Radiative Heat Transfer Properties of Fiber–Aerogel Composites for Thermal Insulation

Abstract

1. Introduction

2. Background and Theoretical Foundations

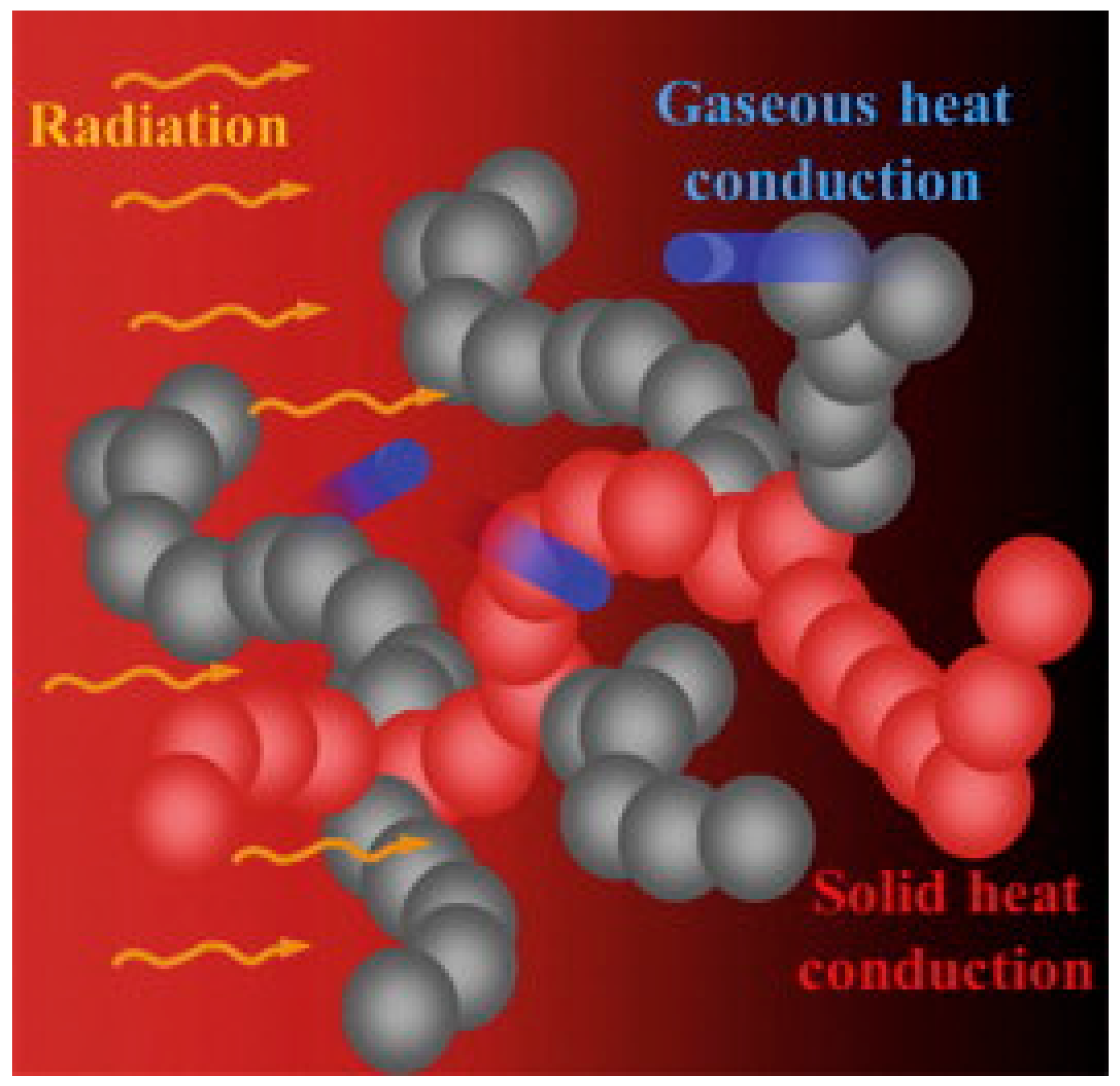

2.1. Radiative Heat Transfer Analysis

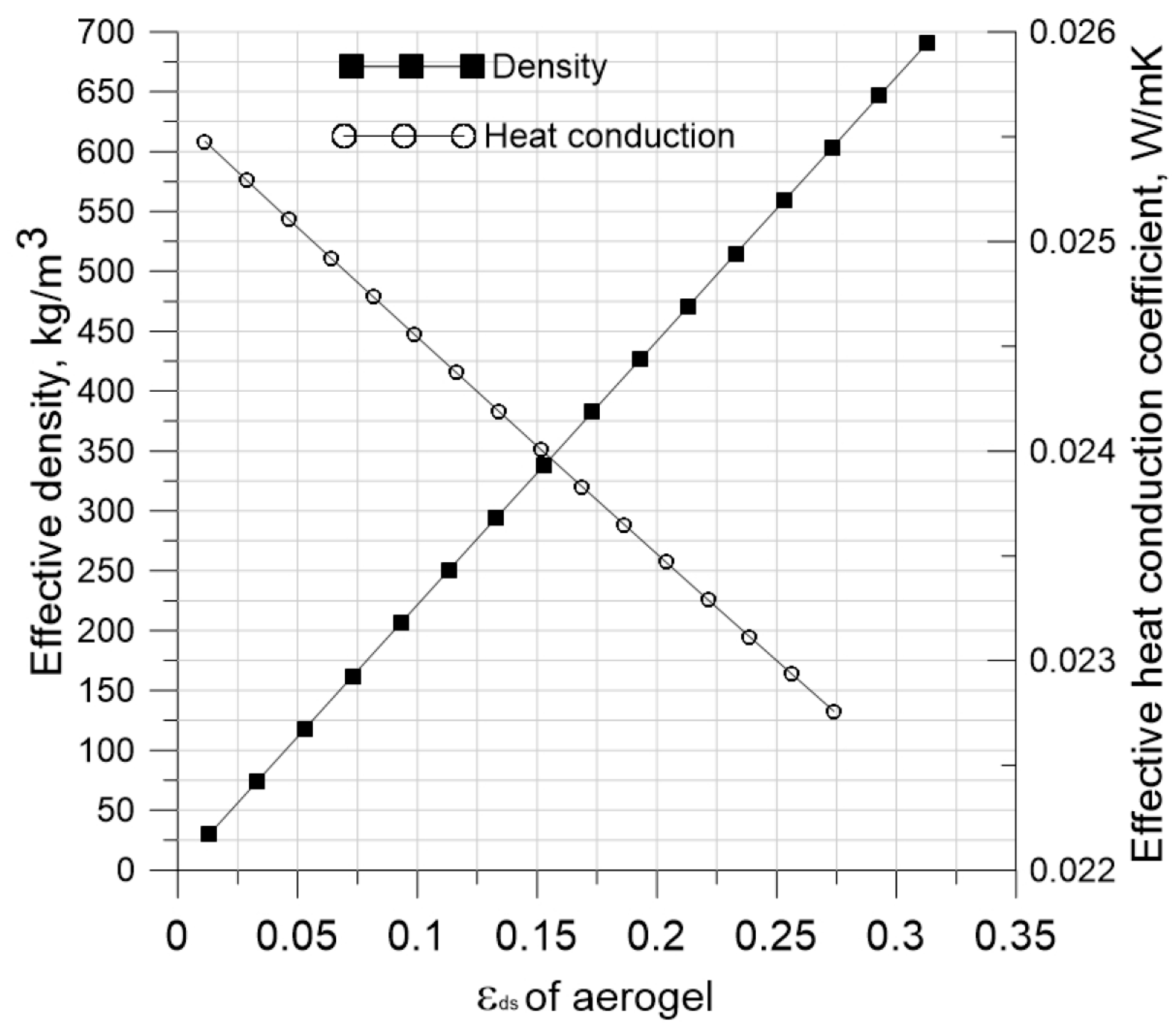

2.2. Thermal Conductivity and Radiative Heat Transfer

- Polyimide Aerogels: It was discovered that 495 °C was the starting point for the polyimide aerogel matrix material’s breakdown when exposed to nitrogen gas. When compared to the pristine matrix, composites made from this aerogel matrix showed better thermal stability and higher breakdown temperatures [64].

- Cellulose–Silica Composite Aerogels: These composites showed remarkable thermal insulation performance, preserving good recovery at 600 °C while providing efficient thermal insulation. Interestingly, they showed excellent thermal stability by not burning in a flame at 1300 °C [65].

- Silica Aerogels: Applications needing low thermal conductivity can benefit from silica aerogels because of their high porosity and ultralow thermal conductivity. To improve performance in high-temperature situations, they may need reinforcing because of their poor thermal stability [66].

