J.-Y. Transparent and Attachable Ionic Communicators Based on Self-Cleanable Triboelectric Nanogenerators. Nat. Commun. 2018, 9, 1804. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Li, C.; Yin, Y.; Cao, R.; Li, H.; Zhang, X.; Zhao, S.; Wang, J.; Wang, B.; Xing, Y.; et al. A Flexible, Lightweight, and Wearable Triboelectric Nanogenerator for Energy Harvesting and Self-Powered Sensing. Adv. Mater. Technol. 2019, 4, 1800216. [Google Scholar] [CrossRef]

- Wu, M.; Wang, X.; Xia, Y.; Zhu, Y.; Zhu, S.; Jia, C.; Guo, W.; Li, Q.; Yan, Z. Stretchable Freezing-Tolerant Triboelectric Nanogenerator and Strain Sensor Based on Transparent, Long-Term Stable, and Highly Conductive Gelatin-Based organohydrogel. Nano Energy 2022, 95, 106967. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, R.; Tao, X.; He, Y.; Li, X.; Tian, F.; Chen, X.; Huang, W. Mechanically Robust and Highly Conductive Ionogels for Soft Ionotronics. Adv. Funct. Mater. 2023, 33, 2208083. [Google Scholar] [CrossRef]

- Wang, S.-J.; Jing, X.; Mi, H.-Y.; Chen, Z.; Zou, J.; Liu, Z.-H.; Feng, P.-Y.; Liu, Y.; Zhang, Z.; Shang, Y. Development and Applications of Hydrogel-Based Triboelectric Nanogenerators: A Mini-Review. Polymers 2022, 14, 1452. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, W.; Liu, Y.; Zhao, J.; Yuan, J.; Chi, M.; Meng, X.; Du, G.; Cai, C.; Wang, S.; et al. Cellulosic Gel-Based Triboelectric Nanogenerators for Energy Harvesting and Emerging Applications. Nano Energy 2023, 106, 108079. [Google Scholar] [CrossRef]

- Torres, F.G.; Troncoso, O.P.; De-La-Torre, G.E. Hydrogel-Based Triboelectric Nanogenerators: Properties, Performance, and Applications. Int. J. Energy Res. 2022, 46, 5603–5624. [Google Scholar] [CrossRef]

- Gao, Z.; Xu, T.; Miao, X.; Lu, J.; Zhu, X.; Song, Y.; Ren, G.; Jia, Y.; Li, X. A thermal-Driven Self-Replenishing Slippery Coating. Surf. Interfaces 2021, 24, 101022. [Google Scholar] [CrossRef]

- Yiming, B.; Guo, X.; Ali, N.; Zhang, N.; Zhang, X.; Han, Z.; Lu, Y.; Wu, Z.; Fan, X.; Jia, Z.; et al. Ambiently and Mechanically Stable Ionogels for Soft Ionotronics. Adv. Funct. Mater. 2021, 31, 2102773. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, X.; Wu, S.; Li, Q.; Lv, J.; Wang, J.; Jiang, L. Bioinspired Solid Organogel Materials with a Regenerable Sacrificial Alkane Surface Layer. Adv. Mater. 2017, 29, 1700865. [Google Scholar] [CrossRef]

- Zhan, W.; Zhang, H.; Lyu, X.; Luo, Z.-Z.; Yu, Y.; Zou, Z. An Ultra-Tough and Super-Stretchable Ionogel with Multi Functions Towards Flexible Iontronics. Sci. China Mater. 2023, 66, 1539–1550. [Google Scholar] [CrossRef]

- Saadatnia, Z.; Mosanenzadeh, S.G.; Li, T.; Esmailzadeh, E.; Naguib, H.E. Polyurethane Aerogel-Based Triboelectric Nanogenerator for High Performance Energy Harvesting and Biomechanical Sensing. Nano Energy 2019, 65, 104019. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Ren, P.; Yu, S.; Cui, P.; Nielsen, C.B.; Abrahams, I.; Briscoe, J.; Lu, Y. Versatile and Recyclable Double-Network Pva/Cellulose Hydrogels for Strain Sensors and Triboelectric Nanogenerators Under Harsh Conditions. Nano Energy 2024, 125, 109599. [Google Scholar] [CrossRef]

- Qin, P. Stretchable and Self-Healable Conductive Hydrogel-Based Multifunctional Triboelectric Nanogenerator for Energy Harvesting and Dance Motion Sensing. APL Mater. 2023, 11, 031117. [Google Scholar] [CrossRef]

- Zhu, L.; Xu, J.; Song, J.; Qin, M.; Gu, S.; Sun, W.; You, Z. Transparent, Stretchable and Anti-Freezing Hybrid Double-Network Organohydrogels. Sci. China Mater. 2022, 65, 2207–2216. [Google Scholar] [CrossRef]

- Yang, Y.; Sha, L.; Zhao, H.; Guo, Z.; Wu, M.; Lu, P. Recent Advances in Cellulose Microgels: Preparations and Functionalized Applications. Adv. Colloid Interface Sci. 2023, 311, 102815. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Chee, P.L.; Sugiarto, S.; Yu, Y.; Shi, C.; Yan, R.; Yao, Z.; Shi, X.; Zhi, J.; Kai, D.; et al. Hydrogel-Based Flexible Electronics. Adv. Mater. 2023, 35, 2205326. [Google Scholar] [CrossRef]

- Zhang, Y.; Tan, Y.; Lao, J.; Gao, H.; Yu, J. Hydrogels for Flexible Electronics. ACS Nano 2023, 17, 9681–9693. [Google Scholar] [CrossRef]

- Yin, H.; Liu, F.; Abdiryim, T.; Liu, X. Self-Healing Hydrogels: From Synthesis to Multiple Applications. ACS Mater. Lett. 2023, 5, 1787–1830. [Google Scholar] [CrossRef]

- Sun, E.; Wang, Y.; Zhang, Z.; Chen, Y.; Shoaib, M.; Cao, X.; Wang, N. Hydrogel-Based Triboelectric Nanogenerators: Current Progress and Future Perspectives. Adv. Funct. Mater. 2025, e11382. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Jyothi, S.J.; Kment, S.; Zboril, R.; Yoon, S.; Jayaramulu, K. Covalent Graphene-Metal–Organic Polyhedra Hybrids: Triboelectric Nanogenerators for Next Generation of Wearable E-Skin Technologies. Small 2025, 21, 2503772. [Google Scholar] [CrossRef]

- Ying, B.; Liu, X. Skin-Like Hydrogel Devices for Wearable Sensing, Soft Robotics and Beyond. iScience 2021, 24, 103174. [Google Scholar] [CrossRef]

- Yang, S.; Klinkov, V.; Grozova, N.; Shalnova, S.; Larionova, T.; Tolochko, O.; Klimova-Korsmik, O. Nanostructures and Nanomaterials Integrated into Triboelectric Nanogenerators. Micromachines 2025, 16, 403. [Google Scholar] [CrossRef]

- Luo, X.; Zhu, L.; Wang, Y.C.; Li, J.; Nie, J.; Wang, Z.L. A Flexible Multifunctional Triboelectric Nanogenerator Based on MXene/PVA Hydrogel. Adv. Funct. Mater. 2021, 31, 2104928. [Google Scholar] [CrossRef]

- Du, G.; Wang, J.; Liu, Y.; Yuan, J.; Liu, T.; Cai, C.; Luo, B.; Zhu, S.; Wei, Z.; Wang, S.; et al. Fabrication of Advanced Cellulosic Triboelectric Materials via Dielectric Modulation. Adv. Sci. 2023, 10, 2206243. [Google Scholar] [CrossRef] [PubMed]

- Dzhardimalieva, G.I.; Yadav, B.C.; Kudaibergenov, S.E.; Uflyand, I.E. Basic Approaches to the Design of Intrinsic Self-Healing Polymers for Triboelectric Nanogenerators. Polymers 2020, 12, 2594. [Google Scholar] [CrossRef] [PubMed]

- Byun, K.-E.; Cho, Y.; Seol, M.; Kim, S.; Kim, S.-W.; Shin, H.-J.; Park, S.; Hwang, S.W. Control of Triboelectrification by Engineering Surface Dipole and Surface Electronic State. ACS Appl. Mater. Interfaces 2016, 8, 18519–18525. [Google Scholar] [CrossRef]

- Chen, Z.; McCuskey, S.R.; Zhang, W.; Yip, B.R.P.; Quek, G.; Jiang, Y.; Ohayon, D.; Ong, S.; Kundukad, B.; Mao, X.; et al. Three-Dimensional Conductive Conjugated Polyelectrolyte Gels Facilitate Interfacial Electron Transfer for Improved Biophotovoltaic performance. Nat. Commun. 2025, 16, 5955. [Google Scholar] [CrossRef]

- Bai, Y.; Xu, L.; Lin, S.; Luo, J.; Qin, H.; Han, K.; Wang, Z.L. Charge Pumping Strategy for Rotation and Sliding Type Triboelectric Nanogenerators. Adv. Energy Mater. 2020, 10, 2000605. [Google Scholar] [CrossRef]

- Akram, W.; Chen, Q.; Xia, G.; Fang, J. A Review of Single Electrode Triboelectric Nanogenerators. Nano Energy 2023, 106, 108043. [Google Scholar] [CrossRef]

- Shao, Y.; Du, G.; Luo, B.; Liu, T.; Zhao, J.; Zhang, S.; Wang, J.; Chi, M.; Cai, C.; Liu, Y.; et al. A Tough Monolithic-Integrated Triboelectric Bioplastic Enabled by Dynamic Covalent Chemistry. Adv. Mater. 2024, 36, e2311993. [Google Scholar] [CrossRef]

- Hasan, S.; Kouzani, A.Z.; Adams, S.; Long, J.; Mahmud, M.A.P. Comparative Study on the Contact-Separation Mode Triboelectric Nanogenerator. J. Electrost. 2022, 116, 103685. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef] [PubMed]

- Wen, H.; Yang, P.; Liu, G.; Xu, S.; Yao, H.; Li, W.; Qu, H.; Ding, J.; Li, J.; Wan, L. Flower-Like Triboelectric Nanogenerator for Blue Energy Harvesting with Six Degrees of Freedom. Nano Energy 2022, 93, 106796. [Google Scholar] [CrossRef]

