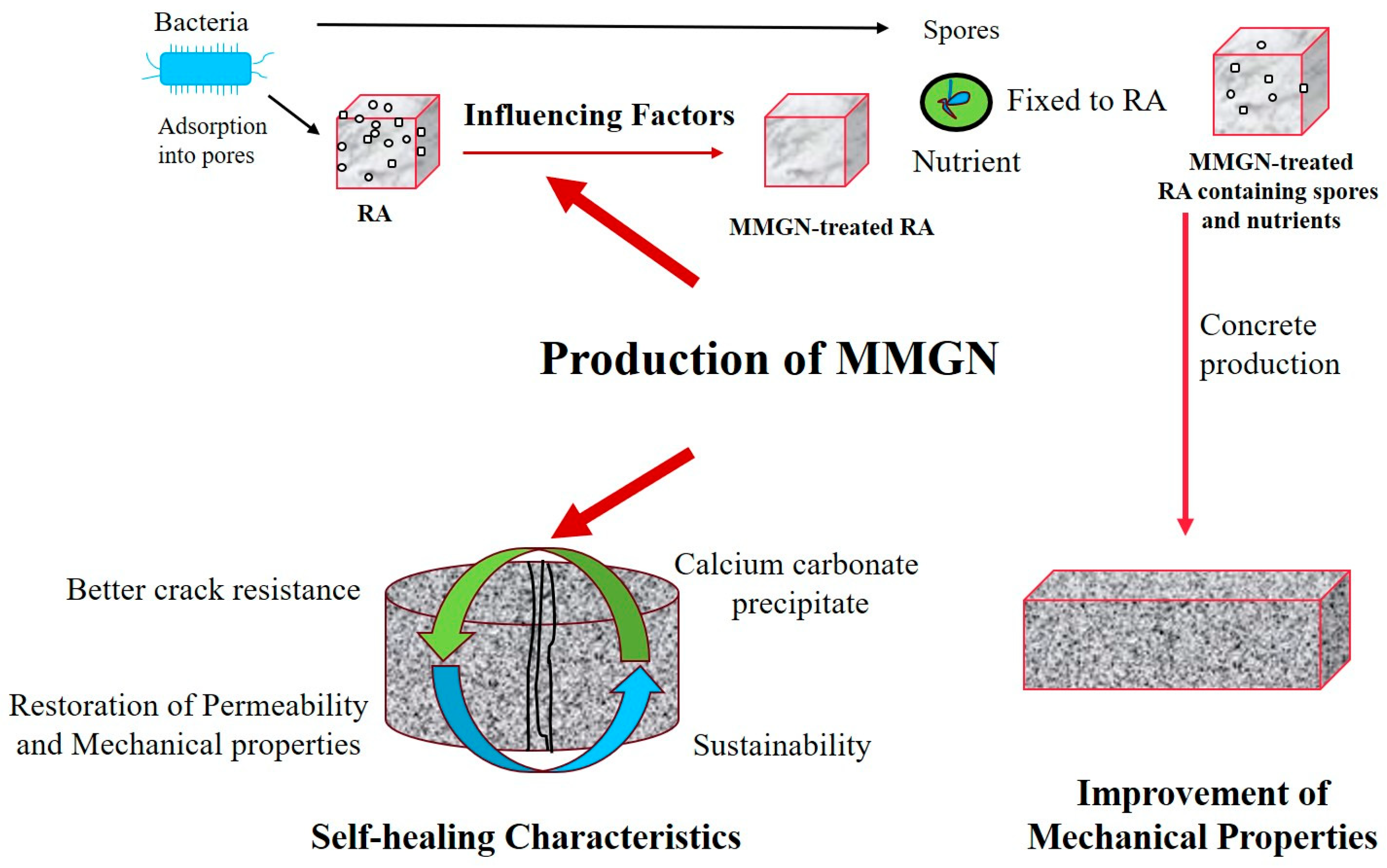

Microbial Mineral Gel Network for Enhancing the Performance of Recycled Concrete: A Review

Abstract

1. Introduction

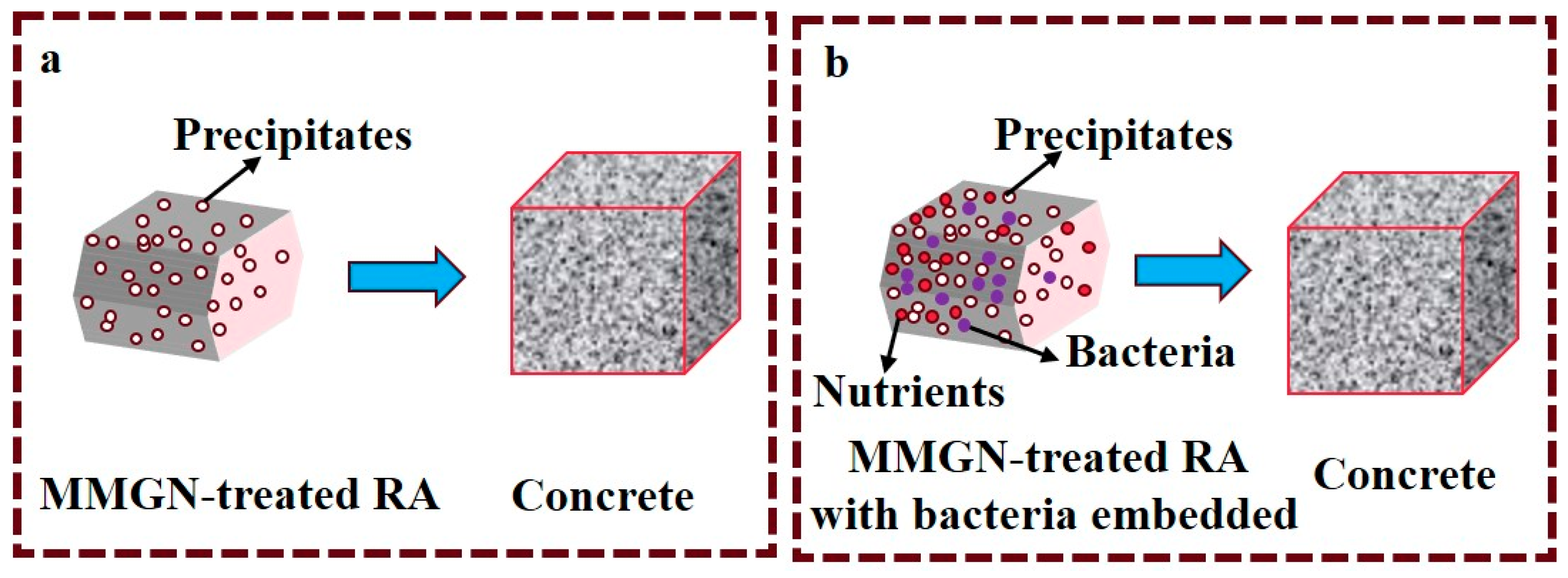

2. Factors Influencing RA Enhancement by MMGN

2.1. Bacteria Applied to Enhance RA

2.1.1. Bacterial Species

- (1)

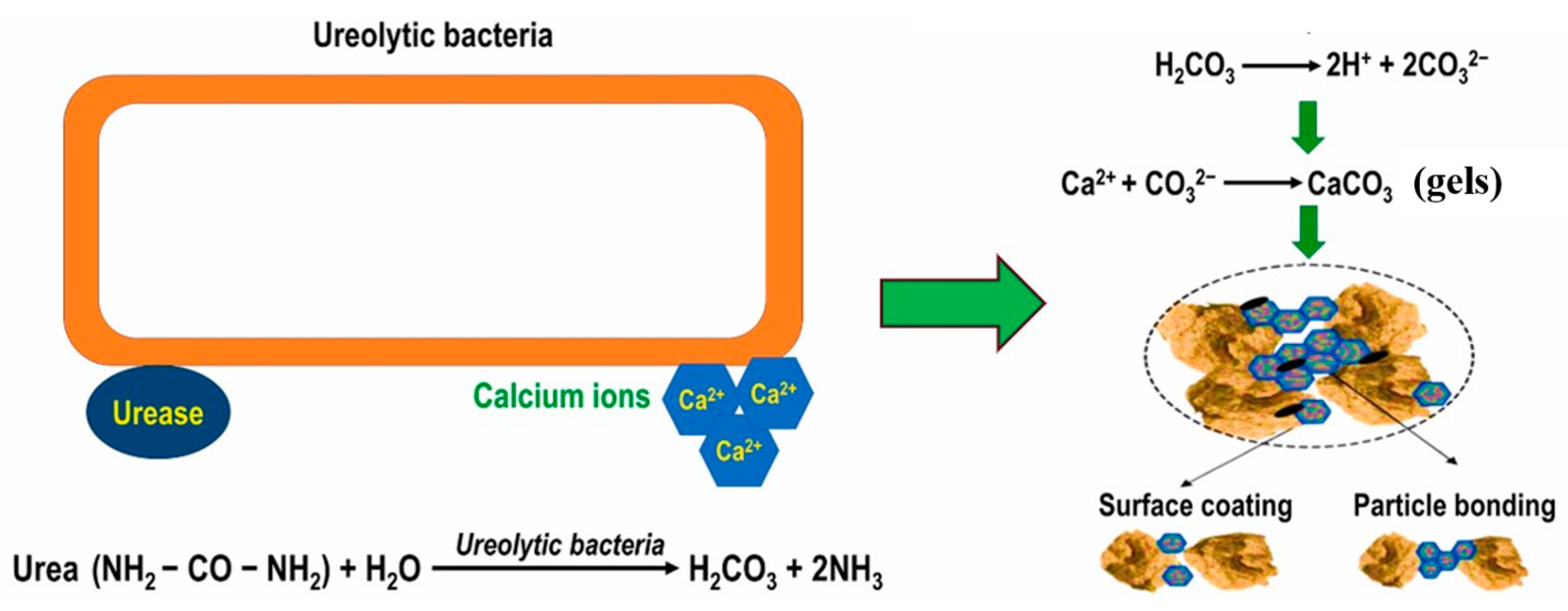

- Ureolytic bacteria

- (2)

