Sol–Gel-Derived Silica/Alumina Particles for Enhancing the Mechanical Properties of Acrylate Composite Materials

Abstract

1. Introduction

2. Results and Discussion

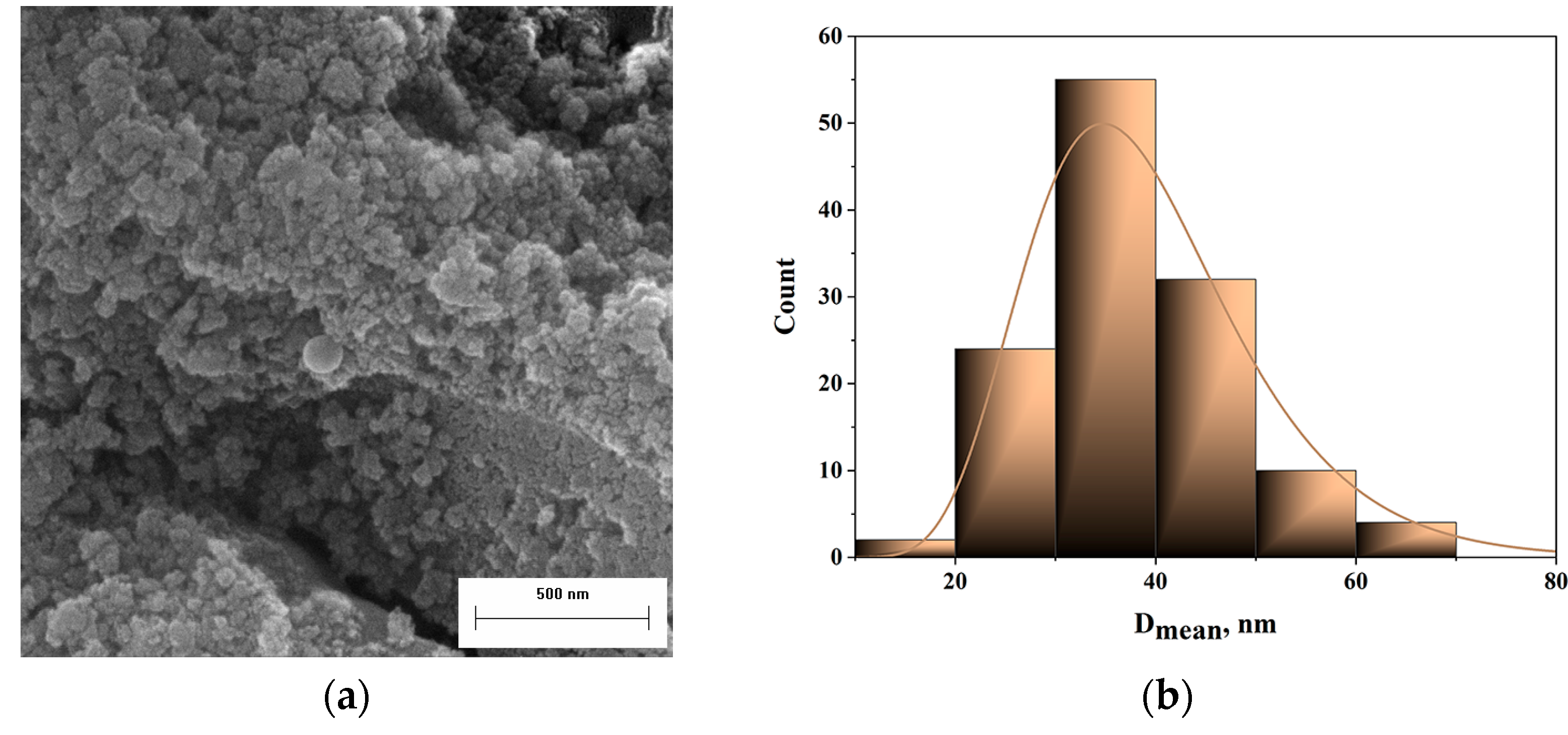

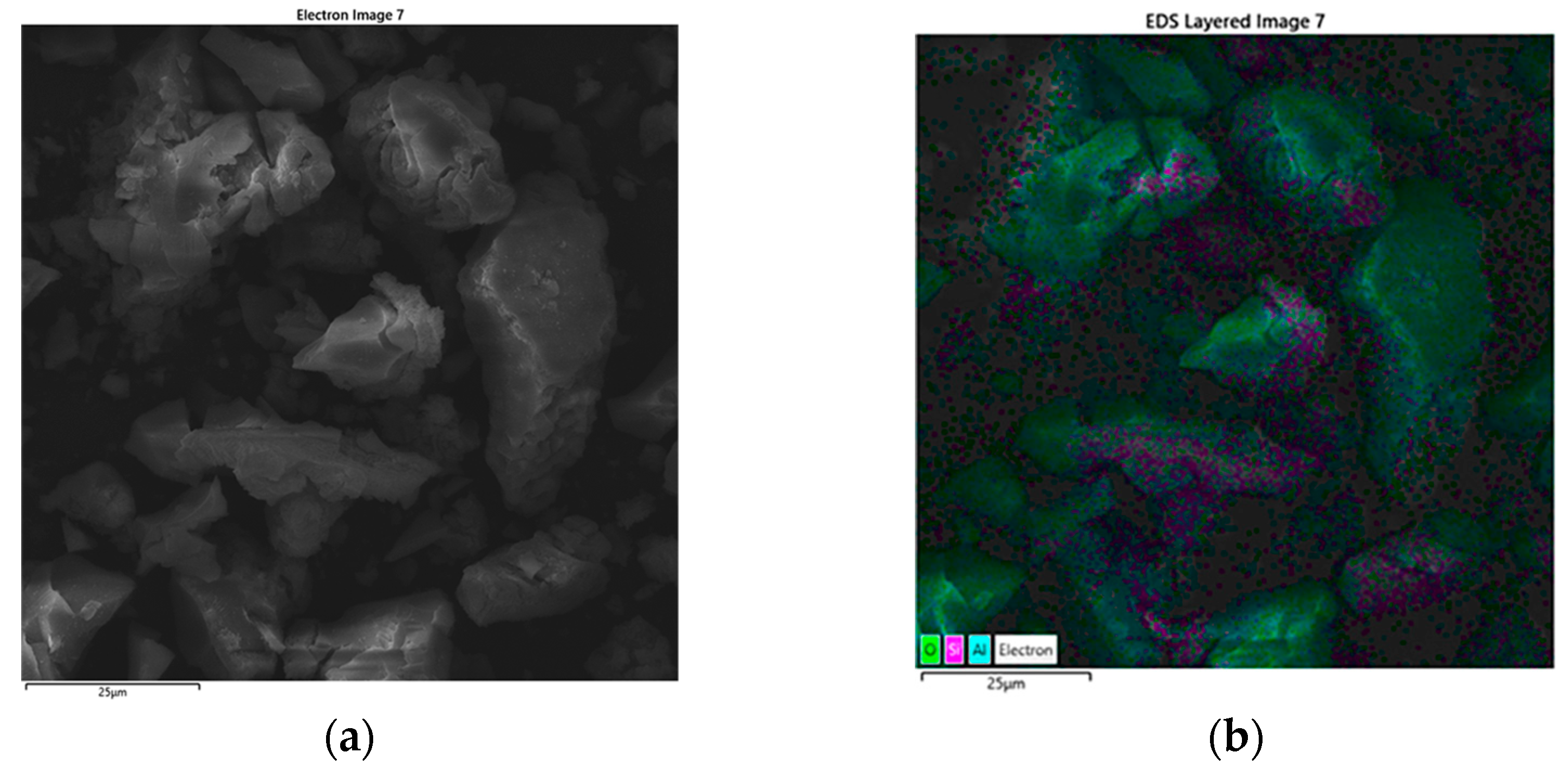

2.1. Morphological Characterization of Particles

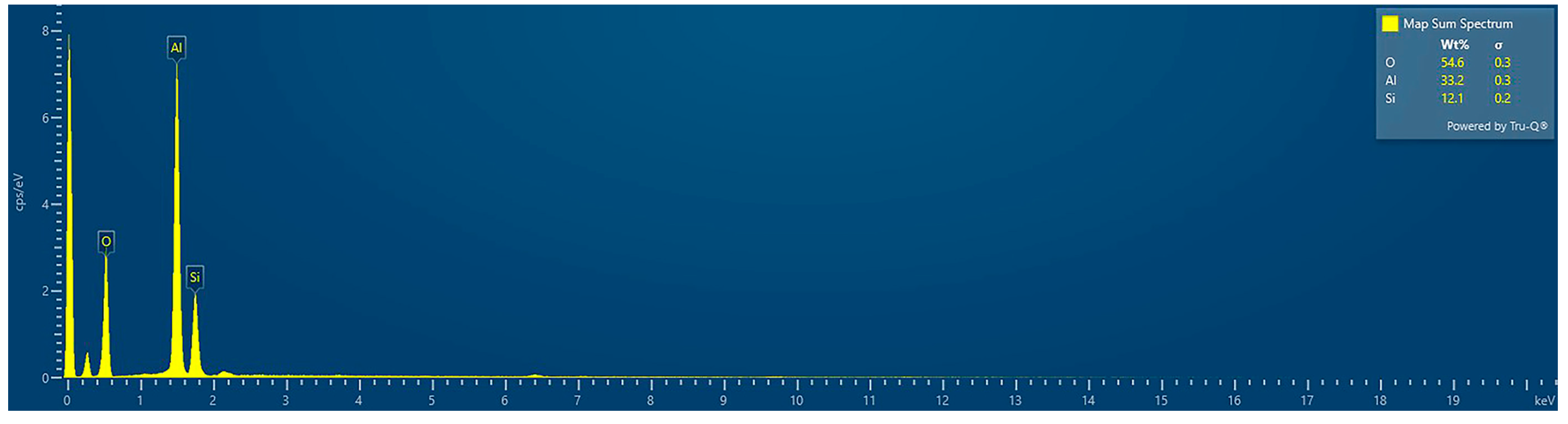

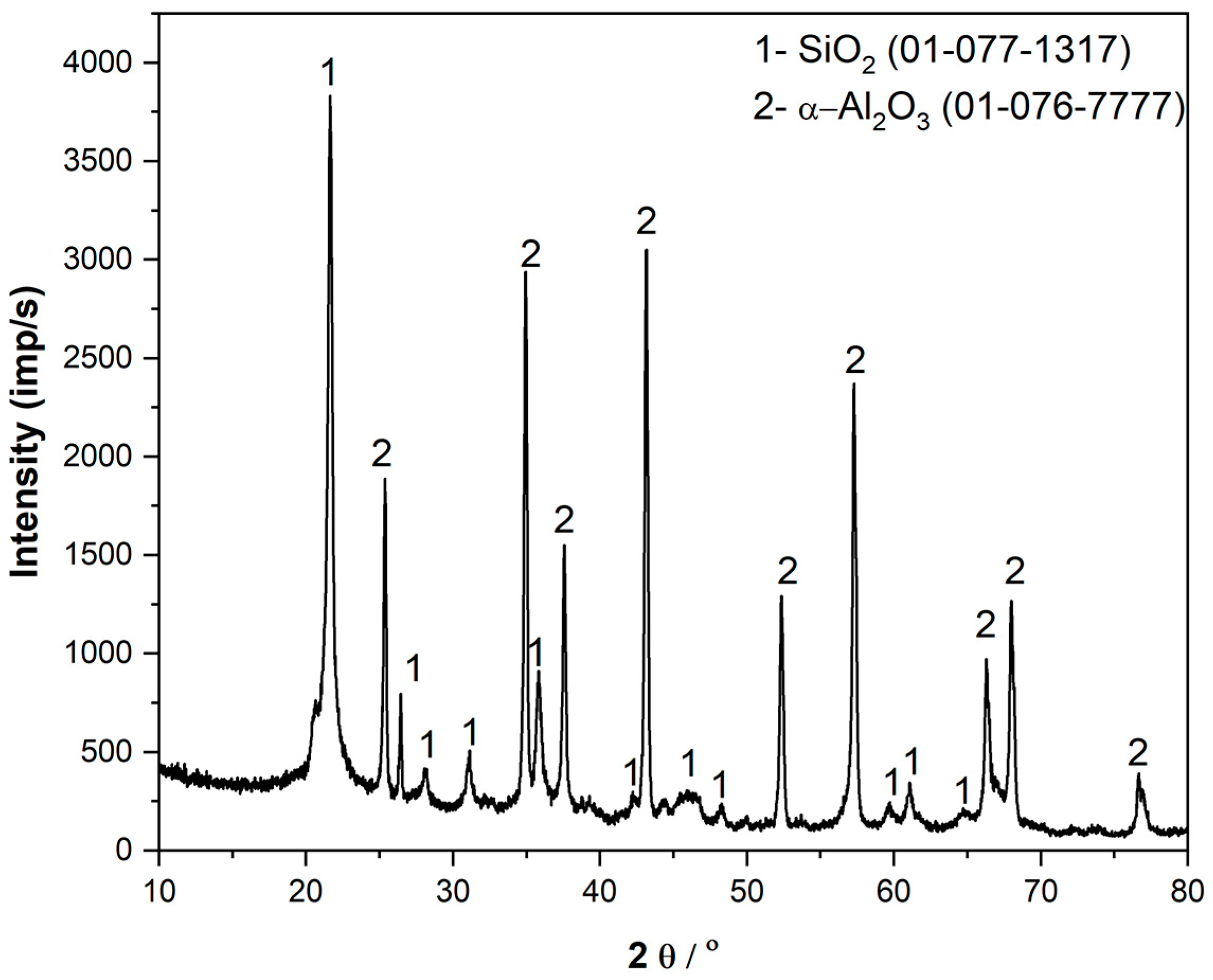

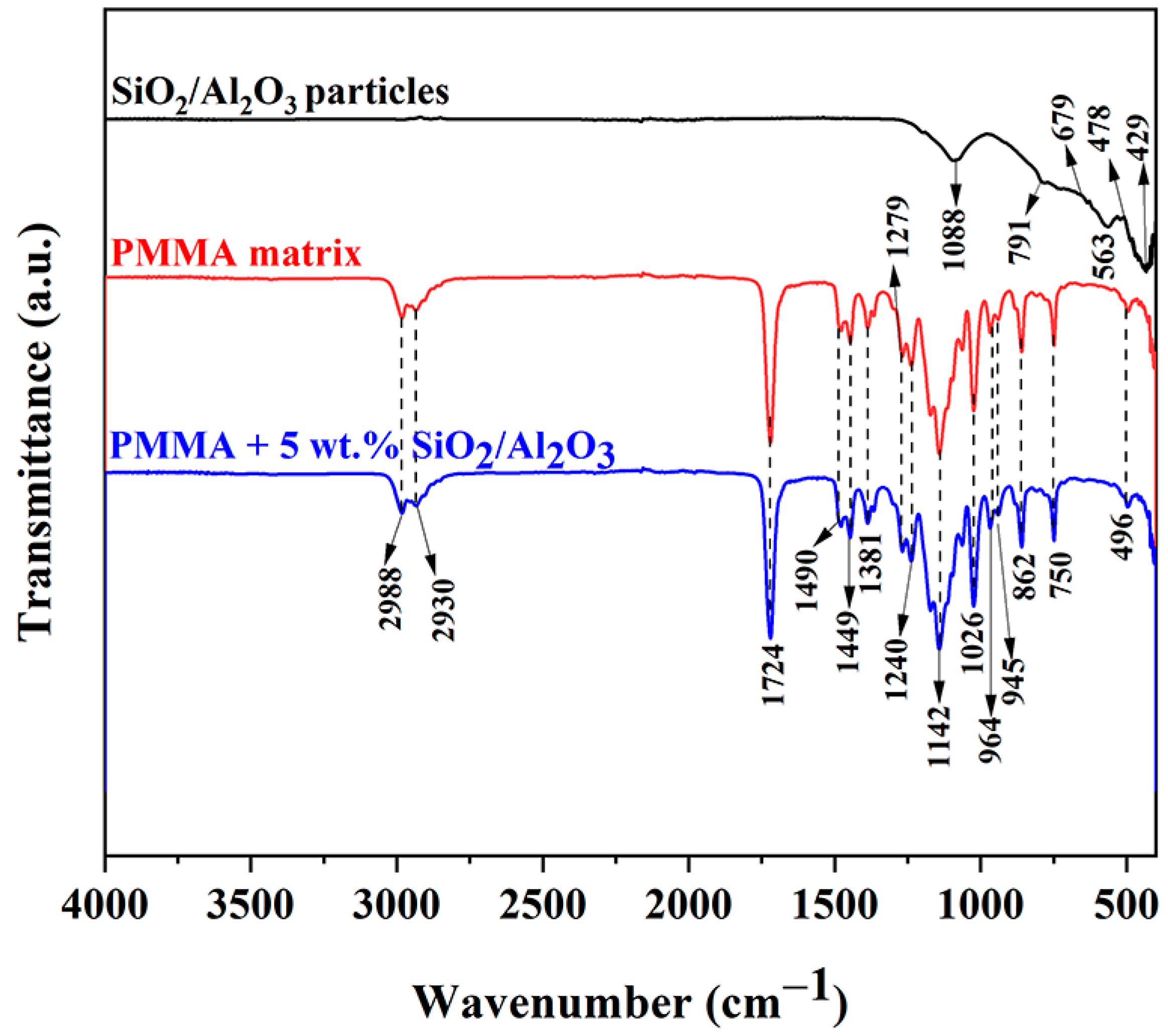

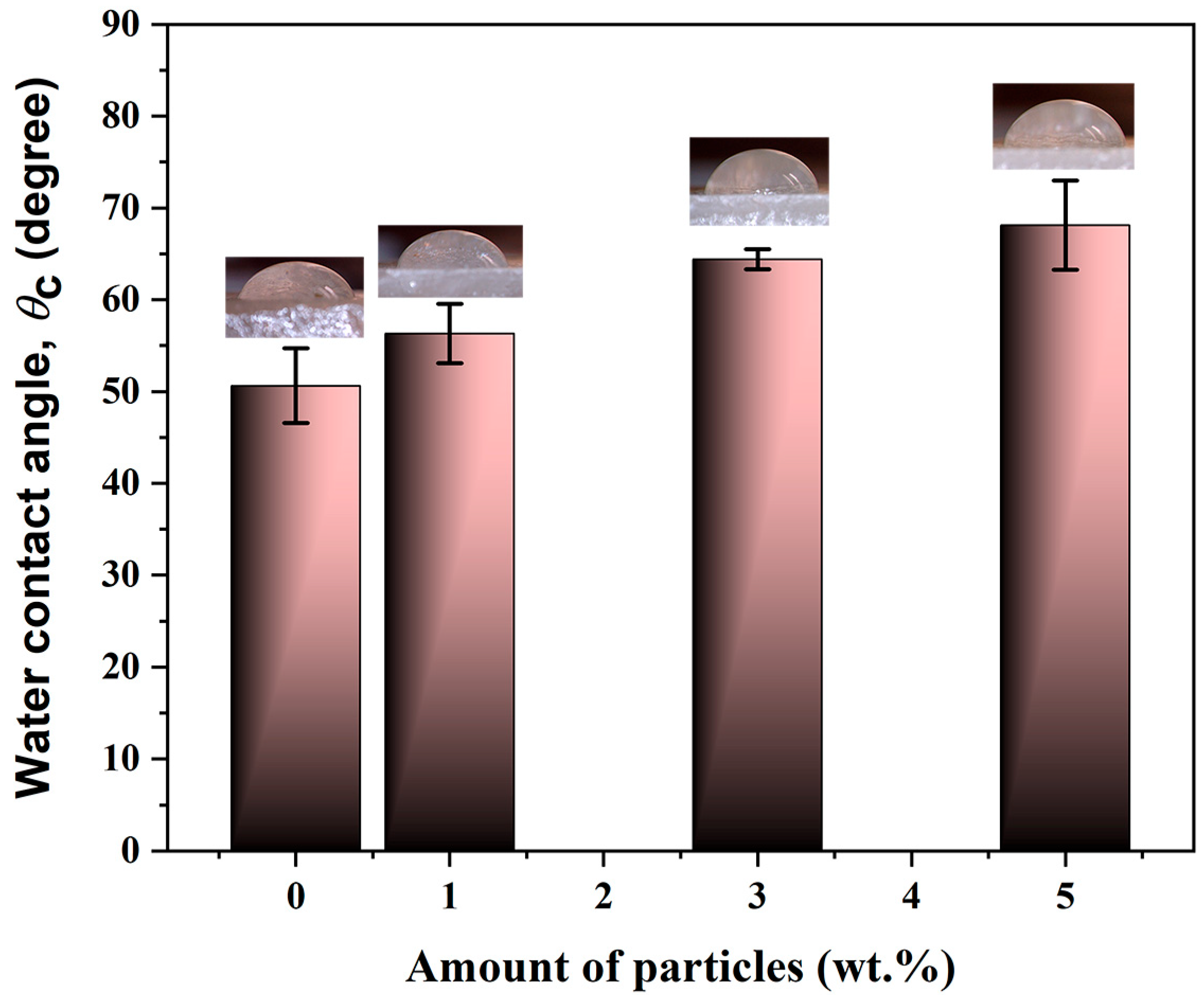

2.2. Structural Characterization of Synthesized Particles and Composites

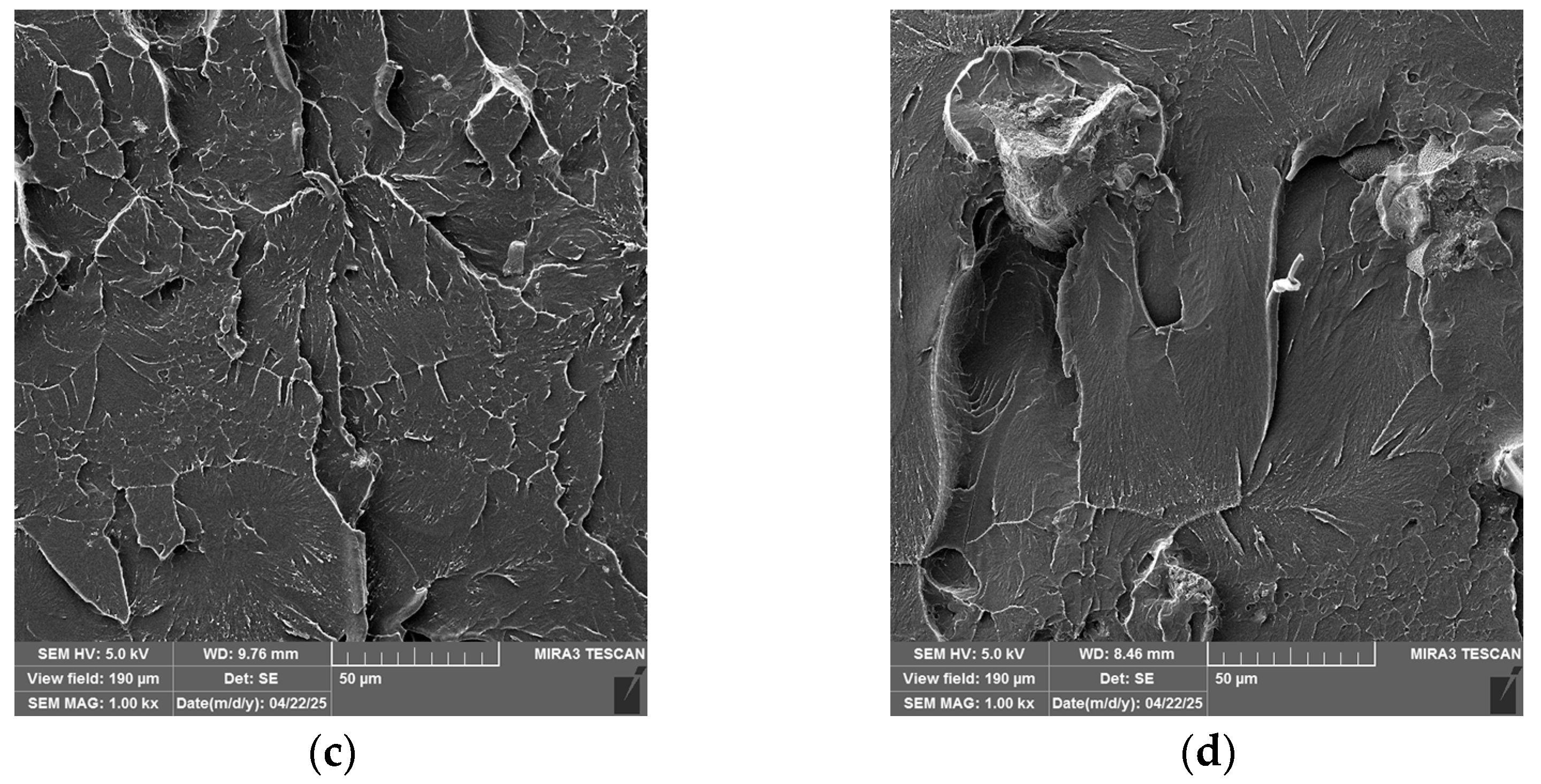

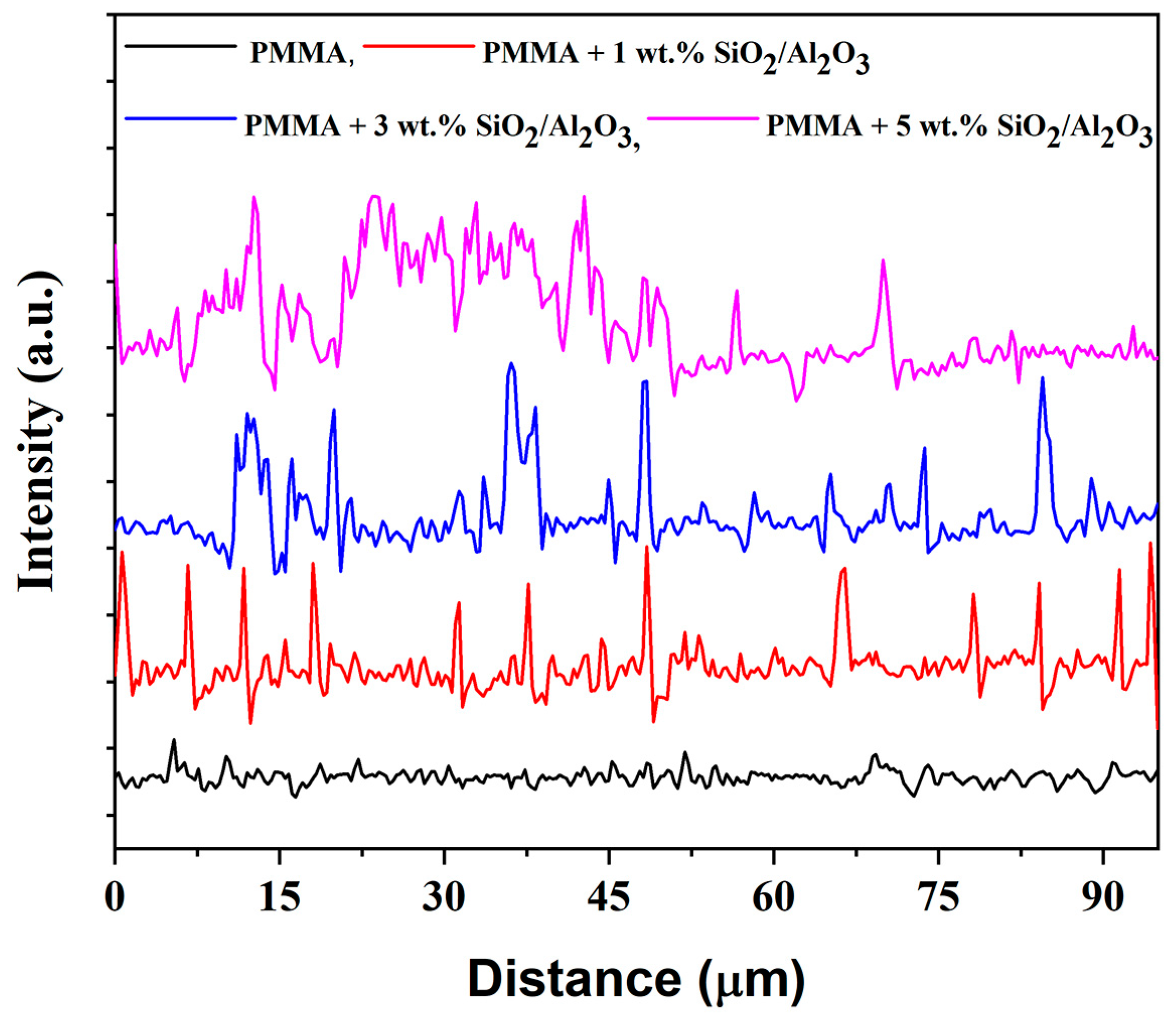

