An Amide-Carboxylic Acid Compound as Gel Structure Breaker to Improve the Rheology of Oil-Based Drilling Fluids

Abstract

:1. Introduction

2. Results and Discussion

2.1. FTIR

2.2. Performance Evaluation of OCD

2.2.1. Effect of OCD on the Rheological Properties of Laboratory-Prepared OBDFs

2.2.2. Effect of OCD on the Rheological Properties of Field OBDFs with Different Densities

2.2.3. Effect of OCD on the HTHP Filtration and Electrical Stability of OBDFs

2.2.4. Evaluation of Temperature Resistance of OCD

2.2.5. OCD’s Effect on the Solid-Phase Settling Stability

2.3. Mechanism Analysis

3. Conclusions

4. Materials and Methods

4.1. Materials

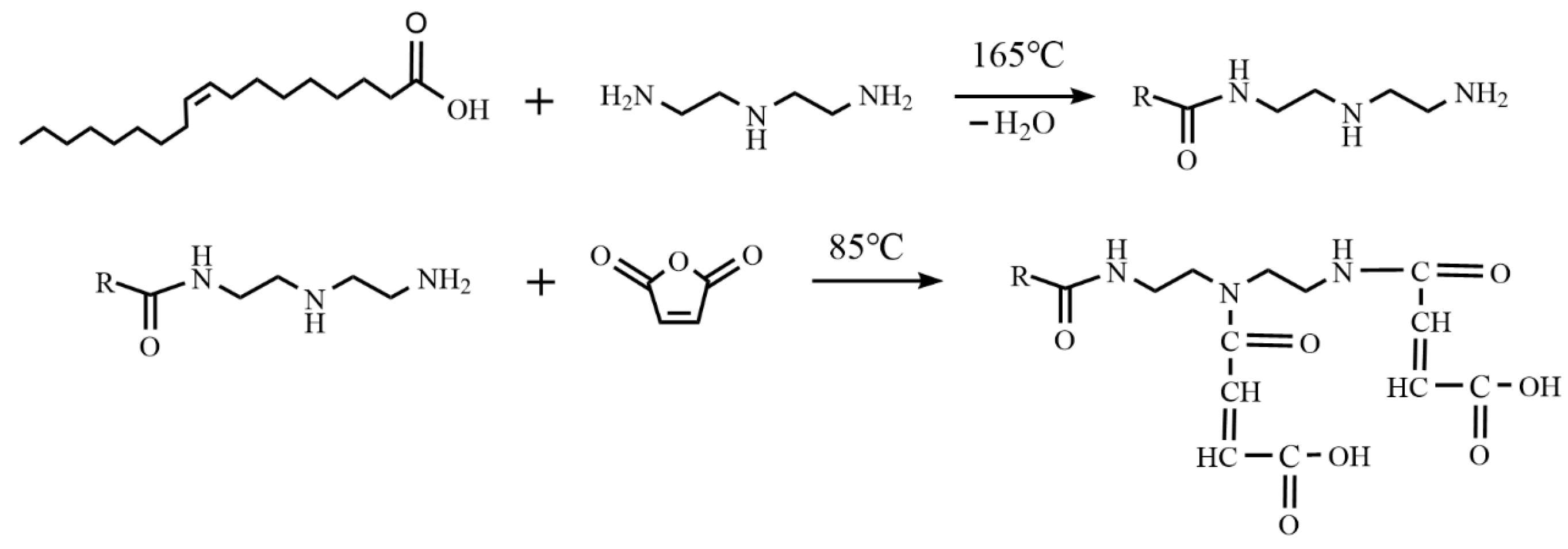

4.2. Synthesis and Characterization of OCD

4.2.1. OCD Synthesis

4.2.2. OCD Characterization

4.3. Drilling Fluid Preparation and Performance Test

4.3.1. Preparation of High-Density OBDFs

4.3.2. Rheological Performance Testing

4.3.3. Electrical Stability (ES) and High-Temperature, High-Pressure (HTHP) Filtration Tests

4.3.4. Solid-Phase Settling Stability Test

4.4. Viscosity Reduction Mechanism Analysis

4.4.1. Solid-Phase Wettability Test

4.4.2. Solid-Phase Particle Size and Micromorphology Test

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhonghua, W. Review of progress on drilling fluid technology in China. Pet. Drill. Tech. 2019, 47, 95–102. [Google Scholar]

