New Trends in Preparation and Use of Hydrogels for Water Treatment

Abstract

1. Introduction

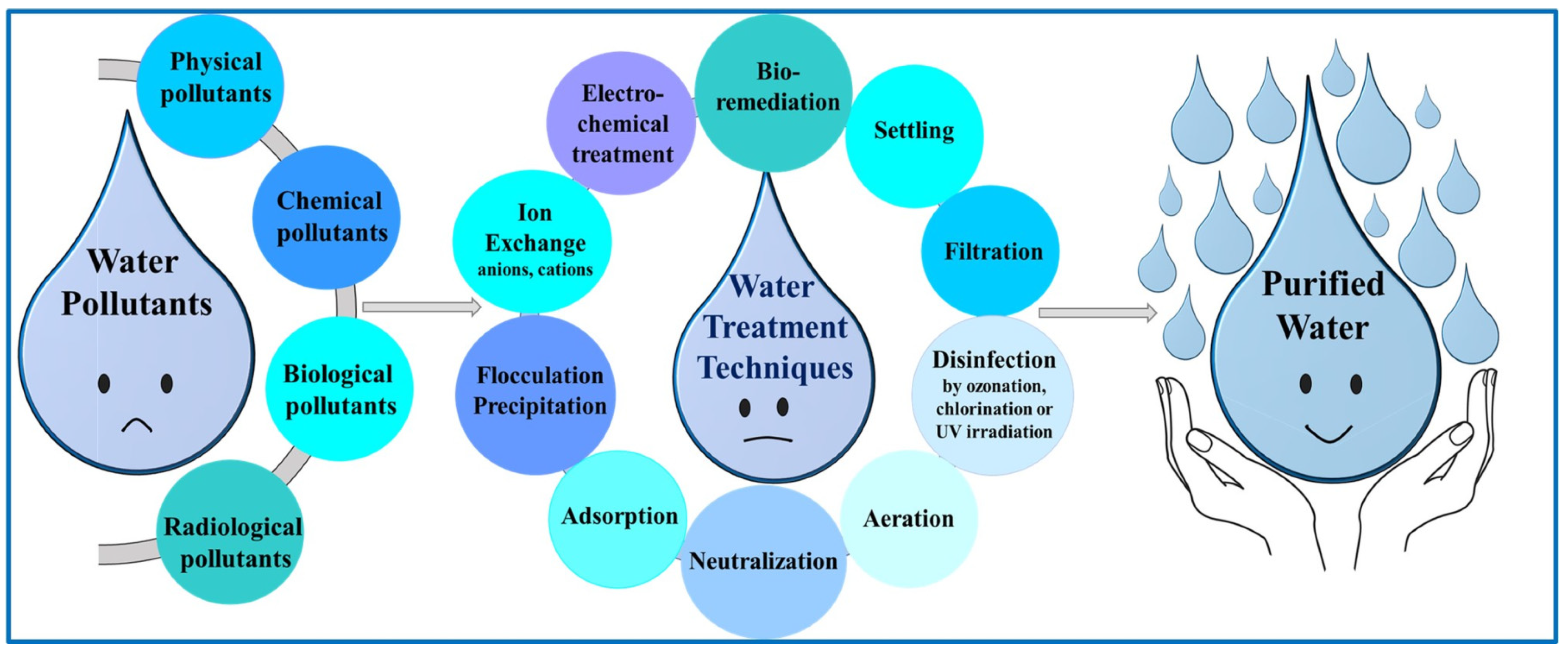

1.1. Water Pollution

1.2. Water Pollutants

1.3. Water Treatments

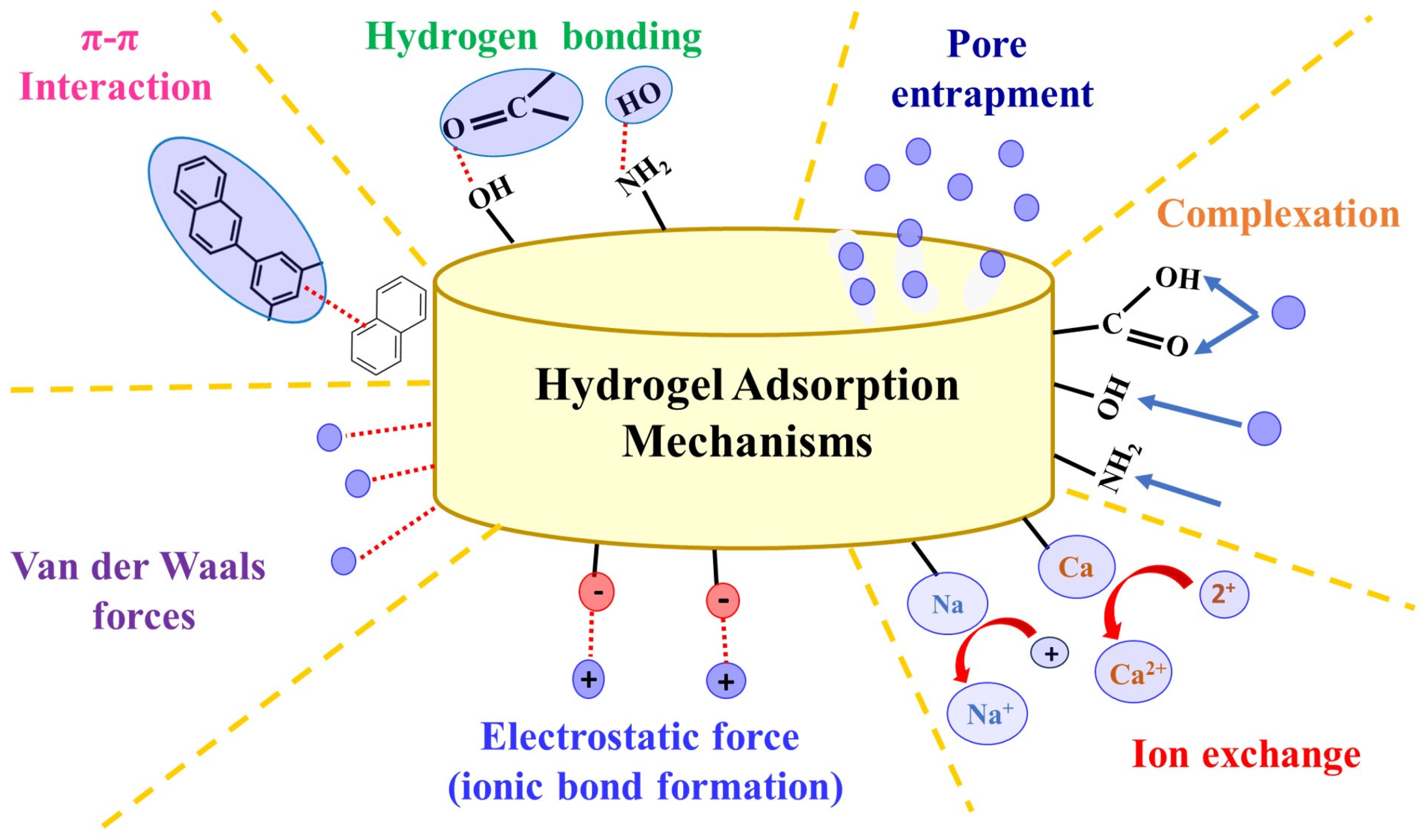

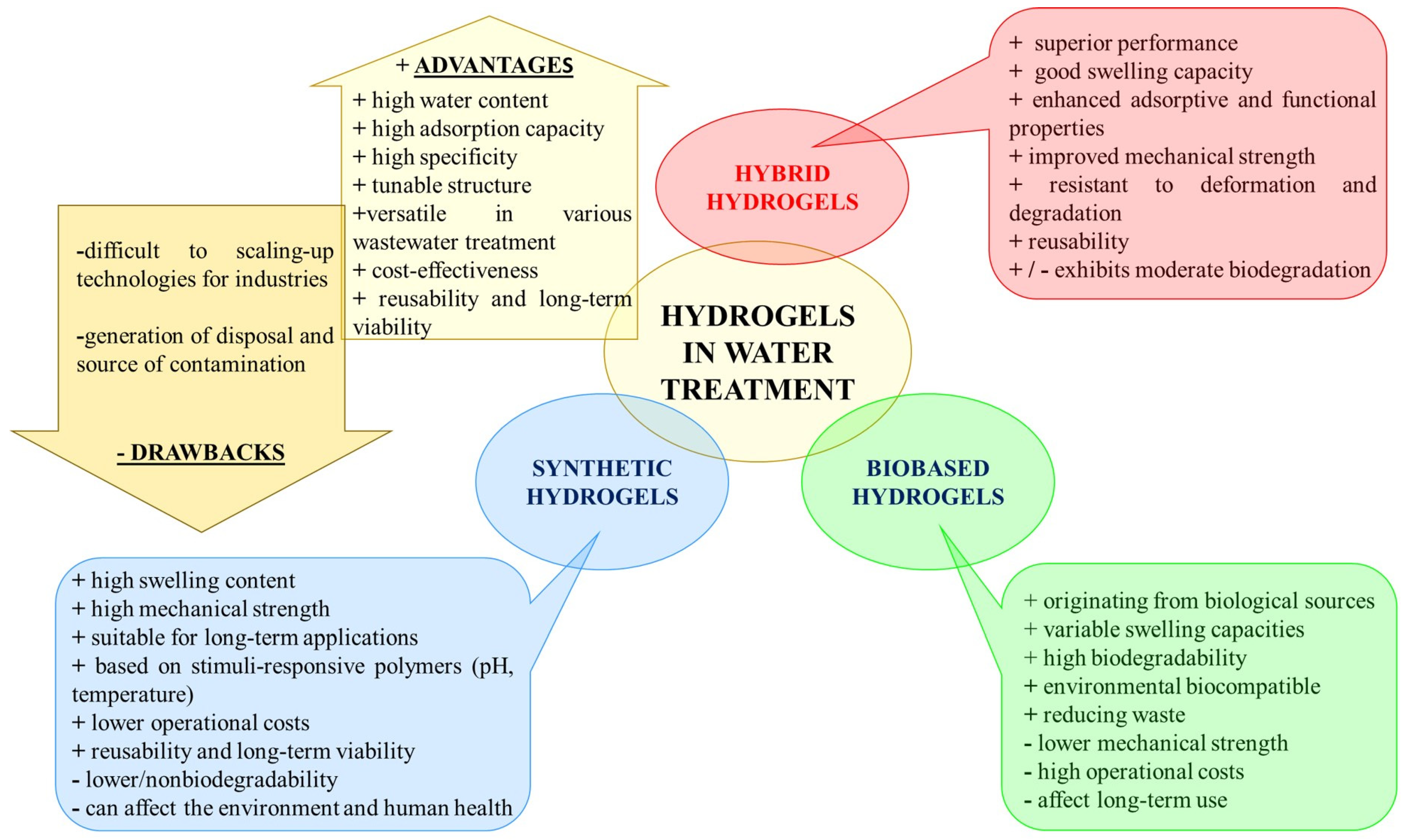

1.4. Hydrogels in Water Treatment

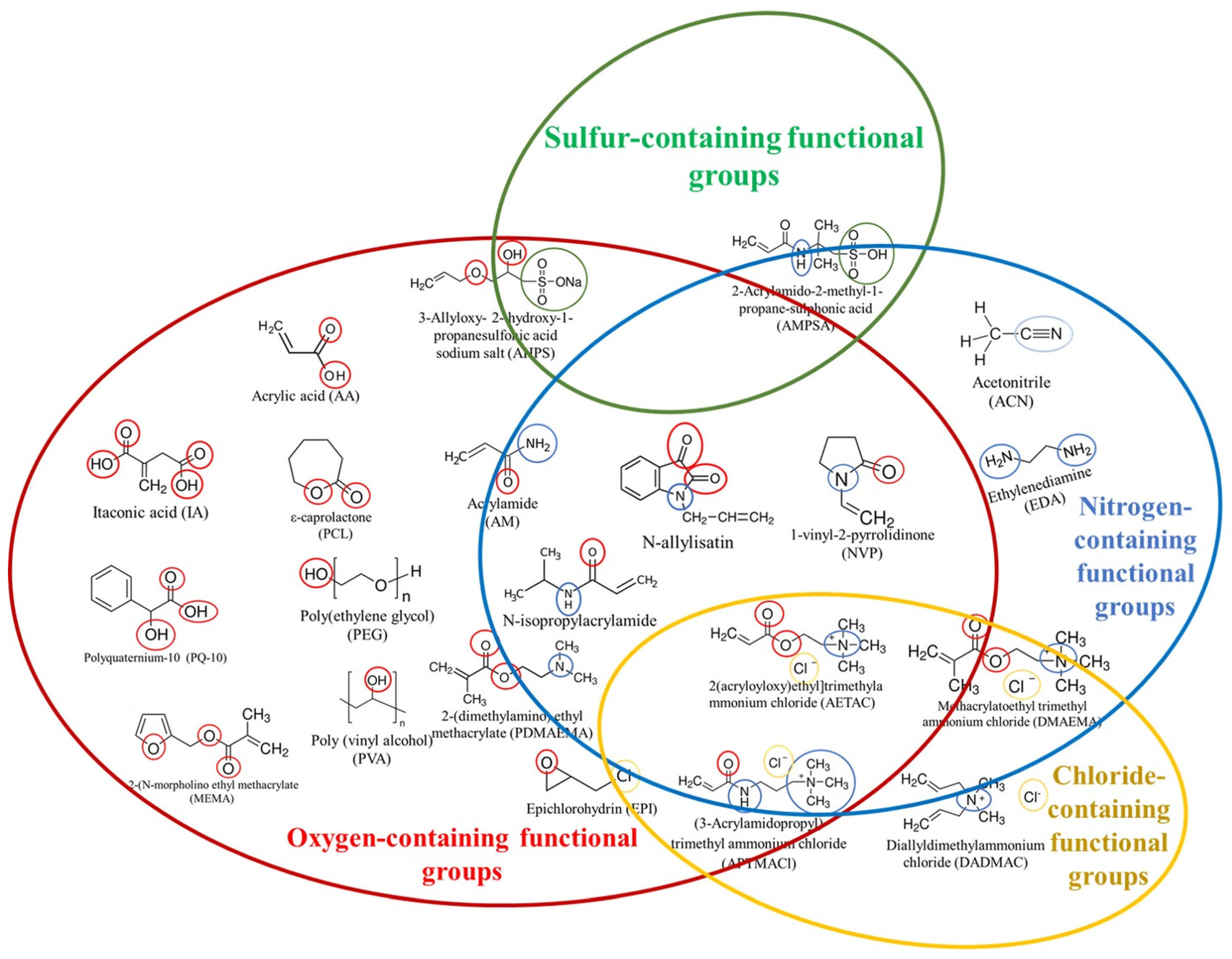

2. Synthetic Polymer-Based Hydrogels for Water Treatments

2.1. Retention of Organic Dyes Using Synthetic Polymer-Based Hydrogels

2.1.1. Polyacrylate Hydrogels and Their Polymer Blends for Efficient Organic Dye Retention

2.1.2. Sulfonic Acid Hydrogels Based on Synthetic Polymers for Efficient Organic Dye Retention

2.1.3. Quaternary Ammonium Hydrogels for Efficient Organic Dye Retention

2.1.4. Nanocomposite Hydrogels Based on Synthetic Polymers for Efficient Organic Dye Retention

2.2. Synthetic Polymer-Based Hydrogels for Heavy Metals Retention

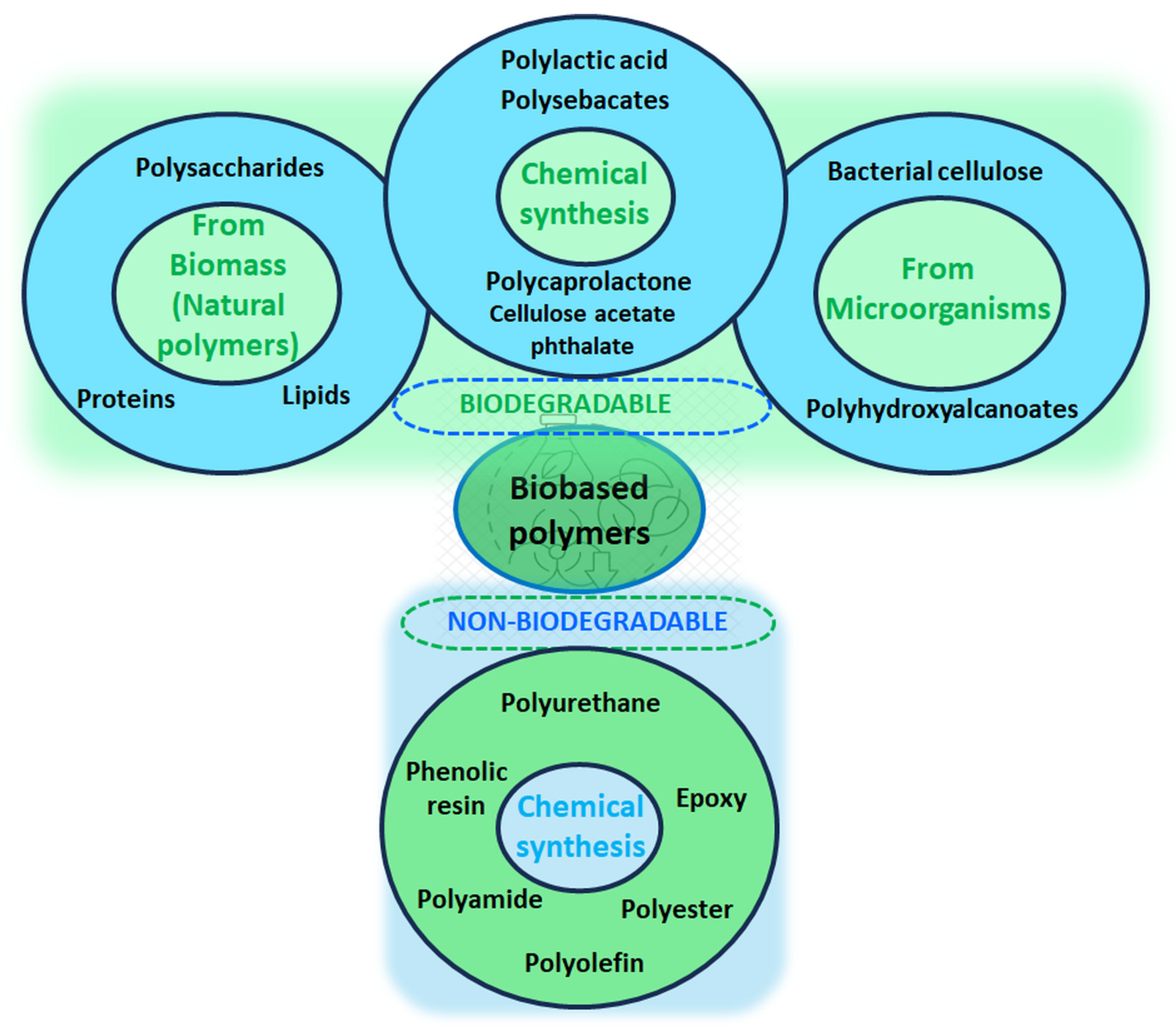

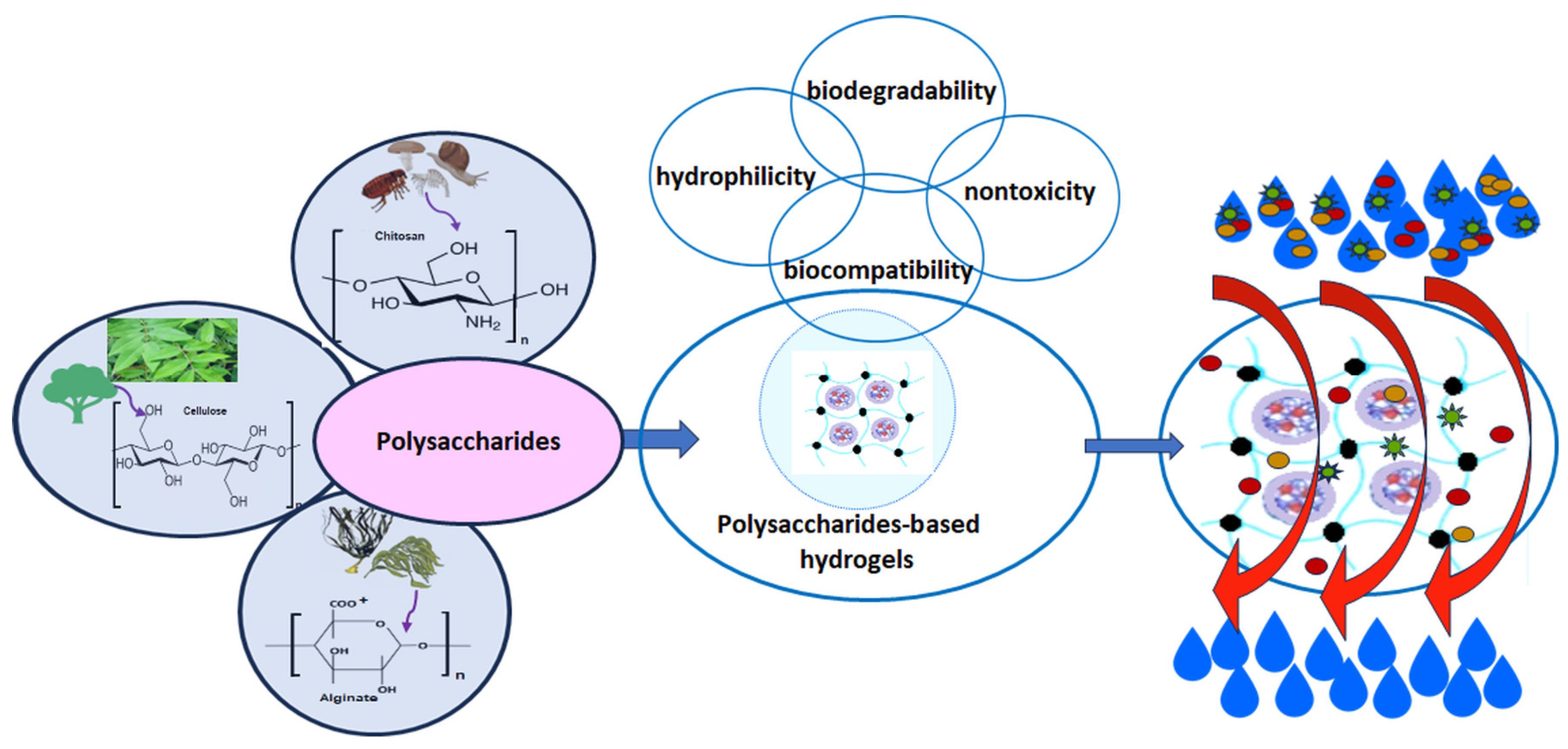

3. Bio-Based Hydrogels Engineered to Capture Water Pollutants

3.1. Polysaccharides-Based Hydrogels for Heavy Metals’ Retention

3.1.1. Cellulose-Based Hydrogels for Heavy Metals’ Retention