2.3. Mechanical Properties Results

3. Conclusions

4. Materials and Methods

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PMMA | Poly (methyl methacrylate) |

| FTIR | Fourier Transform Infrared Spectroscopy |

| SEM | Scanning electron microscope |

| EDS | Energy-Dispersive Spectroscopy |

References

- Pituru, S.M.; Greabu, M.; Totan, A.; Imre, M.; Pantea, M.; Spinu, T.; Tancu, A.M.C.; Popoviciu, N.O.; Stanescu, I.-I.; Ionescu, E. A Review on the Biocompatibility of PMMA-Based Dental Materials for Interim Prosthetic Restorations with a Glimpse into Their Modern Manufacturing Techniques. Materials 2020, 13, 2894. [Google Scholar] [CrossRef]

- Zafar, M.S. Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef] [PubMed]

- Chojnacka, K.; Mikulewicz, M. Cytotoxicity and Endocrine Disruption in Materials Used for Removable Orthodontic Retainers: A Comprehensive Review. Dent. J. 2025, 13, 269. [Google Scholar] [CrossRef] [PubMed]

- Díez-Pascual, A.M. PMMA-Based Nanocomposites for Odontology Applications: A State-of-the-Art. Int. J. Mol. Sci. 2022, 23, 10288. [Google Scholar] [CrossRef] [PubMed]

- Mazur, M.W.; Grudniak, A.; Szałaj, U.; Szerszeń, M.; Mizeracki, J.; Cierech, M.; Mierzwińska-Nastalska, E.; Kostrzewa-Janicka, J. Antifungal Activity