- Siddique, S.; Kwoffie, L.; Addae-Afoakwa, K.; Yates, K.; Njuguna, J. Oil based drilling fluid waste: An overview on environmentally persistent pollutants. IOP Conf. Ser. Mater. Sci. Eng. 2017, 195, 012008. [Google Scholar] [CrossRef]

- Wang, C.-q.; Jin, J.-z.; Lin, X.-y.; Xiong, D.-m.; Mei, X.-d. A study on the oil-based drilling cutting pyrolysis residue resource utilization by the exploration and development of shale gas. Environ. Sci. Pollut. Res. 2017, 24, 17816–17828. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Xie, J.; Huang, S.; Wu, S.; Wu, P.; Huang, W. Research and Application of Evaluation Methods for Functional Characteristics of Oil-Based Drilling Fluid in Shale Gas Wells. Geofluids 2021, 2021, 8814032. [Google Scholar] [CrossRef]

- Zhuang, G.Z.; Zhang, H.X.; Wu, H.; Zhang, Z.P.; Liao, L.B. Influence of the surfactants’ nature on the structure and rheology of organo-montmorillonite in oil-based drilling fluids. Appl. Clay Sci. 2017, 135, 244–252. [Google Scholar] [CrossRef]

- Li, J.; Li, Q.; Li, N.; Teng, X.; Ren, L.; Liu, H.; Guo, B.; Li, S.; Hisham, N.-E.-D.; Al-Mujalhem, M. Ultra-high density oil-based drilling fluids laboratory evaluation and applications in ultra-HPhT reservoir. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Online, 17–19 November 2020; p. D032S009R010. [Google Scholar]

- Mahmoud, A.; Gajbhiye, R.; Elkatatny, S. Evaluating the Effect of Claytone-EM on the Performance of Oil-Based Drilling Fluids. ACS Omega 2024, 9, 12866–12880. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.; Yang, Y.; Zhang, H.; Zheng, J.; Zhong, Y. Conceptual design and methodology for rheological control of water-based drilling fluids in ultra-high temperature and ultra-high pressure drilling applications. J. Pet. Sci. Eng. 2020, 188, 106884. [Google Scholar] [CrossRef]

- Wang, F.; Tan, X.; Wang, R.; Sun, M.; Wang, L.; Liu, J. High temperature and high pressure rheological properties of high-density water-based drilling fluids for deep wells. Pet. Sci. 2012, 9, 354–362. [Google Scholar] [CrossRef]

- Guo, C.-p. Current Status and Prospects of Waste Oil-Based Drilling Fluid Treatment Methods in China. In Proceedings of the International Petroleum and Petrochemical Technology Conference 2020; Springer: Singapore, 2021; pp. 94–104. [Google Scholar]

- Jiancheng, L.; Peng, Y.; Jian, G.; Yande, S.; Kuang, X.; Shasha, C. A new type of whole oil-based drilling fluid. Pet. Explor. Dev. 2014, 41, 538–544. [Google Scholar]

- Li, Q.; Zhu, J.; Li, S.; Zhang, S.; Hisham, N.-E.-D.; Ren, L.; Li, J.; Al-Mujalhem, M. Laboratory evaluation of weighting materials for ultra-high density oil-based drilling fluids in ultra-HPHT wellbore applications. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019; p. D022S052R003. [Google Scholar]

- Shen, H.; Sun, J.; Lv, K.; Li, M.; Geng, Y.; Yang, Z.; Huang, X.; Du, H.; Khan, M.A. Effect of Low Gravity Solids on Weak Gel Structure and the Performance of Oil-Based Drilling Fluids. Gels 2023, 9, 729. [Google Scholar] [CrossRef]