3.1.2. Chitosan-Based Hydrogels for Heavy Metals’ Retention

3.1.3. Alginate-Based Hydrogels for Heavy Metals’ Retention

3.2. Polysaccharides-Based Hydrogels for Dyes’ Removal

3.2.1. Cellulose-Based Hydrogels for Dyes’ Removal

3.2.2. Chitosan-Based Hydrogels for Dyes’ Removal

3.2.3. Alginate-Based Hydrogels for Dyes’ Removal

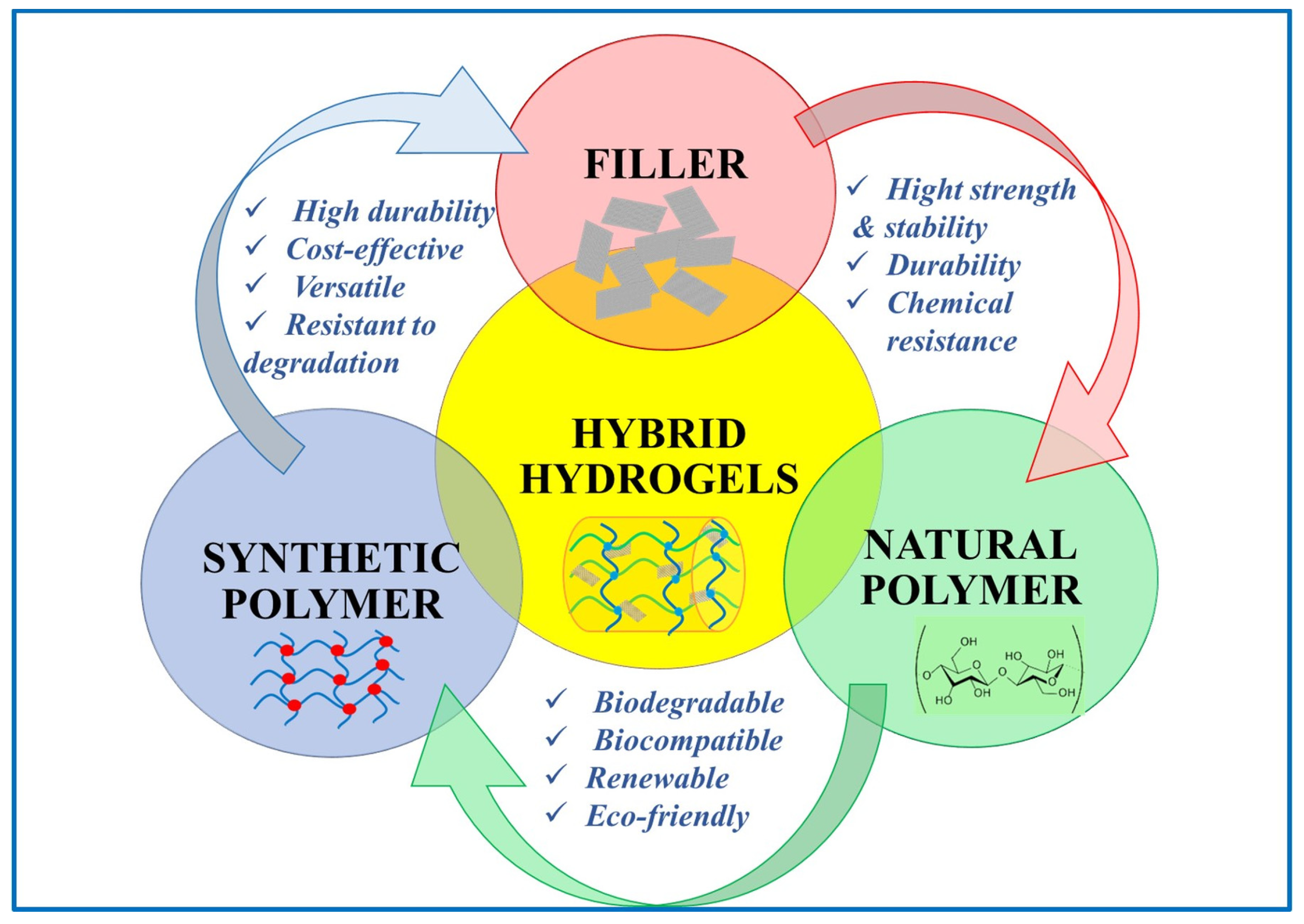

4. Hybrid Hydrogels for Water Treatment

4.1. Hybrid Hydrogels for Dye Removal

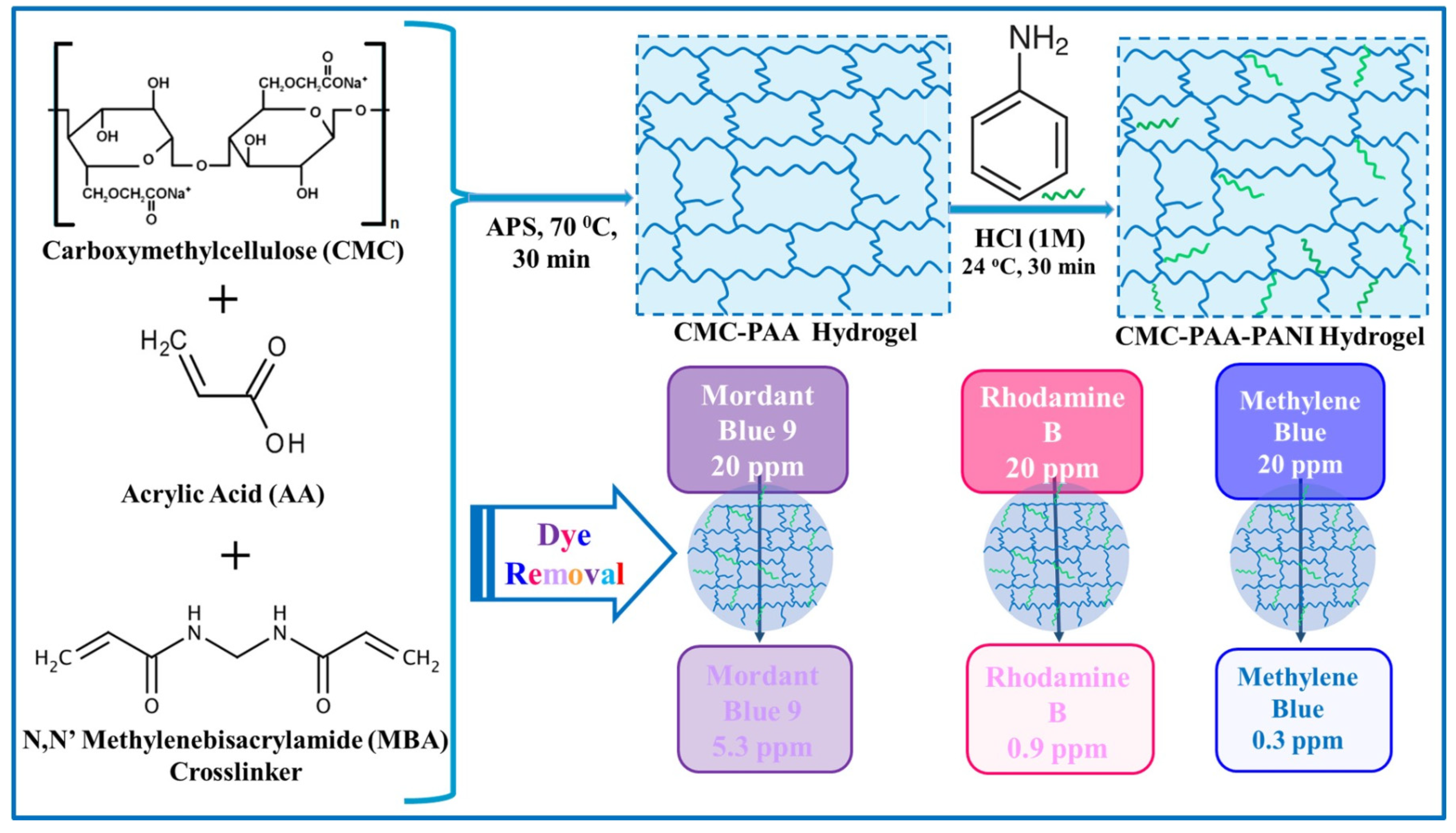

4.1.1. Hybrid Hydrogels Based on Polysaccharides for Dye Removal

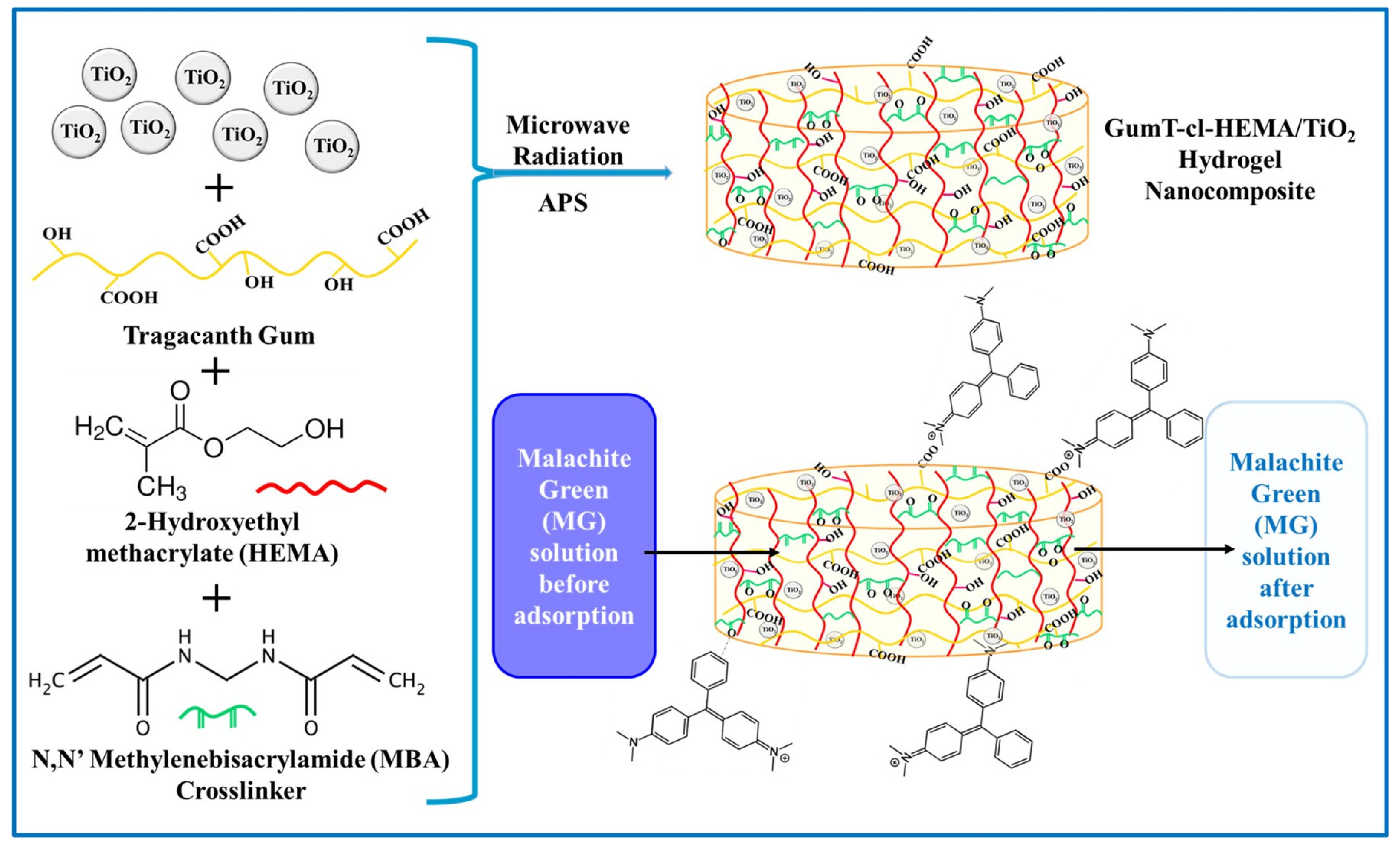

4.1.2. Hybrid Hydrogels Based on Gum Polymers for Dye’ Removal

4.1.3. Hybrid Hydrogels Based on Other Kinds of Polymers for Dye’ Removal

4.2. Hybrid Hydrogels for Heavy Metals’ Retention

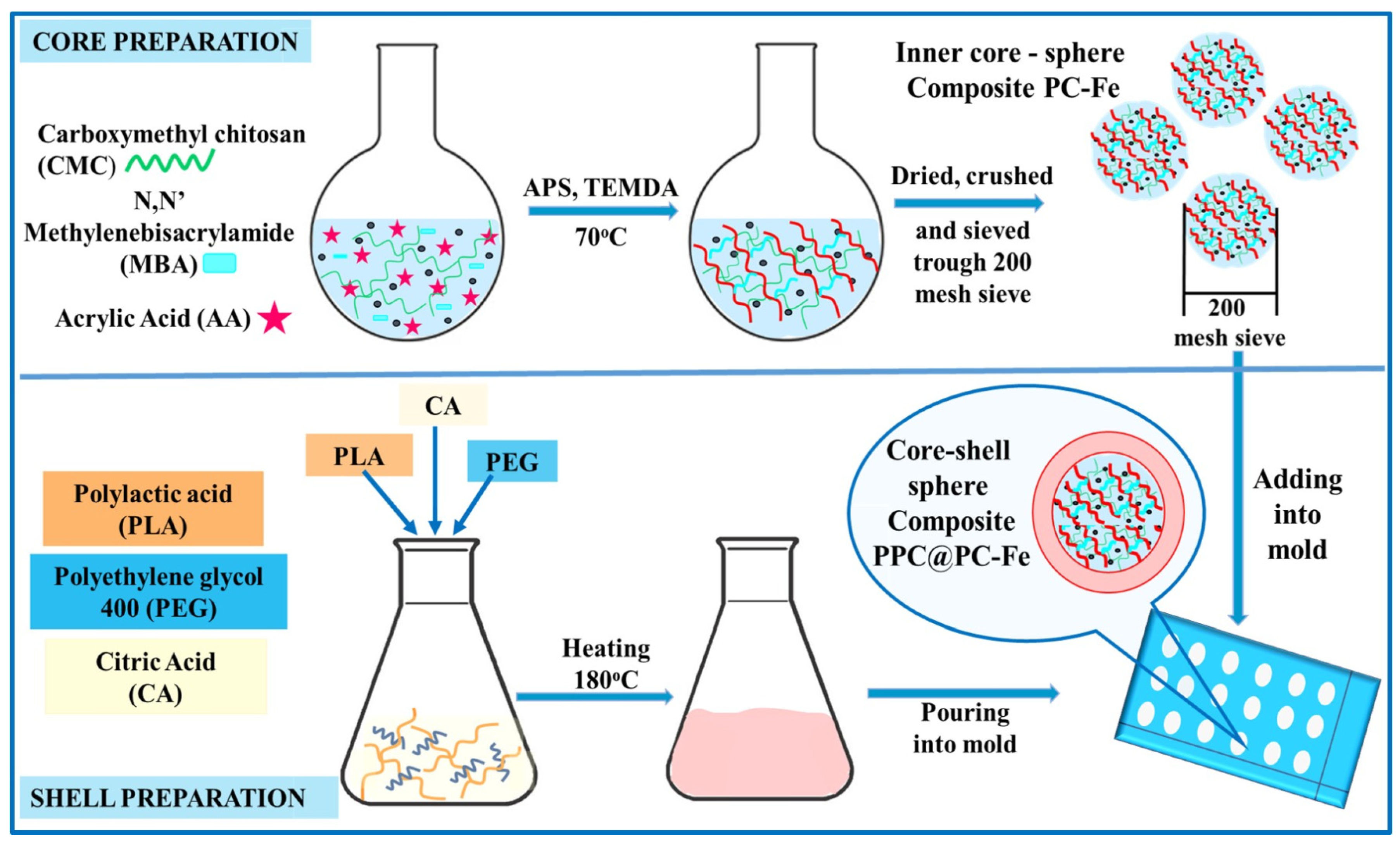

4.2.1. Hybrid Hydrogels Based on Polysaccharides for Heavy Metals’ Removal

4.2.2. Hybrid Hydrogels Based on Gum Polymers for Heavy Metals’ Removal

4.2.3. Hybrid Hydrogels Based on Other Kinds of Polymers for Heavy Metals’ Removal

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AA | acrylic acid | KG | Karaya gum |

