CNTs/CNPs/PVA–Borax Conductive Self-Healing Hydrogel for Wearable Sensors

Abstract

1. Introduction

2. Results and Discussion

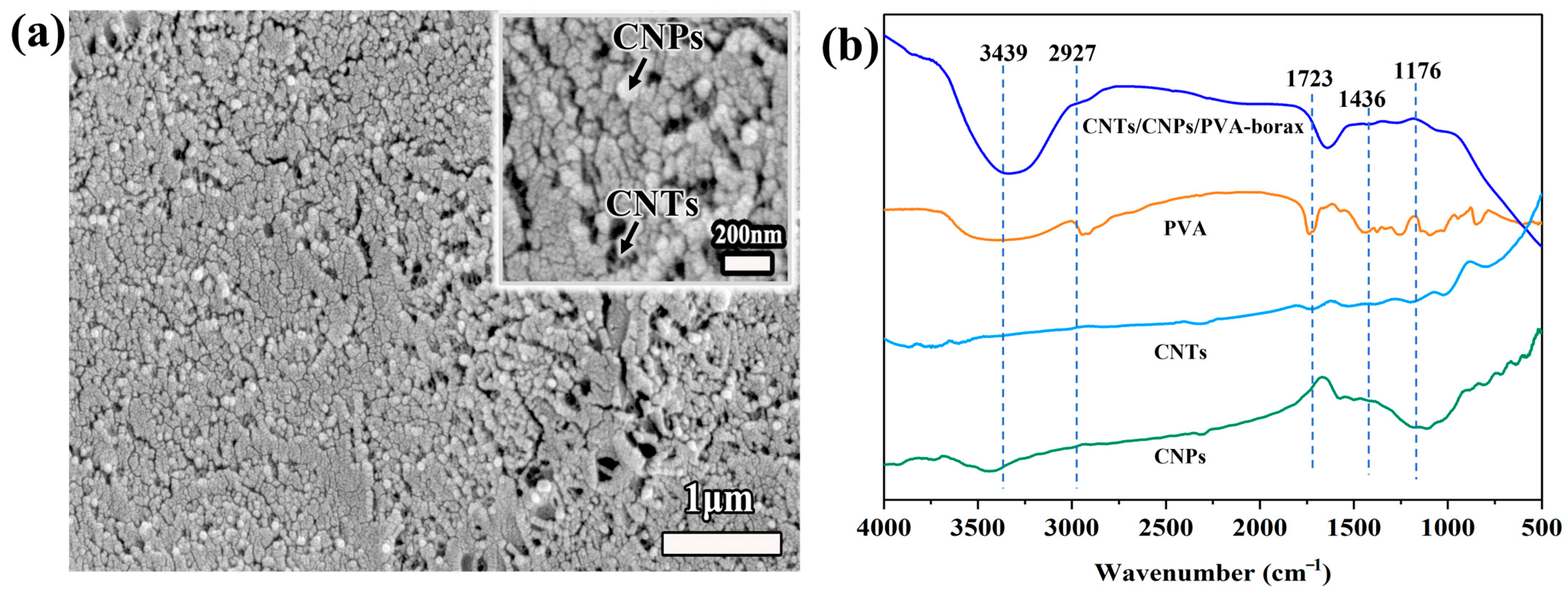

2.1. Material Characterization

2.1.1. FT-IR Analysis of CNT/CNP/PVA–Borax Mixture

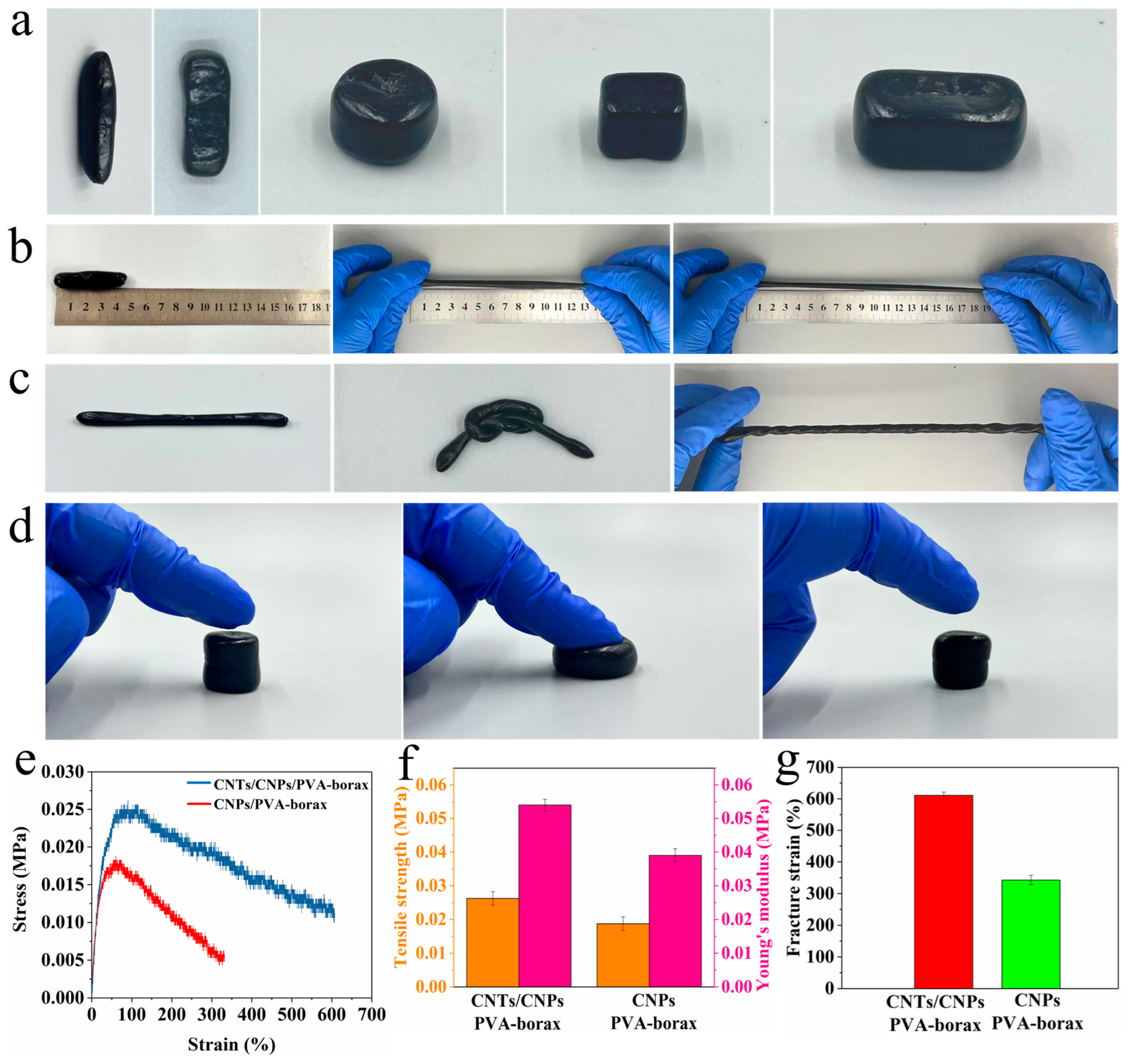

2.1.2. Mechanical Properties of CNT/CNP/PVA–Borax Hydrogel

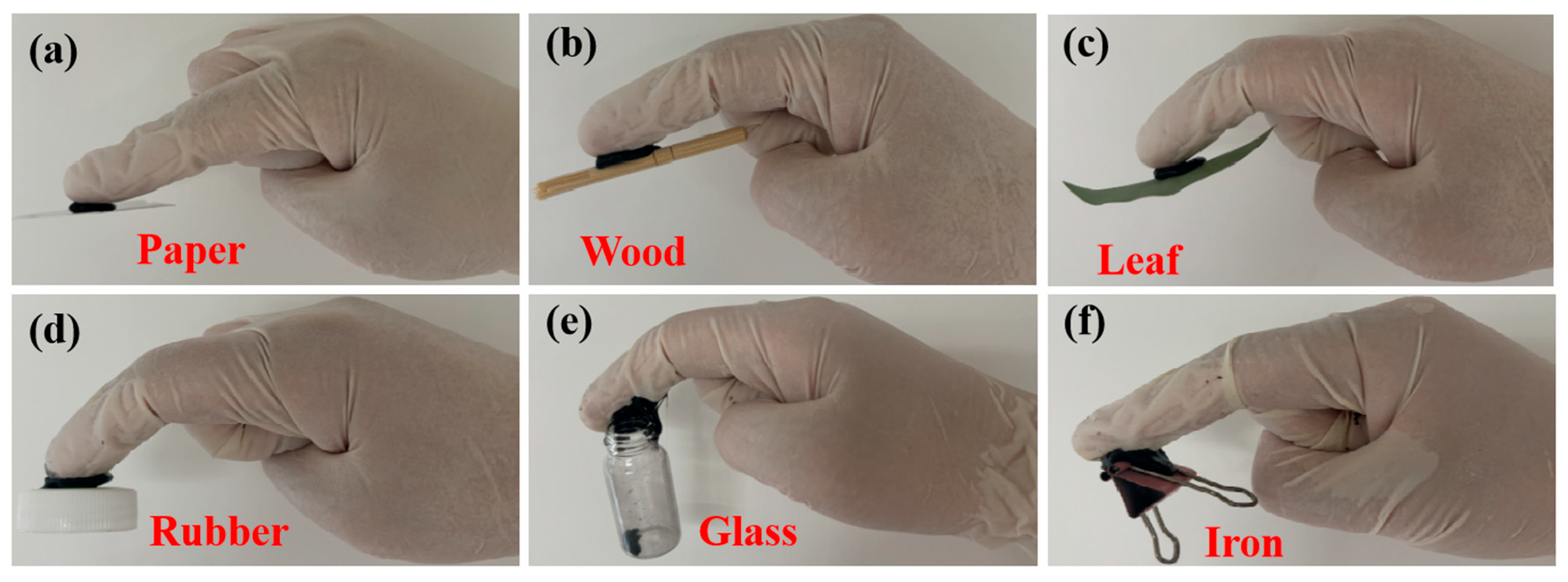

2.1.3. Adhesion of CNT/CNP/PVA–Borax Hydrogel

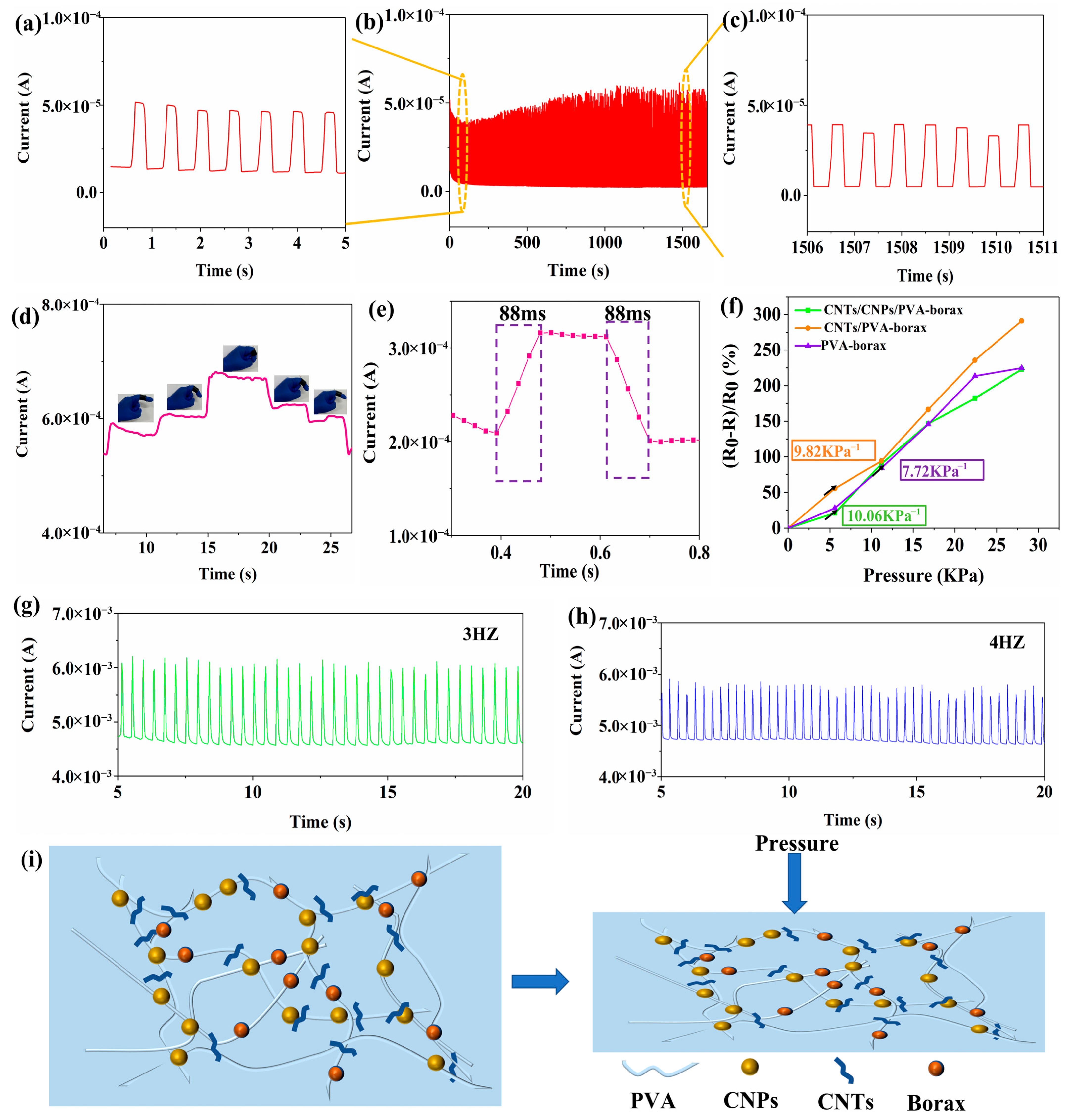

2.2. Sensor Performance of CNT/CNP/PVA–Borax Hydrogel

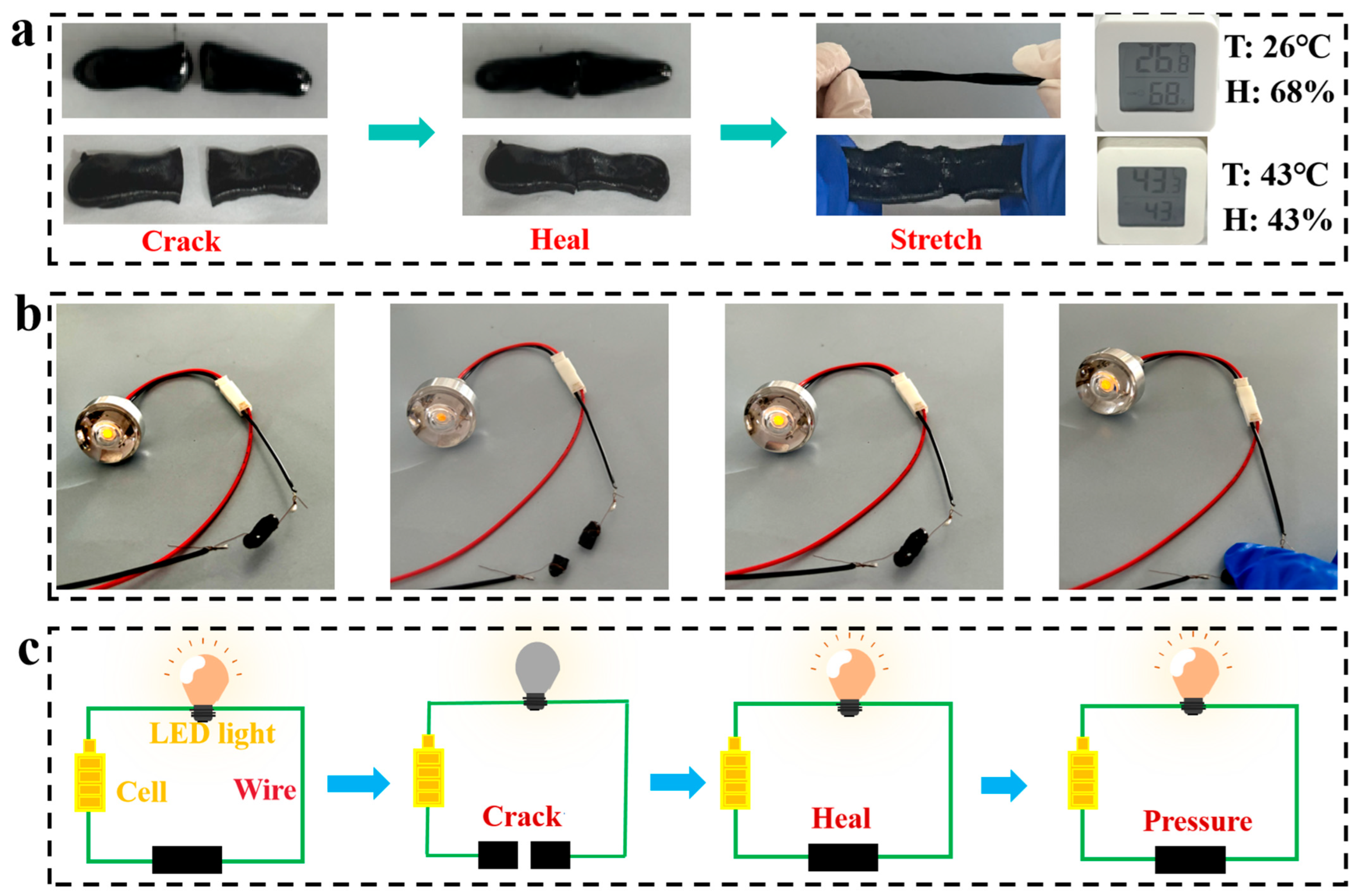

2.3. Self-Healing Properties of CNT/CNP/PVA–Borax Hydrogel

