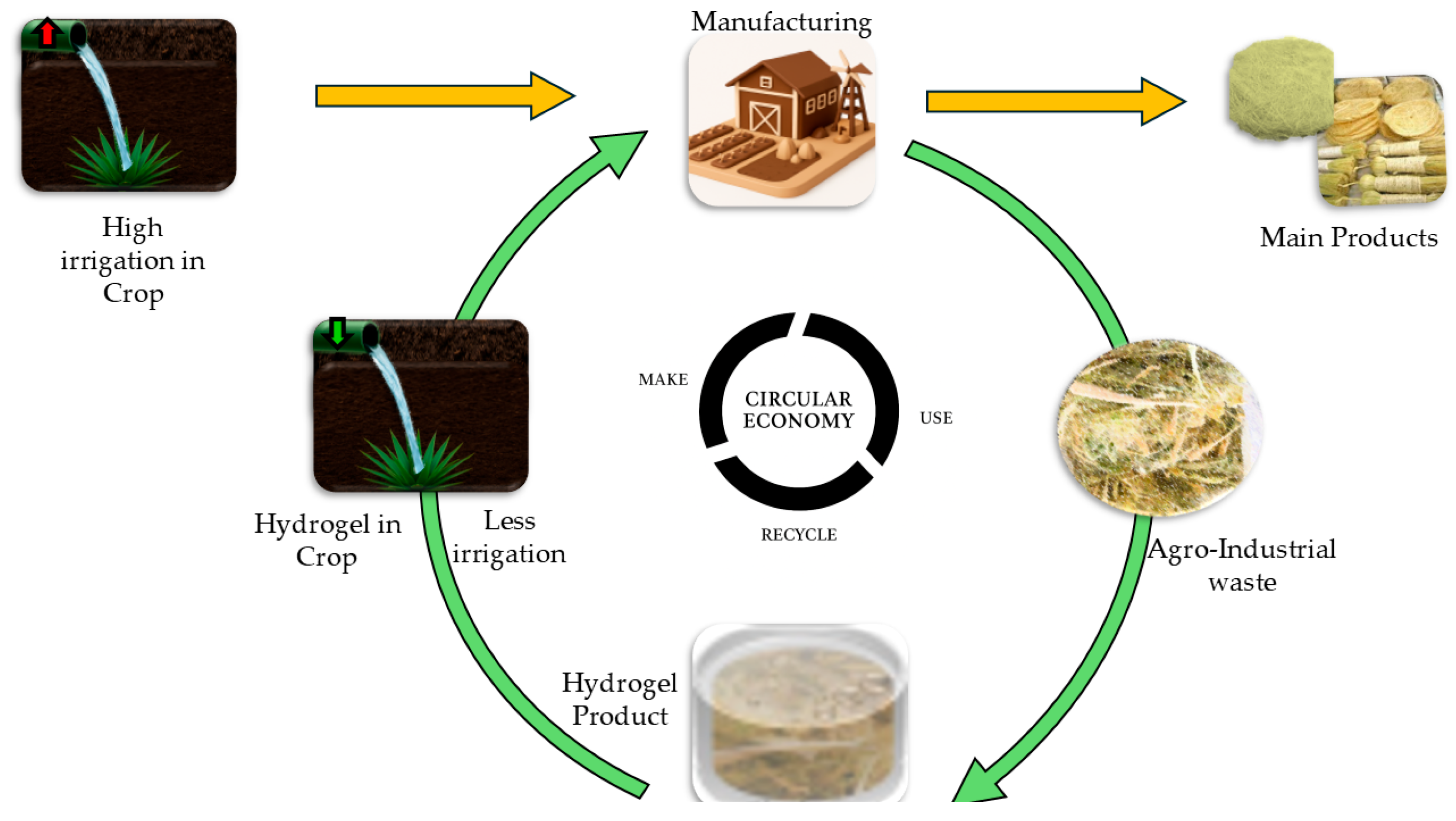

From Agro-Industrial Waste to Natural Hydrogels: A Sustainable Alternative to Reduce Water Use in Agriculture