- Denitrifying bacteria

- (3)

- Organic compound-converting bacteria

- (4)

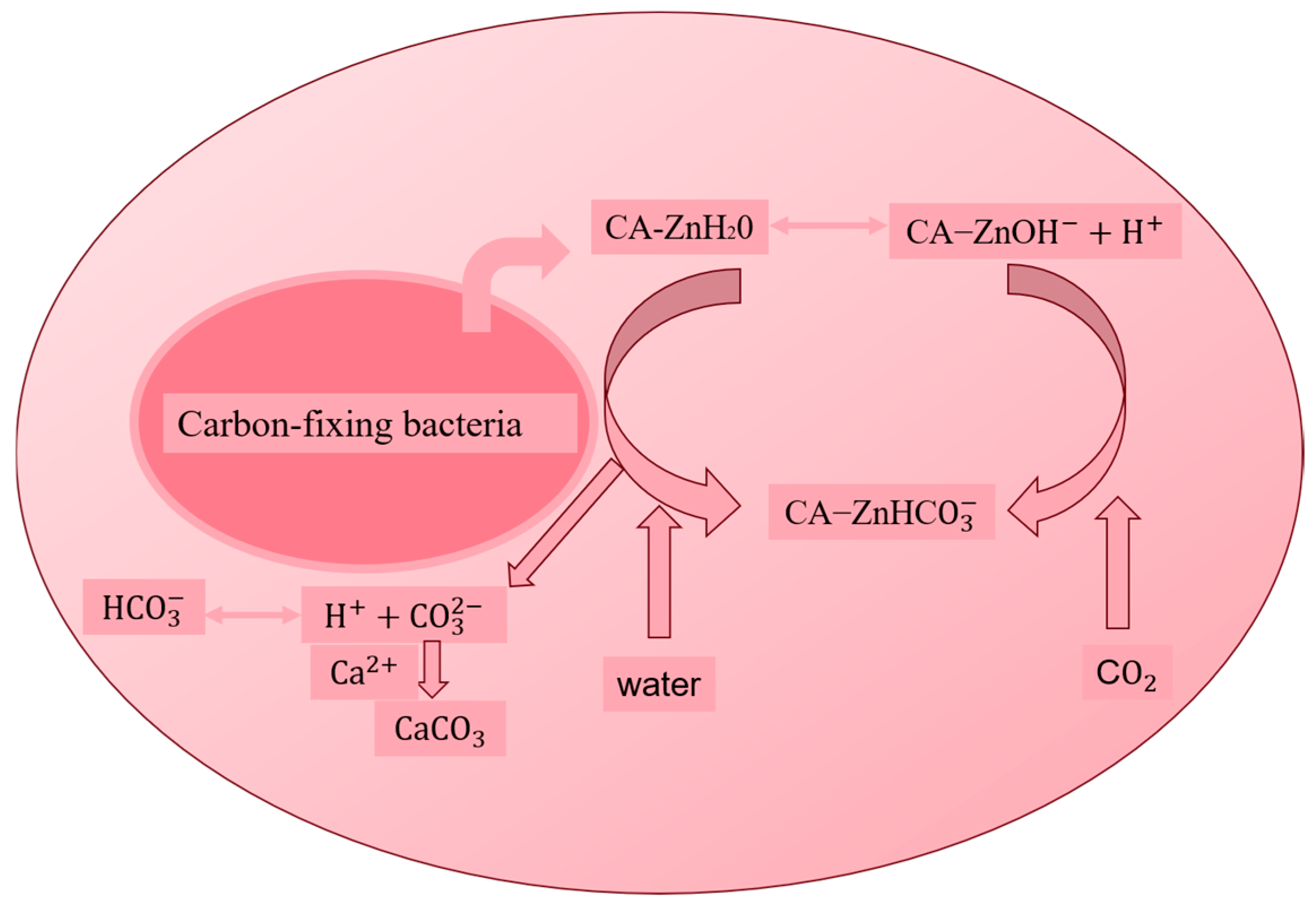

- Carbon-fixing bacteria

- (5)

- Fungi

- (6)