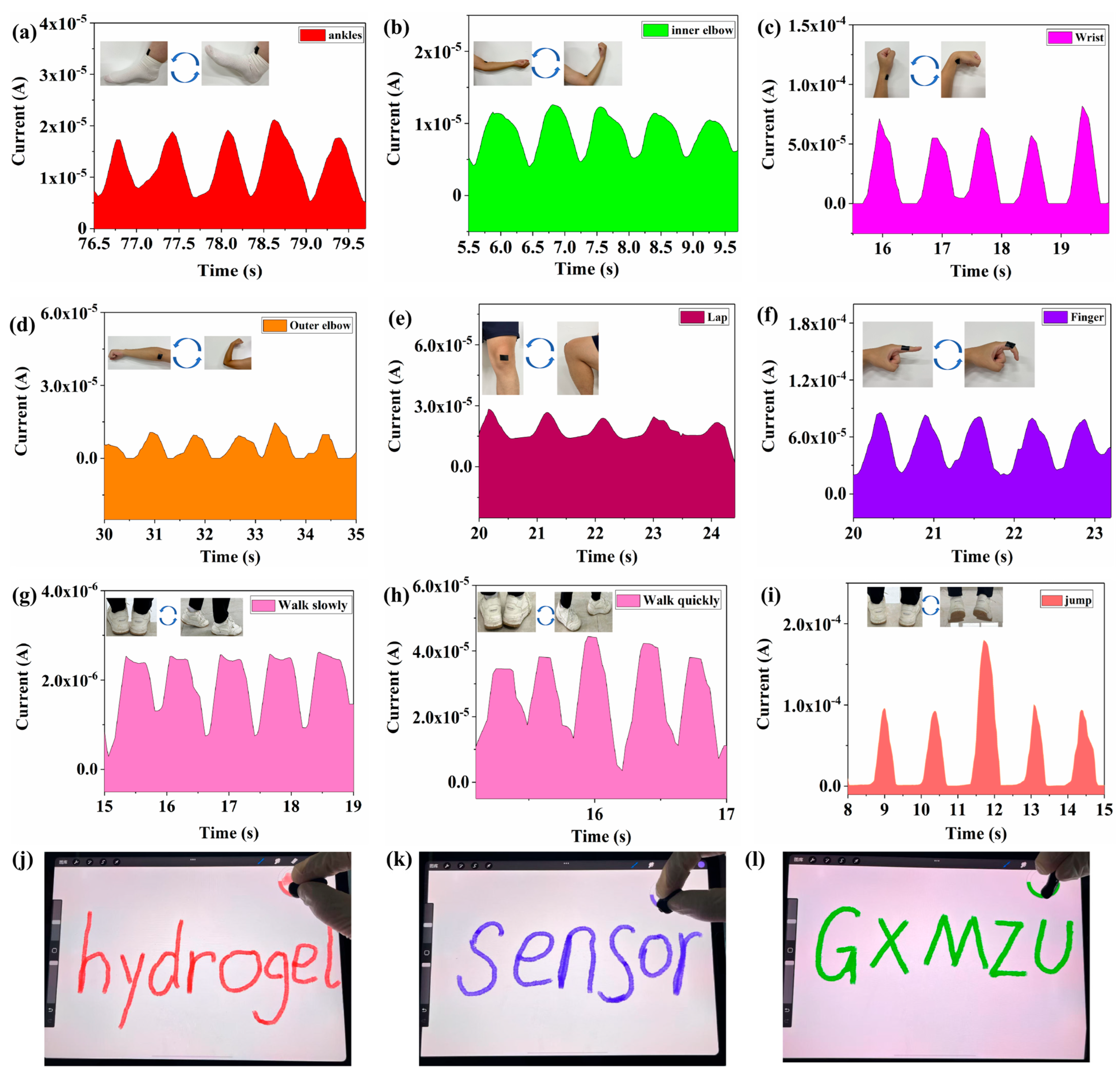

2.4. Applications of CNT/CNP/PVA–Borax Hydrogel Sensors

3. Conclusions

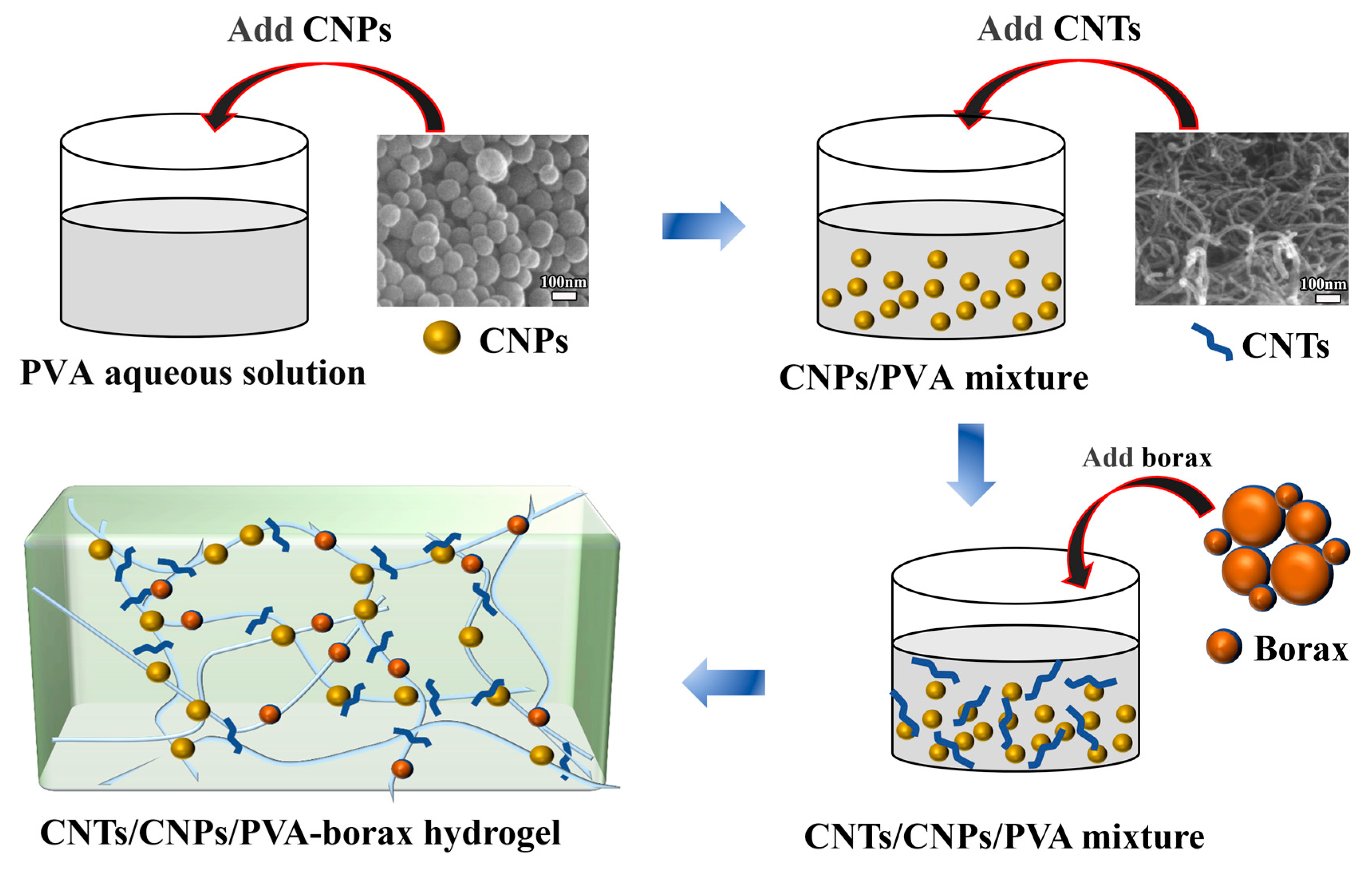

4. Materials and Methods

4.1. Materials

4.2. Preparation of CNPs

4.3. Preparation of CNT/CNP/PVA–Borax Conductive Self-Healing Hydrogels

4.4. Characterization

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PVA | polyvinyl alcohol |

| CNTs | carbon nanotubes |

| CNPs | carbon nanospheres |

| one-dimensional | 1D |

| zero-dimensional | 0D |

References