Abstract

1. Introduction

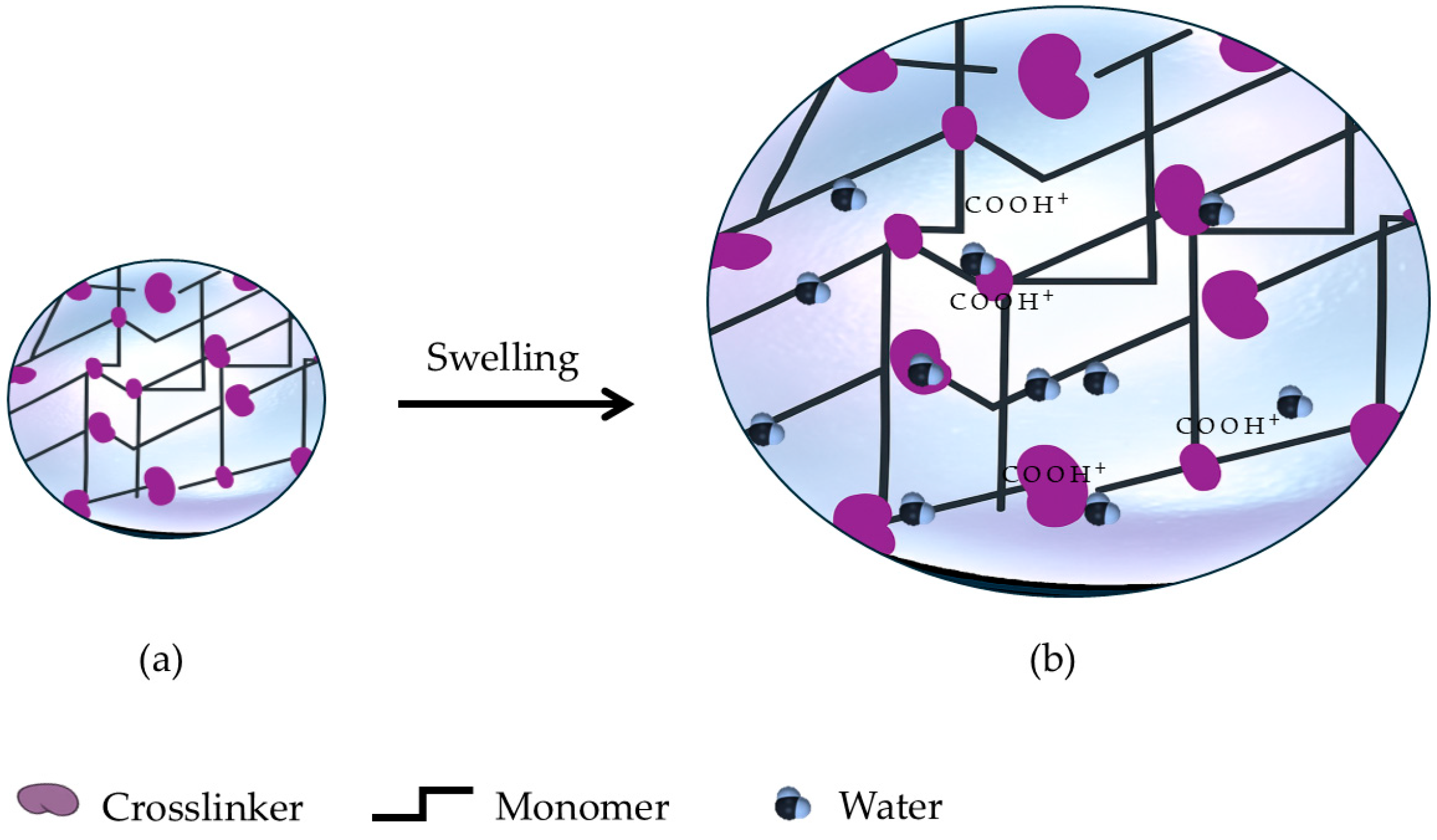

2. Technologies and Trends in Sustainable Food Production

3. Hydrogels in Agriculture

3.1. Synthetic Hydrogels

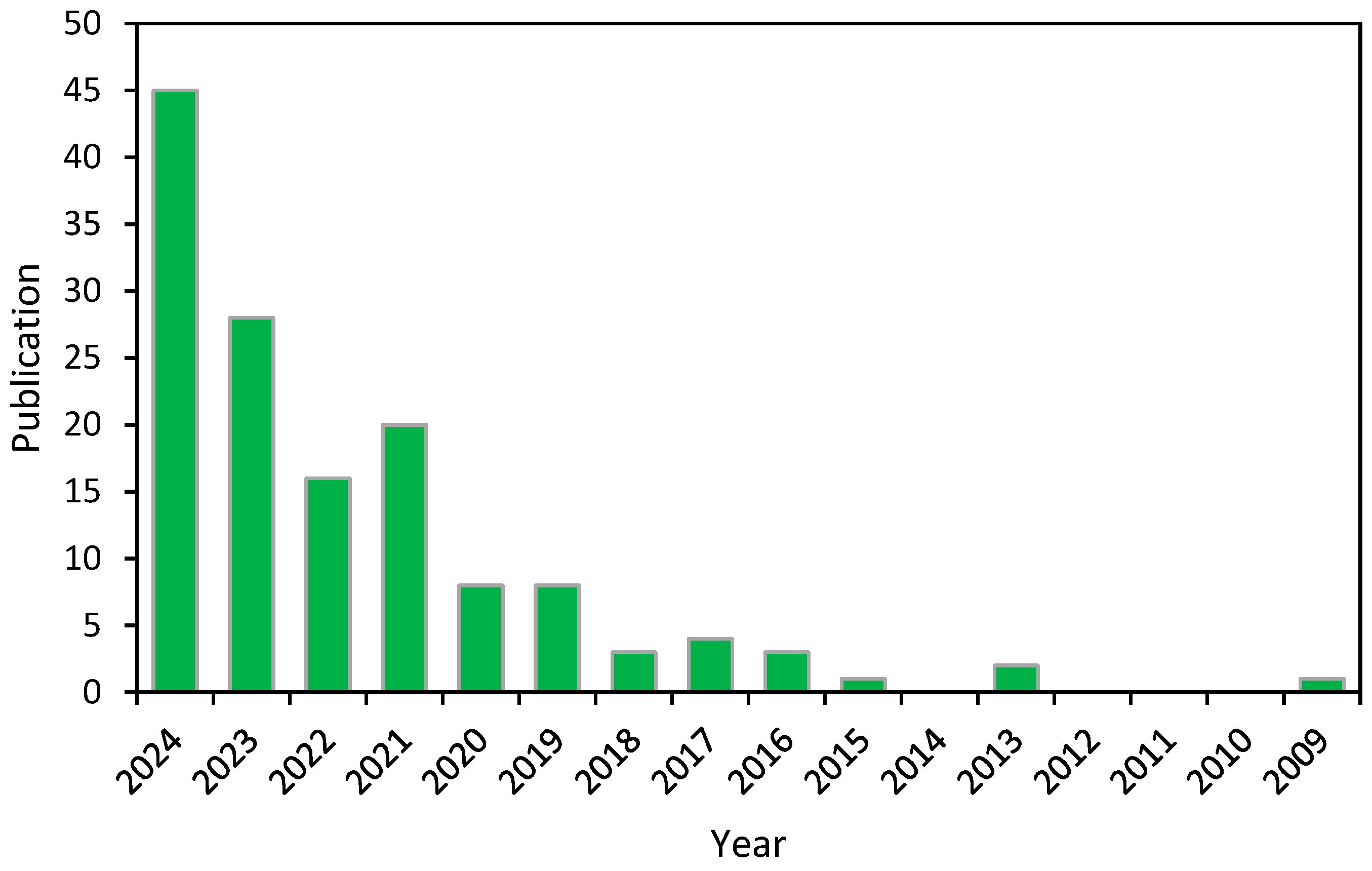

Implications of Hydrogel Nanoplastics in Food Safety

3.2. Natural Hydrogels

3.3. Natural Hydrogels with Agro-Industrial Waste (Hybrids)

4. Natural Components in the Manufacture of Hydrogels