| AB 113 | Acid Blue 113 | KPS | Potassium persulphate |

| AC | activated carbon | Lap | Laponite |

| AETAC | 2-(acryloyloxy)ethyl trimethylammonium chloride | LS | Lignosulfonate |

| AHPS | 3-Allyloxy-2-hydroxy-1-propane sulfonic acid sodium salt | MA | Maleic acid |

| AIBN | azobisisobuteronitrile | MAA | Methacrylic acid |

| AIPH | 2,2′-azobis [2-(2-imidazolin-2-yl)propane] dihydrochloride | MAAn | Methacrylic anhydride |

| AM | acrylamide | MAC | [2-(Methacryloxy) ethyl] trimethyl ammonium chloride |

| AMPSA | 2-acrylamide-2-methylpropane sulfonic acid | MADA | Methacrylamide dopamine |

| ANi | aniline | MB | Methylene Blue |

| AO | Auramine O | MBA | N,N-methylenebisacrylamide |

| AO7 | Acid Orange 7 | MEMA | 2-(N-morpholino ethyl methacrylate) |

| APS | Ammonium persulfate | MEMA@GO | 2-(N-morpholino ethyl) methacrylate/graphene oxide |

| APTMACl | (3-acrylamidopropyl) trimethyl ammonium chloride | MG | Malachite Green |

| APTES | aminopropyltrimethoxysilane | MMA | Methyl methacrylate |

| AR 18 | Acid Red 18 | MMT | Montmorillonite |

| AR | Alizarin Red | MO | Methyl orange |

| ARS | Alizarin red S | MOFs | Metal–organic frameworks |

| AY36 | Acid Yellow 36 | MPS | 2-Acrylamido-2-methyl-1-propanesulfonic acid |

| BCB | Brilliant Cresyl Blue | MV | Methyl Violet |

| BIO | Biochar | MWCNTs | Multi-walled carbon nanotubes |

| BIO-Ox | Oxidized biochar | NA | N-allylisatin |

| BG | Brilliant Green | NIPAM | N-isopropyl acrylamide |

| BMB | Bromophenol Blue | NMBA | N,N-methylenebisacrylamide |

| BPO | Benzoyl peroxide | NVP | 1-vinyl-2-pyrrolidinone |

| BzO2 | Benzoyl peroxide | OG | Orange G |

| BY28 | Basic yellow 28 | O II | Orange II sodium Salt |

| CA | Carminic acid | PAA | Polyacrylic acid |

| CAN | Ceric Ammonium Nitrate | PCL | ε-caprolactone |

| CCA | Calconcarboxylic Acid | PDMAEMA | 2-(dimethylamino) ethyl methacrylate |

| CCB | Coomassie brilliant blue | P(DMC-co-AM) | Poly (methacrylatoethyl trimethyl ammonium chloride-co-acrylamide) |

| CG | Chrysoidine G | P(DMAEMA) | Poly(2-(dimethylamino) ethyl methacrylate) |

| CMC | Carboxymethyl cellulose | PEG1500 | Poly(ethylene glycol)1500 |

| CMS | Carboxymethyl starch | PEGDA | Polyethylene glycol diacrylate |

| CNS | Calcium hydroxide nano-spherulites | PEGDMA | Poly (ethylene glycol) dimetacrylate |

| CNT | Carbon nanotubes | PEI | Polyethyleneimine |

| cPAA | Crosslinked PAA | Ph-In | 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone |

| CR | Congo Red | PHPAm | Partially hydrolyzed polyacrylamide |

| Cur | Curcuma longa rhizome | PLA | Polylactic acid |

| CV | Crystal Violet | PQ-10 | Polyquaternium-10 |

| DADMAC | Diallyl dimethylammonium chloride | PTE | Pentaerythritol Tetraallyl Ether |

| Darocur117 | 3 2-hydroxyl-2-methylpropiophenone | PVA | Polyvinyl alcohol |

| DB 15 | Direct Blue 15 | PVP | Polyvinylpyrrolidone |

| DB 78 | Direct Blue 78 | RBBR | Remazol Brilliant Blue R |

| DMAEMA | 2-(Dimethylamino)ethyl methacrylate | RBP-5 | Reactive black 5 |

| DMC | methacrylatoethyl trimethyl ammonium chloride | RhB | Rhodamine B |

| 2DMMT | Two-dimensional montmorillonite nanosheets | RPGS | Palygorskite clay |

| DR23 | Direct Red 23 | SA | Sodium alginate |

| DY | Direct yellow | SH | Sodium humate |

| EB | Eosin B | SO | Safranin O |

| EBT | Eriochrome Black T | ST | Safranin T |

| EDA | Ethylenediamine | SY | Sunset Yellow |

| EG | Ethylene glycol | TB | Trypan Blue |

| EGDMA | N,N- ethylene glycol dimethacrylate | TEMED | N,N,N′,N′-tetramethylethylenediamine |

| EMS | Electrolytic manganese slag | TEOS | Tetraethyl orthosilicate |

| EPC | Epichlorohydrin | TMPTA | 1,1,1-trimethylolpropane trimethacrylate |

| FBL2 | Food Blue 2 | TiO2 | Titanium dioxide |

| FeCl2·4H2O | Ferrous chloride tetrahydrate | VBC | 4 vinylbenzyl chloride |

| FeCl3·6H2O | Ferric chloride hexahydrate | KG | Karaya gum |

| FR17 | Food Red 17 | KPS | Potassium persulphate |

| FS | Fluorescein sodium salt | Lap | Laponite |

| GA | Glutaraldehyde | LS | Lignosulfonate |

| Gg | Gum ghatti | MA | Maleic acid |

| GO | Graphene oxide | MAA | Methacrylic acid |

| GOX | lyoxal | MAAn | Methacrylic anhydride |

| GumT | Tragacanth gum | MAC | [2-(Methacryloxy) ethyl] trimethyl ammonium chloride |

| HHMP | 2-hydroxy-4′-(2 hydroxyethoxy)-2-methyl-propiophenone | MADA | Methacrylamide dopamine |

| HEC | Hydroxyl ethyl cellulose | WT | Waste textiles |

| HEMA 2 | Hydroxyethyl methacrylate | XG | Xantam gum |

| IA | Itaconic acid | γ-MPS | γ-methacryloxypropyltrimethoxysilane |

| IA-g-poly (AA-co-Ani) | Poly (acrylic acid-co-aniline) | ZnO | Zinc oxide |

| ILA-1VIM | Ionic liquid vinylimidazole | ZSM-5 | Zeolite |

| IC | Indigo Carmine | VG1 | Vat Green 1 |

| KCuHCF | Potassium copper hexacyanoferrate | VOCs | Volatile organic compounds |

| V50 | 2′-azobis(2-amidinopropane dihydrochloride) | ||

| [Vim]Br2 | Bis1-vinylimidazole ethyl bromide |

References

- Available online: https://www.eea.europa.eu/en/analysis/indicators/industrial-pollutant-releases-to-water (accessed on 15 November 2024).

- Shmeis, R.M.A. Chapter Four: Nanotechnology in wastewater treatment. Compr. Anal. Chem. 2022, 99, 105–134. [Google Scholar] [CrossRef]

- Available online: https://www.epa.gov/ccl/types-drinking-water-contaminants (accessed on 15 November 2024).

- Available online: https://www.toppr.com/guides/chemistry/environmental-chemistry/water-pollutants/ (accessed on 15 November 2024).

- Ortiz-Prado, E.; Simbana-Rivera, K.; Cevallos, G.; Gomez-Barreno, L.; Cevallos, D.; Lister, A.; Fernandez-Naranjo, R.; Rios-Touma, B.; Vasconez-Gonzalez, J.; Izquierdo-Condoy, J.S. Waterborne diseases and ethnic-related disparities: A 10 years nationwide mortality and burden of disease analysis from Ecuador. Public Health Front. 2022, 10, 1029375. [Google Scholar] [CrossRef] [PubMed]

- Smith, C.D.; Jackson, K.; Peters, H.; Herrera Lima, S. Lack of Safe Drinking Water for Lake Chapala Basin Communities in Mexico Inhibits Progress toward Sustainable Development Goals 3 and 6. Int. J. Environ. Res. Public Health 2020, 17, 8328. [Google Scholar] [CrossRef] [PubMed]

- Wampler, P.J. Karst aquifers and water resource contamination in Haiti. Hydrogeol. J. 2022, 30, 1453–1467. [Google Scholar] [CrossRef]

- Warren-Vega, W.M.; Campos-Rodríguez, A.; Zárate-Guzmán, A.I.; Romero-Cano, L.A. A Current Review of Water Pollutants in American Continent: Trends and Perspectives in Detection, Health Risks, and Treatment Technologies. Int. J. Environ. Res. Public Health 2023, 20, 4499. [Google Scholar] [CrossRef]

- Shmeis, R.M.A. Water Chemistry and Microbiology. Compr. Anal. Chem. 2018, 81, 1–56. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil, K.P.; Jeevanantham, S.; Karishma, S.; Tajsabreen, B.; Yaashikaa, P.R.; Reshma, B. Effective water/wastewater treatment methodologies for toxic pollutants removal: Processes and applications towards sustainable development. Chemosphere 2021, 280, 130595. [Google Scholar] [CrossRef]

- Available online: https://chinawaterrisk.org/glossary-measurement/drinking-water-preparation (accessed on 19 November 2024).

- Available online: https://www.britannica.com/topic/water-purification/Other-purification-steps (accessed on 19 November 2024).

- Available online: https://www.dombor.com/different-methods-of-wastewater-treatment/ (accessed on 19 November 2024).

- Dutta, D.; Arya, S.; Kumar, S. Industrial wastewater treatment: Current trends, bottlenecks, and best practices. Chemosphere 2021, 285, 131245. [Google Scholar] [CrossRef]

- Kong, Z.; Li, L.; Xue, Y.; Yang, M.; Li, Y.-Y. Challenges and prospects for the anaerobic treatment of chemical-industrial organic wastewater: A review. J. Clean. Prod. 2019, 231, 913–927. [Google Scholar] [CrossRef]

- Deng, Y.; Xi, J.; Meng, L.; Lou, Y.; Seidi, F.; Wu, W.; Xiao, H. Stimuli-Responsive nanocellulose Hydrogels: An overview. Eur. Polym. J. 2022, 180, 111591. [Google Scholar] [CrossRef]

- Sannino, A.; Demitri, C.; Madaghiele, M. Biodegradable cellulose-based hydrogels: Design and applications. Materials 2009, 2, 353–373. [Google Scholar] [CrossRef]

- Maleki, B.; Kargar, P.G.; Ashrafi, S.S.; Ghani, M. Perspective Chapter: Introduction to Hydrogels—Definition, Classifications, Applications and Methods of Preparation. In Ionic Liquids—Recent Advances; Bhowmik, P.K., Ed.; InTech Europe: Rijeka, Croatia, 2016; pp. 7–9. [Google Scholar]

- Zaharia, A.; Radu, A.-L.; Iancu, S.; Florea, A.-M.; Sandu, T.; Minca, I.; Fruth-Oprisan, V.; Teodorescu, M.; Sarbu, A.L.; Iordache, T.-V. Bacterialcellulose-poly(acrylic acid-co-N,N′-methylene-bis-acrylamide) interpenetrated networks for the controlled release of fertilizers. RSC Adv. 2018, 32, 17635–17644. [Google Scholar] [CrossRef]

- Neblea, I.E.; Gavrila, A.-M.; Iordache, T.V.; Zaharia, A.; Stanescu, P.O.; Radu, I.C.; Burlacu, S.G.; Neagu, G.; Chiriac, A.L.; Sarbu, A. Interpenetrating networks of bacterial cellulose and poly (ethylene glycol) diacrylate as potential cephalexin carriers in wound therapy. J. Polym. Res. 2022, 29, 406. [Google Scholar] [CrossRef]

- Neblea, I.E.; Chiriac, A.-L.; Zaharia, A.; Sarbu, A.; Teodorescu, M.; Miron, A.; Paruch, L.; Paruch, A.M.; Olaru, A.G.; Iordache, T.-V. Introducing Semi-Interpenetrating Networks of Chitosan and Ammonium-Quaternary Polymers for the Effective Removal of Waterborne Pathogens from Wastewaters. Polymers 2023, 15, 1091. [Google Scholar] [CrossRef]

- Cursaru, B.; Radu, A.-L.; Perrin, F.-X.; Sarbu, A.; Teodorescu, M.; Gavrila, A.-M.; Damian, C.-M.; Sandu, T.; Iordache, T.-V.; Zaharia, A. Poly(ethylene glycol) Composite Hydrogels with Natural Zeolite as Filler for Controlled Delivery Applications. Macromol. Res. 2020, 28, 211–220. [Google Scholar] [CrossRef]

- Spatarelu, C.P.; Chiriac, A.-L.; Cursaru, B.; Iordache, T.-V.; Gavrila, A.-M.; Cojocaru, C.-T.; Botez, R.-E.; Trica, B.; Sarbu, A.; Teodorescu, M.; et al. Composite Nanogels Based on Zeolite-Poly(ethylene glycol) Diacrylate for Controlled Drug Delivery. Nanomaterials 2020, 10, 195. [Google Scholar] [CrossRef]

- Dumitru, M.-V.; Neagu, A.-L.; Miron, A.; Roque, M.I.; Durães, L.M.R.; Gavrila, A.-M.; Sarbu, A.; Iovu, H.; Chiriac, A.-L.; Iordache, T.-V. Retention of ciprofloxacin and carbamazepine from aqueous solutions using chitosan-based cryostructured composites. Polymers 2024, 16, 639. [Google Scholar] [CrossRef]

- Akhtar, M.F.; Hanif, M.; Ranjha, N.M. Methods of synthesis of hydrogels. A review. Saudi Pharm. J. 2016, 24, 554–559. [Google Scholar] [CrossRef]

- Gulrez, S.K.H.; Al-Assaf, S.; Phillips, G.O. Hydrogels: Chapter 5 Methods of Preparation, Characterisation and Applications. In Progress in Molecular and Environmental Bioengineering—From Analysis and Modeling to Technology Applications; Carpi, A., Ed.; InTech Europe: Rijeka, Croatia, 2011; pp. 118–138. [Google Scholar]

- Bahram, M.; Mohseni, N.; Moghtader, M. Chapter 2: An Introduction to Hydrogels and Some Recent Applications. In Emerging Concepts in Analysis and Applications of Hydrogels; Majee, S.B., Ed.; InTech Europe: Rijeka, Croatia, 2016; pp. 12–15. [Google Scholar] [CrossRef]

- Chamkouri, H.; Chamkouri, M. A Review of Hydrogels, Their Properties and Applications in Medicine. Am. J. Biomed. Sci. Res. 2021, 11, 485–493. [Google Scholar] [CrossRef]

- Ahearne, M.; Yang, Y.; Liu, K.-K. Chapter 12 Mechanical Characterisation of Hydrogels for Tissue Engineering Applications. In Topics in Tissue Engineering; Ashammakhi, N., Reis, R., Chiellini, F., Eds.; Oulu University: Oulu, Finland, 2008; Volume 4. [Google Scholar]

- Santo, V.E.; Prieto, S.; Testera, A.M.; Arias, F.J.; Alonso, M.; Mano, J.F.; Rodríguez-Cabello, J.C. Temperature-responsive bioactive hydrogels based on a multifunctional recombinant elastin-like polymer. Biomater. Biomech. Eng. 2015, 2, 47–59. [Google Scholar] [CrossRef]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed]

- Sultana, M.; Rownok, M.H.; Sabrin, M.; Rahaman, M.; Alam, S.M.N. A review on experimental chemically modified activated carbon to enhance dye and heavy metals adsorption. Clean. Eng. Technol. 2022, 6, 100382. [Google Scholar] [CrossRef]

- Mei, Y.; Zhuang, S.; Wang, J. Adsorption of heavy metals by biochar in aqueous solution: A review. Sci. Total Environ. 2025, 968, 178898. [Google Scholar] [CrossRef] [PubMed]

- Rudžioni, Ž.; Adhikary, S.K.; Manhanga, F.C.; Ashish, D.K.; Ivanauskas, R.; Stelmokaitis, G.; Navickas, A.A. Natural zeolite powder in cementitious composites and its application as heavy metal absorbents. J. Build. Eng. 2021, 43, 103085. [Google Scholar] [CrossRef]

- Lin, G.; Zeng, B.; Li, J.; Wang, Z.; Wang, S.; Hu, T.; Zhang, L. A systematic review of metal organic frameworks materials for heavy metal removal: Synthesis, applications and mechanism. Chem. Eng. J. 2023, 460, 141710. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M.; Roy, P.; Bonilla-Petriciolet, A.; Badawi, M.; Ganachari, S.V.; Shetti, N.P.; Aminabhavi, T.M. Polymeric hydrogels-based materials for wastewater treatment. Chemosphere 2023, 331, 138743. [Google Scholar] [CrossRef]

- Gao, M.; Sun, M.; Guo, X.; Li, F.; Bi, J.; Liu, J.; Wang, S.; Zhao, Y. Removal of ciprofloxacin by PAA-PAM hydrogel: Adsorption performance and mechanism studies. J. Water Process Eng. 2025, 71, 107361. [Google Scholar] [CrossRef]

- Foudazi, R.; Zowada, R.; Manas-Zloczower, I.; Feke, D.L. Porous Hydrogels: Present Challenges and Future Opportunities. Langmuir 2023, 39, 2092–2111. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, S.; Luo, Y. Adsorption mechanisms of hydrogels for heavy metal and organic dyes removal: A short review. J. Agric. Food Res. 2023, 12, 100552. [Google Scholar] [CrossRef]

- Khan, M.; Lo, I.M.C. A holistic review of hydrogel applications in the adsorptive removal of aqueous pollutants: Recent progress, challenges, and perspectives. Water Res. 2016, 106, 259–271. [Google Scholar] [CrossRef]

- Seera, S.D.K.; Kundu, D.; Gami, P.; Naik, P.K.; Banerjee, T. Synthesis and characterization of xylan-gelatin cross-linked reusable hydrogel for the adsorption of methylene blue. Carbohydr. Polym. 2021, 256, 117520. [Google Scholar] [CrossRef] [PubMed]

- Rando, G.; Scalone, E.; Sfameni, S.; Plutino, M.R. Functional Bio-Based Polymeric Hydrogels for Wastewater Treatment: From Remediation to Sensing Applications. Gels 2024, 10, 498. [Google Scholar] [CrossRef] [PubMed]

- Alcalde-Garcia, F.; Prasher, S.; Kaliaguine, S.; Tavares, J.R.; Dumont, M.-J. Desorption Strategies and Reusability of Biopolymeric Adsorbentsand Semisynthetic Derivatives in Hydrogel and HydrogelComposites Used in Adsorption Processes. ACS Eng. Au 2023, 3, 364–545. [Google Scholar] [CrossRef]

- Maroulas, K.N.; Efthymiopoulos, P.; Iliadou, V.; Zamboulis, A.; Bikiaris, N.D.; Bakalis, E.; Kyzas, G.Z. Interfacial interactions in aqueous systems of poly(ε-caprolactone)-co-poly (2-hydroxyethyl methacrylate) hydrogel with dye molecules in synthetic wastewaters. J. Ind. Eng. Chem. 2025, 142, 309–320. [Google Scholar] [CrossRef]