- Other pathways

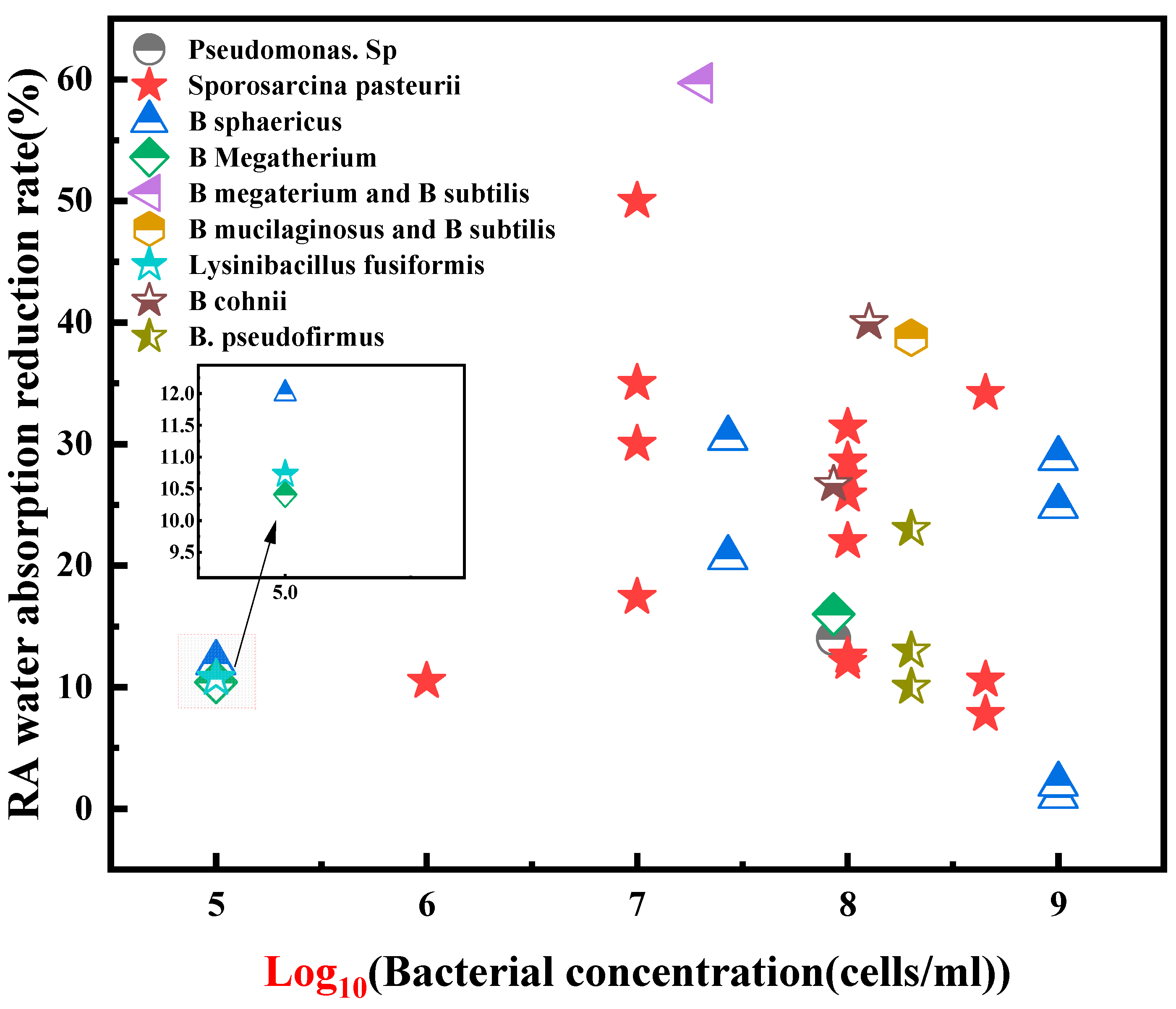

2.1.2. Bacterial Concentration

2.2. Environmental Factors

2.2.1. Temperature

2.2.2. pH

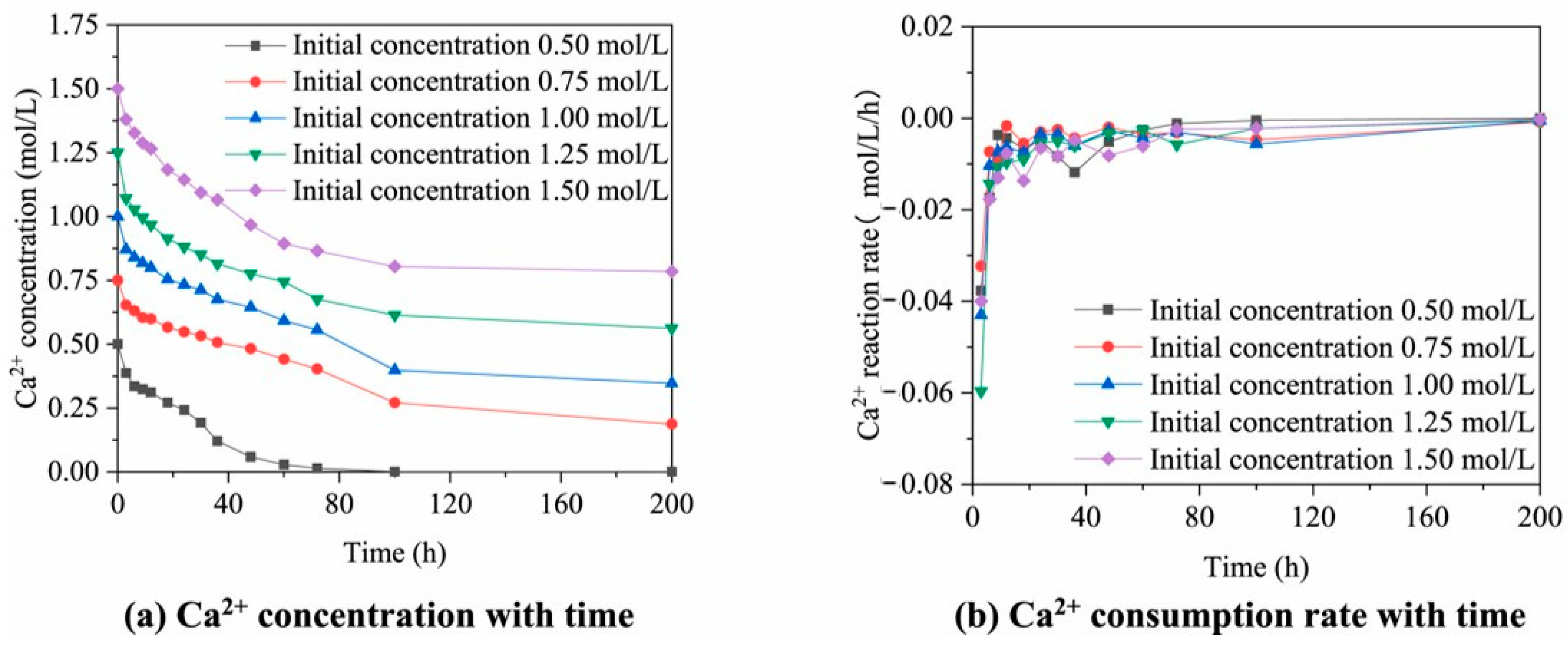

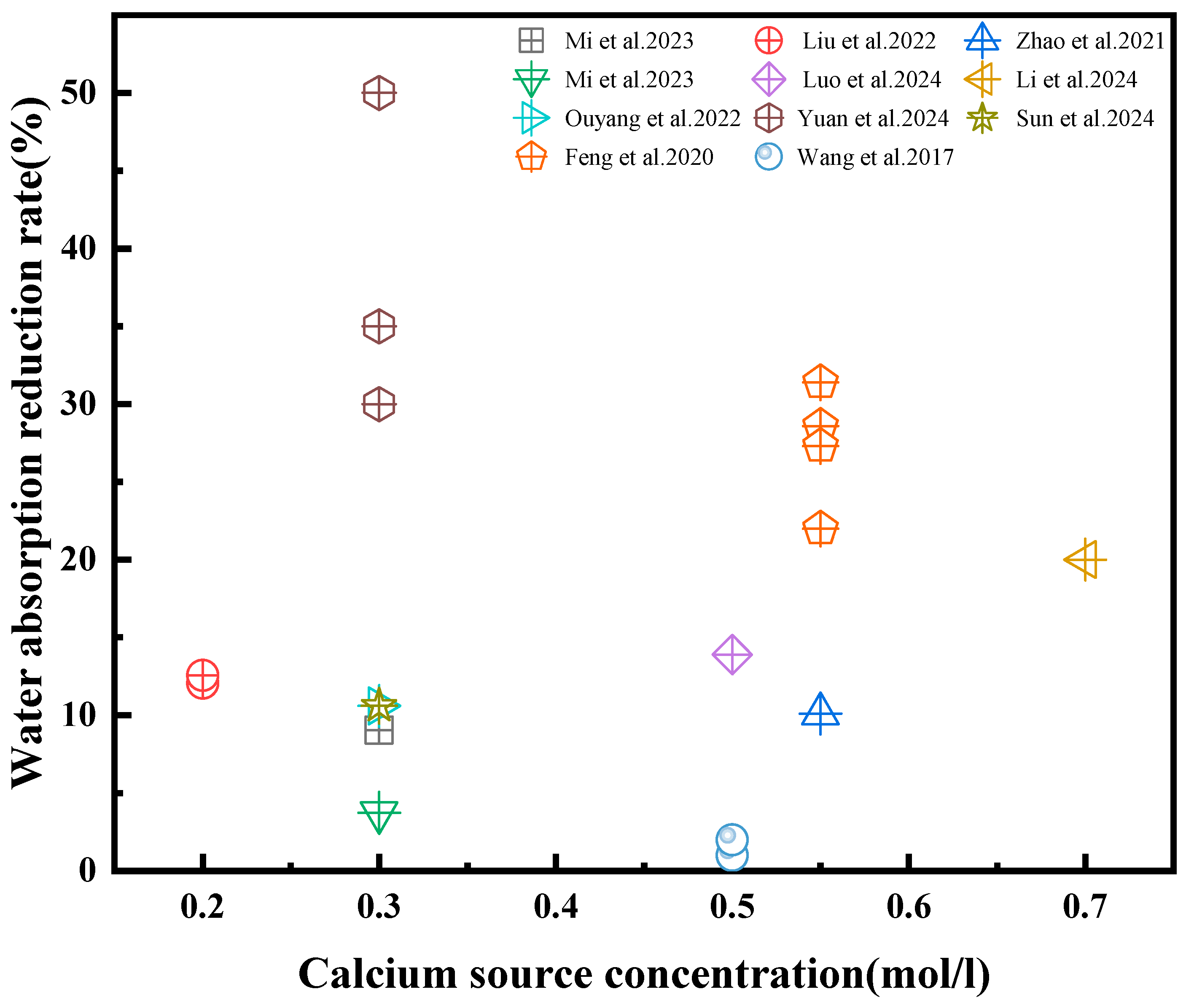

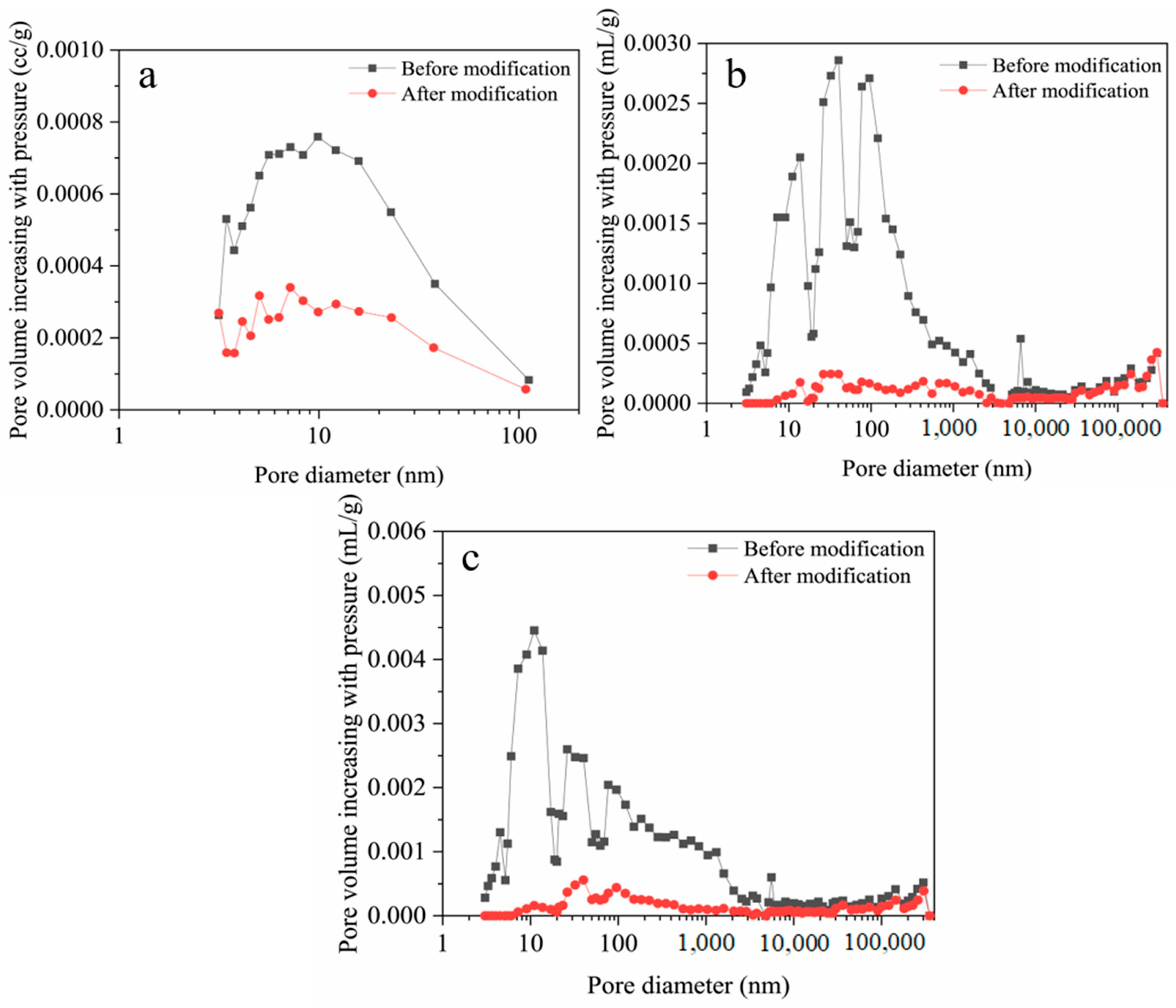

2.2.3. Calcium Ions

2.2.4. Urea

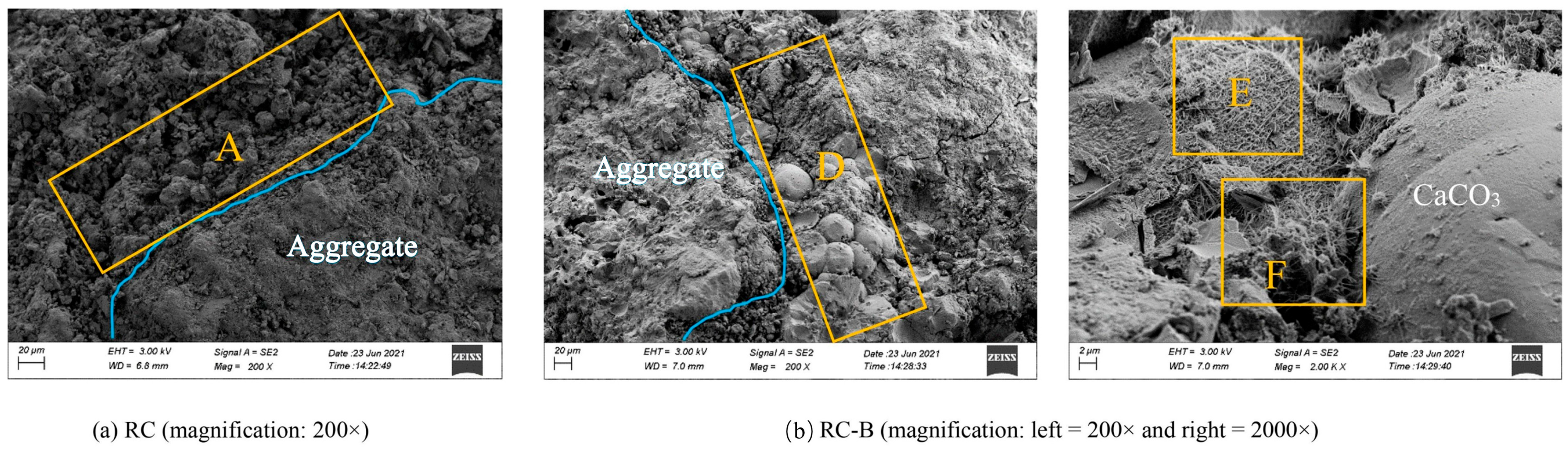

3. Mechanical Properties of MMGN-Enhanced RC

3.1. Compressive Strength

3.2. Splitting Tensile Strength

4. Self-Healing Characteristics of MMGN-Enhanced RC

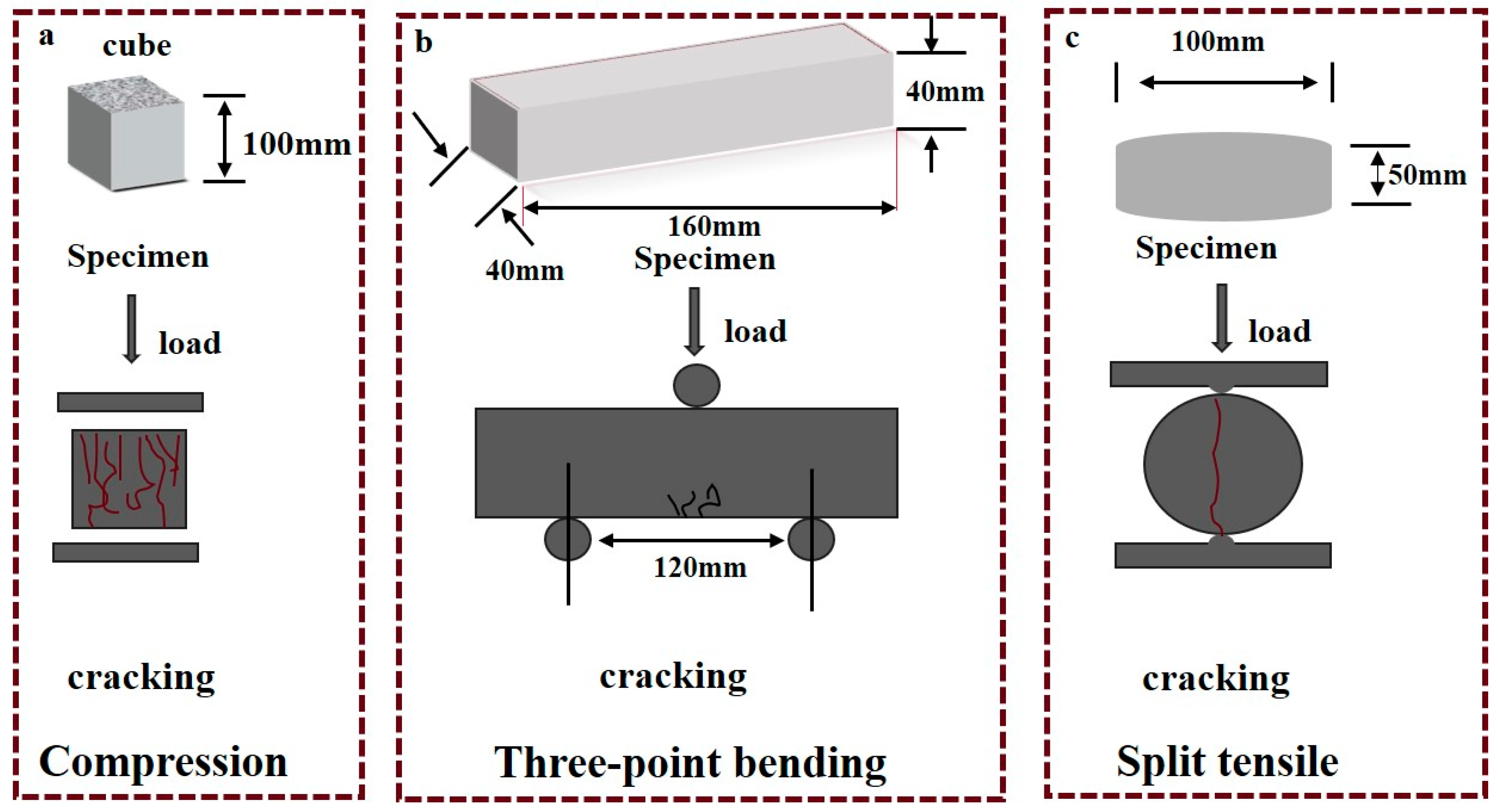

4.1. Crack-Making Method

4.2. Self-Healing Effects

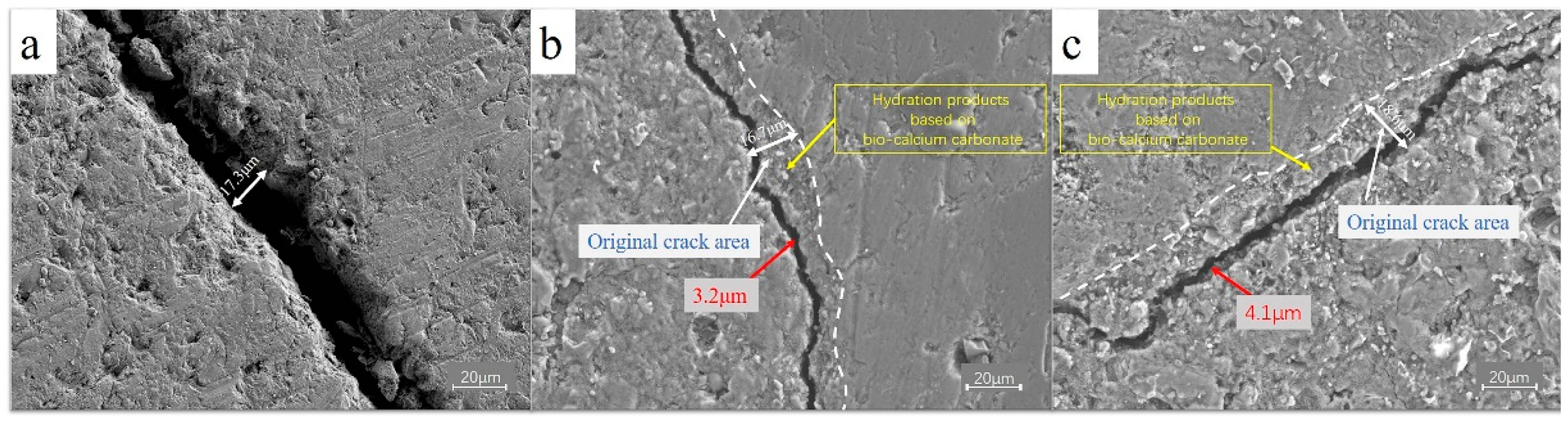

4.2.1. Crack-Healing Effects and Influencing Factors

4.2.2. Mechanical Properties After Self-Healing

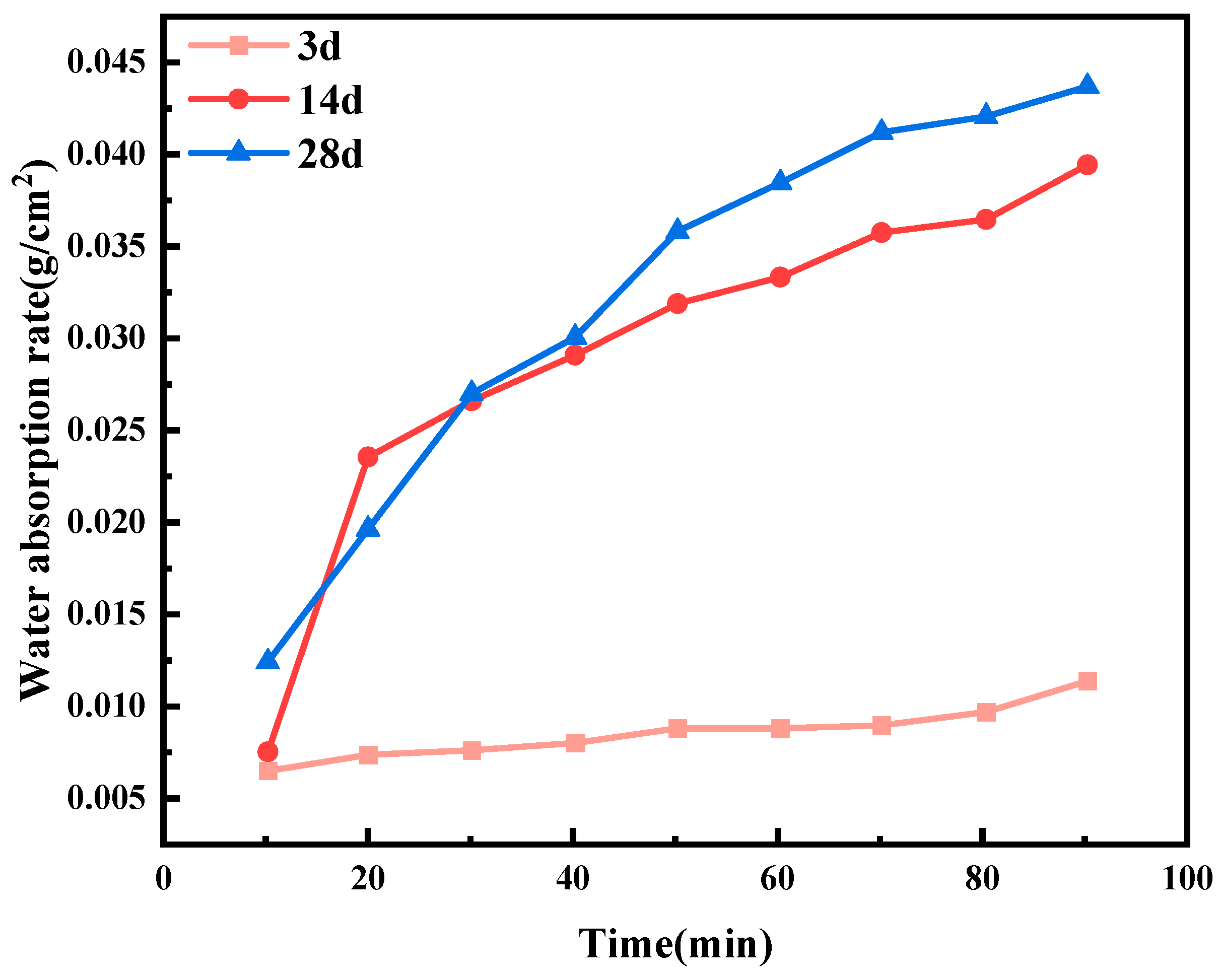

4.2.3. Permeability After Self-Healing

5. Environmental and Economic Benefits of MMGN-Enhanced RC

6. Limitations and Outlook of MMGN-Enhanced RC

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Sainz-Aja, J.; Carrascal, I.; Polanco, J.; Cimentada, A.; Thomas, C.; Brito, J. Aging of recycled aggregates mortars by drying-wetting cycles. Constr. Build. Mater. 2021, 307, 124934. [Google Scholar] [CrossRef]