2.3. Fibrous Materials, Aerogels, and Their Composite Structures

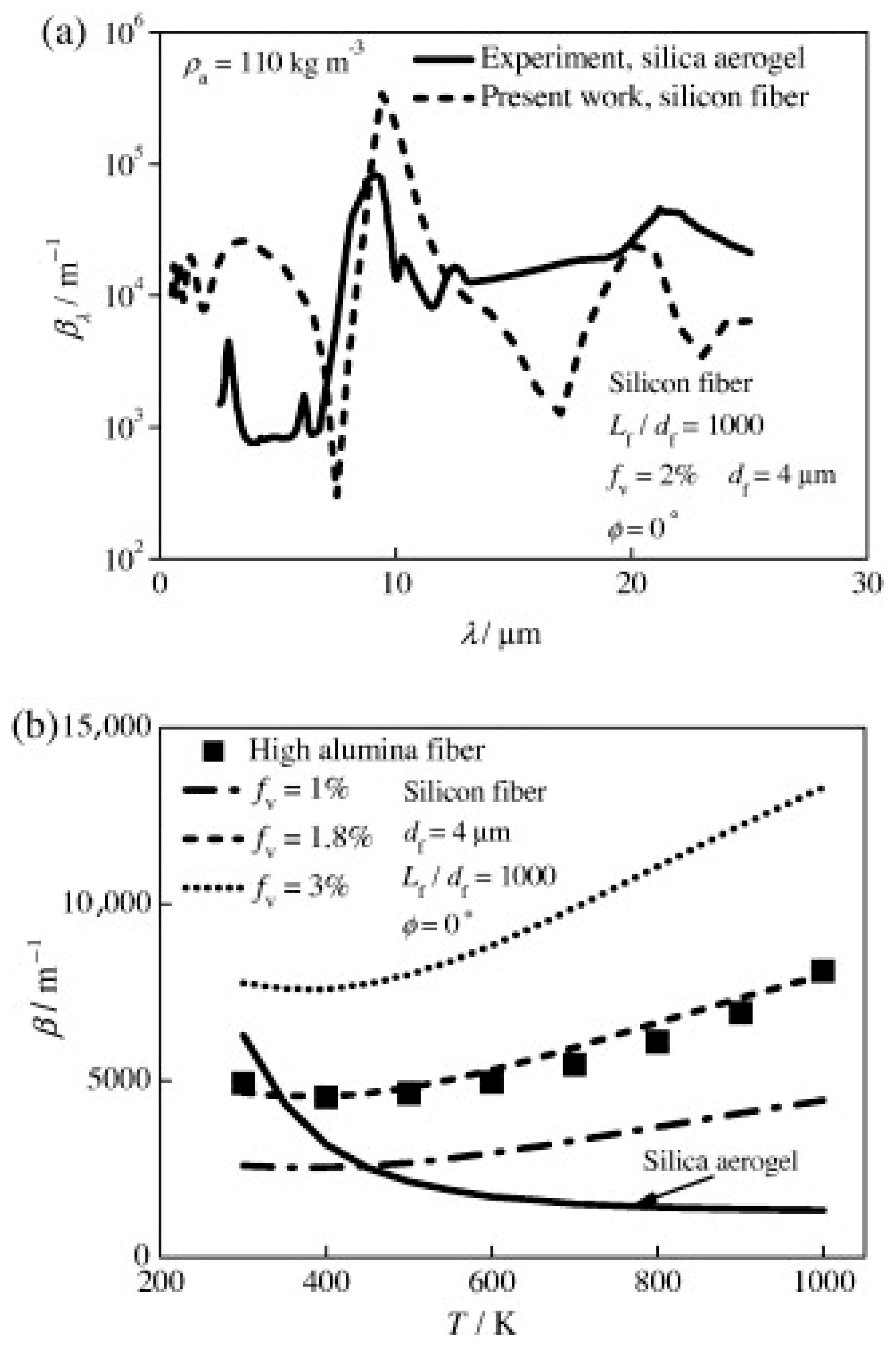

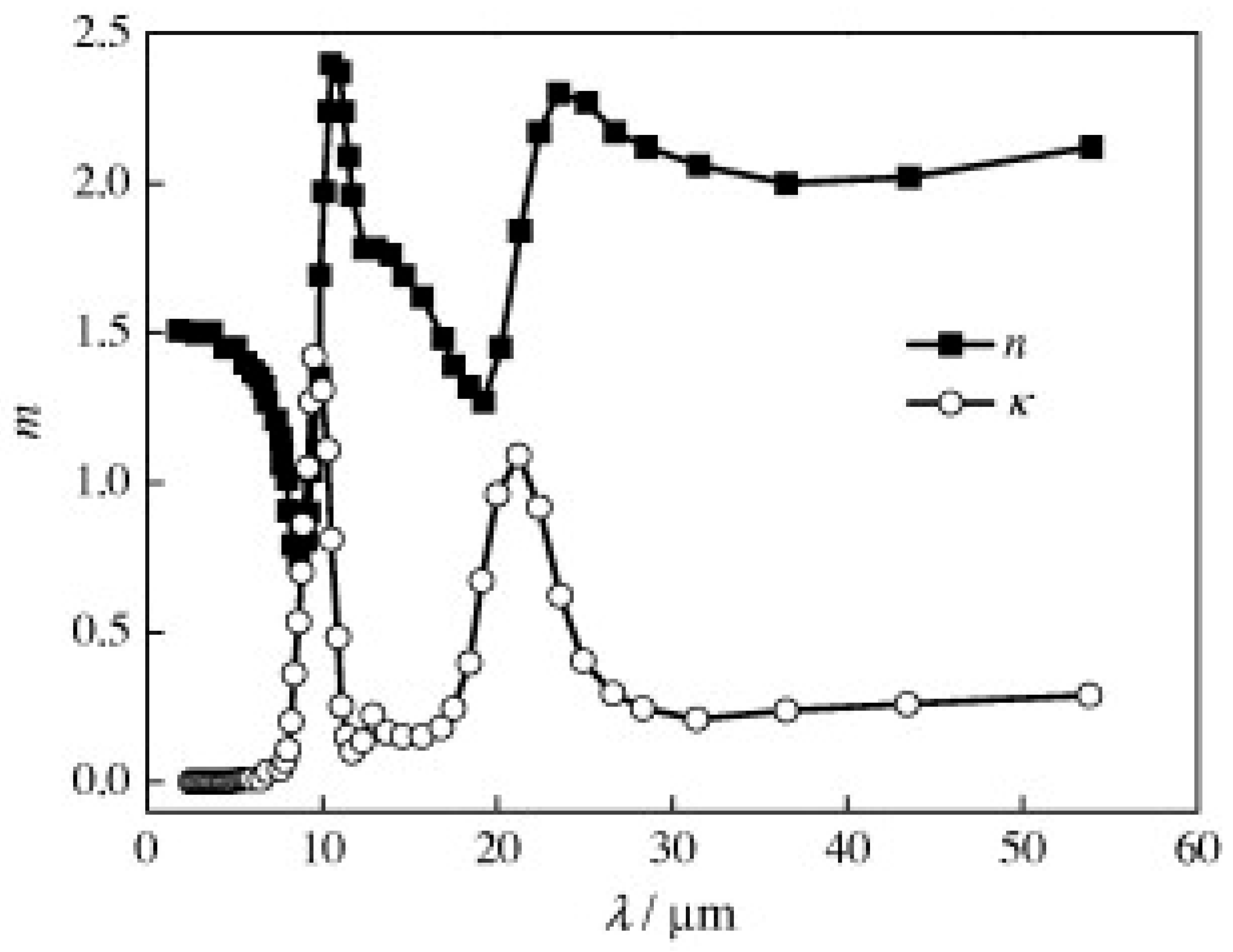

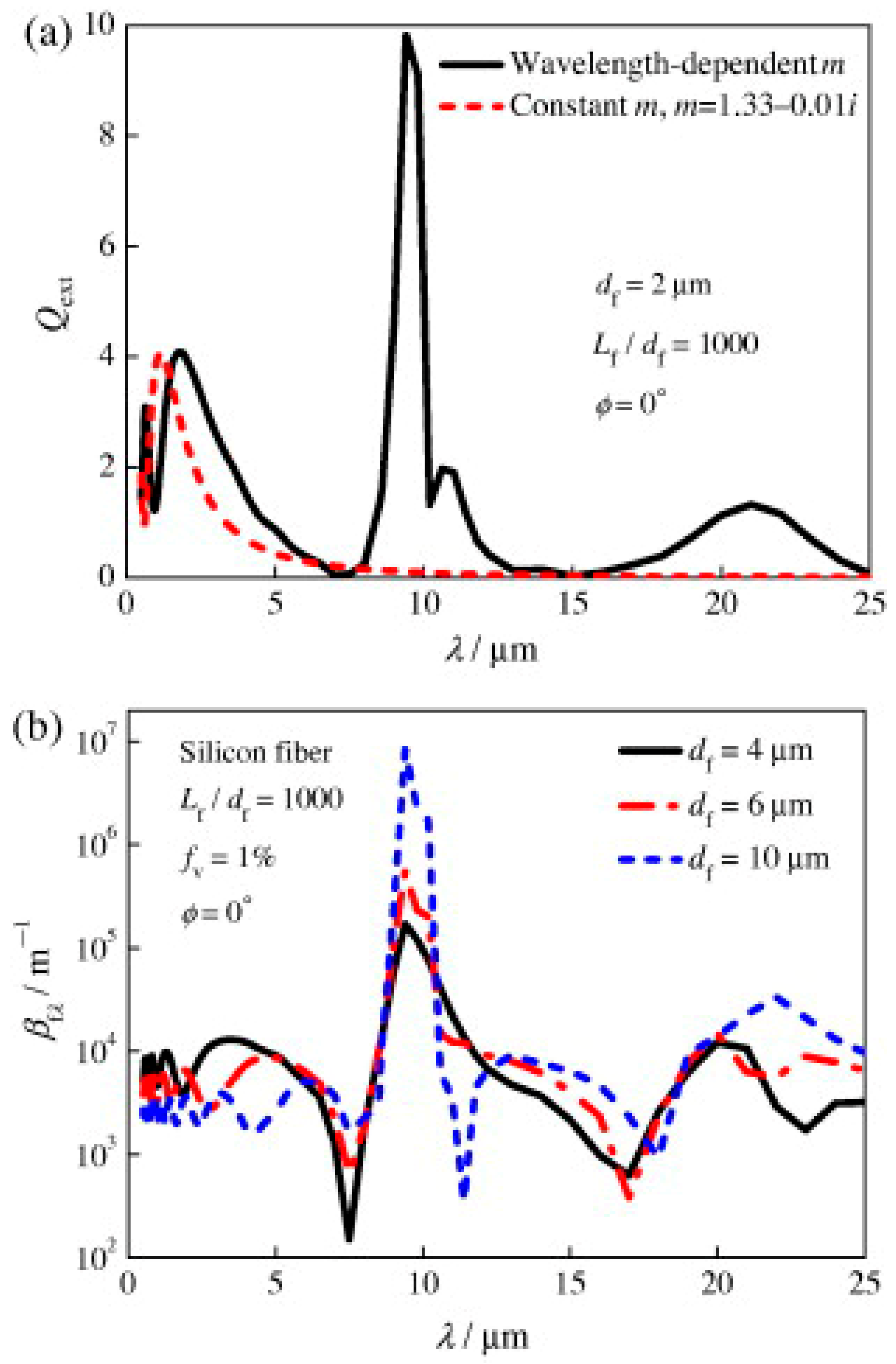

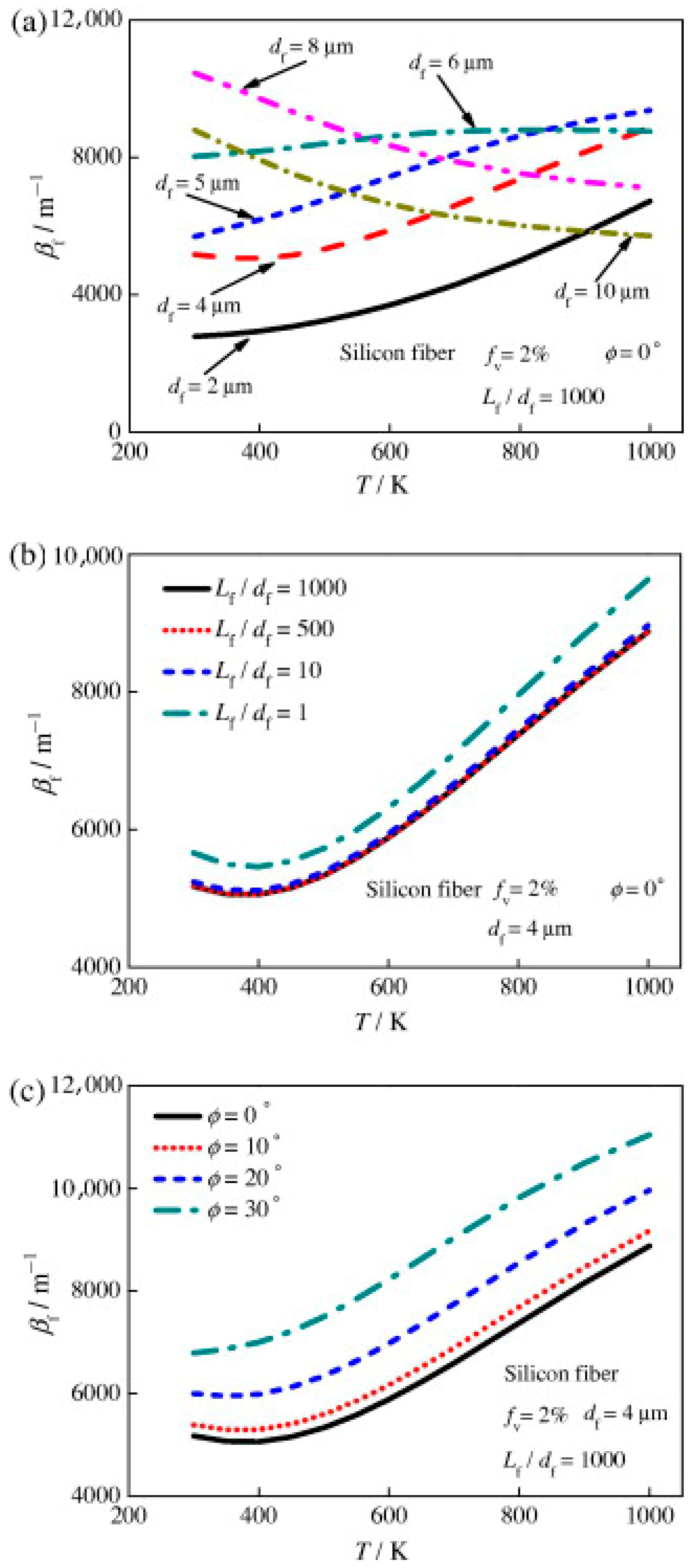

3. Radiative Heat Transfer in Fiber–Aerogel Composites

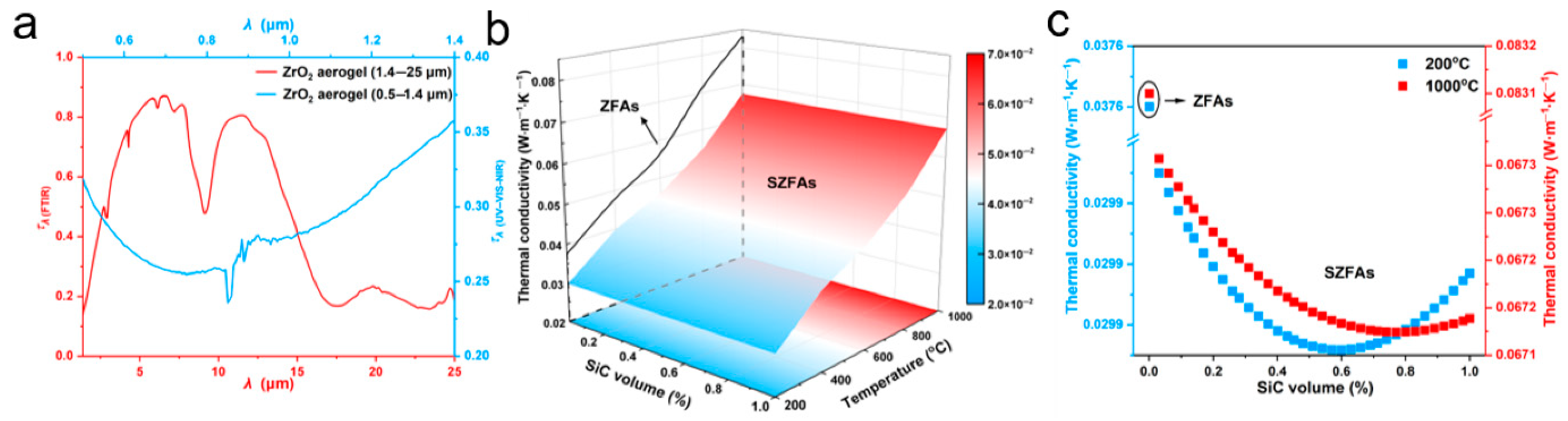

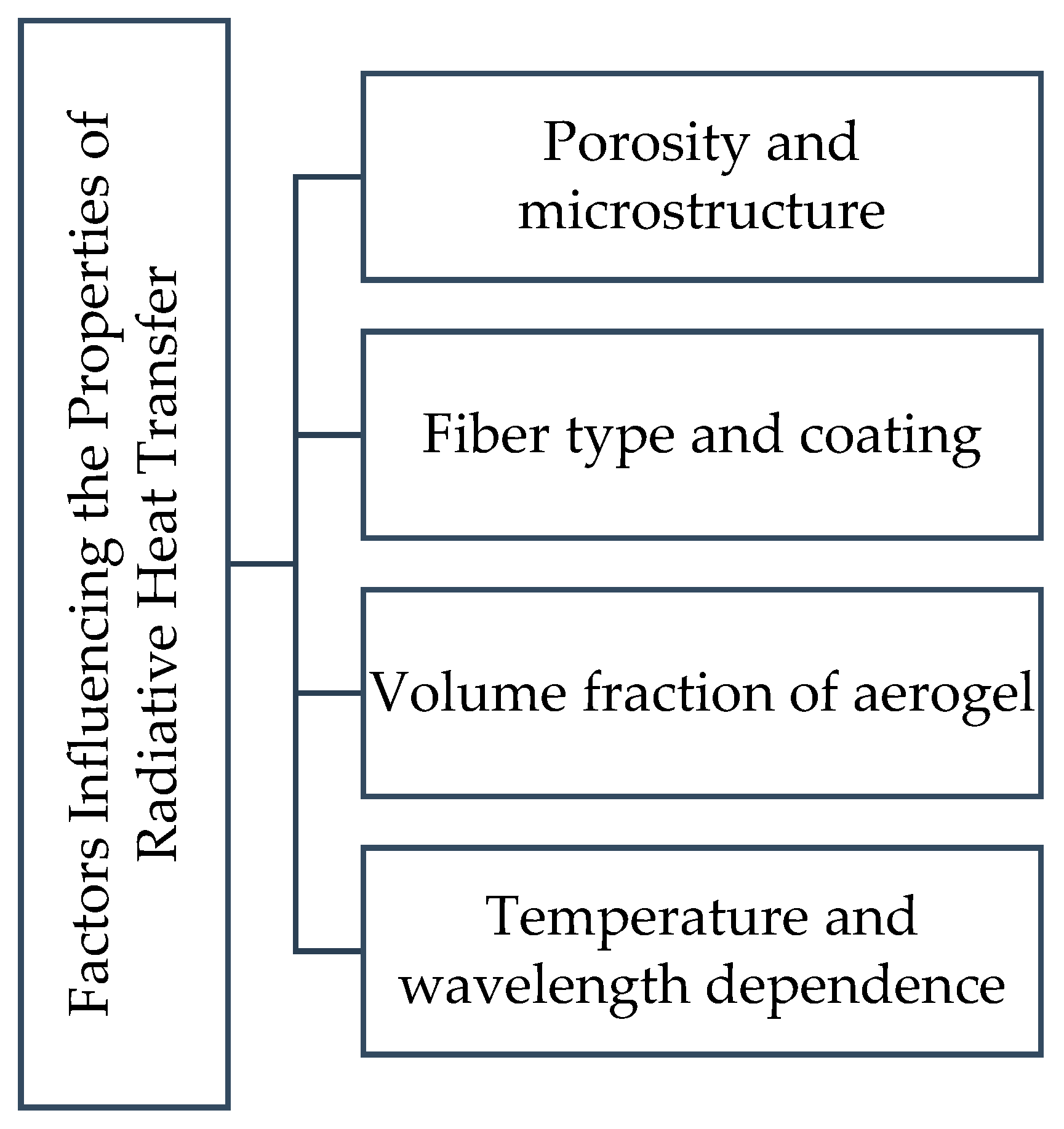

4. Factors Affecting Radiative Heat Transfer Properties

5. Experimental Studies and Results

6. Applications for Fiber–Aerogel Composites

7. Challenges and Limitations

8. Future Directions and Research Gaps

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kistler, S.S. Coherent Expanded Aerogels and Jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Hrubesh, L.W.; Pekala, R.W. Thermal properties of organic and inorganic aerogels. J. Mater. Res. 1994, 9, 731–738. [Google Scholar] [CrossRef]

- Lei, J.; Zheng, S.; Han, Z.; Niu, Y.; Pan, D.; Liu, H.; Liu, C.; Shen, C. A Brief Review on the Preparation and Application of Silica Aerogel. Eng. Sci. 2024, 30, 1214. [Google Scholar] [CrossRef]

- Gurav, J.L.; Jung, I.-K.; Park, H.-H.; Kang, E.S.; Nadargi, D.Y. Silica Aerogel: Synthesis and Applications. J. Nanomater. 2010, 2010, 409310. [Google Scholar] [CrossRef]

- Parale, V.G.; Kim, T.; Choi, H.; Phadtare, V.D.; Dhavale, R.P.; Kanamori, K.; Park, H.-H. Mechanically Strengthened Aerogels Through Multiscale, Multicompositional, and Multidimensional Approaches: A Review. Adv. Mater. 2024, 36, 2307772. [Google Scholar] [CrossRef]

- Zhao, J.-J.; Duan, Y.-Y.; Wang, X.-D.; Wang, B.-X. Radiative properties and heat transfer characteristics of fiber-loaded silica aerogel composites for thermal insulation. Int. J. Heat Mass Transf. 2012, 55, 5196–5204. [Google Scholar] [CrossRef]

- Shklover, V.; Braginsky, L.; Mishrikey, M.; Hafner, C. Radiative heat transport in porous materials. MRS Online Proc. Libr. 2009, 1162, 303. [Google Scholar] [CrossRef]

- Militký, J.; Křemenáková, D.; Venkataraman, M.; Večerník, J.; Martínková, L.; Marek, J. Sandwich Structures Reflecting Thermal Radiation Produced by the Human Body. Polymers 2021, 13, 3309. [Google Scholar] [CrossRef]

- Venkataraman, M.; Mishra, R.; Militky, J.; Kremenakova, D.; Michal, P. Aerogel Based High Performance Thermal Insulation Materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 553, 012043. [Google Scholar] [CrossRef]

- Venkataraman, M.; Mishra, R.; Wiener, J.; Militky, J.; Kotresh, T.; Vaclavik, M. Novel techniques to analyse thermal performance of aerogel-treated blankets under extreme temperatures. J. Text. Inst. 2015, 106, 736–747. [Google Scholar] [CrossRef]

- Tafreshi, O.A.; Mosanenzadeh, S.G.; Karamikamkar, S.; Saadatnia, Z.; Park, C.B.; Naguib, H.E. A review on multifunctional aerogel fibers: Processing, fabrication, functionalization, and applications. Mater. Today Chem. 2022, 23, 100736. [Google Scholar] [CrossRef]