- Zeng, J.; Jing, X.; Lin, L.; Wang, G.; Zhang, Y.; Feng, P. Smart sensing hydrogel actuators conferred by MXene gradient arrangement. J. Colloid Interface Sci. 2025, 677, 816–826. [Google Scholar]

- Yin, R.; Wang, D.; Zhao, S.; Lou, Z.; Shen, G. Wearable sensors-enabled human–machine interaction systems: From design to application. Adv. Funct. Mater. 2021, 31, 2008936. [Google Scholar]

- Sekine, T.; Abe, M.; Muraki, K.; Tachibana, S.; Wang, Y.F.; Hong, J. Microporous induced fully printed pressure sensor for wearable soft robotics machine interfaces. Adv. Intell. Syst. 2020, 2, 2000179. [Google Scholar]

- Lei, K.; Chen, M.; Guo, P.; Fang, J.; Zhang, J.; Liu, X. Environmentally adaptive polymer hydrogels: Maintaining wet-soft features in extreme conditions. Adv. Funct. Mater. 2023, 33, 2303511. [Google Scholar]

- Zhang, Y.; Jing, X.; Zou, J.; Feng, P.; Wang, G.; Zeng, J. Mechanically robust and anti-swelling anisotropic conductive hydrogel with fluorescence for Multifunctional sensing. Adv. Funct. Mater. 2024, 34, 2410698. [Google Scholar]

- Han, F.; Chen, S.; Wang, F.; Liu, M.; Li, J.; Liu, H.; Xu, F. High-Conductivity, Self-Healing, and Adhesive Ionic Hydrogels for Health Monitoring and Human-Machine Interactions Under Extreme Cold Conditions. Adv. Sci. 2025, 12, 2412726. [Google Scholar]

