Stimuli-Responsive Starch-Based Biopolymer Coatings for Smart and Sustainable Fertilizers

Abstract

1. Introduction

2. Methodology

2.1. Methodological Framework for Literature Selection and Analysis

2.2. Inclusion and Exclusion Criteria

- Reported original experimental or review data on starch-based or polysaccharide-modified coatings applied in CRF systems;

- Focused on hydrogel design, smart release mechanisms (e.g., moisture, pH, or temperature responsiveness), or nanomaterial-enhanced coatings;

- Were published in peer-reviewed journals from 2020 onward;

- Were written in English;

- Provided accessible full-text articles (Open Access/Subscription).

- Focused solely on drug delivery or pharmaceutical encapsulation without agrochemical application;

- Addressed fertilizer efficiency without discussing coating mechanisms or polymer matrix design;

- Were editorials, abstracts without full text, or lacked methodological clarity.

2.3. Bibliometric and Publication Trends

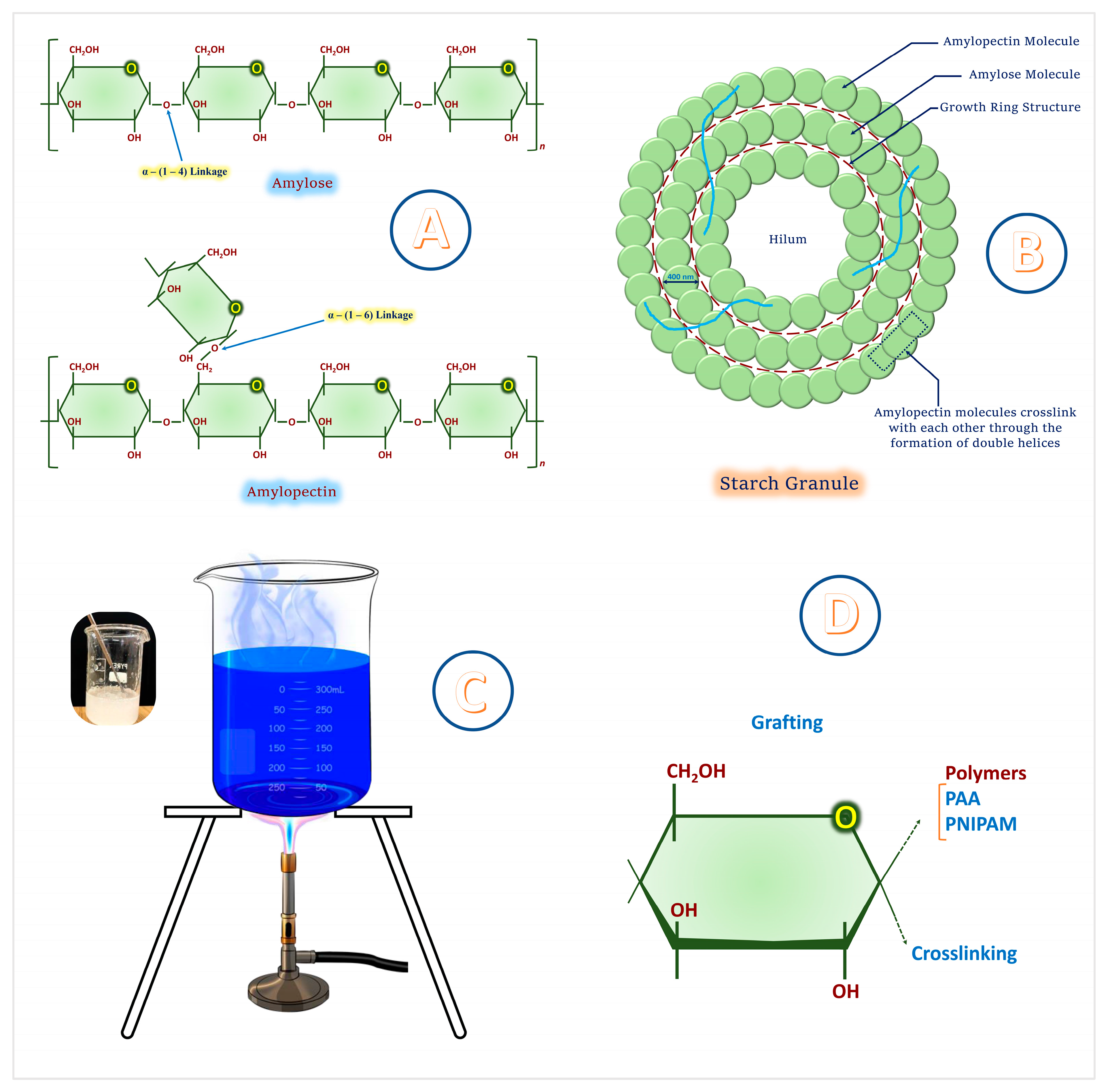

3. Starch as a Functional Biopolymer for Coated Fertilizers

3.1. Structural and Physicochemical Characteristics of Starch

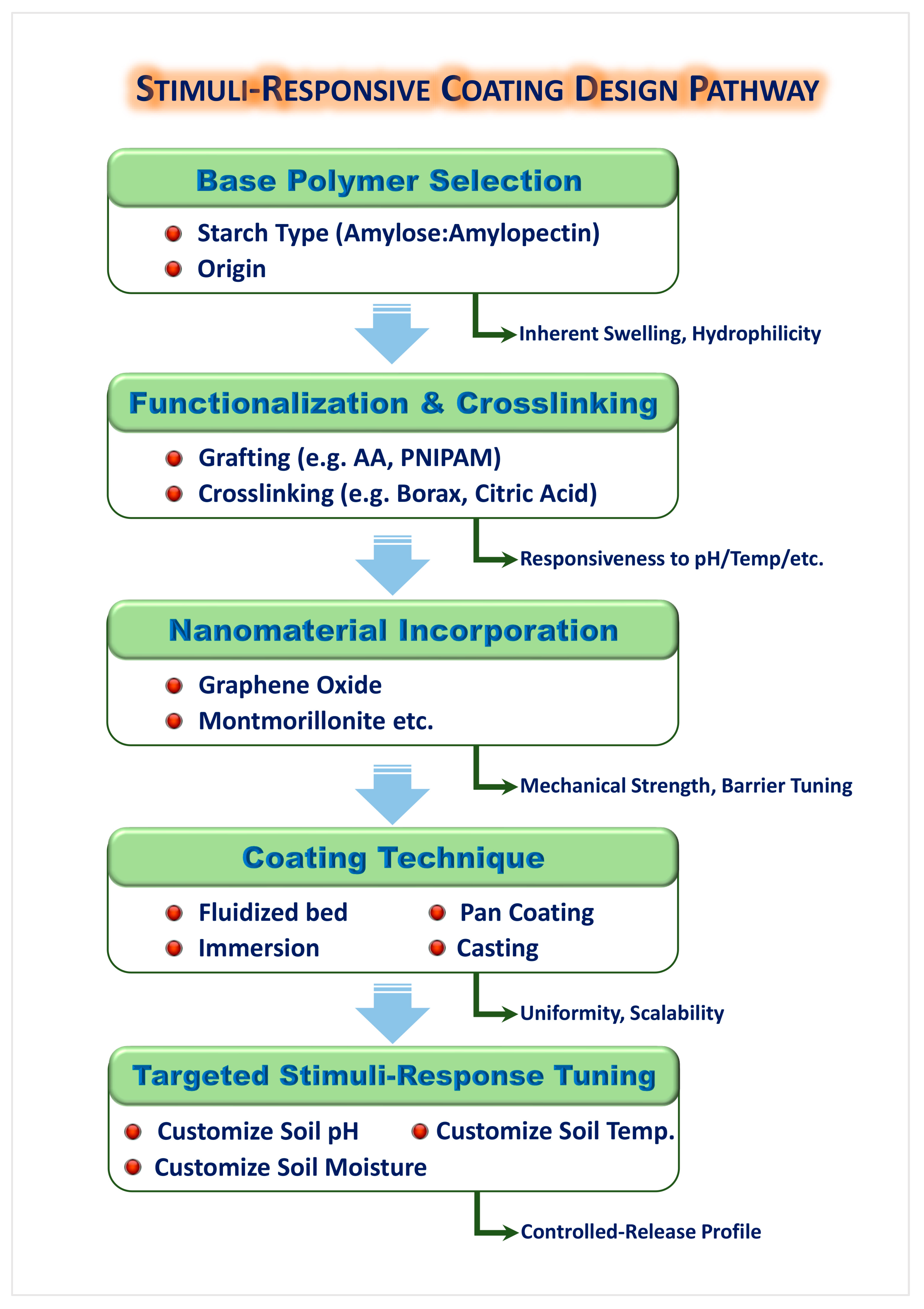

3.2. Modification Techniques and Functionalization Strategies

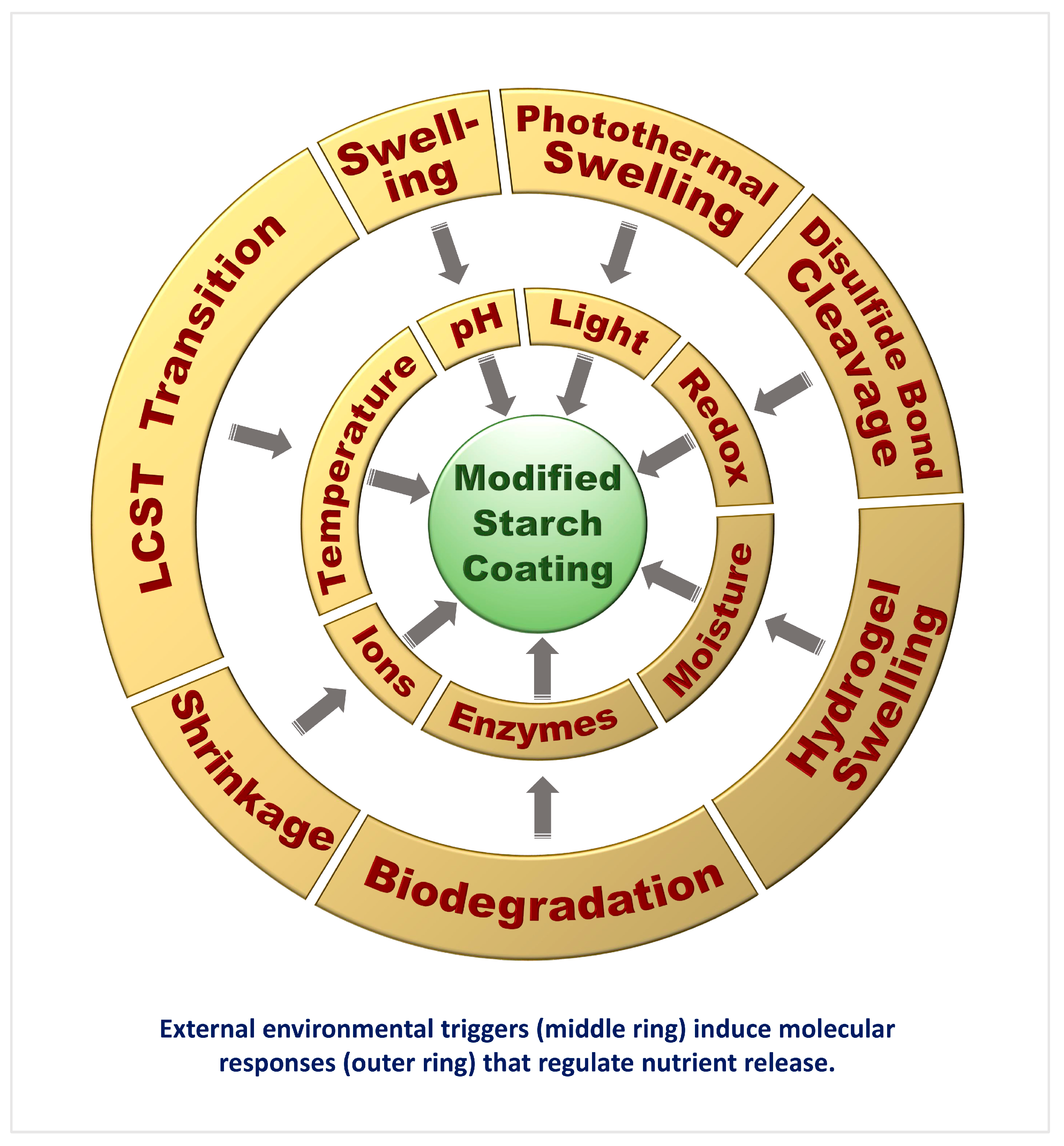

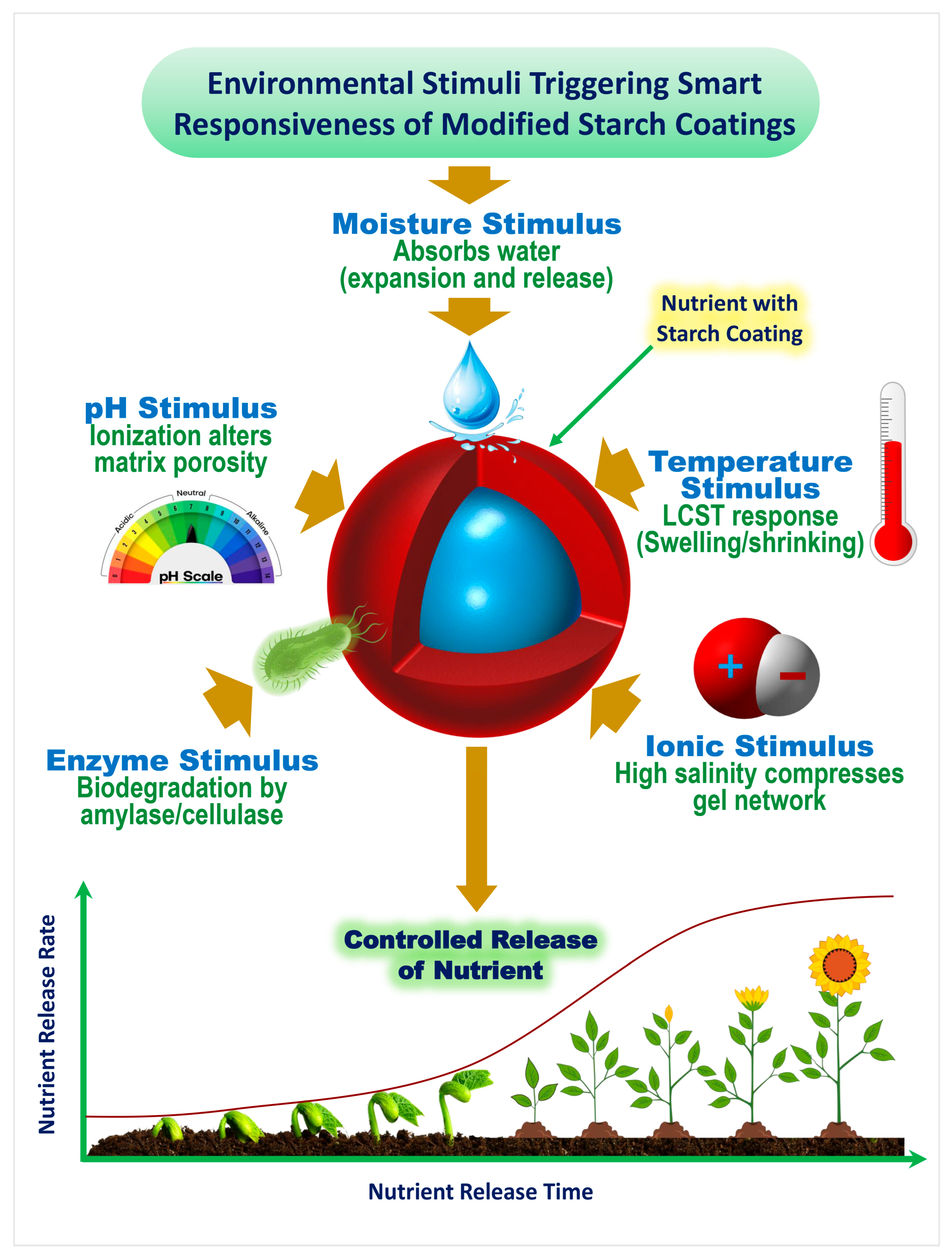

3.3. Stimuli-Responsive Properties of Starch-Based Coatings: Mechanisms and Applications

3.3.1. pH-Responsive Behavior

- Ionization of functional groups (–COOH ⇌ –COO−);

- Hydration-induced expansion or collapse of the matrix;

- Hydrogen bond formation/disruption;

- pH-sensitive ionic crosslink stability (e.g., Ca2+, STMP);

- Matrix relaxation that modulates diffusion pathways.

3.3.2. Temperature-Responsive Behavior

- Reversible disruption of intermolecular hydrogen bonds between hydroxyl groups;

- Temperature-sensitive hydrophobic interactions among grafted or blended moieties;

- Coil-to-globule transitions in synthetic grafts like PNIPAM or NVCL;

- Crosslinking density and type (e.g., ionic vs. covalent) affecting flexibility and collapse.

3.3.3. Moisture-Responsive Behavior

3.3.4. Enzyme-Responsive Behavior

3.3.5. Ionic Strength and Electrolyte Sensitivity

3.3.6. Light Responsive Mechanisms

3.3.7. Redox-Responsive Mechanisms

3.3.8. Toward Climate-Smart and Precision Agriculture

4. Fabrication and Processing Techniques

4.1. Solution Casting and Drying

4.1.1. Film Uniformity and Mechanical Integrity

4.1.2. Role of Additives

4.1.3. Drying and Controlled-Release Behavior

4.1.4. Hydrogel Formation via Controlled Casting

4.1.5. Critical Process Parameters

- Drying Rate: should be optimized to avoid skin formation or brittleness.

- Crosslinking Level: controls film strength and dissolution rate.

- Polymer Blends: influence flexibility, water uptake, and biodegradability.

- Thickness Control: directly affects nutrient diffusion rate.

4.2. Fluidized-Bed Spray Coating (Wurster, Top-Spray, Bottom-Spray)

4.3. Crosslinking and Chemical Grafting Routes

4.4. Encapsulation and Hydrogel Bead Formation

4.5. Use of Nanomaterials and Reinforcing Additives

4.6. Layer-by-Layer Assembly and Multilayer Coatings

5. Evaluation and Characterization of Starch-Based Stimuli-Responsive CRFs

5.1. Morphological, Thermal, and Mechanical Analysis

5.1.1. Morphological Analysis

5.1.2. Thermal Analysis

5.1.3. Mechanical Properties

5.2. Swelling Ratio, Biodegradability, and Water Retention

5.3. Release Kinetics Under Controlled Stimuli

6. Smart Performance of Starch-Based CRFs Under Field-Simulated Conditions

6.1. Performance in Various Soils

6.2. Controlled Release Under Environmental Variability

6.3. Agronomic Impacts: Uptake, Growth, Yield

6.4. Environmental Fate and Degradation of Coating

7. Comparative Analysis and Research Gaps