of Newly Formed Polymethylmethacrylate (PMMA) Modification by Zinc Oxide and Zinc Oxide–Silver Hybrid Nanoparticles. Polymers 2024, 16, 3512. [Google Scholar] [CrossRef] [PubMed]

- Soleymani Eil Bakhtiari, S.; Bakhsheshi-Rad, H.R.; Karbasi, S.; Tavakoli, M.; Hassanzadeh Tabrizi, S.A.; Ismail, A.F.; Seifalian, A.; RamaKrishna, S.; Berto, F. Poly(Methyl Methacrylate) Bone Cement, Its Rise, Growth, Downfall and Future. Polym. Int. 2021, 70, 1182–1201. [Google Scholar] [CrossRef]

- Išljamović, M.; Bonvin, D.; Milojević, M.; Stojanović, S.; Spasić, M.; Stojković, B.; Janošević, P.; Otašević, S.; Ebersold, M.M. Antifungal Effect of Poly(Methyl Methacrylate) with Farnesol and Undecylenic Acid against Candida Albicans Biofilm Formation. Materials 2024, 17, 3936. [Google Scholar] [CrossRef] [PubMed]

- Ramanathan, S.; Lin, Y.-C.; Thirumurugan, S.; Hu, C.-C.; Duann, Y.-F.; Chung, R.-J. Poly(Methyl Methacrylate) in Orthopedics: Strategies, Challenges, and Prospects in Bone Tissue Engineering. Polymers 2024, 16, 367. [Google Scholar] [CrossRef] [PubMed]

- Alraziqi, Z.N.R.; Mansoor, H.S. Experimental Investigation for Some Properties of PMMA Denture Base Strengthened by Different Nanoadditives. Iraqi J. Sci. 2020, 2913–2925. [Google Scholar] [CrossRef]

