Experimental Investigation of Synergistic Enhanced Oil Recovery by Infill Well Pattern and Chemical Flooding After Polymer Flooding

Abstract

1. Introduction

2. Results and Discussion

2.1. Comparative Rheological Analysis of Displacement Agents

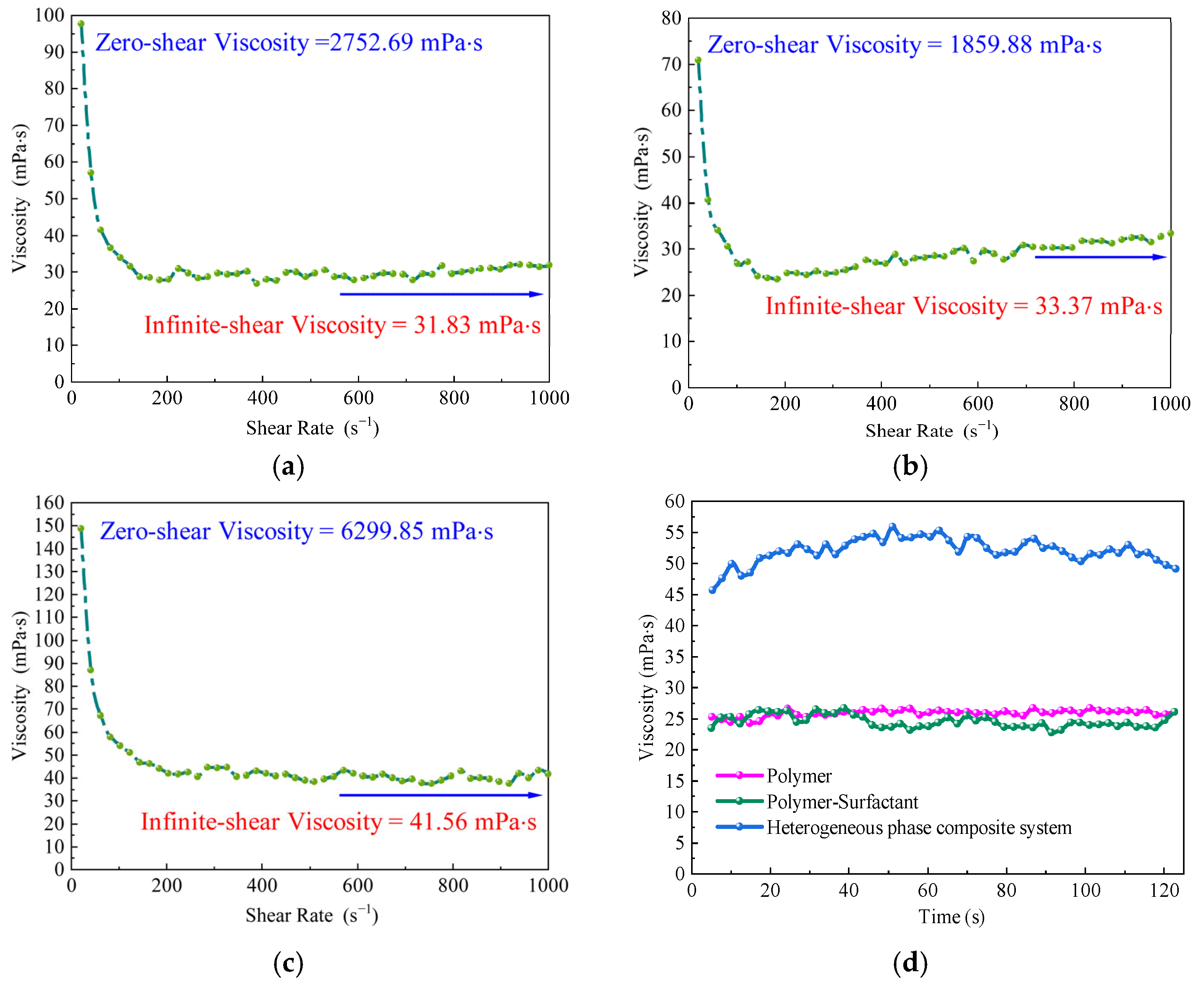

2.1.1. Steady-Shear Rheology of the Three Displacement Systems

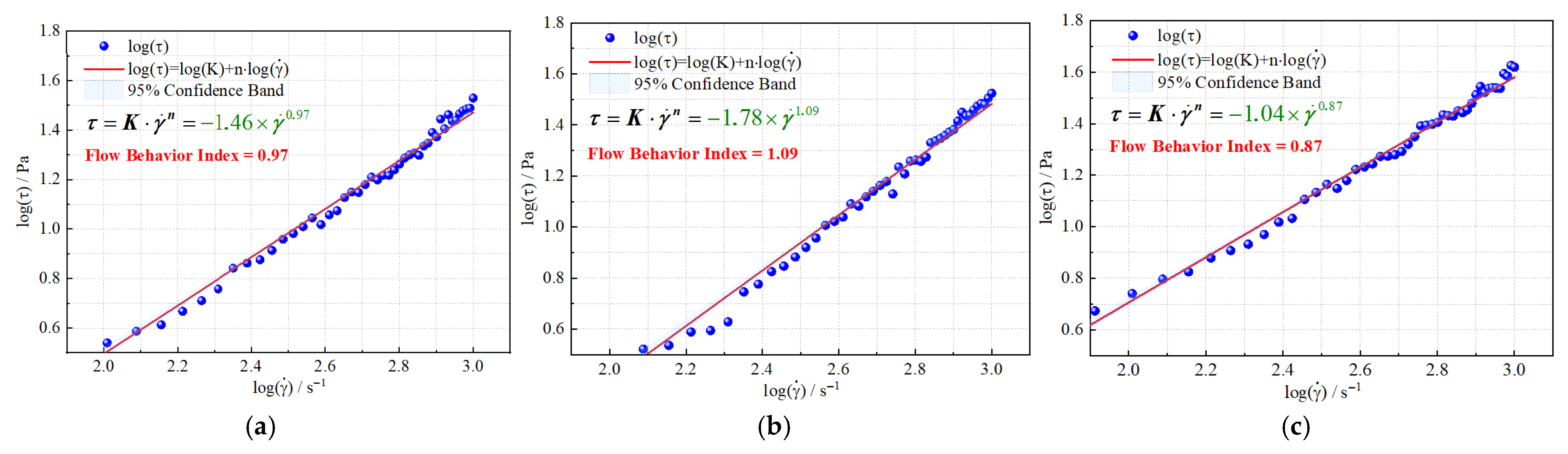

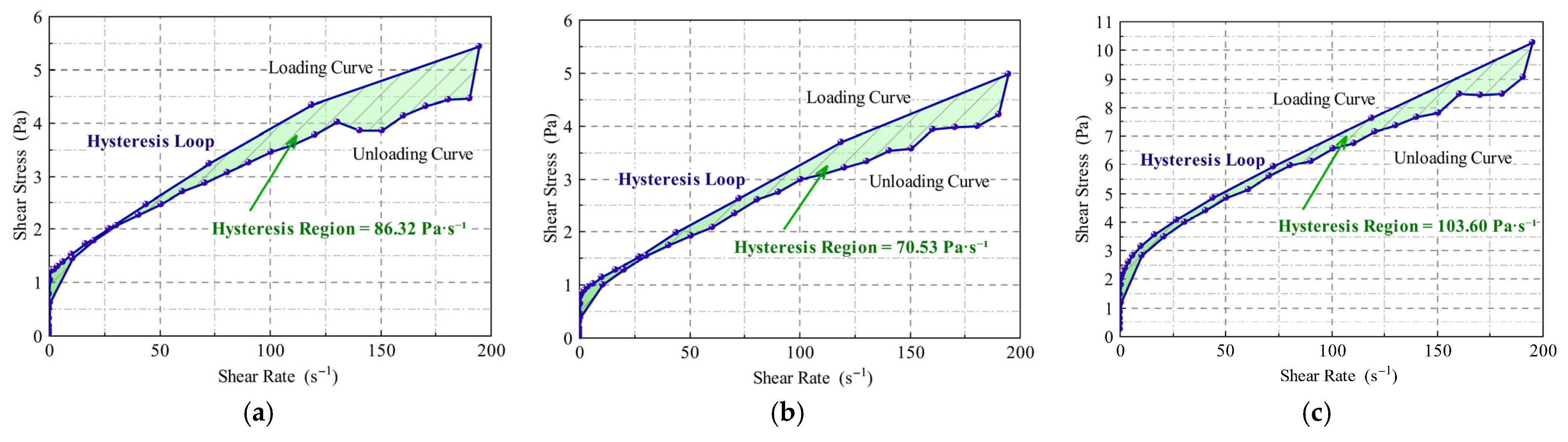

2.1.2. Shear Hysteresis Characteristics of the Three Displacement Systems

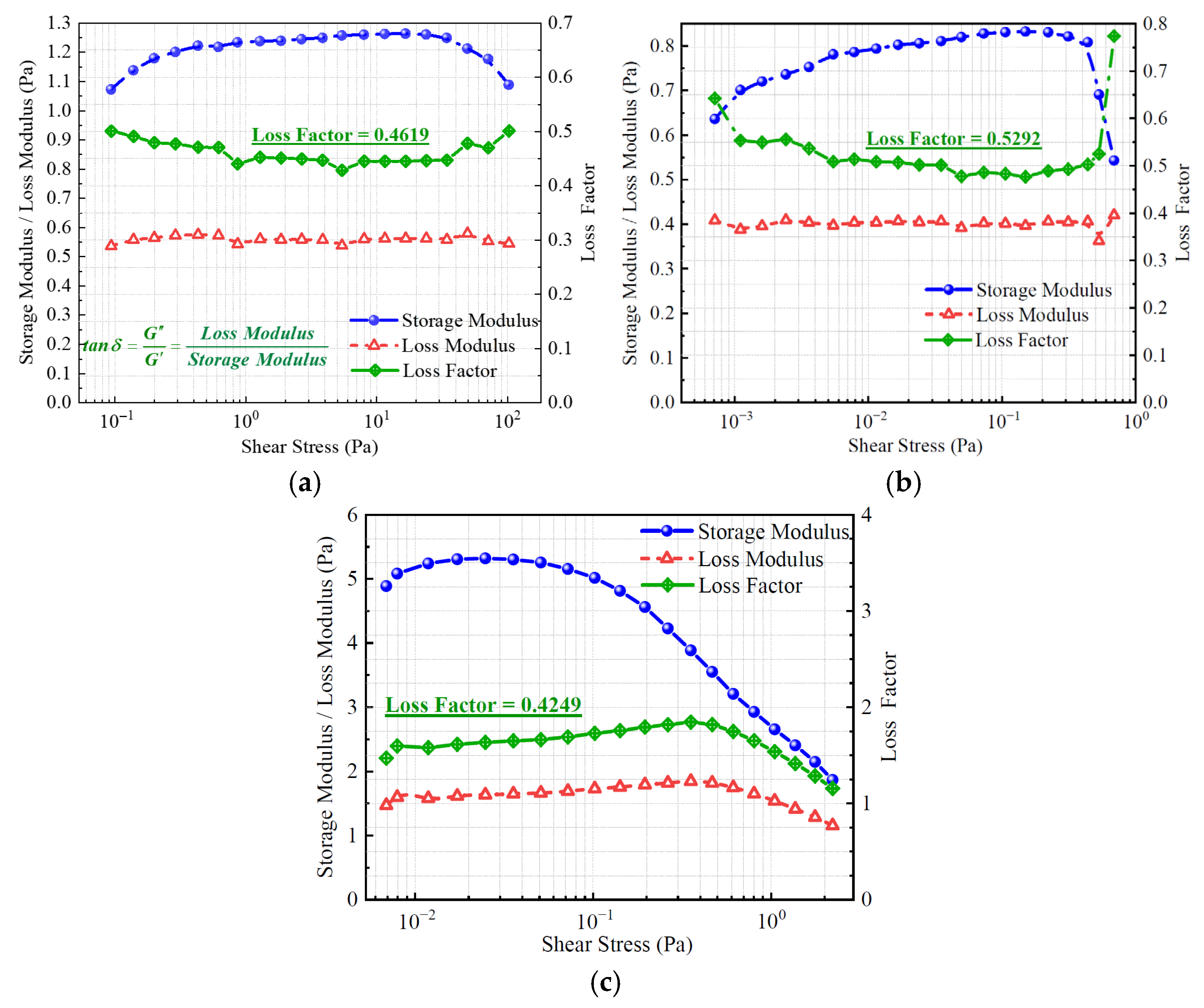