7.1. Comparison with Other Smart Biopolymers

7.2. What Makes Starch Unique?

7.2.1. Structural and Abundance Advantages

7.2.2. Biodegradability and Soil Compatibility

7.2.3. Ease of Functionalization

7.2.4. Smart Release Behavior

7.2.5. Compatibility in Composite Systems

7.2.6. Economic and Agro-Industrial Relevance

7.3. Potential in Multilayer/Composite Systems

7.3.1. Limitations of Single-Component Coatings

7.3.2. Advantages of Multilayer and Hybrid Configurations

7.3.3. Controlled Layer Deposition Techniques

7.3.4. Application in Harsh Soil Conditions

7.3.5. Future Opportunities in Multilayer/Composite Systems

8. Future Perspectives

8.1. Scalability and Industrial Translation

8.2. Multi-Stimuli Responsiveness and Customization

8.3. Long-Term Field Validation

8.4. Environmental Impact and Biodegradation Profiling

8.5. Integration with Precision Agriculture Technologies

8.6. Regulatory, Economic, and Farmer Adoption Aspects

9. Conclusions and Outlook

- Designing multi-responsive and biodegradable systems tailored to specific soil types and crop cycles.

- Incorporating field-scale performance trials to validate lab-scale findings.

- Exploring synergistic interactions with beneficial soil microbes and root exudates.

- Using machine learning and modeling to predict release profiles under real-time conditions.

- Developing policy frameworks that support adoption of smart fertilizers in sustainable agriculture.

- By bridging materials science, agronomy, and environmental engineering, starch-based stimuli-responsive coatings can deliver context-specific benefits, for example, moisture-responsive hydrogels that swell during storm events and de-swell as soils dry to buffer rain-pulse leaching in rain-fed/semi-arid systems (see Section 3.3.3), and ionic-strength/pH-responsive matrices that maintain agronomically useful release profiles in alkaline–calcareous soils where Ca2+/Mg2+ and high salinity otherwise complicate nutrient management (see Section 3.3.1 and Section 3.3.6).

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prabha, M.; Tiwari, P.; Yadav, P.K.; Singh, V.; Tripathi, D.N.; Malviya, T. Biopolymeric starch-based matrix: A sustainable platform for slow release fertilizers. Carbohydr. Res. 2025, 552, 109474. [Google Scholar] [CrossRef]

- Lee, J.H.; Ku, H.H. Optimizing Nitrogen Use Efficiency and Reducing Nutrient Losses in Maize Using Controlled-Release Coated Fertilizers. Agrochemicals 2025, 4, 10. [Google Scholar] [CrossRef]

- Azeem, B. Effect of process parameters on coating mass variability and nitrogen-release kinetics of controlled-release urea granules produced in a Wurster fluidized-bed. Particuology 2025, 98, 67–82. [Google Scholar] [CrossRef]

- Lv, Y.; Cui, Y.; Zhang, W.; Xiang, Y.; Hu, B.; Wei, J.; Bian, H. Preparation and application of water-soluble oxidized starch-based hydrogels for slow-release urea. Int. J. Biol. Macromol. 2025, 315, 144345. [Google Scholar] [CrossRef] [PubMed]

- Goncharuk, O.; Siryk, O.; Frąc, M.; Guzenko, N.; Samchenko, K.; Terpiłowski, K.; Sternik, D.; Szewczuk-Karpisz, K. Synthesis, characterization and biocompatibility of hybrid hydrogels based on alginate, κ-carrageenan, and chitosan filled with montmorillonite clay. Int. J. Biol. Macromol. 2024, 278, 134703. [Google Scholar] [CrossRef]

- Balcerak-Woźniak, A.; Dzwonkowska-Zarzycka, M.; Kabatc-Borcz, J. A Comprehensive Review of Stimuli-Responsive Smart Polymer Materials; Recent Advances and Future Perspectives. Materials 2024, 17, 4255. [Google Scholar] [CrossRef]

- Pellá, M.C.G.; Simão, A.R.; Mauricio, M.R.; Pereira, G.M.; Dragunski, D.C.; da Silva, R.; Rubira, A.F. Multi-responsive dual-purpose smart starch-based hydrogel reinforced with activated carbon for agricultural applications. Colloids Surf. A Physicochem. Eng. Asp. 2025, 716, 136741. [Google Scholar] [CrossRef]