- Ebert, H.-P. Thermal Properties of Aerogels. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer: New York, NY, USA, 2011; pp. 537–564. [Google Scholar] [CrossRef]

- Militky, J.; Bajzík, V. Surface roughness of heat protective clothing textiles. Int. J. Cloth. Sci. Technol. 2003, 15, 258–267. [Google Scholar] [CrossRef]

- Sozcu, S.; Frajova, J.; Wiener, J.; Venkataraman, M.; Tomkova, B.; Militky, J. Synthesis of Acetobacter xylinum Bacterial Cellulose Aerogels and Their Effect on the Selected Properties. Gels 2025, 11, 272. [Google Scholar] [CrossRef] [PubMed]

- He, Y.-L.; Xie, T. Advances of thermal conductivity models of nanoscale silica aerogel insulation material. Appl. Therm. Eng. 2015, 81, 28–50. [Google Scholar] [CrossRef]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Xue, J.; Han, R.; Li, Y.; Zhang, J.; Liu, J.; Yang, Y. Advances in multiple reinforcement strategies and applications for silica aerogel. J. Mater. Sci. 2023, 58, 14255–14283. [Google Scholar] [CrossRef]

- Wang, L.; Lian, W.; Yin, B.; Liu, X.; Tang, S. Silica nanowires-reinforced silica aerogels with outstanding thermal insulation, thermal stability and mechanical properties. Ceram. Int. 2024, 50, 6693–6702. [Google Scholar] [CrossRef]

- Zhan, W.; Chen, L.; Kong, Q.; Li, L.; Chen, M.; Jiang, J.; Li, W.; Shi, F.; Xu, Z. The Synthesis and Polymer-Reinforced Mechanical Properties of SiO2 Aerogels: A Review. Molecules 2023, 28, 5534. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, J.; Wu, A.; Shen, J.; Zhou, B. High strength SiO2 aerogel insulation. J. Non-Cryst. Solids 1998, 225, 101–104. [Google Scholar] [CrossRef]

- Merillas, B.; Almeida, C.M.R.; Álvarez-Arenas, T.E.G.; Rodríguez-Pérez, M.Á.; Durães, L. Enhanced thermal insulation performance of silica aerogel composites through infrared opacifier integration for high-temperature applications. Compos. Part C Open Access 2025, 16, 100573. [Google Scholar] [CrossRef]

- Yu, H.; Tong, Z.; Zhang, B.; Chen, Z.; Li, X.; Su, D.; Ji, H. Thermal radiation shielded, high strength, fire resistant fiber/nanorod/aerogel composites fabricated by in-situ growth of TiO2 nanorods for thermal insulation. Chem. Eng. J. 2021, 418, 129342. [Google Scholar] [CrossRef]

- Liu, F.; He, C.; Jiang, Y.; Feng, J.; Li, L.; Tang, G.; Feng, J. Ultralight Ceramic Fiber Aerogel for High-Temperature Thermal Superinsulation. Nanomaterials 2023, 13, 1305. [Google Scholar] [CrossRef] [PubMed]

- Fedyukhin, A.V.; Strogonov, K.V.; Soloveva, O.V.; Solovev, S.A.; Akhmetova, I.G.; Berardi, U.; Zaitsev, M.D.; Grigorev, D.V. Aerogel Product Applications for High-Temperature Thermal Insulation. Energies 2022, 15, 7792. [Google Scholar] [CrossRef]

- Sozcu, S.; Venkataraman, M.; Wiener, J.; Tomkova, B.; Militky, J.; Mahmood, A. Incorporation of Cellulose-Based Aerogels into the Textile Structure. Materials 2024, 17, 27. [Google Scholar] [CrossRef]