- Ye, X.; Li, Y.; Ma, X.; Gan, L.; Huang, J. Enhancing Output Signals of Sport Monitors Based on Triboelectric Porous PVDF Nanogenerators via Concaving Cells and Cell-Packing Structures. ACS Appl. Bio Mater. 2023, 6, 4168–4177. [Google Scholar] [CrossRef]

- Chun, J.; Kim, J.W.; Jung, W.-S.; Kang, C.-Y.; Kim, S.-W.; Wang, Z.L.; Baik, J.M. Mesoporous Pores Impregnated with Au Nanoparticles as Effective Dielectrics for Enhancing Triboelectric Nanogenerator Performance in Harsh Environments. Energy Environ. Sci. 2015, 8, 3006–3012. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, Z.; Chang, W.; Sun, J.; He, W.; Zeng, Q.; Guo, H.; Hu, C. Interface Static Friction Enabled Ultra-Durable and High Output Sliding Mode Triboelectric Nanogenerator. Adv. Funct. Mater. 2022, 32, 2202055. [Google Scholar] [CrossRef]

- Zhu, G.; Yang, W.Q.; Zhang, T.; Jing, Q.; Chen, J.; Zhou, Y.S.; Bai, P.; Wang, Z.L. Self-Powered, Ultrasensitive, Flexible Tactile Sensors Based on Contact Electrification. Nano Lett. 2014, 14, 3208–3213. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.; Lin, Z.-H.; Zhou, Y.S.; Jing, Q.; Su, Y.; Yang, J.; Chen, J.; Hu, C.; Wang, Z.L. Human Skin Based Triboelectric Nanogenerators for Harvesting Biomechanical Energy and as Self-Powered Active Tactile Sensor System. ACS Nano 2013, 7, 9213–9222. [Google Scholar] [CrossRef]

- Luo, J.; Gao, W.; Wang, Z.L. The Triboelectric Nanogenerator as an Innovative Technology toward Intelligent Sports. Adv. Mater. 2021, 33, 2004178. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Xue, F.; Du, W.; Han, C.; Zhang, C.; Wang, Z. Transparent Paper-Based Triboelectric Nanogenerator as a Page Mark and Anti-Theft Sensor. Nano Res. 2014, 7, 1215–1223. [Google Scholar] [CrossRef]

- Munirathinam, P.; Chandrasekhar, A. Self-Powered Triboelectric Nanogenerator for Security Applications. Micromachines 2023, 14, 592. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, D.; Cai, H.; Yang, Y.; Zhang, H.; Du, C. Performance Enhancement of Triboelectric Nanogenerators Using Contact-Separation Mode in Conjunction with the Sliding Mode and Multifunctional Application for Motion Monitoring. Nano Energy 2022, 102, 107719. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Zhao, G.; Zhang, Z.; Zhao, X.; Wan, X.; Zhang, Y.; Wang, Z.L.; Li, L. Stretchable Unsymmetrical Piezoelectric BaTiO3 Composite Hydrogel for Triboelectric Nanogenerators and Multimodal Sensors. ACS Nano 2022, 16, 1661–1670. [Google Scholar] [CrossRef]

- Zhang, Y.; Ting, J.W.Y.; Rohan, R.; Cai, W.; Li, J.; Xu, G.; Chen, Z.; Lin, A.; Cheng, H. Fabrication of a Proton Exchange Membrane via Blended Sulfonimide Functionalized Polyamide. J. Mater. Sci. 2014, 49, 3442–3450. [Google Scholar] [CrossRef]

- Lin, L.; Wang, S.; Niu, S.; Liu, C.; Xie, Y.; Wang, Z.L. Noncontact Free-Rotating Disk Triboelectric Nanogenerator as a Sustainable Energy Harvester and Self-Powered Mechanical Sensor. ACS Appl. Mater. Interfaces 2014, 6, 3031–3038. [Google Scholar] [CrossRef]

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Wang, Z.L. Freestanding Triboelectric-Layer-Based Nanogenerators for Harvesting Energy from a Moving Object or Human Motion in Contact and Non-contact Modes. Adv. Mater. 2014, 26, 2818–2824. [Google Scholar] [CrossRef]

- Hao, X.; Huang, T.; Li, M.; Pan, Y.; Liao, L.; Zhang, K.; Qin, A. Low-Frequency Ac-Photocatalysis Coupling For High-Efficiency Removal of Organic Pollutants From Water Based on the Self-Powered Triboelectric Nanogenerator. J. Mater. Chem. A 2023, 11, 16403–16413. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, B.; Zou, H.; Wu, Z.; Guo, H.; Zhang, Y.; Yang, J.; Wang, Z.L. Rationally Designed Rotation Triboelectric Nanogenerators with Much Extended Lifetime and Durability. Nano Energy 2020, 68, 104378. [Google Scholar] [CrossRef]

- Trinh, V.-L.; Chung, C.-K. Advances in Triboelectric Nanogenerators for Sustainable and Renewable Energy: Working Mechanism, Tribo-Surface Structure, Energy Storage-Collection System, and Applications. Processes 2023, 11, 2796. [Google Scholar] [CrossRef]

- Lei, T.; Wang, Y.; Zhang, Q.; Wang, H.; Duan, X.; Yan, J.; Xia, Z.; Wang, R.; Shou, W.; Li, X.; et al. Ultra-Stretchable and Anti-Freezing Ionic Conductive Hydrogels as High Performance Strain Sensors and Flexible Triboelectric Nanogenerator in Extreme Environments. Nano Energy 2024, 126, 109633. [Google Scholar] [CrossRef]

- Harnchana, V.; Van Ngoc, H.; He, W.; Rasheed, A.; Park, H.; Amornkitbamrung, V.; Kang, D.J. Enhanced Power Output of a Triboelectric Nanogenerator using Poly(dimethylsiloxane) Modified with Graphene Oxide and Sodium Dodecyl Sulfate. ACS Appl. Mater. Interfaces 2018, 10, 25263–25272. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, Y.S.; Cho, S.; Kang, I.S.; Kim, J.K.; Jeong, U. Output Voltage Modulation in Triboelectric Nanogenerator by Printed Ion Gel Capacitors. Nano Energy 2018, 54, 367–374. [Google Scholar] [CrossRef]

- Guo, R.; Luo, H.; He, S.; Xia, X.; Hou, T.; Wang, H.; Chen, C.; Zhang, D.; Zi, Y. Performance Metrics of Triboelectric Nanogenerator Toward Record-High Output Energy Density. Energy Environ. Sci. 2025, 18, 4893–4904. [Google Scholar] [CrossRef]

- Peng, S.; Wang, H.; Zhao, W.; Xin, Y.; Liu, Y.; Yu, X.; Zhan, M.; Shen, S.; Lu, L. Zwitterionic Polysulfamide Drug Nanogels with Microwave Augmented Tumor Accumulation and On-Demand Drug Release for Enhanced Cancer Therapy. Adv. Funct. Mater. 2020, 30, 2001832. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, X.; Hu, T.; Liang, F.; Guo, B.; Tao, K. Deep-Learning-Assisted Self-Powered Wireless Environmental Monitoring System Based on Triboelectric Nanogenerators with Multiple Sensing Capabilities. Nano Energy 2024, 132, 110301. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, J.; Qian, W.; Wang, Z.L. Triboelectric Nanogenerators as a Clean Energy Scavenging Technology. Mater. Today 2025, 88, 839–854. [Google Scholar] [CrossRef]

- Yang, D. Recent Advances in Hydrogels. Chem. Mater. 2022, 34, 1987–1989. [Google Scholar] [CrossRef]

- Jaipan, P.; Nguyen, A.; Narayan, R.J. Gelatin-Based Hydrogels for Biomedical Applications. MRS Commun. 2017, 7, 416–426. [Google Scholar] [CrossRef]

- Hasan, N.; Bhuyan, M.M.; Jeong, J.-H. Single/Multi-Network Conductive Hydrogels—A Review. Polymers 2024, 16, 2030. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Huang, X.; Wang, X.; Liu, H.; Wu, Y.; Du, F.; Zhang, Y. Highly Transparent, Adhesive, Stretchable and Conductive Pedot:Pss/Polyacrylamide Hydrogels For Flexible Strain Sensors. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126897. [Google Scholar] [CrossRef]

- Jing, X.; Li, H.; Mi, H.-Y.; Feng, P.-Y.; Tao, X.; Liu, Y.; Liu, C.; Shen, C. A Flexible Semitransparent Dual-Electrode Hydrogel Based Triboelectric Nanogenerator with Tough Interfacial Bonding and High Energy Output. J. Mater. Chem. C 2020, 8, 5752–5760. [Google Scholar] [CrossRef]

- Lv, P.; Shi, L.; Fan, C.; Gao, Y.; Yang, A.; Wang, X.; Ding, S.; Rong, M. Hydrophobic Ionic Liquid Gel-Based Triboelectric Nanogenerator: Next Generation of Ultrastable, Flexible, and Transparent Power Sources for Sustainable Electronics. ACS Appl. Mater. Interfaces 2020, 12, 15012–15022. [Google Scholar] [CrossRef] [PubMed]

- Jing, T.; Xu, B.; Yang, Y. Organogel Electrode Based Continuous Fiber with Large-Scale Production for Stretchable Triboelectric Nanogenerator Textiles. Nano Energy 2021, 84, 105867. [Google Scholar] [CrossRef]

- Parida, K.; Kumar, V.; Jiangxin, W.; Bhavanasi, V.; Bendi, R.; Lee, P.S. Highly Transparent, Stretchable, and Self-healing Ionic-skin Triboelectric Nanogenerators for Energy Harvesting and Touch Applications. Adv. Mater. 2017, 29, 1702181. [Google Scholar] [CrossRef]

- Zhao, L.; Fang, C.; Qin, B.; Yang, X.; Poechmueller, P. Conductive Dual-Network Hydrogel-Based Multifunctional Triboelectric Nanogenerator for Temperature and Pressure Distribution Sensing. Nano Energy 2024, 127, 109772. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Q.; Xu, L.; Li, N.; Tan, H.; Du, J.; Yu, M.; Xu, J. Triboelectric Nanogenerators Based on Hydrated Lithium Ions Incorporated Double-Network Hydrogels for Biomechanical Sensing and Energy Harvesting at Low Temperature. Nano Energy 2024, 125, 109521. [Google Scholar] [CrossRef]