- Lu, K.; Lan, X.; Folkersma, R.; Voet, V.S.D.; Loos, K. Borax Cross-Linked Acrylamide-Grafted Starch Self-Healing Hydrogels. Biomacromolecules 2024, 25, 8026–8037. [Google Scholar] [CrossRef] [PubMed]

- Djafaripetroudy, S.; Fatehi, P.; el Idrissi, A.; Kang, K.; Abidi, N.; McLaren, B. Advancing agricultural efficiency and sustainability: Bio-inspired superabsorbent hydrogels for slow and controlled release fertilizers. Sci. Total Environ. 2025, 977, 179366. [Google Scholar] [CrossRef]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.J.; Horsley, T.; Weeks, L.; et al. PRISMA extension for scoping reviews (PRISMA-ScR): Checklist and explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef]

- Marzi, G.; Balzano, M.; Caputo, A.; Pellegrini, M.M. Guidelines for Bibliometric-Systematic Literature Reviews: 10 steps to combine analysis, synthesis and theory development. Int. J. Manag. Rev. 2025, 27, 81–103. [Google Scholar] [CrossRef]

- Peters, M.D.J.; Godfrey, C.M.; Khalil, H.; McInerney, P.; Parker, D.; Soares, C.B. Guidance for conducting systematic scoping reviews. Int. J. Evid.-Based Healthc. 2015, 13, 141–146. [Google Scholar] [CrossRef]

- Grant, M.J.; Booth, A. A typology of reviews: An analysis of 14 review types and associated methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef]

- Almozayen, N.A.; Othman, M.K.B.; Gani, A.B.; Alharethi, S.Z. Data mining techniques: A systematic mapping review. In Lecture Notes on Data Engineering and Communications Technologies: Recent Trends in Information and Communication Technology; Springer: Cham, Switzerland, 2018; Volume 5, pp. 66–77. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Munn, Z.; Peters, M.D.; Stern, C.; Tufanaru, C.; McArthur, A.; Aromataris, E. Systematic review or scoping review? Guidance for authors when choosing between a systematic or scoping review approach. BMC Med. Res. Methodol. 2018, 18, 143. [Google Scholar] [CrossRef]

- Booth, A.; Martyn-St James, M.; Clowes, M.; Sutton, A. Systematic Approaches to a Successful Literature Review; SAGE: Thousand Oaks, CA, USA, 2021. [Google Scholar]

- MacEntee, M.I. A typology of systematic reviews for synthesising evidence on health care. Gerodontology 2019, 36, 303–312. [Google Scholar] [CrossRef] [PubMed]

- Meline, T. Selecting studies for systemic review: Inclusion and exclusion criteria. Contemp. Issues Commun. Sci. Disord. 2006, 33, 21–27. [Google Scholar] [CrossRef]

- Shen, M.; Liu, S.; Jiang, C.; Zhang, T.; Chen, W. Recent advances in stimuli-response mechanisms of nano-enabled controlled-release fertilizers and pesticides. Eco-Environ. Health 2023, 2, 161–175. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, L.; Wang, M.; Li, L.X.; Cao, B.; Wang, H.; Huang, W.Q. Preparation and properties of starch-based polyurethane/montmorillonite composite coatings for controlled-release fertilizer. Polym. Compos. 2021, 42, 2293–2304. [Google Scholar] [CrossRef]

- Chen, F.; Miao, C.; Duan, Q.; Jiang, S.; Liu, H.; Ma, L.; Li, Z.; Bao, X.; Lan, B.; Chen, L.; et al. Developing slow release fertilizer through in-situ radiation-synthesis of urea-embedded starch-based hydrogels. Ind. Crops Prod. 2023, 191, 115971. [Google Scholar] [CrossRef]

- Chen, Y.S.; Phang, S.W.; Shuib, A.S.; Tee, J.L. Release behavior and biodegradability of controlled-release potassium fertilizer encapsulated in starch–alginate matrix. Asia-Pac. J. Chem. Eng. 2023, 18, e2998. [Google Scholar] [CrossRef]

- Lv, Q.; Xiao, T.; Dong, G.; Tan, X.; Zhang, Z.; Zhao, M.; Zhu, M.; Li, J.; Zhang, W. Preparation and characterization of starch carbamate modified natural sodium alginate composite hydrogel blend formulation and its application for slow-release fertilizer. Int. J. Biol. Macromol. 2024, 278, 134713. [Google Scholar] [CrossRef]

- Cornejo-Ramírez, Y.I.; Martínez-Cruz, O.; del Toro-Sánchez, C.L.; Wong-Corral, F.J.; Borboa-Flores, J.; Cinco-Moroyoqui, F.J. The structural characteristics of starches and their functional properties. CYTA-J. Food 2018, 16, 1003–1017. [Google Scholar] [CrossRef]

- Kayati, F.N.; Purnomo, C.W.; Kusumastuti, Y.; Rochmadi. The optimization of hydrogel strength from cassava starch using oxidized sucrose as a crosslinking agent. Green Process. Synth. 2023, 12, 20230151. [Google Scholar] [CrossRef]

- Ali, A.; Xie, F.; Yu, L.; Liu, H.; Meng, L.; Khalid, S.; Chen, L. Preparation and characterization of starch-based composite films reinforced by polysaccharide-based crystals. Compos. Part B Eng. 2018, 133, 122–128. [Google Scholar] [CrossRef]

- Xie, X.; Li, X.; Lei, J.; Zhao, X.; Lyu, Y.; Mu, C.; Li, D.; Ge, L.; Xu, Y. Oxidized starch cross-linked porous collagen-based hydrogel for spontaneous agglomeration growth of adipose-derived stem cells. Mater. Sci. Eng. C 2020, 116, 111165. [Google Scholar] [CrossRef]

- Singh, N.; Singh, J.; Kaur, L.; Sodhi, N.S.; Gill, B.S. Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 2003, 81, 219–231. [Google Scholar] [CrossRef]

- Kvien, I.; Sugiyama, J.; Votrubec, M.; Oksman, K. Characterization of starch based nanocomposites. J. Mater. Sci. 2007, 42, 8163–8171. [Google Scholar] [CrossRef]

- Wang, Y.; Ou, X.; Al-Maqtari, Q.A.; He, H.J.; Othman, N. Evaluation of amylose content: Structural and functional properties, analytical techniques, and future prospects. Food Chem. X 2024, 24, 101830. [Google Scholar] [CrossRef]

- Velasquez, D.; Pavon-Djavid, G.; Chaunier, L.; Meddahi-Pellé, A.; Lourdin, D. Effect of crystallinity and plasticizer on mechanical properties and tissue integration of starch-based materials from two botanical origins. Carbohydr. Polym. 2015, 124, 180–187. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ye, F.; Liu, J.; Zhao, G. Effects of octenylsuccination on physical, mechanical and moisture-proof properties of stretchable sweet potato starch film. Food Hydrocoll. 2015, 46, 226–232. [Google Scholar] [CrossRef]

- Chamorro, A.F.; Palencia, M.; Combatt, E.M. Starch Hydrogels for Slow and Controlled-Release Fertilizers: A Review. Polymers 2025, 17, 1117. [Google Scholar] [CrossRef]

- Channab, B.E.; Tayi, F.; Aqlil, M.; Akil, A.; Essamlali, Y.; Chakir, A.; Zahouily, M. Graphene oxide, starch, and kraft lignin bio-nanocomposite controlled-release phosphorus fertilizer: Effect on P management and maize growth. Int. J. Biol. Macromol. 2024, 282, 137190. [Google Scholar] [CrossRef]

- Song, Y.; Ma, L.; Duan, Q.; Xie, H.; Dong, X.; Zhang, H.; Yu, L. Development of Slow-Release Fertilizers with Function of Water Retention Using Eco-Friendly Starch Hydrogels. Molecules 2024, 29, 4835. [Google Scholar] [CrossRef]

- Niu, Y.; Li, H. Controlled release of urea encapsulated by starch-g-poly(vinyl acetate). Ind. Eng. Chem. Res. 2012, 51, 12173–12177. [Google Scholar] [CrossRef]

- Salimi, M.; Channab, B.-E.; El Idrissi, A.; Zahouily, M.; Motamedi, E. A comprehensive review on starch: Structure, modification, and applications in slow/controlled-release fertilizers in agriculture. Carbohydr. Polym. 2023, 322, 121326. [Google Scholar] [CrossRef] [PubMed]

- Berradi, A.; Aziz, F.; El Achaby, M.; Ouazzani, N.; Mandi, L. A Comprehensive Review of Polysaccharide-Based Hydrogels as Promising Biomaterials. Polymers 2023, 15, 2908. [Google Scholar] [CrossRef]

- Srivastava, N.; Choudhury, A.R. Stimuli-responsive polysaccharide-based smart hydrogels and their emerging applications. Ind. Eng. Chem. Res. 2022, 62, 841–866. [Google Scholar] [CrossRef]

- Majumdar, A.G.; Pany, B.; Si, S.; Mohanty, P.S. Smart stimuli-responsive polymer nanogels as an efficient delivery system for controlling abiotic stress tolerance: Synthesis, characterizations, and properties. In Nanotechnology for Abiotic Stress Tolerance and Management in Crop Plants; Academic Press: Cambridge, MA, USA, 2024; pp. 307–326. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, R.; Cai, Z.; Wu, F.; Hu, Y.; Huang, C.; Hu, K.; Chen, Y. Preparation and properties of pH-sensitive cationic starch nanoparticles. Food Chem. 2024, 437, 137916. [Google Scholar] [CrossRef]

- Bora, A.; Sarmah, D.; Rather, M.A.; Mandal, M.; Karak, N. Nanocomposite of starch, gelatin and itaconic acid-based biodegradable hydrogel and ZnO/cellulose nanofiber: A pH-sensitive sustained drug delivery vehicle. Int. J. Biol. Macromol. 2024, 256, 128253. [Google Scholar] [CrossRef]

- Chang, A. pH-sensitive starch-g-poly(acrylic acid)/sodium alginate hydrogels for controlled release of diclofenac sodium. Iranian Polym. J. 2015, 24, 161–169. [Google Scholar] [CrossRef]

- Lanzalaco, S.; Mingot, J.; Torras, J.; Alemán, C.; Armelin, E. Recent advances in poly (N-isopropylacrylamide) hydrogels and derivatives as promising materials for biomedical and engineering emerging applications. Adv. Eng. Mater. 2023, 25, 2201303. [Google Scholar] [CrossRef]

- Azeem, M.K.; Islam, A.; Khan, R.U.; Rasool, A.; Qureshi, M.A.U.R.; Rizwan, M.; Sher, F.; Rasheed, T. Eco-friendly three-dimensional hydrogels for sustainable agricultural applications: Current and future scenarios. Polym. Adv. Technol. 2023, 34, 3046–3062. [Google Scholar] [CrossRef]

- Bai, W.; Ji, B.; Fan, L.; Peng, Q.; Liu, Q.; Song, J. Preparation and Characterization of a Novel Cassava Starch-Based Phosphorus Releasing Super-Absorbent Polymer, and Optimization of the Performance of Water Absorption and Phosphorus Release. Polymers 2023, 15, 1233. [Google Scholar] [CrossRef]

- Jindor, N.J.; Agorku, E.S.; Adimado, A.A. Starch-Grafted Sodium Alginate-Modified Clay Composites as Environmentally Controlled-Release Materials for NPK Fertilizer. Appl. Environ. Soil Sci. 2023, 2023, 5133023. [Google Scholar] [CrossRef]