- Lee, O.-J.; Lee, K.-H.; Yim, T.J.; Kim, S.Y.; Yoo, K.-P. Determination of mesopore size of aerogels from thermal conductivity measurements. J. Non-Cryst. Solids 2002, 298, 287–292. [Google Scholar] [CrossRef]

- Wang, J.; Kuhn, J.; Lu, X. Monolithic silica aerogel insulation doped with TiO2 powder and ceramic fibers. J. Non-Cryst. Solids 1995, 186, 296–300. [Google Scholar] [CrossRef]

- Daryabeigi, K. Heat Transfer in High-Temperature Fibrous Insulation. J. Thermophys. Heat Transf. 2003, 17, 10–20. [Google Scholar] [CrossRef]

- Wei, G.; Liu, Y.; Zhang, X.; Yu, F.; Du, X. Thermal conductivities study on silica aerogel and its composite insulation materials. Int. J. Heat Mass Transf. 2011, 54, 2355–2366. [Google Scholar] [CrossRef]

- Lu, G.; Wang, X.-D.; Duan, Y.-Y.; Li, X.-W. Effects of non-ideal structures and high temperatures on the insulation properties of aerogel-based composite materials. J. Non-Cryst. Solids 2011, 357, 3822–3829. [Google Scholar] [CrossRef]

- Zeng, S.O.; Hunt, A.; Greif, R. Geometric structure and thermal conductivity of porous medium silica aerogel. J. Heat Transf. 1995, 117, 1055–1058. [Google Scholar] [CrossRef]

- Wei, G.; Liu, Y.; Zhang, X.; Du, X. Radiative heat transfer study on silica aerogel and its composite insulation materials. J. Non-Cryst. Solids 2013, 362, 231–236. [Google Scholar] [CrossRef]

- Fu, Z.; Corker, J.; Papathanasiou, T.; Wang, Y.; Zhou, Y.; Madyan, O.A.; Liao, F.; Fan, M. Critical review on the thermal conductivity modelling of silica aerogel composites. J. Build. Eng. 2022, 57, 104814. [Google Scholar] [CrossRef]

- Zhang, H.; Qiao, Y.; Zhang, X.; Fang, S. Structural and thermal study of highly porous nanocomposite SiO2-based aerogels. J. Non-Cryst. Solids 2010, 356, 879–883. [Google Scholar] [CrossRef]

- Karadagli, I.; Schulz, B.; Schestakow, M.; Milow, B.; Gries, T.; Ratke, L. Production of porous cellulose aerogel fibers by an extrusion process. J. Supercrit. Fluids 2015, 106, 105–114. [Google Scholar] [CrossRef]

- Xiao, L.; Grogan, M.D.; Leon-Saval, S.G.; Williams, R.; England, R.; Wadsworth, W.J.; Birks, T.A. Tapered fibers embedded in silica aerogel. Opt. Lett. 2009, 34, 2724–2726. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Z.; Liu, Z.; Hou, Y.; Jiang, H.; Li, Y.; Li, G.; Zhang, X. The Rising Aerogel Fibers: Status, Challenges, and Opportunities. Adv. Sci. 2023, 10, 2205762. [Google Scholar] [CrossRef]

- Carvajal, S.A.; Daryabeigi, K.; Ramírez, J.H. Predictive radiation heat transfer modeling in fibrous insulation at high temperature. Int. J. Therm. Sci. 2024, 198, 108897. [Google Scholar] [CrossRef]

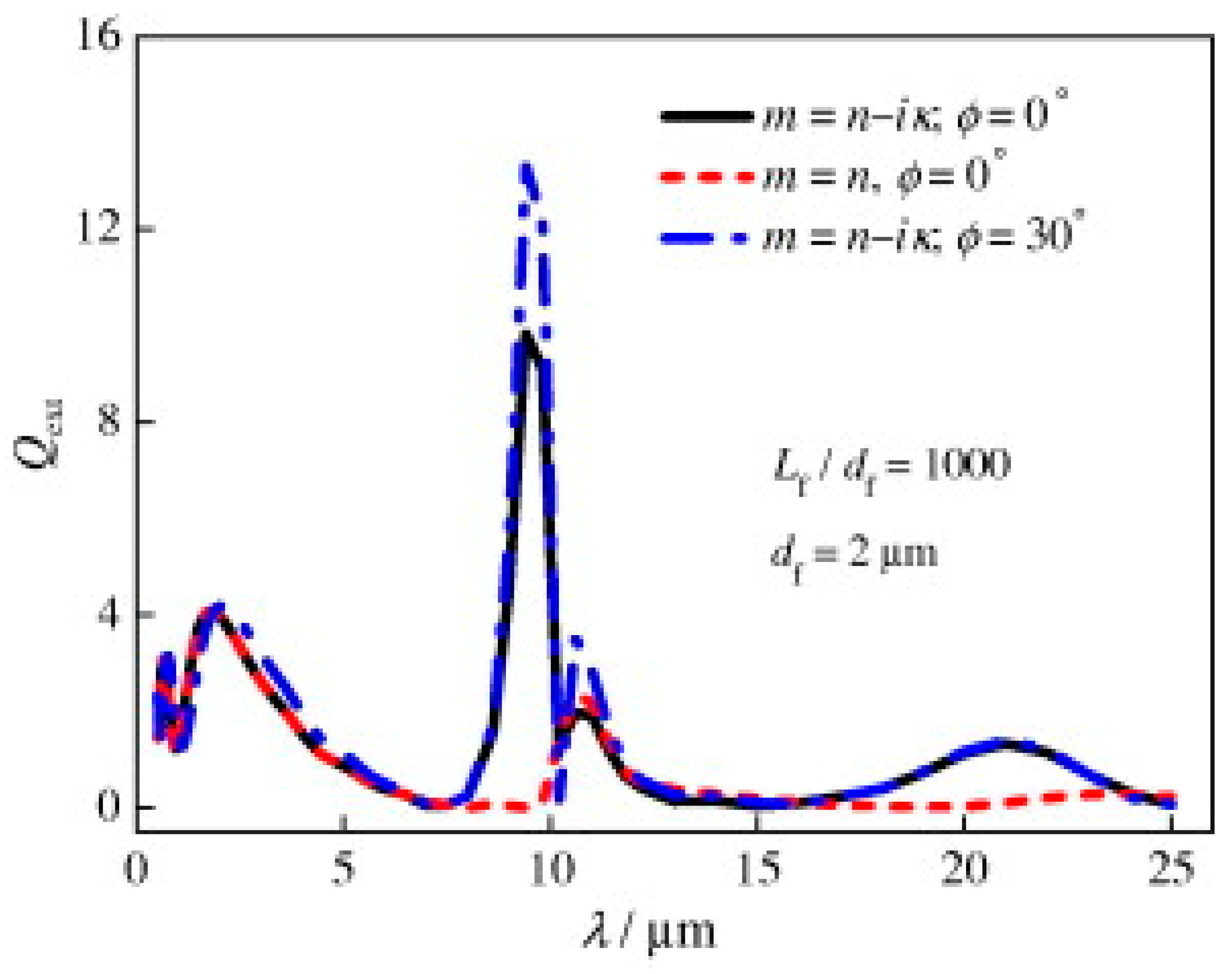

- Carvajal, S.A.; Paulien, L.; Elniski, A.; Daryabeigi, K.; Berg, M.J. Analytical models of radiative transfer in fibrous insulation under collimated irradiation. Int. J. Heat Mass Transf. 2025, 244, 126961. [Google Scholar] [CrossRef]

- Padmanabhan, S.K.; Haq, E.U.; Licciulli, A. Synthesis of silica cryogel-glass fiber blanket by vacuum drying. Ceram. Int. 2016, 42, 7216–7222. [Google Scholar] [CrossRef]

- Xue, J.; Han, R.; Ge, Y.; Liu, L.; Yang, Y. Preparation, mechanical, acoustic and thermal properties of silica composite aerogel using wet-laid glass fiber felt as scaffold. Compos. Part A Appl. Sci. Manuf. 2024, 179, 108058. [Google Scholar] [CrossRef]

- He, S.; Li, H.; Zhang, Y.; Huang, Y.; Pan, Y. High accuracy heat transfer model for aerogel/fiber composite mats. Int. Commun. Heat Mass Transf. 2025, 162, 108584. [Google Scholar] [CrossRef]

- Bi, C.; Tang, G.H.; Hu, Z.J.; Yang, H.L.; Li, J.N. Coupling model for heat transfer between solid and gas phases in aerogel and experimental investigation. Int. J. Heat Mass Transf. 2014, 79, 126–136. [Google Scholar] [CrossRef]

- Zhao, J.-J.; Duan, Y.-Y.; Wang, X.-D.; Wang, B.-X. Effects of solid–gas coupling and pore and particle microstructures on the effective gaseous thermal conductivity in aerogels. J. Nanopart. Res. 2012, 14, 1024. [Google Scholar] [CrossRef]

- Xie, T.; He, Y.-L. Heat transfer characteristics of silica aerogel composite materials: Structure reconstruction and numerical modeling. Int. J. Heat Mass Transf. 2016, 95, 621–635. [Google Scholar] [CrossRef]

- Xu, H.-B.; Zhu, C.-Y.; Tian, L.; Li, Z.-Y. Applicable scope of the Rosseland model in predicting the radiative thermal conductivity of silica aerogel. Int. J. Therm. Sci. 2025, 215, 109953. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Li, Y. Measuring radiative properties of silica aerogel composite from FTIR transmittance test using KBr as diluents. Exp. Therm. Fluid Sci. 2018, 91, 144–154. [Google Scholar] [CrossRef]

- Wei, G.; Liu, Y.; Zhang, X.; Du, X. Thermal Radiation in Silica Aerogel and its Composite Insulation Materials. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition. Volume 10: Heat and Mass Transport Processes, Parts A and B, Denver, CO, USA, 11–17 November 2011; pp. 1223–1231. [Google Scholar] [CrossRef]

- Huang, R.; Jiang, Y.; Feng, J.; Li, L.; Hu, Y.; Wang, X.; Feng, J. Robust and exceptional thermal insulating alumina-silica aerogel composites reinforced by ultra IR-opacified ZrO2 nanofibers. Chem. Eng. J. 2024, 498, 155283. [Google Scholar] [CrossRef]

- Yang, Z.; Su, G.; Sun, F. Theoretical Modeling of the Radiative Properties and Effective Thermal Conductivity of the Opacified Silica Aerogel. CMC 2013, 36, 271–292. [Google Scholar] [CrossRef]

- Pang, H.-Q.; Fan, T.-H.; Zhu, C.-Y.; Liu, T.-Y.; Gao, Y.-F. Representation of the Characteristic Temperature of Correlative Thermal Conductivity of Opacifier-Fiber Doped Silica Aerogel by Steady-State Method at Large Temperature Differences. Int. J. Thermophys. 2022, 43, 150. [Google Scholar] [CrossRef]

- He, S.; Zhang, X.; Wu, X.; Li, P.; Xu, L. Theoretical study of heat transfer model of silica aerogel based on the porous structure of secondary particles. Appl. Therm. Eng. 2024, 238, 121935. [Google Scholar] [CrossRef]

- Xiong, X.; Venkataraman, M.; Jašíková, D.; Yang, T.; Mishra, R.; Militký, J.; Petrů, M. An experimental evaluation of convective heat transfer in multi-layered fibrous materials composed by different middle layer structures. J. Ind. Text. 2021, 51, 362–379. [Google Scholar] [CrossRef]

- Krzemińska, S.; Cieślak, M.; Kamińska, I.; Nejman, A. Application of Silica Aerogel in Composites Protecting Against Thermal Radiation. Autex Res. J. 2020, 20, 274–287. [Google Scholar] [CrossRef]

- Goryunova, K.I.; Gahramanli, Y.N. Insulating materials based on silica aerogel composites: Synthesis, properties and application. RSC Adv. 2024, 14, 34690–34707. [Google Scholar] [CrossRef]

- Xiaoman, X.; Venkataraman, M.; Jašíková, D.; Yang, T.; Rajesh, M.; Militky, J.; Petru, M. Thermal Behavior of Aerogel-Embedded Nonwovens in Cross Airflow. Autex Res. J. 2021, 21, 115–124. [Google Scholar] [CrossRef]