- Long, Y.; Chen, Y.; Liu, Y.; Chen, G.; Guo, W.; Kang, X.; Pu, X.; Hu, W.; Wang, Z.L. A Flexible Triboelectric Nanogenerator Based on a Super-Stretchable and Self-Healable Hydrogel as the Electrode. Nanoscale 2020, 12, 12753–12759. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, W.; Ma, Z.; Zhao, H.; Ren, L. Self-Powered Flexible Electronic Skin Tactile Sensor with 3D Force Detection. Mater. Today 2024, 81, 84–94. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Gong, X.; Zhao, C.; Liu, Y.; Zhang, C. Construction of Carboxymethyl Chitosan Hydrogel with Multiple Cross-linking Networks for Electronic Devices at Low Temperature. ACS Biomater. Sci. Eng. 2023, 9, 508–519. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhao, X.; Wang, Z.; Liu, Z.; Yao, S.; Li, L. Antibacterial, Antifreezing, Stretchable, and Self-Healing Organohydrogel Electrode Based Triboelectric Nanogenerator for Self-Powered Biomechanical Sensing. Adv. Mater. Interfaces 2022, 9, 2200290. [Google Scholar] [CrossRef]

- Feng, C.; Xu, B.; Chen, L.; Qiu, Z.; Guo, J. Cellulose Hydrogels with High Response Sensitivity and Mechanical Adaptability for Flexible Strain Sensor and Triboelectric Nanogenerator. Eur. Polym. J. 2024, 214, 113173. [Google Scholar] [CrossRef]

- Watanabe, K.; Fujinuma, R.; Aizawa, H.; Namigata, H.; Welling, T.A.J.; Suga, K.; Nagao, D. A Practical Process for Effective Thickening of Silica Shells Formed onto Spherical Cores by Considering the Variation in Ionic Strength During Sol-Gel Reaction. Microporous Mesoporous Mater. 2024, 379, 113274. [Google Scholar] [CrossRef]

- Luo, J.M.; Sun, T.Q.; Sun, Y.G.; Lv, R.W.; Cao, A.M.; Wan, L.J. A General Synthesis Strategy for Hollow Metal Oxide Microspheres Enabled by Gel-Assisted Precipitation. Angew. Chem. Int. Ed. Engl. 2021, 60, 21377–21383. [Google Scholar] [CrossRef]

- Jung, H.-N.R.; Parale, V.G.; Choi, H.; Kim, J.; Lee, W.; Kim, S.-H.; Jung, W.K.; Park, H.-H. Investigation of compound state of SiO2-TiO2 aerogel synthesized through controlled sol-gel reaction. J. Alloy. Compd. 2024, 980, 173561. [Google Scholar] [CrossRef]

- Hu, J.; Qian, Y.; Wei, F.; Dai, J.; Li, D.; Zhang, G.; Wang, H.; Zhang, W. High powered output flexible aerogel triboelectric nanogenerator under ultrahigh temperature condition. Nano Energy 2024, 121, 109229. [Google Scholar] [CrossRef]

- Yang, J.; Chang, L.; Deng, H.; Cao, Z. Zwitterionic Eutectogels with High Ionic Conductivity for Environmentally Tolerant and Self-Healing Triboelectric Nanogenerators. ACS Nano 2024, 18, 18980–18991. [Google Scholar] [CrossRef]

- Dang, T.; Zhao, J.; Zeng, J.; Bu, T.; Li, J.; Dai, Y.; Dong, Z.; Feng, Y.; Chen, Y.; Zhang, C. Self-Powered VO 2 Phase Transition Based on Triboelectric Nanogenerator. J. Mater. Chem. A 2024, 12, 19052–19059. [Google Scholar] [CrossRef]

- Rezaei, S.; Omranpour, H.; Rejeb, Z.B.; Fashandi, M.; Monfared, A.R.; Rahmati, R.; Rastegardoost, M.M.; Naguib, H.E.; Park, C.B. Super-hydrophobic and resilient hybrid silica aerogels for thermal insulation, energy harvesting, and electrical applications in harsh environments. J. Mater. Chem. C 2023, 11, 15106–15118. [Google Scholar] [CrossRef]

- Xie, B.; Ma, Y.; Wang, J.; Liu, Y.; Yin, R. Chemical Cross-Linking Cellulose Aerogel-Based Triboelectric Nanogenerators for Energy Harvesting and Sensing Human Activities. ACS Appl. Mater. Interfaces 2024, 16, 19411–19420. [Google Scholar] [CrossRef]

- Zhou, Z.; Sun, W.; Lv, C.; Gu, X.; Ju, J.; Li, Y. Ultra-stretchable, antifreezing, and self-healing ZnO nanofluid-based hydrogels for triboelectric nanogenerators and self-powered biosensors. Eur. Polym. J. 2023, 200, 112500. [Google Scholar] [CrossRef]

- Chen, X.L.; Huang, X.; Li, Y.; Wang, W.S.; Huang, Y.J.; Xiao, H.; Wan, Q.; Zhu, L.Q. Triboelectric potential tuned oxide artificial tactile sensory platform with ultra-low power consumption. Appl. Mater. Today 2024, 36, 102034. [Google Scholar] [CrossRef]

- Li, Y.; Tian, Z.; Gao, X.; Zhao, H.; Li, X.; Wang, Z.L.; Yu, Z.; Yang, D. All-Weather Self-Powered Intelligent Traffic Monitoring System Based on a Conjunction of Self-Healable Piezoresistive Sensors and Triboelectric Nanogenerators. Adv. Funct. Mater. 2023, 33, 2308845. [Google Scholar] [CrossRef]

- Panwar, V.; Babu, A.; Sharma, A.; Thomas, J.; Chopra, V.; Malik, P.; Rajput, S.; Mittal, M.; Guha, R.; Chattopadhyay, N.; et al. Tunable, conductive, self-healing, adhesive and injectable hydrogels for bioelectronics and tissue regeneration applications. J. Mater. Chem. B 2021, 9, 6260–6270. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Choi, S.; Hong, Y.; Chung, J.; Choi, J.; Choi, W.-K.; Park, I.W.; Park, S.H.; Park, H.; Chung, W.-J.; et al. Biocompatible and biodegradable triboelectric nanogenerators based on hyaluronic acid hydrogel film. Appl. Mater. Today 2021, 22, 100920. [Google Scholar] [CrossRef]

- Qian, X.; Lu, A. Transparent, Robust, Nondrying, and Antifreezing Cellulose Organohydrogels for Energy Harvesting and Sensing Applications. ACS Appl. Polym. Mater. 2021, 3, 3747–3754. [Google Scholar] [CrossRef]

- Huang, L.-B.; Dai, X.; Sun, Z.; Wong, M.-C.; Pang, S.-Y.; Han, J.; Zheng, Q.; Zhao, C.-H.; Kong, J.; Hao, J.-X. Environment-resisted flexible high performance triboelectric nanogenerators based on ultrafast self-healing non-drying conductive organohydrogel. Nano Energy 2021, 82, 105724. [Google Scholar] [CrossRef]

- Park, H.; Oh, S.-J.; Kim, M.; Lee, C.; Joo, H.; Bae, J.W.; Lee, J.-H. Plasticizer structural effect for sustainable and high-performance PVC gel-based triboelectric nanogenerators. Nano Energy 2023, 114, 108615. [Google Scholar] [CrossRef]

- Wang, W.; Guo, P.; Liu, X.; Chen, M.; Li, J.; Hu, Z.; Li, G.; Chang, Q.; Shi, K.; Wang, X.; et al. Fully Polymeric Conductive Hydrogels with Low Hysteresis and High Toughness as Multi-Responsive and Self-Powered Wearable Sensors. Adv. Funct. Mater. 2024, 34, 2316346. [Google Scholar] [CrossRef]

- Zhang, H.; Xue, K.; Xu, X.; Wang, X.; Wang, B.; Shao, C.; Sun, R. Green and Low-cost Alkali-polyphenol Synergetic Self-catalysis System Access to Fast Gelation of Self-healable and Self-adhesive Conductive Hydrogels for Self-powered Triboelectric Nanogenerators. Small 2024, 20, 2305502. [Google Scholar] [CrossRef]

- Tan, X.; Huang, Z.; Pei, H.; Jia, Z.; Zheng, J. Highly Porous, Ultralight, Biocompatible Silk Fibroin Aerogel-Based Triboelectric Nanogenerator. ACS Sensors 2024, 9, 3938–3946. [Google Scholar] [CrossRef]

- Rahman, M.T.; Rahman, M.S.; Kumar, H.; Kim, K.; Kim, S. Metal-Organic Framework Reinforced Highly Stretchable and Durable Conductive Hydrogel-Based Triboelectric Nanogenerator for Biomotion Sensing and Wearable Human-Machine Interfaces. Adv. Funct. Mater. 2023, 33, 2303471. [Google Scholar] [CrossRef]

- Kim, J.-N.; Lee, J.; Lee, H.; Oh, I.-K. Stretchable and self-healable catechol-chitosan-diatom hydrogel for triboelectric generator and self-powered tremor sensor targeting at Parkinson disease. Nano Energy 2021, 82, 105705. [Google Scholar] [CrossRef]

- Bagchi, B.; Datta, P.; Fernandez, C.S.; Xu, L.; Gupta, P.; Huang, W.; David, A.L.; Siassakos, D.; Homer-Vanniasinkam, S.; Tiwari, M.K. A stretchable, self-healing and semi-transparent nanogenerator for energy harvesting and sensing. Nano Energy 2023, 107, 108127. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, Z.; Xu, B. Flexible Triboelectric Nanogenerators based on Hydrogel/g-C3N4 Composites for Biomechanical Energy Harvesting and Self-Powered Sensing. ACS Appl. Mater. Interfaces 2024, 16, 13674–13684. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, J.; Deng, Y.; Yu, H.; Zhao, H.; Guo, J.; Zhang, P.; Dang, S.; Liu, D.; Wang, D.; et al. Self-contact-electrification aerogel for all-in-one triboelectricity generation. Nano Energy 2024, 126, 109693. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, W.; Wang, Y.; Wu, C.; Chen, H.; Lyu, G.; Ma, J.; Ni, Y.; Liu, Y. Preparation of strong and tough conductive hydrogel based on Grafting, Fe3+-Catechol complexations and salting out for triboelectric nanogenerators. J. Colloid Interface Sci. 2024, 661, 450–459. [Google Scholar] [CrossRef]