- Galant, K.; Turosz, N.; Chęcińska, K.; Chęciński, M.; Cholewa-Kowalska, K.; Karwan, S.; Chlubek, D.; Sikora, M. Silver Nanoparticles (AgNPs) Incorporation into Polymethyl Methacrylate (PMMA) for Dental Appliance Fabrication: A Systematic Review and Meta-Analysis of Mechanical Properties. Int. J. Mol. Sci. 2024, 25, 12645. [Google Scholar] [CrossRef] [PubMed]

- Marshall, S.K.; Boonpeng, K.; Buapud, N.; Chimhashat, S.; Chuaymuang, J.; Kwandee, P.; Songphum, N. Bismuth Oxide Nanoparticle-Enhanced Poly(Methyl Methacrylate) Composites for I-131 Radiation Shielding: A Combined Simulation and Experimental Investigation. Polymers 2025, 17, 590. [Google Scholar] [CrossRef] [PubMed]

- Adaikalam, K.; Vikraman, D.; Lee, D.-H.; Cho, Y.-A.; Kim, H.-S. Optical and UV Shielding Properties of Inorganic Nanoparticles Embedded in Polymethyl Methacrylate Nanocomposite Freestanding Films. Polymers 2024, 16, 1048. [Google Scholar] [CrossRef] [PubMed]

- Alkayal, N.S.; Al Ghamdi, M.A. Cross-Linked Poly(Methyl Methacrylate) Nanocomposites’ Synthesis, Characterization, and Antibacterial Effects. Polymers 2025, 17, 269. [Google Scholar] [CrossRef] [PubMed]

- Rehner (Costache), A.M.G.; Tudorache, D.-I.; Bîrcă, A.C.; Nicoară, A.I.; Niculescu, A.-G.; Holban, A.M.; Hudiță, A.; Bîclesanu, F.C.; Balaure, P.C.; Pangică, A.M.; et al. Antibacterial Properties of PMMA/ZnO(NanoAg) Coatings for Dental Implant Abutments. Materials 2025, 18, 382. [Google Scholar] [CrossRef] [PubMed]

- Putra, D.F.A.; Qazi, U.; Chen, P.-H.; Shih, S.-J. Preparation and Characterization of SiO2-PMMA and TiO2-SiO2-PMMA Composite Thick Films for Radiative Cooling Application. J. Compos. Sci. 2024, 8, 453. [Google Scholar] [CrossRef]

- Al-Thobity, A.M.; Gad, M.M. Effect of Silicon Dioxide Nanoparticles on the Flexural Strength of Heat-Polymerized Acrylic Denture Base Material: A Systematic Review and Meta-Analysis. Saudi Dent. J. 2021, 33, 775–783. [Google Scholar] [CrossRef] [PubMed]

- Kucukesmen, H.C.; Sarac, M.F. Preparation and Characterization of Fumed Silica Added PMMA Denture Base Materials. Int. J. Polym. Anal. Charact. 2024, 29, 675–684. [Google Scholar] [CrossRef]

- Alazreg, A.; Vuksanović, M.M.; Egelja, A.; Mladenović, I.O.; Radovanović, Ž.; Petrović, M.; Marinković, A.; Heinemann, R.J. Mechanical Properties of Acrylate Matrix Composite Reinforced with Manganese-aluminum Layered Double Hydroxide. Polym. Compos. 2023, 44, 6783–6792. [Google Scholar] [CrossRef]

- Stojanović, D.B.; Zrilić, M.; Jančić-Heinemann, R.; Živković, I.; Kojović, A.; Uskoković, P.S.; Aleksić, R. Mechanical and Anti-stabbing Properties of Modified Thermoplastic Polymers Impregnated Multiaxial p-aramid Fabrics. Polym. Adv. Technol. 2013, 24, 772–776. [Google Scholar] [CrossRef]

- Obradović, V.; Stojanović, D.B.; Jančić-Heinemann, R.; Živković, I.; Radojević, V.; Uskoković, P.S.; Aleksić, R. Ballistic Properties of Hybrid Thermoplastic Composites with Silica Nanoparticles. J. Eng. Fiber. Fabr. 2014, 9, 97–107. [Google Scholar] [CrossRef]

- Vuksanović, M.M.; Egelja, A.; Barudžija, T.; Tomić, N.; Petrović, M.; Marinković, A.; Radojević, V.; Heinemann, R.J. Inorganically Modified Particles FeAl-LDH@SiO 2 as Reinforcement in Poly (Methyl) Methacrylate Matrix Composite. R. Soc. Open Sci. 2021, 8. [Google Scholar] [CrossRef] [PubMed]

- Dzulhijjah, W.A.; Aprilia, S.; Arahman, N.; Barambu, N.U. Synthesis and Characterization of Nanosilica from Rice Husk Waste Sigupai Varieties Endemic to Aceh. Case Stud. Chem. Environ. Eng. 2025, 11, 101145. [Google Scholar] [CrossRef]

- Sharma, R. Prospects of Rice Husk-Derived Nanosilica. Nano Life 2025, 15, 2430009. [Google Scholar] [CrossRef]

- Zewide, Y.T.; Yemata, T.A.; Ayalew, A.A.; Kedir, H.J.; Tadesse, A.A.; Fekad, A.Y.; Shibesh, A.K.; Getie, F.A.; Tessema, T.D.; Wubieneh, T.A.; et al. Application of Response Surface Methodology (RSM) for Experimental Optimization in Biogenic Silica Extraction from Rice Husk and Straw Ash. Sci. Rep. 2025, 15, 132. [Google Scholar] [CrossRef] [PubMed]

- Ashor, A.A.; Vuksanović, M.M.; Tomić, N.Z.; Petrović, M.; Dojčinović, M.; Husović, T.V.; Radojević, V.; Heinemann, R.J. Optimization of Modifier Deposition on the Alumina Surface to Enhance Mechanical Properties and Cavitation Resistance. Polym. Bull. 2019, 77, 3603–3620. [Google Scholar] [CrossRef]

- Alzarrug, F.A.; Dimitrijević, M.M.; Jančić Heinemann, R.M.; Radojević, V.; Stojanović, D.B.; Uskoković, P.S.; Aleksić, R. The Use of Different Alumina Fillers for Improvement of the Mechanical Properties of Hybrid PMMA Composites. Mater. Des. 2015, 86, 575–581. [Google Scholar] [CrossRef]

- Lazouzi, G.A.; Vuksanović, M.M.; Tomić, N.; Petrović, M.; Spasojević, P.; Radojević, V.; Jančić Heinemann, R. Dimethyl Itaconate Modified PMMA—Alumina Fillers Composites With Improved Mechanical Properties. Polym. Compos. 2019, 40, 1691–1701. [Google Scholar] [CrossRef]