- Jia, L.; Jiang, J.; Ren, A.; Wei, Z.; Xiang, T.; Zhou, S. Ultra-fast cryogenic self-healing ionic hydrogel for flexible wearable bioelectronics. Chem. Eng. J. 2024, 495, 153734. [Google Scholar]

- Zheng, Y.; Yin, R.; Zhao, Y.; Liu, H.; Zhang, D.; Shi, X. Conductive MXene/cotton fabric based pressure sensor with both high sensitivity and wide sensing range for human motion detection and E-skin. Chem. Eng. J. 2021, 420, 127720. [Google Scholar]

- Wang, X.; Sun, H.; Yue, X.; Yu, Y.; Zheng, G.; Dai, K. A highly stretchable carbon nanotubes/thermoplastic polyurethane fiber-shaped strain sensor with porous structure for human motion monitoring. Compos. Sci. Technol. 2018, 168, 126–132. [Google Scholar]

- Jin, X.; Wang, J.; Dai, L.; Liu, X.; Li, L.; Yang, Y. Flame-retardant poly(vinyl alcohol)/MXene multilayered films with outstanding electromagnetic interference shielding and thermal conductive performances. Chem. Eng. J. 2020, 380, 122475. [Google Scholar]

- Hu, Y.; Zhao, T.; Zhu, P.; Zhang, Y.; Liang, X.; Sun, R. A low-cost, printable, and stretchable strain sensor based on highly conductive elastic composites with tunable sensitivity for human motion monitoring. Nano Res. 2018, 11, 1938–1955. [Google Scholar]