- Xiao, J.; Li, L.; Shen, L.; Poon, C.S. Compressive behaviour of recycled aggregate concrete under impact loading. Cem. Concr. Res. 2015, 71, 46–55. [Google Scholar] [CrossRef]

- Lei, B.; Li, W.; Tang, Z.; Li, Z.; Tam, V.W. Effects of environmental actions, recycled aggregate quality and modification treatments on durability performance of recycled concrete. J. Mater. Res. Technol. 2020, 9, 13375–13389. [Google Scholar] [CrossRef]

- Muhammad, F.; Harun, M.; Ahmed, A.; Kabir, N.; Khalid, H.R.; Hanif, A. Influence of bonded mortar on recycled aggregate concrete properties: A review. Constr. Build. Mater. 2024, 432, 136564. [Google Scholar] [CrossRef]

- Ma, A.; Zhang, J.; Wang, X.; Meng, Q.; Liu, Y.; Zhou, A. A practical enhancing method of recycled concrete aggregates via combination of mechanical grinding and microbial consortia-spraying: Preliminary tests. J. Clean. Prod. 2024, 472, 143530. [Google Scholar] [CrossRef]

- Wu, C.-R.; Zhu, Y.-G.; Zhang, X.-T.; Kou, S.-C. Improving the properties of recycled concrete aggregate with bio-deposition approach. Cem. Concr. Compos. 2018, 94, 248–254. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Abid, S.R.; Nahhab, A.H.; Al-aayedi, H.K.; Nuhair, A.M. Expansion and strength properties of concrete containing contaminated recycled concrete aggregate. Case Stud. Constr. Mater. 2018, 9, e00201. [Google Scholar] [CrossRef]

- Gong, Y.; Chen, P.; Lin, Y.; Wan, Y.; Zhang, L.; Meng, T. Improvement of recycled aggregate properties through a combined method of mechanical grinding and microbial-induced carbonate precipitation. Constr. Build. Mater. 2022, 342, 128093. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Qian, X.; Chen, P.; Xu, Y.; Guo, J. An environmentally friendly method to improve the quality of recycled concrete aggregates. Constr. Build. Mater. 2017, 144, 432–441. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 2013, 44, 464–476. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, X.; Zhu, P.; Chen, C.; Wang, X.; Yang, W.; Zong, M. Carbonation treatment to repair the damage of repeatedly recycled coarse aggregate from recycled concrete suffering from coupling action of high stress and freeze-thaw cycles. Constr. Build. Mater. 2022, 349, 128688. [Google Scholar] [CrossRef]