- Burgos, M.I.; Velasco, M.I.; Acosta, R.H.; Perillo, M.A. Environmental Topology and Water Availability Modulates the Catalytic Activity of β-Galactosidase Entrapped in a Nanosporous Silicate Matrix. Sci. Rep. 2016, 6, 36593. [Google Scholar] [CrossRef] [PubMed]

- Venkataraman, M.; Militký, J.; Mishra, R.; Jandová, S. Unconventional measurement methods and simulation of aerogel assisted thermoregulation. J. Mech. Eng. (JMechE) 2018, 5, 62–96. [Google Scholar]

- Zhang, H.; Li, Y.; Tao, W. Effect of radiative heat transfer on determining thermal conductivity of semi-transparent materials using transient plane source method. Appl. Therm. Eng. 2017, 114, 337–345. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Smith, D.S.; Alzina, A.; Bourret, J.; Nait-Ali, B.; Pennec, F.; Tessier-Doyen, N.; Otsu, K.; Matsubara, H.; Elser, P.; Gonzenbach, U.T. Thermal conductivity of porous materials. J. Mater. Res. 2013, 28, 2260–2272. [Google Scholar] [CrossRef]

- Howell, J.R.; Menguc, M.P.; Siegel, R. Thermal Radiation Heat Transfer, 6th ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar] [CrossRef]

- Lee, S.W.; Lim, C.H.; Salleh, E.@.I.B. Reflective thermal insulation systems in building: A review on radiant barrier and reflective insulation. Renew. Sustain. Energy Rev. 2016, 65, 643–661. [Google Scholar] [CrossRef]

- Malakooti, S.; Vivod, S.L.; Pereira, M.; Ruggeri, C.R.; Revilock, D.M.; Scheiman, D.A.; Guo, H.; Salem, J.A.; Benafan, O.; Johnston, J.C.; et al. Fabric reinforced polyimide aerogel matrix composites with low thermal conductivity, high flexural strength, and high sound absorption coefficient. Compos. Part B Eng. 2023, 260, 110751. [Google Scholar] [CrossRef]

- Zhan, C.; Lu, Q.; Jiang, H.; Lu, H.; Liu, Y. Facile preparation of lightweight high-elastic celluous/SiO2 composite aerogel with outstanding thermal insulation performance. J. Porous Mater. 2025, 1–13. [Google Scholar] [CrossRef]

- Cai, H.; Jiang, Y.; Feng, J.; Zhang, S.; Peng, F.; Xiao, Y.; Li, L.; Feng, J. Preparation of silica aerogels with high temperature resistance and low thermal conductivity by monodispersed silica sol. Mater. Des. 2020, 191, 108640. [Google Scholar] [CrossRef]

- Lee, S.C. Effect of fiber orientation on thermal radiation in fibrous media. Int. J. Heat Mass Transf. 1989, 32, 311–319. [Google Scholar] [CrossRef]

- Venkataraman, M.; Mishra, R.; Kotresh, T.M.; Sakoi, T.; Militky, J. Effect of compressibility on heat transport phenomena in aerogel-treated nonwoven fabrics. J. Text. Inst. 2016, 107, 1150–1158. [Google Scholar] [CrossRef]

- Ma, Y.; Tang, G.H.; Hu, Y. Modelling of hollow-fiber doping in silica aerogel composites for radiative and conductive insulation under high temperatures. Appl. Therm. Eng. 2024, 254, 123917. [Google Scholar] [CrossRef]

- Dai, Y.; He, Y.; Yu, D.; Dai, J.; Wang, Y.; Bai, F. Study on the effect of semi-transparency on thermal insulation performance of silica aerogel composites. Case Stud. Therm. Eng. 2024, 54, 104010. [Google Scholar] [CrossRef]

- Feng, T.; Nie, Z.; Guo, X.; Yang, X.; Su, K.; Qi, S.; Cheng, B. Aramid nanofibrous aerogels and their phase-change composites for highly efficient thermal management. Compos. Commun. 2025, 54, 102271. [Google Scholar] [CrossRef]

- Venkataraman, M.; Mishra, R.; Subramaniam, V.; Gnanamani, A.; Kotresh, T.M.; Militky, J. Dynamic heat flux measurement for advanced insulation materials. Fibers Polym. 2016, 17, 925–931. [Google Scholar] [CrossRef]

- 5.3.4. Rosseland Radiation Model Theory. Available online: https://ansyshelp.ansys.com/public//Views/Secured/corp/v242/en/flu_th/flu_th_sec_mod_ross.html?utm_source=chatgpt.com (accessed on 21 May 2025).

- Dombrovsky, L.A. Diffusion Approximation in Multidimensional Radiative Transfer Problems; Thermopedia, Begel House Inc.: Danbury, CT, USA, 2011. [Google Scholar] [CrossRef]

- Zhao, S.; Dong, J.; Monte, C.; Sun, X.; Zhang, W. New phase function development and complete spectral radiative properties measurements of aerogel infused fibrous blanket based on simulated annealing algorithm. Int. J. Therm. Sci. 2020, 154, 106407. [Google Scholar] [CrossRef]

- Retailleau, F.; Allheily, V.; Merlat, L.; Henry, J.-F.; Randrianalisoa, J.H. Experimental characterization of radiative transfer in semi-transparent composite materials with rough boundaries. J. Quant. Spectrosc. Radiat. Transf. 2020, 256, 107300. [Google Scholar] [CrossRef]

- Huang, B.; Li, J.; Gong, L.; Dai, P.; Zhu, C. The Influence of Reinforced Fibers and Opacifiers on the Effective Thermal Conductivity of Silica Aerogels. Gels 2024, 10, 300. [Google Scholar] [CrossRef] [PubMed]

- Daoût, C.; Rozenbaum, O.; De Sousa Meneses, D.; Rochais, D. Identification of the spectral complex refractive indices of micrometric phases within a semi-transparent medium up to elevated temperatures. Int. J. Heat Mass Transf. 2024, 223, 125272. [Google Scholar] [CrossRef]

- Markevicius, G.; Ladj, R.; Niemeyer, P.; Budtova, T.; Rigacci, A. Ambient-dried thermal superinsulating monolithic silica-based aerogels with short cellulosic fibers. J. Mater. Sci. 2017, 52, 2210–2221. [Google Scholar] [CrossRef]

- Fan, W.; Zhang, X.; Zhang, Y.; Zhang, Y.; Liu, T. Lightweight, strong, and super-thermal insulating polyimide composite aerogels under high temperature. Compos. Sci. Technol. 2019, 173, 47–52. [Google Scholar] [CrossRef]

- Hou, X.; Mao, Y.; Zhang, R.; Fang, D. Super-flexible polyimide nanofiber cross-linked polyimide aerogel membranes for high efficient flexible thermal protection. Chem. Eng. J. 2021, 417, 129341. [Google Scholar] [CrossRef]

- Wang, C.; Bai, L.; Xu, H.; Qin, S.; Li, Y.; Zhang, G. A Review of High-Temperature Aerogels: Composition, Mechanisms, and Properties. Gels 2024, 10, 286. [Google Scholar] [CrossRef]

- Krasnovskih, M.P.; Maksimovich, N.G.; Vaisman, Y.I.; Ketov, A.A. Thermal stability of mineral-wool heat-insulating materials. Russ. J. Appl. Chem. 2014, 87, 1430–1434. [Google Scholar] [CrossRef]

- Zhou, T.; Cheng, X.; Pan, Y.; Li, C.; Gong, L.; Zhang, H. Mechanical performance and thermal stability of glass fiber reinforced silica aerogel composites based on co-precursor method by freeze drying. Appl. Surf. Sci. 2018, 437, 321–328. [Google Scholar] [CrossRef]

- Xia, C.; Hao, M.; Liu, W.; Zhang, X.; Miao, Y.; Ma, C.; Gao, F. Synthesis of Al2O3-SiO2 aerogel from water glass with high thermal stability and low thermal conductivity. J. Sol-Gel Sci. Technol. 2023, 106, 561–571. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Deng, Y.; Zhang, P. A Review of Research on the Effect of Temperature on the Properties of Polyurethane Foams. Polymers 2022, 14, 4586. [Google Scholar] [CrossRef]

- Lorenzati, A.; Fantucci, S.; Capozzoli, A.; Perino, M. The Effect of Temperature on Thermal Performance of Fumed Silica Based Vacuum Insulation Panels for Buildings. Energy Procedia 2017, 111, 490–499. [Google Scholar] [CrossRef]

- Kaushik, D.; Singh, H.; Tassou, S.A. Vacuum insulation panels for high-temperature applications—Design principles, challenges and pathways. Therm. Sci. Eng. Prog. 2024, 48, 102415. [Google Scholar] [CrossRef]

- Salosina, M.O.; Alifanov, O.M.; Nenarokomov, A.V. Designing Thermal Shield with Choice of Structure Parameters of Composite Based on Carbon Aerogel. J. Engin. Thermophys. 2024, 33, 722–733. [Google Scholar] [CrossRef]

- Zhao, J.-J.; Duan, Y.-Y.; Wang, X.-D.; Wang, B.-X. An analytical model for combined radiative and conductive heat transfer in fiber-loaded silica aerogels. J. Non-Cryst. Solids 2012, 358, 1303–1312. [Google Scholar] [CrossRef]

- Aerogel: From the Nanomaze to Global Thermal Management—How the Microporous Structure Reinvents the Laws of Heat Transfer. Available online: https://insulatewool.com/news/aerogel-from-the-nanomaze-to-global-thermal-management-how-the-microporous-structure-reinvents-the-laws-of-heat-transfer?utm_source=chatgpt.com (accessed on 27 May 2025).

- Arambakam, R.; Tafreshi, H.V.; Pourdeyhimi, B. Dual-scale 3-D approach for modeling radiative heat transfer in fibrous insulations. Int. J. Heat Mass Transf. 2013, 64, 1109–1117. [Google Scholar] [CrossRef]

- Venkataraman, M.; Mishra, R.; Militky, J.; Behera, B.K. Modelling and simulation of heat transfer by convection in aerogel treated nonwovens. J. Text. Inst. 2017, 108, 1442–1453. [Google Scholar] [CrossRef]

- Dent, R.W.; Skelton, J.; Donovan, J.G. Radiant Heat Transfer in Extremely Low Density Fibrous Assemblies. In Insulation Materials, Testing and Applications; ASTM International: West Conshohocken, PA, USA, 1990; pp. 79–105. [Google Scholar] [CrossRef]

- Li, X. Radiative Heat Transfer Through Fibrous Materials. Doctoral Thesis, University of Notre Dame, Notre Dame, IN, USA, 2007. [Google Scholar] [CrossRef]

- Yang, F.; Xie, W.; Meng, S. Effect of porous microstructure and fiber arrangement of thermal protection composites on effective thermal conductivity. Mech. Mater. 2024, 198, 105147. [Google Scholar] [CrossRef]

- Song, W.F.; Yu, W.D. Study on radiative heat transfer property of fiber assemblies using FTIR. J. Therm. Anal. Calorim. 2011, 103, 785–790. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, H.; Huang, K.; Cheng, Y.; Wang, K.; Cheng, S.; Li, W.; Jiang, J.; Li, J.; Tu, C.; et al. Dual-Emitter Graphene Glass Fiber Fabric for Radiant Heating. ACS Nano 2022, 16, 2577–2584. [Google Scholar] [CrossRef]

- Wang, F.; Cheng, L.; Zhang, Q.; Zhang, L. Effects of heat treatment and coatings on the infrared emissivity properties of carbon fibers. J. Mater. Res. 2014, 29, 1162–1167. [Google Scholar] [CrossRef]

- Yang, L.; He, X.; He, F. ITO coated quartz fibers for heat radiative applications. Mater. Lett. 2008, 62, 4539–4541. [Google Scholar] [CrossRef]

- Veiseh, S.; Hakkaki-Fard, A. Numerical Modeling of Combined Radiation and Conduction Heat Transfer in Mineral Wool Insulations. Heat Transf. Eng. 2009, 30, 477–486. [Google Scholar] [CrossRef]