- Sanchez, L.M.; Ollier, R.P.; Alvarez, V.A. Sorption behavior of polyvinyl alcohol/bentonite hydrogels for dyes removal. J. Polym. Res. 2019, 26, 142. [Google Scholar] [CrossRef]

- Lamkhao, S.; Tandorn, S.; Rujijanagul, G.; Randorn, C. A practical approach using a novel porous photocatalyst/hydrogel composite for wastewater treatment. Mater. Today Sustain. 2023, 23, 100482. [Google Scholar] [CrossRef]

- Rahmatpour, A.; Soleimani, P.; Mirkani, A. Eco-friendly poly(vinyl alcohol)/partially hydrolyzed polyacrylamide graphene oxide semi-IPN nanocomposite hydrogel as a reusable and efficient adsorbent of cationic dye methylene blue from water. React. Funct. Polym. 2022, 175, 105290. [Google Scholar] [CrossRef]

- Zhou, G.; Luo, J.; Liu, C.; Chu, L.; Ma, J.; Tang, Y.; Zeng, Z.; Luo, S. A highly efficient polyampholyte hydrogel sorbent based fixed-bed process for heavy metal removal in actual industrial effluent. Water Res. 2016, 89, 151–160. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, P.; Yang, K.; Wang, Q.; Feng, W.; Tang, Y. PAA/TiO2@C composite hydrogels with hierarchical pore structures as high efficiency adsorbents for heavy metal ions and organic dyes removal. Desalination 2023, 558, 116620. [Google Scholar] [CrossRef]

- Adjuik, T.A.; Nokes, S.E.; Montross, M.D. Biodegradability of bio-based and synthetic hydrogels as sustainable soil amendments: A review. J. Appl. Polym. Sci. 2023, 140, 12. [Google Scholar] [CrossRef]

- Pattnaik, A.; Ghosh, P.; Poonia, A.K. An overview on advancements in hydrogels for effective wastewater treatment. J. Mol. Liq. 2025, 424, 127120. [Google Scholar] [CrossRef]

- Wichterle, O.; Lìm, D. Hydrophilic Gels for Biological Use. Nature 1960, 185, 117–118. [Google Scholar] [CrossRef]

- Kumar, M.; Bhujbal, S.K.; Kohli, K.; Prajapati, R.; Sharma, B.K.; Sawarkar, A.D.; Abhishek, K.; Bolan, S.; Ghosh, P.; Kirkham, M.B.; et al. A review on value-addition to plastic waste towards achieving a circular economy. Sci. Total Environ. 2024, 921, 171106. [Google Scholar] [CrossRef]

- Feldman, D.; Barbalata, A. Synthetic Polymers: Technology, Properties, Applications; Chapman & Hall: London, UK, 1996. [Google Scholar]

- Hossain, M.S.; Hossain, M.M.; Khatun, M.K.; Hossain, K.R. Hydrogel-based superadsorbents for efficient removal of heavy metals in industrial wastewater treatment and environmental conservation. Environ. Func. Mater. 2023, 2, 142–158. [Google Scholar] [CrossRef]

- Teodorescu, M.; Lungu, A.; Stanescu, P.O.; Neamtu, C. Preparation and Properties of Novel Slow-Release NPK Agrochemical Formulations Based on Poly(acrylic acid) Hydrogels and Liquid Fertilizers. Ind. Eng. Chem. Res. 2009, 48, 6527–6534. [Google Scholar] [CrossRef]

- Panic, V.V.; Jovanovic, J.D.; Spasojevic, J.P.; Savic, S.I.; Markovic, M.D.; Radulovic, A.M.; Adnadjevic, B.K. Structure-property correlations for composite hydrogels based on poly(methacrylic acid) and high concentrations of LTA zeolite. Chem. Eng. Sci. 2024, 292, 119981. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Lu, Z.; Miao, R.; Zhang, N. Thermal and light-driven soft actuators based on a conductive polypyrrole nanofibers integrated poly(N-isopropylacrylamide) hydrogel with intelligent response. J. Colloid Interface Sci. 2024, 675, 336–346. [Google Scholar] [CrossRef]

- Hanyková, L.; Št’astná, J.; Krakovský, I. Responsive Acrylamide-Based Hydrogels: Advances in Interpenetrating Polymer Structures. Gels 2024, 10, 414. [Google Scholar] [CrossRef]

- Isaac, A.H.; Phillips, S.Y.R.; Ruben, E.; Estes, M.; Rajavel, V.; Baig, T.; Paleti, C.; Landsgaard, K.; Lee, R.H.; Guda, T.; et al. Impact of PEG sensitization on the efficacy of PEG hydrogel-mediated tissue engineering. Nat. Commun. 2024, 15, 3283. [Google Scholar] [CrossRef]

- Negru, I.; Teodorescu, M.; Stănescu, P.O.; Drăghici, C.; Lungu, A.; Sârbu, A. Thermogelation properties of ABA triblock copolymers of poly (ethylene glycol)(B) and copolyacrylates of oligo (ethylene glycol)s (A) in aqueous solution. Soft Mater. 2013, 11, 149–156. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, J.; He, Y.; Zhao, C.; An, M.; Li, L. Porous polyvinyl alcohol/polyacrylamide hydrogels loaded with HTO lithium-ion sieves for highly rapid and efficient Li+ extraction. Desalination 2024, 580, 117587. [Google Scholar] [CrossRef]

- Sekizkardes, B.; Su, E.; Okay, O. Mechanically Strong Superabsorbent Terpolymer Hydrogels Based on AMPS via Hydrogen-Bonding Interactions. ACS Appl. Polym. Mater. 2023, 5, 2043–2050. [Google Scholar] [CrossRef]

- Xue, X.; He, Y.; Jia, R.; Qian, H.; Lin, Y.; Xu, X.; Shi, J.; Chang, S.; Cui, A. pH-Responsive itaconic acid-based villous-like hydrogels for water-plugging materials. J. Appl. Polym. Sci. 2024, 141, e55440. [Google Scholar] [CrossRef]

- Madduma-Bandarage, U.S.K.; Madihally, S.V. Synthetic hydrogels: Synthesis, novel trends, and applications. J. Appl. Polym. Sci. 2021, 138, 50376. [Google Scholar] [CrossRef]

- Henderson, L. Global perceptions of plastic pollution: The contours and limits of debate. Camb. Prism. Plast. 2023, 1, e21. [Google Scholar] [CrossRef]

- Pakdel, P.M.; Peighambardoust, S.J. A review on acrylic based hydrogels and their applications in wastewater treatment. J. Environ. Manag. 2018, 217, 123–143. [Google Scholar] [CrossRef]

- Yu, Y.; Peng, R.; Yang, C.; Tang, Y. Eco-friendly and cost-effective superabsorbent sodium polyacrylate composites for environmental remediation. J. Mater. Sci. 2015, 50, 5799–5808. [Google Scholar] [CrossRef]

- Alkhaldi, H.; Alharthi, S.; Alharthi, S.; AlGhamdi, H.A.; AlZahrani, Y.M.; Mahmoud, S.A.; Amin, L.G.; AlShaalan, N.H.; Boraie, W.E.; Attia, M.S.; et al. Sustainable polymeric adsorbents for adsorption based water remediation and pathogen deactivation: A review. RSC Adv. 2024, 14, 33143. [Google Scholar] [CrossRef]

- Lin, J.; Ye, W.; Xie, M.; Seo, D.H.; Luo, J.; Wan, Y.; Van der Bruggen, B. Environmental impacts and remediation of dye-containing wastewater. Nat. Rev. Earth Environ. 2023, 4, 785–803. [Google Scholar] [CrossRef]

- Tkaczyk, A.; Mitrowska, K.; Posyniak, A. Synthetic organic dyes as contaminants of the aquatic environment and their implications for ecosystems: A review. Sci. Total Environ. 2020, 717, 137222. [Google Scholar] [CrossRef]

- Slama, H.B.; ChenariBouket, A.; Pourhassan, Z.; Alenezi, F.N.; Silini, A.; Cherif-Silini, H.; Oszako, T.; Luptakova, L.; Golinska, P.; Belbahri, L. Diversity of Synthetic Dyes from Textile Industries, Discharge Impacts and Treatment Methods. Appl. Sci. 2021, 11, 6255. [Google Scholar] [CrossRef]

- Azam, K.; Shezad, N.; Shafiq, I.; Akhter, P.; Akhtar, F.; Jamil, F.; Shafique, S.; Park, Y.-K.; Hussain, M. A review on activated carbon modifications for the treatment of wastewater containing anionic dyes. Chemosphere 2022, 306, 135566. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Ji, L.; Guo, J.; Ge, S.; Lu, W.; Chen, Y.; Cai, L.; Wang, Y.; Song, W. An abundant porous biochar material derived from wakame (Undaria pinnatifida) with high adsorption performance for three organic dyes. Bioresour. Technol. 2020, 318, 124082. [Google Scholar] [CrossRef]

- Shabil, S.M.; Anwar, H.; Musthafa, F.N.; Al-Lohedan, H.; Alfarwati, S.; Rajabathar, J.R.; Khalid, A.J.; Cabibihan, J.J.; Karnan, M.; Kumar, S.K. Photocatalytic degradation of organic dyes using reduced graphene oxide (rGO). Sci Rep. 2024, 14, 3608. [Google Scholar] [CrossRef] [PubMed]

- Gadore, V.; Mishra, S.R.; Yadav, N.; Yadav, G.; Ahmaruzzaman, M. Advances in zeolite-based materials for dye removal: Current trends and future prospects. Inorg. Chem. Commun. 2024, 166, 112606. [Google Scholar] [CrossRef]

- Uddin, M.J.; Ampiaw, R.E.; Lee, W. Adsorptive removal of dyes from wastewater using a metal-organic framework: A review. Chemosphere 2021, 284, 131314. [Google Scholar] [CrossRef]

- Zango, Z.U.; Binzowaimil, A.M.; Aldaghri, O.A.; Eisa, M.H.; Garba, A.; Ahmed, N.M.; Lim, J.W.; Ng, H.-S.; Daud, H.; Jumbri, K.; et al. Applications of covalent organic frameworks for the elimination of dyes from wastewater: A state-of-the-arts review. Chemosphere 2023, 343, 140223. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Shunmugam, R. Polymer based gels and their applications in remediation of dyes from textile effluents. J. Macromol. Sci. Part A Pure Appl. Chem. 2020, 57, 906–926. [Google Scholar] [CrossRef]

- Ahmadian, M.; Jaymand, M. Interpenetrating polymer network hydrogels for removal of synthetic dyes: A comprehensive review. Coord. Chem. Rev. 2023, 486, 215152. [Google Scholar] [CrossRef]

- Dey, A.; Bera, R.; Chakrabarty, D. Synthesis of poly(ethylene glycol) di-itaconate and investigation of its influence on acrylamide based hydrogels meant for water treatment. Polymer 2017, 116, 178–190. [Google Scholar] [CrossRef]

- Banerjee, P.; Dinda, P.; Kar, M.; Uchman, M.; Mandal, T.K. Ionic Liquid Cross-Linked High-Absorbent Polymer Hydrogels: Kinetics of Swelling and Dye Adsorption. Langmuir 2023, 39, 9757–9772. [Google Scholar] [CrossRef] [PubMed]

- Mahida, V.P.; Patel, M.P. Removal of some most hazardous cationic dyes using novel poly (NIPAAm/AA/N-allylisatin) nanohydrogel. Arab. J. Chem. 2016, 9, 430–442. [Google Scholar] [CrossRef]

- Üzüm, Ö.B.; Çetin, G.; Kundakcı, S.; Karadağ, E. Swelling and dye adsorption properties of polyelectrolyte semi-IPNs including of acrylamide/(3-acrylamidopropyl)trimethyl ammonium chloride/poly(ethylene glycol). Sep. Sci. Technol. 2020, 55, 18. [Google Scholar] [CrossRef]

- Dalalibera, A.; Vilela, P.B.; Vieira, T.; Becegato, V.A.; Paulino, A.T. Removal and selective separation of synthetic dyes from water using a polyacrylic acid-based hydrogel: Characterization, isotherm, kinetic, and thermodynamic data. J. Environ. Chem. Eng. 2020, 8, 104465. [Google Scholar] [CrossRef]

- Mekewi, M.A.; Madkour, T.M.; Darwish, A.S.; Hashish, Y.M. Does poly(acrylic acid-co-acrylamide) hydrogel be the pluperfect choiceness in treatment of dyeing wastewater? From simple opolymer to gigantic aqua-waste remover. J. Ind. Eng. Chem. 2015, 30, 359–371. [Google Scholar] [CrossRef]

- Sakthivel, M.; Franklin, D.S.; Guhanathan, S. pH-sensitive Itaconic acid based polymeric hydrogels for dye removal applications. Ecotoxicol. Environ. Saf. 2016, 134, 427–432. [Google Scholar] [CrossRef]

- Thakur, S.; Chaudhary, J.; Thakur, A.; Gunduz, O.; Alsanie, W.F.; Makatsoris, C.; Thakur, V.K. Highly efficient poly(acrylic acid-co-aniline) grafted itaconic acid hydrogel: Application in water retention and adsorption of rhodamine B dye for a sustainable environment. Chemosphere 2002, 303, 134917. [Google Scholar] [CrossRef]

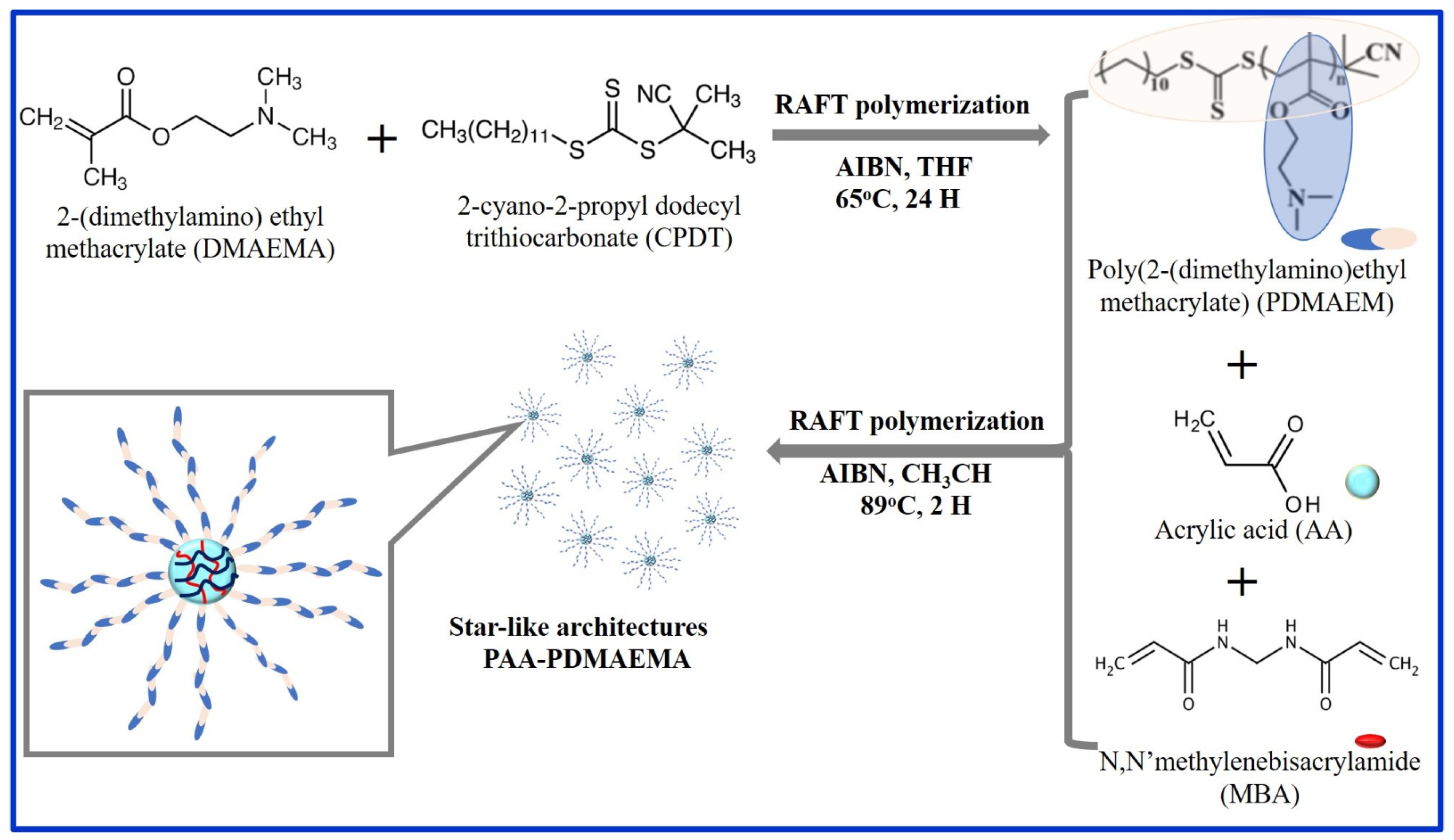

- Mohammadzadeh, F.; Haddadi-Asl, V.; Salami-Kalajahi, M. pH-sensitive multi-arm star polyampholytes: A novel approach for simultaneous adsorption of anionic and cationic dyes. J. Mol. Liq. 2024, 395, 123863. [Google Scholar] [CrossRef]

- Salahshoori, I.; Wang, Q.; Nobre, M.A.L.; Mohammadi, A.H.; Dawi, E.A.; Khonakdar, H.A. Molecular simulation-based insights into dye pollutant adsorption: A perspective review. Adv. Colloid Interface Sci. 2024, 333, 103281. [Google Scholar] [CrossRef]

- Ibrahim, A.G.; Hai, F.A.; El-Wahab, H.A.; Aboelanin, H. Methylene blue removal using a novel hydrogel containing 3-Allyloxy-2-hydroxy-1-propanesulfonic acid sodium salt. Adv. Polym. Technol. 2018, 37, 2699–3899. [Google Scholar] [CrossRef]

- Rehman, T.U.; Shah, L.A.; Khan, M.; Irfan, M.; Khattak, N.S. Zwitterionic superabsorbent polymer hydrogels for efficient and selective removal of organic dyes. RSC Adv. 2019, 9, 18565. [Google Scholar] [CrossRef] [PubMed]

- Shoueira, K.R.; Sarhana, A.A.; Attab, A.M.; Akla, M.A. Macrogel and nanogel networks based on crosslinked poly (vinyl alcohol) for adsorption of methylene blue from aqua system. Environ. Nanotechnol. Monit. Manag. 2016, 5, 62–73. [Google Scholar] [CrossRef]

- Du, J.; Dong, Z.; Yang, X.; Zhao, L. Facile fabrication of polymeric quaternary ammonium salt hydrogel by radiation for dyes removal from aqueous solution. Radiat. Phys. Chem. 2021, 188, 109670. [Google Scholar] [CrossRef]

- Tang, Z.; Guo, H.; Xu, J.; Li, Z.; Sun, G. Cationic poly(diallyldimethylammonium chloride) based hydrogel for effective anionic dyes adsorption from aqueous solution. React. Funct. Polym. 2022, 174, 105239. [Google Scholar] [CrossRef]

- Onder, A.; Ilgin, P.; Ozay, H.; Ozay, O. Removal of dye from aqueous medium with pH-sensitive poly [(2-(acryloyloxy)ethyl]trimethylammonium chloride-co-1-vinyl-2-pyrrolidone] cationic hydrogel. J. Environ. Chem. Eng. 2020, 8, 104436. [Google Scholar] [CrossRef]