4.1. Polysaccharides

4.1.1. Starch

4.1.2. Chitosan

4.1.3. Cellulose

4.2. Proteins

Gelatin

4.3. Cross-Linkers

4.3.1. Tannic Acid

4.3.2. Genipin

4.3.3. Citric Acid

4.4. Agro-Industrial Waste as a Source of Polysaccharides

4.4.1. Furcraea bedinghausii

4.4.2. Agave tequilana Weber

4.4.3. Agave lechuguilla Torr.

5. Waste-Based Hydrogels and Their Impact on Reducing Water Usage in Agriculture

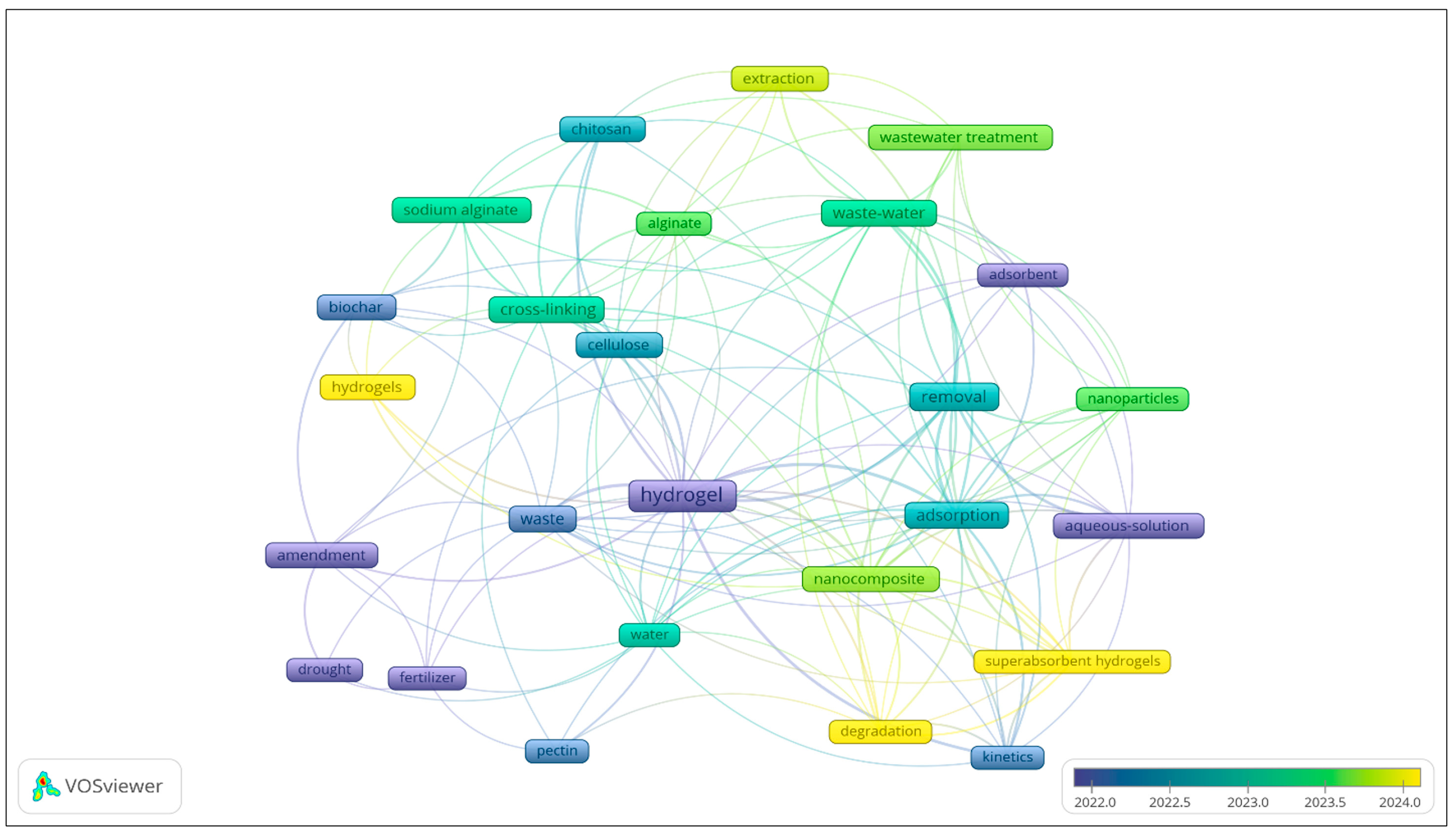

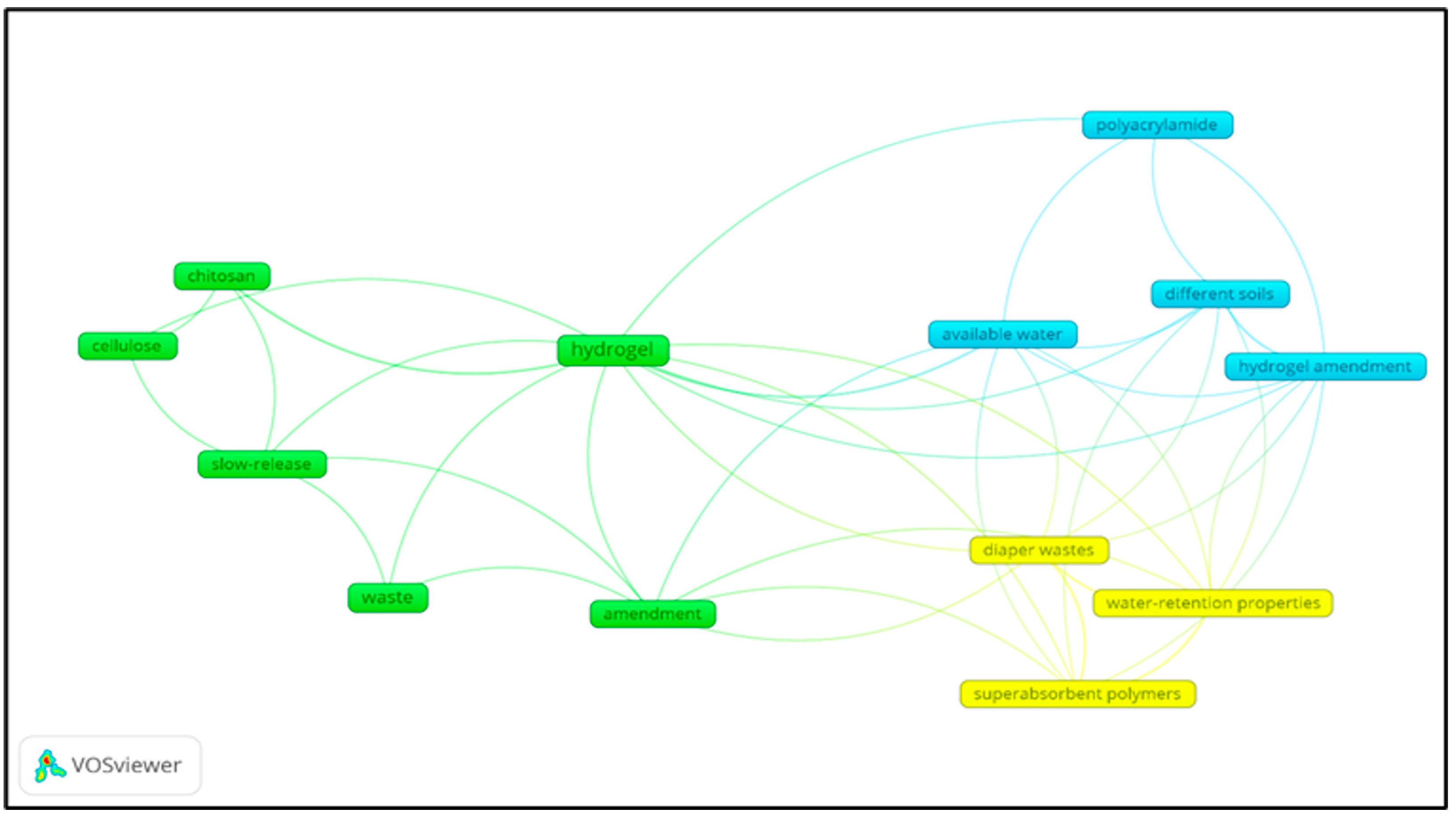

6. Trend in the Formulation of Hydrogels with Agro-Industrial Waste

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdallah, A.M. The effect of hydrogel particle size on water retention properties and availability under water stress. Int. Soil Water Conserv. Res. 2019, 7, 275–285. [Google Scholar] [CrossRef]