- Kang, D.; Jia, S.; Zhao, C.; Ni, Y.; Qi, J.; Kang, Z.; Sui, Y.; Wei, F.; Xiao, B.; Meng, Q. High-temperature resistance performance of silica aerogel composites through fiber reinforcement. Ceram. Int. 2024, 50, 26829–26838. [Google Scholar] [CrossRef]

- Saleh, M.H.; Dhaef, A.H. Heat Transfer in Inclined Enclosure of Silica Aerogel/Glass Fiber Composite Material. Int. J. Comput. Appl. 2015, 117, 5–12. [Google Scholar]

- Liu, H.; Liu, J.; Tian, Y.; Wu, X.; Li, Z. Investigation of high temperature thermal insulation performance of fiber-reinforced silica aerogel composites. Int. J. Therm. Sci. 2023, 183, 107827. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, W.-Z.; Wang, X.; Li, Y.-M.; Tao, W.-Q. Thermal conductivity of fiber and opacifier loaded silica aerogel composite. Int. J. Heat Mass Transf. 2017, 115, 21–31. [Google Scholar] [CrossRef]

- Wu, Q.; Yang, L.; Chen, Z.; Yang, M.; Liu, T.; Li, M.; Mukhopadhyaya, P. SiO2 aerogel multiscale reinforced by glass fibers and SiC nanowhiskers for thermal insulation. J. Porous Mater. 2023, 30, 1587–1596. [Google Scholar] [CrossRef]

- Cherunova, I.; Kornev, N.; Jia, G.; Richter, K.; Plentz, J. Development of Infrared Reflective Textiles and Simulation of Their Effect in Cold-Protection Garments. Appl. Sci. 2023, 13, 4043. [Google Scholar] [CrossRef]

- Lee, K.H.; Arshad, Z.; Dahshan, A.; Alshareef, M.; Alsulami, Q.A.; Bibi, A.; Lee, E.-J.; Nawaz, M.; Zubair, U.; Javid, A. Porous Aerogel Structures as Promising Materials for Photocatalysis, Thermal Insulation Textiles, and Technical Applications: A Review. Catalysts 2023, 13, 1286. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; He, S.; Wang, M. Prediction of Thermal Conductivity of Fiber/Aerogel Composites for Optimal Thermal Insulation. JPM 2015, 18, 971–984. [Google Scholar] [CrossRef]

- Gurav, J.L.; Rao, A.V.; Rao, A.P.; Nadargi, D.Y.; Bhagat, S.D. Physical properties of sodium silicate based silica aerogels prepared by single step sol–gel process dried at ambient pressure. J. Alloys Compd. 2009, 476, 397–402. [Google Scholar] [CrossRef]

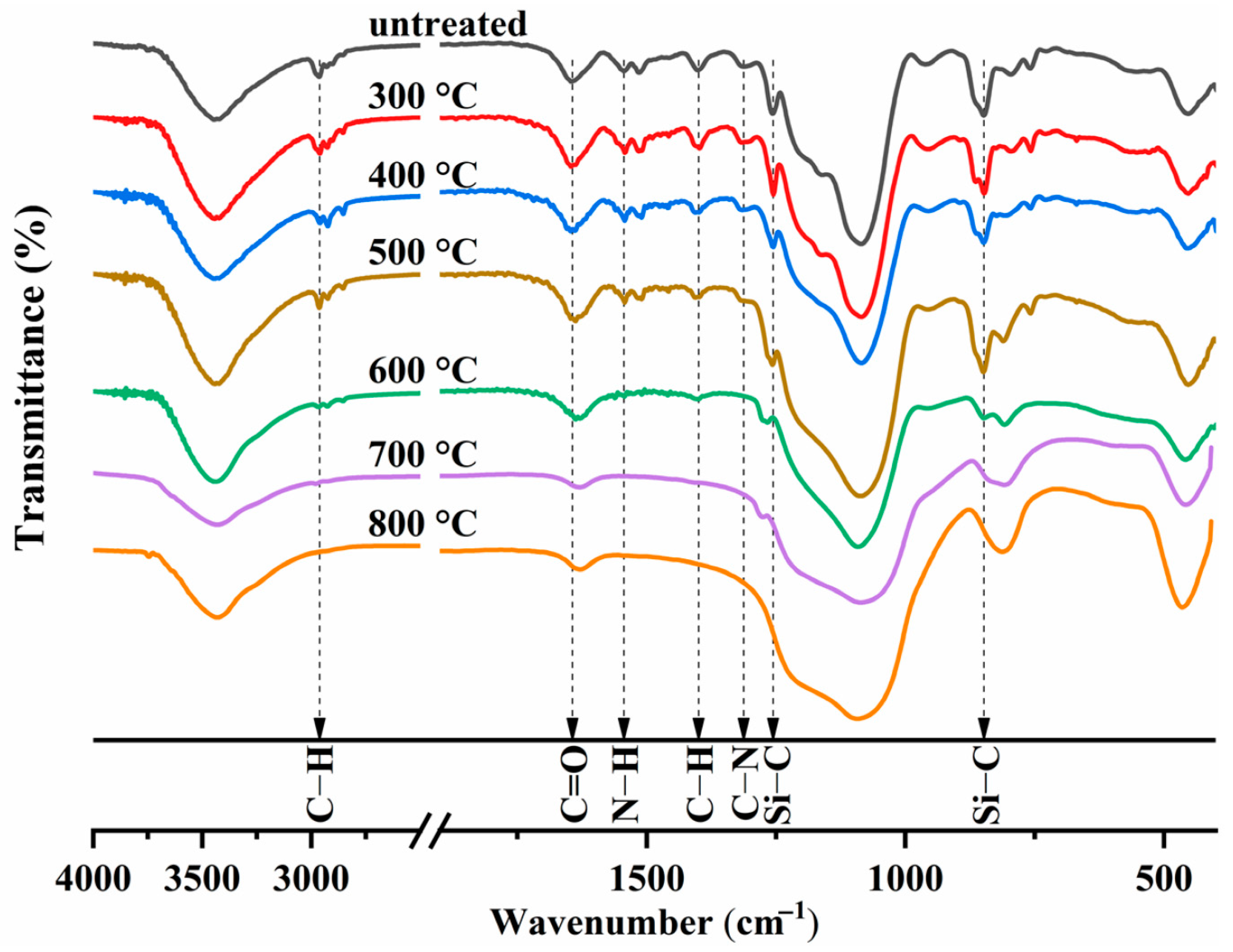

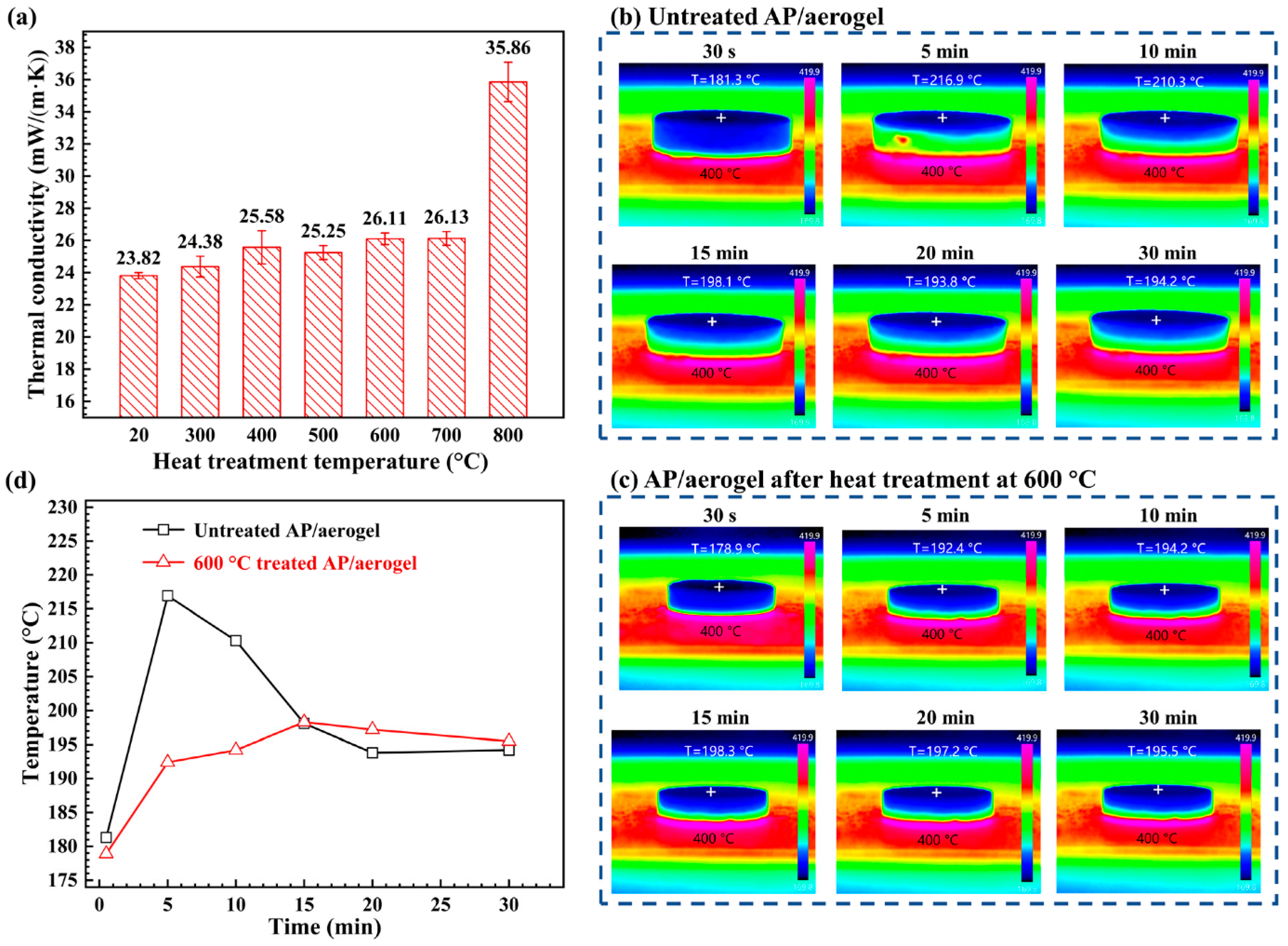

- Li, Z.; Wang, Y.; Wu, X.; Liu, Q.; Li, M.; Shi, L.; Cheng, X. Surface chemistry, skeleton structure and thermal safety of methylsilyl modified silica aerogels by heat treatment in an argon atmosphere. J. Non-Cryst. Solids 2023, 611, 122335. [Google Scholar] [CrossRef]

- Li, Z.; Shen, K.; Hu, M.; Shulga, Y.M.; Chen, Z.; Liu, Q.; Li, M.; Wu, X. Heat-Treated Aramid Pulp/Silica Aerogel Composites with Improved Thermal Stability and Thermal Insulation. Gels 2023, 9, 749. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Sozcu, S.; Frajova, J.; Wiener, J.; Venkataraman, M.; Tomkova, B.; Militky, J. Effect of Drying Methods on the Thermal and Mechanical Behavior of Bacterial Cellulose Aerogel. Gels 2024, 10, 474. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Yang, H.; Li, Y.; Zheng, X. Robust Silk Fibroin/Graphene Oxide Aerogel Fiber for Radiative Heating Textiles. ACS Appl. Mater. Interfaces 2020, 12, 15726–15736. [Google Scholar] [CrossRef]

- Sun, X.; Tang, H.; Yuan, G. Anomalous diffraction approximation method for retrieval of spherical and spheroidal particle size distributions in total light scattering. J. Quant. Spectrosc. Radiat. Transf. 2008, 109, 89–106. [Google Scholar] [CrossRef]

- Zhang, B.-M.; Zhao, S.-Y.; He, X.-D. Experimental and theoretical studies on high-temperature thermal properties of fibrous insulation. J. Quant. Spectrosc. Radiat. Transf. 2008, 109, 1309–1324. [Google Scholar] [CrossRef]

- Lind, A.C.; Greenberg, J.M. Electromagnetic Scattering by Obliquely Oriented Cylinders. J. Appl. Phys. 1966, 37, 3195–3203. [Google Scholar] [CrossRef]