- Mu, Z.; Zhang, W.; Chai, D.F.; Lv, Q.; Tan, X.; Yuan, R.; Dong, G. Preparation and characterization of slow-release urea fertilizer encapsulated by a blend of starch derivative and polyvinyl alcohol with desirable biodegradability and availability. Int. J. Biol. Macromol. 2024, 271, 132693. [Google Scholar] [CrossRef] [PubMed]

- Zafar, N.; Niazi, M.B.K.; Sher, F.; Khalid, U.; Jahan, Z.; Shah, G.A.; Zia, M. Starch and polyvinyl alcohol encapsulated biodegradable nanocomposites for environment friendly slow release of urea fertilizer. Chem. Eng. J. Adv. 2021, 7, 100123. [Google Scholar] [CrossRef]

- Wan Yusof, W.R.; Sabar, S.; Zailani, M.A. Starch-chitosan blends: A comprehensive review on the preparation, physicochemical properties and applications. Biopolymers 2024, 115, e23602. [Google Scholar] [CrossRef]

- Alhaj Hamoud, Y.; Shaghaleh, H.; Guo, X.; Zhang, K. pH-responsive/sustained release nitrogen fertilizer hydrogel improves yield, nitrogen metabolism, and nitrogen use efficiency of rice under alternative wetting and moderate drying irrigation. Environ. Exp. Bot. 2023, 211, 105376. [Google Scholar] [CrossRef]

- Tiamwong, S.; Yukhajon, P.; Noisong, P.; Subsadsana, M.; Sansuk, S. Eco-Friendly Starch Composite Supramolecular Alginate–Ca2+ Hydrogel as Controlled-Release P Fertilizer with Low Responsiveness to Multiple Environmental Stimuli. Gels 2023, 9, 204. [Google Scholar] [CrossRef] [PubMed]

- Bui, P.D.; Nguyen, T.H.; Nguyen, B.A.D.; Chau, P.T.; Nguyen, C.T. Environmentally Friendly Cassava Starch-Based Hydrogel as Absorbent with Slow Release of Fertilizer. J. Technol. Educ. Sci. 2025, 20, 46–57. [Google Scholar] [CrossRef]

- Park, J.; Guan, W.; Yu, G. Smart Hydrogels for Sustainable Agriculture. EcoMat 2025, 7, e70011. [Google Scholar] [CrossRef]

- El Idrissi, A.; Tayi, F.; Dardari, O.; Akil, A.; Amadine, O.; Lu, L.; Zahouily, M.; Essamlali, Y. Development of Multifunctional Carboxymethyl Starch-Based Semi-IPN Hydrogels for Water and Fertilizer Management in Maize Cultivation under Different Water Deficit Conditions. ACS Sustain. Chem. Eng. 2025, 13, 7286–7298. [Google Scholar] [CrossRef]

- Shang, H.; Yang, X.; Liu, H. Temperature-responsive hydrogel prepared from carboxymethyl cellulose-stabilized N-vinylcaprolactam with potential for fertilizer delivery. Carbohydr. Polym. 2023, 313, 120875. [Google Scholar] [CrossRef]

- Feng, C.; Lü, S.; Gao, C.; Wang, X.; Xu, X.; Bai, X.; Gao, N.; Liu, M.; Wu, L. “Smart” Fertilizer with Temperature- and pH-Responsive Behavior via Surface-Initiated Polymerization for Controlled Release of Nutrients. ACS Sustain. Chem. Eng. 2015, 3, 3157–3166. [Google Scholar] [CrossRef]

- Balçık Tamer, Y. A New Design of Poly(N-Isopropylacrylamide) Hydrogels Using Biodegradable Poly(Beta-Aminoester) Crosslinkers as Fertilizer Reservoirs for Agricultural Applications. Gels 2023, 9, 127. [Google Scholar] [CrossRef]

- Figueroa, T.A.V.; Martínez, P.C.J.; Del Castro, C.T.; Martínez, B.E.; Madueño, C.M.A.G.; Alegría, G.A.M.; Ceniceros, L.T.E.; Villegas, A.L. Composite Hydrogel of Poly(acrylamide) and Starch as Potential System for Controlled Release of Amoxicillin and Inhibition of Bacterial Growth. J. Chem. 2020, 2020, 5860487. [Google Scholar] [CrossRef]

- Laddawan, P.; Auecharoenrat, S.; Tongsook, C. Environmentally Friendly Carboxymethyl Cellulose Hydrogels Derived from Waste Paper and Sawdust as a Urea Release Agent. ACS Omega 2025, 10, 17296–17309. [Google Scholar] [CrossRef]

- Xu, Z.; Guo, Y. Preparation and performance of degradable slow-release fertilizer coating material by a new ionic crosslinked hydrogel material. J. Environ. Chem. Eng. 2023, 11, 110785. [Google Scholar] [CrossRef]

- Chen, Y.C.; Chen, Y.H. Thermo and pH-responsive methylcellulose and hydroxypropyl hydrogels containing K2SO4 for water retention and a controlled-release water-soluble fertilizer. Sci. Total Environ. 2019, 655, 958–967. [Google Scholar] [CrossRef]

- Ravindran, A.; Manivannan, A.C.; Kandaiah, R.; Kulanthaisamy, M.; Indirathankam, S.C.; Nachimuthu, G.; Panneerselvan, L.; Palanisami, T. Advancements and challenges in controlled-release fertilisers: An approach to integrate biopolymer-based strategies. Ind. Crops Prod. 2025, 233, 121349. [Google Scholar] [CrossRef]

- Li, Y.; Ma, Y.; Chang, F.; Zhu, H.; Tian, C.; Jia, F.; Ke, Y.; Dai, J. Slow-Release Urea Fertilizer with Water Retention and Photosensitivity Properties Based on Sodium Alginate/Carboxymethyl Starch Sodium/Polydopamine. Processes 2024, 12, 842. [Google Scholar] [CrossRef]

- Pattapulavar, V.; Priyadharshini, S.; Roy, A.; Subramani, K. Nanogels Applications in Nutrient Delivery and Plant Growth Promotion. In Plant Nanotechnology Fundamentals and Methodologies; Springer Nature: Cham, Switzerland, 2025; pp. 359–388. [Google Scholar] [CrossRef]

- He, C.; Huang, Y.; Shao, Q.; Kong, F.; Zheng, D.; Qiu, X. Lignin-based ternary composite hydrogel for slow-release of fertilizer and soil water retention. Int. J. Biol. Macromol. 2025, 296, 139679. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Song, Y.; Li, Z.; Zhang, D.; Li, K.; Duan, Q.; Xie, H.; Yu, X.; Yu, L. Development of slow-release humic acid fertilizer using starch-based hydrogel. Ind. Crops Prod. 2025, 226, 120648. [Google Scholar] [CrossRef]

- Hou, X.; Pan, Y.; Xiao, H.; Liu, J. Controlled Release of Agrochemicals Using pH and Redox Dual-Responsive Cellulose Nanogels. J. Agric. Food Chem. 2019, 67, 6700–6707. [Google Scholar] [CrossRef]

- Mandal, M.; Singh Lodhi, R.; Chourasia, S.; Das, S.; Das, P. A Review on Sustainable Slow-Release N, P, K Fertilizer Hydrogels for Smart Agriculture. ChemPlusChem 2025, 90, e202400643. [Google Scholar] [CrossRef]

- Kilic Boz, R.; Aydin, D.; Kocak, S.; Golba, B.; Sanyal, R.; Sanyal, A. Redox-Responsive Hydrogels for Tunable and “On-Demand” Release of Biomacromolecules. Bioconjug. Chem. 2022, 33, 839–847. [Google Scholar] [CrossRef] [PubMed]

- Mansouri, H.; Said, H.A.; Noukrati, H.; Oukarroum, A.; Ben Youcef, H.; Perreault, F. Advances in Controlled Release Fertilizers: Cost-Effective Coating Techniques and Smart Stimuli-Responsive Hydrogels. Adv. Sustain. Syst. 2023, 7, 2300149. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Muñana-González, S.; Lanceros-Mendez, S.; Ruiz-Rubio, L.; Alvarez, L.P.; Vilas-Vilela, J.L. Biodegradable Natural Hydrogels for Tissue Engineering, Controlled Release, and Soil Remediation. Polymers 2024, 16, 2599. [Google Scholar] [CrossRef]

- Yan, D.; Pan, Y.; Cai, P.; Xiao, H. Redox/pH dual-responsive sodium alginate/cassava starch composite hydrogel beads for slow release of insecticides. React. Funct. Polym. 2025, 215, 106389. [Google Scholar] [CrossRef]

- Dong, G.; Mu, Z.; Liu, D.; Shang, L.; Zhang, W.; Gao, Y.; Zhao, M.; Zhang, X.; Chen, S.; Wei, M. Starch phosphate carbamate hydrogel based slow-release urea formulation with good water retentivity. Int. J. Biol. Macromol. 2021, 190, 189–197. [Google Scholar] [CrossRef]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Degradation behavior of biocomposites based on cassava starch buried under indoor soil conditions. Carbohydr. Polym. 2014, 101, 20–28. [Google Scholar] [CrossRef]

- Gao, X.; Fu, C.; Li, M.; Qi, X.; Jia, X. Effects of Biodegradation of Corn-Starch–Sodium-Alginate-Based Liquid Mulch Film on Soil Microbial Functions. Int. J. Environ. Res. Public Health 2022, 19, 8631. [Google Scholar] [CrossRef]

- Cano, A.I.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Biodegradation behavior of starch-PVA films as affected by the incorporation of different antimicrobials. Polym. Degrad. Stab. 2016, 132, 11–20. [Google Scholar] [CrossRef]

- dos Santos, R.R.; Montagnolli, R.N.; Faez, R. Biodegradation profile and soil microbiota interactions of poly(vinyl alcohol)/starch-based fertilizers. Int. J. Biol. Macromol. 2025, 287, 138395. [Google Scholar] [CrossRef]

- Firmanda, A.; Fahma, F.; Syamsu, K.; Sari, Y.W.; Suryanegara, L.; Wood, K.; Saito, Y. Factors Influencing the Biodegradability of Agro-biopolymer Based Slow or Controlled Release Fertilizer. J. Polym. Environ. 2023, 31, 1706–1724. [Google Scholar] [CrossRef]

- Supare, K.; Mahanwar, P.A. Starch-derived superabsorbent polymers in agriculture applications: An overview. Polym. Bull. 2022, 79, 5795–5824. [Google Scholar] [CrossRef]

- Rodrigo, L.; Munaweera, I. Employing sustainable agriculture practices using eco-friendly and advanced hydrogels. RSC Adv. 2025, 15, 21212–21228. [Google Scholar] [CrossRef]

- Kareem, S.A.; Dere, I.; Gungula, D.T.; Andrew, F.P.; Saddiq, A.M.; Adebayo, E.F.; Tame, V.T.; Kefas, H.M.; Joseph, J.; Patrick, D.O. Synthesis and characterization of slow-release fertilizer hydrogel based on hydroxy propyl methyl cellulose, polyvinyl alcohol, glycerol and blended paper. Gels 2021, 7, 262. [Google Scholar] [CrossRef]

- Agbna, G.H.D.; Zaidi, S.J. Hydrogel Performance in Boosting Plant Resilience to Water Stress—A Review. Gels 2025, 11, 276. [Google Scholar] [CrossRef] [PubMed]

- Sarhan, N.; Arafa, E.G.; Elgedawy, N.; Elsayed, K.N.M.; Mohamed, F. Urea intercalated encapsulated microalgae composite hydrogels for slow-release fertilizers. Sci. Rep. 2024, 14, 15032. [Google Scholar] [CrossRef] [PubMed]