- Anuar, W.A.N.W.; Ramli, R.A.; El-Sayed, M.M.; Warkar, S.G. Recent study on biodegradable hydrogels for agriculture application: A review. J. Environ. Chem. Eng. 2025, 13, 115679. [Google Scholar] [CrossRef]

- Yudaev, P.; Semenova, A.; Chistyakov, E. Gel based on modified chitosan for oil spill cleanup. J. Appl. Polym. Sci. 2024, 141, e54838. [Google Scholar] [CrossRef]

- Tariq, Z.; Iqbal, D.N.; Rizwan, M.; Ahmad, M.; Faheem, M.; Ahmed, M. Significance of biopolymer-based hydrogels and their applications in agriculture: A review in perspective of synthesis and their degree of swelling for water holding. RSC Adv. 2023, 13, 24731–24754. [Google Scholar] [CrossRef] [PubMed]

- Saha, A.; Sekharan, S.; Manna, U. Superabsorbent hydrogel (SAH) as a soil amendment for drought management: A review. Soil Tillage Res. 2020, 204, 104736. [Google Scholar] [CrossRef]

- Caulfield, M.J.; Qiao, G.G.; Solomon, D.H. Some aspects of the properties and degradation of poly-acrylamides. Chem. Rev. 2002, 102, 3067–3083. [Google Scholar] [CrossRef]

- Sahmat, S.S.; Rafii, M.Y.; Oladosu, Y.; Jusoh, M.; Hakiman, M.; Mohidin, H. A systematic review of the potential of a dynamic hydrogel as a substrate for sustainable agriculture. Horticulturae 2022, 8, 1026. [Google Scholar] [CrossRef]

- Li, S.; Chen, G. Agricultural waste-derived superabsorbent hydrogels: Preparation, performance, and socioeconomic impacts. J. Clean. Prod. 2019, 251, 119669. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Sikdar, P.P.; Haque, B.; Bhuiyan, M.A.R.; Ali, A.; Islam, M.N. Cellulose-based hydrogel materials: Chemistry, properties and their prospective applications. Prog. Biomater. 2018, 7, 153–174. [Google Scholar] [CrossRef]

- Adjuik, T.A.; Nokes, S.E.; Montross, M.D.; Wendroth, O. The impacts of bio-based and synthetic hydrogels on soil hydraulic properties: A review. Polymers 2022, 14, 4721. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramírez-Guzmán, N.; Londoño-Hernández, L.; Martínez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macías, V.; Aguilar, C.N. Food waste and byproducts: An opportunity to minimize malnutrition and hunger in developing countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Z.; Wen, Y.; Song, X.; Tan, W.K.; Ong, C.N.; Li, J. Recent advances in superabsorbent hydrogels derived from agro waste materials for sustainable agriculture: A review. J. Agric. Food Chem. 2024, 72, 22399–22419. [Google Scholar] [CrossRef] [PubMed]

- Geng, S.M.; Yan, D.H.; Zhang, T.X.; Weng, B.S.; Zhang, Z.B.; Qin, T.L. Effects of drought stress on agriculture soil. Nat. Hazards 2015, 75, 1997–2011. [Google Scholar] [CrossRef]

- Richard, B.; Qi, A.; Fitt, B.D.L. Control of crop diseases through Integrated Crop Management to deliver climate-smart farming systems for low- and high-input crop production. Plant Pathol. 2022, 71, 1–15. [Google Scholar] [CrossRef]

- De Pascale, S.; Dalla Costa, L.; Vallone, S.; Barbieri, G.; Maggio, A. Increasing water use efficiency in vegetable crop production: From plant to irrigation systems efficiency. HortTechnology 2022, 21, 301–308. [Google Scholar] [CrossRef]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A review on hydroponics and the technologies associated for medium- and small-scale operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Fonteno, W.C.; Bilderback, T.E. Impact of hydrogel on physical properties of coarse-structured horticultural substrates. J. Am. Soc. Hortic. Sci. 2019, 118, 217–222. [Google Scholar] [CrossRef]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef]

- Paradelo, R.; Basanta, R.; Barral, M.T. Water-holding capacity and plant growth in compost-based substrates modified with polyacrylamide, guar gum or bentonite. Sci. Hortic. 2019, 243, 344–349. [Google Scholar] [CrossRef]

- Zhu, J.; Tan, W.K.; Song, X.; Gao, Z.; Wen, Y.; Ong, C.N.; Loh, C.S.; Swarup, S.; Li, J. Converting Okara to superabsorbent hydrogels as soil supplements for enhancing the growth of Choy Sum (Brassica sp.) under water-limited conditions. ACS Sustain. Chem. Eng. 2020, 8, 9425–9433. [Google Scholar] [CrossRef]