- Hasratiningsih, Z.; Cahyanto, A.; Takarini, V.; Karlina, E.; Djustiana, N.; Febrida, R.; Usri, K.; Faza, Y.; Hardiansyah, A.; Purwasasmita, B.S. Basic Properties of PMMA Reinforced Using Ceramics Particles of ZrO2-Al2O3-SiO2 Coated with Two Types of Coupling Agents. Key Eng. Mater. 2016, 696, 93–98. [Google Scholar] [CrossRef]

- Oshida, Y.; Zuccari, A.G. On the Three-Point Flexural Tests of Dental Polymeric Resins. Biomed. Mater. Eng. 1997, 7, 111–119. [Google Scholar] [CrossRef] [PubMed]

- Battegazzore, D.; Bocchini, S.; Alongi, J.; Frache, A. Rice Husk as Bio-Source of Silica: Preparation and Characterization of PLA–Silica Bio-Composites. RSC Adv. 2014, 4, 54703–54712. [Google Scholar] [CrossRef]

- Ubi, P.A.; Anosike-Francis, E.N.; Agbonko, E.B.; Omoyi, C.O.; Nwigwe, E.E.; Agba, A.I.; Itam, D.H.; Rowland Ana, R. Rice Husk-Derived Silica: A Sustainable Alternative to Traditional Fillers in Elastomeric Composites. In Proceedings of the 2023 2nd International Conference on Multidisciplinary Engineering and Applied Science (ICMEAS), Abuja, Nigeria, 1–3 November 2023; IEEE: New York, NY, USA, 2023; pp. 1–7. [Google Scholar]

- Li, J.; Wu, W.; Yang, H.; Wang, X.; Wang, X.; Sun, C.; Hu, Z. Rigid Silica Xerogel/Alumina Fiber Composites and Their Thermal Insulation Properties. J. Porous Mater. 2019, 26, 1177–1184. [Google Scholar] [CrossRef]

- Hasan, S.A.B.; Dimitrijević, M.M.; Kojović, A.; Stojanović, D.B.; Obradović-Đuričić, K.; Jančić Heinemann, R.M.; Aleksić, R. The Effect of the Size and Shape of Alumina Nanofillers on the Mechanical Behavior of PMMA Matrix Composites. J. Serbian Chem. Soc. 2014, 79, 1295–1307. [Google Scholar] [CrossRef]

- Verma, V.; Sayyed, A.H.M.; Sharma, C.; Shukla, D.K. Tensile and Fracture Properties of Epoxy Alumina Composite: Role of Particle Size and Morphology. J. Polym. Res. 2020, 27, 388. [Google Scholar] [CrossRef]

- Munasir; Imam Supardi, Z.A.; Mashadi; Nisa, Z.; Kusumawati, D.H.; Putri, N.P.; Taufiq, A.; Sunaryono; Hidayat, N. Darminto Phase Transition of SiO2 Nanoparticles Prepared from Natural Sand: The Calcination Temperature Effect. J. Phys. Conf. Ser. 2018, 1093, 012025. [Google Scholar] [CrossRef]

- Pujiana, N.; Yulianti, E.; Rahmatulloh, A.; Khalifah, S.N.; Istighfarini, V.N. A low-cost adsorbent coconut waste ash activated nacl for methylene blue removal. J. Neutrino 2020, 12, 43–48. [Google Scholar] [CrossRef]

- Xue, S.-H.; Xie, H.; Ping, H.; Li, Q.-C.; Su, B.-L.; Fu, Z.-Y. Induced Transformation of Amorphous Silica to Cristobalite on Bacterial Surfaces. RSC Adv. 2015, 5, 71844–71848. [Google Scholar] [CrossRef]

- Zhang, S.; Tie, S.; Zhang, F. Cristobalite Formation from the Thermal Treatment of Amorphous Silica Fume Recovered from the Metallurgical Silicon Industry. Micro Nano Lett. 2018, 13, 1465–1468. [Google Scholar] [CrossRef]

- Kimizuka, H.; Kaburaki, H.; Kogure, Y. Mechanism for Negative Poisson Ratios over the α-β Transition of Cristobalite, SiO2. Phys. Rev. Lett. 2000, 84, 5548–5551. [Google Scholar] [CrossRef] [PubMed]

- Kimizuka, H.; Kaburaki, H.; Shimizu, F.; Kogure, Y. Molecular Dynamics Analysis of Negative Poisson Ratios over the α-β Transition in Cristobalite, SiO2. Prog. Theor. Phys. Suppl. 2000, 138, 229–233. [Google Scholar] [CrossRef]

- Güden, M.; Ülker, S.; Movahedi, N. Epoxy Matrix Nano Composites: Modulus, Strength and Ductility Enhancement through Auxeticity of α-Cristobalite Filler. Mater. Lett. 2023, 349, 134759. [Google Scholar] [CrossRef]

- Kwon, S.H.; Park, I.H.; Vu, C.M.; Choi, H.J. Fabrication and Electro-Responsive Electrorheological Characteristics of Rice Husk-Based Nanosilica Suspension. J. Taiwan Inst. Chem. Eng. 2019, 95, 432–437. [Google Scholar] [CrossRef]

- Romero Toledo, R.; Ruiz Santoyo, V.; Moncada Sánchez, C.D.; Martínes Rosales, M. Effect of Aluminum Precursor on Physicochemical Properties of Al2O3 by Hydrolysis/Precipitation Method. Nov. Sci. 2018, 10, 83–99. [Google Scholar] [CrossRef]

- Shrivastava, V.; Singh, A.; Singh, I.B. Effect of Sol–Gel Prepared Nanoalumina Reinforcement Content on the Corrosion Resistances of Al 6061-Al2O3 Nanocomposite in 3.5% NaCl Solution. Mater. Corros. 2017, 68, 1099–1106. [Google Scholar] [CrossRef]

- Veeresh Kumar, G.B.; Rao, C.S.P.; Selvaraj, N. Studies on Mechanical and Dry Sliding Wear of Al6061–SiC Composites. Compos. Part B Eng. 2012, 43, 1185–1191. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, S.; Agnihotry, S.A. Synthesis and Characterization of in Situ Prepared Poly (Methyl Methacrylate) Nanocomposites. Bull. Mater. Sci. 2007, 30, 31–35. [Google Scholar] [CrossRef]

- ASTM D790-07; Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM Inernational: West Conshohocken, PA, USA, 2003.

- ISO 4049:2019; Dentistry—Polymer-Based Restorative Materials. International Organization for Standardization: Geneva, Switzerland, 2019.