- Tang, Z.; Hu, X.; Ding, H.; Li, Z.; Liang, R.; Sun, G. Villi-like poly(acrylic acid) based hydrogel adsorbent with fast and highly efficient methylene blue removing ability. J. Colloid Interface Sci. 2021, 594, 54–63. [Google Scholar] [CrossRef] [PubMed]

- Işıkver, Y.; Saraydın, D.; Karakuş, N. An Experimental and Computational Evaluation of the Interaction Between Intelligent Ampholyte Acrylamide/Acrylic Acid/2-(Acryloyloxy)ethyl Trimethylammonium Chloride Hydrogel and Dyes. J. Polym. Environ. 2024, 32, 441–459. [Google Scholar] [CrossRef]

- Li, D.; Li, Q.; Bai, N.; Dong, H.; Mao, D. One-Step Synthesis of Cationic Hydrogel for Efficient Dye Adsorption and Its Second Use for Emulsified Oil Separation. ACS Sustain. Chem. Eng. 2017, 5, 5598–5607. [Google Scholar] [CrossRef]

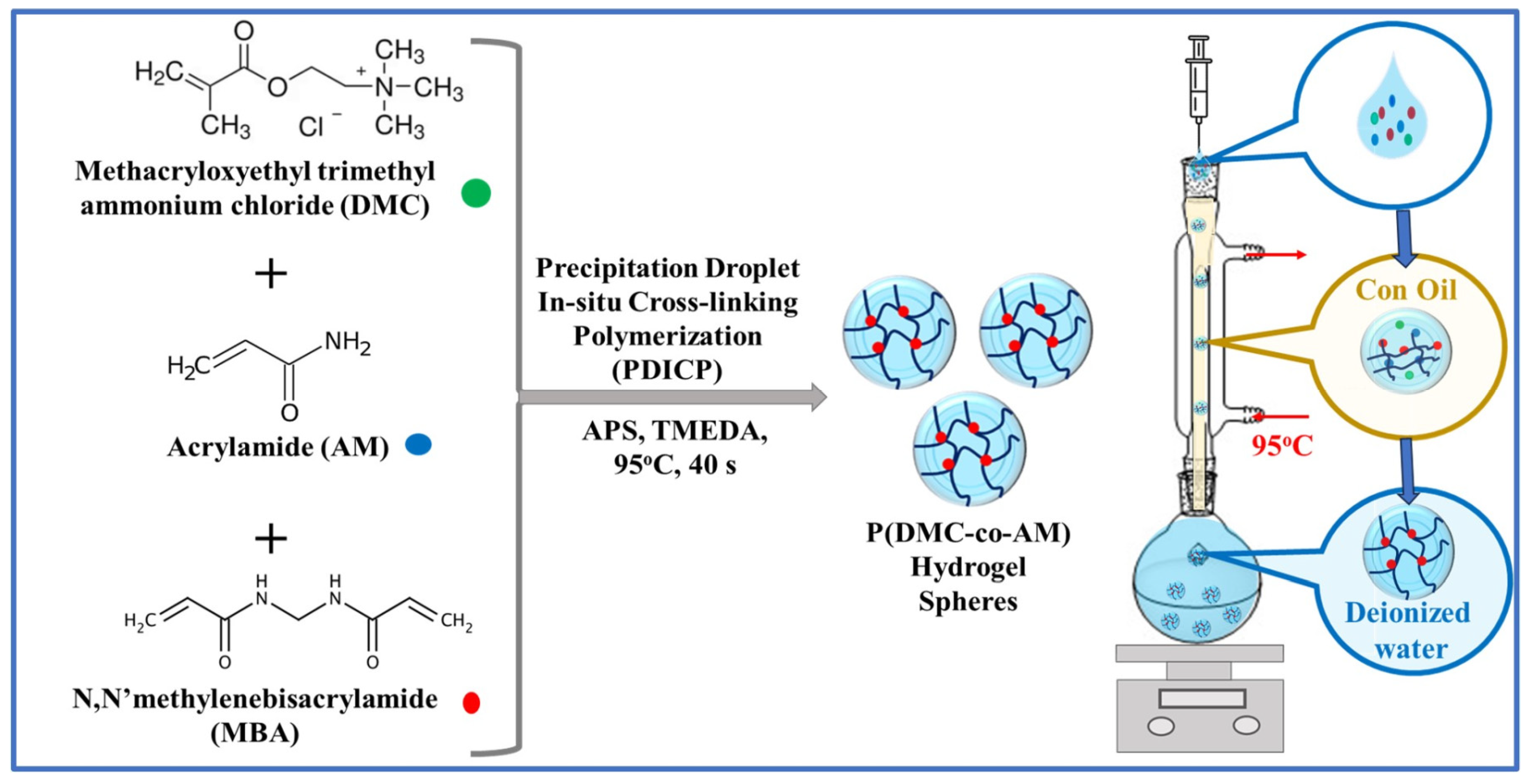

- Liu, X.; Zhoua, Z.; Yina, J.; Hea, C.; Zhaoa, W.; Zhao, C. Fast and environmental-friendly approach towards uniform hydrogel particles with ultrahigh and selective removal of anionic dyes. J. Environ. Chem. Eng. 2020, 8, 104352. [Google Scholar] [CrossRef]

- Zhao, S.; An, X.; An, W.; Hu, J.; Wu, P.; Cui, W. Efficient adsorption of anionic and cationic dyes by PVA/PAA/GO composite hydrogel with three-dimensional porous double network structure. Mater. Chem. Phys. 2024, 313, 128716. [Google Scholar] [CrossRef]

- Mosaffa, E.; Patel, R.I.; Purohit, A.M.; Basak, B.B.; Banerjee, A. Efficient Decontamination of Cationic Dyes from Synthetic Textile Wastewater Using Poly(acrylic acid) Composite Containing Amino Functionalized Biochar: A Mechanism Kinetic and Isotherm Study. J. Polym. Environ. 2023, 31, 2486–2503. [Google Scholar] [CrossRef]

- Wen, T.; Huang, B.; Zhou, L. Facile Fabrication of Magnetic Poly(Vinyl Alcohol)/Activated Carbon Composite Gel for Adsorptive Removal of Dyes. J. Compos. Sci. 2022, 6, 55. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, G.; Wang, X.; Liu, J.; Li, D.; Wu, C.; Zhang, W. Composite hydrogel membrane with high mechanical strength for treatment of dye pollutant. Sep. Purif. Technol. 2021, 275, 119154. [Google Scholar] [CrossRef]

- Liu, J.; Chen, H.; Shi, X.; Nawar, S.; Werner, J.G.; Huang, G.; Ye, M.; Weitz, D.A.; Solovev, A.A.; Mei, Y. Hydrogel microcapsules with photocatalytic nanoparticles for removal of organic pollutants. Environ. Sci. Nano 2020, 7, 656–664. [Google Scholar] [CrossRef]

- Kangwansupamonkon, W.; Klaikaew, N.; Kiatkamjornwong, S. Green synthesis of titanium dioxide/acrylamide-based hydrogel composite, self-degradation and environmental applications. Eur. Polym. J. 2018, 107, 118–131. [Google Scholar] [CrossRef]

- Gao, B.; Yu, H.; Wen, J.; Zeng, H.; Liang, T.; Zuo, F.; Cheng, C. Super-adsorbent poly(acrylic acid)/laponite hydrogel with ultrahigh mechanical property for adsorption of methylene blue. J. Environ. Chem. Eng. 2021, 9, 106346. [Google Scholar] [CrossRef]

- Safarzadeh, H.; Peighambardoust, S.J.; Mousavi, S.H.; Foroutan, R.; Mohammadi, R.; Peighambardoust, S.H. Adsorption ability evaluation of the poly(methacrylic acid-co-acrylamide)/cloisite 30B nanocomposite hydrogel as a new adsorbent for cationic dye removal. Environ. Res. 2022, 212, 113349. [Google Scholar] [CrossRef]

- Jiang, R.N.; Chen, Y.A.; Liu, Y.; Liu, H. Multi-functional nanocomposite hydrogels based on assembled catechin-modified TiO2 nanoparticle crosslinker for efficient dye removal from wastewater. Mater. Commun. 2023, 37, 107216. [Google Scholar] [CrossRef]

- Tasdelen, B.; Cifci, D.I.; Meric, S. Preparation of N-isopropylacrylamide/itaconic acid/Pumice highly swollen composite hydrogels to explore their removal capacity of methylene blue. Colloids Surf. A Physicochem. Eng. Asp. 2017, 519, 245–253. [Google Scholar] [CrossRef]

- Panic, V.V.; Velickovic, S.J. Removal of model cationic dye by adsorption onto poly(methacrylic acid)/zeolite hydrogel composites: Kinetics, equilibrium study and image analysis. Sep. Purif. Technol. 2014, 122, 384–394. [Google Scholar] [CrossRef]

- Taktak, F.; Gokçe, S. Ultrasound-assisted synthesis of biodegradable graphene oxide-based hydrogel nanocomposites for highly efficient and cost-effective removal of methyl orange from aqueous media. J. Water Process Eng. 2024, 58, 104837. [Google Scholar] [CrossRef]

- Mosaffa, E.; Patel, R.I.; Banerjee, A.; Basak, B.B.; Oroujzadeh, M. Comprehensive analysis of cationic dye removal from synthetic and industrial wastewater using a semi-natural curcumin grafted biochar/poly acrylic acid composite hydrogel. RSC Adv. 2024, 14, 7745–7762. [Google Scholar] [CrossRef]

- Yang, C.-X.; Lei, L.; Zhou, P.-X.; Zhang, Z.; Lei, Z.-Q. Preparation and characterization of poly(AA co PVP)/PGS composite and its application for methylene blue adsorption. J. Colloid Interface Sci. 2015, 443, 97–104. [Google Scholar] [CrossRef]

- Kongsen, P.; Amornpitoksuk, P.; Chantarak, S. Development of multifunctional hydrogel composite based on poly(vinyl alcohol-g-acrylamide) for removal and photocatalytic degradation of organic dyes. React. Funct. Polym. 2022, 172, 105207. [Google Scholar] [CrossRef]

- Ortega, J.A.C.; Hernández-Montelong, J.; Hernández-Montelongo, R.; Mendoza, A.G.A. Effective Removal of Cu2+ Ions from Aqueous Media Using Poly(acrylamide-co-itaconic acid) Hydrogels in a Semi-Continuous Process. Gels 2023, 9, 702. [Google Scholar] [CrossRef] [PubMed]

- Diacon, A.; Albota, F.; Mocanu, A.; Brincoveanu, O.; Podaru, A.I.; Rotariu, T.; Ahmad, A.A.; Rusen, E.; Toader, G. Dual-Responsive Hydrogels for Mercury Ion Detection and Removal from Wastewater. Gels 2024, 10, 113. [Google Scholar] [CrossRef]

- Chen, J.; Liao, C.; Guo, X.X.; Hou, S.-C.; He, W.-D. PAAO cryogels from amidoximatedP(acrylic acid-co-acrylonitrile) for the adsorption of lead ion. Eur. Polym. J. 2022, 171, 111192. [Google Scholar] [CrossRef]

- Kafetzi, M.; Borchert, K.B.L.; Steinbach, C.; Schwarz, D.; Pispas, S.; Schwarz, S. Thermoresponsive PNIPAM-b-PAA block copolymers as “smart” adsorbents of Cu(II) for water restore treatments. Colloids Surf. A Physicochem. Eng. Asp. 2021, 614, 126049. [Google Scholar] [CrossRef]

- Lv, Q.; Hu, X.; Zhang, X.; Huang, L.; Liu, Z.; Sun, G. Highly efficient removal of trace metal ions by using poly(acrylic acid) hydrogel adsorbent. Mater. Des. 2019, 181, 107934. [Google Scholar] [CrossRef]

- Wanga, X.; Hou, H.; Li, Y.; Wang, Y.; Hao, C.; Ge, C. A novel semi-IPN hydrogel: Preparation, swelling properties and adsorption studies of Co (II). J. Ind. Eng. Chem. 2016, 41, 82–90. [Google Scholar] [CrossRef]

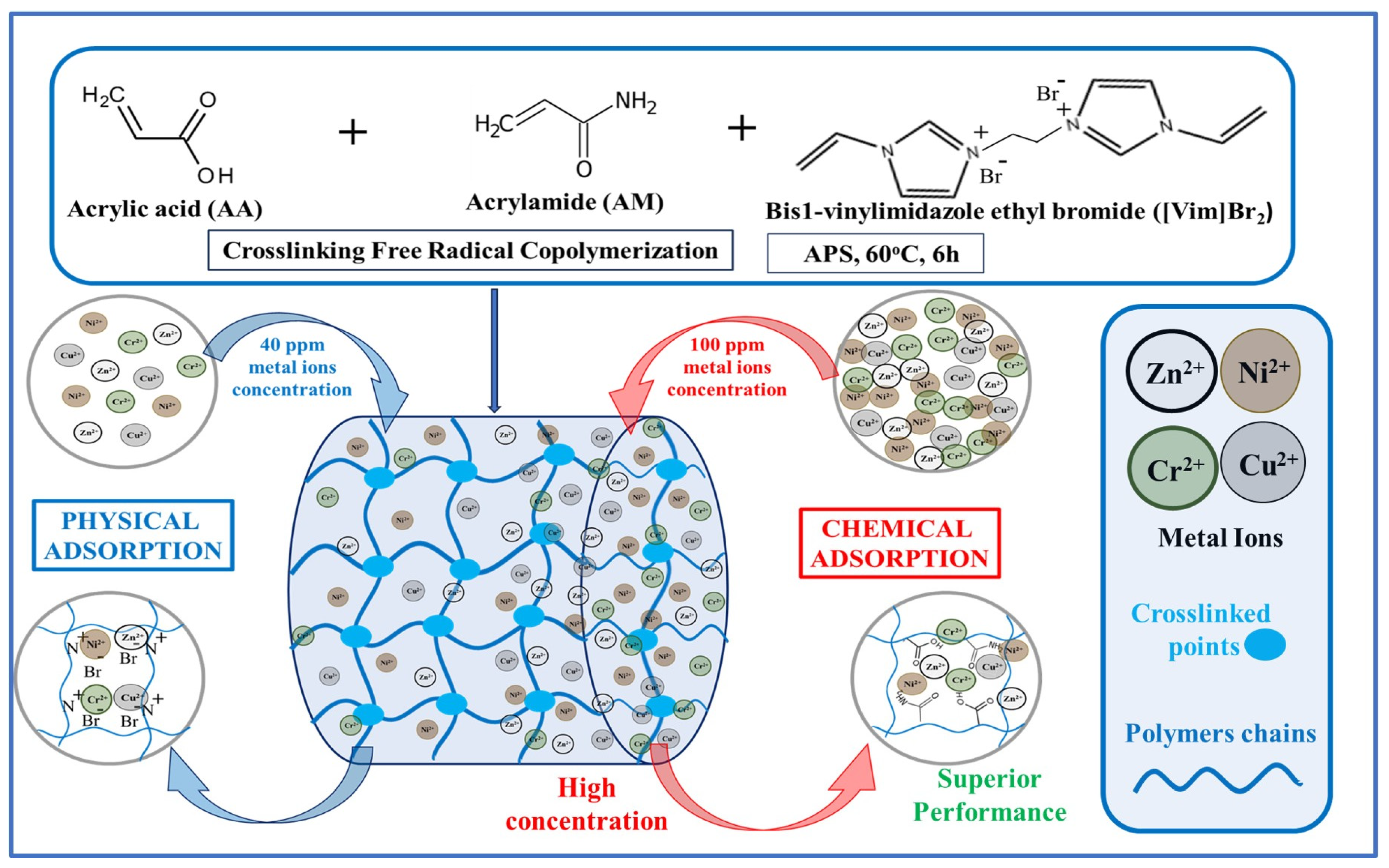

- Sun, J.; Jin, Z.; Wang, J.; Wang, H.; Zhang, Q.; Gao, H.; Jin, Z.; Zhang, J.; Wang, Z. Application of Ionic Liquid Crosslinked Hydrogel for Removing Heavy Metal Ions from Water: Different Concentration Ranges with Different Adsorption Mechanisms. Polymers 2023, 15, 2784. [Google Scholar] [CrossRef] [PubMed]

- Maksoud, I.K.A.; Bassioni, G.; Nady, N.; Younis, S.A.; Ghobashy, M.M.; Abdel-Mottaleb, M.S.A. Radiation synthesis and chemical modifications of p(AAm-co-AAc) hydrogel for improving their adsorptive removal of metal ions from polluted water. Sci. Rep. 2023, 13, 21879. [Google Scholar] [CrossRef]

- Kaya, S.Ç.Y.; Gönder, Z.B.; Gürdaa, G.; Vergili, I. Removal of Cu(II), Ni(II) and Zn(II) from aqueous solutions using poly(2-acrylamido-2-methyl-1-propanesulfonic acid) gel: Sorption kinetics and characterization. Desalin. Water Treat. 2018, 133, 348–358. [Google Scholar] [CrossRef]

- Çavuş, S.; Yasara, G.; Kaya, Y.; Gönder, Z.B.; Gürdag, G.; Vergili, S. Synthesis and characterization of gel beads based on ethyleneglycoldimethacrylate and 2-acrylamido-2-methyl-1-propane sulfonic acid: Removal of Fe(II), Cu(II), Zn(II), and Ni(II) from metal finishing wastewater. Process Saf. Environ. Prot. 2016, 103, 227–236. [Google Scholar] [CrossRef]

- Hui, B.; Ye, L. Structure of polyvinyl alcohol-g-acrylic acid-2-acrylamido-2-methyl-1-propanesulfonic acid hydrogel and adsorption mechanism for advanced Pb(II) removal. J. Ind. Eng. Chem. 2016, 35, 309–317. [Google Scholar] [CrossRef]

- Shoueir, K.R.; Akl, M.A.; Sarhan, A.A.; Atta, A.M. New core@shell nanogel based 2-acrylamido-2-methyl-1-propane sulfonic acid for preconcentration of Pb(II) from various water samples. Appl. Water Sci. 2017, 7, 3729–3740. [Google Scholar] [CrossRef]

- Yang, X.; Debeli, D.K.; Shan, G.; Pan, P. Selective adsorption and high recovery of La3+ using graphene oxide/poly (N-isopropyl acrylamide-maleic acid) cryogel. Chem. Eng. J. 2020, 379, 122335. [Google Scholar] [CrossRef]

- Bakr, A.-S.A.; Al-Shafey, H.I.; Arafa, E.I.; El Naggar, A.M.A. Synthesis and Characterization of Polymerized Acrylamide Coupled with Acrylamido-2-Methyl-1-Propane Sulfonic Acid-Montmorillonite Structure as a Novel Nanocomposite for Cd (II) Removal from Aqueous Solutions. J. Chem. Eng. Data 2020, 65, 4079–4091. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Ai, Z.; Li, M.; Li, H.; Peng, W.; Zhao, Y.; Song, S. Adsorption toward Pb(II) occurring on three-dimensional reticular-structured montmorillonite hydrogel surface. Appl. Clay Sci. 2021, 210, 106153. [Google Scholar] [CrossRef]

- Gao, B.; Yu, H.-R.; Zhang, H.-Y.; Liang, T.; Cheng, C.-J. High-density immobilization of potassium copper hexacyanoferrate in poly (acrylic acid)/laponite hydrogel for enhanced Cs+ removal. J. Environ. Chem. Eng. 2022, 10, 107979. [Google Scholar] [CrossRef]

- Mohammadinezhada, A.; Marandia, G.B.; Farsadroohb, M.; Javadian, H. Synthesis of poly(acrylamide-co-itaconic acid)/MWCNTs superabsorbent hydrogel nanocomposite by ultrasound-assisted technique: Swelling behavior and Pb (II) adsorption capacity. Ultrason. Sonochem. 2018, 49, 1–12. [Google Scholar] [CrossRef]