- Vedovello, P.; Sanches, L.V.; da Silva Teodoro, G.; Majaron, V.F.; Bortoletto-Santos, R.; Ribeiro, C.; Putti, F.F. An overview of polymeric hydrogel applications for sustainable agriculture. Agriculture 2024, 14, 840. [Google Scholar] [CrossRef]

- Bashir, S.; Hina, M.; Iqbal, J.; Rajpar, A.H.; Mujtaba, M.A.; Alghamdi, N.A.; Wageh, S.; Ramesh, K.; Ramesh, S. Fundamental concepts of hydrogels: Synthesis, properties, and their applications. Polymers 2020, 12, 2702. [Google Scholar] [CrossRef]

- Demitri, C.; Scalera, F.; Madaghiele, M.; Sannino, A.; Maffezzoli, A. Potential of cellulose-based superabsorbent hydrogels as water reservoir in agriculture. Int. J. Polym. Sci. 2013, 2013, 435073. [Google Scholar] [CrossRef]

- Xiong, B.; Loss, R.D.; Shields, D.; Pawlik, T.; Hochreiter, R.; Zydney, A.L.; Kumar, M. Polyacrylamide degradation and its implications in environmental systems. NPJ Clean Water 2018, 1, 17. [Google Scholar] [CrossRef]

- Pinzon-Moreno, D.D.; Maurate-Fernandez, I.R.; Flores-Valdeon, Y.; Neciosup-Puican, A.A.; Carranza-Oropeza, M.V. Degradation of hydrogels based on potassium and sodium polyacrylate by ionic interaction and its influence on water. Polymers 2022, 14, 2656. [Google Scholar] [CrossRef]

- Liang, D.; Du, C.; Ma, F.; Shen, Y.; Wu, K.; Zhou, J. Degradation of polyacrylate in the outdoor agricultural soil measured by FTIR-PAS and LIBS. Polymers 2018, 10, 1296. [Google Scholar] [CrossRef]

- Jiang, M.; Wang, B.; Ye, R.; Yu, N.; Xie, Z.; Hua, Y.; Dai, S. Evidence and impacts of nanoplastic accumulation on crop grains. Adv. Sci. 2022, 9, 2202336. [Google Scholar] [CrossRef]

- Vogel, A.; Tentschert, J.; Pieters, R.; Bennet, F.; Dirven, H.; van den Berg, A.; Haase, A. Towards a risk assessment framework for micro- and nanoplastic particles for human health. Part. Fibre Toxicol. 2024, 21, 48. [Google Scholar] [CrossRef] [PubMed]

- Klein, M.; Poverenov, E. Natural biopolymer-based hydrogels for use in food and agriculture. J. Sci. Food Agric. 2020, 100, 3255–3262. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, M.; Hasanuzzaman, M.; Rahman, M.; Khan, M.A.R.; Bhowmik, P.; Bhowmik, P.; Mahmud, N.U.; Tanveer, M.; Islam, T. Mechanism of plant growth promotion and disease suppression by chitosan biopolymer. Agriculture 2020, 10, 624. [Google Scholar] [CrossRef]

- Mortier, C.; Costa, D.C.S.; Oliveira, M.B.; Haugen, H.J.; Lyngstadaas, S.P.; Blaker, J.J.; Mano, J.F. Advanced hydrogels based on natural macromolecules: Chemical routes to achieve mechanical versatility. Mater. Today Chem. 2022, 26, 101222. [Google Scholar] [CrossRef]

- Krishna, V.V.; Mkondiwa, M. Economics of crop residue management. Ann. Rev. Resour. Econ. 2025, 15, 19–39. [Google Scholar] [CrossRef]

- Heise, K.; Kirsten, M.; Schne-ider, Y.; Jaros, D.; Keller, H.; Rohm, H.; Kalbitz, K.; Fischer, S. From agricultural byproducts to value-added materials: Wheat straw-based hydrogels as soil conditioners? ACS Sustain. Chem. Eng. 2019, 7, 8604–8612. [Google Scholar] [CrossRef]

- Ismail, H.; Irani, M.; Ahmad, Z. Starch-based hydrogels: Present status and applications. Int. J. Polym. Mater. Polym. Biomater. 2013, 62, 411–420. [Google Scholar] [CrossRef]

- Mahmoud, G.A.; Abdel-Aal, S.E.; Badway, N.A.; Abo Farha, S.A.; Alshafei, E.A. Radiation synthesis and characterization of starch-based hydrogels for removal of acid dye. Starch/Stärke 2014, 66, 400–408. [Google Scholar] [CrossRef]

- Tian, S.; Chen, Y.; Chen, Z.; Yang, Y.; Wang, Y. Preparation and characteristics of starch esters and its effects on dough physicochemical properties. Int. J. Food Sci. 2018, 1, 1395978. [Google Scholar] [CrossRef]

- Kou, S.; Peters, L.; Mucalo, M. Chitosan: A review of sources and preparation methods. Int. J. Biol. Macromol. 2021, 169, 85–94. [Google Scholar] [CrossRef]