- Han, M.; Hao, M.; Li, Z.; Jian, S.; Ma, C.; Miao, Y. Ultra-light, flame-retardant nano-TiO2 coated silica-zirconia ceramic fiber aerogel for thermal insulation. J. Porous Mater. 2025, 1–13. [Google Scholar] [CrossRef]

- Hoseini, A.; McCague, C.; Andisheh-Tadbir, M.; Bahrami, M. Aerogel blankets: From mathematical modeling to material characterization and experimental analysis. Int. J. Heat Mass Transf. 2016, 93, 1124–1131. [Google Scholar] [CrossRef]

- Ablaoui, E.M.; Malendowski, M.; Szymkuc, W.; Pozorski, Z. Determination of Thermal Properties of Mineral Wool Required for the Safety Analysis of Sandwich Panels Subjected to Fire Loads. Materials 2023, 16, 5852. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, M.K.; Eastes, W. Effective thermal conductivity of fiberglass insulation. Int. J. Appl. Glass Sci. 2024, 15, 307–316. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, W.-Z.; Li, Y.-M.; Tao, W.-Q. Experimental study of the thermal conductivity of polyurethane foams. Appl. Therm. Eng. 2017, 115, 528–538. [Google Scholar] [CrossRef]

- Li, X.; Peng, C.; Liu, L. Experimental study of the thermal performance of a building wall with vacuum insulation panels and extruded polystyrene foams. Appl. Therm. Eng. 2020, 180, 115801. [Google Scholar] [CrossRef]

- Meliță, L.; Croitoru, C. Aerogel, a high performance material for thermal insulation—A brief overview of the building applications. E3S Web Conf. 2019, 111, 06069. [Google Scholar] [CrossRef]

- Jelle, B.P.; Baetens, R.; Gustavsen, A. Aerogel Insulation for Building Applications. In The Sol-Gel Handbook; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; pp. 1385–1412. [Google Scholar] [CrossRef]

- Nannan, Z.; Chinese Academy of Sciences. Advanced Aerogel Composite Developed for Extreme Thermal Environments. Available online: https://phys.org/news/2025-04-advanced-aerogel-composite-extreme-thermal.html (accessed on 8 June 2025).

- Shang, L.; Lyu, Y.; Han, W. Microstructure and Thermal Insulation Property of Silica Composite Aerogel. Materials 2019, 12, 993. [Google Scholar] [CrossRef]

- Liu, R.; Dong, X.; Xie, S.; Jia, T.; Xue, Y.; Liu, J.; Jing, W.; Guo, A. Ultralight, thermal insulating, and high-temperature-resistant mullite-based nanofibrous aerogels. Chem. Eng. J. 2019, 360, 464–472. [Google Scholar] [CrossRef]

- Nocentini, K.; Ibrahim, M.; Biwole, P.H.; Achard, P. Multi-scale thermal, energetic and economic analysis of composite insulating materials made of silica aerogel in a fibrous inorganic mat. Energy Build. 2022, 272, 112365. [Google Scholar] [CrossRef]

- Lakatos, Á.; Trník, A. Thermal Diffusion in Fibrous Aerogel Blankets. Energies 2020, 13, 823. [Google Scholar] [CrossRef]

- Kovács, Z.; Csík, A.; Lakatos, Á. Thermal stability investigations of different aerogel insulation materials at elevated temperature. Therm. Sci. Eng. Prog. 2023, 42, 101906. [Google Scholar] [CrossRef]

- Yue, J.; Qin, M.; Yu, H.; He, Q.; Feng, W. Superelastic Graphene-Based Composite Aerogel for Thermal and Electromagnetic Protection in Extreme Temperature Environments. Adv. Funct. Mater. 2025, 2508319. [Google Scholar] [CrossRef]

- Yu, D.; Xue, T.; Ma, Z.; Hu, Z.; Long, L.; Miao, Y.-E.; Fan, W.; Liu, T. 3D Printed Polyimide/Silica Composite Aerogels for Customizable Thermal Insulation from −50 °C to 1300 °C. Chin. J. Polym. Sci. 2024, 42, 936–945. [Google Scholar] [CrossRef]

- Zhao, G.; Shi, L.; Yang, G.; Zhuang, X.; Cheng, B. 3D fibrous aerogels from 1D polymer nanofibers for energy and environmental applications. J. Mater. Chem. A 2023, 11, 512–547. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, C.; Han, X.; Li, S.; Wang, Z.; Huang, J.; Liu, H.; Chen, Z. Fabrication of aerogel scaffolds with adjustable macro/micro-pore structure through 3D printing and sacrificial template method for tissue engineering. Mater. Des. 2022, 217, 110662. [Google Scholar] [CrossRef]

- Liu, C.; Wang, S.; Wang, N.; Yu, J.; Liu, Y.-T.; Ding, B. From 1D Nanofibers to 3D Nanofibrous Aerogels: A Marvellous Evolution of Electrospun SiO2 Nanofibers for Emerging Applications. Nano-Micro Lett. 2022, 14, 194. [Google Scholar] [CrossRef]

- Si, Q.L.; Tang, G.H.; Yang, M.Y.; Yang, R.; Hu, Y.; Du, M.; Zhang, H. Ambient-dried hydrophobic silica aerogels for both enhanced transparency and thermal insulation. Ceram. Int. 2024, 50, 48680–48691. [Google Scholar] [CrossRef]

- Ren, S. Scalable and Cost-Effective Roll-to-Roll Additive Manufacturing of Highly Durable and Thermal Insulating Silica-Carbon Aerogel; Final Report; State University of New York SUNY: Buffalo, NY, USA, 2023. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, F.; Wang, Z.; Ma, P.; Dong, W.; Hou, H.; Fan, W.; Liu, T. Mechanically strong and thermally insulating polyimide aerogels by homogeneity reinforcement of electrospun nanofibers. Compos. Part B Eng. 2020, 182, 107624. [Google Scholar] [CrossRef]

- Yang, M.; Lixia, Y.; Chen, Z.; Qiong, W.; Wang, Y.; Liu, T.; Li, M. Flexible Electrospun strawberry-like structure SiO2 aerogel nanofibers for thermal insulation. Ceram. Int. 2023, 49, 9165–9172. [Google Scholar] [CrossRef]

- He, Y.; Wu, S.; Yuen, A.C.Y.; Huang, F.; Boyer, C.; Wang, C.H.; Zhang, J. Scalable Manufacturing Process and Multifunctional Performance of Cotton Fibre-Reinforced Poly(Lactic Acid) (PLA) Bio-Composites Coated by Graphene Oxide. Polymers 2022, 14, 3946. [Google Scholar] [CrossRef]

- Lu, L.; Wang, H.; Yun, S.; Hu, J.; Wang, M. A state-of-the-art review of novel aerogel insulation materials for building exterior walls. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 16231–16252. [Google Scholar] [CrossRef]

- Illera, D.; Mesa, J.; Gomez, H.; Maury, H. Cellulose Aerogels for Thermal Insulation in Buildings: Trends and Challenges. Coatings 2018, 8, 345. [Google Scholar] [CrossRef]

- Koh, C.H.; Schollbach, K.; Gauvin, F.; Brouwers, H.J.H. Aerogel composite for cavity wall rehabilitation in the Netherlands: Material characterization and thermal comfort assessment. Build. Environ. 2022, 224, 109535. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Y.; Liu, J. Optimization of the thermal conductivity test for building insulation materials under multifactor impact. Constr. Build. Mater. 2022, 332, 127380. [Google Scholar] [CrossRef]

- Sambucci, M.; Savoni, F.; Valente, M. Aerogel Technology for Thermal Insulation of Cryogenic Tanks—Numerical Analysis for Comparison with Traditional Insulating Materials. Gels 2023, 9, 307. [Google Scholar] [CrossRef]

- Park, M. Recent Advances in Wearable Thermal Devices for Virtual and Augmented Reality. Micromachines 2025, 16, 383. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Yu, X.; Gao, M.; Xu, C.; Zhang, J.; Zhang, X.; Zhu, M.; Cheng, Y. Renewable biomass-based aerogels: From structural design to functional regulation. Chem. Soc. Rev. 2024, 53, 7489–7530. [Google Scholar] [CrossRef]

- Pyrogel, X.T.E. Aspen Aerogels. Available online: https://www.aerogel.com/product/pyrogel-xte/ (accessed on 28 June 2025).

- High Performance Thermal Insulation—Thermablok Aerogel, Thermablok–Intelligent Insulation—High Performance Thermal Insulation. Available online: https://www.thermablok.co.uk/ (accessed on 28 June 2025).

- Aerogel Technologies, LLC|Classic Aerogel Products. Available online: https://www.aerogeltechnologies.com/classic-aerogels/classic-aerogel-products/ (accessed on 28 June 2025).

- Trifu, R.; Begag, R.; Gould, G.; White, S. Aerogel Composites Having Thermal Storage Capacity. U.S. Patent 11130895B2, 28 September 2021. Available online: https://patents.google.com/patent/US11130895B2/en?q=(US+Patent+Aerogel+Composites+Enhanced+Thermal+Stability)&oq=US+Patent+Aerogel+Composites+with+Enhanced+Thermal+Stability (accessed on 28 June 2025).

- Ristic-Lehmann, C.; Farnworth, B.; Dutta, A. Aerogel/PTFE Composite Insulating Material. U.S. Patent 7226969B2, 5 June 2007. Available online: https://patents.google.com/patent/US7226969B2/en (accessed on 28 June 2025).

- Liao, Y.; Wu, H.; Ding, Y.; Yin, S.; Wang, M.; Cao, A. Engineering thermal and mechanical properties of flexible fiber-reinforced aerogel composites. J. Sol-Gel Sci. Technol. 2012, 63, 445–456. [Google Scholar] [CrossRef]

- Song, Z.; Lei, Y.; Ran, W.; Yuan, M.; Shang, S.; Cui, S. Structural properties and barrier performance of low-cost aerogel composites for building insulation. J. Build. Eng. 2024, 90, 109485. [Google Scholar] [CrossRef]

- Wang, H.; Huang, Y.; Liu, S.; Gao, Y.; Cheng, X.; Meng, C. A review of silica fiber-based aerogels: Composition, construction methods, mechanical enhancement strategies and applications. Eur. Polym. J. 2024, 220, 113367. [Google Scholar] [CrossRef]

- Wu, Q.; Yang, M.; Chen, Z.; Lu, L.; Ma, Z.; Ding, Y.; Yin, L.; Liu, T.; Li, M.; Yang, L.; et al. A layered aerogel composite with silica fibers, SiC nanowires, and silica aerogels ternary networks for thermal insulation at high-temperature. J. Mater. Sci. Technol. 2025, 204, 71–80. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, W.; Huang, H.; Li, W.; Ling, H.; Zhang, H. A Review of High-Temperature Resistant Silica Aerogels: Structural Evolution and Thermal Stability Optimization. Gels 2025, 11, 357. [Google Scholar] [CrossRef]

- Huang, W.; Yang, Y.; Gu, H.; Yu, W.; Shao, G. A core–shell carbon–ceramic fibrous aerogel derived from aramid-polysilsesquioxane for broadband electromagnetic wave absorption. J. Mater. Chem. C 2025, 13, 10658–10670. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y.; Li, J. Sustainable 3D Printing Aerogel Materials and Application: A Review. IFFTI Annu. Proc. 2024, 3, 306–312. [Google Scholar]

- Chen, Y.; Shafiq, M.; Liu, M.; Morsi, Y.; Mo, X. Advanced fabrication for electrospun three-dimensional nanofiber aerogels and scaffolds. Bioact. Mater. 2020, 5, 963–979. [Google Scholar] [CrossRef] [PubMed]

- RMishra; Behera, B.K.; Muller, M.; Petru, M. Finite element modeling based thermodynamic simulation of aerogel embedded nonwoven thermal insulation material. Int. J. Therm. Sci. 2021, 164, 106898. [Google Scholar] [CrossRef]

- Wang, M. A Multiscale Method Across Three Length Scales for Progressive Damage Analysis of Plain Woven Composites. Appl Compos. Mater. 2021, 28, 1919–1944. [Google Scholar] [CrossRef]