- Ge, H.; Wang, J. Ear-like poly (acrylic acid)-activated carbon nanocomposite: A highly efficient adsorbent for removal of Cd(II) from aqueous solutions. Chemosphere 2017, 169, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Souda, P.; Sreejith, L. Magnetic hydrogel for better adsorption of heavy metals from aqueous solutions. J. Environ. Chem. Eng. 2015, 3, 1882–1891. [Google Scholar] [CrossRef]

- Chen, J.; Ahmad, A.L.; Lim, J.K.; Ooi, B.S. Adsorption-desorption characteristic of thermo-magneto-responsive poly(Nisopropylacrylamide)-co-acrylic acid composite hydrogel towards chromium (III) ions. J. Water Process Eng. 2019, 32, 100957. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Y.; Wu, Y.; Liu, C.; Liu, X. Preparation of Graphene Oxide Hydrogels and Their Adsorption Applications toward Various Heavy Metal Ions in Aqueous Media. Appl. Sci. 2023, 13, 11948. [Google Scholar] [CrossRef]

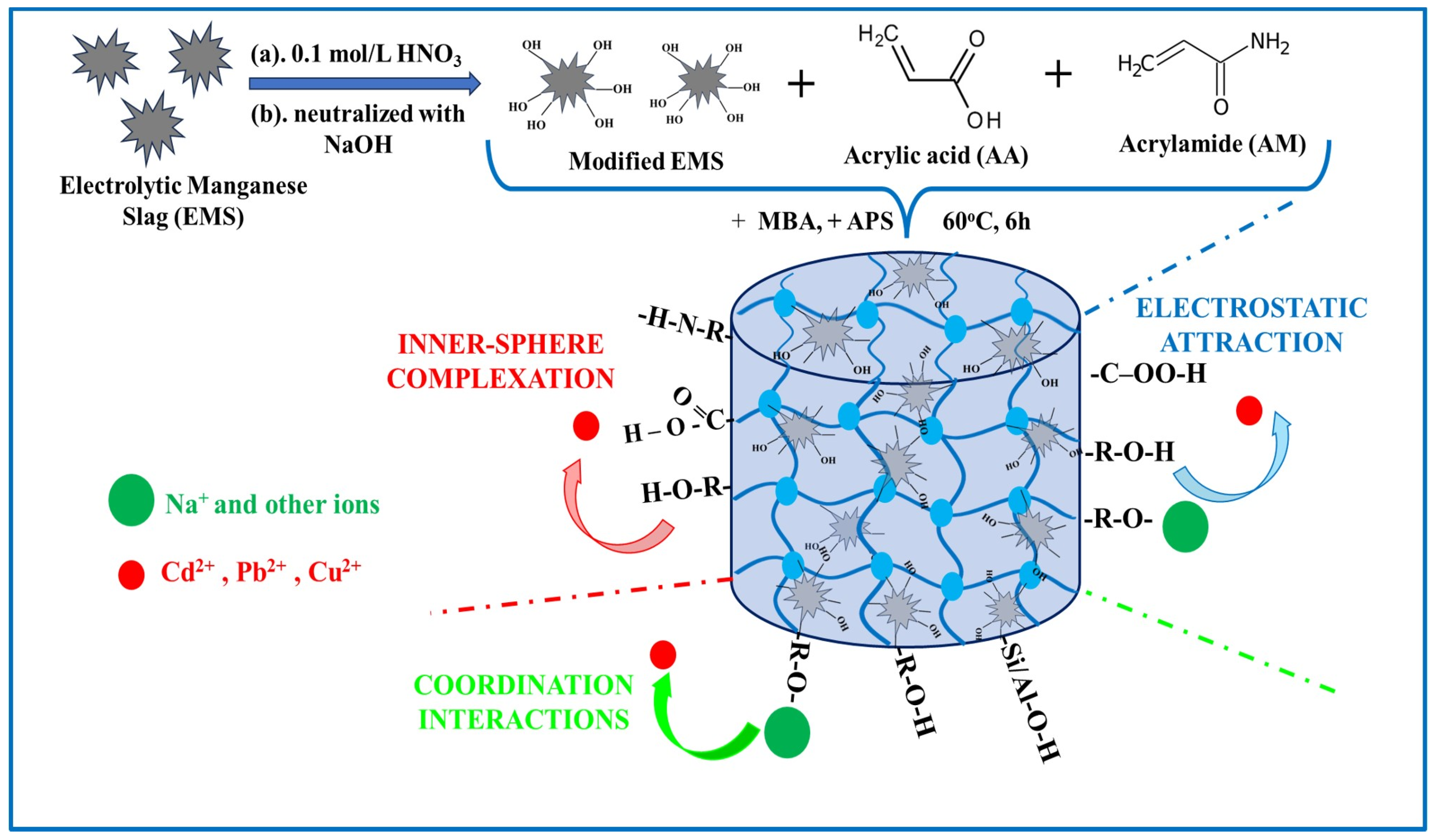

- Ma, M.; Ke, X.; Wang, T.; Li, J.; Ye, H. A novel double-network hydrogel made from electrolytic manganese slag and polyacrylic acid-polyacrylamide for removal of heavy metals in wastewater. J. Hazard. Mater. 2024, 462, 132722. [Google Scholar] [CrossRef]

- Jamnongkan, T.; Kantarot, K.; Niemtang, K.; Pansila, P.P.; Wattanakornsiri, A. Kinetics and mechanism of adsorptive removal of copper from aqueous solution with poly(vinyl alcohol) hydrogel. Trans. Nonferrous Met. Soc. China 2014, 24, 3386–3393. [Google Scholar] [CrossRef]

- Zhou, T.; Xia, F.; Deng, Y.; Zhao, Y. Removal of Pb(II) from aqueous solutions using waste textiles/poly(acrylic acid) composite synthesized by radical polymerization technique. J. Environ. Sci. 2018, 67, 368–377. [Google Scholar] [CrossRef]

- Muñoz-Bonilla, A.; Echeverria, C.; Sonseca, Á.; Arrieta, M.P.; Fernández-García, M. Bio-Based Polymers with Antimicrobial Properties towards Sustainable Development. Materials 2019, 12, 641. [Google Scholar] [CrossRef]

- Benalaya, I.; Alves, G.; Lopes, J.; Silva, L.R. A Review of Natural Polysaccharides: Sources, Characteristics, Properties, Food, and Pharmaceutical Applications. Int. J. Mol. Sci. 2024, 25, 1322. [Google Scholar] [CrossRef]

- Tudu, M.; Samanta, A. Natural polysaccharides: Chemical properties and application in pharmaceutical formulations. Eur. Polym. J. 2023, 184, 111801. [Google Scholar] [CrossRef]

- Qi, X.; Tong, X.; Pan, W.; Zeng, Q.; You, S.; Shen, J. Recent advances in polysaccharide-based adsorbents for wastewater treatment. J. Clean. Prod. 2021, 315, 128221. [Google Scholar] [CrossRef]

- Cywar, R.M.; Rorrer, N.A.; Hoyt, C.B.; Beckham, G.T.; Chen, E.Y.-X. Bio-based polymers with performance-advantaged properties. Nat. Rev. Mater. 2022, 7, 83–103. [Google Scholar] [CrossRef]

- Qureshi, M.A.; Nishat, N.; Jadoun, S.; Ansari, M.Z. Polysaccharide based superabsorbent hydrogels and their methods of synthesis: A review. Carbohydr. Polym. Technol. Appl. 2020, 1, 100014. [Google Scholar] [CrossRef]

- Berradi, A.; Aziz, F.; El Achaby, M.; Ouazzani, N.; Mandi, L. A Comprehensive Review of Polysaccharide-Based Hydrogels as Promising Biomaterials. Polymers 2023, 15, 2908. [Google Scholar] [CrossRef]

- Alsaka, L.; Alsaka, L.; Altaee, A.; Zaidi, S.J.; Zhou, J.; Kazwini, T. A Review of Hydrogel Application in Wastewater Purification. Separations 2025, 12, 51. [Google Scholar] [CrossRef]

- El Halah, A.; López-Carrasquero, F.; Contreras, J. Applications of hydrogels in the adsorption of metallic ions. Cienc. Ing. 2018, 39, 57–69. [Google Scholar]

- Zhou, G.; Luo, J.; Liu, C.; Chu, L.; Crittenden, J. Efficient heavy metal removal from industrial melting effluent using fixed-bed process based on porous hydrogel adsorbents. Water Res. 2018, 131, 246–254. [Google Scholar] [CrossRef]

- Blachnio, M.; Zienkiewicz-Strzalka, M. Evaluation of the Dye Extraction Using Designed Hydrogels for Further Applications towards Water Treatment. Gels 2024, 10, 159. [Google Scholar] [CrossRef]

- Qi, X.; Wu, L.; Su, T.; Zhang, J.; Dong, W. Polysaccharide-based cationic hydrogels for dye adsorption. Colloids Surf. B Biointerfaces 2018, 170, 364–372. [Google Scholar] [CrossRef]

- Utzeri, G.; Verissimo, L.; Ribeiro, A.C.F.; Valente, A.J.M. Pesticides and Their Environment and Health Impact: An Approach to Remediation Using Hydrogels. In Optical and Molecular Physics; Apple Academic Press: Palm Bay, FL, USA, 2021; pp. 447–472. [Google Scholar]

- Akter, M.; Bhattacharjee, M.; Dhar, A.K.; Rahman, F.B.A.; Haque, S.; Rashid, T.U.; Kabir, S.M.F. Cellulose-Based Hydrogels for Wastewater Treatment: A Concise Review. Gels 2021, 7, 30. [Google Scholar] [CrossRef] [PubMed]

- Sjahro, N.; Yunus, R.; Abdullah, L.C.; Rashid, S.A.; Asis, A.J.; Akhlisah, Z.N. Recent advances in the application of cellulose derivatives for removal of contaminants from aquatic environments. Cellulose 2021, 28, 7521–7557. [Google Scholar] [CrossRef]

- Chen, C.; Xi, Y.; Weng, Y. Recent advances in cellulose-based hydrogels for tissue engineering applications. Polymers 2022, 14, 3335. [Google Scholar] [CrossRef] [PubMed]

- Topare, N.S.; Wadgaonkar, V.S. A review on application of low-cost adsorbents for heavy metals removal from wastewater. Mater. Today Proc. 2023, 77, 8–18. [Google Scholar] [CrossRef]

- Zainal, S.H.; Mohd, N.H.; Suhaili, N.; Anuar, F.H.; Lazim, A.M.; Othaman, R. Preparation of cellulose-based hydrogel: A review. J. Mater. Res. Technol. 2021, 10, 935–952. [Google Scholar] [CrossRef]

- Yang, L.; Bao, L.; Dong, T.; Xie, H.; Wang, X.; Wang, H.; Wu, J.; Hao, C. Adsorption properties of cellulose/guar gum/biochar composite hydrogel for Cu2+, Co2+ and methylene blue. Ind. Crops Prod. 2024, 210, 118179. [Google Scholar] [CrossRef]

- Lunardi, V.B.; Santoso, S.P.; Angkawijaya, A.E.; Cheng, K.-C.; Tran-Nguyen, P.L.; Go, A.W.; Nakamura, Y.; Lin, S.-P.; Hsu, H.-Y.; Yuliana, M.; et al. Synthesis of cellulose hydrogel by utilizing agricultural waste and zeolite for adsorption of copper metal ions. Ind. Crops Prod. 2024, 210, 118179. [Google Scholar] [CrossRef]

- Yang, S.-C.; Liao, Y.; Karthikeyan, K.G.; Pan, X.J. Mesoporous cellulose-chitosan composite hydrogel fabricated via the co-dissolution-regeneration process as biosorbent of heavy metals. Environ. Pollut. 2021, 286, 117324. [Google Scholar] [CrossRef]

- Rahman, A.S.A.; Khalil, N.A.; Hossain, M.S.; Yahaya, A.N.A.; Zulkifli, M. A composite hydrogel beads bio-sorbent for removal of copper: Effect of pH of copper solution. Mater. Today 2023, 74, 485–488. [Google Scholar] [CrossRef]

- Hisham, F.; Maziati Akmal, M.H.; Ahmad, F.; Ahmad, K.; Samat, N. Biopolymer chitosan: Potential sources, extraction methods, and emerging applications. Ain Shams Eng. J. 2024, 15, 102424. [Google Scholar] [CrossRef]

- Aranaz, I.; Alcántara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Caballero, A.H.; Acosta, N. Chitosan: An Overview of Its Properties and Applications. Polymers 2021, 13, 3256. [Google Scholar] [CrossRef] [PubMed]

- Abdelwahab, H.E.; Hassan, S.Y.; Mostafa, M.A.; El Sadek, M.M. Synthesis and Characterization of Glutamic-Chitosan Hydrogel for Copper and Nickel Removal from Wastewater. Molecules 2016, 21, 684. [Google Scholar] [CrossRef] [PubMed]

- Zidan, T.A.; Abdelhamid, A.E.; Zaki, E.G. N-Aminorhodanine modified chitosan hydrogel for antibacterial and copper ions removal from aqueous solutions. Int. J. Biol. Macromol. 2020, 158, 32–42. [Google Scholar] [CrossRef]

- Lone, S.; Ho Yoon, D.; Leea, H.; Cheong, I.W. Gelatin-chitosan hydrogel particles for efficient removal of Hg(II) from wastewater. Environ. Sci. Water Res. Technol. 2019, 5, 83. [Google Scholar] [CrossRef]

- Facchi, D.P.; Cazetta, A.L.; Canesin, E.A.; Almeida, V.C.; Bonafé, E.G.; Kipper, M.J.; Martins, A.F. New magnetic chitosan/alginate/Fe3O4@SiO2 hydrogel composites applied for removal of Pb(II) ions from aqueous systems. J. Chem. Eng. 2018, 337, 595–608. [Google Scholar] [CrossRef]

- Zhang, H.; Omer, A.M.; Hu, Z.; Yang, L.-Y.; Ji, C.; Ouyang, X.-K. Fabrication of magnetic bentonite/carboxymethyl chitosan/sodium alginate hydrogel beads for Cu (II) adsorption. Int. J. Biol. Macromol. 2019, 135, 490–500. [Google Scholar] [CrossRef]

- Yang, J.; Li, M.; Wang, Y.; Wu, H.; Ji, N.; Dai, L.; Li, Y.; Xiong, L.; Shi, R.; Sun, Q. High-Strength Physically Multi-Cross-Linked Chitosan Hydrogels and Aerogels for Removing Heavy-Metal Ions. J. Agric. Food Chem. 2019, 67, 13648–13657. [Google Scholar] [CrossRef]

- Khalil, N.A.; Syafiqah, A.; Rahman, A.; Huraira, A.M.A.; Janurin, S.N.D.F.; Fizal, A.N.S.; Ahmad, N.; Zulkifli, M.; Hossain, M.S.; Yahaya, A.N.A. Magnetic chitosan hydrogel beads as adsorbent for copper removal from aqueous solution. Mater. Today 2023, 74, 499–503. [Google Scholar] [CrossRef]

- Miron, A.; Iordache, T.-V.; Valente, A.J.M.; Durães, L.M.R.; Sarbu, A.; Ivan, G.R.; Zaharia, A.; Sandu, T.; Iovu, H.; Chiriac, A.-L. Chitosan-Based Beads Incorporating Inorganic–Organic Composites for Copper Ion Retention in Aqueous Solutions. Int. J. Mol. Sci. 2024, 25, 2411. [Google Scholar] [CrossRef]

- Arafa, E.G.; Mahmoud, R.; Gadelhak, Y.; Gawad, O.F.A. Design, preparation, and performance of different adsorbents based on carboxymethyl chitosan/sodium alginate hydrogel beads for selective adsorption of Cadmium (II) and Chromium (III) metal ions. Int. J. Biol. Macromol. 2024, 273, 132809. [Google Scholar] [CrossRef]

- Tang, S.; Yang, J.; Lin, L.; Peng, K.; Chen, Y.; Jin, S.; Yao, W. Construction of physically crosslinked chitosan/sodium alginate/calciumion double-network hydrogel and its application to heavy metal ions removal. J. Chem. Eng. 2020, 393, 124728. [Google Scholar] [CrossRef]

- Perumal, S.; Atchudan, R.; Ho Yoon, D.; Joo, J.; Cheong, I.W. Spherical Chitosan/Gelatin Hydrogel Particles for Removal of Multiple Heavy Metal Ions from Wastewater. Ind. Eng. Chem. Res. 2019, 58, 9900–9907. [Google Scholar] [CrossRef]

- Meetam, P.; Phonlakan, K.; Nijpanich, S.; Budsombat, S. Chitosan-grafted hydrogels for heavy metal ion adsorption and catalytic reduction of nitroaromatic pollutants and dyes. Int. J. Biol. Macromol. 2024, 255, 128261. [Google Scholar] [CrossRef]

- Bi, S.C.; Wang, P.J.; Hu, S.H.; Li, S.K.; Pang, J.H.; Zhou, Z.Z.; Sun, G.; Huang, L.; Cheng, X.; Xing, S.; et al. Construction of physical-crosslink chitosan/PVA double-network hydrogel with surface mineralization for bone repair. Carbohydr. Polym. 2019, 224, 115176. [Google Scholar] [CrossRef]

- Tao, H.C.; Li, S.; Zhang, L.J.; Chen, Y.Z.; Deng, L.P. Magnetic chitosan/sodium alginate gel bead as a novel composite adsorbent for Cu(II) removal from aqueous solution. Environ. Geochem. Health 2019, 41, 297–308. [Google Scholar] [CrossRef]

- Bojorges, H.; López-Rubio, A.; Martínez-Abad, A.; Fabra, M.J. Overview of alginate extraction processes: Impact on alginate molecular structure and techno-functional properties. Trends Food Sci. 2023, 140, 104142. [Google Scholar] [CrossRef]

- Ren, H.; Gao, Z.; Wu, D.; Jiang, J.; Sun, Y.; Luo, C. Efficient Pb(II) removal using sodium alginate-carboxymethyl cellulose gel beads: Preparation, characterization, and adsorption mechanism. Carbohydr. Polym. 2016, 137, 402–409. [Google Scholar] [CrossRef]

- Benettayeb, A.; Ghosh, S.; Usman, M.; Seihoub, F.Z.; Sohoo, I.; Chia, C.H.; Sillanpää, M. Some Well-Known Alginate and Chitosan Modifications Used in Adsorption: A Review. Water 2022, 14, 1353. [Google Scholar] [CrossRef]

- Gao, X.; Guo, C.; Hao, J.; Zhao, Z.; Long, H.; Li, M. Adsorption of heavy metal ions by sodium alginate-based adsorbent-a review and new perspectives. Int. J. Biol. Macromol. 2020, 164, 4423–4434. [Google Scholar] [CrossRef]

- Shehzad, H.; Ahmed, E.; Sharif, A.; Farooqi, Z.H.; Din, M.I.; Begum, R.; Nawaz, I. Modified alginate-chitosan-TiO2 composites for adsorptive removal of Ni(II) ions from aqueous medium. Int. J. Biol. Macromol. 2022, 194, 117–127. [Google Scholar] [CrossRef]

- Song, Q.; Ouyang, B.; Lin, Y.; Wang, C. Cross-linked sodium alginate-carboxymethyl chitosan hydrogel beads for adsorption of Ni(II) ions. Desalin. Water Treat. 2023, 286, 183–191. [Google Scholar] [CrossRef]