- Mustafa, A.; Aloyaydi, B.; Sivasankaran, S.; Al-Mufadi, F.A. Shore Hardness Characterization of FDM Printed PLA/Epoxy/MGFs Composite Material Structure. In Recent Advances in Manufacturing Processes and Systems; Springer: Singapore, 2022; pp. 919–926. [Google Scholar]

- Available online: https://Mediacy.Com/Image-pro/ (accessed on 15 June 2025).

- Mesgarnejad, A.; Pan, C.; Erb, R.M.; Shefelbine, S.J.; Karma, A. Crack Path Selection in Orientationally Ordered Composites. Phys. Rev. E 2020, 102, 013004. [Google Scholar] [CrossRef] [PubMed]

- Vuksanović, M.M.; Tomić, N.Z.; Gajić-Kvaščev, M.; Djokić, V.R.; Dojčinović, M.; Husović, T.V.; Heinemann, R.J. The Influence of Alumina Crystal Structures on the Morphology and Surface Erosion of PMMA Composite Materials Exposed to Cavitation Testing. Wear 2019, 436–437, 203033. [Google Scholar] [CrossRef]

- Bharatish, A.; Kumar, A.; Siddhanth, K.S.; Manikant, V.; Jagdish, P.; Sharma, A.; Solaiachari, S. On Optimizing Wettability, Surface Roughness and Swelling Behaviour of Laser-Polished 3D-Printed PETG Polymer for Bio-Medical Implants. Polymer 2025, 330, 128482. [Google Scholar] [CrossRef]

- Mahmoudian, M.; Poursattar Marjani, A.; Hasanzadeh, R.; Nozad, E.; Mamaghani Shishavan, S.; Mohamadi, H. Effect of In-Situ Modification of α -Alumina Nanoparticles on Mechanical Properties of Poly(Methyl Methacrylate)-Based Nanocomposites for Biomedical Applications. Mater. Res. Express 2019, 6, 105410. [Google Scholar] [CrossRef]

- Yang, B.-H.; Chang, S.-Y.; Zhang, Y.; Yang, F.; Lee, S. Kinetic Analysis of the Cracking Behavior in Methanol-Treated Poly(Methyl Methacrylate)/Functionalized Graphene Composites. J. Compos. Sci. 2025, 9, 84. [Google Scholar] [CrossRef]

- Saladino, M.L.; Motaung, T.E.; Luyt, A.S.; Spinella, A.; Nasillo, G.; Caponetti, E. The Effect of Silica Nanoparticles on the Morphology, Mechanical Properties and Thermal Degradation Kinetics of PMMA. Polym. Degrad. Stab. 2012, 97, 452–459. [Google Scholar] [CrossRef]

- Topouzi, M.; Kontonasaki, E.; Bikiaris, D.; Papadopoulou, L.; Paraskevopoulos, K.M.; Koidis, P. Reinforcement of a PMMA Resin for Interim Fixed Prostheses with Silica Nanoparticles. J. Mech. Behav. Biomed. Mater. 2017, 69, 213–222. [Google Scholar] [CrossRef] [PubMed]

- Vuksanovic, M.; Mladenovic, I.; Tomic, N.; Petrovic, M.; Radojevic, V.; Marinkovic, A.; Jancic-Heinemann, R. Mechanical Properties of Biomass-Derived Silica Nanoparticles Reinforced PMMA Composite Material. Sci. Sinter. 2022, 54, 211–221. [Google Scholar] [CrossRef]

- Alhareb, A.O.; Ahmad, Z.A. Effect of Al2O3/ZrO2 Reinforcement on the Mechanical Properties of PMMA Denture Base. J. Reinf. Plast. Compos. 2011, 30, 86–93. [Google Scholar] [CrossRef]

| Specimen | Flexural Modulus, Ef (GPa) | Flexural Strength, σf (MPa) | Flexural Strain at Break, εfM (%) |

|---|---|---|---|

| PMMA matrix only | 1.62 ± 0.081 | 59.07 ± 2.95 | 6.75 |

| PMMA + 1 wt.% SiO2/Al2O3 | 1.64 ± 0.085 | 56.91 ± 2.67 | 4.74 |

| PMMA + 3 wt.% SiO2/Al2O3 | 1.76 ± 0.089 | 64.42 ± 3.16 | 5.29 |

| PMMA + 5 wt.% SiO2/Al2O3 | 1.92 ± 0.092 | 57.26 ± 2.86 | 4.00 |

| Composite | Ra (Units) | Rq (Units) | Rz (Units) | Skewness | Flexural Strength (MPa) | Maximum Energy in Impact Test J |

|---|---|---|---|---|---|---|

| PMMA matrix only | ~1100 | ~1350 | ~5200 | Negative | 59.07 | 0.6 |

| PMMA + 1 wt.% SiO2/Al2O3 | ~1280 | ~1580 | ~6550 | Negative | 56.91 | 0.8 |

| PMMA + 3 wt.% SiO2/Al2O3 | ~1700 | ~2100 | ~8800 | Negative | 64.42 | 1.4 |

| PMMA + 5 wt.% SiO2/Al2O3 | ~1920 | ~2350 | ~9600 | Positive | 57.26 | 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altwair, K.; Tadić, V.; Petrović, M.; Savić, A.; Radojević, V.; Heinemann, R.J.; Vuksanović, M.M. Sol–Gel-Derived Silica/Alumina Particles for Enhancing the Mechanical Properties of Acrylate Composite Materials. Gels 2025, 11, 575. https://doi.org/10.3390/gels11080575

Altwair K, Tadić V, Petrović M, Savić A, Radojević V, Heinemann RJ, Vuksanović MM. Sol–Gel-Derived Silica/Alumina Particles for Enhancing the Mechanical Properties of Acrylate Composite Materials. Gels. 2025; 11(8):575. https://doi.org/10.3390/gels11080575

Chicago/Turabian StyleAltwair, Khaled, Vladisav Tadić, Miloš Petrović, Andrija Savić, Vesna Radojević, Radmila Jančić Heinemann, and Marija M. Vuksanović. 2025. "Sol–Gel-Derived Silica/Alumina Particles for Enhancing the Mechanical Properties of Acrylate Composite Materials" Gels 11, no. 8: 575. https://doi.org/10.3390/gels11080575

APA StyleAltwair, K., Tadić, V., Petrović, M., Savić, A., Radojević, V., Heinemann, R. J., & Vuksanović, M. M. (2025). Sol–Gel-Derived Silica/Alumina Particles for Enhancing the Mechanical Properties of Acrylate Composite Materials. Gels, 11(8), 575. https://doi.org/10.3390/gels11080575