- Karaaslan, M.A.; Kadla, J.F.; Ko, F.K. 5-Lignin-Based Aerogels. In Lignin in Polymer Composites; Faruk, O., Sain, M., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 67–93. [Google Scholar] [CrossRef]

- Zhang, R.; Gu, H.; Hou, X.; Zhou, P. High-temperature resistant Y2SiO5–TiO2 aerogel composite for efficient thermal insulation. J. Porous Mater. 2021, 28, 57–64. [Google Scholar] [CrossRef]

- Li, L.; Lyu, J.; Cheng, Q.; Fu, C.; Zhang, X. Versatile Recyclable Kevlar Nanofibrous Aerogels Enabled by Destabilizing Dynamic Balance Strategy. Adv. Fiber Mater. 2023, 5, 1050–1062. [Google Scholar] [CrossRef]

- García-González, C.A.; Blanco-Vales, M.; Barros, J.; Boccia, A.C.; Budtova, T.; Durães, L.; Erkey, C.; Gallo, M.; Herman, P.; Kalmár, J.; et al. Review and Perspectives on the Sustainability of Organic Aerogels. ACS Sustain. Chem. Eng. 2025, 13, 6469–6492. [Google Scholar] [CrossRef] [PubMed]

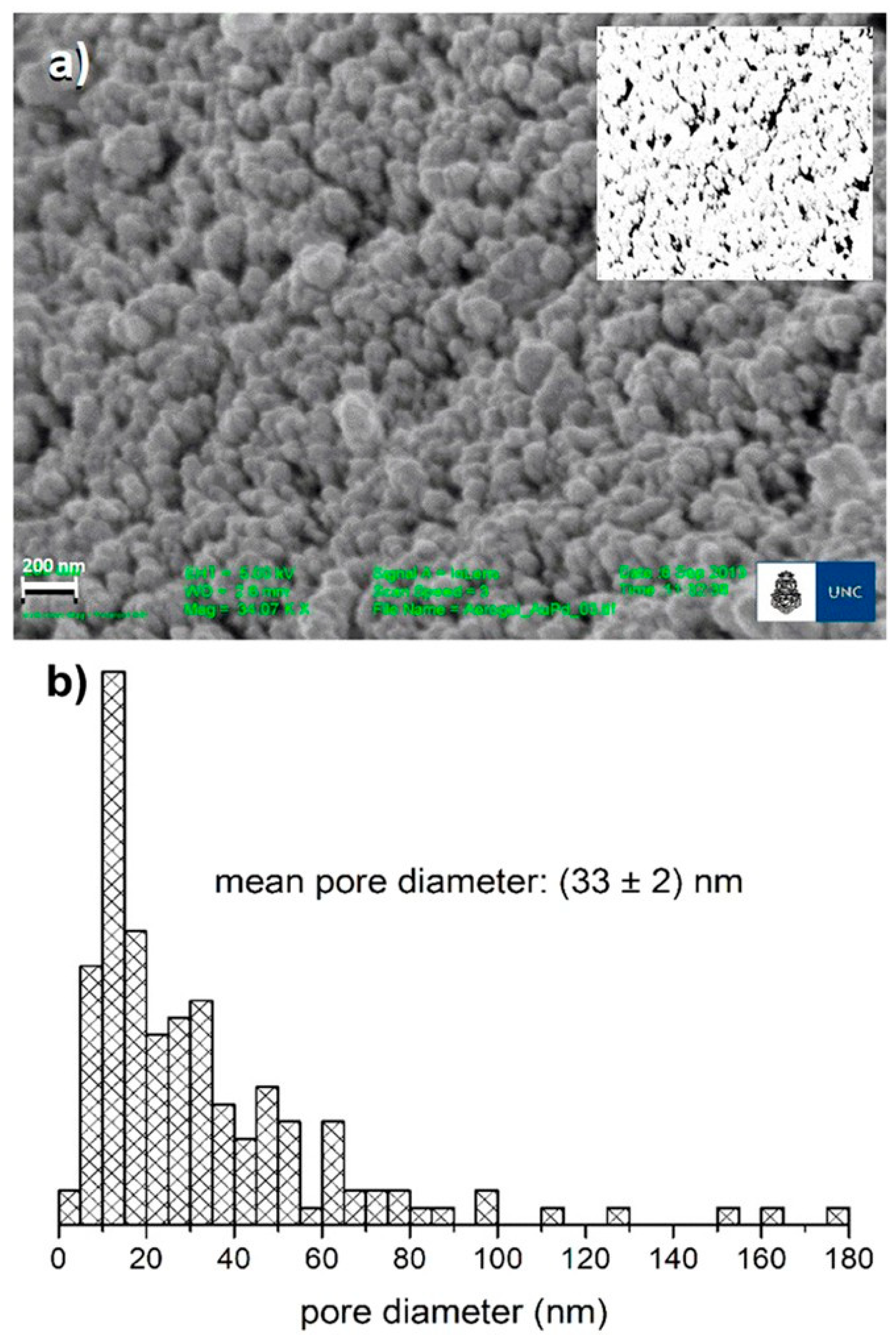

- An, L.; Wang, J.; Petit, D.; Armstrong, J.N.; Li, C.; Hu, Y.; Huang, Y.; Shao, Z.; Ren, S. A scalable crosslinked fiberglass-aerogel thermal insulation composite. Appl. Mater. Today 2020, 21, 100843. [Google Scholar] [CrossRef]

- Maleki, H.; Durães, L.; Portugal, A. Synthesis of lightweight polymer-reinforced silica aerogels with improved mechanical and thermal insulation properties for space applications. Microporous Mesoporous Mater. 2014, 197, 116–129. [Google Scholar] [CrossRef]

| Material Type | Structure | Typical Temperature Range | Key Properties | References |

|---|---|---|---|---|

| Fibrous-Aerogel Composites | A network of fibers implanted in an aerogel matrix | Up to 1200–1500 °C | Lightweight, flexible, extremely low heat conductivity, and strong mechanical properties at high temperatures | [17,79] |

| Polyimide Aerogels | Network of polyimide polymers | Up to 1000 °C | Excellent mechanical qualities, low density, and high thermal stability | [80,81,82] |

| Zirconia Aerogels | Zirconia-based aerogel structure | Up to 1300 °C | Low heat conductivity and outstanding thermal resistance | [82] |

| Silica Aerogels | Silica-based aerogel network | Up to 1500 °C | High porosity, extremely low heat conductivity, and brittle nature | |

| Alumina Aerogels | Alumina-based aerogel structure | Up to 1800 °C | Low heat conductivity, high thermal stability, and adaptability to harsh environments | |

| Carbon Aerogels | Carbon-based aerogel network | Up to 2500 °C | Superior mechanical strength, low heat conductivity, and exceptional heat resistance | [82] |

| Mineral Wool | Fibrous mineral-based structure | Up to 1000–1650 °C | Cost-effective, fire-resistant, and with good thermal insulation | [83] |

| Fiberglass | Glass fiber network | Up to 230–260 °C | Cost-effective, lightweight, and well-insulated from heat | [84,85] |

| Polyurethane Foam | Polymer foam structure | Up to 120 °C | Flexibility, low heat conductivity, and light weight | [86] |

| Panels for Vacuum Insulation | Core material in vacuum-sealed envelope | Up to 120 °C | High insulation performance, extremely low heat conductivity, and fragility | [87,88] |

| Material Type | Thermal Conductivity (W/m·K) | Radiative Heat Transfer Characteristics | Reference |

|---|---|---|---|

| Fiber–Aerogel Composites | ~0.02–0.03 | Infrared opacifiers and high porosity reduce radiative heat transmission, making them useful in hot conditions. | [47] |

| Mineral Wool | ~0.035–0.045 | Performance may suffer at high temperatures due to moderate radiative heat transfer. | [121] |

| Fiberglass | ~0.035–0.045 | Like mineral wool, it is frequently used for insulation in buildings. | [122] |

| Polyurethane Foam | ~0.022–0.030 | At high temperatures, radiative heat transfer can be substantial despite lower thermal conductivity. | [123] |

| Vacuum Insulation Panels (VIPs) | ~0.004–0.007 | Very low thermal conductivity; great thermal insulation, yet fragile and expensive. | [124] |

| Category | Key Findings | Methods and Techniques | Challenges | Future Research Directions | References |

|---|---|---|---|---|---|

| Radiative Heat Transfer Mechanisms | - Radiative heat transfer varies between optically thick and thin aerogels. - Diffusive radiative heat transfer is a property in optically thick aerogels, but nonlocal in thin, semitransparent ones. | - Fourier transform infrared (FTIR) spectroscopy for measuring absorption. - Numerical modeling for predicting radiative heat transfer. | - Variability in experimental setups leads to challenges in accurate measurement of thermal conductivity. - Complex behavior of radiative transfer in nonlocal, thin aerogels. | - Develop standardized measurement techniques for low thermal conductivity values. - Advanced computational models to predict radiative heat transfer behavior. | [32,33,125,126] |

| Fiber–Aerogel Composite Materials | - Fibrous materials enhance mechanical properties without significantly compromising thermal insulation performance. - Integration of infrared opacifiers (SiC, TiO2, carbon) reduces radiative heat transfer. | - Composite preparation techniques involve incorporating fibers like glass, carbon, and natural fibers into aerogels. - Infrared opacifiers enhance thermal insulation. | - Need for optimization of the aerogel–fiber ratio to balance thermal and mechanical properties. - Difficulty in processing high-temperature-resistant composites. | - Synthesis of new aerogel types with improved properties. - Explore new opacifiers for improved radiative heat transfer suppression. | [108,127,128] |

| Experimental Methods | - FTIR spectroscopy effectively measures absorption coefficients. - Numerical simulations can predict radiative heat transfer in complex composites. | - Use of FTIR to measure absorption properties. - Numerical simulations (e.g., Monte Carlo methods, Rayleigh scattering models) for radiative heat transfer. | - Experimental setups and results may vary, leading to inconsistencies. - High uncertainty in predicting behavior of composites under extreme conditions. | - Refining numerical models to handle various composite structures and conditions. - Enhance experimental methods for accurate heat transfer data at extreme temperatures. | [6,45,129,130,131] |

| High-Temperature Applications | - Fiber–aerogel composites are viable for high-temperature insulation (e.g., aerospace, energy-efficient buildings). - Aerogels can provide low thermal conductivity even in extreme environments. | - Experimentation under high-temperature conditions for insulation performance. - Thermo-gravimetric analysis (TGA) to assess stability. | - Maintaining low thermal conductivity at high temperatures. - Ensuring long-term stability of aerogels in demanding applications. | - Focus on aerospace and thermal management systems. - Exploration of new opacifiers and fiber materials for high-temperature applications. | [30,104,132,133] |

| Future Directions and Innovations | - Continued development of sustainable materials for aerogel composites. - New techniques in 3D printing and nanotechnology are expected to improve manufacturing | - 3D printing of aerogel composites. - Integration of nanotechnology to enhance aerogel properties. | - High production costs and complex processing techniques. - Development of scalable, reproducible aerogels for mass production. | - Innovation in synthesis techniques and advanced materials. - Improve manufacturing processes for large-scale production and cost reduction. | [134,135,136,137] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venkataraman, M.; Sözcü, S.; Militký, J. Radiative Heat Transfer Properties of Fiber–Aerogel Composites for Thermal Insulation. Gels 2025, 11, 538. https://doi.org/10.3390/gels11070538

Venkataraman M, Sözcü S, Militký J. Radiative Heat Transfer Properties of Fiber–Aerogel Composites for Thermal Insulation. Gels. 2025; 11(7):538. https://doi.org/10.3390/gels11070538

Chicago/Turabian StyleVenkataraman, Mohanapriya, Sebnem Sözcü, and Jiří Militký. 2025. "Radiative Heat Transfer Properties of Fiber–Aerogel Composites for Thermal Insulation" Gels 11, no. 7: 538. https://doi.org/10.3390/gels11070538

APA StyleVenkataraman, M., Sözcü, S., & Militký, J. (2025). Radiative Heat Transfer Properties of Fiber–Aerogel Composites for Thermal Insulation. Gels, 11(7), 538. https://doi.org/10.3390/gels11070538