- Zhao, L.; Ling, Q.; Fan, X.; Gu, H. Self-Healable, Adhesive, Anti-Drying, Freezing-Tolerant, and Transparent Conductive Organohydrogel as Flexible Strain Sensor, Triboelectric Nanogenerator, and Skin Barrier. ACS Appl. Mater. Interfaces 2023, 15, 40975–40990. [Google Scholar] [CrossRef]

- Peng, H.; Xin, Y.; Xu, J.; Liu, H.; Zhang, J. Ultra-stretchable hydrogels with reactive liquid metals as asymmetric force-sensors. Mater. Horiz. 2019, 6, 618–625. [Google Scholar] [CrossRef]

- Wang, M.; Chen, H.; Li, X.; Wang, G.; Peng, C.; Wang, W.; Zhang, F.; Wang, J.; Liu, H.; Yan, G.; et al. An extremely transparent and multi-responsive healable hydrogel strain sensor. J. Mater. Chem. A 2022, 10, 24096–24105. [Google Scholar] [CrossRef]

- Park, J.; Jeon, N.; Lee, S.; Choe, G.; Lee, E.; Lee, J.Y. Conductive hydrogel constructs with three-dimensionally connected graphene networks for biomedical applications. Chem. Eng. J. 2022, 446, 137344. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, S.; Qian, L.; Wei, N.; Nica, V.; Coseri, S.; Han, F. Super Stretchable, Self-Healing, Adhesive Ionic Conductive Hydrogels Based on Tailor-Made Ionic Liquid for High-Performance Strain Sensors. Adv. Funct. Mater. 2022, 32, 202204565. [Google Scholar] [CrossRef]

- Sui, X.; Guo, H.; Cai, C.; Li, Q.; Wen, C.; Zhang, X.; Wang, X.; Yang, J.; Zhang, L. Ionic conductive hydrogels with long-lasting antifreezing, water retention and self-regeneration abilities. Chem. Eng. J. 2021, 419, 129478. [Google Scholar] [CrossRef]

- Guo, X.; Facchetti, A. The journey of conducting polymers from discovery to application. Nat. Mater. 2020, 19, 922–928. [Google Scholar] [CrossRef]

- Gan, D.; Han, L.; Wang, M.; Xing, W.; Xu, T.; Zhang, H.; Wang, K.; Fang, L.; Lu, X. Conductive and Tough Hydrogels Based on Biopolymer Molecular Templates for Controlling in Situ Formation of Polypyrrole Nanorods. ACS Appl. Mater. Interfaces 2018, 10, 36218–36228. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Chen, Y.; Gao, C.; Li, J.; Bai, Z.; Guo, J. In situ synthesis of highly stretchable, freeze-tolerant silk-polyelectrolyte double-network hydrogels for multifunctional flexible sensing. Chem. Eng. J. 2022, 446, 137405. [Google Scholar] [CrossRef]

- Hu, S.; Han, J.; Shi, Z.; Chen, K.; Xu, N.; Wang, Y.; Zheng, R.; Tao, Y.; Sun, Q.; Wang, Z.L.; et al. Biodegradable, Super-Strong, and Conductive Cellulose Macrofibers for Fabric-Based Triboelectric Nanogenerator. Nano-Micro Lett. 2022, 14, 115. [Google Scholar] [CrossRef]

- Yue, J.; Li, C.; Ji, X.; Tao, Y.; Lu, J.; Cheng, Y.; Du, J.; Wang, H. Highly tough and conductive hydrogel based on defect-patched reduction graphene oxide for high-performance self-powered flexible sensing micro-system. Chem. Eng. J. 2023, 466, 143358. [Google Scholar] [CrossRef]

- Huang, T.; Long, Y.; Dong, Z.; Hua, Q.; Niu, J.; Dai, X.; Wang, J.; Xiao, J.; Zhai, J.; Hu, W. Ultralight, Elastic, Hybrid Aerogel for Flexible/Wearable Piezoresistive Sensor and Solid–Solid/Gas–Solid Coupled Triboelectric Nanogenerator. Adv. Sci. 2022, 9, e2204519. [Google Scholar] [CrossRef] [PubMed]

- Lai, B.-Y.; Lai, S.-N.; Lin, H.-Y.; Wu, J.M. Silane-modified MXene/PVA hydrogel for enhanced streaming vibration potential in high-performance flexible triboelectric nanogenerators. Nano Energy 2024, 125, 109554. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D.; Wang, Z.; Xi, G.; Mao, R.; Ma, Y.; Wang, D.; Tang, M.; Xu, Z.; Luan, H. Ultrastretchable, Self-Healing Conductive Hydrogel-Based Triboelectric Nanogenerators for Human–Computer Interaction. ACS Appl. Mater. Interfaces 2023, 15, 5128–5138. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Jin, X.; Wang, Q.; Zhang, Q.; Yuan, H.; Jiao, T.; Cao, X.; Ma, J. A transparent, flexible triboelectric nanogenerator for anti-counterfeiting based on photothermal effect. Matter 2023, 6, 1514–1529. [Google Scholar] [CrossRef]

- Yan, R.; Sun, Q.; Shi, X.; Sun, Z.; Tan, S.; Tang, B.; Chen, W.; Liang, F.; Yu, H.-D.; Huang, W. Skin-interfaced self-powered pressure and strain sensors based on fish gelatin-based hydrogel for wireless wound strain and human motion detection. Nano Energy 2023, 118, 108932. [Google Scholar] [CrossRef]

- Yu, H.; Kong, J.; Mao, M.; Ge, X.; Sun, Y.; Liu, J.; Ye, J.; Wang, Y. Self-powered biodegradable and antibacterial MoS2-based triboelectric nanogenerators for the acceleration of wound healing in diabetes. Nano Energy 2024, 121, 109225. [Google Scholar] [CrossRef]

- Shen, S.; Fu, J.; Yi, J.; Ma, L.; Sheng, F.; Li, C.; Wang, T.; Ning, C.; Wang, H.; Dong, K.; et al. High-Efficiency Wastewater Purification System Based on Coupled Photoelectric–Catalytic Action Provided by Triboelectric Nanogenerator. Nano-Micro Lett. 2021, 13, 194. [Google Scholar] [CrossRef]

- Guo, F.; Jiang, Y.; Xu, Z.; Xiao, Y.; Fang, B.; Liu, Y.; Gao, W.; Zhao, P.; Wang, H.; Gao, C. Highly stretchable carbon aerogels. Nat. Commun. 2018, 9, 881. [Google Scholar] [CrossRef]

- Pekala, R.W.; Kong, F.M. A Synthetic Route to Organic Aerogels—Mechanism, Structure, and Properties. J. Phys. Colloq. 1989, 24, C4-33–C4-40. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, C.; Fang, L.; Cao, B.; Tu, X.; Zhang, R.; Dong, K.; Lai, Y.-C.; Wang, P. Biodegradable, conductive, moisture-proof, and dielectric enhanced cellulose-based triboelectric nanogenerator for self-powered human-machine interface sensing. Nano Energy 2023, 107, 108151. [Google Scholar] [CrossRef]

- Zhang, L.; Liao, Y.; Wang, Y.C.; Zhang, S.; Yang, W.; Pan, X.; Wang, Z.L. Cellulose II Aerogel-Based Triboelectric Nanogenerator. Adv. Funct. Mater. 2020, 30, 2001763. [Google Scholar] [CrossRef]

- Mi, H.-Y.; Jing, X.; Cai, Z.; Liu, Y.; Turng, L.-S.; Gong, S. Highly porous composite aerogel based triboelectric nanogenerators for high performance energy generation and versatile self-powered sensing. Nanoscale 2018, 10, 23131–23140. [Google Scholar] [CrossRef] [PubMed]

- Cui, S.; Zhou, L.; Liu, D.; Li, S.; Liu, L.; Chen, S.; Zhao, Z.; Yuan, W.; Wang, Z.L.; Wang, J. Improving performance of triboelectric nanogenerators by dielectric enhancement effect. Matter 2022, 5, 180–193. [Google Scholar] [CrossRef]

- Sun, H.; Yang, B.; Ji, D.; Ma, C.; Pang, R.; Yuan, B.; Liu, J.; Zhang, H.; Zhang, M. Bioinspired Aerogels: Ingenious Structure, Remarkable Performance, and Versatile Applications. J. Mater. Chem. A 2024, 12, 12358–12380. [Google Scholar] [CrossRef]

- Liang, S.; Li, C.; Niu, M.; Zhu, P.; Pan, Z.; Mao, Y. Ionic hydrogels-based triboelectric nanogenerators for self-powered human–machine interfaces. J. Physics Mater. 2023, 7, 012001. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Huang, F.; Wu, S.; Wang, C.-H.; Peng, S. Transparent, stretchable and high-performance triboelectric nanogenerator based on dehydration-free ionically conductive solid polymer electrode. Nano Energy 2021, 88, 106289. [Google Scholar] [CrossRef]

- Zhu, Q.; Liao, W.; Sun, C.; Qin, X.; Zhang, F.; Ji, H.; Li, Y.; Wen, Z.; Sun, X. Highly stretchable, conductive, and wide-operating temperature ionogel based wearable triboelectric nanogenerator. Nano Res. 2023, 16, 11638–11645. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, D.; Seong, J.; Bak, B.; Choi, U.H.; Kim, J. Ionic liquid-based molecular design for transparent, flexible, and fire-retardant triboelectric nanogenerator (TENG) for wearable energy solutions. Nano Energy 2021, 84, 105925. [Google Scholar] [CrossRef]

- Zhong, X.; Sun, P.; Wei, R.; Dong, H.; Jiang, S. Object recognition by a heat-resistant core-sheath triboelectric nanogenerator sensor. J. Mater. Chem. A 2022, 10, 15080–15088. [Google Scholar] [CrossRef]

- Wu, S.; Kan, H.; Gao, J.; Yue, W.; Zhang, C.; Gao, S.; Li, Y. Convolutional Neural Networks-motivated High-performance Multi-functional Electronic Skin for Intelligent Human-computer Interaction. Nano Energy 2024, 122, 109313. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Y.; Jiang, W.; Liu, Q.; Wang, X.; Zhang, J.; Zhou, Z.; Zheng, H.; Wang, Z.; Wang, Z.L. A Universal Power Management Strategy Based on Novel Sound-Driven Triboelectric Nanogenerator and Its Fully Self-Powered Wireless System Applications. Adv. Funct. Mater. 2021, 31, 2103081. [Google Scholar] [CrossRef]