- Wu, K.; Luo, S.; Zheng, J.; Yan, J.; Xiao, J. Influence of carbonation treatment on the properties of multiple interface transition zones and recycled aggregate concrete. Cem. Concr. Compos. 2022, 127, 104402. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Properties of concrete prepared with PVA-impregnated recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 649–654. [Google Scholar] [CrossRef]

- Olofinnade, O.M.; Osoata, O.P. Performance assessment of mechanical properties of green normal strength concrete produced with metakaolin-cement coated recycled concrete aggregate for sustainable construction. Constr. Build. Mater. 2023, 407, 133508. [Google Scholar] [CrossRef]

- Chen, J.J.; Thomas, J.J.; Jennings, H.M. Decalcification shrinkage of cement paste. Cem. Concr. Res. 2006, 36, 801–809. [Google Scholar] [CrossRef]

- Li, J.; Wang, T.; Du, C.; Wang, C.; Cao, F.; Su, T. Multi-faceted assessment of microbial-reinforced recycled brick aggregate concrete. Chem. Eng. J. 2024, 497, 154481. [Google Scholar] [CrossRef]

- Dupraz, C.; Reid, R.P.; Braissant, O.; Decho, A.W.; Norman, R.S.; Visscher, P.T. Processes of carbonate precipitation in modern microbial mats. Earth-Sci. Rev. 2009, 96, 141–162. [Google Scholar] [CrossRef]

- Tang, Q.; Tian, A.; Ling, C.; Huang, Y.; Gu, F. Physical and mechanical properties of recycled aggregates modified by microbially induced calcium carbonate precipitation. J. Clean. Prod. 2023, 382, 135409. [Google Scholar] [CrossRef]

- Han, R.; Xu, S.; Zhang, J.; Liu, Y.; Zhou, A. Insights into the effects of microbial consortia-enhanced recycled concrete aggregates on crack self-healing in concrete. Constr. Build. Mater. 2022, 343, 128138. [Google Scholar] [CrossRef]

- Rais, M.S.; Khan, R.A. Effect of biomineralization technique on the strength and durability characteristics of recycled aggregate concrete. Constr. Build. Mater. 2021, 290, 123280. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, K.; Sun, D.; Jiang, N.; Xu, W.; Wang, A. Evaluation of urea hydrolysis for MICP technique applied in recycled aggregate: Concentration of urea and bacterial spores. Constr. Build. Mater. 2024, 419, 135366. [Google Scholar] [CrossRef]

- Tang, Y.; Xu, J. Application of microbial precipitation in self-healing concrete: A review on the protection strategies for bacteria. Constr. Build. Mater. 2021, 306, 124950. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, R.; Liu, H.; Nong, X. Self-healing concrete with recycled coarse aggregate: The performance of biochemical-chloride ion transport. J. Build. Eng. 2022, 57, 104925. [Google Scholar] [CrossRef]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Hussain, A.; Ali, D.; Koner, S.; Hseu, Z.-Y.; Hsu, B.-M. Microbial induce carbonate precipitation derive bio-concrete formation: A sustainable solution for carbon sequestration and eco-friendly construction. Environ. Res. 2025, 270, 121006. [Google Scholar] [CrossRef] [PubMed]

- Vanjinathan, J.; Sampathkumar, V.; Pannirselvam, N.; Krishnan, R.; Sivasubramanian, M.; Kandasamy, S.; Selvasofia, S.A.; Kavisri, M. Microbially-induced self-healing bioconcrete for sustainable development. Biomass Convers. Biorefinery 2024, 14, 29941–29947. [Google Scholar] [CrossRef]

- Mi, T.; Peng, L.; Yu, K.; Zhao, Y. Enhancement strategies for recycled brick aggregate concrete using MICP and EICP treatments. J. Build. Eng. 2023, 79, 107909. [Google Scholar] [CrossRef]

- Krajewska, B. Urease-aided calcium carbonate mineralization for engineering applications: A review. J. Adv. Res. 2018, 13, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Chin, C.S.; Xia, J. Improving recycled coarse aggregate (RCA) and recycled coarse aggregate concrete (RCAC) by biological denitrification phenomenon. Constr. Build. Mater. 2021, 301, 124338. [Google Scholar] [CrossRef]

- Ersan, Y.C.; Boon, N.; De Belie, N. Microbial self-healing concrete: Denitrification as an enhanced and environment-friendly approach. In Proceedings of the 5th International Conference on Self-Healing Materials, Durham, UK, 22–24 June 2015. [Google Scholar]

- Van Paassen, L.A.; Daza, C.M.; Staal, M.; Sorokin, D.Y.; van der Zon, W.; van Loosdrecht, M.C. Potential soil reinforcement by biological denitrification. Ecol. Eng. 2010, 36, 168–175. [Google Scholar] [CrossRef]

- Feng, C.; Cui, B.; Wang, J.; Guo, H.; Zhang, W.; Zhu, J. Changing the soaking method of microbially induced calcium carbonate precipitation technology to improve the reinforcement effect of recycled concrete aggregates. J. Build. Eng. 2023, 68, 106128. [Google Scholar] [CrossRef]

- Fan, Q.; Fan, L.; Quach, W.-M.; Zhang, R.; Duan, J.; Sand, W. Application of microbial mineralization technology for marine concrete crack repair: A review. J. Build. Eng. 2023, 69, 106299. [Google Scholar] [CrossRef]

- Wang, J.; Pang, S.; Zhan, X.; Wei, W.; Li, X.; Wang, L.; Huang, X.; Zhang, L. Improving Recycled Concrete Aggregate Performance via Microbial-Induced Calcium Carbonate Precipitation: Effects of Bacterial Strains and Mineralization Conditions. Buildings 2025, 15, 825. [Google Scholar] [CrossRef]

- Liu, X.; Si, Z.; Huang, L.; Zhao, P.; Zhang, L.; Li, M.; Yang, L. Research on the properties and modification mechanism of microbial mineralization deposition modified recycled concrete. J. Build. Eng. 2025, 102, 111963. [Google Scholar] [CrossRef]

- Lindskog, S. Structure and mechanism of carbonic anhydrase. Pharmacol. Ther. 1997, 74, 1–20. [Google Scholar] [CrossRef]

- Kanth, B.K.; Min, K.; Kumari, S.; Jeon, H.; Jin, E.S.; Lee, J.; Pack, S.P. Expression and characterization of codon-optimized carbonic anhydrase from Dunaliella species for CO2 sequestration application. Appl. Biochem. Biotechnol. 2012, 167, 2341–2356. [Google Scholar] [CrossRef]

- Durga, C.S.S.; Ruben, N.; Chand, M.S.R.; Indira, M.; Venkatesh, C. Comprehensive microbiological studies on screening bacteria for self-healing concrete. Materialia 2021, 15, 101051. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Li, M.; Samia, A.; Yu, X.B. Study on the behaviors of fungi-concrete surface interactions and theoretical assessment of its potentials for durable concrete with fungal-mediated self-healing. J. Clean. Prod. 2021, 292, 125870. [Google Scholar] [CrossRef]

- Menon, R.R.; Luo, J.; Chen, X.; Zhou, H.; Liu, Z.; Zhou, G.; Zhang, N.; Jin, C. Screening of fungi for potential application of self-healing concrete. Sci. Rep. 2019, 9, 2075. [Google Scholar] [CrossRef]

- Khan, N.; Khan, H.A.; Khushnood, R.A.; Bhatti, M.F.; Baig, D.I. Self-healing of recycled aggregate fungi concrete using Fusarium oxysporum and Trichoderma longibrachiatum. Constr. Build. Mater. 2023, 392, 131910. [Google Scholar] [CrossRef]

- Mi, T.; Peng, L.; Yu, K.; Zhao, Y. Optimizing microbial-and enzyme-induced carbonate precipitation treatment regimes to improve the performance of recycled aggregate concrete. Case Stud. Constr. Mater. 2023, 19, e02261. [Google Scholar] [CrossRef]

- Xie, D.; Zhang, R.; Wang, J. The influence of environmental factors and precipitation precursors on enzyme-induced carbonate precipitation (EICP) process and its application on modification of recycled concrete aggregates. J. Clean. Prod. 2023, 395, 136444. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, L.; Feng, Z.; Lu, Z. Optimization of microbial induced carbonate precipitation treatment process to improve recycled fine aggregate. Clean. Mater. 2021, 1, 100003. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, R.; Hou, F.; Ye, G. Influence of pore property and alkalinity on the bio-deposition treatment efficiency of recycled aggregates. J. Build. Eng. 2024, 89, 109381. [Google Scholar] [CrossRef]

- Qiu, J.; Tng, D.Q.S.; Yang, E.-H. Surface treatment of recycled concrete aggregates through microbial carbonate precipitation. Constr. Build. Mater. 2014, 57, 144–150. [Google Scholar] [CrossRef]

- Bakr, M.A.; Hussain, A.; Singh, P.K.; Singh, B.K.; Prajakti. Effects of bacterial consortium enhanced recycled coarse aggregates on self-healing concrete immobilized with Bacillus megaterium MTCC 1684 and Bacillus subtilis NCIM 2193. Struct. Concr. 2024, 25, 1840–1864. [Google Scholar] [CrossRef]