2.1.3. Dynamic Viscoelastic Behavior of the Three Displacement Systems

2.1.4. Surface and Interfacial Tension Regulation of the Three Displacement Systems

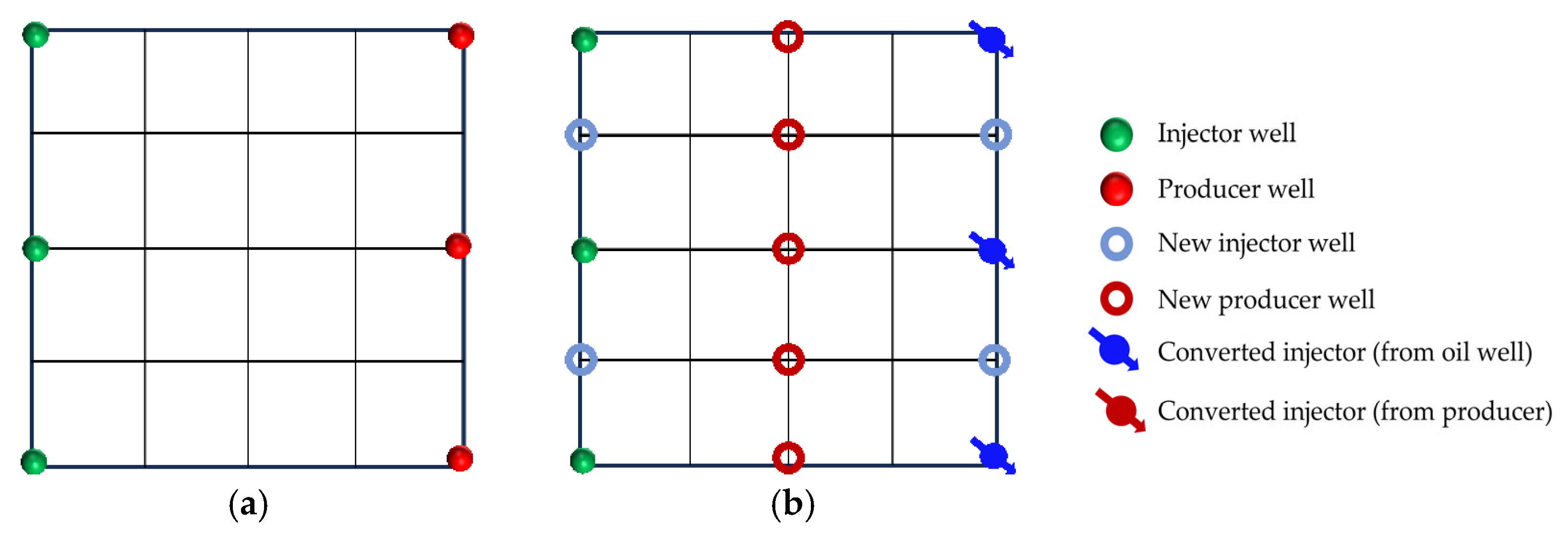

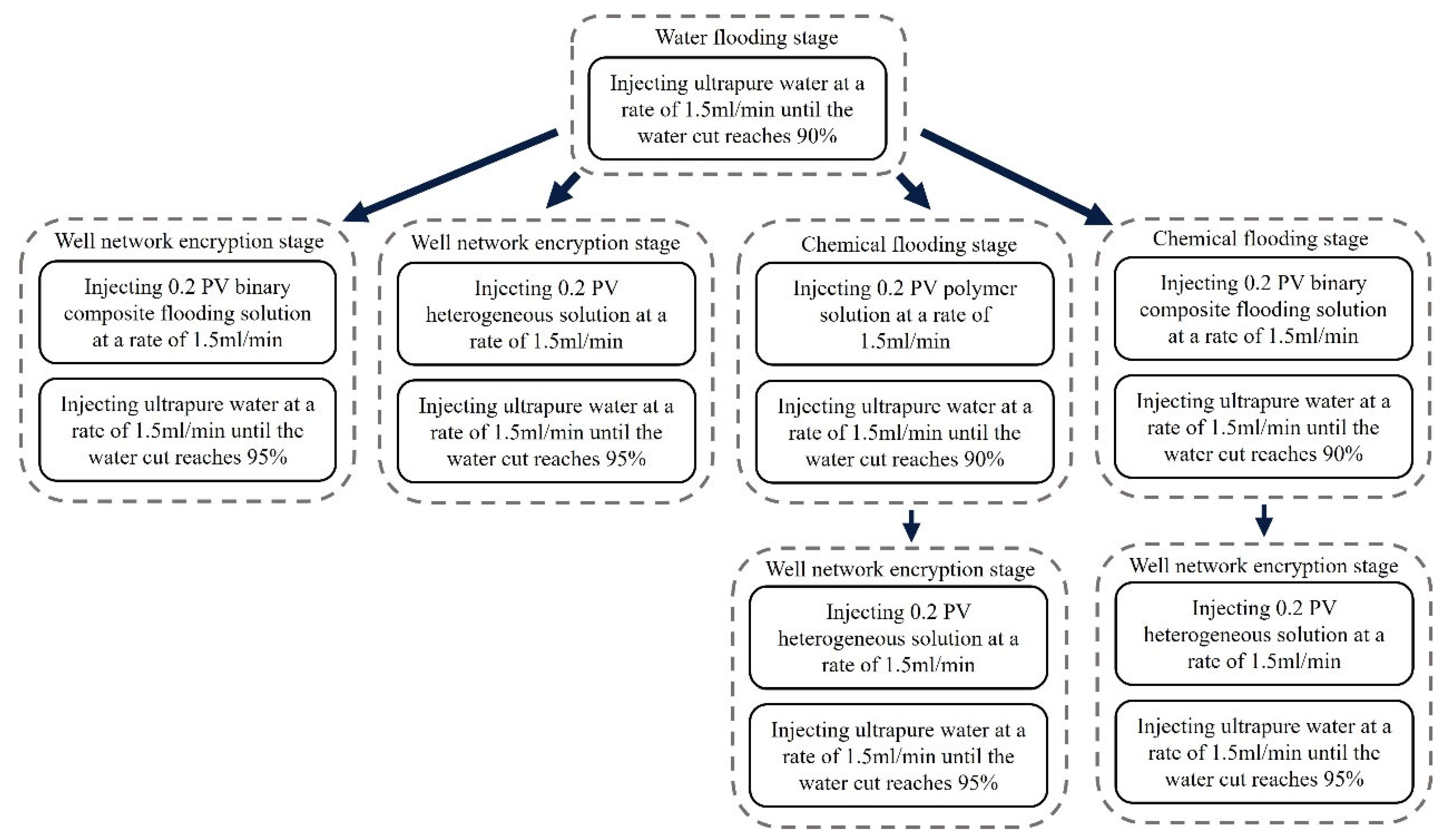

2.2. Infill Well Pattern Flooding Experiments with Various Chemical Systems

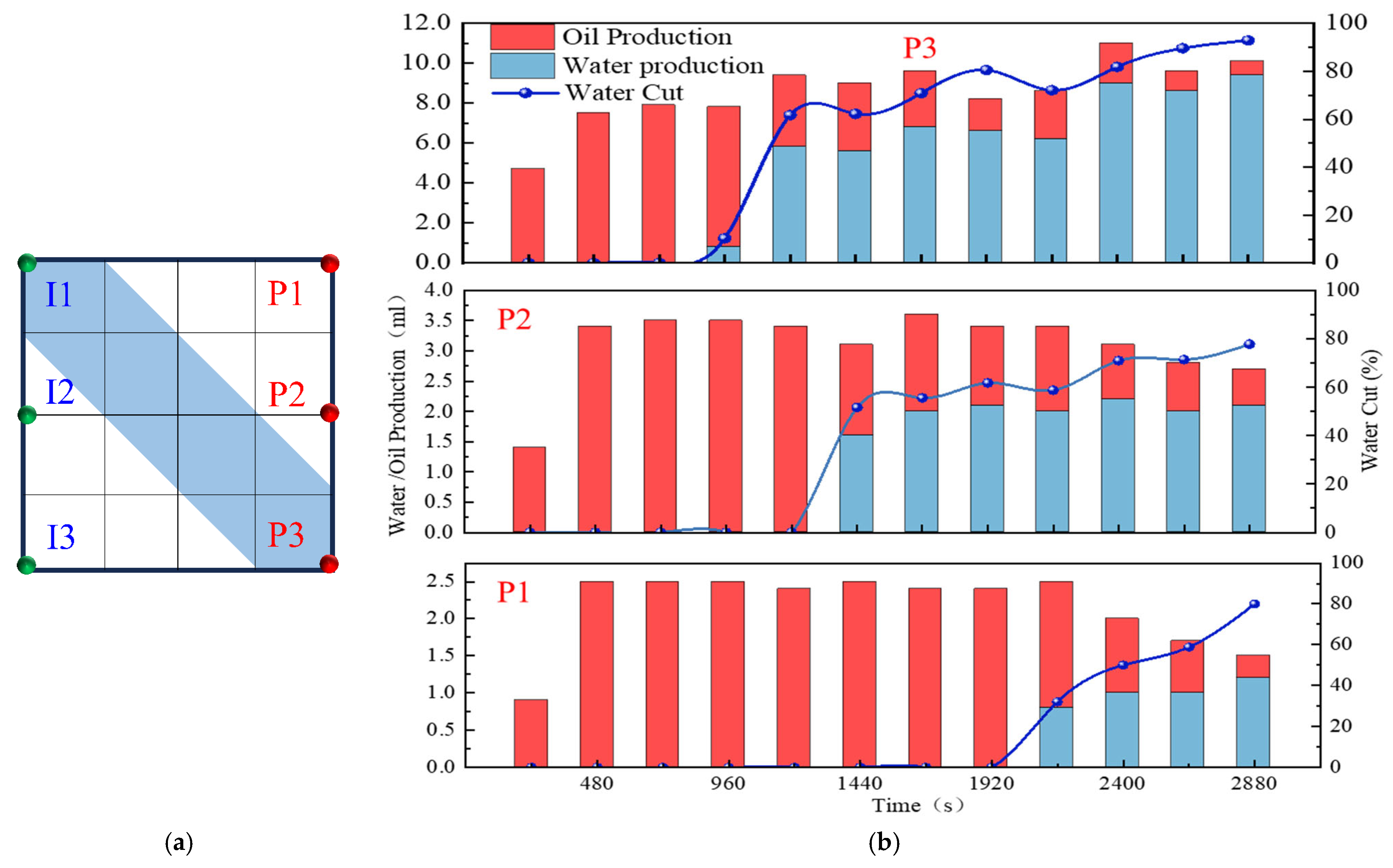

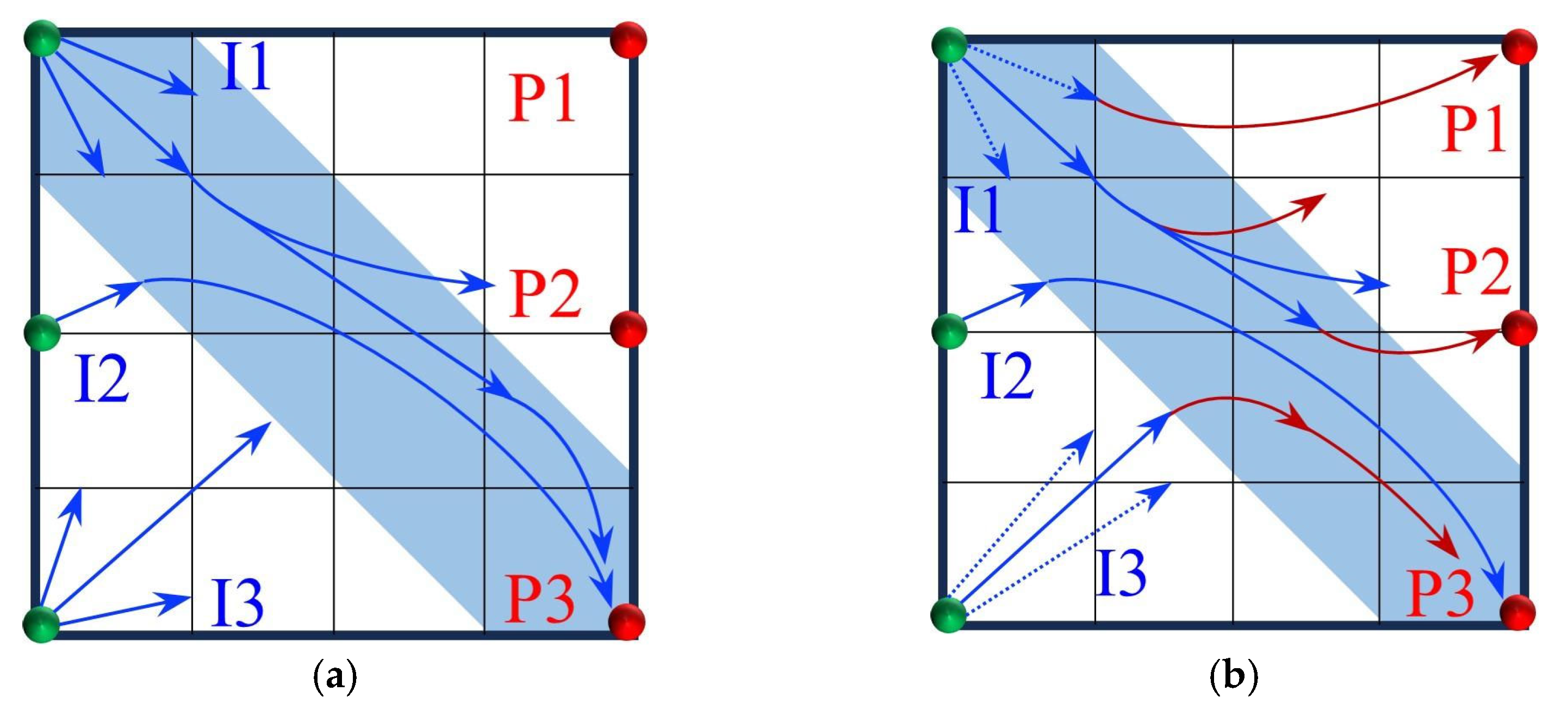

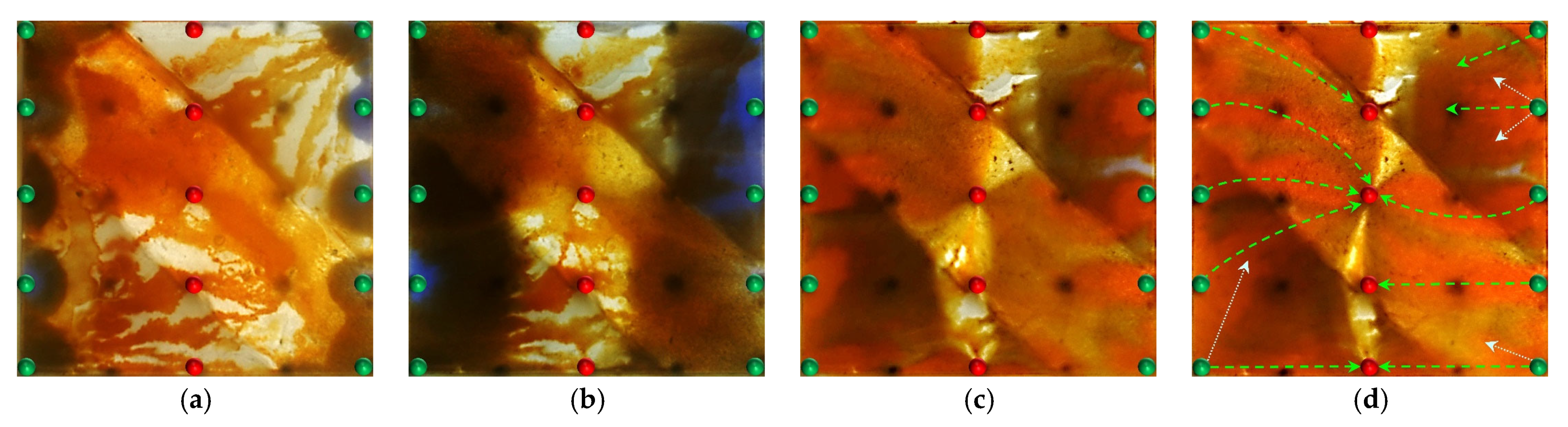

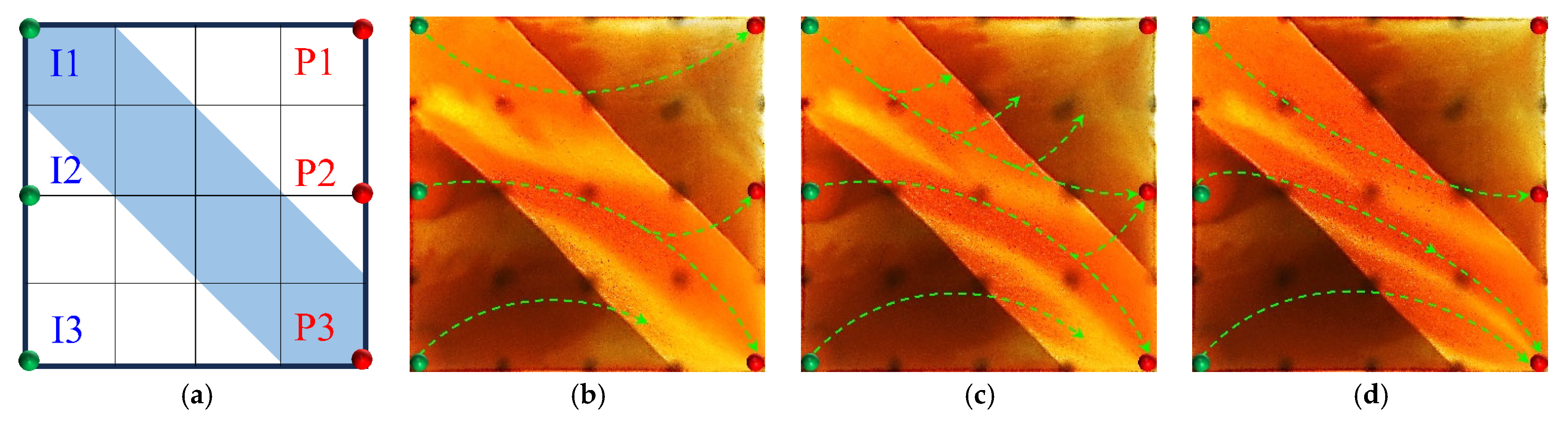

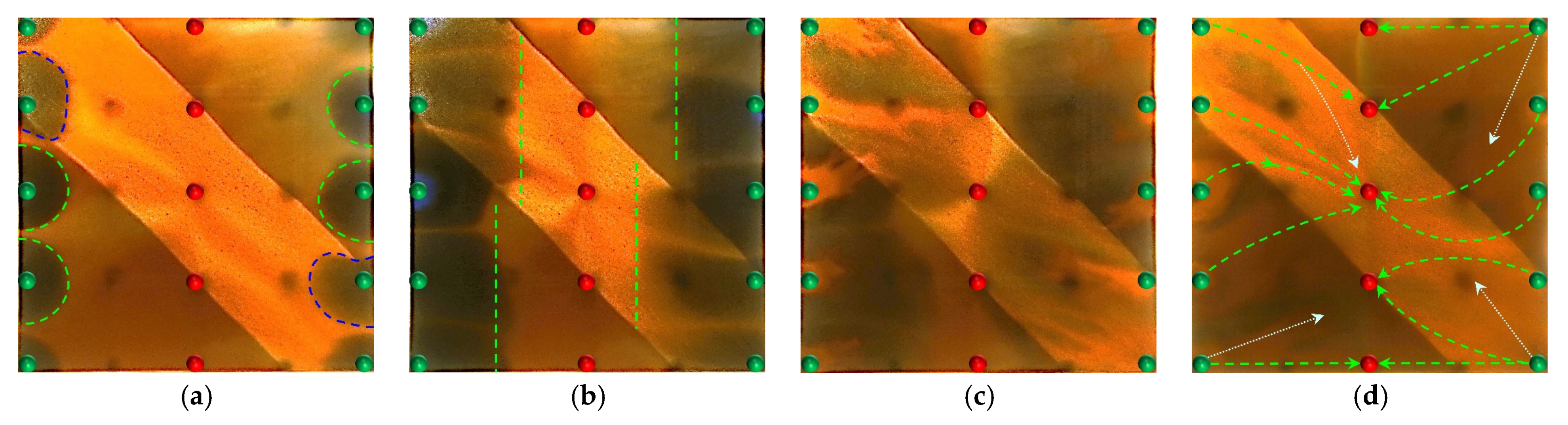

2.2.1. Visual Results During the Water Flooding Stage