- Giraldo Pedraza, J.D.; Universidad Austral de Chile, Valdivia, Chile. Propiedades, Obtención, Caracterización y Aplicaciones del Quitosano. 2015. Available online: https://www.researchgate.net/publication/277302110_PROPIEDADES_OBTENCION_CARACTERIZACION_Y_APLICACIONES_DEL_QUITOSANO (accessed on 25 June 2025). [CrossRef]

- Bhaladhare, S.; Das, D. Cellulose: A fascinating biopolymer for hydrogel synthesis. RSC Adv. 2022, 10, 1923–1945. [Google Scholar] [CrossRef] [PubMed]

- Zainal, S.H.; Mohd, N.H.; Suhaili, N.; Anuar, F.H.; Lazim, A.M.; Othaman, R. Preparation of cellulose-based hydrogel: A review. J. Mater. Res. Technol. 2021, 10, 1–15. [Google Scholar] [CrossRef]

- Haug, I.J.; Draget, K.I. Gelatin. Handbook of Hydrocolloids, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2009; pp. 142–163. [Google Scholar] [CrossRef]

- Charoenchaitrakool, M.; Tulathon, P.; Meesangnil, W.; Niamnuy, C.; Seubsai, A.; Sudsakorn, K. Carboxymethyl cellulose and gelatin composite hydrogel for environmentally friendly urea delivery. Colloids Surf. A Physicochem. Eng. Asp. 2024, 690, 133774. [Google Scholar] [CrossRef]

- Andreazza, R.; Morales, A.; Pieniz, S.; Labidi, J. Gelatin-based hydrogels: Potential biomaterials for remediation. Polymers 2023, 15, 1026. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Wu, J.; Lin, J.; Fan, S.; Hu, D. A multifunctional poly(acrylic acid)/gelatin hydrogel. J. Mater. Res. 2009, 24, 1653–1661. [Google Scholar] [CrossRef]

- Torres-León, C.; Ventura-Sobrevilla, J.; Serna-Cock, L.; Ascacio-Valdés, J.A.; Contreras-Esquivel, J.; Aguilar, C.N. Pentagalloylglucose (PGG): A valuable phenolic compound with functional properties. J. Funct. Foods 2017, 37, 1–10. [Google Scholar] [CrossRef]

- Zheng, L.Y.; Shi, J.M.; Chi, Y.H. Tannic acid physically cross-linked responsive hydrogel. Macromol. Chem. Phys. 2018, 219, 1900234. [Google Scholar] [CrossRef]

- Moghaddam, S.Y.Z.; Biazar, E.; Esmaeili, J.; Kheilnezhad, B.; Goleij, F.; Heidari, S. Tannic acid as a green cross-linker for biomaterial applications. Mini-Rev. Med. Chem. 2022, 23, 1320–1340. [Google Scholar] [CrossRef]

- Meena, R.; Prasad, K.; Siddhanta, A.K. Development of a stable hydrogel network based on agar-kappa-carrageenan blend cross-linked with genipin. Food Hydrocoll. 2009, 23, 497–509. [Google Scholar] [CrossRef]

- Franklin, D.S.; Guhanathan, S. Synthesis and characterization of citric acid-based pH-sensitive biopolymeric hydrogels. Polym. Bull. 2014, 71, 93–110. [Google Scholar] [CrossRef]

- Demitri, C.; Del Sole, R.; Scalera, F.; Sannino, A.; Vasapollo, G.; Maffezzoli, A.; Ambrosio, L.; Nicolais, L. Novel superabsorbent cellulose-based hydrogels crosslinked with citric acid. J. Appl. Polym. Sci. 2008, 110, 2453–2460. [Google Scholar] [CrossRef]

- Jong, S.J.; KarunaKaran, K.; Wasli, M.E.; Musa, Z.; Chin, S.F. Cellulose-based hydrogel as a natural medium for paddy seed germination. Starch/Stärke 2023, 76, 2200234. [Google Scholar] [CrossRef]

- Guancha-Chalapud, M.A.; Serna-Cock, L.; Tirado, D.F. Hydrogels are reinforced with Colombian fique nanofibers to improve techno-functional properties for agricultural purposes. Agriculture 2022, 12, 117. [Google Scholar] [CrossRef]

- Tovar-Carrillo, K.L.; Nakasone, K.; Sugita, S.; Tagaya, M.; Kobayashi, T. Effects of sodium hypochlorite on Agave tequilana Weber bagasse fibers used to elaborate cyto and biocompatible hydrogel films. Mater. Sci. Eng. C 2014, 42, 808–815. [Google Scholar] [CrossRef]

- Hernández, R.; Lugo, E.C.; Díaz, L.; Villanueva, S. Extracción y cuantificación indirecta de las saponinas de agave lechuguilla Torrey. e-Gnosis 2005, 3, 3–12. [Google Scholar]

- Carmona, J.E.; Morales-Marti, T.K.; Mussatto, S.I.; Castillo-Quiroz, D.; Ri, L.J. Propiedades químicas, estructurales y funcionales de la lechuguilla (Agave lechuguilla Torr.). Rev. Mex. De Cienc. For. 2017, 8, 100–122. [Google Scholar]