- Ali, K.; Asad, Z.; Agbna, G.H.D.; Saud, A.; Khan, A.; Zaidi, S.J. Progress and Innovations in Hydrogels for Sustainable Agriculture. Agronomy 2024, 14, 2815. [Google Scholar] [CrossRef]

- Simão, A.R.; Pellá, M.C.G.; Girotto, H.F.; Francisco, J.P.; Da Silva, R.; De Carvalho, F.R.; Batistela, V.R. Water-Retaining Efficiency of Starch-Based Hydrogel in Clay and Sandy Soils Under Different Administration Conditions. Ens. Ciência Ciências Biológicas Agrárias Saúde 2024, 28, 672–681. [Google Scholar] [CrossRef]

- Lawrencia, D.; Wong, S.K.; Low, D.Y.S.; Goh, B.H.; Goh, J.K.; Ruktanonchai, U.R.; Soottitantawat, A.; Lee, L.H.; Tang, S.Y. Controlled release fertilizers: A review on coating materials and mechanism of release. Plants 2021, 10, 238. [Google Scholar] [CrossRef]

- Govil, S.; van Duc Long, N.; Escribà-Gelonch, M.; Hessel, V. Controlled-release fertiliser: Recent developments and perspectives. Ind. Crops Prod. 2024, 219, 119160. [Google Scholar] [CrossRef]

- Han, X.; Chen, S.; Hu, X. Controlled-release fertilizer encapsulated by starch/polyvinyl alcohol coating. Desalination 2009, 240, 21–26. [Google Scholar] [CrossRef]

- Azeem, B.; KuShaari, K.; Naqvi, M.; Keong, L.K.; Almesfer, M.K.; Al-Qodah, Z.; Naqvi, S.R.; Elboughdiri, N. Production and characterization of controlled release urea using biopolymer and geopolymer as coating materials. Polymers 2020, 12, 400. [Google Scholar] [CrossRef]

- Weng, J.; Zhai, X.; Zhang, G.; Su, X.; Yang, Y.; Ding, F.; Wang, W.; Xu, J.; Xie, J. Densified and water-repellent biodegradable starch/PBAT composite films-packaged fertilizers: Prediction model, controlled-release mechanism and rice application. Chem. Eng. J. 2023, 475, 146242. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, J.; Duan, Q.; Xie, H.; Dong, X.; Yu, L. Strategies and Methodologies for Improving Toughness of Starch Films. Foods 2024, 13, 4036. [Google Scholar] [CrossRef]

- Che Hamzah, N.H.; Khairuddin, N.; Muhamad, I.I. Preparation and characterization of starch-based pH indicator films for anthocyanin release. Food Res. 2024, 8, 110–116. [Google Scholar] [CrossRef]

- Saini, R.; Manjaiah, K.M.; Roy, D.; Kumar, R.; Gawdiya, S.; Meena, S.; Naveenkumar, A.; Kumar, A.; El-Hendawy, S.; Mattar, M.A. Synthesis and Evaluation of Starch-Grafted-Poly[(Acrylic Acid)-Co-Acrylamide] Based Nanoclay Polymer Composite Fertilizers for Slow Release of Nitrogen in Soil. Polymers 2024, 16, 3013. [Google Scholar] [CrossRef]

- Jumpapaeng, P.; Suwanakood, P.; Nanan, S.; Saengsuwan, S. Novel biodegradable nanocomposite hydrogels based on biopolymers and various montmorillonite contents as high-strength coating membranes for efficient slow-release fertilizers. J. Ind. Eng. Chem. 2023, 127, 191–209. [Google Scholar] [CrossRef]

- Nasri-Nasrabadi, B.; Behzad, T.; Bagheri, R. Preparation and characterization of cellulose nanofiber reinforced thermoplastic starch composites. Fibers Polym. 2014, 15, 347–354. [Google Scholar] [CrossRef]

- Pimsen, R.; Porrawatkul, P.; Nuengmatcha, P.; Ramasoot, S.; Chanthai, S. Efficiency enhancement of slow release of fertilizer using nanozeolite–chitosan/sago starch-based biopolymer composite. J. Coat. Technol. Res. 2021, 18, 1321–1332. [Google Scholar] [CrossRef]

- Sayed, A.; Yasser, M.; Abdel-Raouf, M.E.-S.; Mohsen, R. Green starch/graphene oxide hydrogel nanocomposites for sustained release applications. Chem. Pap. 2022, 76, 5119–5132. [Google Scholar] [CrossRef]

- Qiao, D.; Liu, H.; Yu, L.; Bao, X.; Simon, G.P.; Petinakis, E.; Chen, L. Preparation and characterization of slow-release fertilizer encapsulated by starch-based superabsorbent polymer. Carbohydr. Polym. 2016, 147, 146–154. [Google Scholar] [CrossRef]

- Chiaregato, C.G.; Faez, R. Micronutrients encapsulation by starch as an enhanced efficiency fertilizer. Carbohydr. Polym. 2021, 271, 118419. [Google Scholar] [CrossRef]

- Qi, T.; Lü, S.; Zhang, S.F.; Bai, X.; Chen, J.; Huang, M.; Liu, M. Zein coated porous carboxymethyl starch fertilizer for iron promoting and phosphate sustainable release. J. Clean. Prod. 2020, 258, 120778. [Google Scholar] [CrossRef]

- Salimi, M.; Motamedi, E.; Motesharezedeh, B.; Hosseini, H.M.; Alikhani, H.A. Starch-g-poly(acrylic acid-co-acrylamide) composites reinforced with natural char nanoparticles toward environmentally benign slow-release urea fertilizers. J. Environ. Chem. Eng. 2020, 8, 103765. [Google Scholar] [CrossRef]

- Tanan, W.; Panichpakdee, J.; Suwanakood, P.; Saengsuwan, S. Biodegradable hydrogels of cassava starch-g-polyacrylic acid/natural rubber/polyvinyl alcohol as environmentally friendly and highly efficient coating material for slow-release urea fertilizers. J. Ind. Eng. Chem. 2021, 101, 237–252. [Google Scholar] [CrossRef]

- Dubey, A.; Mailapalli, D.R. Zeolite coated urea fertilizer using different binders: Fabrication, material properties and nitrogen release studies. Environ. Technol. Innov. 2019, 16, 100452. [Google Scholar] [CrossRef]

- Jungsinyatam, P.; Suwanakood, P.; Saengsuwan, S. Multicomponent biodegradable hydrogels based on natural biopolymers as environmentally coating membrane for slow-release fertilizers: Effect of crosslinker type. Sci. Total Environ. 2022, 843, 157050. [Google Scholar] [CrossRef]

- Cheng, J.; Liao, Z.; Hu, S.C.; Geng, Z.C.; Zhu, M.Q.; Xu, W.Z. Synthesis of an environmentally friendly binding material using pyrolysis by-products and modified starch binder for slow-release fertilizers. Sci. Total Environ. 2022, 819, 153146. [Google Scholar] [CrossRef]

- Uzoh, C.F.; Onukwuli, O.D.; Ozofor, I.H.; Odera, R.S. Encapsulation of urea with alkyd resin-starch membranes for controlled N2 release: Synthesis, characterization, morphology and optimum N2 release. Process Saf. Environ. Prot. 2019, 121, 133–142. [Google Scholar] [CrossRef]

- Versino, F.; Urriza, M.; García, M.A. Eco-compatible cassava starch films for fertilizer controlled-release. Int. J. Biol. Macromol. 2019, 134, 302–307. [Google Scholar] [CrossRef] [PubMed]

- 157 Qi, T.; Lü, S.; Li, T.; Chen, J.; Huang, M.; Ji, Y.; Zhang, S.F.; Liu, M. A multielement compound fertilizer used polydopamine and sodium carboxymethyl starch matrices as coatings. Int. J. Biol. Macromol. 2019, 124, 582–590. [Google Scholar] [CrossRef] [PubMed]

- Zhong, K.; Lin, Z.T.; Zheng, X.L.; Jiang, G.B.; Fang, Y.S.; Mao, X.Y.; Liao, Z.W. Starch derivative-based superabsorbent with integration of water-retaining and controlled-release fertilizers. Carbohydr. Polym. 2013, 92, 1367–1376. [Google Scholar] [CrossRef]

- Sofyane, A.; Ablouh, E.; Lahcini, M.; Elmeziane, A.; Khouloud, M.; Kaddami, H.; Raihane, M. Slow-release fertilizers based on starch acetate/glycerol/polyvinyl alcohol biocomposites for sustained nutrient release. Mater. Today Proc. 2020, 36, 74–81. [Google Scholar] [CrossRef]

- Kumar, R.; Ashfaq, M.; Verma, N. Synthesis of novel PVA–starch formulation-supported Cu–Zn nanoparticle carrying carbon nanofibers as a nanofertilizer: Controlled release of micronutrients. J. Mater. Sci. 2018, 53, 7150–7164. [Google Scholar] [CrossRef]

- Wei, H.; Wang, H.; Chu, H.; Li, J. Preparation and characterization of slow-release and water-retention fertilizer based on starch and halloysite. Int. J. Biol. Macromol. 2019, 133, 1210–1218. [Google Scholar] [CrossRef]

- Xiao, X.; Yu, L.; Xie, F.; Bao, X.; Liu, H.; Ji, Z.; Chen, L. One-step method to prepare starch-based superabsorbent polymer for slow release of fertilizer. Chem. Eng. J. 2017, 309, 607–616. [Google Scholar] [CrossRef]

- Seddighi, H.; Shayesteh, K.; Omrani, N.; Es’haghi, P. Fertilizers Coating Methods: A Mini Review of Various Techniques. Chem. Res. Technol. 2024, 1, 38–48. [Google Scholar] [CrossRef]

- Ali, A.M.; Azeem, B.; Alghamdi, A.M.; Shahzad, K.; Al-Zahrani, A.A.; Rashid, M.I.; Mahpudz, A.B.; Jamil, A. Optimization of Fluidized-Bed Process Parameters for Coating Uniformity and Nutrient-Release Characteristics of Controlled-Release Urea Produced by Modified Lignocellulosic Coating Material. Agronomy 2023, 13, 725. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H.; Zhao, S.; Yan, S.; Li, J.; Yang, X. Optimization of Ethyl Cellulose-Coated Urea for High-Performance Controlled Release. Carbohydr. Polym. Technol. Appl. 2025, 11, 100920. [Google Scholar] [CrossRef]

- Chen, X.; Ji, N.; Li, F.; Qin, Y.; Wang, Y.; Xiong, L.; Sun, Q. Dual cross-linked starch–borax double network hydrogels with tough and self-healing properties. Foods 2022, 11, 1315. [Google Scholar] [CrossRef]

- Panpinit, S.; Jumpapaeng, P.; Prasertsri, S.; Suwanakood, P.; Nanan, S.; Saengsuwan, S. Optimizing modified natural rubber in starch-based hydrogels: A cost-effective approach for high-performance sustainable slow-release fertilizer coatings. J. Ind. Eng. Chem. 2025, 142, 392–407. [Google Scholar] [CrossRef]

- Channab, B.E.; el Idrissi, A.; Zahouily, M.; Essamlali, Y.; White, J.C. Starch-based controlled release fertilizers: A review. Int. J. Biol. Macromol. 2023, 238, 124075. [Google Scholar] [CrossRef]

- Jafari, H.; Atlasi, Z.; Mahdavinia, G.R.; Hadifar, S.; Sabzi, M. Magnetic κ-carrageenan/chitosan/montmorillonite nanocomposite hydrogels with controlled sunitinib release. Mater. Sci. Eng. C 2021, 124, 112042. [Google Scholar] [CrossRef]