- Wang, C.-q.; Lin, X.-y.; Wang, D.; He, M.; Zhang, S.-l. Utilization of oil-based drilling cuttings pyrolysis residues of shale gas for the preparation of non-autoclaved aerated concrete. Constr. Build. Mater. 2018, 162, 359–368. [Google Scholar] [CrossRef]

- Yang, J.; Sun, J.; Wang, R.; Qu, Y. Treatment of drilling fluid waste during oil and gas drilling: A review. Environ. Sci. Pollut. Res. 2023, 30, 19662–19682. [Google Scholar] [CrossRef] [PubMed]

- Pereira, L.B.; Sad, C.M.; Castro, E.V.; Filgueiras, P.R.; Lacerda, V., Jr. Environmental impacts related to drilling fluid waste and treatment methods: A critical review. Fuel 2022, 310, 122301. [Google Scholar] [CrossRef]

- Soares, A.A.; de Oliveira Freitas, J.C.; de Araujo Melo, D.M.; Braga, R.M.; Amaral-Machado, L.; Santos, P.H.S.; Soares, L.W.O. Cement slurry contamination with oil-based drilling fluids. J. Pet. Sci. Eng. 2017, 158, 433–440. [Google Scholar] [CrossRef]

- Ghavami, M.; Hasanzadeh, B.; Zhao, Q.; Javadi, S.; Kebria, D.Y. Experimental study on microstructure and rheological behavior of organobentonite/oil-based drilling fluid. J. Mol. Liq. 2018, 263, 147–157. [Google Scholar] [CrossRef]

- Humood, M.; Ghamary, M.H.; Lan, P.; Iaccino, L.L.; Bao, X.; Polycarpou, A.A. Influence of additives on the friction and wear reduction of oil-based drilling fluid. Wear 2019, 422, 151–160. [Google Scholar] [CrossRef]

- Lin, Z.; Li, F.; Liu, X.; Su, J. Synthesis of a network-structured polymer with low viscosity effect and its use as filtrate reducer for water-based drilling fluids. J. Appl. Polym. Sci. 2023, 140, e54581. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.; Alkinani, H.H.; Dunn-Norman, S.; Alashwak, N.A.; Alshammari, A.F.; Alkhamis, M.M.; Albazzaz, H.W.; Mutar, R.A.; Alsaba, M.T. Environmental friendly drilling fluid additives: Can food waste products be used as thinners and fluid loss control agents for drilling fluid? In Proceedings of the SPE Asia Pacific Health, Safety, Security, Environment and Social Responsibility Symposium, Kuala Lumpur, Malaysia, 23–24 April 2019; p. D021S005R004. [Google Scholar]

- Xiansen, M.; Huaizhi, T.; Junbin, C. A viscosity reducer for oil based drilling fluids and its field application. Drill. Fluid Complet. Fluid 2021, 38, 423–427. [Google Scholar]

- Kania, D.; Yunus, R.; Omar, R.; Rashid, S.A.; Jan, B.M.; Arsanjani, N. Nonionic polyol esters as thinner and lubricity enhancer for synthetic-based drilling fluids. J. Mol. Liq. 2018, 266, 846–855. [Google Scholar] [CrossRef]

- Huang, W.; Zhao, C.; Qiu, Z.; Leong, Y.K.; Zhong, H.; Cao, J. Synthesis, characterization and evaluation of a quadripolymer with low molecular weight as a water based drilling fluid viscosity reducer at high temperature (245 °C). Polym. Int. 2015, 64, 1352–1360. [Google Scholar] [CrossRef]

- Zhao, S.-y.; Yan, J.-n.; Shu, Y.; Zhang, H.-x. Rheological properties of oil-based drilling fluids at high temperature and high pressure. J. Cent. South Univ. Technol. 2008, 15, 457–461. [Google Scholar] [CrossRef]