- Wang, J.; Vandevyvere, B.; Vanhessche, S.; Schoon, J.; Boon, N.; De Belie, N. Microbial carbonate precipitation for the improvement of quality of recycled aggregates. J. Clean. Prod. 2017, 156, 355–366. [Google Scholar] [CrossRef]

- Liu, K.; Ouyang, J.; Sun, D.; Jiang, N.; Wang, A.; Huang, N.; Liang, P. Enhancement mechanism of different recycled fine aggregates by microbial induced carbonate precipitation. J. Clean. Prod. 2022, 379, 134783. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, Y.; Zeng, W.; Lu, Z.; Shah, S.P. Using microbial carbonate precipitation to improve the properties of recycled fine aggregate and mortar. Constr. Build. Mater. 2020, 230, 116949. [Google Scholar] [CrossRef]

- Ouyang, J.; Liu, K.; Sun, D.; Xu, W.; Wang, A.; Ma, R. A focus on Ca2+ supply in microbial induced carbonate precipitation and its effect on recycled aggregate. J. Build. Eng. 2022, 51, 104334. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, L.; Zeng, W.; sun Poon, C.; Lu, Z. Improvement in properties of concrete with modified RCA by microbial induced carbonate precipitation. Cem. Concr. Compos. 2021, 124, 104251. [Google Scholar] [CrossRef]

- Ahmad, J.; Khan, M.A.; Ahmad, S. State of the art on factors affecting the performance of MICP treated fine aggregates. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Kadhim, F.J.; Zheng, J. Review of the factors that influence on the microbial induced calcite precipitation. J. Civ. Environ. Res. 2016, 8, 69–76. [Google Scholar]

- Okwadha, G.D.; Li, J. Optimum conditions for microbial carbonate precipitation. Chemosphere 2010, 81, 1143–1148. [Google Scholar] [CrossRef]

- Chaparro-Acuña, S.P.; Becerra-Jiménez, M.L.; Martínez-Zambrano, J.J.; Rojas-Sarmiento, H.A. Soil bacteria that precipitate calcium carbonate: Mechanism and applications of the process. Acta Agron. 2018, 67, 277–288. [Google Scholar] [CrossRef]

- Mathur, S.; Bhatt, A.; Patel, R. Role of microbial induced calcite precipitation in sustainable development. Ann. Biol. Res. 2018, 9, 11–27. [Google Scholar]

- Su, J.-F.; Shi, J.-X.; Huang, T.-L.; Ma, F. Kinetic analysis of simultaneous denitrification and biomineralization of novel Acinetobacter sp. CN86. Mar. Pollut. Bull. 2016, 109, 87–94. [Google Scholar] [CrossRef]

- Matsumoto, M.; Fukunaga, T.; Onoe, K. Polymorph control of calcium carbonate by reactive crystallization using microbubble technique. Chem. Eng. Res. Des. 2010, 88, 1624–1630. [Google Scholar] [CrossRef]

- Kojima, Y.; Kawanobe, A.; Yasue, T.; Arai, Y. Controls of polymorphism and morphology of calcium carbonate compounds formed by crystallizing amorphous calcium carbonate hydrate. J. Ceram. Soc. Jpn. 1994, 102, 1128–1136. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, T.; Wang, Q.; Chen, H.e.; Lin, S.; Wang, X.; Xu, X. An experimental investigation of dispersive soils treated by microbially induced calcium carbonate precipitation (MICP). Constr. Build. Mater. 2024, 446, 137941. [Google Scholar] [CrossRef]

- Luo, M.; Ji, A.; Li, X.; Yang, D. Performance evaluation of self-healing recycled concrete using biomineralization modified recycled aggregate as bacterial carrier. J. Build. Eng. 2024, 86, 109000. [Google Scholar] [CrossRef]

- Wen, K.; Li, Y.; Amini, F.; Li, L. Impact of bacteria and urease concentration on precipitation kinetics and crystal morphology of calcium carbonate. Acta Geotech. 2020, 15, 17–27. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Chu, J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. 2019, 14, 615–626. [Google Scholar] [CrossRef]

- Cui, M.-J.; Lai, H.-J.; Hoang, T.; Chu, J. One-phase-low-pH enzyme induced carbonate precipitation (EICP) method for soil improvement. Acta Geotech. 2021, 16, 481–489. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, J. Effect of regulating urease activity on the properties of bio-CaCO3 precipitated on recycled aggregates. Constr. Build. Mater. 2023, 403, 133119. [Google Scholar] [CrossRef]

- Wang, J.; Jonkers, H.M.; Boon, N.; De Belie, N. Bacillus sphaericus LMG 22257 is physiologically suitable for self-healing concrete. Appl. Microbiol. Biotechnol. 2017, 101, 5101–5114. [Google Scholar] [CrossRef]

- Li, L.G.; Chen, J.-J.; Kwan, A.K. Roles of packing density and water film thickness in strength and durability of limestone fines concrete. Mag. Concr. Res. 2017, 69, 595–605. [Google Scholar] [CrossRef]

- Wu, C.-R.; Hong, Z.-Q.; Zhang, J.-L.; Kou, S.-C. Pore size distribution and ITZ performance of mortars prepared with different bio-deposition approaches for the treatment of recycled concrete aggregate. Cem. Concr. Compos. 2020, 111, 103631. [Google Scholar] [CrossRef]

- Bolobova, A.; Kondrashchenko, V. Use of yeast fermentation waste as a biomodifier of concrete. Appl. Biochem. Microbiol. 2000, 36, 205–214. [Google Scholar] [CrossRef]

- Amiri, A.; Bundur, Z.B. Use of corn-steep liquor as an alternative carbon source for biomineralization in cement-based materials and its impact on performance. Constr. Build. Mater. 2018, 165, 655–662. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Wang, Z.; Yao, W. Use of recycled concrete aggregates as carriers for self-healing of concrete cracks by bacteria with high urease activity. Constr. Build. Mater. 2022, 337, 127581. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Vaezi, M.; Zareei, S.A.; Jahadi, M. Recycled microbial mortar: Effects of bacterial concentration and calcium lactate content. Constr. Build. Mater. 2020, 234, 117349. [Google Scholar] [CrossRef]

- Schreiberová, H.; Bílý, P.; Fládr, J.; Šeps, K.; Chylík, R.; Trtík, T. Impact of the self-healing agent composition on material characteristics of bio-based self-healing concrete. Case Stud. Constr. Mater. 2019, 11, e00250. [Google Scholar] [CrossRef]

- Feng, C.; Wang, J.; Cui, B.; Ye, Z.; Guo, H.; Zhang, W.; Zhu, J. Evaluation of techniques for enhancing recycled concrete aggregates: Chemical treatment, biological modification and synergistic reinforcement. Constr. Build. Mater. 2024, 420, 135641. [Google Scholar] [CrossRef]

- Wang, J.; Feng, C.; Zong, X.; Zhang, W.; Zhu, J.; Bian, Y. Microbial self-healing cement-based materials co-reinforced by Mg2+: Using recycled aggregates as carriers. J. Build. Eng. 2024, 98, 111091. [Google Scholar] [CrossRef]

- Le, T.; Le Saout, G.; Garcia-Diaz, E.; Betrancourt, D.; Rémond, S. Hardened behavior of mortar based on recycled aggregate: Influence of saturation state at macro-and microscopic scales. Constr. Build. Mater. 2017, 141, 479–490. [Google Scholar] [CrossRef]

- Amjad, H.; Zeb, M.S.; Khushnood, R.A.; Khan, N. Impacts of biomimetic self-healing of Lysinibacillus boronitolerans immobilized through recycled fine and coarse brick aggregates in concrete. J. Build. Eng. 2023, 76, 107327. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ali, A.M.; Bhatti, M.F.; Khan, H.A. Self-healing fungi concrete using potential strains Rhizopus oryzae and Trichoderma longibrachiatum. J. Build. Eng. 2022, 50, 104155. [Google Scholar] [CrossRef]

- Akhtar, M.K.; Kanwal, M.; Khushnood, R.A.; Khan, M.B.E. Assessment of mechanical attributes and microstructural densification of self-healing recycled coarse aggregate concrete using various bacterial immobilizers. J. Build. Eng. 2023, 69, 106229. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y. Integrated interface parameters of recycled aggregate concrete. Constr. Build. Mater. 2015, 101, 861–877. [Google Scholar] [CrossRef]

- Prokopski, G.; Halbiniak, J. Interfacial transition zone in cementitious materials. Cem. Concr. Res. 2000, 30, 579–583. [Google Scholar] [CrossRef]

- Wang, R.; Jin, P.; Ding, Z.; Zhang, W. Surface modification of recycled coarse aggregate based on Microbial Induced Carbonate Precipitation. J. Clean. Prod. 2021, 328, 129537. [Google Scholar] [CrossRef]