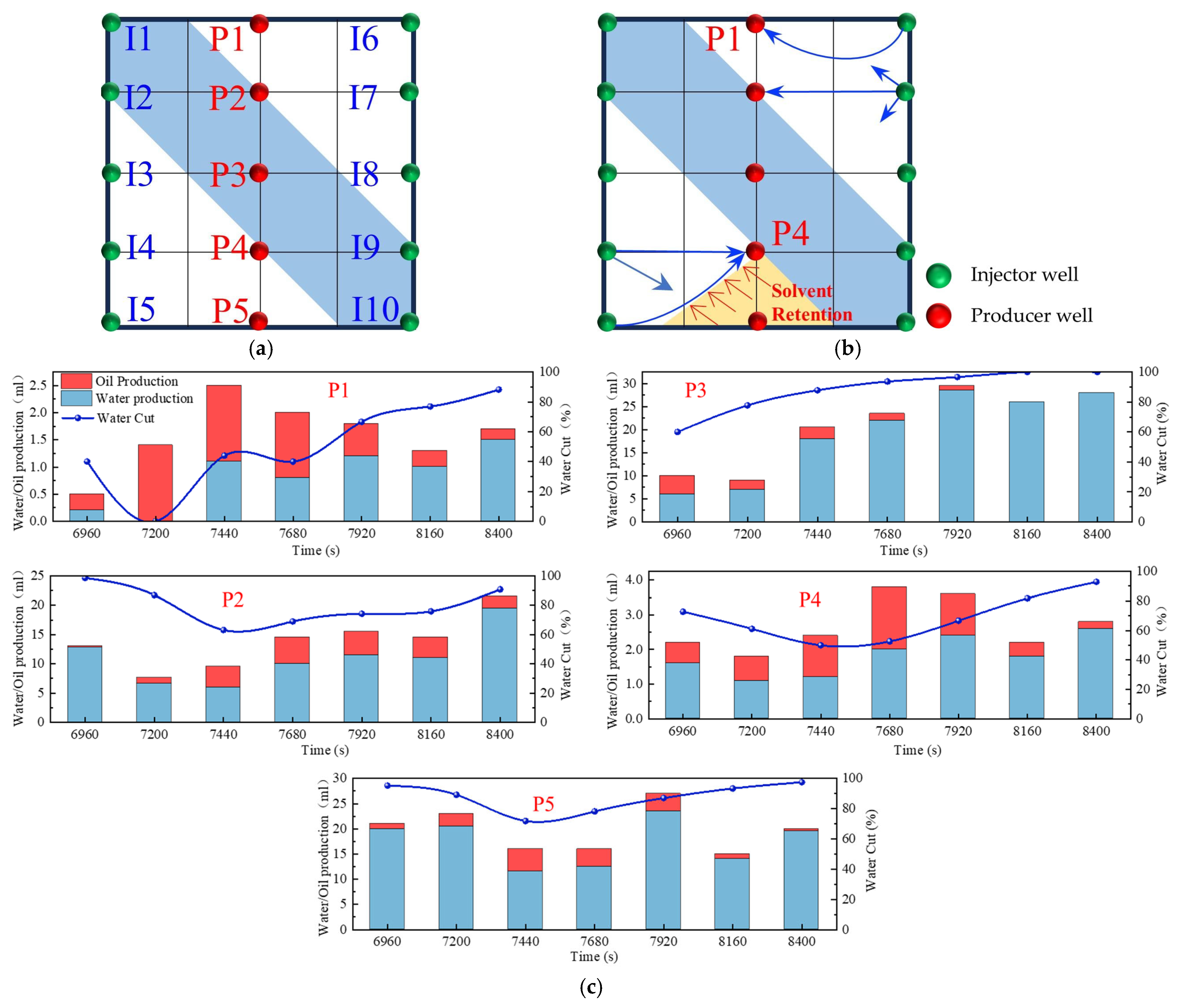

2.2.2. Visual Results During the Post-Waterflood Infill Chemical Flooding Stage

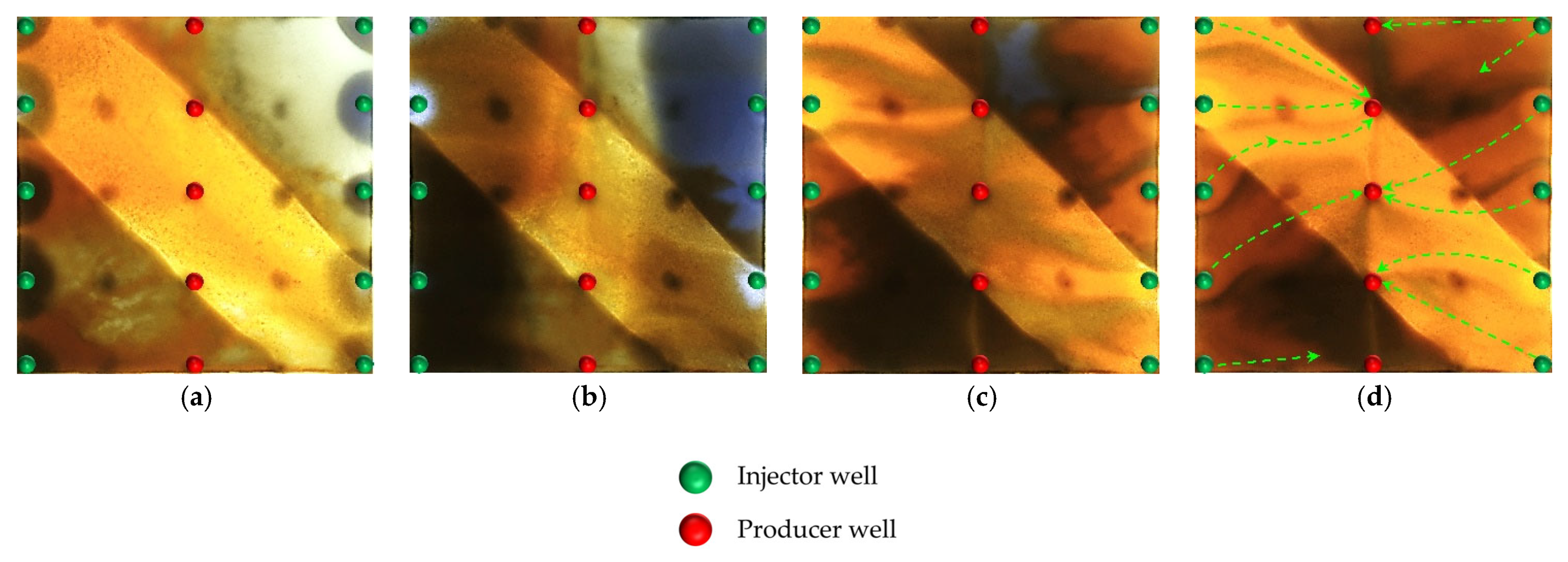

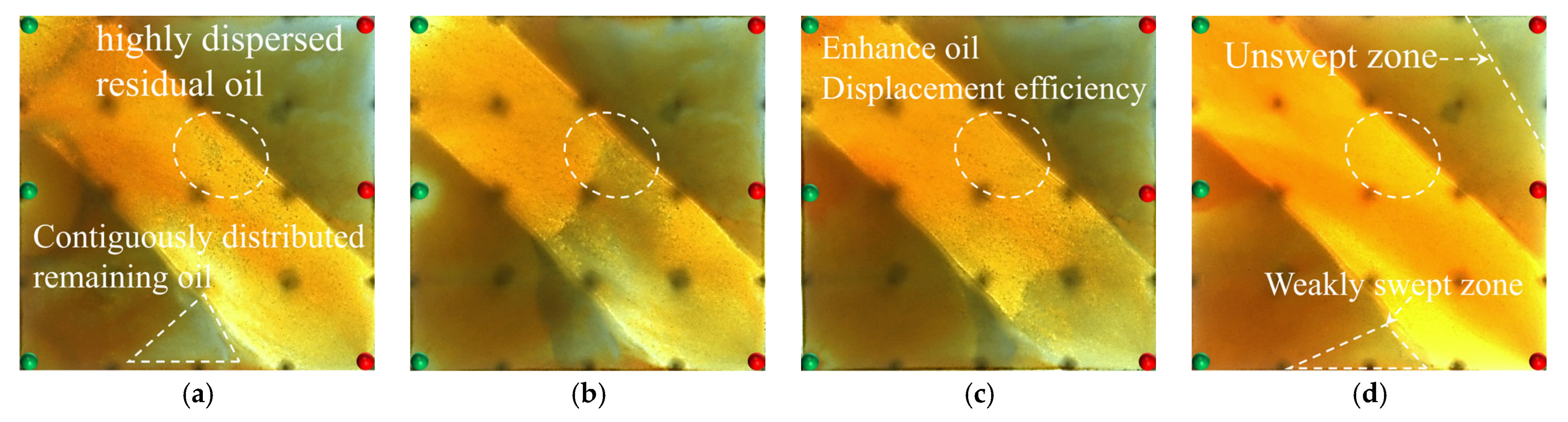

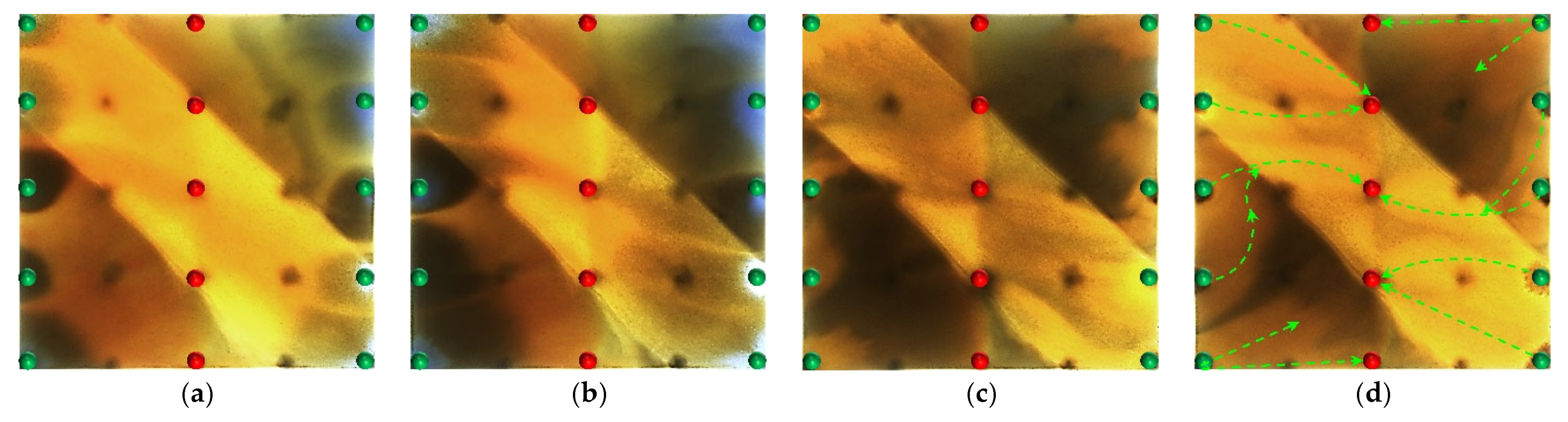

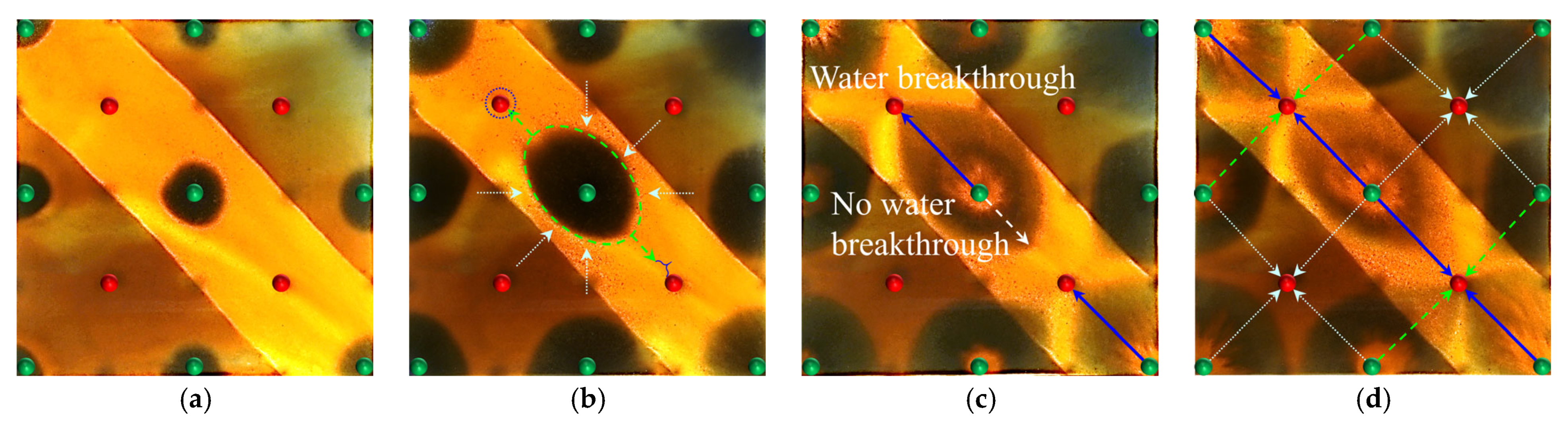

2.2.3. Visual Results of the Post-Waterflood Chemical Flooding Stage

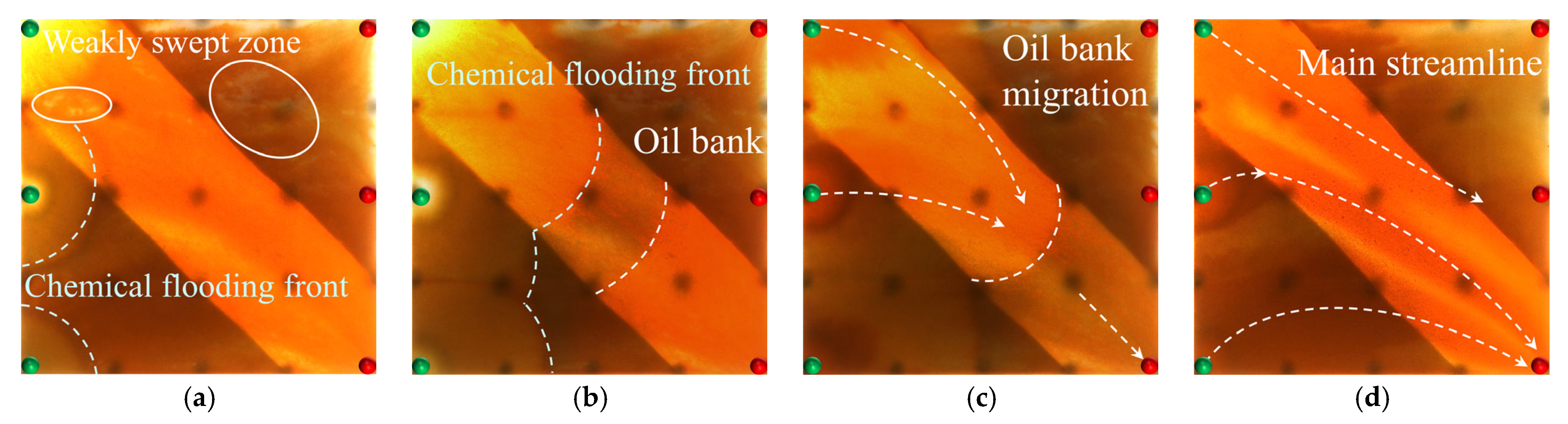

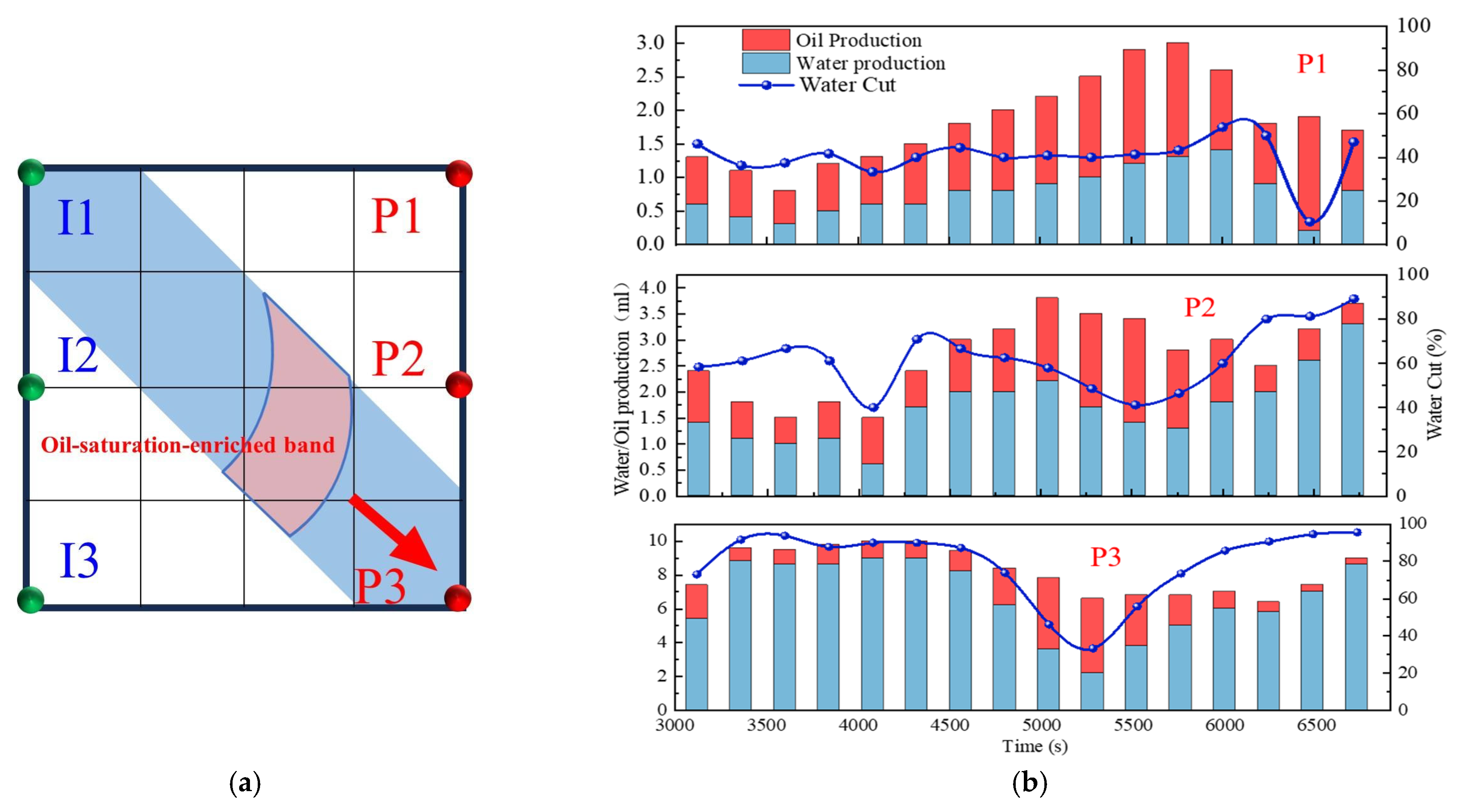

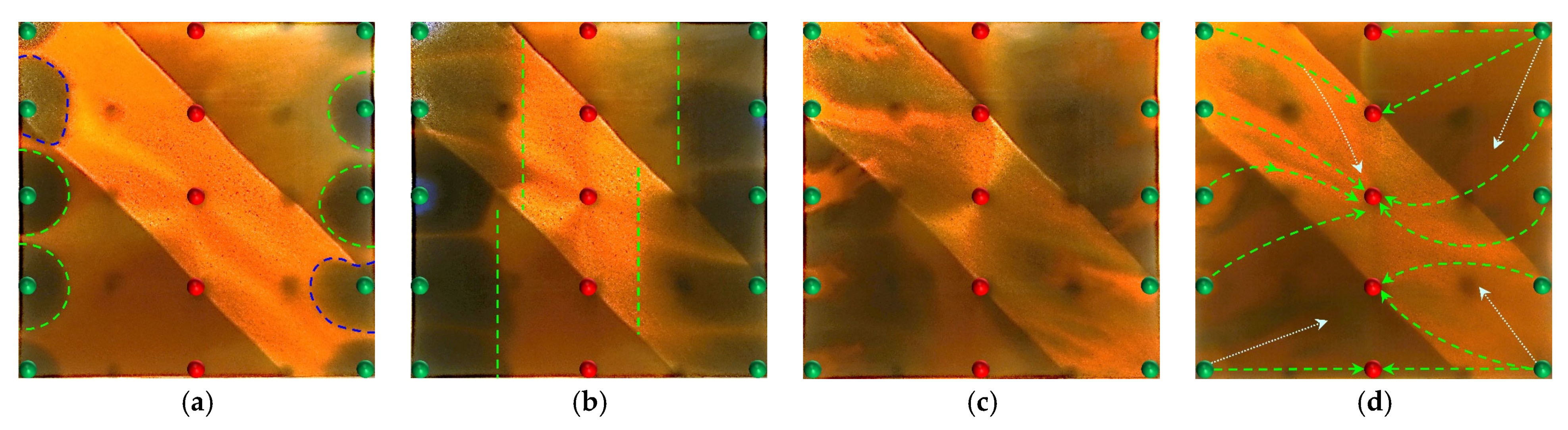

2.2.4. Visual Results of Infill Well Pattern Heterogeneous Flooding After Chemical Flooding