- Yu, C.; Wang, M.; Dong, X.; Shi, Z.; Zhang, X.; Lin, Q. Removal of Cu(II) from aqueous solution using Fe3O4–alginate modified biochar microspheres. RSC Adv. 2017, 7, 53135–53144. [Google Scholar] [CrossRef]

- Yu, C.; Li, H.; Ma, H.; Zhang, L.; Li, Y.; Lin, Q. Characteristics and mechanism of Cu(II) adsorption on prepared calcium alginate/carboxymethyl cellulose@MnFe2O4. Polym. Bull. 2022, 79, 1201–1216. [Google Scholar] [CrossRef]

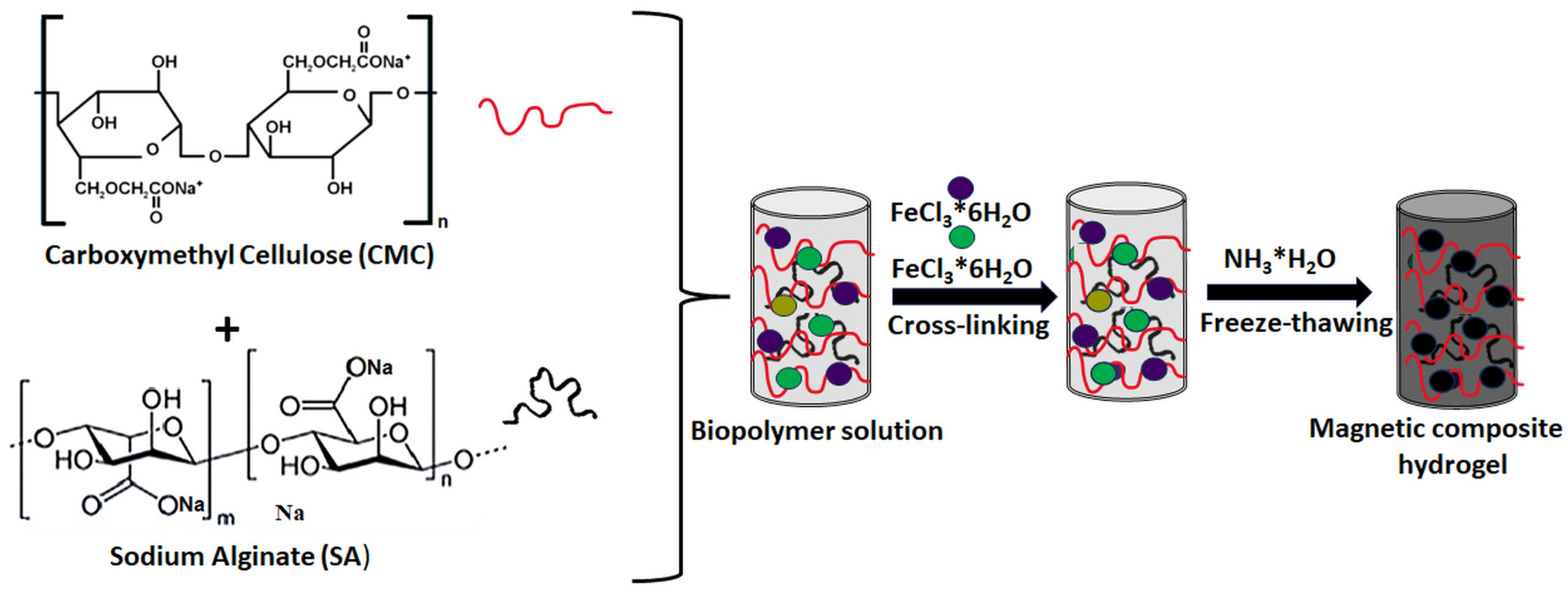

- Wu, S.; Guo, J.; Wang, Y.; Huang, C.; Hu, Y. Facile preparation of magnetic sodium alginate/carboxymethyl cellulose composite hydrogel for removal of heavy metal ions from aqueous solution. J. Mater. Sci. 2021, 56, 13096–13107. [Google Scholar] [CrossRef]

- Zhou, S.; Xie, Y.; Zhu, F.; Gao, Y.; Liu, Y.; Tang, Z.; Duan, Y. Amidoxime modified chitosan/graphene oxide composite for efficient adsorption of U(VI) from aqueous solutions. J. Environ. Chem. Eng. 2021, 9, 106363. [Google Scholar] [CrossRef]

- Ji, D.-B.; Yang, J.-L.; Wang, T.-Y.; Li, X.-R.; Li, G.-H.; Bai, Z.-H.; Yuan, D.-D.; Zhao, X.-F.; Wu, H.-J. Nano-ZnO enhanced amidoxime-functionalized sodium alginate composite hydrogel microspheres for uranium capture from wastewater. Sep. Purif. Technol. 2024, 338, 126568. [Google Scholar] [CrossRef]

- Yaseen, D.A.; Scholz, M. Textile dye wastewater characteristics and constituents of synthetic effluents: A critical review. Int. J. Environ. Sci. Technol. 2019, 16, 1193–1226. [Google Scholar] [CrossRef]

- Raj, S.; Singh, H.; Bhattacharya, J. Treatment of textile industry wastewater based on coagulation-flocculation aided sedimentation followed by adsorption: Process studies in an industrial ecology concept. Sci. Total Environ. 2023, 857, 159464. [Google Scholar] [CrossRef]

- Li, M.; Wang, Z.; Li, B. Adsorption behaviour of congo red by cellulose/chitosan hydrogel beads regenerated from ionic liquid. Desalin. Water Treat. 2016, 57, 16970–16980. [Google Scholar] [CrossRef]

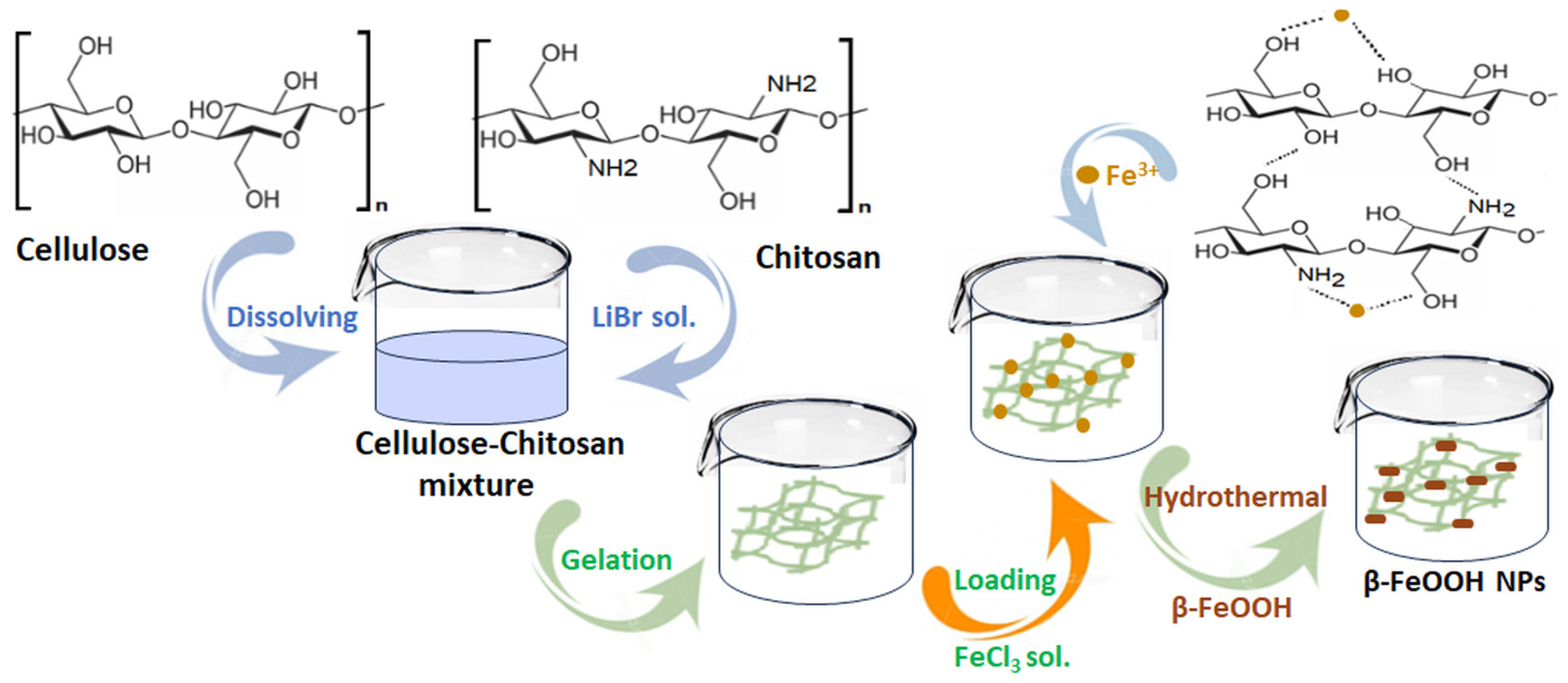

- Yang, X.; Ci, Y.; Zhu, P.; Chen, T.; Li, F.; Tang, Y. Preparation and characterization of cellulose-chitosan/β-FeOOH composite hydrogels for adsorption and photocatalytic degradation of methyl orange. Int. J. Biol. Macromol. 2024, 274, 133201. [Google Scholar] [CrossRef]

- Wang, W.; Hu, J.; Zhang, R.; Yan, C.; Cui, L.; Zhu, J. A pH-responsive carboxymethyl cellulose/chitosan hydrogelfor adsorption and desorption of anionic and cationic dyes. Cellulose 2021, 28, 897–909. [Google Scholar] [CrossRef]

- Meas, A.; Wi, E.; Chang, M.; Hwang, H.S. Carboxylmethyl cellulose produced from wood sawdust for improving properties of sodium alginate hydrogel in dye adsorption. Sep. Purif. Technol. 2024, 341, 126906. [Google Scholar] [CrossRef]

- Mohammed, N.; Grishkewich, N.; Berry, R.M.; Tam, K.C. Cellulose nanocrystal-alginate hydrogel beads as novel adsorbents for organic dyes in aqueous solutions. Cellulose 2015, 22, 3725–3738. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.; Zhu, S.; Yu, M. Green and facile fabrication of nano-ZnO coated cellulose/starch/activated carbon hydrogel for enhanced dyes adsorption and antibacterial activity. Mater. Today Commun. 2022, 33, 104355. [Google Scholar] [CrossRef]

- Ngwabebhoh, F.A.; Gazi, M.; Oladipo, A.A. Adsorptive removal of multi-azo dye from aqueous phase using a semi-IPN superabsorbent chitosan-starch hydrogel. Chem. Eng. Res. Des. 2016, 112, 274–288. [Google Scholar] [CrossRef]

- Cui, L.; Xiong, Z.; Guo, Y.; Liu, Y.; Zhao, J.; Zhang, C.; Zhu, P. Fabrication of interpenetrating polymer network chitosan/gelatin porous materials and study on dye adsorption properties. Carbohydr. Polym. 2015, 132, 330–337. [Google Scholar] [CrossRef]

- Peng, Q.; Liu, M.; Zheng, J.; Zhou, C. Adsorption of dyes in aqueous solutions by chitosan-halloysite nanotubes composite hydrogel beads. Micropor. Mesopor. Mater. 2015, 201, 190–201. [Google Scholar] [CrossRef]

- Cınar, S.; Kaynarb, Ü.H.; Aydemir, T.; Kaynar, S.C.; Ayvacıklı, M. An efficient removal of RB5 from aqueous solution by adsorption onto nano-ZnO/Chitosan composite beads. Int. J. Biol. Macromol. 2017, 96, 459–465. [Google Scholar] [CrossRef]

- Gonçalves, J.O.; Santos, J.P.; Rios, E.C.; Crispim, M.M.; Dotto, G.L.; Pinto, L.A.A. Development of chitosan based hybrid hydrogels for dyes removal fromaqueous binary system. J. Mol. Liq. 2017, 225, 265–270. [Google Scholar] [CrossRef]

- Murcia-Salvador, A.; Rodríguez-López, M.I.; Pellicer, J.A.; Gómez-Morte, T.; Aunón-Calles, D.; Yánez-Gascón, M.J.; Cerón-Carrasco, J.P.; Gil-Izquierdo, Á.; Núnez-Delicado, E.; Gabaldón, J.A. Development of Chitosan Polysaccharide-Based Magnetic Gel for Direct Red 83:1 Removal from Water. Gels 2024, 10, 496. [Google Scholar] [CrossRef]

- Ohemeng-Boahen, G.; Sewu, D.D.; Tran, H.N.; Woo, S.H. Enhanced adsorption of congo red from aqueous solution using chitosan/hematite nanocomposite hydrogel capsule fabricated via anionic surfactant gelation. Colloids Surf. A. 2021, 625, 126911. [Google Scholar] [CrossRef]

- Han, D.; Zhao, H.; Gao, L.; Qin, Z.; Ma, J.; Han, Y.; Jiao, T. Preparation of carboxymethyl chitosan/phytic acid composite hydrogels for rapid dye adsorption in wastewater treatment. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127355. [Google Scholar] [CrossRef]

- Far, B.F.; Naimi-Jamal, M.R.; Jahanbakhshi, M.; Khalafvandi, S.A.; Alian, M.; Jahromi, D.R. Decontamination of Congo red dye from aqueous solution using nanoclay/chitosan-graft-gelatin nanocomposite hydrogel. J. Mol. Liq. 2024, 395, 123839. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Q.; Bai, X.; Li, X.; Zhang, G.; Zou, J.; Fei, P.; Lai, W. Double network self-healing hydrogels based on carboxyethyl chitosan/oxidized sodium alginate/Ca2+: Preparation, characterization and application in dye adsorption. Int. J. Biol. Macromol. 2024, 264, 130564. [Google Scholar] [CrossRef]

- Mittal, H.; Alili, A.A.; Morajka, P.P.; Alhassan, S.M. GO crosslinked hydrogel nanocomposites of chitosan/carboxymethyl cellulose—A versatile adsorbent for the treatment of dyes contaminated wastewater. Int. J. Biol. Macromol. 2021, 167, 1248–1261. [Google Scholar] [CrossRef]

- Tu, H.; Yu, Y.; Chen, J.; Shi, X.; Zhou, J.; Deng, H.; Dua, Y. Highly cost-effective and high-strength hydrogels as dye adsorbents from natural polymers: Chitosan and cellulose. Polym. Chem. 2017, 8, 2913. [Google Scholar] [CrossRef]

- Wang, C.; Feng, X.; Shang, S.; Liu, H.; Song, Z.; Zhang, H. Lignin/sodium alginate hydrogel for efficient removal of methylene blue. Int. J. Biol. Macromol. 2023, 237, 124200. [Google Scholar] [CrossRef]

- Belhouchat, N.; Zaghouane-Boudiaf, H.; Viseras, C. Removal of anionic and cationic dyes from aqueous solution with activated organo-bentonite/sodium alginate encapsulated beads. Appl. Clay Sci. 2017, 135, 9–15. [Google Scholar] [CrossRef]

- Gan, L.; Li, H.; Chen, L.; Xu, L.; Liu, J.; Geng, A.; Mei, C.; Shang, S. Graphene oxide incorporated alginate hydrogel beads for the removal of various organic dyes and bisphenol A in water. Colloid Polym. Sci. 2018, 296, 607–615. [Google Scholar] [CrossRef]

- Mittal, H.; Maity, A.; Ray, S.S. Effective removal of cationic dyes from aqueous solution using gum ghatti-based biodegradable hydrogel. Int. J. Biol. Macromol. 2015, 79, 8–20. [Google Scholar] [CrossRef]

- Zhang, P.; Raza, S.; Cheng, Y.; Claudine, U.; Hayat, A.; Bashir, T.; Ali, T.; Ghasali, E.; Orooji, Y. Fabrication of maleic anhydride-acrylamide copolymer based sodium alginate hydrogel for elimination of metal ions and dyes contaminants from polluted water. Int. J. Biol. Macromol. 2024, 261, 129146. [Google Scholar] [CrossRef] [PubMed]

- Malatji, N.; Makhado, E.; Modibane, K.D.; Ramohlola, K.E.; Maponya, T.C.; Monama, G.R.; Hato, M.J. Removal of methylene blue from wastewater using hydrogel nanocomposites. Nanomater. Nanotechnol. 2021, 11, 1–27. [Google Scholar] [CrossRef]

- Turkmen, D.; Bakhshpour, M.; Akgonullu, S.; Asir, S.; Denizli, A. Heavy metal ions removal from wastewater using cryogels: A review. Front. Sustain. 2022, 3, 765592. [Google Scholar] [CrossRef]

- Yu, C.; Wang, F.; Zhang, C.; Fu, S.; Lucia, L.A. The synthesis and adsorption dynamics of lignin-based hydrogel for remediation of cationic dye-contaminated effluent. React. Funct. Polym. 2016, 106, 137–142. [Google Scholar] [CrossRef]

- Krishnappa, P.B.; Badalamoole, V. Karaya gum-graft-poly(2-(dimethylamino)ethyl methacrylate) gel: An efficient adsorbent for removal of ionic dyes from water. Int. J. Biol. Macromol. 2019, 122, 997–1007. [Google Scholar] [CrossRef]

- Bagheri, N.; Lakouraj, M.M.; Hasantabar, V.; Mohseni, M. Biodegradable macro-porous CMC-polyaniline hydrogel: Synthesis, characterization and study of antimicrobial elimination and sorption capacity of dyes from waste water. J. Hazard. Mater. 2021, 403, 123631. [Google Scholar] [CrossRef]

- Li, F.; Miao, G.; Gao, Z.; Xu, T.; Zhu, X.; Miao, X.; Song, Y.; Ren, G.; Li, X. A versatile hydrogel platform for oil/water separation, dye adsorption, and wastewater purification. Cellulose 2022, 29, 4427–4438. [Google Scholar] [CrossRef]

- Huang, Q.; Zhou, Y.; Fu, Z.; Zhu, J. Preparation of an injectable hydrogel reinforced by graphene oxide and its application in dye wastewater treatment. J. Mater. Sci. 2023, 58, 3117–3133. [Google Scholar] [CrossRef]

- Zhang, F.; Guo, Y.; Wu, X.; Gao, C.; An, Q.; Tian, Z.; Sun, R. Preparation of a novel lactose-lignin hydrogel catalyst with self-reduction capacity for nitrogeneous wastewater treatment. Front. Chem. Sci. Eng. 2024, 18, 99. [Google Scholar] [CrossRef]

- Zamani-Babgohari, F.; Irannejad, A.; Pour, M.K.; Khayati, G.R. Synthesis of carboxymethyl starch co(polyacrylamide/polyacrylic acid) hydrogel for removing methylene blue dye from aqueous solution. Int. J. Biol. Macromol. 2024, 269, 132053. [Google Scholar] [CrossRef]

- Saber-Samandari, S.; Gulcan, H.O.; Saber-Samandari, S.; Gazi, M. Efficient removal of anionic cationic dyes from an aqueous solution using pullulan-graft-polyacrylamide porous hydrogel. Water Air Soil Pollut. 2014, 225, 2177. [Google Scholar] [CrossRef]

- Qian, H.; Wang, J.; Yan, L. Synthesis of lignin-poly(N-methylaniline)-reduced graphene oxide hydrogel for organic dye and lead ions removal. J. Bioresour. Bioprod. 2020, 5, 204–210. [Google Scholar] [CrossRef]

- Gong, G.; Zhang, F.; Cheng, Z.; Zhou, L. Facile fabrication of magnetic carboxymethyl starch/poly(vinyl alcohol) composite gel for methylene blue removal. Int. J. Biol. Macromol. 2015, 81, 205–211. [Google Scholar] [CrossRef] [PubMed]