- Huo, X.; Wang, J.; Cong, Z.; Liu, C.; Cai, C.; Wang, Y.; Niu, J. Strong and Tough Eutectogels with Broad-Range Tunable Mechanical Properties via the Hydrogen Bond Network-Specific Effect. Adv. Funct. Mater. 2025, 35, 2422464. [Google Scholar]

- Chen, Y.; Sun, X.; Luo, L.; Li, H.; Chen, N.; Yan, C.; Cheng, P. Super Strong and Tough PVA Hydrogel Fibers Based on an Ordered-to-Disordered Structural Construction Strategy Targeting Artificial Ligaments. Adv. Funct. Mater. 2025, 35, 2415737. [Google Scholar]

- Zhang, Y.; Xiong, Y.; Li, X.; Zhang, S.; Xu, W.; Chen, H.; Xu, L. Oxidization and Salting Out Synergistically Induced Highly Elastic, Conductive, and Sensitive Polyvinyl Alcohol Hydrogels. Adv. Funct. Mater. 2025, 35, 2415207. [Google Scholar]

- Yang, Z.; He, Y.; Liao, S.; Ma, Y.; Tao, X.; Wang, Y. Renatured hydrogel painting. Adv. Sci. 2021, 7, eabf9117. [Google Scholar]

- Coskun, M.B.; Akbari, A.; Lai, D.T.; Neild, A. Ultrasensitive strain sensor produced by direct patterning of liquid crystals of graphene oxide on a flexible substrate. ACS Appl. Mater. Interfaces 2016, 8, 22501–22505. [Google Scholar]

- Yang, C.; Zhang, D.; Wang, D.; Luan, H.; Chen, X. In situ polymerized mxene/polypyrrole/hydroxyethyl cellulose-based flexible strain sensor enabled by machine learning for handwriting recognition. ACS Appl. Mater. Interfaces 2023, 15, 5811–5821. [Google Scholar]

- Souri, H.; Bhattacharyya, D. Wearable strain sensors based on electrically conductive natural fiber yarns. Mater. Des. 2018, 154, 217–227. [Google Scholar]

- Chen, H.; Liu, Y.; Gao, S.; Jiang, B.; Liu, M.; Huang, J. Organic solvent-free and high-productive fabrication of lignin nanospheres via soft templating and their mechanical enhancement on PVA hydrogels. Ind. Crops. Prod. 2024, 210, 118211. [Google Scholar]

- Liu, D.; Huyan, C.; Wang, Z.; Guo, Z.; Zhang, X.; Torun, H. Conductive polymer based hydrogels and their application in wearable sensors: A review. Mater. Horiz. 2023, 10, 2800–2823. [Google Scholar]

- Liu, P.; Yao, D.; Lu, C.; Gao, X. Highly sensitive strain sensors based on PVA hydrogels with a conductive surface layer of graphene. J. Mater. Sci. Mater. 2024, 35, 97. [Google Scholar]

- Dong, X.; Song, T.; Ren, D.; Dai, K.; Leng, Y.; Wang, T. Preparation of wearable strain sensor based on PVA/MWCNTs hydrogel composite. Mater. Today Commun. 2022, 31, 103278. [Google Scholar]

- Zhang, X.; Zhang, H.; Zhang, Y.; Huangfu, H.; Yang, Y.; Qin, Q. 3D printed reduced graphene oxide-GelMA hybrid hydrogel scaffolds for potential neuralized bone regeneration. J. Mater. Chem. B. 2023, 11, 1288–1301. [Google Scholar]

- Wu, Y.; Chen, E.; Weng, X.; He, Z.; Chang, G.; Pan, X. Conductive polyvinyl alcohol/silver nanoparticles hydrogel sensor with large draw ratio, high sensitivity and high stability for human behavior monitoring, engineered. Science 2022, 18, 113–120. [Google Scholar]

- Huang, X.; Wang, L.; Shen, Z.; Ren, J.; Chen, G.; Li, Q. Super-stretchable and self-healing hydrogel with a three-dimensional silver nanowires network structure for wearable sensor and electromagnetic interference shielding. Chem. Eng. J. 2022, 446, 137136. [Google Scholar]

- Shi, J.; Li, X.; Cheng, H.; Liu, Z.; Zhao, L.; Yang, T. Graphene reinforced carbon nanotube networks for wearable strain sensors. Adv. Funct. Mater. 2016, 26, 2078–2084. [Google Scholar]

- Kumar, S.; Mehdi, S.M.Z.; Taunk, M.; Kumar, S.; Aherwar, A.; Singh, S. Synergistic Impacts on Properties, Stability, and Applications of MXenes via Polymer Integration. J. Mater. Chem. A 2025, 13, 11050–11113. [Google Scholar]

- Bian, H.; Jiao, L.; Wang, R.; Wang, X.; Zhu, W. Lignin nanoparticles as nano-spacers for tuning the viscoelasticity of cellulose nanofibril reinforced polyvinyl alcohol-borax hydrogel. Eur. Polym. J. 2018, 107, 267–274. [Google Scholar]

- Zhao, X.; Zheng, H.; Qu, D.; Jiang, H.; Fan, W.; Sun, Y. A supramolecular approach towards strong and tough polymer nanocomposite fibers. RSC. Adv. 2018, 8, 10361–10366. [Google Scholar]