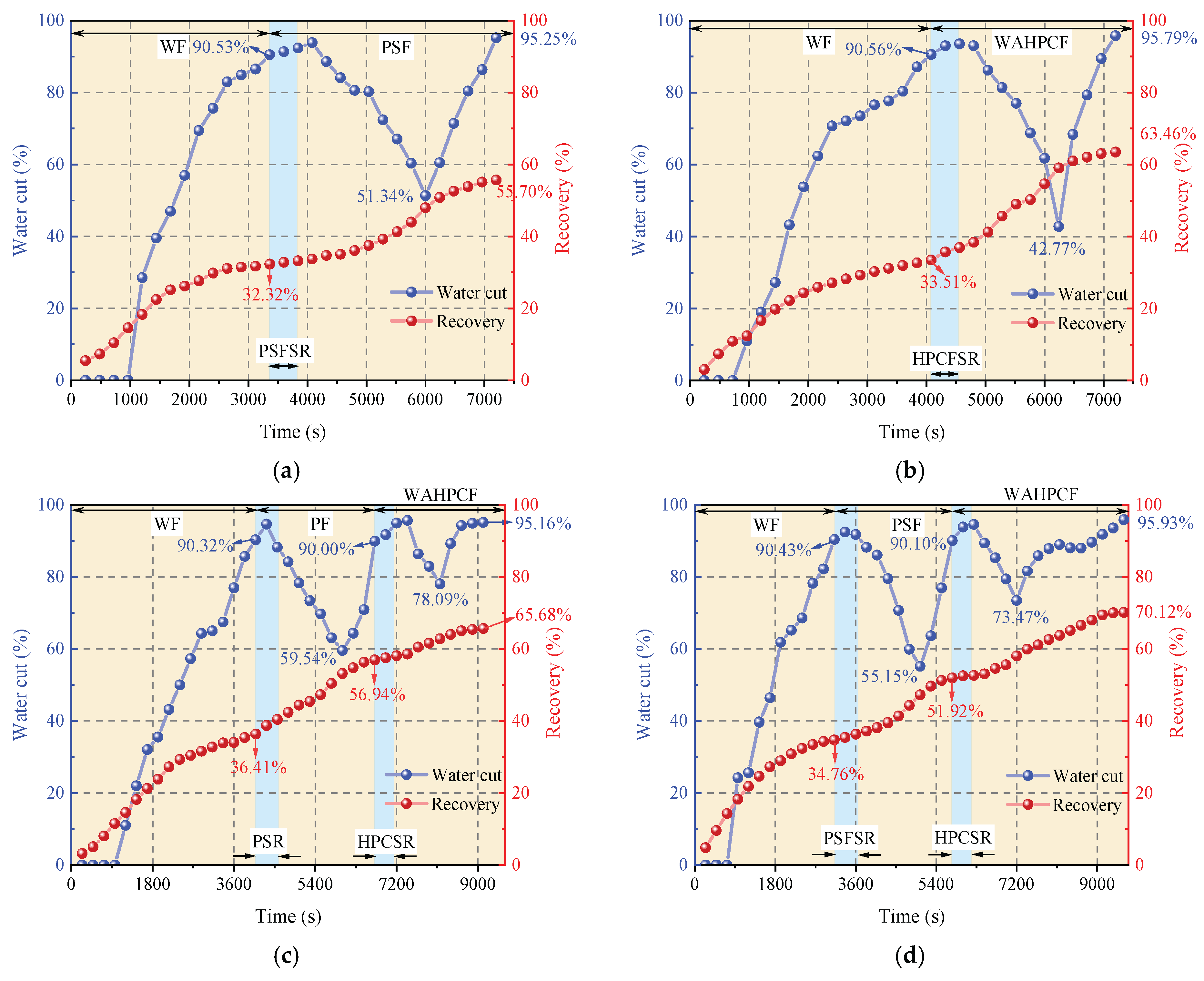

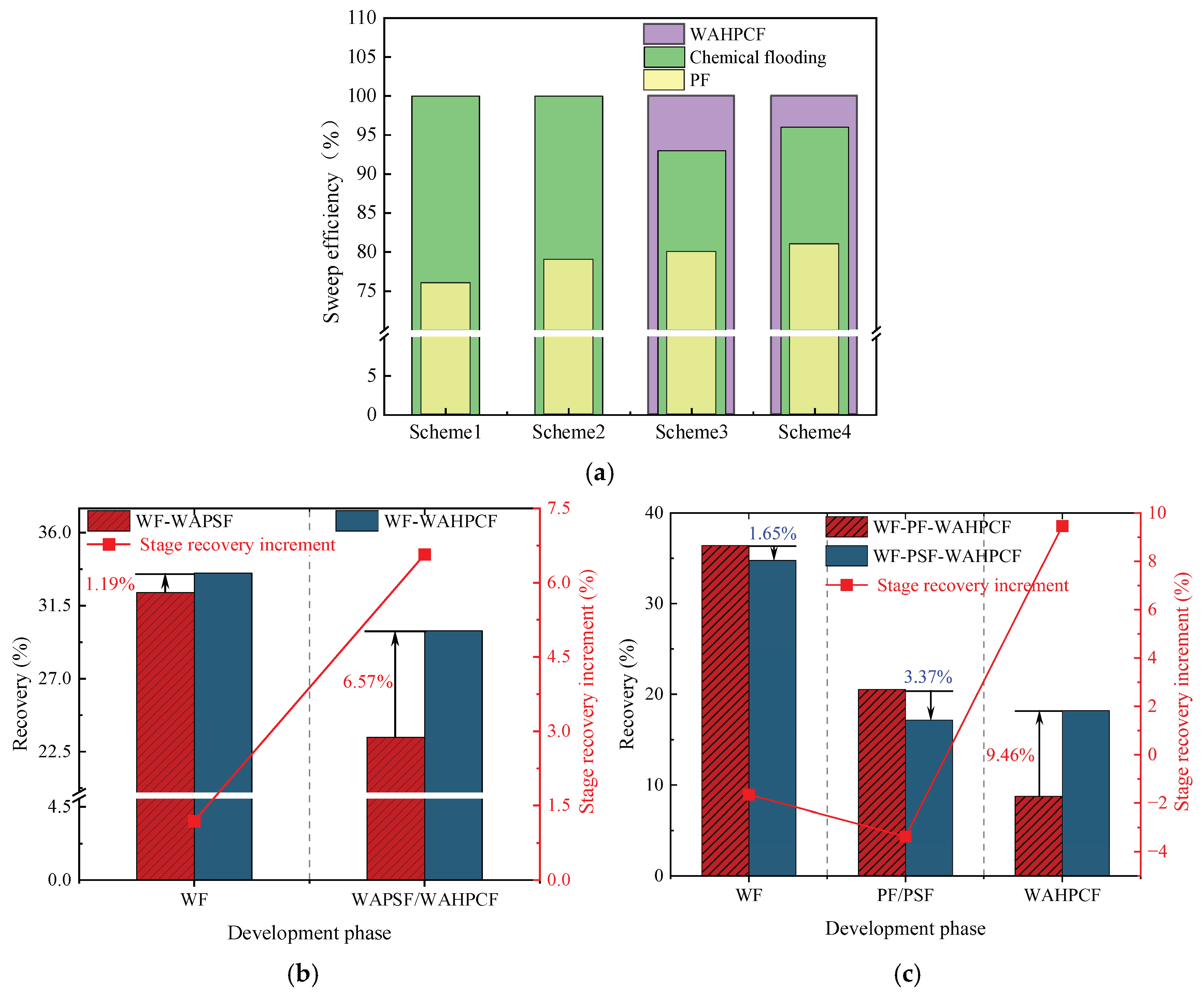

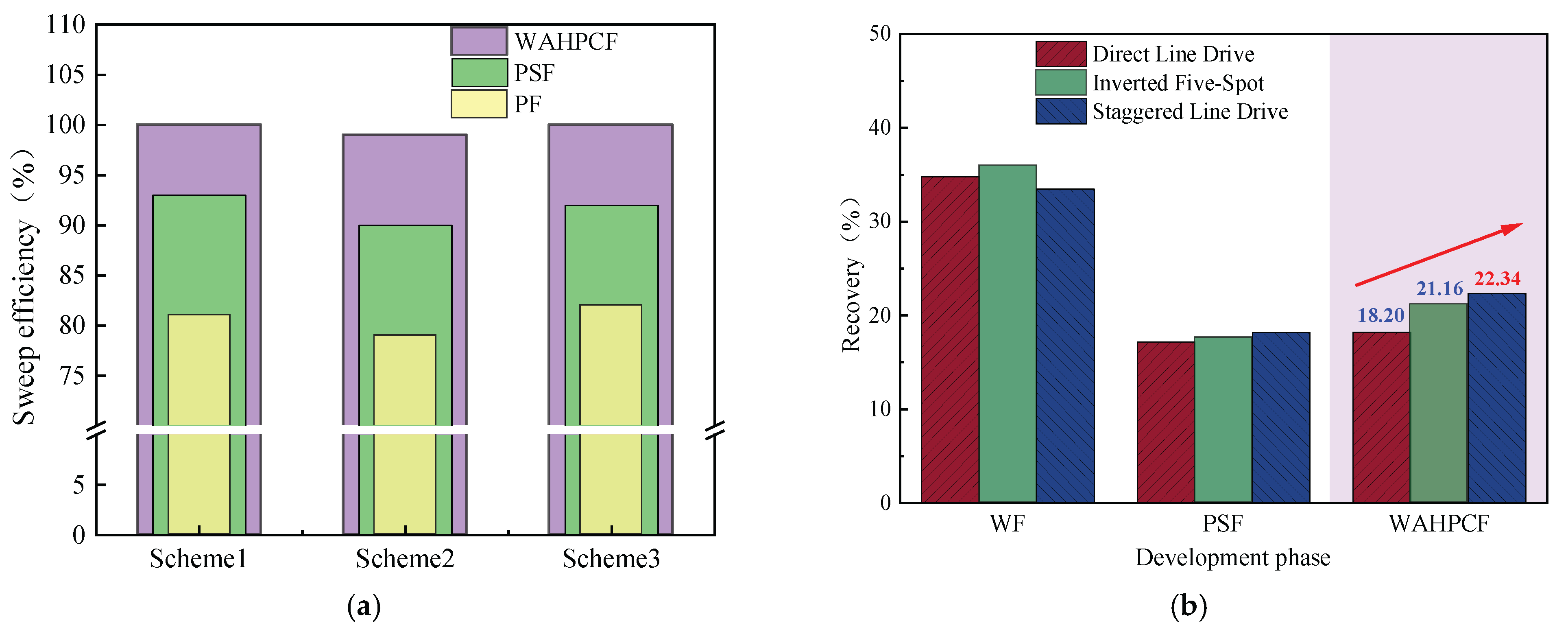

2.2.5. Variation Characteristics of Sweep Efficiency, Water Cut, and Oil Recovery Factor

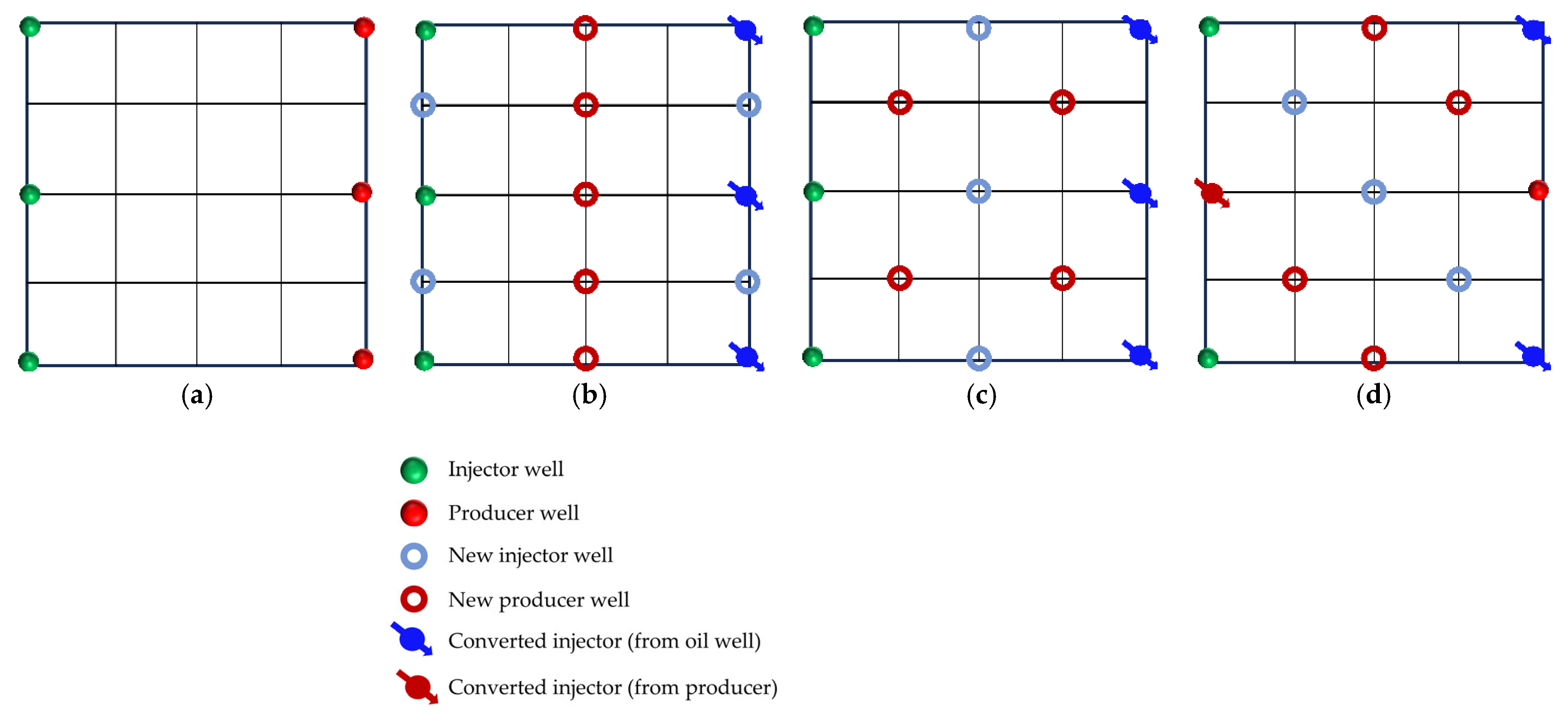

2.3. Heterogeneous System Flooding Experiments with Various Infill Well Patterns

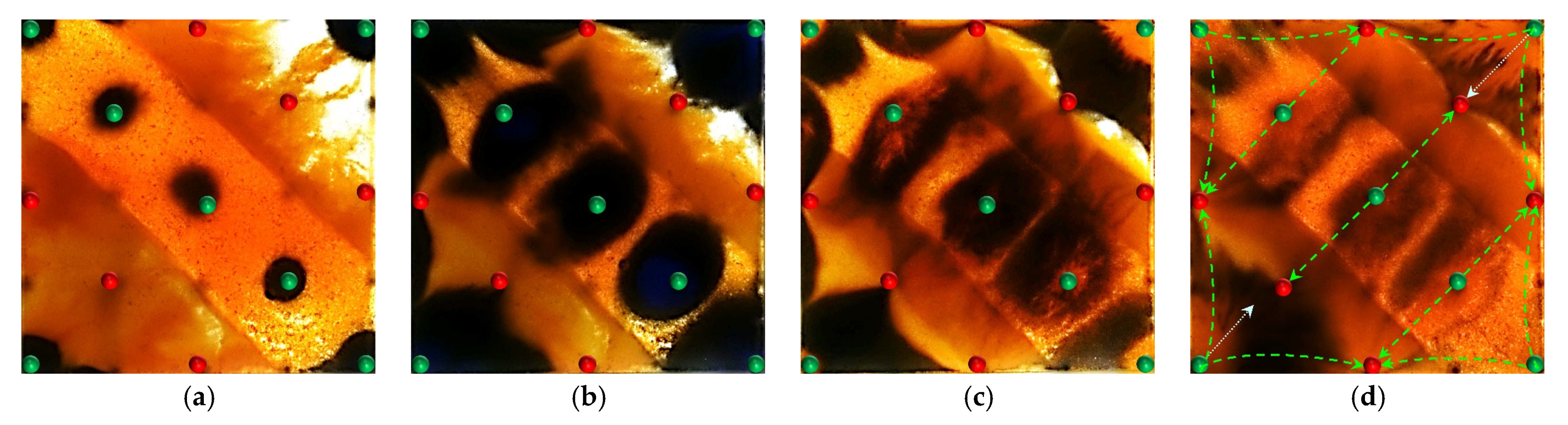

2.3.1. Visual Experimental Results

2.3.2. Variation Characteristics of Sweep Efficiency, Water Cut, and Oil Recovery Factor

3. Conclusions

- When the effectiveness of a single chemical flooding technique is limited, the optimized combination of infill well pattern and heterogeneous composite flooding can effectively improve the unbalanced displacement pattern dominated by preferential flow channels in the late stage of water flooding. The results indicate that the synergistic approach outperforms traditional single chemical flooding strategies in enhancing sweep efficiency and mobilizing the remaining oil in poorly swept zones, providing an effective technical path for improving oil recovery in the high-water-cut stages of complex heterogeneous reservoirs.