- Berg, J.; Seiffert, S. Composite hydrogels based on calcium alginate and polyethyleneimine for wastewater treatment. J. Polym. Sci. 2023, 61, 2203–2222. [Google Scholar] [CrossRef]

- Qi, X.; Wei, W.; Su, T.; Zhang, J.; Dong, W. Fabrication of a new polysaccharide-based adsorbent for water purification. Carbohydr. Polym. 2018, 195, 368–377. [Google Scholar] [CrossRef]

- Toledo, P.V.O.; Limeira, D.P.C.; Siqueira, N.C.; Petri, D.F.S. Carboxymethyl cellulose/poly(acrylic acid) interpenetrating polymer network hydrogels as multifunctional adsorbents. Cellulose 2019, 26, 597–615. [Google Scholar] [CrossRef]

- Rahman, O.; Halim, A.; Deb, A.; Ahmed, S.; Rahman, W.; Dafader, N.C.; Alam, S.M.N.; Khandaker, S.; Alam, J. Modification of superabsorbent hydrogels for industrial wastewater treatment. Adv. Polym. Technol. 2022, 2022, 8405230. [Google Scholar] [CrossRef]

- Getya, D.; Lucas, A.; Gitsov, I. Composite hydrogels based on poly(ethylene glycol) and cellulose macromonomers as fortified materials for environmental cleanup and clean water safeguarding. Int. J. Mol. Sci. 2023, 24, 7558. [Google Scholar] [CrossRef]

- Liu, Z.; Li, D.; Dai, H.; Huang, H. Enhanced properties of tea residue cellulose hydrogels by addition of graphene oxide. J. Mol. Liq. 2017, 244, 110–116. [Google Scholar] [CrossRef]

- Tao, E.; Yang, S.; Hao, X. Graphene oxide-montmorillonite/sodium alginate aerogel beads for selective adsorption of methylene blue in wastewater. J. Alloys Compd. 2020, 832, 154833. [Google Scholar] [CrossRef]

- Mittal, H.; Kumar, V.; Alhassan, S.M.; Ray, S.S. Modification of gum ghatti via grafting with acrylamide and analysis of its flocculation, adsorption, and biodegradation properties. Int. J. Biol. Macromol. 2018, 114, 283–294. [Google Scholar] [CrossRef] [PubMed]

- Raza, S.; Ghasali, E.; Hayat, A.; Zhang, P.; Orooji, Y.; Lin, H. Sodium alginate hydrogel-encapsulated trans-anethole based polymer: Synthesis and applications as an eradicator of metals and dyes from wastewater. Int. J. Biol. Macromol. 2024, 254, 127153. [Google Scholar] [CrossRef] [PubMed]

- Mittal, H.; Maity, A.; Ray, S.S. Gum karaya based hydrogel nanocomposites for the effective removal of cationic dyes from aqueous solutions. Appl. Surf. Sci. 2016, 364, 917–930. [Google Scholar] [CrossRef]

- Bardajee, G.R.; Mahmoodian, H.; Boraghi, S.A.; Elmizadeh, H.; Ziarani, N.B.; Rezanejad, Z.; Tyagi, I.; Gaur, R.; Javadian, H. Nanoporous hydrogel adsorbent based on salep: Swelling behavior and methyl orange adsorption capacity. Environ. Res. 2023, 225, 115571. [Google Scholar] [CrossRef]

- Goddeti, S.R.M.; Bhaumik, M.; Maity, A.; Ray, S.S. Removal of Congo red from aqueous solution by adsorption using gum ghatti and acrylamide graft copolymer coated with zero valent iron. Int. J. Biol. Macromol. 2020, 149, 21–30. [Google Scholar] [CrossRef]

- Tang, Y.; Zeng, Y.; Hu, T.; Zhou, Q.; Peng, Y. Preparation of lignin sulfonate-based mesoporous materials for adsorbing malachite green from aqueous solution. J. Environ. Chem. Eng. 2016, 4, 2900–2910. [Google Scholar] [CrossRef]

- Aljeboree, A.M.; Hasan, I.T.; Al-Warthan, A.; Alkaim, A.F. Preparation of sodium alginate-based SA-g-poly(ITA-co-VBS)/RC hydrogel nanocomposites: And their application towards dye adsorption. Arab. J. Chem. 2024, 17, 105589. [Google Scholar] [CrossRef]

- Sharma, B.; Thakur, S.; Mamba, G.; Prateek; Gupta, R.K.; Gupta, V.K.; Thakur, V.K. Titania modified gum tragacanth based hydrogel nanocomposite for water remediation. J. Environ. Chem. Eng. 2021, 9, 104608. [Google Scholar] [CrossRef]

- Salzano de Luna, M.; Castaldo, R.; Altobelli, R.; Gioiella, L.; Filippone, G.; Gentile, G.; Ambrogi, V. Chitosan hydrogels embedding hyper-crosslinked polymer particles as reusable broad-spectrum adsorbents for dye removal. Carbohydr. Polym. 2017, 177, 347–354. [Google Scholar] [CrossRef]

- Peighambardoust, S.J.; Zarkhaneh, S.I.; Foroughi, M.; Foroutan, R.; Azimi, H.; Ramavandi, B. Effectiveness of polyacrylamide-g-gelatin/ACL/Mg-Fe LDH composite hydrogel as an eliminator of crystal violet dye. Environ. Res. 2024, 258, 119428. [Google Scholar] [CrossRef]

- Liu, B.; Zheng, H.; Wang, Y.; Chen, X.; Zhao, C.; An, Y.; Tang, X. A novel carboxyl-rich chitosan-based polymer and its application for clay flocculation and cationic dye removal. Sci. Total Environ. 2018, 640–641, 107–115. [Google Scholar] [CrossRef]

- Wu, L.; Shi, M.; Guo, R.; Dong, W. Development of a novel pullulan/polydopamine composite hydrogel adsorbent for dye removal. Colloids Surf. A Physicochem. Eng. Asp. 2022, 652, 129632. [Google Scholar] [CrossRef]

- Mohamed, R.R.; Abu Elella, M.H.; Sabaa, M.W.; Saad, G.R. Synthesis of an efficient adsorbent hydrogel based on biodegradable polymers for removing crystal violet dye from aqueous solution. Cellulose 2018, 25, 6513–6529. [Google Scholar] [CrossRef]

- Ullah, B.; Alam, S.; Shah, L.A.; Zahoor, M.; Umar, M.N.; Ullah, R.; Ali, E.A. Synthesis, characterization and adsorption studies of hydroxyl ethyl cellulose grafted polyacrylic acid hydrogels; using basic yellow-28 as model dye. Desalination Water Treat. 2024, 318, 100360. [Google Scholar] [CrossRef]

- Mandal, B.; Kumar, R. Removal of safranine T and brilliant cresyl blue dyes from water by carboxy methyl cellulose incorporated acrylic hydrogels: Isotherms, kinetics and thermodynamic study. J. Taiwan Inst. Chem. Eng. 2016, 60, 313–327. [Google Scholar] [CrossRef]

- Qasem, N.A.A.; Mohammed, R.H.; Lawal, D.U. Removal of heavy metal ions from wastewater: A comprehensive and critical review. Npj Clean Water. 2021, 4, 36. [Google Scholar] [CrossRef]

- Ying, Z.; Yu, C.; Jian, Z.; Zongrui, T.; Shaoghua, J. Preparation of SA-g-(PAA-co-PDMC) polyampholytic superabsorbent polymer and its application to the anionic dye adsorption removal from effluents. Sep. Purif. Technol. 2017, 188, 329–340. [Google Scholar] [CrossRef]

- Kono, H.; Ogasawara, K.; Kusumoto, R.; Oshima, K.; Hashimoto, H.; Shimizu, Y. Cationic cellulose hydrogels cross-linked by poly(ethylene glycol): Preparation, molecular dynamic, and adsorption of anionic dyes. Carbohydr. Polym. 2016, 152, 170–180. [Google Scholar] [CrossRef]

- Skoric, M.L.; Terzic, I.; Milosavljevic, N.; Radetic, M.; Saponjic, Z.; Radoicic, M.; Kalagasidis Krusic, M. Chitosan-based microparticles for immobilization of TiO2 nanoparticles and their application for degradation of textile dyes. Eur. Polym. J. 2016, 82, 57–70. [Google Scholar] [CrossRef]

- Becalli Vilela, P.; Dalalibera, A.; Costa Duminelli, E.; Becegato, V.A.; Paulino, A.T. Adsorption and removal of chromium (VI) contained in aqueous solutions using a chitosan-based hydrogel. Environ. Sci. Pollut. Res. 2019, 26, 28481–28489. [Google Scholar] [CrossRef]

- Nowruzi, R.; Heydari, M.; Javanbakht, V. Synthesis of a chitosan/polyvinyl alcohol/activate carbon biocomposite for removal of hexavalent chromium from aqueous solution. Int. J. Biol. Macromol. 2020, 147, 209–216. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zou, K.; Yan, L.; Liu, J.; Liu, B.; Qing, T.P.; Feng, B. A biomass resource strategy for alginate-polyvinyl alcohol double network hydrogels and their adsorption to heavy metals. Sep. Purif. Technol. 2022, 301, 122050. [Google Scholar] [CrossRef]

- Haque, O.; Mondal, I.H. Synthesis and characterization of cellulose-based eco-friendly hydrogels. Rajshahi Univ. J. Sci. Eng. 2016, 44, 45–53. [Google Scholar] [CrossRef]

- Darban, Z.; Shahabuddin, S.; Gaur, R.; Ahmad, I.; Sridewi, N. Hydrogel-based adsorbent material for the effective removal of heavy metals from wastewater: A comprehensive review. Gels 2022, 8, 263. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, L.; Tan, B.; Li, J.; Gao, X.; He, Y.; Du, X.; Zhang, W.; Wang, W. Adsorption behavior of heavy metal ions from aqueous solution onto composite dextran-chitosan macromolecule resin adsorbent. Int. J. Biol. Macromol. 2019, 141, 738–746. [Google Scholar] [CrossRef]

- Jamaluddin, S.S.; Ghazi, R.M.; Yusoff, N.R.M.; Yusoff, S.F.M. Adsorption of Cu2+ ions using rubber-based hydrogel. BIO Web Conf. 2023, 73, 05003. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, Y.; Wu, Y.; Li, S.; Yin, H.; Wang, J. α-ketoglutaric acid modified chitosan/polyacrylamide semi-interpenetrating polymer network for removal of heavy metal ions. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127262. [Google Scholar] [CrossRef]

- Zheng, Y.; Hua, S.; Wang, A. Adsorption behavior of Cu2+ from from aqueous solutions onto starch-g-poly(acrylic acid)/sodium humate hydrogels. Desalination 2010, 263, 170–175. [Google Scholar] [CrossRef]

- Apopei, D.F.; Dinu, M.V.; Trochimczuk, A.W.; Drăgan, E.S. Sorption isotherms of heavy metal ions onto semi-interpenetrating polymer network hydrogels based on polyacrylamide and anionically modified potato starch. Ind. Eng. Chem. Res. 2012, 51, 10462–10471. [Google Scholar] [CrossRef]

- Dolgormaa, A.; Lv, C.-J.; Li, Y.; Yang, J.; Yang, J.-X.; Chen, P.; Wang, H.-P.; Huang, J. Adsorption of Cu (II) and Zn (II) ions from aqueous solution by Gel/PVA-modified super-paramagnetic iron oxide nanoparticles. Molecules 2018, 23, 2982. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, L.; Fu, S.; Zheng, L.; Zhan, H. Adsorption behavior of Cd2+, Pb2+, and Ni2+ from aqueous solutions on cellulose-based hydrogels. Bioresources 2012, 7, 2752–2765. [Google Scholar] [CrossRef]

- Jafarigol, E.; Ghotli, R.A.; Hajipour, A.; Pahlevani, H.; Salehi, M.B. Tough dual-network GAMAAX hydrogel for efficient removal of cadmium and nickel ions in wastewater treatment applications. J. Ind. Eng. Chem. 2021, 94, 352–360. [Google Scholar] [CrossRef]

- Ma, J.; Zhou, G.; Chu, L.; Liu, Y.; Liu, C.; Luo, S.; Wei, Y. Efficient removal of heavy metal ions with an EDTA functionalized chitosan/polyacrylamide double network hydrogel. ACS Sustain. Chem. Eng. 2017, 5, 843–851. [Google Scholar] [CrossRef]

- Astrini, N.; Anah, L.; Haryadi, H.R. Adsorption of heavy metal ion from aqueous solution by using cellulose based hydrogel composite. Macromol. Symp. 2015, 353, 191–197. [Google Scholar] [CrossRef]

- Zhu, Y.; Zheng, Y.; Wang, F.; Wang, A. Fabrication of magnetic macroporous chitosan-g-poly(acrylic acid) hydrogel for removal of Cd2+ and Pb2+. Int. J. Biol. Macromol. 2016, 93, 483–492. [Google Scholar] [CrossRef]

- Huang, S.; Liu, X.; Hu, Q.; Wei, T.; Wang, J.; Chen, H.; Wu, C. Temperature-driven metalloprotein-based hybrid hydrogels for selective and reversible removal of cadmium (II) from water. ACS Appl. Mater. Interfaces 2020, 12, 2991–2998. [Google Scholar] [CrossRef]

- Hu, T.; Liu, B.N.; Bu, H.; Hu, H.J.; Zhu, Q.S.; Tang, S.; Li, Y.; Wang, J.; Jiang, G.B. Self-separating core-shell spheres with a carboxymethyl chitosan/acrylic acid/Fe3O4 composite core for soil Cd removal. Carbohydr. Polym. 2024, 343, 122428. [Google Scholar] [CrossRef]

- Zhou, G.; Liu, C.; Chu, L.; Tang, Y.; Luo, S. Rapid and efficient treatment of wastewater with high-concentration heavy metals using a new type of hydrogel-based adsorption process. Bioresour. Technol. 2016, 219, 451–457. [Google Scholar] [CrossRef]

- Khademi, F.; Salehi, M.B.; Mortaheb, H.R.; Nozaeim, A.A.; Ahmadi, S.H. Design and fabrication of co([CHITOSAN-AMPS-AA]/PEI-MBA) nanocomposite hydrogel as an effective solution for removing tin and platinum ions in wastewater treatment applications: Selective recovery of platinum. J. Environ. Polym. Degrad. 2024, 32, 6011–6028. [Google Scholar] [CrossRef]

- El-saied, H.A.A.; Motawea, E.A.T. Optimization and adsorption behavior of nanostructured NiFe2O4/poly AMPS grafted biopolymer. J. Polym. Environ. 2020, 28, 2335–2351. [Google Scholar] [CrossRef]

- Weerasundara, L.; Gabriele, B.; Figoli, A.; Ok, Y.-S.; Bundschuh, J. Hydrogels: Novel materials for contaminant removal in water-A review. Crit. Rev. Environ. Sci. Technol. 2021, 51, 1970–2014. [Google Scholar] [CrossRef]

- Sivagangi Reddy, N.; Krishna Rao, K.S.V. Polymeric Hydrogels: Recent Advances in Toxic Metal Ion Removal and Anticancer Drug Delivery Applications. Int. J. Adv. Chem. Sci. 2016, 4, 214–234. [Google Scholar]

- Zhang, M.; Yu, X.; Zhu, M.; Xiang, A.; Bai, Y.; Zhou, H. Adsorptive behaviors and mechanisms for removing three organic pollutants from aqueous solutions by polyvinyl alcohol/porous carbon composite hydrogels. J. Environ. Chem. Eng. 2023, 11, 111095. [Google Scholar] [CrossRef]

- Lotfi, M.; Bahram, M.; Moghadam, P.N. The study of the removal of penconazole fungicide from surface water using carboxymethyl tragacanth-based hydrogel grafted with poly(acrylic acid-co-acrylamide). Sci. Rep. 2023, 13, 13569. [Google Scholar] [CrossRef]

- Li, I.-C.; Chen, Y.-H.; Chen, Y.-C. Adsorption properties of ammonium nitrogen from aqueous solutions using sodium humate/poly(sodium acrylate) hydrogel. J. Taiwan Inst. Chem. Eng. 2024, 161, 105516. [Google Scholar] [CrossRef]

- Wang, H.; Chen, X.; Gong, C.; Bu, Y.; Wu, T.; Yan, H.; Lin, Q. Intelligent response organo-montmorillonite/Fe3+-alginate/poly(N-isopropylacrylamide) interpenetrating network composite hydrogels for controlled release of water-insoluble pesticides. Appl. Clay Sci. 2024, 251, 107302. [Google Scholar] [CrossRef]

- Kunori, M.; Tokuyama, H. Development of a polyethyleneimine/poly(N-isopropylacrylamide) semi-IPN hydrogel for use in the temperature-swing adsorption and selective desorption of hydrophobic organic compounds. J. Taiwan Inst. Chem. Eng. 2024, 156, 105331. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, Y.; Zhong, L.; Feng, Q.; Dong, Z.; Xu, Z. Dialdehyde modified and cationic aerogel for efficient microplastics adsorption from environmental waters. Int. J. Biol. Macromol. 2024, 256, 128326. [Google Scholar] [CrossRef]

- Madhuranthakam, C.M.R.; Alsubaei, A.; Elkamel, A. Performance of polyacrylamide and poly(acrylamide/sodium acrylate) hydrogel-coated mesh for separation of oil/water mixture. J. Water Process Eng. 2018, 26, 62–71. [Google Scholar] [CrossRef]

- Drinking Water Adsorbents Market Size, Share & Trends Analysis Report by Product (Activated Carbon, Zeolite, Alumina, Clay, Manganese Oxide, Cellulose), by Region, and Segment Forecasts. 2019–2025. Available online: https://www.grandviewresearch.com/industry-analysis/drinking-water-adsorbents-market (accessed on 12 February 2025).

- Ighalo, J.O.; Omoarukhe, F.O.; Ojukwu, V.E.; Iwuozor, K.O.; Igwegbe, C.A. Cost of adsorbent preparation and usage in wastewater treatment: A review. Clean. Chem. Eng. 2022, 3, 100042. [Google Scholar] [CrossRef]

- Hydrogel Market Size, Share, Competitive Landscape and Trend Analysis Report, by Raw Material Type, by Composition, by Form, by Product, by Application: Global Opportunity Analysis and Industry Forecast. 2024–2033. Available online: https://www.alliedmarketresearch.com/hydrogel-market (accessed on 12 February 2025).

- Urban Wastewater. Available online: https://environment.ec.europa.eu/topics/water/urban-wastewater_en (accessed on 12 February 2025).

| Dyes | Hydrogel-Based Materials | Preparation Method | Performance | Regeneration and Reusability | Ref. |

|---|---|---|---|---|---|

| MB cationic dye RBBR anionic dye | - Monomers: PCL and HEMA - Initiator: AIBN | - by radical copolymerization | - maximum swelling equilibrium (%)—929% - removal efficiency (%)—95% cationic dyes (MB) and 40% anionic dyes (RBBR) - adsorption capacity (Qmax, mg/g)—521.39 mg/g for MB (24 h, ci = 100 mg/L, pH = 12) and 197.84 mg/g for RBBR (24 h, c0 = 100 mg/L, pH = 2) - best-fit kinetic—pseudo-second-order kinetic model (R2 = 0.992) - best fit isotherm—Langmuir isotherm (R2 = 0.999) - negative ΔG0 values; positive ΔH0 and ΔS0 values indicate that MB and RBBR adsorption spontaneous and thermodynamically favorable | - desorption eluent: HCl and NaOH solutions - 10th regeneration run - 10th reusable run with 80% removal efficiency | [44] |