- Yang, W.; Han, X.; Yin, C.; Zhang, X.; Peng, Q. Biomass carbon nanosphere-based piezoresistive flexible pressure sensors for motion capture and health monitoring. Compos. Commun. 2024, 51, 102041. [Google Scholar]

- Dang, Z.M.; Zheng, M.S.; Zha, J.W. 1D/2D carbon nanomaterial-polymer dielectric composites with high permittivity for power energy storage applications. Small 2016, 12, 1688–1701. [Google Scholar] [PubMed]

- Bokobza, L. Multiwall carbon nanotube elastomeric composites: A review. Polymer 2007, 48, 4907–4920. [Google Scholar]

- Chen, J.; Li, H.; Yu, Q.; Hu, Y.; Cui, X.; Zhu, Y.; Jiang, W. Strain sensing behaviors of stretchable conductive polymer composites loaded with different dimensional conductive fillers. Compos. Sci. Technol. 2018, 168, 388–396. [Google Scholar]

- Chen, M.; Zhang, L.; Duan, S.; Jing, S.; Jiang, H.; Luo, M.; Li, C. Highly conductive and flexible polymer composites with improved mechanical and electromagnetic interference shielding performances. Nanoscale 2014, 6, 3796–3803. [Google Scholar] [PubMed]

- Spoljaric, S.; Salminen, A.; Luong, N.D. self-healing hydrogels from nanofibrillated cellulose, poly (vinyl alcohol) and borax via reversible crosslinking. Eur. Polym. J. 2014, 56, 105–117. [Google Scholar]

- Liu, Y.; Wang, W.; Gu, K.; Yao, J.; Shao, Z.; Chen, X. Poly (vinyl alcohol) hydrogels with integrated toughness, conductivity, and freezing tolerance based on ionic liquid/water binary solvent systems. ACS Appl. Mater. Interfaces 2021, 13, 29008–29020. [Google Scholar]

- Zhou, H.; Wang, M.; Jin, X.; Liu, H.; Lai, J.; Du, H.; Ma, A. Capacitive pressure sensors containing reliefs on solution-processable hydrogel electrodes. ACS Appl. Mater. Interfaces 2021, 13, 1441–1451. [Google Scholar]

- He, S.; Cui, Z.; Fang, H.; Wei, X.; Shao, W. Incorporation of multi-dynamic interactions into carboxyl graphene oxide-enhanced PVA/PAA/agarose hydrogels for multifunctional wearable sensors. Int. J. Biol. Macromol. 2025, 314, 144336. [Google Scholar]

- Zhang, Y.; Ren, E.; Li, A.; Cui, C.; Guo, R.; Tang, H.; Liu, L. A porous self-healing hydrogel with an island-bridge structure for strain and pressure sensors. J. Mater. Chem. B 2021, 9, 719–730. [Google Scholar]

- Xin, Q.; Hu, D.; Zhou, L.; Yang, G.; Liang, S.; Lin, J. Polydopamine-Based Multifunctional Hydrogel for Flexible Supercapacitor and Pressure Sensor Applications. ACS Appl. Electron. Mater. 2023, 5, 3756–3764. [Google Scholar]

| Raw Materials | Sensitivity (Kpa−1) | Sensing Range (KPa) | Response Time (ms) | Recovery Time (ms) | Ref |

|---|---|---|---|---|---|

| CNT/CNP/PVA -borax | 10.06 | 0–28 | 88 | 88 | This work |

| PVA/EMImAc/H2O | 1.18 | 0.2–43 | - | - | [36] |

| PVA/PANI | 7.70 | 0–7.4 | - | - | [37] |

| PVA/PAA/AG | 0.121 | 0–31.83 | - | - | [38] |

| PVA/CNTs/graphene | 0.127 | 0–10 | - | - | [39] |

| PDAX−PVA/PEG | 0.57 | 0–30 | 210 | 330 | [40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, C.; Shu, Z.; Zhang, X.; Yin, C. CNTs/CNPs/PVA–Borax Conductive Self-Healing Hydrogel for Wearable Sensors. Gels 2025, 11, 572. https://doi.org/10.3390/gels11080572

Peng C, Shu Z, Zhang X, Yin C. CNTs/CNPs/PVA–Borax Conductive Self-Healing Hydrogel for Wearable Sensors. Gels. 2025; 11(8):572. https://doi.org/10.3390/gels11080572

Chicago/Turabian StylePeng, Chengcheng, Ziyan Shu, Xinjiang Zhang, and Cailiu Yin. 2025. "CNTs/CNPs/PVA–Borax Conductive Self-Healing Hydrogel for Wearable Sensors" Gels 11, no. 8: 572. https://doi.org/10.3390/gels11080572

APA StylePeng, C., Shu, Z., Zhang, X., & Yin, C. (2025). CNTs/CNPs/PVA–Borax Conductive Self-Healing Hydrogel for Wearable Sensors. Gels, 11(8), 572. https://doi.org/10.3390/gels11080572