- The heterogeneous composite flooding system (HPC) exhibits a strong synergistic effect of plugging and displacement under infill well pattern conditions. Experimental results show that the HPC slug can effectively suppress breakthrough in high-permeability channels and promote the diversion of the displacement fluid toward medium- and low-permeability zones, thereby significantly enhancing the sweep volume and the mobilization efficiency of the remaining oil.

- Significant differences exist in the synergistic oil displacement performance among different well pattern configurations. Among them, the combination of the staggered line-drive well pattern and the HPC system achieves the best results, with an incremental oil recovery of 22.34% and a water cut reduction of 33.85%. This configuration demonstrates prominent advantages in displacement uniformity and overall recovery enhancement. The staggered line-drive well pattern optimizes the fluid streamline distribution, effectively weakens the conductivity of preferential flow channels, improves slug utilization, and enhances displacement efficiency in poorly swept zones. It outperforms the other two infill well pattern schemes, highlighting the technical significance of rational well pattern design in combination with heterogeneous flooding for enhanced oil recovery.

- The displacement condition during early-stage chemical flooding has a significant impact on the subsequent mobilization performance of heterogeneous composite flooding under the infill well pattern. Compared with the infill scheme following polymer flooding, the scheme following binary composite flooding demonstrates better supplementary displacement performance in low-permeability zones due to the sustained action of the surfactant, resulting in a greater improvement in the final oil recovery. This reflects the amplifying and inheriting relationship between the infill well pattern and chemical flooding technologies in enhancing development performance.

4. Materials and Methods

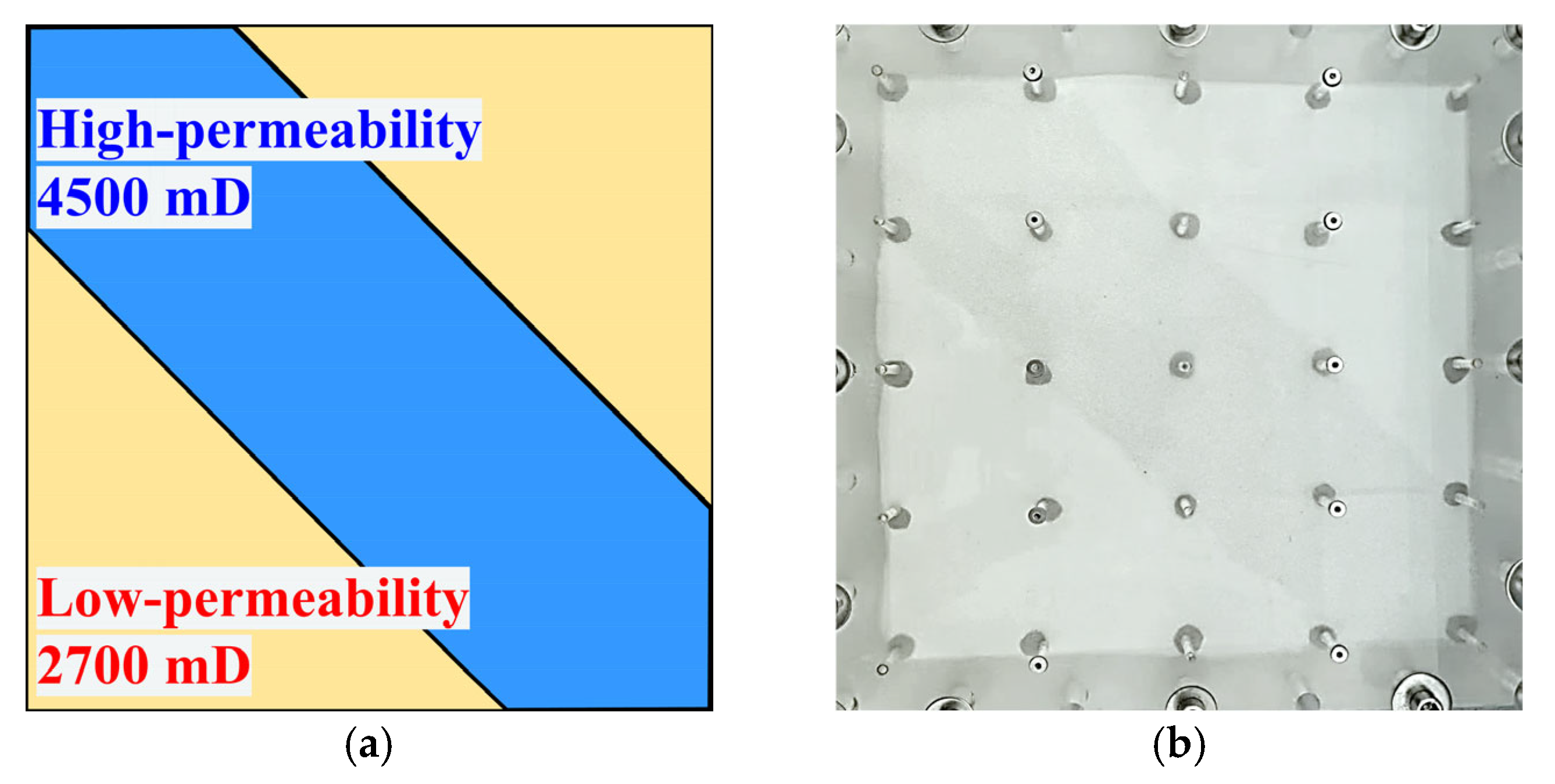

4.1. Fundamentals of Experimental Design

- 1.

- Geometric similarity

- 2.

- Production pressure differential similarity

- 3.

- Injection volume similarity

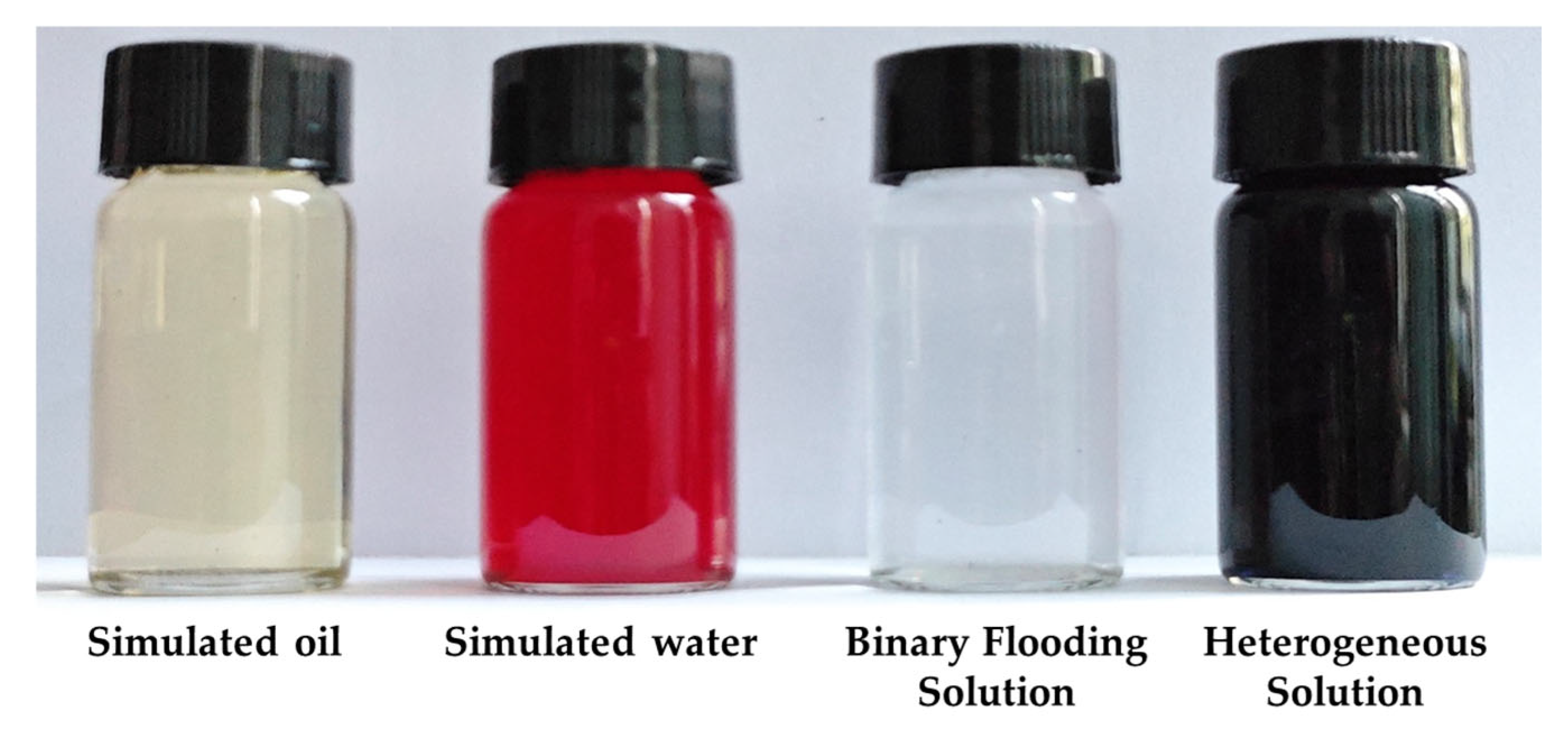

4.2. Materials

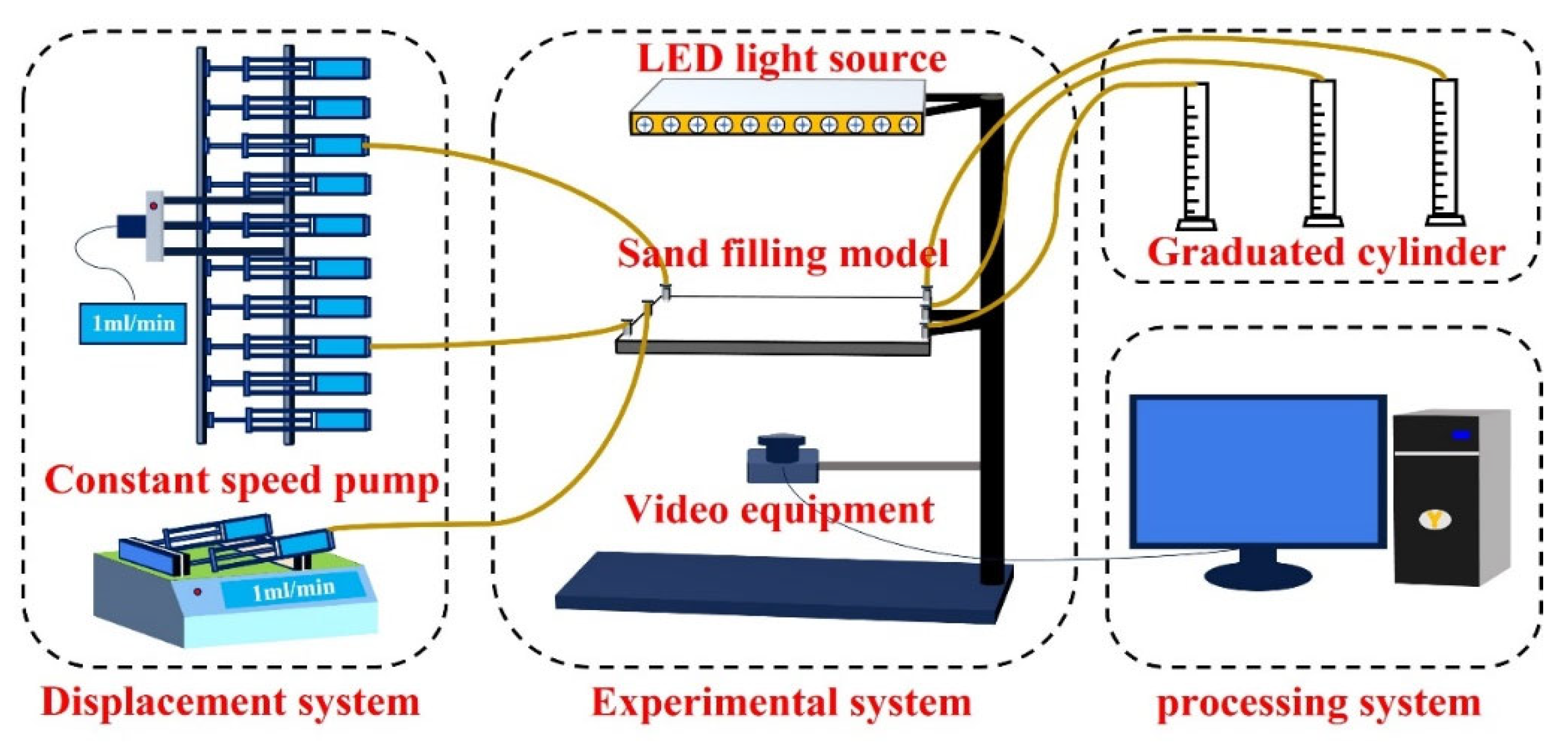

4.3. Experimental Setup

4.4. Experimental Procedures

- Clean the glass beads using ultrapure water to remove impurities, and then dry them at a high temperature (120 °C) to ensure consistent wettability. The glass beads of different mesh sizes used in the experiment are shown in Figure 30.