- Duan, H.; Zhang, Y.; Zhang, Y.; Zhu, P.; Mao, Y. Recent Advances of Stretchable Nanomaterial-Based Hydrogels for Wearable Sensors and Electrophysiological Signals Monitoring. Nanomaterials 2024, 14, 1398. [Google Scholar] [CrossRef]

- Sun, X.; Yuan, J.; Zhu, Q.; Sun, Y.; Chen, H.; Liao, S.; Yan, J.; Cai, J.; Wei, Y.; Luo, L. Wood Fiber-Based Triboelectric Material with High Filtration Efficiency and Antibacterial Properties and Its Respiratory Monitoring in Mask. ACS Omega 2024, 9, 33643–33651. [Google Scholar] [CrossRef]

- Song, B.; Fan, X.; Shen, J.; Gu, H. Ultra-stable and self-healing coordinated collagen-based multifunctional double-network organohydrogel e-skin for multimodal sensing monitoring of strain-resistance, bioelectrode, and self-powered triboelectric nanogenerator. Chem. Eng. J. 2023, 474, 145780. [Google Scholar] [CrossRef]

- Fan, X.; Ke, T.; Gu, H. Multifunctional, Ultra-Tough Organohydrogel E-Skin Reinforced by Hierarchical Goatskin Fibers Skeleton for Energy Harvesting and Self-Powered Monitoring. Adv. Funct. Mater. 2023, 33, 2304015. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Sun, S.; He, T.; Hu, Q.; Yang, Y.; Yuan, G. Flexible and Ultrasensitive Piezoelectric Composites Based on Highly (00l)-Assembled BaTiO3 Microplatelets for Wearable Electronics Application. Adv. Mater. Technol. 2019, 4, 1900689. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J.; Ding, X. Highly Compressible, Thermally Stable, Light-Weight, and Robust Aramid Nanofibers/Ti3AlC2 MXene Composite Aerogel for Sensitive Pressure Sensor. ACS Nano 2020, 14, 10633–10647. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Xu, Z.; Li, L.; Wei, J.; Wang, W.; Yan, Z.; Chen, T. Breakage-resistant hydrogel electrode enables ultrahigh mechanical reliability for triboelectric nanogenerators. Chem. Eng. J. 2023, 454, 140261. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Q.; Wan, X.; Yang, M.; Liu, C.; Xu, C.; Hu, B.; Feng, J.; Luo, Z. Wireless electrical stimulation of the vagus nerves by ultrasound-responsive programmable hydrogel nanogenerators for anti-inflammatory therapy in sepsis. Nano Energy 2021, 89, 106327. [Google Scholar] [CrossRef]

- Pu, X.; Liu, M.; Chen, X.; Sun, J.; Du, C.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Ultrastretchable, transparent triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and tactile sensing. Sci. Adv. 2017, 3, e1700015. [Google Scholar] [CrossRef]

- Qian, Z.; Li, R.; Guo, J.; Wang, Z.; Li, X.; Li, C.; Zhao, N.; Xu, J. Triboelectric nanogenerators made of polybenzazole aerogels as fire-resistant negative tribo-materials. Nano Energy 2019, 64, 103900. [Google Scholar] [CrossRef]

- He, H.; Qin, Y.; Liu, J.; Wang, Y.; Wang, J.; Zhao, Y.; Zhu, Z.; Jiang, Q.; Wan, Y.; Qu, X.; et al. A wearable self-powered fire warning e-textile enabled by aramid nanofibers/MXene/silver nanowires aerogel fiber for fire protection used in firefighting clothing. Chem. Eng. J. 2023, 460, 141661. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, W.; Liu, T.; Luo, B.; Cai, C.; Chi, M.; Zhang, S.; Liu, Y.; Wang, J.; Zhao, J.; et al. Hierarchical porous triboelectric aerogels enabled by heterointerface engineering. Nano Energy 2024, 121, 109223. [Google Scholar] [CrossRef]

- Jing, T.; Xu, B.; Yang, Y.; Li, M.; Gao, Y. Organogel electrode enables highly transparent and stretchable triboelectric nanogenerators of high power density for robust and reliable energy harvesting. Nano Energy 2020, 78, 105373. [Google Scholar] [CrossRef]

- Hu, K.; Zhao, Z.; Wang, Y.; Yu, L.; Liu, K.; Wu, H.; Huang, L.; Chen, L.; Ni, Y. A tough organohydrogel-based multiresponsive sensor for a triboelectric nanogenerator and supercapacitor toward wearable intelligent devices. J. Mater. Chem. A 2022, 10, 12092–12103. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, J.; Li, C.; Yang, J.; Li, H.; Jiang, T.; Chen, B. Double-Network Hydrogel for Stretchable Triboelectric Nanogenerator and Integrated Electroluminescent Skin with Self-Powered Rapid Visual Sensing. Electronics 2022, 11, 1928. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, R.; Wang, R.; Chen, B.; Li, H.; Shen, A.; Mao, Y. Recent advances in stretchable hydrogel-based triboelectric nanogenerators for on-skin electronics. Mater. Chem. Front. 2024, 8, 4003–4028. [Google Scholar] [CrossRef]

- Cheong, J.Y.; Koay, J.S.C.; Chen, R.; Aw, K.C.; Velayutham, T.S.; Chen, B.; Li, J.; Foo, C.Y.; Gan, W.C. Maximizing the output power density enhancement of solid polymer electrolyte based-triboelectric nanogenerators via contact electrification-induced ionic polarization. Nano Energy 2021, 90, 106616. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Wang, S.; Wang, J.; Cheng, F.; Tong, Y.; Wei, L.; Fang, Z.; Mao, J. Fundamentals and design strategies of electrolytes for high-temperature zinc-ion batteries. Energy Storage Mater. 2024, 70, 103471. [Google Scholar] [CrossRef]

- Thombre, A.V.; Kundu, D. A-priori framework of viscosity and ionic conductivity estimation of ionogel. Next Res. 2024, 1, 100029. [Google Scholar] [CrossRef]

- Bari, G.A.K.M.R.; Jeong, J.-H.; Barai, H.R. Conductive Gels for Energy Storage, Conversion, and Generation: Materials Design Strategies, Properties, and Applications. Materials 2024, 17, 2268. [Google Scholar] [CrossRef]

- Najafloo, M.; Naji, L. The electrochemical and physicochemical impacts of sodium chloride on the formation of a self-healing double network hydrogel using two methods—Post-treatment and in situ integration. Sustain. Energy Fuels 2025, e11382. [Google Scholar] [CrossRef]

- Li, X.; Cao, C.; Yuan, D.; Liu, Q.; Zhao, J. Effects of the Incorporation of Calcium Chloride on the Physical and Oxidative Stability of Filled Hydrogel Particles. Foods 2022, 11, 278. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Shi, W.; Yan, K.; Pan, L.; Yu, G. Doping engineering of conductive polymer hydrogels and their application in advanced sensor technologies. Chem. Sci. 2019, 10, 6232–6244. [Google Scholar] [CrossRef]

- Chen, T.; Liu, A.; Lei, W.; Wu, G.; Xiang, J.; Dong, Y.; Chen, Y.; Chen, B.; Ye, M.; Zhao, J.; et al. Anti-Freezing Conductive Ionic Hydrogel-Enabled Triboelectric Nanogenerators for Wearable Speech Recognition. Materials 2025, 18, 2014. [Google Scholar] [CrossRef]

- Fan, X.; Liu, S.; Jia, Z.; Koh, J.J.; Yeo, J.C.C.; Wang, C.-G.; Surat’MAn, N.E.; Loh, X.J.; Le Bideau, J.; He, C.; et al. Ionogels: Recent advances in design, material properties and emerging biomedical applications. Chem. Soc. Rev. 2023, 52, 2497–2527. [Google Scholar] [CrossRef]

- Tang, J.; Muchakayala, R.; Song, S.; Wang, M.; Kumar, K.N. Effect of EMIMBF4 ionic liquid addition on the structure and ionic conductivity of LiBF4-complexed PVdF-HFP polymer electrolyte films. Polym. Test. 2016, 50, 247–254. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, W.; Ge, X.; Liang, J.; Xing, Z.; Zhang, Q.; Wang, Z.-X. A flexible, highly conductive, tough ionogel electrolyte containing LiTFSI salt and ionic liquid [EMIM][TFSI] based on PVDF-HFP for high-performance supercapacitors. Polymer 2023, 289, 126501. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, T.; Zheng, C.; Zhang, H.; Xia, Y.; He, Y. Ultra-stable ionogels based on hydrogen networks with broad temperature, environment, and long-term stability. Mater. Today Chem. 2024, 40, 102275. [Google Scholar] [CrossRef]

- Patel, V.; Das, E.; Bhargava, A.; Deshmukh, S.; Modi, A.; Srivastava, R. Ionogels for flexible conductive substrates and their application in biosensing. Int. J. Biol. Macromol. 2024, 254, 127736. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, S.; Li, L.; Wang, X.; Xiong, J.; Li, Q.; Li, W.; Yan, F. Glassy ionogels with high compressibility and strength for impact protection. Proc. Natl. Acad. Sci. USA 2025, 122, e2417978122. [Google Scholar] [CrossRef] [PubMed]

- Noor, S.A.M.; Bayley, P.M.; Forsyth, M.; MacFarlane, D.R. Ionogels based on ionic liquids as potential highly conductive solid state electrolytes. Electrochim. Acta 2013, 91, 219–226. [Google Scholar] [CrossRef]

- Entifar, N.A.E.; Kim, G.W.; Entifar, S.A.N.; Oh, J.; Lee, J.; Lim, D.C.; Kim, S.; Kim, M.-S.; Kim, Y.H. High-performance PVA/xanthan gum hydrogel via dual cross-linking with ionic treatment for wearable sensing and hydrovoltaic energy generation. Chem. Eng. J. 2025, 520, 165637. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Liu, Y.; Odent, J.; Takeoka, Y. Covalent design of ionogels: Bridging with hydrogels and covalent adaptable networks. Polym. Chem. 2025, 16, 2327–2357. [Google Scholar] [CrossRef]