- Rozo, G.; Bohorques, L.; Santamaría, J. Controlled release fertilizer encapsulated by a κ-carrageenan hydrogel. Polimeros 2019, 29, e2019033. [Google Scholar] [CrossRef]

- Hidayat, E.; Sarbani, N.M.M.; Samitsu, S.; Nugroho, F.A.A.; Lahiri, S.K.; Aoyagi, M.; Yonemura, S.; Harada, H. Evaluation of slow-release fertilizers derived from hydrogel beads: Sodium alginate-poly (acrylic acid) and humic acid-encapsulated struvite for soil salinity amelioration. Arab. J. Chem. 2024, 17, 105877. [Google Scholar] [CrossRef]

- Dovzhenko, A.P.; Yapryntseva, O.A.; Sinyashin, K.O.; Doolotkeldieva, T.; Zairov, R.R. Recent progress in the development of encapsulated fertilizers for time-controlled release. Heliyon 2024, 10, e34895. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Xu, J.; Bi, H.; Shang, Y.; Shao, Q. A slow-release fertilizer of urea prepared via biochar-coating with nano-SiO2-starch-polyvinyl alcohol: Formulation and release simulation. Environ. Technol. Innov. 2023, 32, 103264. [Google Scholar] [CrossRef]

- Picart, C. Polyelectrolyte Multilayer Films: From Physico-Chemical Properties to the Control of Cellular Processes. Curr. Med. Chem. 2008, 15, 685–697. [Google Scholar] [CrossRef]

- Singh, A.K. Bio-based materials for fabrication of controlled-release coated fertilizers to enhance soil fertility: A review. Next Mater. 2025, 8, 100701. [Google Scholar] [CrossRef]

- Liu, J.; Yuan, Y.; Gao, J.; Qin, Z.; Peng, W.; Lakra, A.; Zhang, Y.; Zhang, S.; Liu, G.; Chen, Y.; et al. Programmable bionanocomposite coated fertilizers for prolonged controlled release of nitrogen. Chem. Eng. J. 2024, 497, 154907. [Google Scholar] [CrossRef]

- Kavitha, R.; Latifah, O.; Ahmed, O.H.; Charles, P.W.; Susilawati, K. Potential of Rejected Sago Starch as a Coating Material for Urea Encapsulation. Polymers 2023, 15, 1863. [Google Scholar] [CrossRef]

- Li, T.; Lü, S.; Yan, J.; Bai, X.; Gao, C.; Liu, M. An Environment-Friendly Fertilizer Prepared by Layer-by-Layer Self-Assembly for pH-Responsive Nutrient Release. ACS Appl. Mater. Interfaces 2019, 11, 10941–10950. [Google Scholar] [CrossRef]

- Das, S.K.; Ghosh, G.K. Hydrogel-biochar composite for agricultural applications and controlled release fertilizer: A step towards pollution free environment. Energy 2022, 242, 122977. [Google Scholar] [CrossRef]

- Quintanilla de Stéfano, J.C.; Abundis-Correa, V.; Herrera-Flores, S.D.; Alvarez, A.J. PH-sensitive starch-based hydrogels: Synthesis and effect of molecular components on drug release behavior. Polymers 2020, 12, 1974. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, J.; Jiang, S.; Fu, C.; Li, Y.; Xiang, H.; Lu, R.; Zhu, J.; Yu, B. Enhancing slow-release performance of biochar-based fertilizers with kaolinite-infused polyvinyl alcohol/starch coating: From fertilizer development to field application. Int. J. Biol. Macromol. 2025, 302, 140665. [Google Scholar] [CrossRef]

- Nayak, P.; Nandipamu, T.M.K.; Chaturvedi, S.; Dhyani, V.C.; Chandra, S. Synthesis, properties, and mechanistic release-kinetics modeling of biochar-based slow-release nitrogen fertilizers and their field efficacy. J. Soil Sci. Plant Nutr. 2024, 24, 7460–7479. [Google Scholar] [CrossRef]

- de Lima Souza, J.; Chiaregato, C.G.; Balieiro, A.G.; Faez, R. Impact of NPK and KNO3 fertilizers on biodegradation, kinetics, and nutrient release in enhanced-efficiency fertilizer green composites. Polym. Bull. 2025, 82, 7697–7717. [Google Scholar] [CrossRef]

- Dere, I.; Gungula, D.T.; Kareem, S.A.; Andrew, F.P.; Saddiq, A.M.; Tame, V.T.; Kefas, H.M.; Patrick, D.O.; Joseph, J.I. Preparation of slow-release fertilizer derived from rice husk silica, hydroxypropyl methylcellulose, polyvinyl alcohol and paper composite coated urea. Heliyon 2025, 11, e42036. [Google Scholar] [CrossRef]

- Vo, P.T.; Nguyen, H.T.; Trinh, H.T.; Nguyen, V.M.; Le, A.T.; Tran, H.Q.; Nguyen, T.T.T. The nitrogen slow-release fertilizer based on urea incorporating chitosan and poly(vinyl alcohol) blend. Environ. Technol. Innov. 2021, 22, 101528. [Google Scholar] [CrossRef]

- Etminani-Esfahani, N.; Rahmati, A.; Mansouri, O. Preparation of green hydrogel for slow-release urea and its positive effect on improving wheat yield under deficit irrigation conditions and remediation of soil. Ind. Crops Prod. 2025, 231, 121168. [Google Scholar] [CrossRef]

- Boonying, P.; Sottiudom, S.; Nontasorn, P.; Laohhasurayotin, K.; Kangwansupamonkon, W. Novel coating films containing micronutrients for controlled-release urea fertilizer: Release mechanisms and kinetics study. Polym. Bull. 2023, 80, 9627–9649. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, C.; Tao, C.; Fan, X.; Liu, R. Preparation of Phosphogypsum–Bentonite-Based Slow-Release Potassium Magnesium Sulfate Fertilizer. Agriculture 2025, 15, 692. [Google Scholar] [CrossRef]

- Yadav, E.; Pandey, K.; Khushbu Rani, I.; Warkar, S.G. Synthesis and application of zinc-loaded carboxymethyl tamarind kernel gum and xanthan gum-based superabsorbent hydrogels to investigate the effect on sesame plant growth. Polym. Bull. 2024, 81, 9009–9030. [Google Scholar] [CrossRef]

- Wang, C.; Song, S.; Du, L.; Yang, Z.; Liu, Y.; He, Z.; Zhou, C.; Li, P. Nutrient controlled release performance of bio-based coated fertilizer enhanced by synergistic effects of liquefied starch and siloxane. Int. J. Biol. Macromol. 2023, 236, 123994. [Google Scholar] [CrossRef]

- Wang, D.; Li, B.; Ma, J.; Wang, J.; Wang, H.; Li, W. Pseudoplastic liquid mulch film incorporating waste lignin and starch to improve its sprayability and available soil nitrogen. Chem. Eng. J. 2023, 475, 146392. [Google Scholar] [CrossRef]

- Motamedi, E.; Safari, M.; Salimi, M. Improvement of tomato yield and quality using slow release NPK fertilizers prepared by carnauba wax emulsion, starch-based latex and hydrogel nanocomposite combination. Sci. Rep. 2023, 13, 11118. [Google Scholar] [CrossRef]

- Rychter, P.; Kot, M.; Bajer, K.; Rogacz, D.; Šišková, A.; Kapuśniak, J. Utilization of starch films plasticized with urea as fertilizer for improvement of plant growth. Carbohydr. Polym. 2016, 137, 127–138. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Chang, R.; Ma, R.; Qiu, H.; Tian, Y. Eco-friendly and pH-responsive nano-starch-based superhydrophobic coatings for liquid-food residue reduction and freshness monitoring. ACS Sustain. Chem. Eng. 2021, 9, 10142–10153. [Google Scholar] [CrossRef]

- Nzenguet, A.M.; Essamlali, Y.; Zahouily, M.; Amadine, O. Development and characterization of eco-friendly starch/polyacrylamide/graphene oxide-based slow-release fertilizers for sustainable agriculture. J. Polym. Res. 2025, 32, 141. [Google Scholar] [CrossRef]

- Beig, B.; Niazi, M.B.K.; Jahan, Z.; Kakar, S.J.; Shah, G.A.; Shahid, M.; Zia, M.; Haq, M.U.; Rashid, M.I. Biodegradable polymer coated granular urea slows down N release kinetics and improves spinach productivity. Polymers 2020, 12, 2623. [Google Scholar] [CrossRef]

- Abg Ahmad, D.F.B.; Wasli, M.E.; Tan, C.S.Y.; Musa, Z.; Chin, S.F. Eco-friendly cellulose hydrogels as controlled release fertilizer for enhanced growth and yield of upland rice. Sci. Rep. 2023, 13, 20453. [Google Scholar] [CrossRef]

- Nassaj-Bokharaei, S.; Motesharezedeh, B.; Etesami, H.; Motamedi, E. Effect of hydrogel composite reinforced with natural char nanoparticles on improvement of soil biological properties and the growth of water deficit-stressed tomato plant. Ecotoxicol. Environ. Saf. 2021, 223, 112576. [Google Scholar] [CrossRef]

- Chamorro, A.F.; Palencia, M.; Arrieta, Á.A. Development of High-Efficiency Fertilizer by Hydrogels Obtained from Cassava Starch and Citric Acid for Slow Release of Ammonium and Potassium. Gels 2024, 10, 434. [Google Scholar] [CrossRef]

- Zhu, Y.; Deng, K.; Wu, P.; Feng, K.; Zhao, S.; Li, L. Effects of slow-release fertilizer on lotus rhizome yield and starch quality under different fertilization periods. Plants 2023, 12, 1311. [Google Scholar] [CrossRef]

- Hu, G.; Lan, X.; Peng, B.; Liao, J.; Xiong, Y. Water resistant, biodegradable and flexible corn starch/carboxymethyl cellulose composite film for slow-release fertilizer coating materials. Int. J. Biol. Macromol. 2024, 260, 129476. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Kaur, G.; Singh, A.; Dar, B.N. Effect of montmorillonite and starch nanocrystals based biodegradable films loaded with lemongrass oil nanoemulsion on quality, enzymatic activity and shelf life of strawberry. Food Chem. Adv. 2023, 3, 100343. [Google Scholar] [CrossRef]

- Lü, S.; Gao, C.; Wang, X.; Xu, X.; Bai, X.; Gao, N.; Feng, C.; Wei, Y.; Wu, L.; Liu, M. Synthesis of a starch derivative and its application in fertilizer for slow nutrient release and water-holding. RSC Adv. 2014, 4, 51208–51214. [Google Scholar] [CrossRef]

- Riseh, R.S.; Vazvani, M.G.; Kennedy, J.F. The application of chitosan as a carrier for fertilizer: A review. Int. J. Biol. Macromol. 2023, 252, 126483. [Google Scholar] [CrossRef]

- Eddarai, E.M.; El Mouzahim, M.; Ragaoui, B.; Eladaoui, S.; Bourd, Y.; Bellaouchou, A.; Boussen, R. Review of current trends in chitosan based controlled and slow-release fertilizer: From green chemistry to circular economy. Int. J. Biol. Macromol. 2024, 278, 134982. [Google Scholar] [CrossRef]

- Firmanda, A.; Fahma, F.; Syamsu, K.; Suryanegara, L.; Wood, K. Controlled/slow-release fertilizer based on cellulose composite and its impact on sustainable agriculture. Biofuels Bioprod. Biorefin. 2022, 16, 1909–1930. [Google Scholar] [CrossRef]

- Pang, L.; Gao, Z.; Feng, H.; Wang, S.; Wang, Q. Cellulose based materials for controlled release formulations of agrochemicals: A review of modifications and applications. J. Control. Release 2019, 316, 105–115. [Google Scholar] [CrossRef]