- Weigh the cleaned glass beads to ensure the same sand-packing mass across all experimental groups. Pack the beads into the model zone by zone, ensuring similar porosity among the experiments. After repeated vibration and compaction, place the upper glass plate, tighten the screws, and further compress and seal the glass beads.

- Use a vacuum pump to evacuate air from the sand-packed model, ensuring a vacuum state and checking the airtightness of the system.

- Inject ultrapure water into the sand-packed model using a multi-cylinder constant-rate injection pump at a steady rate of 3 mL/min until the model is fully saturated. Calculate the porosity using the material balance method. Afterward, leave the model undisturbed for 4 h to stabilize the simulated formation water.

- Inject the simulated oil at a constant rate of 2 mL/min until 100% oil is produced at the model outlet. Record the injected oil volume as the geological reserves. Let the model stand for 24 h to balance the fluid distribution.

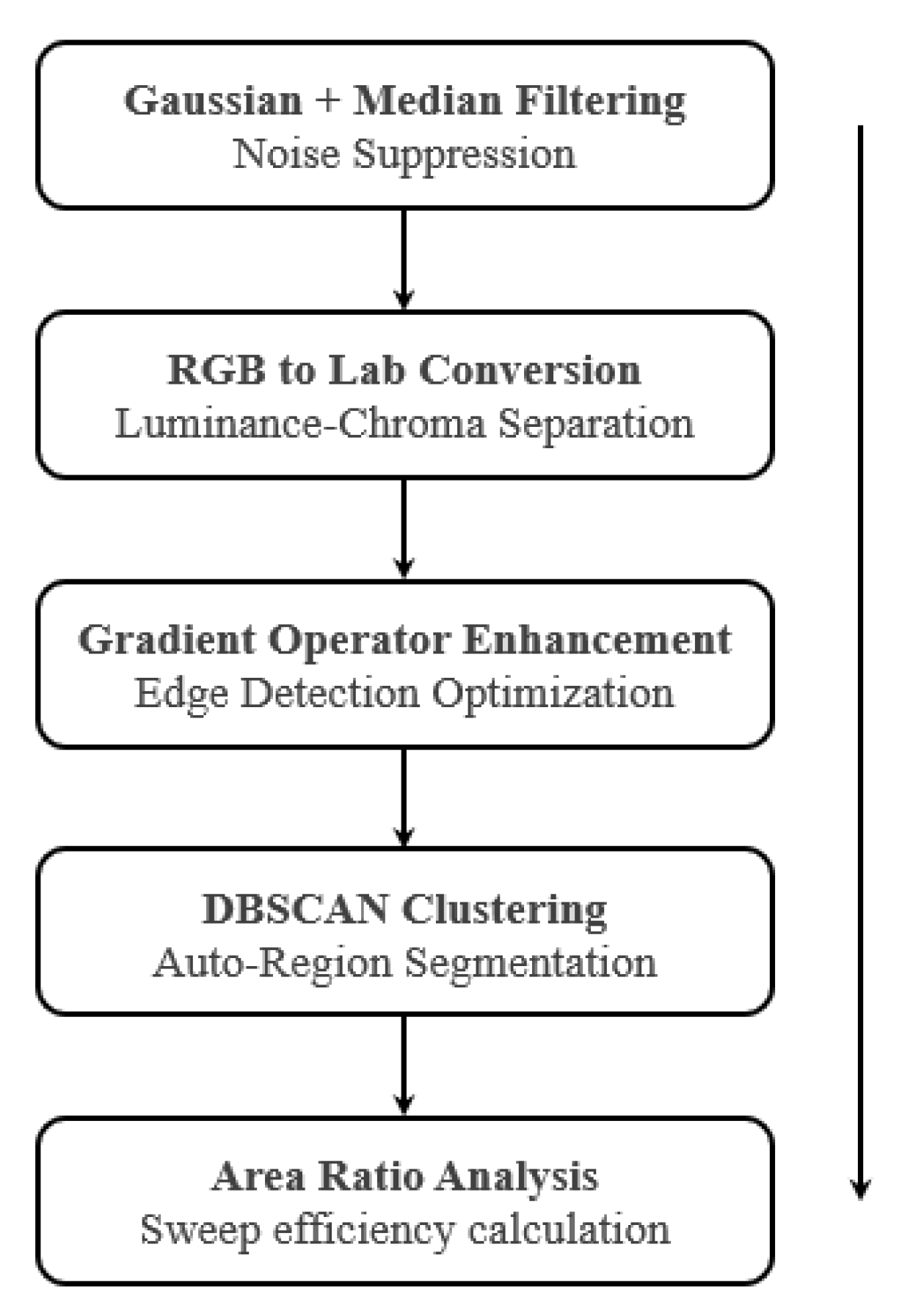

4.5. Experimental Data Processing

- 1.

- Method Development

- 2.

- Image Processing Workflow

- 3.

- Validation of Effectiveness

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WF | Water flooding |

| PF | Polymer flooding |

| PS | Polymer–surfactant binary composite system |

| PSF | Polymer–surfactant flooding |

| WAPSF | Well pattern densification and adjustment combined with PS flooding |

| HPC | Heterogeneous phase composite system |

| HPCF | Heterogeneous phase composite flooding |

| WAHPCF | Well pattern densification and adjustment combined with HPC flooding |

References

- Guo, H.; Song, K.; Liu, S.; Zhao, F.; Wang, Z.; Xu, Y.; Liu, J.; Tang, E.; Yang, Z. Recent advances in polymer flooding in China: Lessons learned and continuing development. SPE J. 2021, 26, 2038–2052. [Google Scholar] [CrossRef]

- Sun, X.D.; Suo, L.M.; Huang, Y.J.; Wang, H.Y.; Yu, H.; Xu, C.W.; Xu, J.; Qin, X.D.; Sun, W.Y.; Cao, Y.D.; et al. Study on the Occurrence Characteristics of the Remaining Oil in Sandstone Reservoirs with Different Permeability after Polymer Flooding. Polymers 2024, 16, 1902. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.L.; Zhang, Z.Q.; Wang, Q.M.; Xu, Z.S.; Guo, Z.D.; Sun, H.Q.; Cao, X.L.; Qiao, Q. Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the People’s Republic of China. J. Pet. Technol. 2006, 58, 84–89. [Google Scholar] [CrossRef]

- Tongwa, P.; Bai, B. Degradable nanocomposite preformed particle gel for chemical enhanced oil recovery applications. J. Pet. Sci. Eng. 2014, 124, 35–45. [Google Scholar] [CrossRef]

- Jadhawar, P.S.; Sarma, H.K. Effect of well pattern and injection well type on the CO2-assisted gravity drainage enhanced oil recovery. J. Pet. Sci. Eng. 2013, 101, 14–24. [Google Scholar] [CrossRef]

- Zhou, K.; Wu, D.J.; An, Z.B.; Liu, S. Selective Penetration and Profile Control Performance of Preformed Particle Gels for Heterogeneous Oil Reservoirs. Gels 2022, 8, 601. [Google Scholar] [CrossRef] [PubMed]

- Romero-Zerón, L.; Kantzas, A. The effect of wettability and pore geometry on foamed-gel-blockage performance. SPE Reserv. Eval. Eng. 2007, 10, 150–163. [Google Scholar] [CrossRef]

- Gao, J.C.; Lu, X.G.; He, X.; Liu, J.X.; Zheng, K.Q.; Cao, W.J.; Cui, T.Y.; Sun, H.R. Effect Evaluation and Action Mechanism Analysis of “Profile Control + Plugging Removal” after Chemical Flooding. Gels 2022, 8, 396. [Google Scholar] [CrossRef]

- Wang, X.; Yin, H.W.; Zhao, X.; Li, B.X.; Yang, Y.F. Microscopic remaining oil distribution and quantitative analysis of polymer flooding based on CT scanning. Adv. Geo-Energy Res. 2019, 3, 448–456. [Google Scholar] [CrossRef]

- Sun, X.D.; Zhao, M.Q.; Fan, X.Q.; Zhang, Y.S.; Xu, C.W.; Wang, L.H.; Sang, G.Q. Study on Micro Production Mechanism of Corner Residual Oil after Polymer Flooding. Polymers 2022, 14, 878. [Google Scholar] [CrossRef]

- He, H.; Tian, Y.H.; Zhang, L.F.; Li, H.S.; Guo, Y.; Liu, Y.; Liu, Y.F. Insights into the Injectivity and Propagation Behavior of Preformed Particle Gel (PPG) in a Low–Medium-Permeability Reservoir. Gels 2024, 10, 475. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.L.; He, Y.X.; Zhu, Y.Y.; Han, P.H.; Peng, S.K.; Liu, X.B. Associated Polymer ASP Flooding Scheme Optimization Design and Field Test after Polymer Flooding in Daqing Oilfield. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 31 August–4 September 2020; Society of Petroleum Engineers: Calgary, AB, Canada, 2020; pp. 1–13. [Google Scholar] [CrossRef]

- Zhong, H.Y.; He, Y.Y.; Yang, E.L.; Bi, Y.B.; Yang, T.B. Modeling of microflow during viscoelastic polymer flooding in heterogenous reservoirs of Daqing Oilfield. J. Pet. Sci. Eng. 2022, 210, 110091. [Google Scholar] [CrossRef]

- Nie, C.L.; Wu, X.L.; Hou, Z.W.; Li, J.J.; Jiang, H.Q. Evaluation of the Factors Influencing Residual Oil Evolution after Alkali/Surfactant/Polymer Flooding in Daqing Oilfield. Energies 2022, 15, 1048. [Google Scholar] [CrossRef]

- He, H.; Fu, J.Y.; Zhao, H.; Yuan, F.Q.; Guo, L.L.; Li, Z.Y.; Wang, X.; Peng, H. Synergistic mechanism of hydrolyzed polyacrylamide enhanced branched-preformed particle gel for enhanced oil recovery in mature oilfields. Energy Fuels 2018, 32, 11093–11104. [Google Scholar] [CrossRef]

- Wang, L.L.; Wang, T.F.; Wang, J.X.; Tian, H.T.; Chen, Y.; Song, W. Enhanced Oil Recovery Mechanism and Technical Boundary of Gel Foam Profile Control System for Heterogeneous Reservoirs in Changqing. Gels 2022, 8, 371. [Google Scholar] [CrossRef]

- Yue, M.; Zhu, W.Y.; Han, H.Y.; Song, H.Q.; Long, Y.Q.; Lou, Y. Experimental research on remaining oil distribution and recovery performances after nano-micron polymer particles injection by direct visualization. Fuel 2018, 212, 506–514. [Google Scholar] [CrossRef]

- Yang, Y.F.; Tao, L.; Iglauer, S.; Hejazi, S.H.; Yao, J.; Zhang, W.J.; Zhang, K. Quantitative Statistical Evaluation of Micro Residual Oil after Polymer Flooding Based on X ray Micro Computed-Tomography Scanning. Energy Fuels 2020, 34, 10762–10772. [Google Scholar] [CrossRef]

- Fu, H.T.; Bai, Z.Q.; Guo, H.; Yang, K.N.; Guo, C.P.; Liu, M.X.; Liang, L.H.; Song, K.P. Remaining Oil Distribution Law and Development Potential Analysis after Polymer Flooding Based on Reservoir Architecture in Daqing Oilfield, China. Polymers 2023, 15, 2137. [Google Scholar] [CrossRef]

- Yao, X.; Su, X.; Zheng, X.; Ma, J.; Gai, L.; Cui, C. 3D physical simulation experiments of development effects after well pattern adjustment in extra-high water cut reservoirs. Pet. Geol. Recovery Effic. 2023, 30, 139–146. [Google Scholar] [CrossRef]

- He, H.; Fu, J.Y.; Hou, B.F.; Yuan, F.Q.; Guo, L.L.; Li, Z.Y.; You, Q. Investigation of Injection Strategy of Branched-Preformed Particle Gel/Polymer/Surfactant for Enhanced Oil Recovery after Polymer Flooding in Heterogeneous Reservoirs. Energies 2018, 11, 1950. [Google Scholar] [CrossRef]

- Sun, Q.; Ertekin, T. Screening and optimization of polymer flooding projects using artificial-neural-network (ANN) based proxies. J. Pet. Sci. Eng. 2020, 185, 106617. [Google Scholar] [CrossRef]

- Yu, L.; Li, Y.; Gong, H.; Sang, Q.; Li, K.; Dong, M. EOR of branched-preformed particle gel (B-PPG) flooding after polymer flooding in heterogeneous reservoirs. Pet. Geol. Recovery Effic. 2016, 23, 113–118. [Google Scholar] [CrossRef]

- Aitkulov, A.; Dao, E.; Mohanty, K.K. ASP flood after a polymer flood vs. ASP flood after a water flood. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. Paper No. SPE-190271-MS. [Google Scholar] [CrossRef]

- Sun, C.; Hou, J.; Pan, G.; Xia, Z. Optimized polymer enhanced foam flooding for ordinary heavy oil reservoir after cross-linked polymer flooding. J. Pet. Explor. Prod. Technol. 2016, 6, 777–785. [Google Scholar] [CrossRef] [PubMed]

- Han, J.L.; Sun, J.S.; Lv, K.H.; Yang, J.B.; Li, Y.H. Polymer Gels Used in Oil–Gas Drilling and Production Engineering. Gels 2022, 8, 637. [Google Scholar] [CrossRef] [PubMed]

- Pi, Y.F.; Liu, J.X.; Cao, R.B.; Liu, L.; Ma, Y.X.; Gu, X.Y.; Li, X.J.; Fan, X.Y.; Zhao, M.J. Visualized Study on a New Preformed Particle Gels (PPG) + Polymer System to Enhance Oil Recovery by Oil Saturation Monitoring Online Flooding Experiment. Gels 2023, 9, 81. [Google Scholar] [CrossRef]

- Gong, H.; Zhang, H.; Xu, L.; Li, K.; Yu, L.; San, Q.; Li, Y.; Dong, M. The synergistic effect of branched-preformed particle gel and hydrolyzed polyacrylamide on further-enhanced oil recovery after polymer flooding. Energy Fuels 2017, 31, 7904–7910. [Google Scholar] [CrossRef]