- Han, D.; Wang, G.; Xu, X.; Chen, J.; Lu, M.; Liu, X.; Zhang, L.; Lai, L. Ultra-stretchable, self-healing, bonding, and skin-inspired conductive triple network hydrogel for wearable strain sensors and friction nanogenerators. Polymer 2024, 305, 127169. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, X.; Xu, Q.; Zhang, L.; Safaa, N.; Ibrahim, M.; Zhang, J.; El-Bahy, Z.; Guo, N.; Gao, J.; et al. Poly(vinyl alcohol)/polyacrylamide double-network ionic conductive hydrogel strain sensor with high sensitivity and high elongation at break. J. Polym. Sci. 2024, 62, 4599–4611. [Google Scholar] [CrossRef]

- Aazem, I.; Mathew, D.T.; Radhakrishnan, S.; Vijoy, K.V.; John, H.; Mulvihill, D.M.; Pillai, S.C. Electrode materials for stretchable triboelectric nanogenerator in wearable electronics. RSC Adv. 2022, 12, 10545–10572. [Google Scholar] [CrossRef]

- Marsden, A.J.; Papageorgiou, D.G.; Vallés, C.; Liscio, A.; Palermo, V.; Bissett, M.A.; Young, R.J.; Kinloch, I.A. Electrical percolation in graphene–polymer composites. 2D Mater. 2018, 5, 032003. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Jiang, Z.; Liu, Y.; Zhou, L.; Liu, Z.; Tang, L. Recent Advances of Conductive Hydrogels for Flexible Electronics. Electron. Mater. 2024, 5, 101–131. [Google Scholar] [CrossRef]

- Mishra, V.; Alagumalai, K.; Kim, S.-C.; Almutairi, T.M. Hybrid polypyrrole/poly(3,4-ethylenedioxythiophene) polystyrene sulfonate flexible electrode for monoamine transmitter serotonin in human fluids. Chem. Eng. J. 2025, 503, 158341. [Google Scholar] [CrossRef]

- McCord, M.R.; Seppälä, A.; Pourakbari-Kasmaei, M.; Zimmerman, J.B.; Rojas, O.J. From low conductivity to high energy efficiency: The role of conductive polymers in phase change materials. Chem. Eng. J. 2025, 508, 160804. [Google Scholar] [CrossRef]

- Matias, M.L.; Pereira, C.; Almeida, H.V.; Jana, S.; Panigrahi, S.; Menda, U.D.; Nunes, D.; Fortunato, E.; Martins, R.; Nandy, S. 3D printed MXene architectures for a plethora of smart applications. Mater. Today Adv. 2024, 23, 100512. [Google Scholar] [CrossRef]

- Ghorbanzadeh, S.; Zhang, W. Advances in MXene-based triboelectric nanogenerators. Nano Energy 2024, 125, 109558. [Google Scholar] [CrossRef]

- Shin, Y.; Lee, H.S.; Jeong, H.; Kim, D.-H. Recent advances in conductive hydrogels for soft biointegrated electronics: Materials, properties, and device applications. Wearable Electron. 2024, 1, 255–280. [Google Scholar] [CrossRef]

- Khandaker, T.; Anik, M.A.A.M.; Nandi, A.; Islam, T.; Islam, M.M.; Hasan, M.K.; Dhar, P.K.; Latif, M.A.; Hossain, M.S. Recent progress in gel catalysts: Boosting efficiency for sustainable energy applications. Catal. Sci. Technol. 2025, 15, 1357–1389. [Google Scholar] [CrossRef]

- Wang, M.; Li, L.; Zhang, T. Hysteresis-free, fatigue-resistant and self-adhesive conductive hydrogel electronics towards multimodal wearable application. Nano Energy 2024, 126, 109586. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, Y.; Tian, Y.; Nabavi, N.; Ashrafizadeh, M.; Conde, J.; Li, Z.; Guo, L. Conductive polymers in smart wound healing: From bioelectric stimulation to regenerative therapies. Mater. Today Bio 2025, 34, 102114. [Google Scholar] [CrossRef]

- Kozuki, H.; Yoshida, K.; Yasuga, H.; Kurashina, Y. Hydrogel-polymer hybrid actuator with soft lattice skeleton for excellent connectivity. Sensors Actuators B Chem. 2025, 430, 137377. [Google Scholar] [CrossRef]

- Li, Y.; Tan, S.; Zhang, X.; Li, Z.; Cai, J.; Liu, Y. Design Strategies and Emerging Applications of Conductive Hydrogels in Wearable Sensing. Gels 2025, 11, 258. [Google Scholar] [CrossRef]

- Aljabali, A.A.A.; Alkaraki, A.; Gammoh, O.; Qnais, E.; Alqudah, A.; Mishra, V.; Mishra, Y.; El-Tanani, M. Design, structure, and application of conductive polymer hybrid materials: A comprehensive review of classification, fabrication, and multifunctionality. RSC Adv. 2025, 15, 27493–27523. [Google Scholar] [CrossRef] [PubMed]

- Rumon, M.M.; Rahman Khan, M.M.; Amin, M.K. Design, Synthesis, and Morphological Behavior of Polymer Gel-Based Materials for Thermoelectric Devices: Recent Progress and Perspectives. Gels 2025, 11, 508. [Google Scholar] [CrossRef]

- Gan, N.; Wei, M.; Zhou, Q.; Dong, K.; Gao, B. Silk Fibroin-Based Triboelectric Nanogenerators for Energy Harvesting and Biomedical Applications. ACS Appl. Nano Mater. 2024, 7, 8407–8423. [Google Scholar] [CrossRef]

- Tian, J.; Zhang, J.; Zhang, Y.; Liu, J.; Hu, Y.; Liu, C.; Zhu, P.; Lu, L.; Mao, Y. Recent Advances in Electrospun Nanofiber-Based Self-Powered Triboelectric Sensors for Contact and Non-Contact Sensing. Nanomaterials 2025, 15, 1080. [Google Scholar] [CrossRef]

- Chen, J.; Liu, F.; Abdiryim, T.; Liu, X. An overview of conductive composite hydrogels for flexible electronic devices. Adv. Compos. Hybrid Mater. 2024, 7, 35. [Google Scholar] [CrossRef]

- Algarra, M.; Vinacua, S.; Gil-Korilis, A.; Gil, A. Recent developments in the use of carbon-based nanomaterials in cancer therapy. J. Control. Release 2025, 386, 114100. [Google Scholar] [CrossRef]

- Fritea, L.; Banica, F.; Costea, T.O.; Moldovan, L.; Dobjanschi, L.; Muresan, M.; Cavalu, S. Metal Nanoparticles and Carbon-Based Nanomaterials for Improved Performances of Electrochemical (Bio)Sensors with Biomedical Applications. Materials 2021, 14, 6319. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.; Ji, S.; Cho, H.; Park, J. Highly Flexible Triboelectric Nanogenerator Using Porous Carbon Nanotube Composites. Polymers 2023, 15, 1135. [Google Scholar] [CrossRef]

- Wang, H.; Shi, M.; Zhu, K.; Su, Z.; Cheng, X.; Song, Y.; Chen, X.; Liao, Z.; Zhang, M.; Zhang, H. High performance triboelectric nanogenerators with aligned carbon nanotubes. Nanoscale 2016, 8, 18489–18494. [Google Scholar] [CrossRef]

- Li, S.; Xu, Z.; Meng, R.; Wen, E.; Peng, Q. MXene-based functional nanomaterials and their applications in cancer diagnosis and therapy. Precis. Med. Eng. 2025, 2, 100029. [Google Scholar] [CrossRef]

- Wicklein, B.; Valurouthu, G.; Yoon, H.; Yoo, H.; Ponnan, S.; Mahato, M.; Kim, J.; Ali, S.S.; Park, J.Y.; Gogotsi, Y.; et al. Influence of MXene Composition on Triboelectricity of MXene-Alginate Nanocomposites. ACS Appl. Mater. Interfaces 2024, 16, 23948–23959. [Google Scholar] [CrossRef]

- Wang, J.; Xia, G.; Xia, L.; Chen, Y.; Li, Q.; Zeng, H.; Yang, W.; Du, Y.; He, W.; Chen, Y. HCNT/AgNPs/PVA/PAM hydrogel-based flexible pressure sensor for physiological monitoring. J. Mater. Sci. Mater. Electron. 2024, 35, 1931. [Google Scholar] [CrossRef]

- Deng, S.; Akram, W.; Ye, X.; Zhang, L.; Yang, Y.; Cheng, S.; Fang, J. Comprehensive Insights on MXene-Based TENGs: From Structures, Functions to Applications. Small 2024, 20, e2404872. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Li, Z.; Hu, H.; Chen, B.; Wang, Y.; Mao, Y.; Li, H.; Zhang, B. Recent Progress in Self-Healing Triboelectric Nanogenerators for Artificial Skins. Biosensors 2025, 15, 37. [Google Scholar] [CrossRef]

- Zhao, Z.; Cao, X.; Wang, N. Beyond energy harvesting: A review on the critical role of MXene in triboelectric nanogenerator. Energy Mater. 2024, 4, 400035. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, G.; Yang, J.; Zhou, A. MXenes in triboelectric nanogenerators (TENGs): Present status and the future. J. Adv. Ceram. 2025, 14, 9221087. [Google Scholar] [CrossRef]

- Almansoori, A.; Balázsi, K.; Balázsi, C. Advances, Challenges, and Applications of Graphene and Carbon Nanotube-Reinforced Engineering Ceramics. Nanomaterials 2024, 14, 1881. [Google Scholar] [CrossRef]

- Song, Y.; Ao, Q.; Jiang, T.; Tong, X.; Ding, R.; Li, X.; Tang, J. Sustainable and high performance MXene hydrogel with interlocked structure for machine learning-facilitated human-interactive sensing. Chem. Eng. J. 2024, 499, 156432. [Google Scholar] [CrossRef]

- Zhao, X.; Jiang, H.; Sun, P.; Wei, R.; Jiang, S.; Hu, J.; Zhang, S. Multifunction E-Skin Based on MXene–PA–Hydrogel for Human Behavior Monitoring. ACS Appl. Mater. Interfaces 2023, 15, 56275–56284. [Google Scholar] [CrossRef]

- Das, P.; Marvi, P.K.; Ganguly, S.; Tang, X.; Wang, B.; Srinivasan, S.; Rajabzadeh, A.R.; Rosenkranz, A. MXene-Based Elastomer Mimetic Stretchable Sensors: Design, Properties, and Applications. Nano-Micro Lett. 2024, 16, 135. [Google Scholar] [CrossRef]