- Colin, C.; Akpo, E.; Perrin, A.; Cornu, D.; Cambedouzou, J. Encapsulation in Alginates Hydrogels and Controlled Release: An Overview. Molecules 2024, 29, 2515. [Google Scholar] [CrossRef]

| Ref | Material | Stimuli | Modification Method | Crop or Test Condition | Performance | Kinetic Model | Key Findings |

|---|---|---|---|---|---|---|---|

| [4] | Oxidized starch (OS)/PVA hydrogel (OSHU) | Moisture (swelling), biodegradation in soil | Oxidation of potato starch with NaClO; crosslinked with PVA | Soil incubation; pakchoi plant trial | 34.6–57% urea released in 35 days; high swelling (2125.6%); water retention improved | First-order; Fickian diffusion | Pakchoi biomass improved; hydrogel showed excellent reusability, mechanical integrity, and nutrient release potential |

| [7] | Starch-g-GMA hydrogel + DMAAm + activated carbon (GMAAC) | pH, temperature, ionic strength | Grafting of glycidyl methacrylate (GMA) onto starch; incorporation of GMA-modified activated carbon (GMAAC) | No crop; tested for urea release and recyclability | Urea release sustained for >3 h; release only after matrix degradation; stable for ≥15 cycles | Not specified | Multi-responsive hydrogel with high swelling (438 g/g); mechanical stability and reusability confirmed; suitable for sustainable agriculture |

| [8] | Acrylamide-grafted starch hydrogel crosslinked with borax | Temperature | Free radical grafting using ceric ammonium nitrate (CAN); dynamic borate ester and H-bonding network | No specific crop; developed as material for smart agriculture and sensors | Exhibits temperature-responsive self-healing and mechanical recovery | Not applied | Demonstrated high mechanical strength and full self-repair within 12 h due to reversible borate ester formation; promising for smart agricultural carriers |

| [27] | Cassava starch hydrogel crosslinked with oxidized sucrose | Moisture (swelling), cytocompatibility | Central composite design (CCD); OS addition; crosslinking confirmed via FTIR and 1H NMR | Biomedical; no agricultural use or crop | 95% swelling; WVTR = 714.9 g/m2·24 h; contact angle = 74.8° | None | Optimized for high tensile strength (27 MPa), high swelling, and excellent cytocompatibility (>100% cell viability); potential wound dressing application |

| [28] | Starch films reinforced with cellulose crystals or starch crystals | Environmental exposure (UV, thermal) | Melt blending with polysaccharide-based crystals | No crop—material characterization only | Improved Young’s modulus and tensile strength; UV shielding by starch crystal composite | None | Cellulose crystals enhanced thermal and mechanical performance; starch crystals improved UV shielding; fully edible and biodegradable films for packaging or capsule use |

| [31] | Modified potato starch with 5 wt% cellulose nanowhiskers (CNWs) or layered silicates (LSs) | Moisture, thermal (mechanical testing at various temperatures) | Plasticized with water and sorbitol; TEM used for structure assessment | No crop; mechanical and thermal characterization only | No fertilizer release tested | None (not a release study) | Nanocomposites showed significantly enhanced tensile and thermal properties; LSs gave higher storage modulus at elevated T; CNWs and LSs well dispersed via TEM |

| [36] | Starch/kraft lignin/graphene oxide (GO) bio-nanocomposite | Moisture (soil), mechanical resistance | Physical blending; GO added to enhance strength and barrier properties | Maize (Zea mays) in soil | Improved phosphorus retention; delayed release; increased crush resistance of coated TSP | Not specified | Coated TSP enhanced maize growth parameters; showed excellent structural integrity and sustainable release profile |

| [38] | Starch-g-poly(vinyl acetate) (St-g-PVAc) composite films | Water immersion and biodegradation in soil | In situ graft copolymerization of starch with vinyl acetate (VAc) using K2S2O8 initiator | No specific crop; studied in water and soil environments | Slow urea release: up to 28 h in water; films degraded in soil | Not specified | Grafting with hydrophobic PVAc reduced water swellability and improved release control; FTIR confirmed structural integrity; eco-friendly matrix for CRFs |

| [47] | Cassava starch–alginate–Ca2+ supramolecular hydrogel beads (s-PHBs) | pH, temperature, ionic strength, water hardness | Ca2+-induced crosslinking with phosphate encapsulation | Water and real rice field samples; no plant tested | Low initial burst, parabolic diffusion; low responsiveness to stimuli; stable release under extremes | Parabolic diffusion model | s-PHBs improved rigidity and stability; controlled P-release with high tolerance to environmental variation; commercial-scale potential as environmentally friendly CRFs |

| [58] | Starch–poly(acrylic acid) hydrogel crosslinked with Fe3+ | Water degradation, biodegradation | Grafting and ionic crosslinking with Fe3+; 25% PAA in starch-based matrix | Soil burial for 60 days (no specific crop) | Extended nitrogen release due to denser membrane; 71.11% weight loss in 60 days | Not specified | Ionic crosslinking enhanced mechanical and thermal stability; biodegradable coating offers eco-friendly CRF alternative |

| [84] | Carboxymethyl starch sodium/sodium alginate/polydopamine composite | Water retention, photosensitive (light-triggered) | Crosslinking and surface coating in two-step method | Winter wheat under water stress conditions | Extended release over 30 days; photothermal conversion under light | Ritger–Peppas (best fit), Fickian diffusion | Excellent light-induced heating and water retention; SEM showed smooth coating; significantly improved wheat growth under drought |

| [68] | Starch-grafted polyacrylamide hydrogel encapsulating humic acid (HA) | Water-induced swelling, biodegradation | In situ radiation grafting of acrylamide onto starch; surface coating of HA with stearic acid/wax | Not crop-tested; release tested over 60 days | 90% HA release in 53–60 days; initial burst reduced to ~30% | Not specified | Surface-coated HA prevented radical quenching; grafting efficiency up to 42.7%; performance met ISO/ASTM for SRFs; demonstrated structure–release relationship |

| [91] | Dialdehyde cassava starch/sodium alginate composite hydrogel beads | pH, redox | Covalent crosslinking with cystamine and ionic crosslinking with Ca2+ | Aqueous and simulated soil medium with DIN pesticide | Dual-stimuli-responsive release; higher DIN release at neutral/alkaline pH and under reducing conditions | Korsmeyer–Peppas | Environmentally friendly formulation for targeted, sustained pesticide release using a green dual-responsive system |

| [72] | Cassava starch-based biodegradable composite films | Biodegradation (soil microbes) | Box–Behnken statistical design to optimize formulation | Indoor soil burial (no crop) for 28 days | Degradation rate linked to microbial activity, water absorption, and film structure | Second-order polynomial (RSM) | Weight loss and SEM confirmed microbial degradation; films suitable for landfill disposal due to limited lifetime in soil |

| [73] | Corn starch–sodium alginate liquid mulch film | Biodegradation (soil microbial) | Moist heat modification; blended with 50% glycerol and 4% citric acid | Soil burial at 25 °C for 25 days (no specific crop) | Fully degraded macroscopically by day 25; increased soil organic matter | Microbial community succession analysis (no drug-release kinetics) | Degradation altered bacterial diversity and reduced abundance; film had improved mechanical integrity via H-bonded network among –COOH and –OH groups |

| [75] | Starch–KNO3 microspheres embedded in PVA matrix | Biodegradation (microbial) | Spray drying of starch microspheres; melt extrusion with PVA | 100-day soil burial test; microbial activity tracking | Gradual nutrient and polymer degradation; increased CO2 and fungal growth over time | Not applied | Starch promoted microbial adhesion and enhanced biodegradation of the PVA–starch fertilizer matrix, supporting sustainable nutrient delivery and soil health |

| [67] | Microalgae–chitosan–starch hydrogel | Moisture/swelling | Crosslinked hydrogel with encapsulated urea; physical blending with microalgae | Soil-blended test (no specific plant) | 78–95% urea released in 30 days; loading up to 440% | Freundlich (loading), Zero-order, Higuchi, Korsmeyer–Peppas (release) | Excellent water retention and re-swelling in soil; potential soil conditioner; enhanced WHC with only 1 g hydrogel per 50 g soil |

| [79] | Starch-based hydrogel (HG) for water retention | Ionic strength, pH | Not chemically modified; tested in dry/swollen/sandwich forms | Tested in sandy and clayey soils; no crop | Up to 62 mL water/g HG in sandy soil; no quantity dependence in clay | Not specified | Swollen/sandwich application was less effective; dry application best; water absorption 5× higher in low ionic strength; effective at pH 5 and 7 |

| [91] | Starch/polyvinyl alcohol blend film crosslinked with formaldehyde | Water immersion, biodegradation in soil | Blended at 7:3 (starch:PVA) and chemically crosslinked using 10 wt% formaldehyde | No specific crop; material tested in soil for biodegradability | Smooth, dense crosslinked membrane reduced release rate of urea | Not specified | Crosslinking enhanced compatibility and reduced porosity; FTIR and XRD confirmed chemical bonding and structure; film biodegraded in soil with controlled nutrient release |

| [92] | Tapioca starch modified with PVA and citric acid; outer geopolymer layer | Moisture | Crosslinking (citric acid), plasticizing (PVA), dual-layer coating via rotary fluidized bed | Laboratory-scale fluidized bed; no specific crop | Extended N release up to 22 days; R2 > 0.99 for optimal model | Not explicitly reported; focus on empirical release and optimization | Process optimized using RSM and GA; double coating significantly delayed nitrogen release |

| [93] | Starch/PBAT composite film-coated urea | Water exposure (hydrolytic degradation) | Melt blending and film compression with PBAT and glycerol; no solvents | Rice field trials and water incubation at 25 °C and 40 °C | Tunable nutrient release from 20 to 100 days depending on film thickness and PBAT ratio | Prediction model (RSM), no standard kinetic model | Solvent-free biodegradable CRF films with excellent water resistance and low material usage (1–2%); validated by CT imaging and rice yield improvement |

| [95] | Sago starch films with red cabbage anthocyanins (RCA) (8–16% w/v) | pH, temperature | Solvent casting with glycerol plasticizer | Food simulants: 3% acetic acid and 10% ethanol; no crop | Lower anthocyanin release at room temp than fridge temp; RCA reduced crystallinity and increased WVP | None specified | Indicator films showed color change with spoilage simulants; 16% RCA film had 74% lower crystallinity and 0.6% less release at room temp; simple smart packaging tool |

| [96] | Nanoclay-reinforced starch-grafted poly[(acrylic acid)-co-acrylamide] hydrogel composites | Soil type (acidic vs. neutral), water | Graft polymerization of acrylic acid and acrylamide onto wheat/maize starch with nanoclay integration | Soil incubation under Assam and Delhi soil conditions | Maize starch-based NCPCs showed slowest N release (~62–65% in 30 days) | Not specified | Maize starch grafts performed best in acidic soil; FTIR and XRD confirmed structural reinforcement; nanoclay reduced burst release and improved water retention |

| [97] | Cassava starch/polyacrylamide/natural rubber + montmorillonite (0–10 wt%) | Moisture, biodegradability | Free-radical polymerization + semi-IPN + glutaraldehyde crosslinking | Field soil, urea encapsulation in wax-coated hydrogel | BHM3 (3% MMT) showed best release: high swelling (7074%), 58% biodegradation, sustained release > 35 days | Not specified | BHM3 improved N release by 39.1%, mechanical strength by 260%; low-cost SRF alternative with field growth success; best bio-safety and yield profile among formulations |