- Liu, X.; Li, Y.; Meng, Y.; Lu, J.; Cheng, Y.; Tao, Y.; Wang, H. Pulping black liquor-based polymer hydrogel as water retention material and slow-release fertilizer. Ind. Crops Prod. 2021, 165, 113445. [Google Scholar] [CrossRef]

- Madramootoo, C.A.; Jain, A.; Oliva, C.; Wang, Y.; Abbasi, N.A. Growth and yield of tomato on soil amended with waste paper based hydrogels. Sci. Hortic. 2023, 310, 111752. [Google Scholar] [CrossRef]

- Saha, A.; Gupt, C.B.; Sekharan, S. Recycling natural fibre to superabsorbent hydrogel composite for conservation of irrigation water in semi-arid regions. Waste Biomass Valorization 2021, 12, 6433–6448. [Google Scholar] [CrossRef]

- Gayen, T.K.; Ali, M.A.; Warkar, S.G. Cellulose microfibers-embedded carboxymethyl tamarind kernel gum hydrogels as soil conditioners and plant nutrients carriers. ACS Agric. Sci. Technol. 2025, 5, 1132–1144. [Google Scholar] [CrossRef]

- Alsubaie, F.S.; Srdar, M.; Fayraa, O.; Alsulami, F.M.; Omran, F.; Alamry, K.A. Development of eco-friendly date palm biomass-based hydrogels for enhanced water retention in soil. Gels 2025, 11, 349. [Google Scholar] [CrossRef] [PubMed]

- Sulianto, A.A.; Adiyaksa, I.P.; Wibisono, Y.; Khan, E.; Ivanov, A.; Drannikov, A.; Di Martino, A. From fruit waste to hydrogels for agricultural applications. Clean Technol. 2023, 6, 1–17. [Google Scholar] [CrossRef]

| Hydrogel Classification | Advantage | Disadvantage |

|---|---|---|

| Synthetics |

|

|

| Natural |

|

|

| Hybrids |

|

|

| Residue | Application | Results | Polysaccharide | Swelling Capacity (%) | Authorship |

|---|---|---|---|---|---|

| Paper waste | Seed germination | Increases percentage of germination compared to soil without hydrogel | Cellulose | 465 | [51] |

| Paper waste | Tomato cultivation | They had a better response to water reabsorption | Cellulose | 415 | [57] |

| Waste from the paper industry | Water retention and controlled release of fertilizers | The values recorded for absorption capacity were better compared to the control. | Lignin | 386 | [56] |

| Fique plant residue | Reinforcing the mechanical properties of hydrogels | Increased absorption capacity | Cellulose | 474 | [52] |

| Coconut fiber | Reinforcing the mechanical properties of hydrogels | Good reswelling capacity | Cellulose and lignin | 342 | [58] |

| Rice straw and Tamarind seeds | Reinforcing mechanical properties and nutrient releaser | Great swelling capacity, long release nutrient | Cellulose | 7722 | [59] |

| Date Palm rachis | Seed germination, polymer component | Increases swelling capacity as germination seed | Lignin and Cellulose | 777.8 | [60] |

| Orange, apple, and banana peels | water content in sandy soils | High swelling capacity and increase in water content in sandy soils up to 12 days | Pectin and Starch | 400 | [61] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso-Cuevas, C.F.; Ramírez-Guzmán, N.; Serna-Cock, L.; Guancha-Chalapud, M.; Aguirre-Joya, J.A.; Aguillón-Gutiérrez, D.R.; Claudio-Rizo, A.; Torres-León, C. From Agro-Industrial Waste to Natural Hydrogels: A Sustainable Alternative to Reduce Water Use in Agriculture. Gels 2025, 11, 616. https://doi.org/10.3390/gels11080616

Alonso-Cuevas CF, Ramírez-Guzmán N, Serna-Cock L, Guancha-Chalapud M, Aguirre-Joya JA, Aguillón-Gutiérrez DR, Claudio-Rizo A, Torres-León C. From Agro-Industrial Waste to Natural Hydrogels: A Sustainable Alternative to Reduce Water Use in Agriculture. Gels. 2025; 11(8):616. https://doi.org/10.3390/gels11080616

Chicago/Turabian StyleAlonso-Cuevas, César F., Nathiely Ramírez-Guzmán, Liliana Serna-Cock, Marcelo Guancha-Chalapud, Jorge A. Aguirre-Joya, David R. Aguillón-Gutiérrez, Alejandro Claudio-Rizo, and Cristian Torres-León. 2025. "From Agro-Industrial Waste to Natural Hydrogels: A Sustainable Alternative to Reduce Water Use in Agriculture" Gels 11, no. 8: 616. https://doi.org/10.3390/gels11080616

APA StyleAlonso-Cuevas, C. F., Ramírez-Guzmán, N., Serna-Cock, L., Guancha-Chalapud, M., Aguirre-Joya, J. A., Aguillón-Gutiérrez, D. R., Claudio-Rizo, A., & Torres-León, C. (2025). From Agro-Industrial Waste to Natural Hydrogels: A Sustainable Alternative to Reduce Water Use in Agriculture. Gels, 11(8), 616. https://doi.org/10.3390/gels11080616