- Zhou, K.; Zhao, F.; Zhou, X. Study on Main Factors Controlling Development Performance of Heterogeneous Composite Flooding in Post-Polymer Flooding Reservoir. Processes 2024, 12, 269. [Google Scholar] [CrossRef]

- Vargo, J.; Turner, J.; Vergnani, B.; Pitts, M.J.; Wyatt, K.; Surkalo, H.; Patterson, D. Alkaline-Surfactant-Polymer Flooding of the Cambridge Minnelusa Field. SPE Res. Eval. Eng. 2000, 3, 552–558. [Google Scholar] [CrossRef]

- Lu, X.; Wang, Y.; Wei, C.; Pan, G.; Guo, L.; Yuan, F. Study on layer adjustment for surfactant-polymer flooding reservoirs after polymer flooding—Case of Gudong West 7 area. Pet. Geol. Recovery Effic. 2014, 21, 25–28. [Google Scholar] [CrossRef]

- Liu, Y.X.; Ge, L.Z.; Ma, K.Q.; Chen, X.M.; Zhu, Z.Q.; Hou, J.R. Study on Surfactant–Polymer Flooding after Polymer Flooding in High-Permeability Heterogeneous Offshore Oilfields: A Case Study of Bohai S Oilfield. Polymers 2024, 16, 2004. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Wang, C.; Lu, C.; Yan, F. The polymer-enhanced foam injection process: An improved-oil-recovery technique for light oil reservoirs after polymer flooding. Energy Sources Part A Recovery Util. Environ. Effects 2016, 38, 354–361. [Google Scholar] [CrossRef]

- Udy, J.; Hansen, B.; Maddux, S.; Petersen, D.; Heilner, S.; Stevens, K.; Lignell, D.; Hedengren, J.D. Review of field development optimization of waterflooding, EOR, and well placement focusing on history matching and optimization algorithms. Processes 2017, 5, 34. [Google Scholar] [CrossRef]

- Gao, Q.; Zhong, C.R.; Han, P.H.; Cao, R.B.; Jiang, G.Q. Synergistic Effect of Alkali Surfactant Polymer and Preformed Particle Gel on Profile Control after Polymer Flooding in Heterogeneous Reservoirs. Energy Fuels 2020, 34, 15957–15968. [Google Scholar] [CrossRef]

- Chen, H.; Feng, Q.; Zhang, X.; Wang, S.; Zhou, W.; Geng, Y. Well placement optimization using an analytical formula-based objective function and cat swarm optimization algorithm. J. Pet. Sci. Eng. 2017, 157, 1067–1083. [Google Scholar] [CrossRef]

- Naderi, M.; Khamehchi, E. Well placement optimization using metaheuristic bat algorithm. J. Pet. Sci. Eng. 2017, 150, 348–354. [Google Scholar] [CrossRef]

- Moolya, A.; Rodríguez-Martínez, A.; Grossmann, I.E. Optimal producer well placement and multiperiod production scheduling using surrogate modeling. Comput. Chem. Eng. 2022, 165, 107941. [Google Scholar] [CrossRef]

- Davudov, D.; Venkatraman, A.; Mabadeje, A.O.; Malkov, A.; Singh, G.; Dindoruk, B.; Al-Aulaqi, T. Machine learning assisted well placement optimization. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 22–25 May 2023. Paper No. SPE-213038-MS. [Google Scholar] [CrossRef]

- An, Z.B.; Zhou, K.; Wu, D.J.; Hou, J. Production characteristics and displacement mechanisms of infilling polymer-surfactant-preformed particle gel flooding in post-polymer flooding reservoirs: A review of practice in Ng3 block of Gudao Oilfield. Pet. Sci. 2023, 20, 2354–2371. [Google Scholar] [CrossRef]

- Gao, S.L.; Jiang, Z.H.; Zhang, K.Y.; Liu, H.B.; Fu, Q.C.; Yan, W.; Fu, B.Z. High Concentration Polymer Flooding Field Test with Well Infilling to Change Fluid Flowing Direction After Polymer Flooding. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 21–23 March 2016; Society of Petroleum Engineers: Calgary, AB, Canada, 2016; pp. 1–11. [Google Scholar] [CrossRef]

- Xu, H.G.; Wang, L.S.; Cao, Y.B.; Yu, T.T.; Tang, H.L.; Lin, J.S. Experimental Research of Remaining Oil Distribution for Inverted Nine Sport Pattern and Infill Well Pattern. Arab. J. Sci. Eng. 2022, 47, 11297–11312. [Google Scholar] [CrossRef]

- Liao, G.; Wang, Q.; Wang, H.; Liu, W.; Wang, Z. Chemical flooding development status and prospects. Acta Pet. Sin. 2017, 38, 196–207. (In Chinese) [Google Scholar] [CrossRef]

- Gu, H.; Yang, R.; Guo, S.; Guan, W.; Yue, X. Study on reservoir engineering: ASP flooding pilot test in Karamay oilfield. In Proceedings of the SPE International Conference and Exhibition, Beijing, China, 2–6 November 1998; Society of Petroleum Engineers: Calgary, AB, Canada, 1998. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, M.; Li, L. Pilot field test of microbial surfactant-polymer-alkali flooding with small well spacing. Pet. Geol. Oilfield Dev. Daqing 2001, 20, 114–116. (In Chinese) [Google Scholar]

- Onwunalu, J.E.; Durlofsky, L.J. A new well-pattern-optimization procedure for large-scale field development. SPE J. 2011, 16, 594–607. [Google Scholar] [CrossRef]

- Sun, H. Application of pilot test for well pattern adjusting heterogeneous combination flooding after polymer flooding—Case of Zhongyiqu Ng3 block, Gudao oilfield. Pet. Geol. Recovery Effic. 2014, 21, 1–4. (In Chinese) [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.; Dong, X.; Wang, Q.; Wang, W.; Wang, Z. Mechanism and visualization of streamline adjustment in enhanced oil recovery: A comparative study between well pattern adjustment and polymer flooding. J. Pet. Explor. Prod. Technol. 2023, 13, 1919–1933. [Google Scholar] [CrossRef]

- Tao, L.; Wu, M.J.; Zhang, N.; Shi, W.Y.; Bai, J.J.; Xu, Z.X.; Song, Y.; Cao, L.L. Investigation on EOR by composite surfactant-polymer (SP) flooding and streamline adjustment through well pattern encryption: A case study of Shengli’s strong heterogeneous reservoir. Fuel 2025, 385, 134189. [Google Scholar] [CrossRef]

- Jiao, T. Well pattern optimization of chemical flooding streamline changing mode after polymer flooding in Class I reservoirs in north Daqing Placanticline. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 103–108. [Google Scholar] [CrossRef]

- Du, Q.J.; Pan, G.M.; Hou, J.; Guo, L.L.; Wang, R.R.; Xia, Z.Z.; Zhou, K. Study of the mechanisms of streamline-adjustment-assisted heterogeneous combination flooding for enhanced oil recovery for post-polymer-flooded reservoirs. Pet. Sci. 2019, 16, 606–618. [Google Scholar] [CrossRef]

- Zhang, X.M.; Zhang, Y.M.; Liu, H.C.; Li, S.S.; Liu, L.J. Dynamic Sweep Experiments on a Heterogeneous Phase Composite System Based on Branched-Preformed Particle Gel in High Water-Cut Reservoirs after Polymer Flooding. Gels 2023, 9, 364. [Google Scholar] [CrossRef]

- He, H.; Liu, W.; Chen, Y.; Liu, H.; Liu, H.; Luo, G. Synergistic mechanism of well pattern adjustment and heterogeneous phase combined flooding on enhancing oil recovery in mature fault-block reservoirs. J. Pet. Explor. Prod. Technol. 2022, 12, 3387–3398. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, K.; An, Z.; Jian, H. Experimental Study on the Matching Relationship between PPG Size and Reservoir Heterogeneity. In Proceedings of the SPE International Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 10–12 December 2018. [Google Scholar] [CrossRef]

- Li, Z. Insights into enhanced oil recovery by coupling branched-preformed particle gel and viscosity reducer flooding in ordinary heavy oil reservoir. In Geofluids; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Chen, R.; He, H.; Tian, Y.; Xiong, Z.; Ke, W.; Pei, H.; Zhang, P. Transport Characteristics of Branched-Preformed Particle Gel in Porous Media: Influence of Elastic Modulus, Matching Coefficient, and Injection Rate. Gels 2025, 11, 315. [Google Scholar] [CrossRef] [PubMed]

- Sang, Q.; Li, Y.; Yu, L.; Li, Z.; Dong, M. Enhanced oil recovery by branched-preformed particle gel injection in parallel-sandpack models. Fuel 2014, 136, 295–306. [Google Scholar] [CrossRef]

- Li, J.; Jiang, Z.; Wang, Y.; Zheng, J.; Huang, G. Stability, seepage and displacement characteristics of heterogeneous branched-preformed particle gels for enhanced oil recovery. RSC Adv. 2018, 8, 4881–4889. [Google Scholar] [CrossRef] [PubMed]

- Hosseini-Nasab, S.M.; Padalkar, C.; Battistutta, E.; Zitha, P.L.J. Mechanistic modeling of the alkaline/surfactant/polymer flooding process under sub-optimum salinity conditions for enhanced oil recovery. Ind. Eng. Chem. Res. 2016, 55, 6875–6888. [Google Scholar] [CrossRef]

- Hosseini-Nasab, S.M.; Zitha, P.L.J. Investigation of certain physical–chemical features of oil recovery by an optimized alkali–surfactant–foam (ASF) system. Colloid Polym. Sci. 2017, 295, 1873–1886. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Zhou, K.; Hou, J.; An, Z.; Zhai, M.; Liu, W. Experimental study on combining heterogeneous phase composite flooding and streamline adjustment to improve oil recovery in heterogeneous reservoirs. J. Pet. Sci. Eng. 2020, 194, 107478. [Google Scholar] [CrossRef]

| System | Zero-Shear Viscosity (mPa·s) | Infinite-Shear Viscosity (mPa·s) | Viscosity mPa·s |

|---|---|---|---|

| Polymer | 2752.69 | 31.83 | 25.85 |

| Binary Composite Flooding | 1859.88 | 33.37 | 24.55 |

| Heterogeneous Composite Flooding | 6299.85 | 41.56 | 52.03 |

| Stage | 0.1 PV | 0.3 PV | 0.6 PV | 0.8 PV |

|---|---|---|---|---|

| Sweep Efficiency (%) | 17.56 | 47.61 | 68.42 | 87.15 |

| Recovery Factor (%) | 7.23 | 19.54 | 26.81 | 32.32 |

| Displacement Process | Stage | Initial Stage of Slug Injection | End of Slug Injection | Initial Stage of Subsequent Water Injection | Water Cut up to 95% |

|---|---|---|---|---|---|

| WF-WAPSF | Sweep Efficiency | 72.56% | 89.63% | 93.21% | 95.72% |

| Recovery factor | 34.17% | 38.61% | 47.56% | 55.70% | |

| WF-WAHPCF | Sweep Efficiency | 74.24% | 92.15% | 100% | — |

| Recovery factor | 33.51% | 42.38% | 56.14% | 63.46% |

| Parameter | Unit | Reservoir Data | Simulation Data |

|---|---|---|---|

| Temperature | °C | 80 | 26 |

| Pressure | MPa | 12.56 | 0.1 |

| Porosity | % | 31 | 30 |

| Permeability | 10−3 μm | 3650 | 3500 |

| Oil Density | g/cm3 | 0.89 | 0.86 |

| Oil Viscosity | mPa∙s | 44.6 | 45 |

| Water Density | g/cm3 | 1.02 | 1.02 |

| Water Viscosity | mPa∙s | 0.46 | 0.46 |

| Injection Rate | (m3/d) or (mL/min) | 160 | 1.5 |

| Solution Name | Composition | Concentration (mg/L) | Solution Color |

|---|---|---|---|

| Polymer Solution | HPAM | 1000 | Colorless and transparent |

| Binary Flooding Solution | HPAM | 1000 | Colorless/blue |

| Surfactant | 1000 | ||

| Heterogeneous Solution | HPAM | 1000 | Blue |

| Surfactant | 1000 | ||

| B-PPG | 500 |

| Chemical Flooding Method | Infill Well Pattern | Pore Volume (mL) | Porosity | Reserves (mL) | Injection Rate | |

|---|---|---|---|---|---|---|

| 1 | WF-WAPSF | Aligned row pattern | 52.0 | 0.330 | 264 | 1.5 mL/min |

| WF-WAHPCF | 52.0 | 0.325 | 262 | |||

| WF-PF-WAHPCF | 53.0 | 0.340 | 265 | |||

| WF-PSF-WAHPCF | 49.0 | 0.290 | 258 | |||

| 2 | WF-PSF-WAHPCF | Aligned row pattern | 50.5 | 0.314 | 261 | |

| WF-PSF-WAHPCF | Reverse five-spot pattern | 52.5 | 0.338 | 263 | ||

| WF-PSF-WAHPCF | Staggered row pattern | 51.0 | 0.319 | 261 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yu, J.; Liu, L.; Liu, X.; Lu, X.; Feng, Q. Experimental Investigation of Synergistic Enhanced Oil Recovery by Infill Well Pattern and Chemical Flooding After Polymer Flooding. Gels 2025, 11, 660. https://doi.org/10.3390/gels11080660

Zhang X, Yu J, Liu L, Liu X, Lu X, Feng Q. Experimental Investigation of Synergistic Enhanced Oil Recovery by Infill Well Pattern and Chemical Flooding After Polymer Flooding. Gels. 2025; 11(8):660. https://doi.org/10.3390/gels11080660

Chicago/Turabian StyleZhang, Xianmin, Junzhi Yu, Lijie Liu, Xilei Liu, Xuan Lu, and Qihong Feng. 2025. "Experimental Investigation of Synergistic Enhanced Oil Recovery by Infill Well Pattern and Chemical Flooding After Polymer Flooding" Gels 11, no. 8: 660. https://doi.org/10.3390/gels11080660

APA StyleZhang, X., Yu, J., Liu, L., Liu, X., Lu, X., & Feng, Q. (2025). Experimental Investigation of Synergistic Enhanced Oil Recovery by Infill Well Pattern and Chemical Flooding After Polymer Flooding. Gels, 11(8), 660. https://doi.org/10.3390/gels11080660