- Xiang, J.; Song, Y.; Shu, H.; Li, Z.; Qiu, J.; Gu, X. Expanded polystyrene (EPS) particles as a carrier to improve the growth of microorganisms in concrete. J. Clean. Prod. 2022, 369, 133363. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef]

- Rais, M.S.; Khan, R.A. Experimental investigation on the strength and durability properties of bacterial self-healing recycled aggregate concrete with mineral admixtures. Constr. Build. Mater. 2021, 306, 124901. [Google Scholar] [CrossRef]

- Bakr, M.A.; Hasnain, S.M.; Zairov, R.; Ragab, A.E. Effect of MICP-treated recycled coarse aggregates and banana fibres on the self-healing and flexural property restoration. Constr. Build. Mater. 2025, 462, 139912. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.; Yao, W.; Kulminskaya, A.A.; Shah, S.P. Microbial-inspired self-healing of concrete cracks by sodium silicate-coated recycled concrete aggregates served as bacterial carrier. Front. Struct. Civ. Eng. 2024, 18, 14–29. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, R.; Liu, H.; Xu, X.; Lv, Z. Experimental and analytical study on the flexural rigidity of microbial self-healing concrete based on recycled coarse aggregate (RCA). Constr. Build. Mater. 2021, 285, 122941. [Google Scholar] [CrossRef]

- Luo, M.; Qian, C.-X.; Li, R.-Y. Factors affecting crack repairing capacity of bacteria-based self-healing concrete. Constr. Build. Mater. 2015, 87, 1–7. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Hammes, F.; Boon, N.; de Villiers, J.; Verstraete, W.; Siciliano, S.D. Strain-specific ureolytic microbial calcium carbonate precipitation. Appl. Environ. Microbiol. 2003, 69, 4901–4909. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Xu, Y.; Chen, B.; Chai, L.; Ding, C.; Fei, C. Self-healing characteristics and micro-mechanism of high ductility cementitious composites micro-cracks under chloride salt wet-dry cycles. J. Chin. Chem. Soc. 2019, 47, 874–883. [Google Scholar]

- Chang, J.; Yang, D.; Lu, C.; Shu, Z.; Deng, S.; Tan, L.; Wen, S.; Huang, K.; Duan, P. Application of microbially induced calcium carbonate precipitation (MICP) process in concrete self-healing and environmental restoration to facilitate carbon neutrality: A critical review. Environ. Sci. Pollut. Res. 2024, 31, 38083–38098. [Google Scholar] [CrossRef] [PubMed]

- Alshalif, A.F.; Irwan, J.; Tajarudin, H.A.; Othman, N.; Al-Gheethi, A.; Shamsudin, S.; Altowayti, W.A.H.; Abo Sabah, S. Optimization of bio-foamed concrete brick strength via bacteria based self-healing and bio-sequestration of CO2. Materials 2021, 14, 4575. [Google Scholar] [CrossRef]

- Nayana, A.; Kavitha, S. Evaluation of CO2 emissions for green concrete with high volume slag, recycled aggregate, recycled water to build eco environment. Int. J. Civ. Eng. Technol. 2017, 8, 703–708. [Google Scholar]

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O. Comparative analysis on costs and benefits of producing natural and recycled concrete aggregates: A South African case study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Feng, C.; Cui, B.; Huang, Y.; Guo, H.; Zhang, W.; Zhu, J. Enhancement technologies of recycled aggregate–Enhancement mechanism, influencing factors, improvement effects, technical difficulties, life cycle assessment. Constr. Build. Mater. 2022, 317, 126168. [Google Scholar] [CrossRef]

| Bacteria | Type of Concrete | w/c | Bacterial Concentration | Percentage Increase in Compressive Strength (28 Days) Relative to Untreated RC | Reference |

|---|---|---|---|---|---|

| B. pseudofirmus | a | 0.5/0.35 | 1 × 108 cells/mL | 35.5%/20.9% | [7] |

| B. subtilis | a | 0.55 | - | 16.7% | [19] |

| B. cohnii | b | 0.40 | OD600 = 1 | 10.8% | [22] |

| B. megaterium | a | 0.4 | 3 × 106 cells/mL | 27.8% | [23] |

| B. pasteurii | a | 0.49 | - | 19.54% | [24] |

| Pseudomonas Sp. | b | 0.45 | 1 × 109 CFU/mL | 25.7% | [32] |

| B. pasteurii | a | 0.49 | 4.5 × 108 cells/mL | 15.04% | [54] |

| S. pasteurii | a | 0.5 | 1.85 × 108 cells/mL | 14.3% | [53] |

| B. mucilaginosus and B. subtilis | a | 0.5 | 2 × 108 cells/mL | 19.02% | [35] |

| S. pasterurii | b | 0.49 | - | 16.6% | [65] |

| b | 0.5 | 4.73 × 108 cells/mL | −14% | [75] | |

| a | 0.55 | 1 × 108 cells/mL | 6.2% | [55] | |

| a | 0.5 | - | 5.8% | [45] | |

| B. subtilis | b | 0.5 | 1 × 109 cells/mL | 30% | [78] |

| B. mucilaginosus and B. subtilis | a | 0.5 | B. mucilaginosus:1.2 × 108 cells/mL; B. subtilis: 2.4 × 108 cells/mL | 11.1% | [79] |

| B. sphaericus | b | 0.5 | 1 × 105 cells/mL | −44.2% | [80] |

| Method of Crack Creation | Bacterial Spore Sequestration | Healing Condition | Healing Effect | Reference |

|---|---|---|---|---|

| Splitting resistance | MMGN-treated RCA-fixed bacterial spores | - | For a crack with a width of approximately 0.4 mm which healed in 56 d, the repair rate of the crack width was 94.5% | [65] |

| Half of the RCA is fixed with bacterial spores, while the other half is fixed with substrate and calcium sources | Specimens were immersed in water for 16 h and exposed to air for 8 h | At a crack width of 0.6 mm, the average healing rate and crack area healing rate were 71% and 84%, respectively, with a crack healing depth of 17.8 mm and approximately 100% recovery of water tightness | [75] | |

| Pressure-resistant methods | RCA and 50% natural fine aggregate (NFA) | Underwater curing | Successfully healed a maximum width of 1.1 mm | [90] |

| Recycled coarse brick aggregate | Underwater curing | 0.6- mm crack healing | [82] | |

| RCA | Underwater curing | Cracks of 0.2–0.8 mm basically healed in 28 d, and the crack-healing rate was related to crack width and crack age | [91] | |

| Three-point flexural | RCA | Oxygenated by an oxygenating pump with the specimen completely submerged in water | At 28 d, a 0.25 mm crack was healed | [94] |

| RCA | Subject the samples to a 24 h water immersion followed by an 8 h room temperature drying period, repeating this cycle continuously | Following a 28 d healing period, cracks initially narrower than 300 μm exhibited near-complete closure | [80] |

| Bacteria Type | Bacterial Spore Sequestration | Bacterial Concentration | Mechanical Property Recovery Effect | Reference |

|---|---|---|---|---|

| S. pasteurii | RCA | 4.73 × 109 cells per cubic meter of concrete present | 99.7% recovery of compressive strength | [75] |

| Lysinibacillus boronitolerans | RCA | Biomimetic agent (3 × 106 cells/mL) | 89.7% restoration of compressive strength | [82] |

| B. pumilus | RCA | 2.23 × 109 cells/mL cubic meter of concrete | 79% restoration of compressive strength | [84] |

| B. subtilis | RCA and 50%NFA | 1.9 × 107 cells/cubic centimeter of concrete | 85% compressive strength recovery at 3 days, 82% recovery at 7 days, and 78% recovery at 28 days of age at cracking | [90] |

| B. pasteurii | RCA | The concentration of bacterial spores was 2.8 × 109 cells/ml | The bending stiffness healing rate was 12.25% at 28 days and 53.02% at 56 days of healing | [94] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Wang, L.; Xu, H.; Zhang, T.; Zhang, P.; Qi, M. Microbial Mineral Gel Network for Enhancing the Performance of Recycled Concrete: A Review. Gels 2025, 11, 581. https://doi.org/10.3390/gels11080581

Zheng Y, Wang L, Xu H, Zhang T, Zhang P, Qi M. Microbial Mineral Gel Network for Enhancing the Performance of Recycled Concrete: A Review. Gels. 2025; 11(8):581. https://doi.org/10.3390/gels11080581

Chicago/Turabian StyleZheng, Yuanxun, Liwei Wang, Hongyin Xu, Tianhang Zhang, Peng Zhang, and Menglong Qi. 2025. "Microbial Mineral Gel Network for Enhancing the Performance of Recycled Concrete: A Review" Gels 11, no. 8: 581. https://doi.org/10.3390/gels11080581

APA StyleZheng, Y., Wang, L., Xu, H., Zhang, T., Zhang, P., & Qi, M. (2025). Microbial Mineral Gel Network for Enhancing the Performance of Recycled Concrete: A Review. Gels, 11(8), 581. https://doi.org/10.3390/gels11080581