| [98] | Thermoplastic starch films with 5–10 wt% cellulose nanofibers from rice straw | Moisture (humidity), mechanical stress | Chemo-mechanical extraction of CNF + film casting + ultrasonication | No crop tested; mechanical and moisture barrier testing only | Not tested for fertilizer release | None | CNFs enhanced yield strength, Young’s modulus, and humidity resistance; glass transition temp increased with CNF content; reduced transparency with higher CNF; good fiber dispersion seen in SEM |

| [99] | Nanozeolite–chitosan/sago starch (NZ–CS/ST) composite | Moisture/swelling | Ionotropic gelation with sodium tripolyphosphate; NZ prepared by co-precipitation + annealing | Philodendron sp. pot experiment | 41.93% urea and 64.0% P released in 14 days; improved water retention | Not specified | Superior growth over control and urea-only group; enhanced swelling with higher MW chitosan and crosslinking time |

| [100] | ST–PHEMA–GO hydrogels (starch, 2-hydroxyethyl methacrylate, graphene oxide) | pH-responsive swelling | Gamma-radiation induced polymerization; GO ratios varied | Not crop-tested; general release system studied | Swelling varied with pH (3, 7, 11), GO content, and irradiation dose; Fickian diffusion observed | Korsmeyer–Peppas (n < 0.5) | High mechanical stability and tunable swelling; potential for sustained release in various environments |

| [101] | Double-coated urea: Inner EC, outer starch-based SAP (from maize, potato, and pea starches) | Moisture-responsive (water absorption and swelling) | Twin-roll mixer to synthesize starch-based SAPs; inner EC coating applied | Soil incubation studies (no crop tested) | Steady nitrogen release for >96 h; potato starch-SAP most effective in prolonging release | Not explicitly stated | Potato starch-based SAP significantly improved water retention and slowed nutrient release under soil conditions |

| [102] | Starch microspheres encapsulating Fe, Cu, Mn | Moisture/swelling | Spray-dried gelatinized starch with micronutrients (monoelemental dispersions) | Water-based nutrient release (no crop) | Larger particles swelled more and released nutrients more slowly | Peppas-Sahlin model | Swelling delayed micronutrient release; different metals altered morphology, swelling, and release kinetics |

| [103] | Porous carboxymethyl starch (PCS) + Fe-P complex, zein coating | Moisture | Phosphorus and Fe loaded onto PCS; coated with zein | Soybean; pot experiment | 18% phosphorus released in 30 days; sustained release | Isotherm and kinetic studies applied | Phosphorus use efficiency increased to 68%, ~3× higher than conventional phosphate fertilizer; Fe acts as a bridge and nutrient source |

| [104] | Starch-g-poly(acrylic acid-co-acrylamide) with natural char nanoparticles (NCNPs) | pH, ionic strength | Reinforcement with NCNPs as nano-filler and crosslinker | Soil column test with urea leaching | 70% nitrogen released in 21 days; enhanced retention in basic and neutral pH | Not explicitly modeled | NCNPs doubled water retention and reduced nitrate leaching from 591.8 to 49.5 mg/L; enhanced degradation and nutrient efficiency |

| [105] | Cassava starch-g-poly(acrylic acid)/natural rubber/PVA semi-IPN hydrogel | pH, temperature, ionic strength | Grafting PAA onto starch, blended with NR and PVA, coated over urea with wax layer | Soil and water; chili plant test | 47.5% release in water (168 h), 38.5% in soil (30 d); best for NR:PVA 9:1 | Korsmeyer–Peppas | Low-cost biodegradable formulation; sustained nutrient release; responsive to environmental triggers; improved chili growth |

| [106] | Zeolite-coated urea using corn starch as binder | Water exposure (leaching) | Pan granulation with five binders including starch | 30-day soil column study for UZ-AP vs. uncoated urea | Acrylic polymer gave best performance; starch-bonded coatings less stable with faster N release | Not specified | Corn starch served as a natural binder for zeolite coating, but had lower crushing strength and faster N release vs. synthetic binders; zeolite + binder system reduced leaching by 65% (UZ-AP) |

| [107] | Cassava starch-g-PAA/NR/PVA hydrogel | Moisture, biodegradation | Grafting with acrylic acid, semi-IPN with NR/PVA, crosslinked using GA, MBA, or EGDMA | Maize plant growth performance and soil tests | 67.7–78.3% release in 30 days; best for GA (UCSBw-G2); 20.2% WHC retained at 30 days | Not explicitly mentioned | GA-crosslinked hydrogel showed highest water retention, best degradation rate (1.37%/day), improved biosafety and plant performance compared to other variants and commercial urea |

| [108] | Modified starch binder (MSB) blended with pyroligneous acid and bio-oil in biochar-based fertilizer | Moisture | MSB derived via chemical modification; combined with PA and BO as binders | No plant growth test; characterization + nutrient leaching | PA + BO + MSB combination slowed P release by 4.7–21.2% compared to individual binders | Ritger–Peppas model (best fit) | Triple-binder system improved structural integrity and economic efficiency; MSB viscosity crucial for NPK retention |

| [109] | Cassava starch with alkyd resin (from castor and rubber seed oils) | pH, Time | Alkyd resins modified with sorbitol, maleic/phthalic anhydride; blended with starch | No plant used; urea release tested at pH 8 over 24 days | 31.66–48.61% N release depending on coating thickness | First-order and Korsmeyer–Peppas models | SEM and FTIR confirmed compact coatings; release rates met EN 13266 standard for CRFs |

| [110] | Cassava starch + cassava bagasse composite | Soil moisture | Physical blending with up to 50 wt% urea; plasticized films | Soil incubation (no specific crop); 15 days | 95% urea release in 15 days for films with 50 wt% urea | Not explicitly stated | Urea improved flexibility and biodegradability; 57% weight loss in 15 days; suitable for eco-friendly fertilizer delivery |

| [111] | Sodium carboxymethyl starch (SCS) with polydopamine | Moisture | Chelation with Fe ions; coating with Pdop and SCS for macro/micronutrient integration | Corn field test (multi-nutrient delivery) | Zn, P, Fe reached 60% release in 30 days; ~60% nutrient use efficiency | Not specified | Novel coating system improves macronutrient uptake and micronutrient efficiency (e.g., Fe chelation); environmentally friendly approach |

| [112] | Sulfonated corn starch/poly(acrylic acid) with phosphate rock | Moisture | Synthesis of a superabsorbent (SCS/PAA) embedding phosphate rock (PHR) | Soil incubation (no specific crop) | Max swelling: 498 g/g (H2O), 65 g/g (NaCl); slow P and K release confirmed via experiments | Not specified | Integrated water retention with nutrient delivery; SCS improved P release from PHR matrix |

| [113] | Starch acetate/glycerol/polyvinyl alcohol (SA/GLY/PVA) biocomposites | Moisture | SA grafted with GLY and PVA to form multilayer hydrophobic coatings on DAP granules | Water-based nutrient release tests (no crop) | Double-layer coating delayed nitrogen release 3.2× compared to uncoated DAP | Not specified | 70% SA-based coatings formed smooth cohesive films with strong adhesion, reducing burst release of N and P |

| [114] | PVA–starch formulation with Cu–Zn/CNF nanocomposite | Moisture/biodegradation | In situ dispersion of Cu–Zn-loaded carbon nanofibers (CNFs) in PVA–starch during polymerization | Chickpea plant growth in garden soil | Gradual release of Cu and Zn; 5.3 ± 0.05 mg/g Cu and 2.8 ± 0.1 mg/g Zn; enhanced growth and reduced ROS | Not explicitly modeled | PVA–starch matrix enabled micronutrient-controlled release; improved plant height, ROS scavenging, and nutrient translocation |

| [115] | Starch + maleic-anhydride-modified β-cyclodextrin + acid-treated halloysite nanotubes | Moisture, ionic strength | Free radical copolymerization with acrylic acid and acrylamide | Water and soil conditions; no specific crop | Slower release in soil than in water; high water retention; release fitted Fickian diffusion in soil | Fickian diffusion model | Halloysite enhanced urea loading and controlled release; excellent swelling and retention properties for agro-applications |

| [116] | High-amylose or waxy starch grafted with acrylamide and crosslinked with N,N′-MBA | Moisture, water absorption | One-step reactive melt-mixing with ceric ammonium nitrate (CAN) initiator and NaOH saponification | Urea release in water (no specific crop) | Urea release rate influenced by gel strength and microstructure; slower release from stronger high-amylose gel networks | Not explicitly stated | Crosslinked high-amylose gels showed higher storage modulus, smaller pore size, and controlled nutrient release |

| Evaluation Aspect | Methods Used | Purpose |

|---|---|---|

| Morphology | SEM, AFM | Surface uniformity, coating thickness |

| Thermal Behavior | DSC, TGA | Stability of coating |

| Chemical Structure | FTIR, XRD | Functional groups, crystallinity |

| Stimuli Response | Swelling, LCST, pH-responsiveness | Triggered release |

| Release Performance | Kinetic modeling | Rate and mechanism of release |

| Agronomic Effectiveness | Pot/field trials | Real-soil validation |

| Parameter | Starch | Chitosan | Cellulose | Alginate |

|---|---|---|---|---|

| Source and Availability | Abundant, derived from cereals, tubers | Obtained from chitin in crustacean shells | Widely available from plant biomass | Extracted from brown seaweed |

| Biodegradability | High, enzymatically degradable | High, enzymatically degradable | High, slow degradation in some soils | High, ionically and enzymatically degradable |

| Cost-effectiveness | Very low cost | Moderate cost | Low–moderate cost | Moderate cost |

| Mechanical Properties | Moderate strength; can be improved via crosslinking/nanofillers | Good film-forming, moderate tensile strength | High tensile strength, low flexibility | Flexible gels, low tensile strength |

| Functional Groups for Nutrient Binding | Hydroxyl groups; modifiable to introduce carboxyl/amine | Amino groups (cationic), hydroxyl groups | Hydroxyl groups | Carboxylate groups (anionic) |

| Responsive Capabilities | pH, moisture, temperature, ionic strength, enzymatic | pH, moisture, temperature, enzymatic | Limited pH/moisture response | pH, ionic strength, moisture |

| Representative Applications | CRF coatings, drug delivery, biodegradable packaging | CRF coatings, antimicrobial films, drug delivery | Composite CRF films, reinforcement in bioplastics | Encapsulation of fertilizers, biomedical gels |

| Challenges | Future Directions |

|---|---|

| High formulation cost | Low-cost, bio-derived polymers and green synthesis |

| Variable soil conditions (pH, enzymes, moisture) | Soil-specific smart coating customization |

| Uncertainty in long-term biodegradability | Eco-safety and residue toxicity studies |

| Limited field performance data | Field validation under diverse agro-ecosystems |

| Weak regulatory frameworks | Integration of machine learning and modeling tools |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azeem, B. Stimuli-Responsive Starch-Based Biopolymer Coatings for Smart and Sustainable Fertilizers. Gels 2025, 11, 681. https://doi.org/10.3390/gels11090681

Azeem B. Stimuli-Responsive Starch-Based Biopolymer Coatings for Smart and Sustainable Fertilizers. Gels. 2025; 11(9):681. https://doi.org/10.3390/gels11090681

Chicago/Turabian StyleAzeem, Babar. 2025. "Stimuli-Responsive Starch-Based Biopolymer Coatings for Smart and Sustainable Fertilizers" Gels 11, no. 9: 681. https://doi.org/10.3390/gels11090681

APA StyleAzeem, B. (2025). Stimuli-Responsive Starch-Based Biopolymer Coatings for Smart and Sustainable Fertilizers. Gels, 11(9), 681. https://doi.org/10.3390/gels11090681