- Huang, X.; Jinsheng, S.; Kaihe, L.; Xiaodong, D.; Fengbao, L.; Chongyang, G. A high-temperature resistant and high-density polymeric saturated brine-based drilling fluid. Pet. Explor. Dev. 2023, 50, 1215–1224. [Google Scholar] [CrossRef]

- Murtaza, M.; Alarifi, S.A.; Kamal, M.S.; Onaizi, S.A.; Al-Ajmi, M.; Mahmoud, M. Experimental investigation of the rheological behavior of an oil-based drilling fluid with rheology modifier and oil wetter additives. Molecules 2021, 26, 4877. [Google Scholar] [CrossRef]

- Wang, D.; Qiu, Z.; Zhong, H.; Zhao, X.; Su, J.; Fan, L. Performance control of high temperature and high density drilling fluid based on fractal grading theory. Geoenergy Sci. Eng. 2023, 221, 211377. [Google Scholar] [CrossRef]

- Xiong, L.; Xiaoqiang, D.; Junbin, J.; Xiaohua, Y. Study and application of an ultra-high temperature high density drilling fluid. Drill. Fluid Complet. Fluid 2020, 37, 694–700. [Google Scholar]

- Wang, T.; Sun, M.; Pan, Y.; Fu, L.; Yang, S. Development a new type of oil based drilling fluid with good temperature resistant. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–15. [Google Scholar] [CrossRef]

| Order | Additives | Addition | Stirring Speed (rpm) | Stirring Time (min) | Function |

|---|---|---|---|---|---|

| 1 | White oil | 240 mL | / | / | Base oil as continuous phase |

| 2 | Primary emulsifier | 7.5 g | 10,000 | 10 | Helps in forming a stable oil–water emulsion |

| 3 | Secondary emulsifier | 7.5 g | 10,000 | 10 | Helps in forming a stable oil–water emulsion |

| 4 | 30% CaCl2 | 60 mL | 10,000 | 20 | Controls water activity and enhances water-in-oil emulsion formation |

| 5 | CaO | 15 g | 10,000 | 20 | Adjusts the pH |

| 6 | Organoclay | 6 g | 10,000 | 20 | Maintains the suspension of solids |

| 7 | Asphalt | 7.5 g | 10,000 | 20 | Controls Fluid loss |

| 8 | Lignite | 7.5 g | 10,000 | 20 | Controls Fluid loss |

| 9 | Bentonite | 7.5 g | 10,000 | 20 | Deleterious solid phases |

| 10 | Rev dust | 7.5 g | 10,000 | 20 | Deleterious solid phases |

| 11 | Barite | 660 g | 10,000 | 20 | Increases the density of drilling fluid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lv, K.; Huang, X.; Li, Z.; Zhang, Y.; Yuan, Z. An Amide-Carboxylic Acid Compound as Gel Structure Breaker to Improve the Rheology of Oil-Based Drilling Fluids. Gels 2025, 11, 97. https://doi.org/10.3390/gels11020097

Zhang Y, Lv K, Huang X, Li Z, Zhang Y, Yuan Z. An Amide-Carboxylic Acid Compound as Gel Structure Breaker to Improve the Rheology of Oil-Based Drilling Fluids. Gels. 2025; 11(2):97. https://doi.org/10.3390/gels11020097

Chicago/Turabian StyleZhang, Yu, Kaihe Lv, Xianbin Huang, Zhe Li, Yang Zhang, and Zhenhang Yuan. 2025. "An Amide-Carboxylic Acid Compound as Gel Structure Breaker to Improve the Rheology of Oil-Based Drilling Fluids" Gels 11, no. 2: 97. https://doi.org/10.3390/gels11020097

APA StyleZhang, Y., Lv, K., Huang, X., Li, Z., Zhang, Y., & Yuan, Z. (2025). An Amide-Carboxylic Acid Compound as Gel Structure Breaker to Improve the Rheology of Oil-Based Drilling Fluids. Gels, 11(2), 97. https://doi.org/10.3390/gels11020097