- Priya, A.S.; Kannan, K.; Henry, J.; Aepuru, R.; Shanmugaraj, K.; Pabba, D.P.; Sathish, M. Advancements in hydrogel materials for next-generation energy devices: Properties, applications, and future prospects. Cellulose 2025, 32, 6307–6335. [Google Scholar] [CrossRef]

- Jia, L.; Jiang, J.; Ren, A.; Wei, Z.; Xiang, T.; Zhou, S. Ultra-fast cryogenic self-healing ionic hydrogel for flexible wearable bioelectronics. Chem. Eng. J. 2024, 495, 153734. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, H.; Zhang, Y.; Yang, J.; Chen, Q.; Wu, J.; Liu, Y.; Zhao, C.; Tang, Y.; Zheng, J. Antifreezing hydrogels: From mechanisms and strategies to applications. Chem. Soc. Rev. 2025, 54, 5292–5341. [Google Scholar] [CrossRef]

- Huang, S.; Wang, W.; Yang, C.; Liu, J.; Li, K.; Zhou, L.; Zhang, H.; Zhang, D. Highly Stretchable Conductive Hydrogel-Based Flexible Triboelectric Nanogenerators for Ultrasensitive Tactile Sensing. Polymers 2025, 17, 342. [Google Scholar] [CrossRef] [PubMed]

- Ba, Y.-Y.; Bao, J.-F.; Liu, X.-T.; Li, X.-W.; Deng, H.-T.; Wen, D.-L.; Zhang, X.-S. Electron-Ion Coupling Mechanism to Construct Stable Output Performance Nanogenerator. Research 2021, 2021, 9817062. [Google Scholar] [CrossRef] [PubMed]

- Cheng, T.; Shao, J.; Wang, Z.L. Triboelectric Nanogenerators. Nat. Rev. Methods Prim. 2023, 3, 39. [Google Scholar] [CrossRef]

- Sun, G.; Wang, P.; Jiang, Y.; Sun, H.; Meng, C.; Guo, S. Recent advances in flexible and soft gel-based pressure sensors. Soft Sci. 2022, 2, 17. [Google Scholar] [CrossRef]

- Wang, C.; Qu, X.; Zheng, Q.; Liu, Y.; Tan, P.; Shi, B.; Ouyang, H.; Chao, S.; Zou, Y.; Zhao, C.; et al. Stretchable, Self-Healing, and Skin-Mounted Active Sensor for Multipoint Muscle Function Assessment. ACS Nano 2021, 15, 10130–10140. [Google Scholar] [CrossRef]

- Chen, Y.; Pu, X.; Liu, M.; Kuang, S.; Zhang, P.; Hua, Q.; Cong, Z.; Guo, W.; Hu, W.; Wang, Z.L. Shape-Adaptive, Self-Healable Triboelectric Nanogenerator with Enhanced Performances by Soft Solid–Solid Contact Electrification. ACS Nano 2019, 13, 8936–8945. [Google Scholar] [CrossRef] [PubMed]

- Pradel, K.C.; Fukata, N. Systematic optimization of triboelectric nanogenerator performance through surface micropatterning. Nano Energy 2021, 83, 105856. [Google Scholar] [CrossRef]

- Ibrahim, M.; Jiang, J.; Wen, Z.; Sun, X. Surface Engineering for Enhanced Triboelectric Nanogenerator. Nanoenergy Adv. 2021, 1, 58–80. [Google Scholar] [CrossRef]

- Fan, F.-R.; Lin, L.; Zhu, G.; Wu, W.; Zhang, R.; Wang, Z.L. Transparent Triboelectric Nanogenerators and Self-Powered Pressure Sensors Based on Micropatterned Plastic Films. Nano Lett. 2012, 12, 3109–3114. [Google Scholar] [CrossRef]

- Sun, J.-G.; Yang, T.N.; Kuo, I.-S.; Wu, J.-M.; Wang, C.-Y.; Chen, L.-J. A leaf-molded transparent triboelectric nanogenerator for smart multifunctional applications. Nano Energy 2017, 32, 180–186. [Google Scholar] [CrossRef]

- Rasel, M.S.U.; Park, J.-Y. A sandpaper assisted micro-structured polydimethylsiloxane fabrication for human skin based triboelectric energy harvesting application. Appl. Energy 2017, 206, 150–158. [Google Scholar] [CrossRef]

- Pandey, P.; Maharjan, P.; Seo, M.-K.; Thapa, K.; Sohn, J.I.; Roy, S. Recent Progress in Wearable Triboelectric Nanogenerator for Advanced Health Monitoring and Rehabilitation. Int. J. Energy Res. 2024, 2024, 5572736. [Google Scholar] [CrossRef]

- Yi, Z.; Lin, M.; Jiang, W.; Zhang, Z.; Li, H.; Gao, J. Pore network extraction from pore space images of various porous media systems. Water Resour. Res. 2017, 53, 3424–3445. [Google Scholar] [CrossRef]

- Mi, Y.; Zhao, Z.; Wu, H.; Lu, Y.; Wang, N. Porous Polymer Materials in Triboelectric Nanogenerators: A Review. Polymers 2023, 15, 4383. [Google Scholar] [CrossRef]

- Lei, H.; Ji, H.; Liu, X.; Lu, B.; Xie, L.; Lim, E.G.; Tu, X.; Liu, Y.; Zhang, P.; Zhao, C.; et al. Self-Assembled Porous-Reinforcement Microstructure-Based Flexible Triboelectric Patch for Remote Healthcare. Nano-Micro Lett. 2023, 15, 109. [Google Scholar] [CrossRef]

- Liao, J.; Dai, X.; Han, J.; Yang, J.; Wu, Y.; Cao, Y.; Qiu, Y.; Wang, Y.; Huang, L.-B.; Ni, H.; et al. Tunable and hierarchically porous self-powered sensor with high sensitivity. Nano Energy 2024, 121, 109252. [Google Scholar] [CrossRef]

- Haleem, A.; Haider, Z.; Ahmad, R.U.S.; Claver, U.P.; Shah, A.; Zhao, G.; He, W. Highly porous and thermally stable tribopositive hybrid bimetallic cryogel to boost up the performance of triboelectric nanogenerators. Int. J. Energy Res. 2020, 44, 8442–8454. [Google Scholar] [CrossRef]

- Rajaboina, R.K.; Khanapuram, U.K.; Kulandaivel, A. 2D Layered Materials Based Triboelectric Self-Powered Sensors. Adv. Sens. Res. 2024, 3, 2400045. [Google Scholar] [CrossRef]

- Wu, C.; Kim, T.W.; Choi, H.Y. Reduced graphene-oxide acting as electron-trapping sites in the friction layer for giant triboelectric enhancement. Nano Energy 2017, 32, 542–550. [Google Scholar] [CrossRef]

- Wu, C.; Kim, T.W.; Park, J.H.; An, H.; Shao, J.; Chen, X.; Wang, Z.L. Enhanced Triboelectric Nanogenerators Based on MoS2 Monolayer Nanocomposites Acting as Electron-Acceptor Layers. ACS Nano 2017, 11, 8356–8363. [Google Scholar] [CrossRef]

- Wen, R.; Guo, J.; Yu, A.; Zhang, K.; Kou, J.; Zhu, Y.; Zhang, Y.; Li, B.-W.; Zhai, J. Remarkably enhanced triboelectric nanogenerator based on flexible and transparent monolayer titania nanocomposite. Nano Energy 2018, 50, 140–147. [Google Scholar] [CrossRef]

- Yi, F.; Zhang, Z.; Kang, Z.; Liao, Q.; Zhang, Y. Recent Advances in Triboelectric Nanogenerator-Based Health Monitoring. Adv. Funct. Mater. 2019, 29, 1808849. [Google Scholar] [CrossRef]

- Gao, F.; Liu, C.; Zhang, L.; Liu, T.; Wang, Z.; Song, Z.; Cai, H.; Fang, Z.; Chen, J.; Wang, J.; et al. Wearable and flexible electrochemical sensors for sweat analysis: A review. Microsyst. Nanoeng. 2023, 9, 1. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Huang, X.; Shi, R.; Yang, Y.; Wu, P.; Zhou, J.; He, X.; Li, J.; Zen, Y.; Jiao, Y.; et al. Triboelectric Nanogenerator Enabled Sweat Extraction and Power Activation for Sweat Monitoring. Adv. Funct. Mater. 2024, 34, 2310777. [Google Scholar] [CrossRef]

- Lin, P.-H.; Sheu, S.-C.; Chen, C.-W.; Huang, S.-C.; Li, B.-R. Wearable hydrogel patch with noninvasive, electrochemical glucose sensor for natural sweat detection. Talanta 2022, 241, 123187. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Yu, M.; Zhang, H.; Li, N.; Du, J.; Xu, L.; Xu, J. Triboelectric nanogenerator based on well-dispersed and oxide-free liquid metal-doped conductive hydrogel as self-powered wearable sensor for respiratory and thyroid cartilage signal monitoring. Nano Energy 2025, 134, 110530. [Google Scholar] [CrossRef]

- Fu, Q.; Liu, Y.; Liu, T.; Mo, J.; Zhang, W.; Zhang, S.; Luo, B.; Wang, J.; Qin, Y.; Wang, S.; et al. Air-permeable cellulosic triboelectric materials for self-powered healthcare products. Nano Energy 2022, 102, 107739. [Google Scholar] [CrossRef]

- Long, Y.; Jiang, B.; Huang, T.; Liu, Y.; Niu, J.; Wang, Z.L.; Hu, W. Super-Stretchable, Anti-Freezing, Anti-Drying Organogel Ionic Conductor for Multi-Mode Flexible Electronics. Adv. Funct. Mater. 2023, 33, 2304625. [Google Scholar] [CrossRef]

- Qian, C.; Li, L.; Gao, M.; Yang, H.; Cai, Z.; Chen, B.; Xiang, Z.; Zhang, Z.; Song, Y. All-printed 3D hierarchically structured cellulose aerogel based triboelectric nanogenerator for multi-functional sensors. Nano Energy 2019, 63, 103885. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, C.; Xia, W.; Yin, X.; Wang, Z.; Fu, X.; Liu, D.; Lv, J.; Liu, R.; Peng, Z.; et al. Strong, flexible and robust aramid nanofibers-based textile-triboelectric nanogenerators for high temperature escape monitoring and multifunctional applications. Nano Energy 2024, 123, 109359. [Google Scholar] [CrossRef]

- Chi, M.; Zhang, S.; Liu, T.; Liu, Y.; Luo, B.; Wang, J.; Cai, C.; Meng, X.; Wang, S.; Duan, Q.; et al. Tunable Anisotropic Structural Aramid Triboelectric Aerogels Enabled by Magnetic Manipulation. Adv. Funct. Mater. 2024, 34, 2310280. [Google Scholar] [CrossRef]

- Park, H.; Oh, S.J.; Kim, D.; Kim, M.; Lee, C.; Joo, H.; Woo, I.; Bae, J.W.; Lee, J.H. Plasticized PVC-Gel Single Layer-Based Stretchable Triboelectric Nanogenerator for Harvesting Mechanical Energy and Tactile Sensing. Adv. Sci. 2022, 9, e2201070. [Google Scholar] [CrossRef]

- Liu, Y.; Wong, T.H.; Huang, X.; Yiu, C.K.; Gao, Y.; Zhao, L.; Zhou, J.; Park, W.; Zhao, Z.; Yao, K.; et al. Skin-integrated, stretchable, transparent triboelectric nanogenerators based on ion-conducting hydrogel for energy harvesting and tactile sensing. Nano Energy 2022, 99, 107442. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Zhang, P.; Chang, C.; Xu, F.; Pu, X. Ultra-stretchable and healable hydrogel-based triboelectric nanogenerators for energy harvesting and self-powered sensing. RSC Adv. 2021, 11, 17437–17444. [Google Scholar] [CrossRef]

- Kaymazlar, E.; Dikbas, C.; Matar, G.H.; Andac, O.; Andac, M. Self-healable and conductive mussel inspired PVA/borax@PDA–LiTFSI hydrogel-based self-adhesive for human motion sensor. Polym. Bull. 2024, 81, 8751–8764. [Google Scholar] [CrossRef]

- Zhao, K.; Lv, H.; Meng, J.; Song, Z.; Meng, C.; Liu, M.; Zhang, D. Triboelectrification-Induced Electricity in Self-Healing Hydrogel for Mechanical Energy Harvesting and Ultra-sensitive Pressure Monitoring. ACS Omega 2022, 7, 18816–18825. [Google Scholar] [CrossRef]

- Han, X.; Jiang, D.; Qu, X.; Bai, Y.; Cao, Y.; Luo, R.; Li, Z. A Stretchable, Self-Healable Triboelectric Nanogenerator as Electronic Skin for Energy Harvesting and Tactile Sensing. Materials 2021, 14, 1689. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Zhao, Y.; Sun, X.; Yuan, Z.; Zheng, G.; Dai, K.; Mi, L.; Pan, C.; Liu, C.; Shen, C. Ultra-stretchable triboelectric nanogenerator as high-sensitive and self-powered electronic skins for energy harvesting and tactile sensing. Nano Energy 2020, 70, 104546. [Google Scholar] [CrossRef]

- Yang, J.; Wang, H. A hydrogel triboelectric nanogenerator with self-healing function to obtain bio-mechanical energy and boxing training monitoring. J. Mater. Sci. Mater. Electron. 2023, 34, 1124. [Google Scholar] [CrossRef]

- Zhang, H.; Li, D.; Ren, Y.; Han, L.; Teng, H. Instant-healing hydrogel-based triboelectric nanogenerator fornon-contact sensing and energy harvesting. Chem. Eng. J. 2025, 511, 161803. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, L.; Yue, O.; Feng, Y.; Zeng, B.; Wu, Y.; Wang, Y.; Wang, J.; Zhao, L.; Wang, X.; et al. Thermal enhancement of gelatin hydrogels for a multimodal sensor and self-powered triboelectric nanogenerator at low temperatures. Adv. Compos. Hybrid Mater. 2023, 6, 112. [Google Scholar] [CrossRef]

- Wang, T.; Liu, Y.; Sun, Z.; Liu, C.; Ma, R.; Chen, Z.; Han, L.; Liu, R.; Liu, Y.; Zhou, Y. Strong flexible conductive hydrogel based on adaptive temperature and humidity characteristics. Surf. Interfaces 2024, 51, 104794. [Google Scholar] [CrossRef]

- Zhao, J.; Shi, Y. Improving the Durability of Triboelectric Nanogenerator BT—Handbook of Triboelectric Nanogenerators; Wang, Z.L., Yang, Y., Zhai, J., Wang, J., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1–37. ISBN 978-3-031-05722-9. [Google Scholar]

- Xiao, L.; Jiang, H.; Zhang, D.; Ou, C.; Lai, J.; Wang, M.; Ma, Y.; Huang, Y. Designing anti-dehydration and ion-conductive tough hydrogels as environment-adaptable strain sensors for e-skin. Chem. Eng. J. 2023, 474, 145944. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, S.; Jin, K.; Cheng, Y.; Li, Y.; Zhao, Y.; Liu, R.; Tian, Y. Advances in polysaccharide-based conductive hydrogel for flexible electronics. Carbohydr. Polym. 2025, 348, 122836. [Google Scholar] [CrossRef]

- Cai, N.; Sun, P.; Jiang, S. Rapid prototyping, customizable multifunctional structure: 3D printing technology promotes the rapid development of TENG. J. Mater. Chem. A 2021, 9, 16255–16280. [Google Scholar] [CrossRef]

- Kazharskaia, M.; Yu, Y.; Chenguang, L. An Advanced Adhesive Electrolyte Hydrogel Intended for Iontophoresis Enhances the Effective Delivery of Glycolic Acid Via Microbeads. Gels 2025, 11, 682. [Google Scholar] [CrossRef]

- Han, Q.; Wang, H.; Wang, J. Multi-Mode/Signal Biosensors: Electrochemical Integrated Sensing Techniques. Adv. Funct. Mater. 2024, 34, 2403122. [Google Scholar] [CrossRef]

- Prasanna, A.P.S.; Anithkumar, M.; Kim, S.-J. Hybrid triboelectric nanogenerators: Revolutionizing the energy harvesting through material diversity and device architecture for different applications. Nano Energy 2024, 131, 110253. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A Comprehensive Review on the State-of-the-Art of Piezoelectric Energy Harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Ro, Y.G.; Na, S.; Kim, J.; Chang, Y.; Lee, S.; Kwak, M.S.; Jung, S.; Ko, H. Iontronics: Neuromorphic Sensing and Energy Harvesting. ACS Nano 2025, 19, 24425–24507. [Google Scholar] [CrossRef] [PubMed]

- Baburaj, A.; Jayadevan, S.; Aliyana, A.K.; Sk, N.K.; Stylios, G.K. AI-Driven TENGs for Self-Powered Smart Sensors and Intelligent Devices. Adv. Sci. 2025, 12, e2417414. [Google Scholar] [CrossRef] [PubMed]

- Musa, S.S.; Ibrahim, A.M.; Alhassan, M.Y.; Musa, A.H.; Jibo, A.G.; Auwal, A.R.; Okesanya, O.J.; Othman, Z.K.; Abubakar, M.S.; Ahmed, M.M.; et al. Nanotechnology and machine learning: A promising confluence for the advancement of precision medicine. Intell. Med. 2025, 12, 100267. [Google Scholar] [CrossRef]

- Zhou, Y.; Shen, M.; Cui, X.; Shao, Y.; Li, L.; Zhang, Y. Triboelectric nanogenerator based self-powered sensor for artificial intelligence. Nano Energy 2021, 84, 105887. [Google Scholar] [CrossRef]

- Shu, X.; Kang, M.; Zhou, Y.; Cui, X.; Nie, J.; Zhao, Z.; Zhang, Y. Triboelectric nanogenerators based self-powered visualized weight sensor with high accuracy and real time. Nano Energy 2024, 135, 110624. [Google Scholar] [CrossRef]

- Zhang, Q.; Soham, D.; Liang, Z.; Wan, J. Advances in wearable energy storage and harvesting systems. Med-X 2025, 3, 3. [Google Scholar] [CrossRef]

- Zhang, B.; Ren, T.; Li, H.; Chen, B.; Mao, Y. Recent Progress of Nature Materials Based Triboelectric Nanogenerators for Electronic Skins and Human–Machine Interaction. Adv. Energy Sustain. Res. 2024, 5, 2300245. [Google Scholar] [CrossRef]

- Choi, D.; Lee, Y.; Lin, Z.-H.; Cho, S.; Kim, M.; Ao, C.K.; Soh, S.; Sohn, C.; Jeong, C.K.; Lee, J.; et al. Recent Advances in Triboelectric Nanogenerators: From Technological Progress to Commercial Applications. ACS Nano 2023, 17, 11087–11219. [Google Scholar] [CrossRef] [PubMed]

| Type | Material Composition | Key Performance | Voc | Isc | Ref. |

|---|---|---|---|---|---|

| Single-Network Gel | PAM | Enhanced interface tear resistance by 1200% | 311 V | 32.4 μA | [97] |

| Single-Network Gel | PAM | High optical transmittance (89%) and stable performance across −25 °C to 60 °C | 120 V | 16.6 μA | [98] |

| Single-Network Gel | ACMO | Achieved instantaneous power density of 40 mW/m2 | 40 V | 138 μA | [99] |

| Single-Network Gel | PVA | High transmittance (92%) and uniaxial stretchability up to 700% | 50 V | 13 μA | [100] |

| Double-Network Gel | PVA/PAAm | High bacteriostasis and biocompatibility | 270.5 V | 16.2 μA | [106] |

| Double-Network Gel | PHEA-co-AA | Pressure detection limit of 0.016 kPa | 182 V | 2.61 μA | [102] |

| Double-Network Gel | PAA/rGO | Stretchability up to 650% | 21.77 V | 48.7 μA | [22] |

| Multi-Network Gel | MCC | High sensitivity with 60 ms response time | 10.3 V | — | [107] |

| Multi-Network Gel | CMC | Stable performance at −40 °C | 70 V | — | [105] |

| Matrix Type | Material Composition | Key Performance | Voc | Isc | Ref. |

|---|---|---|---|---|---|

| Inorganic Gel | Succinonitrile/Acrylic Ester UV Glue | Reduced VO2 infrared transmittance by 28% | 8 V | — | [113] |

| Inorganic Gel | AMPS/PEGDA | High stretchability (2750%), conductivity (1.375 S/m) | 135 V | — | [116] |

| Organic Gel | Chitosan/Catechol | Biocompatible hydrogel for wearable applications | 110 V | 3.8 μA | [128] |